PL

RU

EN

INSTRUKCJA MONTA¯U I U¯YTKOWANIA

INSTRUCTION MANUAL

KGE-3416ZB Plus

KGE-3416ZX Plus

KGE-3416ZN Plus

ИНСТРУКЦИЯ ПО OБСЛУЖИВАНИЮ И ЭКСПЛУАТАЦИИ

1

6.8.1

6.8.2

6.6.1

1.1.1

2.6.1

7.4.1

8.1.1

2

10.1.1

10.2.1

10.5.1

10.8.1 10.8.2

11.1.1

11.7.2

11.8.2

11.8.1

10.3.1 10.3.2 10.3.3

10.4.1

11.3.1

11.2.1

11.8.3

11.9.1

11.9.2

11.9.3 11.9.4

11.7.1

3

13.2.1

13.3.1

13.4.1

13.4.2

13.4.3

13.4.4

4

PL

2.1 Przeznaczenie

Kuchnia jest przeznaczona do przygotowywania

potraw wyłącznie w gospodarstwie domowym.

Stosowanie jej do innych celów jest niedozwolone.

2.2 Klasa urządzenia – 1 (wolnostojące)

2.3 Kategoria gazu - II

2ELwLs3B/P

2.4 Moc znamionowa palników:

Palnik mały – 1,0 kW

Palnik średni – 1,75 kW

Palnik duży – 3,0 kW

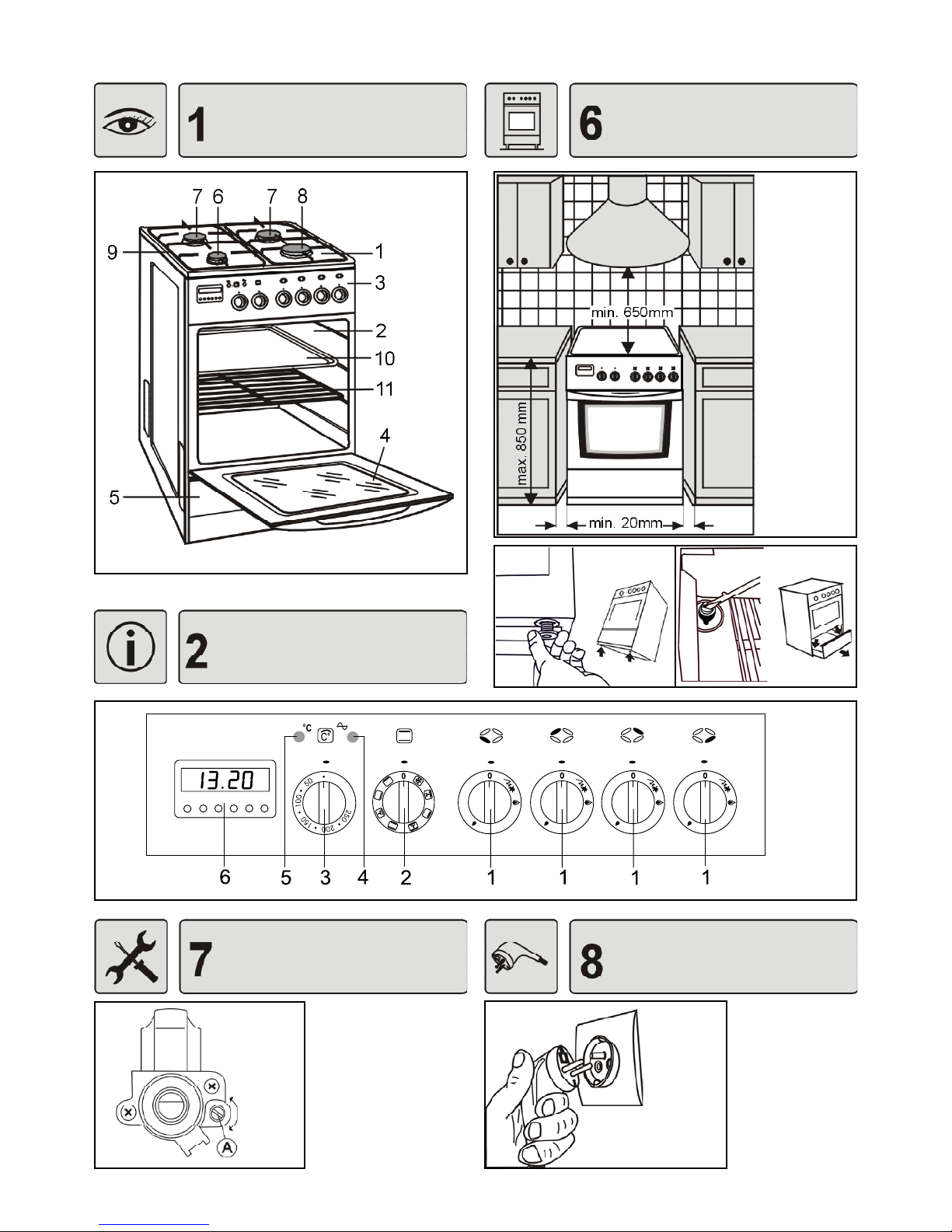

2.5 Opis elementów kuchni (1.1.1)

1 – płyta grzejna

2 – piekarnik elektryczny

3 – panel sterujący

4 – drzwi piekarnika

5 – pojemnik na naczynia lub osłona

6 – palnik mały

7 – palnik średni

8 – palnik duży

9 – ruszt płyty grzejnej

10 – blacha do pieczenia

11 – ruszt do pieczenia

2.6 Panel sterujący (2.6.1)

1 – pokrętła do palników gazowych

2 – pokrętło wyboru funkcji piekarnika

3 – pokrętło regulatora temperatury

4 – lampka kontrolna pracy piekarnika

5 – lampka kontrolna regulatora temperatury

6 – elektroniczny programator

Na rysunku 1.1.1 pokazano urządzenie, które Pań-

stwo posiadacie.

Niniejszy sprzęt nie jest przeznaczony do 1.

użytkowania przez osoby (w tym dzieci) o

ograniczonej zdolności zycznej, czuciowej

lub psychicznej, lub osoby nie mające doświadczenia lub znajomości sprzętu, chyba

że odbywa się to pod nadzorem lub zgodnie z

instrukcją użytkowania sprzętu, przekazanej

przez osoby odpowiadające za ich bezpieczeństwo. Należy zwracać uwagę na dzieci,

aby nie bawiły się sprzętem.

Kuchnię należy zainstalować zgodnie z obo-2.

wiązującymi przepisami i użytkować tylko w

odpowiednio wentylowanym pomieszczeniu.

Elementy opakowania prosimy trzymać z dala 3.

od dzieci, ponieważ mogą być dla nich niebezpieczne.

Wyrób należy instalować po 8 godzinach se-4.

zonowania w pomieszczeniu kuchennym.

Przed zainstalowaniem urządzenia upewnić 5.

się, czy lokalne warunki dystrybucji (rodzaj

i ciśnienie gazu) i nastawy są odpowiednie.

Warunki nastawy urządzenia są podane na tabliczce znamionowej.

Urządzenie to nie jest podłączane do prze-6.

wodów odprowadzających spaliny. Powinno

być ono zainstalowane i przyłączone zgodnie

z aktualnymi przepisami instalacyjnymi. W

szczególności należy uwzględnić odpowiednie wymagania dotyczące wentylacji.

Podłączenie kuchni do wewnętrznej instalacji 7.

gazowej lub do butli z gazem płynnym oraz

jej regulację powinien wykonać wyłącznie

uprawniony instalator urządzeń gazowych

lub technik autoryzowanego zakładu serwisowego, co winno być potwierdzone na karcie

gwarancyjnej wyrobu. Brak takiego potwierdzenia unieważnia gwarancję.

W przypadku awarii urządzenia, zwłaszcza 8.

przy ulatnianiu się gazu lub wystąpieniu zwarcia, urządzenie należy wyłączyć i niezwłocznie

Kuchnie spełniają wymagania następujących dyrektyw:

2006/95/WE – Niskonapięciowe wyroby elektryczne

2004/108/WE – Kompatybilność elektromagnetyczna

90/396/EEC – Zasadnicze wymagania dla urządzeń spalających paliwa gazowe [GAD]

WAŻNE !

Przed zainstalowaniem i użytkowaniem kuchni prosimy dokładnie

przeczytać instrukcję obsługi. Instrukcja zawiera ilustracje a numery

ilustracji odpowiadają numeracji punktów w tekście.

5

PL

skontaktować się z autoryzowanym zakładem

serwisowym. Uszkodzonej kuchni nie wolno

użytkować.

Producent nie ponosi odpowiedzialności za 9.

obrażenia lub uszkodzenia spowodowane

przez nieprawidłowe zainstalowanie urządzenia, podłączenie do niesprawnej instalacji gazowej lub elektrycznej lub jego nieprawidłowe

użytkowanie.

Nie zezwala się na wykonywanie we własnym 10.

zakresie jakichkolwiek napraw z wyjątkiem

wymiany oświetlenia piekarnika, pod rygorem utraty uprawnień gwarancyjnych.

Kuchni nie wolno podnosić za uchwyt drzwi 11.

piekarnika

.

Producent zastrzega sobie możliwość wpro-12.

wadzania zmian w celu unowocześniania

wyrobu i stałego polepszania jakości, bez

uprzedniego powiadomienia użytkowników.

Zmiany te jednak nie będą stwarzały trudności przy obsłudze.

Podczas użytkowania kuchnia staje się gorąca. •

Zaleca się zachować ostrożność i unikać dotykania

gorących elementów wewnątrz piekarnika. Szczególną uwagę prosimy zwrócić na dzieci.

Przewody przyłączeniowe zmechanizowanego •

sprzętu gospodarstwa domowego używanego w

pobliżu włączonej kuchni, powinny być z dala od

jej gorących elementów. Należy zwrócić uwagę,

aby przewody te nie zostały przyciśnięte gorącymi

drzwiami piekarnika.

Do zestawiania potraw z płyty grzejnej i wyjmowa-•

nia form z piekarnika należy używać suchych ręka-

wic ochronnych.

Nie pozostawiać bez nadzoru urządzenia z zapa-•

lonymi palnikami, zwłaszcza podczas smażenia,

gdyż przegrzany tłuszcz może się zapalić.

Przedmioty łatwopalne przechowywać z dala od •

palników.

W piekarniku i w pojemniku na naczynia nie prze-•

chowywać przedmiotów łatwopalnych i wrażliwych

na działanie podwyższonej temperatury.

Nie przeciążać otwartych drzwi piekarnika. Nie •

wolno na nich siadać ani stawać.

Przed otwarciem drzwi piekarnika należy się od •

niego odsunąć, aby nagromadzone gorące powietrze mogło sie rozproszyć.

Na płycie grzejnej nie używać naczyń kuchennych, •

które wystają poza jej brzegi.

Użytkowanie urządzenia do gotowania i piecze-•

nia powoduje wydzielanie się ciepła i wilgoci w

pomieszczeniu, w którym jest ono zainstalowane.

Należy upewnić się, czy pomieszczenie kuchenne jest dobrze przewietrzane. Należy utrzymywać

otwarte naturalne otwory wentylacyjne lub zainstalować środki wentylacji mechanicznej (okap z mechanicznym wyciągiem).

Długotrwałe intensywne użytkowanie urządzenia •

może wymagać dodatkowego przewietrzania, na

przykład otwarcia okna lub bardziej skutecznej

wentylacji, np. zwiększenia wydajności wentylacji

mechanicznej, jeśli jest stosowana.

Zabrania się samowolnie dokonywać przeróbek •

kuchni na inny rodzaj gazu, dokonywać zmian w

instalacji gazowej i elektrycznej urządzenia.

Urządzenia nie wykorzystywać do ogrzewania po-•

mieszczeń.

W przypadku ulatniania się gazu należy na-

tychmiast zamknąć zawór na instalacji gazowej lub na butli z gazem, dokładnie przewietrzyć pomieszczenie i wezwać pogotowie

gazowe. W tym czasie nie wolno zapalać zapałek, palić papierosów, włączać bądź wyłączać

odbiorników elektrycznych (radio, dzwonek,

włącznik oświetlenia) lub mechanicznych powodujących iskrzenie.

W przypadku zapalenia się gazu uchodzącego

z nieszczelnego zaworu butli z gazem należy

zarzucić na butlę mokry koc, w celu ostudzenia butli i zakręcić zawór na butli. Zabrania

się używania uszkodzonej butli !

Na rusztach nie stawiać zdeformowanych lub –

niestabilnych naczyń, gdyż mogą się przewrócić

i zalać palniki.

Nie stawiać pustych naczyń nad włączonym pal- –

nikiem.

Przed zdjęciem naczyń z palników należy zmniej- –

szyć płomień lub zgasić go całkowicie.

Palniki utrzymywać w należytej czystości. Nie –

dopuszczać do wykipienia potraw i zalewania

palników.

6.1.Po rozpakowaniu urządzenia sprawdzić, czy nie

ma ono widocznych uszkodzeń. Jeśli kuchnia

została uszkodzona podczas transportu nie wol-

6

PL

no jej podłączać.

6.2 Z kuchni usunąć ewentualne naklejki i dokładnie

umyć ją z resztek kleju po naklejkach.

6.3 Pomieszczenie kuchenne powinno być suche i

powinno mieć dobrą wentylację.

6.4 Ustawienie urządzenia powinno gwarantować

swobodny dostęp do wszystkich elementów sterowania. Nie zaleca się ustawiania kuchni na

podstawie.

6.5 Urządzenie powinno być zainstalowane z dala od

materiałów łatwopalnych. Ściana pomieszczenia

przylegająca do kuchni powinna być wykonana z

materiałów niepalnych.

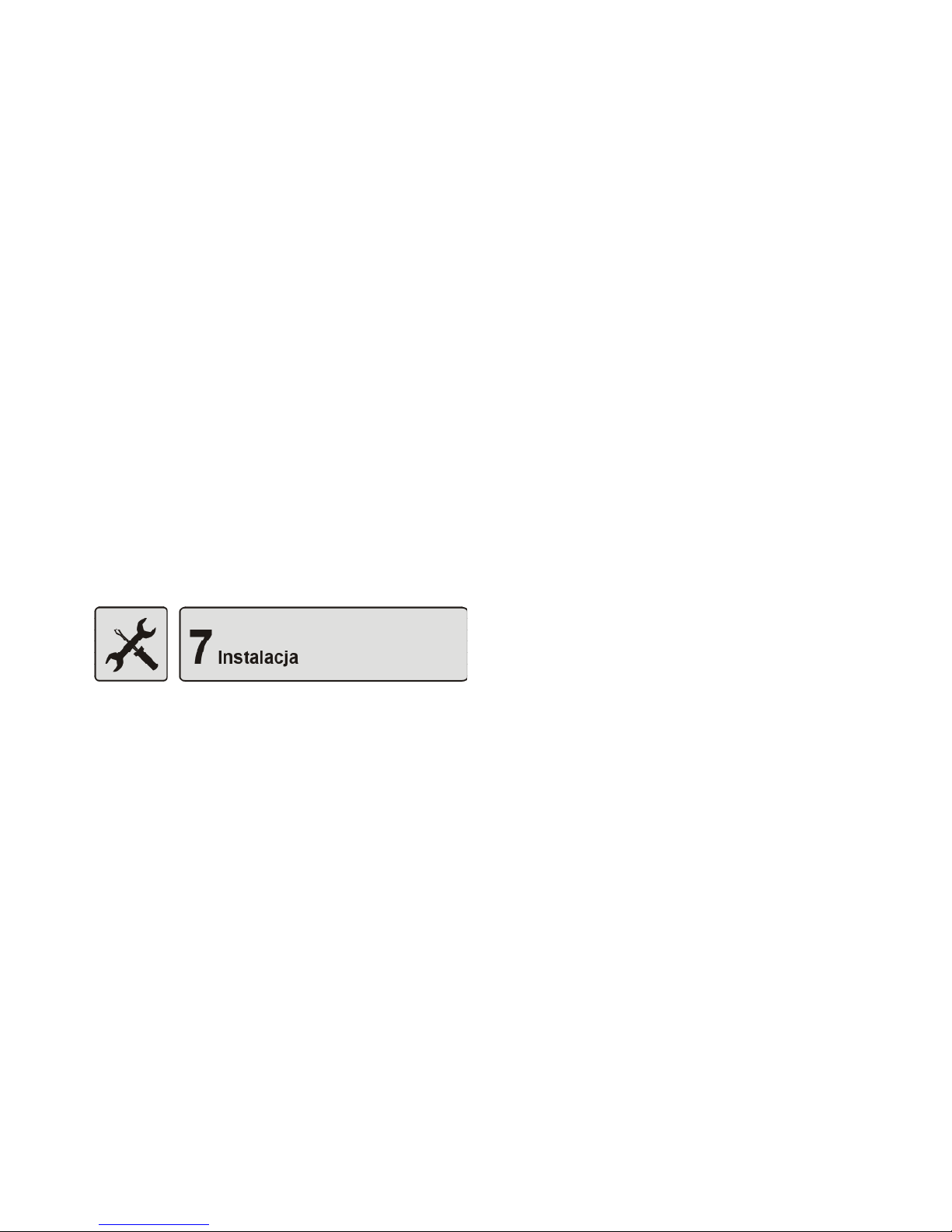

6.6 Nad kuchnią powinna być wolna przestrzeń dla

odpływu oparów kuchennych. Najlepiej zamontować okap nadkuchenny, który będzie absorbować lub odprowadzać te opary. Odległość pomiędzy okapem i płytą grzejną powinna wynosić

co najmniej 650mm (6.6.1).

6.7 Nie wolno zawieszać górnych szafek kuchennych bezpośrednio nad kuchnią.

6.8 Kuchnia jest wyposażona w regulowane nóżki

służące do jej poziomowania. Nóżki są dostępne po przechyleniu kuchni (6.8.1) lub po wyjęciu

pojemnika na naczynia (6.8.2). Nóżki obracać w

jedną lub drugą stronę, zależnie od potrzeby.

Kuchnia jest zaopatrzona w rurowy króciec z •

gwintem G½”. Do króćca podłączyć gaz z zastosowaniem odpowiedniego osprzętu.

Kuchnię można podłączyć do wewnętrznej insta-•

lacji domowej lub do butli z gazem płynnym.

Przed przystąpieniem do czynności podłączania •

kurek gazowy powinien być zamknięty.

Połączenie zaleca się uszczelnić taśmą teono-•

wą.

7.1 Podłączenie do gazu ziemnego

Kuchnię można podłączyć do instalacji gazowej •

na sztywno lub za pomocą elastycznego przewodu metalowego, mającego certykat.

Maksymalna długość przewodu elastycznego nie •

powinna przekraczać 2,0m. Przewód nie powinien stykać się z żadnymi częściami ruchomymi

i nie powinien przechodzić przez przestrzeń, w

której nie ma wystarczająco dużo miejsca.

Przy podłączaniu do sztywnej instalacji rurowej •

należy zwrócić uwagę, aby nie wywołać naprężeń w żadnym punkcie instalacji ani w żadnej

części urządzenia.

7.2 Podłączenie do gazu płynnego

Jeżeli użytkownik zamierza korzystać z butli z •

gazem, kuchni nie należy instalować w piwnicy

lub w innym pomieszczeniu, w którym podłoga

znajduje się poniżej poziomu terenu, ponieważ

gaz płynny jest cięższy od powietrza i zbiera się

na poziomie podłogi.

Do podłączenia urządzenia z butlą należy zasto-•

sować przewód gumowy, posiadający certykat.

Do podłączenia kuchni z przewodem gumowym •

należy zastosować rurę stalową o długości co

najmniej 0,5m.

Przewód gumowy nie powinien być dłuższy niż •

1,5m. Po podłączeniu, z obu stron powinien on

być zabezpieczony opaskami zaciskowymi.

Przewód nie powinien mieć załamań ani przewę-•

żeń i na całej długości powinien być dostępny.

Przewodu nie należy prowadzić w pobliżu źródeł •

wysokiej temperatury (maks. 50

0

C).

Przewód nieszczelny powinien być natychmiast •

wymieniony. Zabrania się napraw nieszczelnego

przewodu.

Po każdorazowym podłączeniu kuchni do butli z gazem należy sprawdzić szczelność zaworu na butli i

połączenie reduktora z butlą oraz jego działanie.

UWAGA !

Niedopuszczalne jest sprawdzanie szczel-1.

ności za pomocą otwartego płomienia (np.

zapałką lub świecą). Grozi to wybuchem! Do

sprawdzenia szczelności można użyć wody z

mydłem.

Okresowo należy sprawdzać stan przewodu i 2.

szczelność połączenia, zgodnie z obowiązującymi przepisami.

Przewód gumowy nie powinien dotykać gorą-3.

cych elementów kuchni.

7.3 Wymiana dysz

W razie konieczności dostosowania kuchni do zasilania innym rodzajem gazu, należy wymienić dysze

i wypełnić etykietę zmiany gazu, która znajduje się

w woreczku z instrukcją obsługi i kartą gwarancyjną.

Po opisaniu, do jakiego rodzaju gazu kuchnia została

przystosowana, etykietę przykleić na urządzeniu.

Wymiana dysz:

zamknąć kurek odcinający instalację gazową lub –

butlę od kuchni,

zamknąć wszystkie kurki w kuchni, –

zdjąć ruszty oraz nakrywki i kołpaki palników. –

odkręcić dotychczasowe dysze i wymienić je na –

nowe wg tabeli 1,

założyć kołpaki i nakrywki palników, –

wyregulować kurki palników, –

sprawdzić szczelność połączeń. –

7

PL

napięcie w sieci odpowiada napięciu podanemu –

na tabliczce znamionowej urządzenia,

sieć elektryczna, do której ma być podłączona –

kuchnia ma wystarczającą moc w porównaniu z

maksymalną mocą pobieraną przez kuchnię, podaną na tabliczce znamionowej urządzenia.

Gniazdo wtykowe powinno być łatwo dostęp-•

ne dla użytkownika.

Prosimy zwrócić uwagę, aby przewód zasila-•

jący nie dotykał gorących elementów kuchni.

Powierzchnie emaliowane i szklane przetrzeć •

miękką, wilgotną ściereczką.

Sprawdzić poprawność ułożenia poszczególnych •

elementów palników.

Z piekarnika wyjąć wyposażenie, zdjąć z niego fo-•

lię i umyć je w wodzie z dodatkiem płynu do mycia

naczyń.

Jeżeli kuchnia jest wyposażona w elektroniczny •

programator, po podłączeniu urządzenia do sieci

należy ustawić czas bieżący. Opis programatora

znajduje się w oddzielnej instrukcji.

Przed pierwszym użyciem kuchni należy zamknąć •

drzwi piekarnika i uruchomić go na ok. 30 minut.

Piekarnik powinien być pusty. Pokrętło wyboru

funkcji ustawić na pozycji

lub , a pokrętłem

regulatora temperatury ustawić 2500C. Powstający

przy tym dym i zapach są nieznaczne, jeśli zadba

się o wystarczającą wentylację pomieszczenia,

np. przez otwarcie okien. Po ostudzeniu, piekarnik

wyczyścić zgodnie z instrukcjami podanymi w rozdziale „Czyszczenie i konserwacja”.

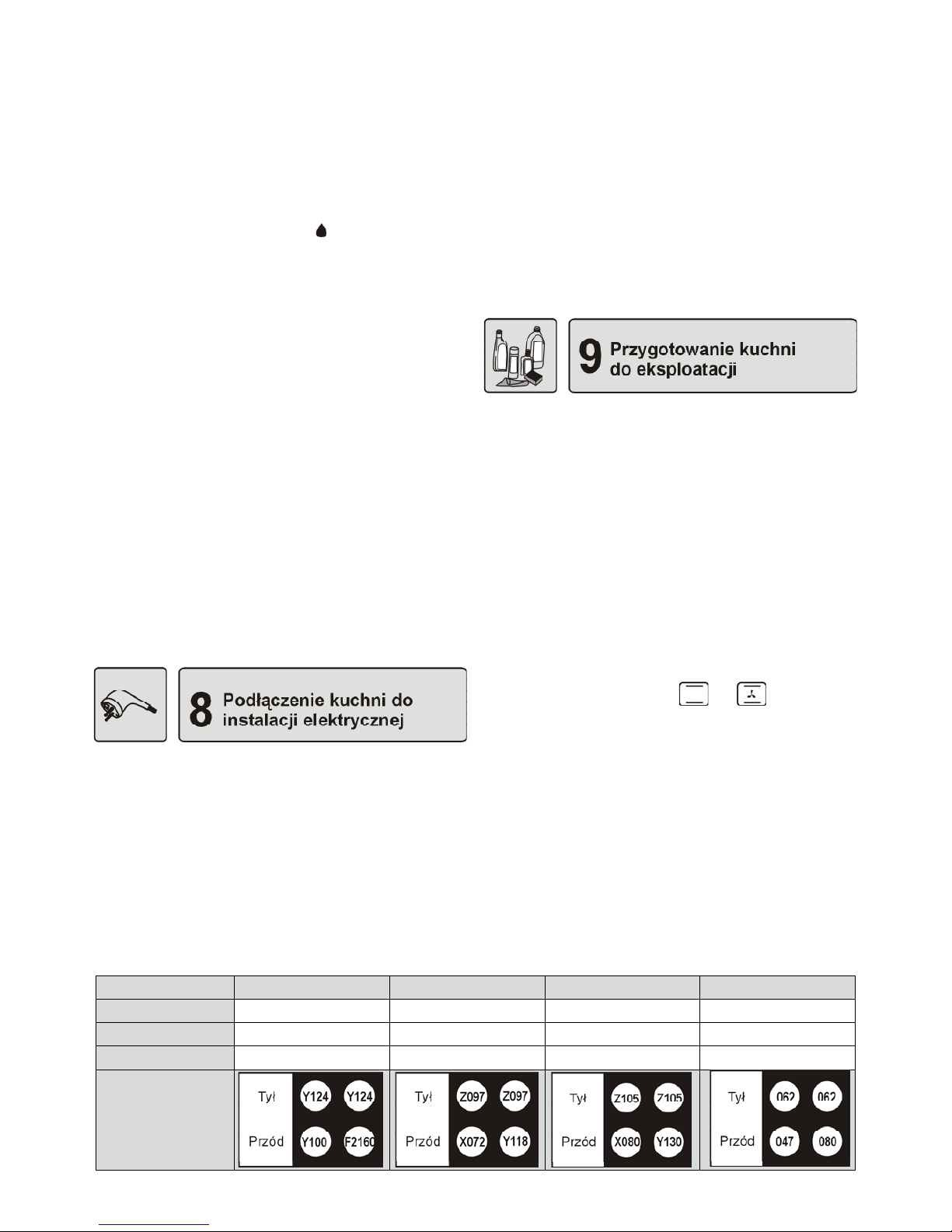

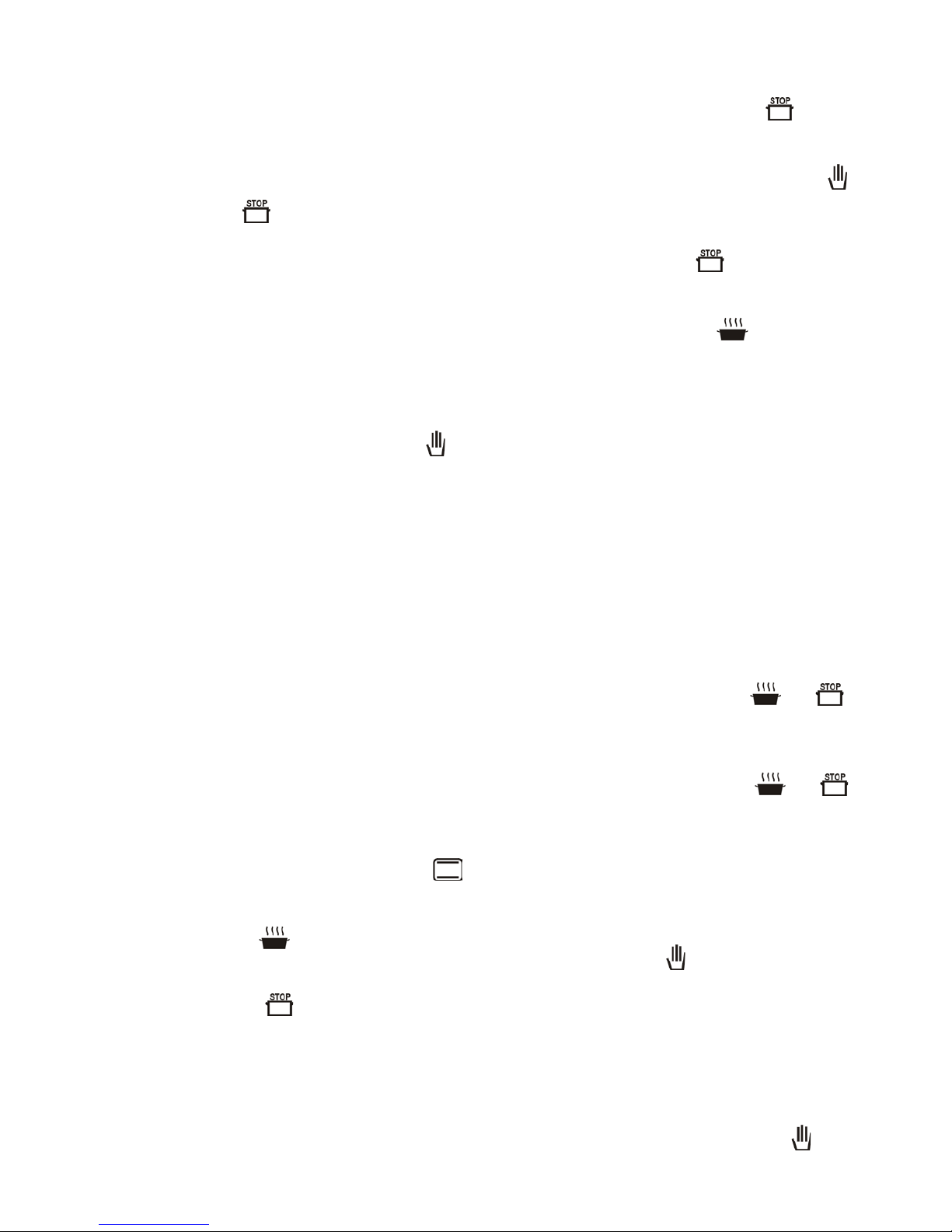

Tabela 1 Oznaczenia dysz

7.4 Regulacja kurków

Regulacja kurka gazowego polega na ustawieniu

płomienia oszczędnościowego palnika.

Regulacja kurków:

pokrętłem otworzyć przepływ gazu i zapalić re- –

gulowany palnik,

pokrętło ustawić na pozycji –

– płomień oszczędnościowy, a następnie nie zmieniając tej pozycji

zdjąć je z trzpienia kurka i obserwować płomień

palnika,

śrubę regulacyjną „ – A” (7.4.1) obracać i obserwować płomień; płomień ustawić na taką wysokość,

aby nie zgasł przy lekkim przeciągu oraz przy

szybkim przestawieniu kurka z płomienia pełnego na oszczędnościowy i odwrotnie,

regulację można uznać za prawidłową, gdy jądro –

płomienia ma kształt stożka koloru zielono-niebieskiego o wysokości ok. 2 – 4mm,

jeżeli w instalacji doprowadzającej gaz wystę- –

pują widoczne zmiany ciśnienia gazu (zmiana

wielkości płomienia przy pełnym przepływie),

płomień oszczędnościowy należy ustawić przy

niskim ciśnieniu w instalacji tak, aby palnik nie

zgasł podczas jego normalnego użytkowania,

po wyregulowaniu kurków, założyć pokrętło i –

zgasić płomień.

Zużycie gazu przy płomieniu minimalnym stanowi

ok. 25% zużycia przy płomieniu pełnym.

8.1 Kuchnie wyposażone w przewód zasilający z

wtyczką powinny być podłączone do gniazdka sieciowego wyposażonego w prawidłowo

podłączony bolec ochronny (8.1.1)

8.2 W kuchniach wyposażonych w przewód zasilający bez wtyczki należy podłączyć wtyczkę.

Przewód podłączyć do wtyczki z prawidłowym uziemieniem. Przed podłączeniem do

sieci należy sprawdzić czy:

2Ls-G2.350 13mbar 2E-G20 20mbar 2Lw-G27 20mbar 3B/P-G30 37mbar

Palnik mały Y100 X072 X080 047

Palnik sredni Y124 Z097 Z105 062

Palnik duży F2 160 Y118 Y130 080

Rozmieszczenie

dysz na płycie

grzejnej

8

PL

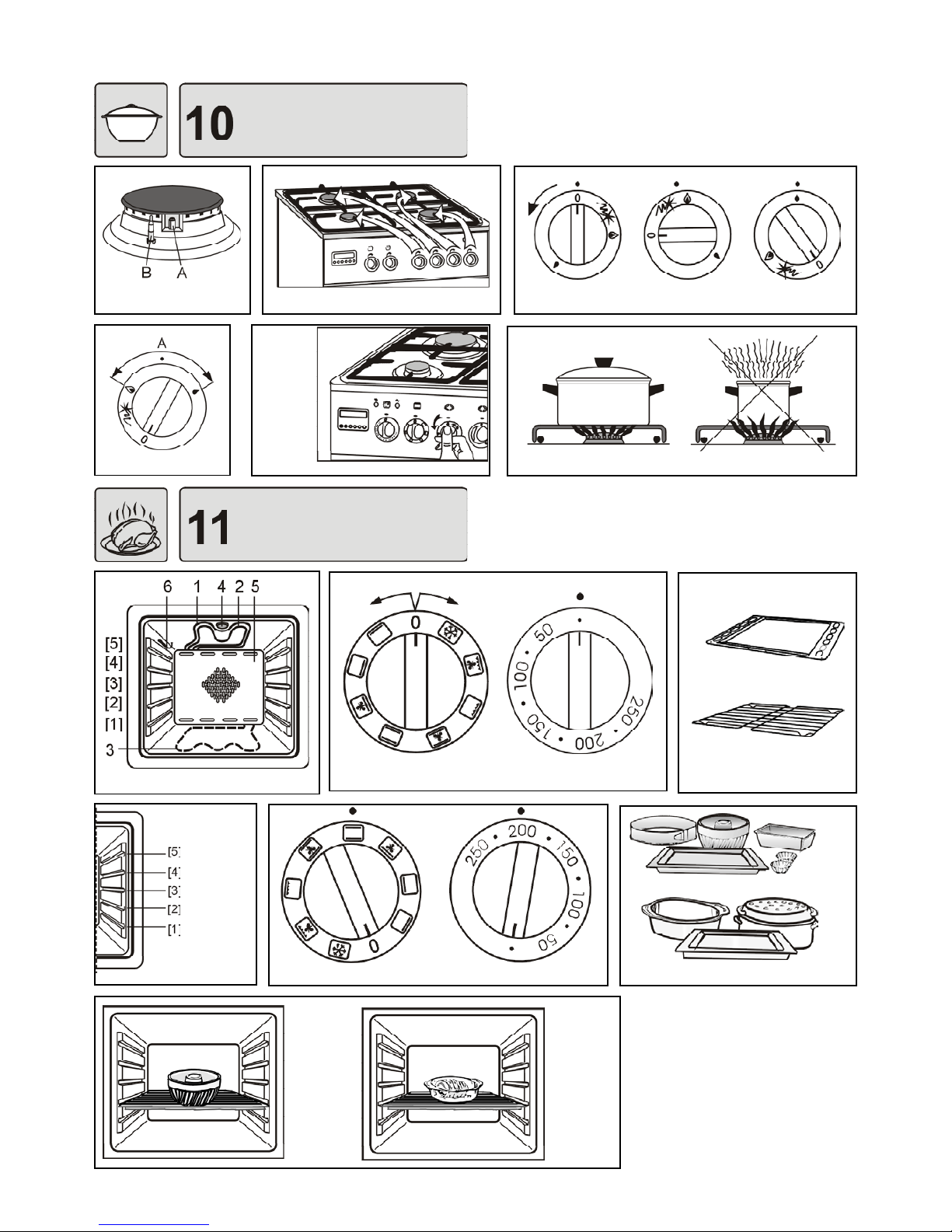

10.1 Palniki gazowe (10.1.1)

A - zapalacz

B - końcówka termopary (zabezpieczenie prze-

ciwwypływowe)

10.2 Pokrętła. Przepływ gazu w palnikach reguluje

się pokrętłami kurków gazowych. Przed włączeniem palnika należy upewnić się, czy pokrętło,

które zamierzamy uruchomić odpowiada palnikowi, który chcemy zapalić. Przyporządkowanie

palników do pokręteł pokazano na rys. (10.2.1).

10.3 Dobór płomienia

Płomień nie powinien wychodzić poza dno na-

czynia. Wielkość płomienia zależy od pozycji pokrętła (10.3.1; 10.3.2; 10.3.3).

0 - palnik zgaszony (przepływ gazu zamknięty)

- płomień duży

- płomień mały (oszczędnościowy)

10.4 Płomienia dużego

(10.3.2) należy używać do

czasu zagotowania potrawy, a do dalszego gotowania należy go zmniejszyć i najlepiej ustawić

na pozycji płomień oszczędnościowy (10.3.3).

Wielkość płomienia należy regulować tylko w za-

kresie pomiędzy pozycją

i (10.4.1).

10.5 Zapalanie palników

Kuchnie są wyposażone w urządzenie odcinające

dopływ gazu do palnika po zaniku płomienia np. po

zalaniu palnika potrawą.

Pokrętło wybranego palnika obrócić przeciwnie –

do kierunku ruchu wskazówek zegara, nacisnąć

je i przytrzymać wciśnięte do oporu tak długo, aż

zapali się gaz (10.5.1),

Po zapaleniu gazu pokrętło trzymać wciśnięte –

do oporu jeszcze ok. 5 sek. celem zadziałania

zabezpieczenia,

zwolnić nacisk na pokrętło i ustawić żądaną wiel- –

kość płomienia.

W razie przypadkowego zaniku płomienia zamknąć kurek palnika i nie ponawiać próby zapłonu przez co najmniej 1 minutę.

10.6 Gaszenie palników

Pokrętło obrócić zgodnie z kierunkiem ruchu wskazówek zegara i ustawić je na pozycji „0”.

10.7 Zapalanie palników przy zasilaniu gazem

płynnym z butli

Przed zapaleniem pierwszego palnika, otworzyć za-

wór na butli gazowej a następnie zapalić gaz jak podano powyżej.

Przy zamykaniu dopływu gazu, przed zgaszeniem

ostatniego palnika należy:

zamknąć zawór na butli gazowej, –

po zgaszeniu płomienia zamknąć kurek tego pal- –

nika.

W czasie gdy kuchnia nie jest używana, zawór butli

gazowej powinien być zamknięty

.

10.8 Dobór naczyń

Średnica dna naczynia powinna być 2,5 – 3 razy •

większa od korony palnika (10.8.1). Naczynia nie

powinny wystawać poza ruszt a płomień nie powinien wychodzić poza dno naczynia (10.8.2).

Naczynia zawsze powinny być czyste i suche, po-•

nieważ wtedy dobrze przewodzą i zatrzymują ciepło.

W czasie gotowania naczynia powinny być przy-•

kryte pokrywkami, co zapobiegnie gromadzeniu

się nadmiernej ilości oparów w pomieszczeniu kuchennym.

Minimalne wymiary naczyń• :

Dla palnika małego - f 90mm

Dla palnika średniego - f 160mm

Dla palnika dużego - f 200mm

11.1 Elementy piekarnika (11.1.1)

[1], [2], [3], [4], [5] – poziomy prowadnic

1 – grzałka górna

2 – grzałka opiekacza

3 – grzałka dolna

4 – lampka oświetlenia piekarnika

5 – perforowana osłona

6 – czujnik temperatury

11.2 Pokrętło wyboru funkcji (11.2.1) umożliwia

wybranie najbardziej odpowiedniej funkcji dla

danej potrawy. Można je obracać w obie strony.

Poniżej są opisane funkcje piekarnika.

Ogrzewanie z góry

Funkcja służy do mocniejszego zapiekania potraw od góry.

Ogrzewanie od dołu

Ciepło oddaje grzałka dolna, usytuowana pod

podłogą piekarnika. Tę funkcję włączamy, gdy

chcemy dopiec spód potrawy. Zaleca się ją stosować podczas ostatnich 10-15 minut piecze-

nia.

9

PL

Ogrzewanie od dołu z wentylatorem

Wentylator równomiernie rozprowadza ciepło

wytwarzane w dolnej części piekarnika.

Pieczenie tradycyjne

Przy tej funkcji ciepło dochodzi od góry i od dołu.

Potrawy należy umieszczać na jednym poziomie, najlepiej w centralnym miejscu piekarnika.

Doskonale nadaje się do pieczenia ciast, mięsa,

ryb, chleba, pizzy itp.

Pieczenie tradycyjne z wentylatorem

Wentylator wymusza cyrkulację gorącego powietrza wokół potrawy. Przy tej metodzie wybrać

temperaturę niższą niż przy pieczeniu tradycyjnym.

Opiekanie tradycyjne

Funkcja przeznaczona do opiekania potraw o

małych rozmiarach (steki, szaszłyki, kiełbaski,

ryby, tosty, grzanki, zapiekanki itp.).

Potrawę należy umieścić na blasze lub ruszcie,

w środkowej części.

Czas opiekania przyjmuje się orientacyjnie od

8–10 minut na każdy centymetr grubości. Piekarnik powinno się wstępnie rozgrzać przy maksymalnej temperaturze. Opiekane porcje, po

upływie połowy czasu powinno się przewrócić

na drugą stronę.

Przy opiekaniu mięsa na ruszcie zaleca się na

niższym poziomie umieścić blachę do zbierania ociekającego tłuszczu i wlać do niej ok. 0,5l

wody.

Opiekanie z wentylatorem

Funkcja umożliwiająca opiekanie z równomiernym rozprowadzaniem ciepła przez wentylator.

Rozmrażanie

Przy tej funkcji jest włączony wentylator, który wymusza obieg powietrza wokół potrawy. W

ten sposób uzyskuje się jednorodne rozmrażanie produktów spożywczych. Tę metodę można

stosować do wszystkich zamrożonych potraw.

Mrożone warzywa można piec od razu, bez rozmrażania.

11.3 Pokrętło regulatora temperatury (11.3.1)

Regulator temperatury umożliwia ustawienie i

automatyczne utrzymywanie temperatury w piekarniku na zadanym poziomie.

Na pokrętle oznaczono nastawy, które odpowiadają temperaturom w piekarniku (po nagrzaniu).

Ustawienie temperatury – pokrętło obrócić w

prawo i ustawić na żądanej pozycji z zakresu

50–250

0

C.

Po zakończeniu pieczenia – pokrętło obrócić w

lewo i ustawić je na pozycji zerowej „•”.

11.4 Lampki kontrolne (panel 2.6.1)

Lampka kontrolna pomarańczowa• sygnalizuje

pracę piekarnika. Lampka włącza się zawsze po

wybraniu dowolnej funkcji piekarnika, a gaśnie

po ustawieniu pokrętła wyboru funkcji na pozycji

„0”.

Lampka kontrolna czerwona• sygnalizuje dzia-

łanie regulatora temperatury. Lampka włącza się

po ustawieniu dowolnej temperatury a gaśnie po

uzyskaniu ustawionej temperatury. Następnie

będzie się zapalać i gasnąć w trakcie pieczenia,

sygnalizując włączanie i wyłączanie grzałek w

celu utrzymania temperatury.

11.5 Elektroniczny programator

Programator umożliwia sterowanie pracą piekarnika

w cyklu automatycznym lub półautomatycznym.

Zastosowanie programatora nie wyklucza możliwości ręcznego sterowania pracą piekarnika.

Opis programatora znajduje się w oddzielnej instruk-

cji.

11.6 Lampka oświetlenia piekarnika

Dla Państwa bezpieczeństwa i wygody, w piekarniku

podczas pieczenia jest włączona lampka. Lampka

włącza się po wybraniu dowolnej funkcji piekarnika.

Po wyłączeniu piekarnika lampka gaśnie.

11.7 Akcesoria

Kuchnie są standardowo wyposażone w jedną lub

dwie blachy (11.7.1) i ruszt do pieczenia (11.7.2).

Ruszt służy do stawiania na nim wszelkich naczyń z

potrawą przeznaczoną do pieczenia lub zapiekania.

Można na nim również kłaść niektóre potrawy np.

mięso, kiełbaski, ryby. W takim przypadku pod rusztem należy umieścić blachę na ociekający tłuszcz i

wlać do niej ok. 0,5l wody, wtedy piekarnik pozosta-

nie czysty.

11.8 Działanie piekarnika

1. Rozgrzać piekarnik a następnie potrawę umieścić

w naczyniu na odpowiednim poziomie piekarnika

(11.8.1).

2. Pokrętłem wyboru funkcji wybrać sposób ogrzewania piekarnika, np.

(11.8.2).

3. Pokrętłem regulatora temperatury ustawić temperaturę odpowiednią dla potrawy, np. 200

0

C

(11.8.3).

4. W kuchniach z programatorem można zaprogramować pracę piekarnika.

10

PL

5. Po zakończeniu pieczenia pokrętło wyboru funkcji

i pokrętło regulatora temperatury ustawić na po-

zycji zerowej.

Uwaga !

1. Podczas użytkowania piekarnika, nie należy

pozostawiać go bez nadzoru. Dostępne części

kuchni stają się gorące. Nie dopuszczać do

nich dzieci !

2. Potraw nie należy umieszczać na najwyższej

[5] prowadnicy.

11.9 Eksploatacja piekarnika

Do pieczenia ciast można używać tradycyjnych •

foremek blaszanych a także powlekanych teonem, ceramicznych, szklanych i z folii aluminiowej

(11.9.1). Ze względu na różnorodność kształtów i

możliwość zastosowań najbardziej uniwersalne są

foremki blaszane. Przed pierwszym użyciem nową

formę blaszaną powinno się wypiec w silnie rozgrzanym piekarniku, aby utraciła swój zapach.

Foremki należy wypełniać ciastem do 2/3 wysoko-•

ści, pozostawiając wystarczająco dużo miejsca do

wyrośnięcia.

Do pieczenia mięsa można używać naczyń cera-•

micznych, szklanych, stalowych emaliowanych

i żeliwnych, z uchwytami odpornymi na działanie

wysokich temperatur (11.9.2).

Potrawy powinny być wkładane do nagrzanego •

piekarnika.

Podczas pieczenia, ciasto powinno być równo-•

miernie ogrzewane. Ten warunek jest spełniony po

wybraniu funkcji

lub .

Jeżeli wierzch ciasta jest zbyt ciemny, to następ-•

nym razem foremkę z ciastem należy wsunąć na

niższy poziom piekarnika i wybrać niższą temperaturę, lecz nieco dłużej piec.

Jeśli spód ciasta jest zbyt ciemny, to w przyszłości •

wsunąć je wyżej i wybrać niższą temperaturę.

Przy pieczeniu, należy wystrzegać się temperatury •

zbyt wysokiej, ponieważ ciasto nie wyrośnie i może

powstać zakalec. Natomiast zbyt długie trzymanie

ciasta w nagrzanym piekarniku może spowodować

jego przypalenie i wyschnięcie.

Przy doborze temperatury i czasu pieczenia należy •

uwzględnić masę i konsystencję pieczonego cia-

sta.

Naczynia z potrawami należy umieszczać na od-•

powiednim poziomie piekarnika.

Użytkownik kierując się swoimi spostrzeżeniami i •

doświadczeniem sam powinien dobrać najbardziej

optymalny poziom ułożenia potraw oraz temperaturę i tryb pracy piekarnika.

Przy pierwszym pieczeniu najlepiej zaczynać od •

średnich wartości temperatur podanych w recepturach, a w razie potrzeby następnym razem ustawić

temperaturę wyższą lub niższą. Niższa temperatura powoduje bardziej równomierne zrumienienie

wypieku.

Aby sprawdzić, czy wypiek jest gotowy, należy •

na kilka minut przed wyłączeniem piekarnika włożyć do niego drewniany patyczek. Jeśli ciasto nie

przykleja się do patyczka – wypiek jest gotowy. Po

upieczeniu, ciasto pozostawić w piekarniku jeszcze ok. 5 minut.

Podczas użytkowania piekarnika należy przestrze-•

gać poniższych zaleceń:

nie trzymać w piekarniku niepotrzebnego wy- –

posażenia,

formy do ciast i zapiekanek oraz naczynia –

do pieczenia mięsa stawiać na ruszcie a nie

na blasze, w centralnym miejscu piekarnika

(11.9.3 i 11.9.4),

przy wybieraniu parametrów pieczenia należy –

uwzględnić rodzaj naczynia; naczynia w zależności od rodzaju materiału, grubości ścian i

barwy mają różne przewodnictwo cieplne.

Pieczenie mięsa w sosie własnym, najlepiej udaje się

po zastosowaniu funkcji

, szczególnie dla mięsa

chudego. Inne gatunki mięsa, w tym również mielone

i drób można piec przy funkcji

.

Pizza

W piekarniku można upiec pizzę przygotowaną samodzielnie lub pizzę mrożoną.

Pizzę można piec po wybraniu funkcji

w tem-

peraturze ok. 200

0

C. Ciepło rozchodzi się głównie z

dołu. Potrawę umieścić na jednym, najlepiej na [2]

poziomie piekarnika.

Pizzę zamrożoną można wkładać bezpośrednio do

nagrzanego piekarnika.

W przypadku zaobserwowania silnego parowania

w trakcie pieczenia mocno wilgotnych potraw,

zaleca się przykrycie naczynia pokrywą i zdjęcie

jej w końcowej fazie w celu przyrumienienia potrawy,

Ważne !

Poniżej w tabelach podano orientacyjne temperatury i czasy pieczenia dla różnych potraw. W

praktyce mogą występować różnice, które użytkownik powinien skorygować na podstawie własnych doświadczeń. Najlepiej wykonać kilka prób

dla poszczególnych potraw, a następnie zanotować optymalny czas i temperaturę.

11

PL

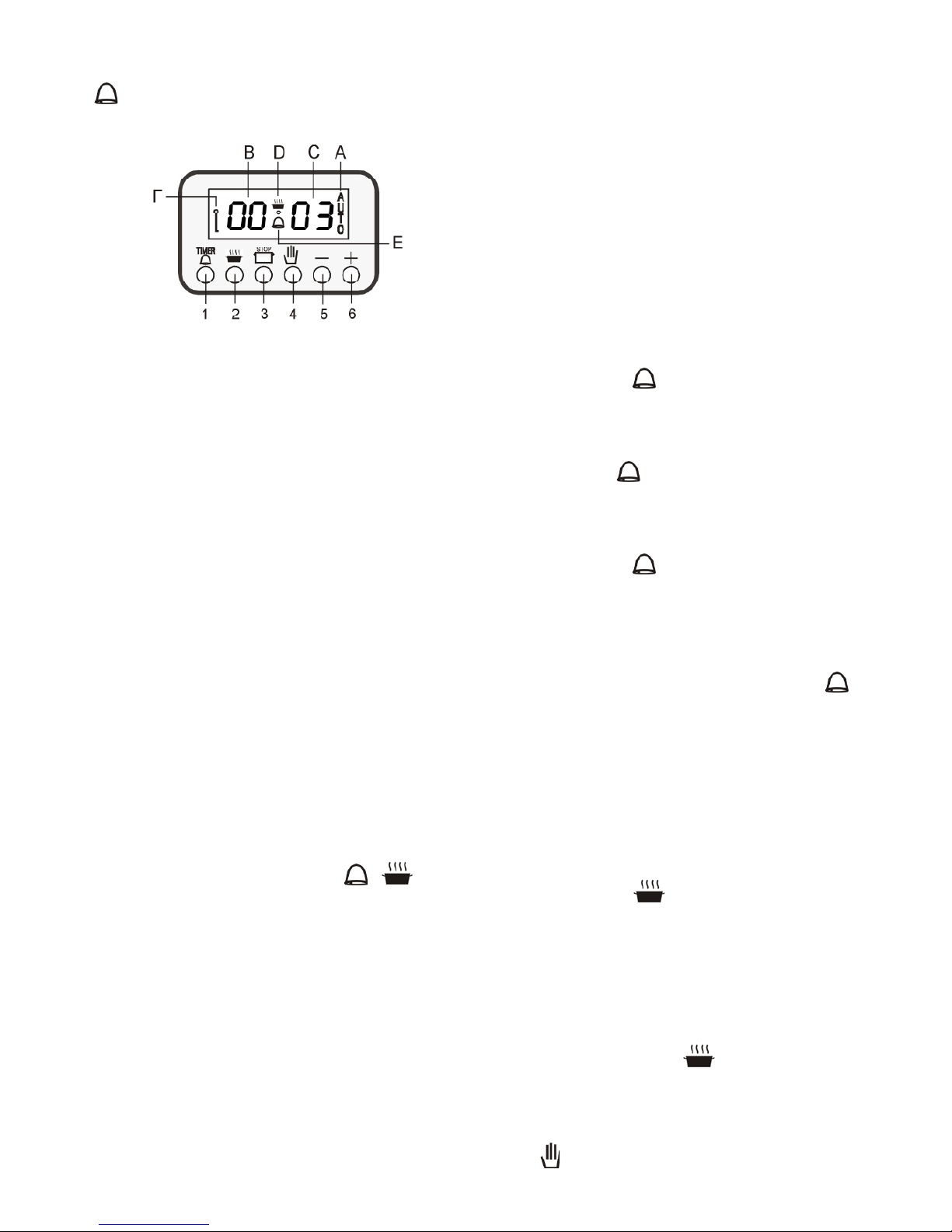

Wypieki metodą tradycyjną

Tabela 2

Rodzaj wypieku Temperatura [0C] Czas pieczenia [godz:min]

Babka piaskowa 160 - 175 1:15 - 1:20

Babka drożdżowa 175 - 190 0:50 - 1:00

Biszkopt 170 - 180 0:30 - 0:40

Spód pod owoce na kruchym cieście Rozgrzany piekarnik 210 - 220 0:10 - 0:25

Chałka drożdżowa 190 - 200 0:30 - 0:40

Strucla (z jabłkami) 220 0:40 - 0;50

Placek z owocami 200 - 210 0:25 - 0:50

Placek z kruszonką 200 - 220 0;20 - 0;30

Tabela 3

Pieczenie mięsa metodą tradycyjną

Rodzaj mięsa Ilość [kg] Temperatura [0C] Czas pieczenia [godz:min]

Wołowina 1 220 - 250 2:00 - 2:30

Wieprzowina 1 210 - 225 1:30 - 2:00

Cielęcina 1 210 - 225 1:45 - 2:00

Baranina 1 210 - 225 1:30 - 2:00

Dziczyzna (zając) 2 Rozgrzany piekarnik 210 - 230 1:00 - 1:50

Kurczak 1 225 - 250 0:45 - 1:00

Ryby 1 210 - 225 0:45 - 1:00

Pieczenie i duszenie mięsa z wykorzystaniem nawiewu

Tabela 4

Rodzaj mięsa Ilość [kg] Temperatura [0C] Czas pieczenia [godz:min]

Kurczaki 1 180 0:50 - 1:00

Dziczyzna 1 - 1,5 160 2:00 - 2:20

Cielęcina 1 160 1:40 - 2:20

Wieprzowina 1 175 1:50 - 2:00

Wołowina 1 160 2:00 - 2:30

Gęś, kaczka - 175 w zależności od wagi

Wypieki z wykorzystaniem nawiewu

Tabela 5

Rodzaj wypieku Temperatura [0C] Czas pieczenia [godz:min]

Bezy 100 1:00 - 1:10

Babka piaskowa 160 1:05 - 1:10

Babka drożdżowa 160 1:00 - 1:10

Ciasto drożdżowe 175 0:40 - 0:45

Placek z kruszonką 175 0:20 - 0:30

Placek z owocami 175 0:40 - 0:55

Biszkopt 160 0:30 - 0:40

12

PL

Opiekanie na ruszcie

Tabela 6

Rodzaj potrawy

Czas opiekania [min]

1 strona 2 strona

Kotlet i sznycel wieprzowy 8 - 10 6 - 10

Sztuka mięsa wieprzowego 10 - 12 6 - 8

Kiełbaski 8 - 10 6 - 8

Szaszłyki 7 - 8 5 - 6

Stek wołowy 6 - 7 5 - 6

Sztuka mięsa wołowego 10 - 12 10 - 12

Kotlet cielęcy 6 - 8 6 - 8

Stek cielęcy 6 - 7 5 - 6

Kotlet barani 8 - 10 6 - 8

Kurczak - połówka 10 - 15 (strona wewn.) 10 - 12 (strona zewn.)

Filet z ryby 6 - 7 4 - 5

Pstrąg 4 - 7 6

Grzanki 2 - 3 2 - 3

Tosty 3 - 5 2 - 3

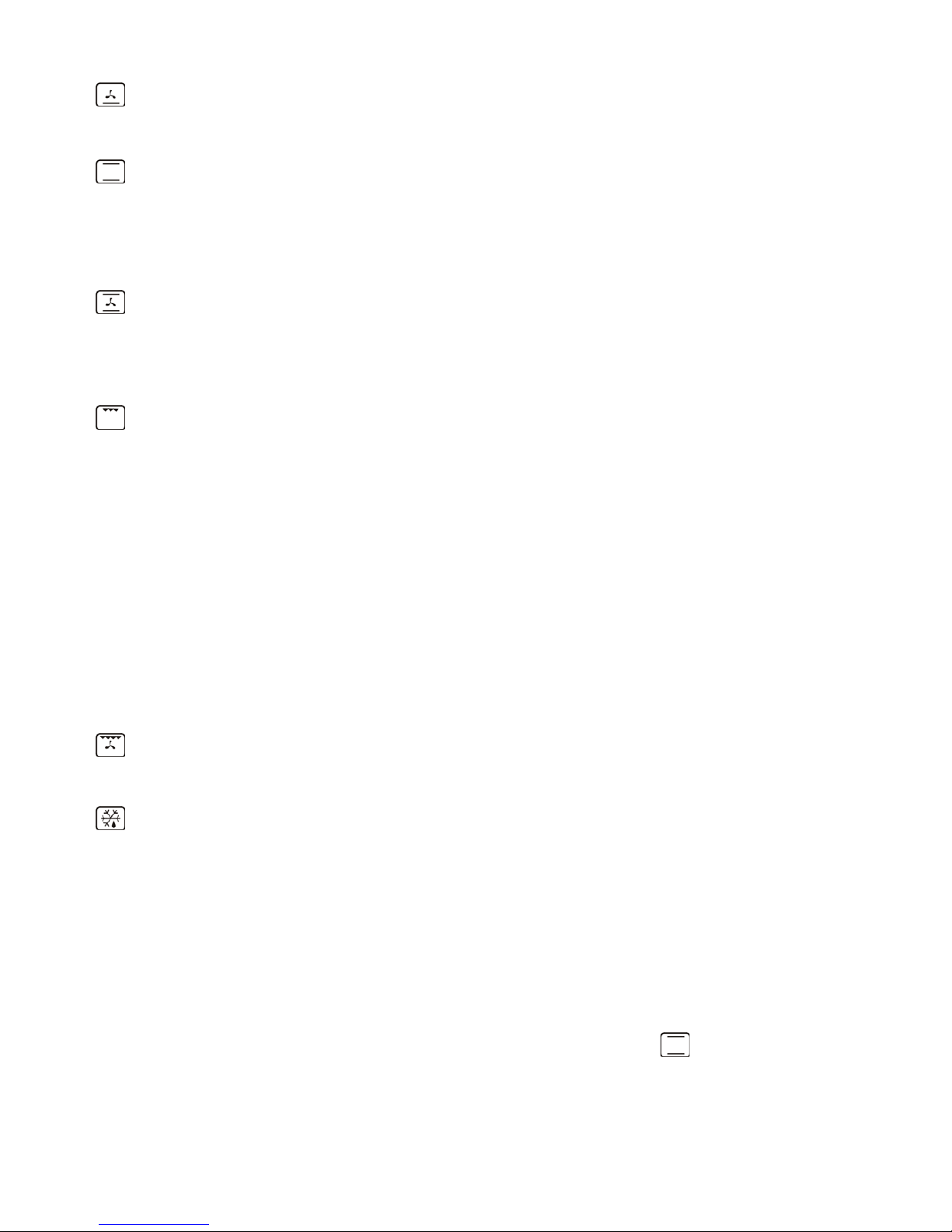

12.1. Uwagi ogólne

Elektroniczny programator cyfrowy steruje pracą piekarnika. Programator wskazuje aktualny czas z dokładnością do 1 minuty. Po każdym zrealizowanym

programie emituje sygnał dźwiękowy i samoczynnie

wyłącza piekarnik.

Programator umożliwia realizację następujących

funkcji:

ustawienie czasu bieżącego,•

ustawienie czasu trwania pieczenia,•

ustawienie godziny wyłączenia piekarnika, •

ustawienie czasu trwania pieczenia i godziny wy-•

łączenia kuchni w cyklu 24-godzinnym,

ustawienie minutnika,•

Możliwe jest sterowanie pracą piekarnika bez udziału programatora, po naciśnięciu przycisku

.

Jeżeli program automatycznego sterowania został

zakończony, a potrawa wymaga dalszego pieczenia,

wówczas pracę piekarnika można ponownie zapro-

gramować lub nacisnąć przycisk pracy ręcznej

i

kontrolować dalsze pieczenie.

Programator może działać jako minutnik, przy czym

minutnik działa niezależnie od programu.

Programowanie polega na naciśnięciu przycisku wy-

branej funkcji np.

i ustawieniu żądanego czasu

przyciskiem „+”. Przyciskiem „-” czas można skorygować.

Krótkotrwałe naciśnięcie przycisków „+” lub „-” powoduje zmianę czasu o jedną minutę, zaś dłuższe ich

przytrzymanie - włączenie trybu szybkiego przewija-

nia.

Programowanie:

nacisnąć i zwolnić przycisk wybranej funkcji,•

w czasie do 5 sekund po zwolnieniu przycisku funk-•

cji, przyciskami „+” i ewentualnie „-” ustawić wymagany czas; jeżeli w czasie tych 5s programowanie

nie zostanie rozpoczęte - wywołana funkcja znika,

po ok. 5s od zakończenia programowania, progra-•

mator wyświetla czas bieżący i zaczyna realizować

program.

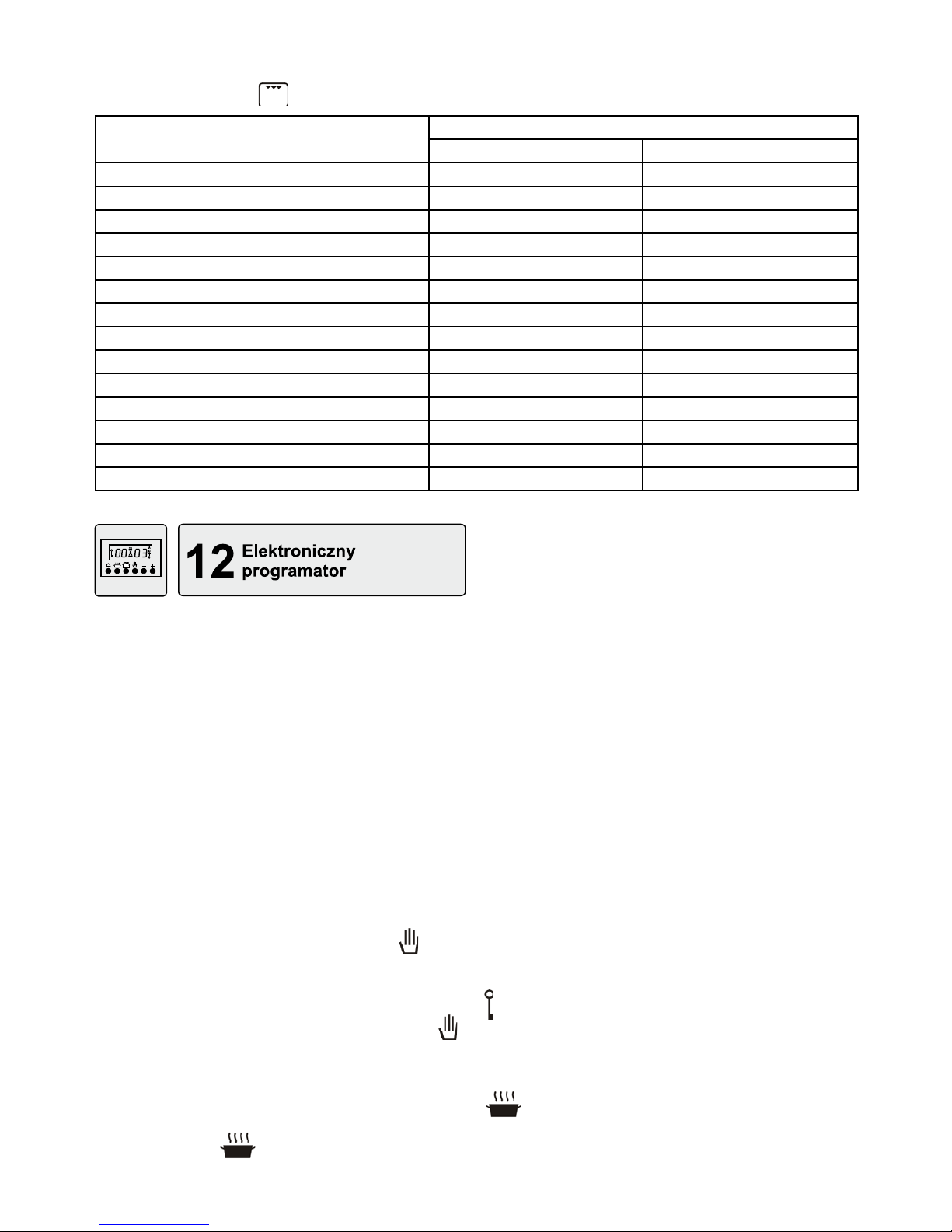

Na wyświetlaczu programatora pojawiają się następujące symbole graczne:

„AUTO” - Symbol pracy automatycznej

Ciągłe świecenie oznacza, że jest wykonywany program. Pulsowanie informuje o zakończeniu programu.

- Symbol blokady

Piekarnik można zabezpieczyć przed zmianą nastaw

lub przypadkowym włączeniem, zwłaszcza przez

dzieci.

- Symbol pracy piekarnika

Ciągłe świecenie sygnalizuje pracę piekarnika (o ile

jest on załączony).

13

PL

- Symbol minutnika

Ciągłe świecenie oznacza, że ustawiono minutnik.

A – praca automatyczna

B – godziny

C – minuty

D – symbol pracy piekarnika

E – symbol minutnika

F – symbol blokady

1 - przycisk minutnika

2 - przycisk czasu trwania

3 – przycisk godziny zakończenia

4 - przycisk pracy ręcznej

5 - przycisk nastawy zmniejszania czasu „-”;

6 - przycisk nastawy zwiększania czasu „+”

Po przyłączeniu kuchni do sieci zasilającej na 1.

wyświetlaczu programatora pojawiają się pulsujące „0.00” oraz „AUTO”.

Pierwszą czynnością jaką należy wykonać po 2.

podłączeniu kuchni do zasilania jest ustawienie czasu bieżącego.

Czas bieżący należy ustawić również po zaniku 3.

napięcia w sieci, trwającego dłużej niż 5s.

Dokładność wskazań programatora zależy od 4.

parametrów sieci zasilającej, dlatego okresowo należy go korygować, porównując z innym

zegarem.

12.2 Ustawienie czasu bieżącego

jednocześnie nacisnąć przyciski –

i ,

przyciskiem „ – +” (i ewentualnie „-”) ustawić żądany

czas np. 11.38,

po ustawieniu czasu zwolnić wszystkie przyciski. –

W czasie ok. 5s od zwolnienia przycisków czas zostanie zapamiętany. Na wyświetlaczu ukazuje się

ustawiony czas. Po ustawieniu czasu bieżącego

kuchnia pracuje w trybie ręcznym.

12.3 Wyłączenie sygnału dźwiękowego

Po zakończeniu każdego programu, piekar-•

nik automatycznie wyłącza się, a włącza się

sygnał dźwiękowy.

Po pewnym czasie sygnał dźwiękowy sam •

się wyłącza.

Użytkownik może wcześniej wyłączyć sygnał •

dźwiękowy naciskając dowolny przycisk programatora.

12.4 Minutnik

Minutnik służy do dźwiękowej sygnalizacji po upływie ustawionego czasu. Można go wykorzystać przy

wykonywaniu krótkotrwałych czynności kulinarnych

(np. gotowanie jaj). Minutnik można ustawić w trakcie realizowania dowolnego programu. Minutnik nie

wyłącza piekarnika.

Ustawienie minutnika:

nacisnąć przycisk –

,

przyciskami: „ – +” i ewentualnie „-” ustawić żądany

czas (np. 3 minuty).

Po ok. 5 s na wyświetlaczu ukaże się czas bieżący

i świeci wskaźnik

. Po upływie zadanego czasu

(tj. 3 minuty) włącza się sygnał dźwiękowy. Sygnał

można wyłączyć naciskając dowolny przycisk.

Kasowanie nastawy minutnika:

nacisnąć przycisk –

,

nacisnąć przycisk „ – -” i przytrzymać go, aż do pojawienia się na wyświetlaczu komunikatu „0.00”,

UWAGA !

Aby sprawdzić ile czasu pozostało do końca

pracy minutnika należy nacisnąć przycisk

Naciśnięcie tego przycisku nie przerywa odmierzania czasu.

12.5 Programowanie czasu trwania pieczenia

Po zaprogramowaniu czasu trwania pieczenia i wybraniu funkcji piekarnika, piekarnik włącza się natychmiast.

Programowanie czasu pracy:

nacisnąć przycisk –

,

przyciskami „ – +” i ewentualnie „-” ustawić żądany

czas pracy np. 35 minut

Po upływie ustawionego czasu:

automatycznie wyłącza się piekarnik, –

włącza się sygnał dźwiękowy, –

na wyświetlaczu programatora pulsuje symbol –

„AUTO” i gaśnie symbol

.

Jeżeli istnieje potrzeba dalszej pracy piekarnika (np.

w celu dopieczenia ciasta) wówczas można ponownie zaprogramować czas lub nacisnąć przycisk pracy

ręcznej

i kontrolować dalszą pracę piekarnika.

14

PL

12.6 Programowanie godziny zakończenia pie-

czenia

Tej funkcji najczęściej używa się z funkcją programowanie czasu trwania pieczenia.

Programowanie godziny wyłączenia:

nacisnąć przycisk –

,

przyciskami „ – +” i ewentualnie „-” ustawić godzinę

wyłączenia piekarnika np. 11.50.

Po upływie ustawionego czasu:

piekarnik automatycznie wyłącza się, –

włącza się sygnał dźwiękowy, –

na wyświetlaczu programatora pulsuje „ – AUTO”.

Jeżeli potrawa nie jest dostatecznie upieczona,

można ponownie zaprogramować czas pracy jak w

punkcie powyżej lub ustawić godzinę wyłączenia pie-

karnika albo nacisnąć przycisk pracy ręcznej

i

kontrolować dalszą pracę piekarnika.

12.7 Sterowanie automatyczne

Praca w cyklu automatycznym polega na zaprogramowaniu czasu trwania pieczenia i godziny wyłącze-

nia piekarnika.

Piekarnik o określonej godzinie samoczynnie włączy

się, a po upływie nastawionego czasu automatycznie

wyłączy się.

Przykład:

Pieczenie wołowiny:

aktualny czas na zegarze - godzina 13.00 –

wymagany czas pieczenia 2 godziny –

temperatura pieczenia 220 –

0

C

potrawę przygotować na godzinę 17.00 –

Mięso włożyć do brytfanny, dodać ok. 10 łyżek •

wo-dy i przykryć pokrywką. Następnie brytfannę

włożyć do piekarnika, ustawić na ruszcie na wybranym poziomie i zamknąć drzwi piekarnika.

Pokrętłem wyboru funkcji wybrać pozycję •

,

a pokrętłem regulatora temperatury ustawić temperaturę 2200C.

Nacisnąć przycisk •

a następnie przyciskami

„+” i ewentualnie „-” odmierzyć czas trwania pie-

czenia tj. 2 godziny.

Nacisnąć przycisk •

i przyciskami „+” oraz

ewentualnie „-” ustawić godzinę 17.00 (czas zakończenia pieczenia.

1. Praca piekarnika została zaprogramowana i odbędzie się automatycznie.

2. O godzinie 15.00 piekarnik samoczynnie włączy

się i będzie pracować przez 2 godziny. O godzinie 17.00 urządzenie samoczynnie wyłączy się,

co jest sygnalizowane sygnałem dźwiękowym. W

tym czasie pulsuje „AUTO” i gaśnie

.

3. Jeżeli potrawa nie została dostatecznie upieczona, pracę piekarnika można ponownie zaprogra-

mować lub nacisnąć przycisk pracy ręcznej

i

kontrolować dalsze pieczenie.

UWAGA !

Naciśnięcie przycisku •

w czasie pracy

piekarnika pozwoli na wyświetlenie zaprogramowanej godziny wyłączenia.

Po naciśnięciu przycisku •

jest wyświetlany zaprogramowany czas trwania pieczenia. Jeżeli piekarnik już rozpoczął pracę, to

ukaże się czas jaki pozostał do zakończenia

programu.

Niemożliwe jest wprowadzanie czasów nie-•

logicznych. Tzn. jeśli na programatorze aktualnie jest godzina 12.00, a wymagany czas

pieczenia wynosi 1 godzina 30 minut to czasu zakończenia pieczenia nie można ustawić

wcześniej niż na 13.30.

12.8 Zmiana nastaw

Zmianę nastawy można przeprowadzić w czasie do

5s od rozpoczęcia programowania lub po skasowaniu programu.

Zmiana czasu trwania lub godziny wyłączenia piekarnika:

nacisnąć przycisk danej funkcji np. –

lub ,

przyciskami „ – +” i „-”ustawić nowy czas.

12.9 Kasowanie nastaw

nacisnąć przycisk danej funkcji np. –

lub ,

nacisnąć przycisk „ – -” i przytrzymać go, aż do pojawienia się na wyświetlaczu komunikatu „0.00”.

Po skasowaniu programu, pracę piekarnika można

ponownie zaprogramować.

12.10 Sterowanie ręczne

UWAGA !

Naciśnięcie przycisku

spowoduje przejście

do trybu pracy ręcznej. Oznacza to, że grzałki

piekarnika włączają się na czas nieokreślony i

użytkownik musi kontrolować dalsze pieczenie.

W celu wyłączenia piekarnika pokrętło wyboru

funkcji należy ustawić na pozycji zerowej.

Jeżeli w trakcie trwania programu, użytkownik •

zamierza przejść do trybu pracy ręcznej, należy

skasować program i nacisnąć przycisk

.

15

PL

Naciśnięcie przycisku • wyłącza funkcje programatora. Piekarnik obsługuje się wtedy wyłącznie

pokrętłem wyboru funkcji i pokrętłem regulatora

temperatury.

Przy sterowaniu ręcznym można korzystać z mi-•

nutnika.

12.11 Funkcja blokowania

Funkcja ta umożliwia zabezpieczenie przed ingerencją dzieci. Oznacza to, że po ustawieniu tej funkcji,

dziecko może wybrać na programatorze dowolny

program, ale program nie będzie aktywny. Przed

przystąpieniem do czynności zabezpieczania, pro-

gramator powinien być w trybie pracy ręcznej

.

Blokowanie programatora:

jednocześnie nacisnąć przyciski –

oraz i

przytrzymać je w tej pozycji ok. 8 sekund, aż do

pojawienia się na wyświetlaczu napisu „ON”,

nacisnąć przycisk „ – +”,

na wyświetlaczu pojawia się napis „ – OFF” i świeci

symbol blokady

,

po upływie ok. 5s na wyświetlaczu obok symbolu –

blokady

pojawia się czas bieżący; piekarnik jest

zablokowany.

Odblokowanie programatora:

programator powinien być w trybie ręcznym, –

jednocześnie nacisnąć przyciski –

oraz i

przytrzymać je w tej pozycji ok. 8 sekund, aż do

pojawienia się na wyświetlaczu napisu „OFF”,

nacisnąć przycisk „ – +”,

na wyświetlaczu pojawia się napis „ – ON” i gaśnie

symbol blokady

,

po upływie ok. 5s na wyświetlaczu pojawi się po- –

nownie czas bieżący; piekarnik jest odblokowany.

12.12 Zmiana intensywności świecenia

W godzinach pomiędzy 22.00 i 5.59 programator

samoczynnie redukuje intensywność świecenia wyświetlacza.

W tych godzinach, wyświetlacz świeci intensywnie

tylko wtedy gdy:

minutnik odmierza czas, –

aktualnie jest wykonywany program, –

naciśnięto dowolny przycisk. –

UWAGA !

Przed przystąpieniem do czyszczenia, kuchnię

odłączyć od sieci elektrycznej.

13.1 Uwagi ogólne

Kuchnię należy systematycznie czyścić. Do •

czyszczenia nie należy stosować gruboziarnistych środków rysujących powierzchnie, drucianych gąbek, agresywnych środków chemicznych

i ostrych przedmiotów.

Części z blachy nierdzewnej, pokrętła i tablicę •

rozdzielczą czyścić łagodnymi płynami, nie zawierającymi środków ściernych.

Powierzchnie emaliowane czyścić miękką ście-•

reczką lub gąbką zwilżoną w ciepłej wodzie z delikatnym detergentem, unikając nadmiaru wody.

Silne zabrudzenia usuwać specjalnymi środkami

do czyszczenia kuchni.

Nie używać szorstkich środków czyszczących •

lub metalowych przedmiotów do czyszczenia powierzchni szklanych, gdyż mogą je porysować,

co może doprowadzić do popękania szkła.

Powierzchnia płyty wokół palników zawsze powin-•

na być czysta, gdyż zanieczyszczenia pogarszają spalanie mieszanki gazowej. Przy czyszczeniu

płyty grzejnej nie dopuszczać do przedostania

się wody pod płytę.

Palniki i zapalacze zawsze powinny być czyste i •

suche, co zapewni ich prawidłowe działanie.

Zanieczyszczone ruszty zdjąć z płyty grzejnej, •

wymoczyć je w ciepłej wodzie z detergentem, a

następnie umyć i osuszyć.

Blachy i foremki do pieczywa oraz blachy do •

pieczenia mięsa i brytfanny, zaraz po użyciu wymoczyć w ciepłej wodzie z dodatkiem płynu do

mycia naczyń kuchennych, starannie je umyć i

wytrzeć do sucha.

Prosimy kontrolować czystość uszczelki drzwi •

piekarnika.

13.2 Czyszczenie palników

UWAGA !

Palniki i zapalacze należy czyścić po każdorazowym zalaniu potrawą a także okresowo, usuwając z nich naloty i zanieczyszczenia.

Elementy palnika (13.2.1)

1 – nakrywka 4 – dysza

2 – kołpak 5 – zapalacz

3 – korpus 6 – termopara

16

PL

Demontaż drzwi piekarnika

Drzwi całkowicie otworzyć, –

Unieruchomić oba zawiasy (13.4.1) po obu stro- –

nach drzwi przez założenie obejmy 1 na zaczep

2 pałąka 3 zawiasu (13.4.2),

Następnie drzwi chwycić oburącz, powoli je ob- –

racać w kierunku zamykania o kąt 45

0

i wycią-

gnąć zawiasy z gniazd (13.4.3).

UWAGA !

1. Pałąk zawiasu jest napięty ze znaczną siłą i

dlatego podczas wyjmowania drzwi piekarnika

należy zachować ostrożność, aby nie przyciąć

sobie palców.

2. Zabrania się czyścić piekarnik urządzeniami

do wytwarzania pary pod ciśnieniem.

W przypadku zabrudzenia klosza lampki piekarnika należy go wykręcić, umyć i wytrzeć do sucha

(13.4.4).

Piekarniki są pokryte emalią ceramiczną.•

Piekarnik czyścić środkami do czyszczenia kuch-•

ni.

Do czyszczenia trudnych do usunięcia zapieczeń •

można użyć specjalnych środków przeznaczonych

do czyszczenia piekarników. Preparaty te są jednak żrące i dlatego należy ich używać minimalnie

i bardzo ostrożnie, przestrzegając zaleceń producenta tych środków.

UWAGA !

Przed przystąpieniem do usuwania usterek, aby

uniknąć możliwości porażenia prądem elektrycznym, kuchnię odłączyć od sieci elektrycznej.

W okresie gwarancji wszelkie naprawy poza niżej •

wymienionymi powinien wykonać upoważniony

Zakład Usługowy.

Jeżeli podczas użytkowania urządzenia wystąpią •

zakłócenia, należy sprawdzić na podstawie niżej

podanych wskazówek, czy mogą Państwo samodzielnie usunąć usterkę.

Zdjąć nakrywki i kołpaki palników, wymoczyć je w •

ciepłej wodzie z detergentem, a następnie każdą

część palnika osobno umyć.

Elementy palników można myć gąbką lub szczo-•

teczką, a do przetykania otworów płomieniowych

można użyć stalowego drucika. Po umyciu sprawdzić, czy otwory płomieniowe są drożne.

Kołpaki należy myć po każdym zabrudzeniu aby •

uniknąć trwałych plam.

Korpus w pobliżu dyszy zawsze powinien być czy-•

sty. Brud gromadzący się w pobliżu dyszy może

spowodować jej zatykanie się a palniki mogą palić

się słabym płomieniem lub w ogóle nie będą się

palić.

Dysze przetrzeć pędzelkiem zwilżonym w rozpusz-•

czalniku.

Czyste elementy palników dokładnie osuszyć, •

gdyż zawilgocone mogą utrudnić zapalenie gazu

lub spowodować jego nieprawidłowe spalanie. Po

osuszeniu elementy palników założyć w odwrotnej

kolejności jak przy zdejmowaniu, zwracając przy

tym uwagę, aby nie uszkodzić zapalaczy.

13.3 Czyszczenie płyty grzejnej

Płyty emaliowane należy czyścić dostępnymi na •

rynku środkami do czyszczenia kuchni (13.3.1)

13.4 Czyszczenie piekarnika

Przed przystąpieniem do czyszczenia, należy po-•

czekać aż piekarnik ostygnie. Gorące grzałki grożą

poparzeniem.

Piekarnik najlepiej czyścić po każdorazowym uży-•

ciu, aby nie dopuścić do ponownego zapiekania

resztek potraw i odprysków z tłuszczu.

Na dno piekarnika nie należy wlewać wody, ponie-•

waż może ona przedostać się do grzałki dolnej.

Podczas mycia górnej ściany piekarnika należy •

zwrócić uwagę na znajdujące się tam grzałki elektryczne, czujnik temperatury oraz lampkę oświetlenia piekarnika. Nie naruszyć pozycji osadzenia

czujnika.

Aby ułatwić czyszczenie piekarnika, można wyjąć •

drzwi.

Problem Rozwiązanie

Iskrownik nie zapala gazu lub nie zawsze

go zapala

Sprawdź, czy kuchnia jest podłączona do sieci elektrycznej. –

Wyczyść i osusz elementy palnika i iskrownik. –

Sprawdź, czy nakrywki palników i kołpaki są założone prawidłowo. –

Naciskając z góry na nakrywkę palnika, potrzyj ją o kołpak, obracając –

w prawo i w lewo (14.1.1).

Przetrzyj elektrodę iskrownika twardą szczoteczką lub delikatnie pil- –

niczkiem (14.1.2).

14.1.1 14.1.2

17

PL

Problem Rozwiązanie

Gaz w palniku nie zapala się Sprawdź, czy nie doszło do zgniecenia przewodu gumowego, przy –

zasilaniu gazem płynnym z butli.

Sprawdź, czy główny zawór gazu jest otwarty. –

Sprawdź, czy butla gazowa nie jest pusta. –

Jeżeli zainstalowano nową kuchnię lub wymieniono butlę z gazem na –

nową, wówczas należy powtarzać procedurę zapalania do momentu

aż gaz dotrze do palnika.

Sprawdź, czy dysza lub otwory płomieniowe w palniku nie są zanie- –

czyszczone lub zalane. Jeżeli tak, przeczyść otwór dyszy używając

szpilki lub igły. Do wyczyszczenia otworów w palniku użyj szczoteczki.

Następnie wszystkie elementy osusz.

Po zwolnieniu pokrętła gaśnie gaz

Masz kuchnię z zabezpieczeniem

ustaw pokrętło na duży płomień –

, naciśnij je, a po zapaleniu gazu,

trzymaj je wciśnięte do oporu jeszcze przez kilka sekund.

Przy zapalaniu jednego z palników iskrzą

zapalacze wszystkich pozostałych palników płyty

Zjawisko normalne

Naciśnięcie wybranego pokrętła (z zapalaczem) lub naciśnięcie przycisku zapalacza wyzwala iskrę przy wszystkich palnikach.

Po ustawieniu pokrętła na pozycji płomień

oszczędnościowy

- gaz gaśnie lub pło-

mień jest za wysoki

Unikaj przeciągów w pomieszczeniu kuchennym –

Skontaktuj się z instalatorem w celu wyregulowania płomienia oszczęd- –

nościowego

.

Niestabilny płomień Sprawdź, czy elementy palnika są czyste, suche i czy są prawidłowo –

założone.

Na częściach ze stali nierdzewnej (inoks)

pojawiają się plamy, których nie można

usunąć standardowymi środkami

Powierzchnie ze stali nierdzewnej – czyścić po każdym zabrudzeniu,

używając wyłącznie środka przeznaczonego do stali nierdzewnej.

Wypiek nie udaje się

Parametry pieczenia podane w instrukcji obsługi są orientacyjne. W

praktyce parametry te zależą od masy potrawy, konsystencji ciasta, poziomu na którym znajduje się potrawa, itp. Dlatego radzimy wykonać kilka prób dla ulubionych potraw, a następnie zanotować optymalny czas i

temperaturę.

Z piekarnika wydobywa się dym Przy opiekaniu powstający dym jest zjawiskiem normalnym.

Otwórz okna, aby przewietrzyć pomieszczenie. –

Po wystudzeniu piekarnika, wyczyść jego wnętrze a szczególnie rożen. –

Podczas opiekania potraw używaj tacy ociekowej. –

18

PL

Nie działa oświetlenie piekarnika 1. Sprawdź, czy kuchnia jest podłączona do sieci elektrycznej.

2. Nie dokręcona lub przypalona żarówka.

Przed usunięciem usterek, odłącz kuchnię od sieci elektrycznej.

odkręć szklaną osłonę 1 lampki z oprawy 2 i dokręć żarówkę 3 lub wymień ją –

na nową (typ żarówki: E14 230V 25W odporność na temperaturę 300

0

C).

Na wyświetlaczu programatora pulsują zera

„0.00”

Spadek lub chwilowe wyłączenie napięcia. Kuchnię odłączyć od sieci elektrycznej, chwilę odczekać, ponownie włączyć ją do sieci a na programatorze ustawić

czas bieżący.

Uszkodzony przewód zasilający Jeżeli przewód zasilający kuchni ulegnie uszkodzeniu, to powinien go wymienić

wytwórca lub specjalistyczny zakład naprawczy albo wykwalikowana osoba, w

celu uniknięcia zagrożenia.

UWAGA !

Jeżeli po wykonaniu powyższych czynności urządzenie nadal nie działa, należy skontaktować się z infolinią

tel. 0703 103 131 lub zgłosić naprawę w punkcie obsługi serwisowej.

To urządzenie jest oznaczone zgodnie z Dyrektywą Europejską 2002/96/EC symbolem

przekreślonego kontenera na odpady.

Takie oznakowanie informuje, że sprzęt ten, po okresie

jego użytkowania nie może być umieszczany łącznie z

innymi odpadami pochodzącymi z gospodarstwa domo-

wego.

Użytkownik jest zobowiązany do oddania go odpowiednim

jednostkom prowadzącym zbiórkę zużytego sprzętu elek-

trycznego i elektronicznego.

Właściwe postępowanie ze zużytym sprzętem elektrycznym i elektronicznym przyczynia się do uniknięcia szkodliwych dla zdrowia ludzi i środowiska naturalnego konsekwencji, wynikających z niewłaściwego składowania i

przetwarzania takiego sprzętu.

Charakterystyka techniczna piekarnika

KGE 3416 ZB Plus

KGE 3416 ZX Plus

KGE 3416 ZN Plus

Klasa efektywności energetycznej

1)

A

Zużycie energii elektrycznej - pieczenie konwencjonalne [kWh]

2)

0,79

Zużycie energii elektrycznej - pieczenie z wymuszonym obiegiem powietrza [kWh]

2)

0,88

Pojemność użytkowa piekarnika [l] 55

Rozmiar komory piekarnika Średni

Czas potrzebny na ogrzanie standardowego wsadu [min] 45

Powierzchnia użytkowa największej blachy do pieczenia [cm

2

] 1080

1)

W skali od A (bardziej efektywna) do G (mniej efektywna)

2)

Dla standardowego wsadu

19

RU

Кухонные плиты соответствуют требованиям следующих директив:

2006/95/WE – низковольтные электрические изделия

2004/108/WE – электромагнитная совместимость

90/396/ЕЕС – основные требования к устройствам сжигающим газовые виды топлив [GAD]

ВАЖНО!

Перед установкой и пользованием плиты просим внимательно изучить

инструкцию по эксплуатации. Инструкция содержит рисунки, а номера

рисунков соответствуют нумерации глав в тексте.

Приобретенный Вами прибор указан на рис.

1.1.1.

2.1 Предназначение

Кухонная плита предназначена для приготовления

пищи исключительно в домашнем хозяйстве.

Запрещается ее применение в иных целях.

2.2 Класс устройства – 1 (свободностоящее)

2.3. Категория газа - II

2H+3B/P

2.4. Номинальная мощность конфорок:

Конфорка малая – 1,0 кВт

Конфорка средняя – 1,75 кВт

Конфорка большая – 3,0 кВт

2.5. Описание составных частей кухонной

плиты (1.1.1)

1 – плита

2 – электрический духовой шкаф

3 – панель управления

4 – дверь духового шкафа

5 – ящик для посуды

6 – конфорка малая

7 – конфорка средняя

8 – конфорка большая

9 – решетка плиты

10 – поднос духового шкафа

11 – решетка духового шкафа

2.6 Панель управления (2.6.1)

1 – ручки газовых вентилей

2 – ручка выбора функции духового шкафа

3 – ручка регулировки температуры

4 – контрольная лампочка работы духового

шкафа

5 – контрольная лампочка регулятора температуры

6 – электронный программатор

1. Данное оборудование не предназначено для

использования лицами (в том числе детьми) с

физическими либо психическими дефектами

или лицами без опыта и знания оборудования,

за исключением, если это происходит под

наблюдением либо согласно инструкции

эксплуатации устройства, предоставленной

лицами, отвечающими за их безопасность.

Следует обращать внимание на детей, чтобы

они не играли с оборудованием.

2. Кухонные плиты следует устанавливать в

соответствие с существующими правилами и

эксплуатировать исключительно в помещениях

с соответствующей вентиляцией.

3. Элементы упаковки просим хранить вне

досягаемости детей, поскольку они несут

опасность для детей.

4. Устройство следует устанавливать после 8

часового содержания в помещении кухни.

5. Перед монтажом устройства следует убедиться,

что местные параметры газоснабжения (вид

и давление газа) соответствуют устройству.

Условия настройки устройства представлены

на идентификационной табличке.

6. Данное устройство не подсоединено к системе

вытяжки. Оно должно быть установлено и

подсоединено в соответствии с существующими

правилами монтажа. В особенности, следует

обратить внимание на требования, касающиеся

вентиляции.

7. Подсоединение плиты к газопроводу или

газовому баллону должен осуществлять

исключительно квалифицированный монтер

или мастер авторизированного сервисного

пункта, что должно быть отмечено в гарантийной

книжке изделия. Отсутствие соответствующей

отметки означает потерю гарантии.

8. В случае поломки устройства, в особенности при

20

RU

утечке газа или замыкании электропроводки,

устройство необходимо выключить, и следует

немедленно обратиться в сервисный центр.

Запрещается пользоваться неисправной

кухонной плитой.

9. Производитель не несет ответственность

за травмы либо повреждения, вызванные

неправильной установкой устройства,

подсоединением к неисправной газовой

либо электрической сети или вследствие

неправильной эксплуатации устройства.

10. Самостоятельное выполнение каких-либо

ремонтных работ, за исключением замены

лампочки подсветки камеры духового шкафа,

приведет к потере гарантии на устройство.

11. Кухонную плиту запрещается поднимать за

ручку дверей духового шкафа

.

12. Производитель оставляет за собой право на

внесение изменений в целях модернизации

устройства и постоянного улучшения

уровня качества, без предварительного

информирования пользователей. Однако эти

изменения не будут вызывать трудностей с

использованием устройств.

• Во время использования, плита становиться

горячей. Рекомендуется соблюдать осторожность и избегать контакта с горячими

элементами внутри духового шкафа. Просим

обратить особое внимание на детей.

• Соединительные провода механического

кухонного оборудования, используемого в

близи включенной кухонной плиты, должны

находиться вдали от ее горячих элементов.

Следует следить, чтобы эти провода не были

зажаты горячей дверью духовой плиты.

• Для снятия посуды с конфорок или вынимания

подносов из духового шкафа следует

использовать сухие кухонные варежки.

• Не оставлять без присмотра устройство с

зажженными конфорками, в особенности во

время жаренья, поскольку перегретый жир

может загореться.

• Легковоспламеняемые предметы содержать

вдали од конфорок.

• Не хранить в духовом шкафу и контейнере

для посуды предметов легковоспламеняемых

и чувствительных к воздействию высоких

температур.

• Не нагружать открытую дверь духового шкафа.

Запрещается садиться или вставать на нее.

• Перед открыванием двери духового шкафа,

следует отодвинуться от него, чтобы

накопившийся горячий воздух мог развеяться.

• Не использовать на плите посуды, которая

выступает за периметр плиты.

• Использование устройства для приготовления

пищи вызывает выделение тепла и влажности

в помещении, в котором это оборудование

установлено. Следует убедиться, что

помещение кухни хорошо вентилируется.

Вентиляционные отверстия должны быть

открытыми, либо необходимо установить

устройства принудительной вентиляции

(кухонную вытяжку).

• При интенсивном длительном пользовании

устройством может возникнуть необходимость

дополнительной вентиляции, например

открытия окна либо более эффективной

вентиляции, например увеличения интенсивности механической вентиляции, если такова

установлена.

• Запрещается самостоятельно переделывать

кухонную плиту на другой вид газа, осуществлять

изменения в газовой и электрической сети

устройства.

• Не использовать устройства для отопления

помещений.

В случае утечки газа, следует незамедлительно перекрыть вентиль газовой сети или

на газовом баллоне, тщательно проветрить

помещение и вызвать аварийную газовую

службу. В это время запрещается зажигать

спички, курить, включать или выключать

электрические приемники ( радио, звонок,

включатель осветления) либо механические

устройства, вызывающие искрение.

В случае воспламенения газа, улетучивающегося из поврежденного вентиля газового

баллона, в целях охлаждения баллона

следует набросить на баллон мокрое одеяло

и закрыть вентиль баллона. Запрещается

использование поврежденного баллона!

Не ставить на решетках плиты деформиро- –

ванной или нестабильной посуды, поскольку

она может перевернуться и залить конфорки.

Не ставить пустой посуды над горящей –

21

RU

конфоркой.

Перед снятием посуды с конфорки следует –

уменьшить пламя или полностью его

погасить.

Конфорки следует содержать в чистоте. –

Не допускать вскипания блюд и заливания

конфорок.

6.1. После распаковывания устройства проверить,

не имеет ли оно явных повреждений. Если плита

была повреждена во время транспортировки,

подсоединять ее запрещается.

6.2. Удалить с плиты возможные наклейки и

тщательно смыть с нее остатки клея.

6.3. Кухонное помещение должно быть сухим и

хорошо вентилируемым.

6.4. Установка устройства должна гарантировать

свободный доступ ко всем элементам

управления. Не рекомендуется устанавливать

плиту на подставке.

6.5. Устройство должно быть установлено вдали

от легковоспламеняющихся материалов.

Стена помещения, которая прилегает к

плите, должна быть выполнена из негорящих

материалов.

6.6. Над плитой должен быть свободный простор

для оттока кухонного пара. Наилучшим

решением является установка кухонной

вытяжки, которая будет впитывать или

отводить этот пар. Расстояние между

вытяжкой и плитой должно составлять не

менее 650 мм (6.6.1).

6.7. Запрещается монтаж кухонной мебели

непосредственно над плитой.

6.8. Кухонная плита оборудована регулировочными

ножками, предназначенными для установки

уровня плиты. Для получения доступа

к регулировочным ножкам, необходимо

наклонить плиту (6.8.1) или вынуть контейнер

для посуды (6.8.2). Вращать ножки в одну

либо другую сторону, в зависимости от

потребности.

• Кухонная плита оборудована штуцером с

резьбой G1/2”. Подключить к штуцеру газ,

используя соответствующие инструменты.

• Кухонную плиту можно подключить к

внутренней домашней газовой сети либо к

баллону со сжиженным газом.

• Перед началом подсоединения кухонной

плиты, газовый вентиль должен бить закрыт.

• Соединение рекомендуется уплотнить тефлоновой лентой.

7.1 Подсоединение к газовой сети

• Кухонную плиту можно подсоединить

к газовой сети жестко или с помощью

сертифицированного эластического металлического шланга.

• Максимальная длина эластического шланга

не должна превышать 2,0 метров. Шланг не

должен касаться никаких подвижных элементов

и не должен пролегать в пространстве, в

котором нет достаточно места.

• При подключении к жесткой системе труб,

следует обратить внимание, чтобы не создать

напряжений в какой-либо точке сети либо

какой-либо части устройства.

7.2 Подсоединение баллона со сжиженным

газом

• Если вы планируете использовать баллоны

со сжиженным газом, кухонную плиту не

следует устанавливать в подвале или другом

помещении, в котором пол находится ниже

уровня земли, поскольку сжиженный газ

тяжелее воздуха и накапливается на уровне

пола.

• Для подсоединения баллона к устройству

следует использовать сертифицированный

резиновый шланг.

• Для подсоединения кухонной плиты с

резиновым шлангом, следует использовать

стальную трубу длинной не менее 0,5м.

• Длина резинового шланга не должна

превышать 1,5 м. После подсоединения,

шланг должен быть зажат с обоих концов

зажимными хомутами.

• Шланг не может быть переломан или сжат и

должен быть доступен на всей длине.

• Шланг не должен пролегать в непосредственной близости от источников тепла (макс.

50°С).

• Протекающий шланг должен быть заменен

незамедлительно. Запрещается ремонт протекающего шланга.

После каждого подсоединения газового баллона

к кухонной плите, необходимо проверить

герметичность вентиля баллона и соединение

редуктора с баллоном, а также его работу.

22

RU

ВНИМАНИЕ!

1. Запрещается проверка герметичности с

помощью открытого пламени (например,

зажигалки или свечки). Опасность взрыва!

Для проверки герметичности можно

использовать мыльную воду.

2. Следует периодически контролировать

состояние шланга и герметичность

соединения, согласно с существующими

требованиями.

3. Резиновый шланг не должен прикасаться к

горячим частям кухонной плиты.

7.3 Замена жиклеров

В случае необходимости приспособления

кухонной плиты к системе газоснабжения с

другим видом газа, следует заменить жиклеры

и заполнить этикетку смены газа, которая

находиться в мешочке вместе с инструкцией и

гарантийным талоном. После описания, к какому

виду газа приспособлена кухонная плита, этикетку

приклеить на устройстве.

Замена жиклеров:

перекрыть вентиль, отсекающий систему –

газоснабжения или баллона от кухонной

плиты,

перекрыть все вентили кухонной плиты, –

снять решетки, а также крышки и рассекатели –

конфорок.

открутить старые жиклеры и заменить их –

новыми, согласно с таблицей 1,

установить на место рассекатели и крышки –

конфорок,

отрегулировать вентили конфорок, –

проверить герметичность соединений. –

7.4 Регулировка вентилей

Регулировка газового вентиля конфорок призвана

настроить минимальное пламя конфорки.

Регулировка вентилей:

открыть доступ газа и зажечь регулируемую –

конфорку,

установить ручку в позиции –

- минимум

(маленькое пламя), далее не меняя позиции

ручки вентиля снять ручку с оси вентиля и

наблюдать за племенем конфорки,

вращать регулировочным болтом „ – А” (7.4.1)

и наблюдать за пламенем; установить

высоту языка пламени таким образом,

чтобы оно не гасло при легком сквозняке, а

также при быстром изменении положения

регулировочной ручки с максимальное на

минимальное пламя и обратно,

можно считать, что регулировка выполнена –

правильно, если ядро пламени имеет

форму конуса зелено-синего цвета высотой

приблизительно 2-4 мм,

если в системе газоснабжения имеют место –

видимые колебания давления газа (изменение

величины пламени при полном открытии

вентиля), минимальное пламя следует

отрегулировать при низком давлении таким

образом, чтобы конфорка не гасла во время

ее использования,

после регулировки вентилей, установить –

обратно ручку и погасить пламя.

Расход газа при минимальном пламени составляет

приблизительно 25% расхода при максимальном

пламени.

8.1 Кухонные плиты, укомплектованные силовым

кабелем с вилкой, должны быть подсоединены

к розетке с правильно подключенным штырем

заземления (8.1.1)

8.2 В кухонных плитах, укомплектованных

силовым кабелем без розетки, следует

подсоединить розетку. Кабель подсоединить

к розетке с правильным заземлением. Перед

G20 13mbar G20 20mbar G30 30mbar

Малая конфорка 084 X072 050

Средняя конфорка 110 Z097 065

Большая конфорка 145 Y118 085

Расположение

жиклеров

Таблица 1 Данные жиклеров

23

RU

подсоединением необходимо убедиться, что:

напряжение сети соответствует напряжению, –

представленному на идентификационной

табличке.

электрическая сеть, к которой должна –

быть подсоединена кухонная плита, имеет

соответствующую мощность по отношению

к максимальной мощности, потребляемой

кухонной плитой, представленной на

идентификационной табличке.

Розетка должна быть расположена в легко

доступном для пользователя месте.

Просим обратить внимание, чтобы силовой

кабель не касался горячих частей кухонной

плиты.

Эмалированные и стеклянные поверхности •

протереть мягкой и влажной тряпкой.

Проверить правильность размещения отдель-•

ных частей конфорки.

Вынуть из духового шкафа все дополнительное •

оборудование, снять с него пленку и вымыть в

воде, добавляя жидкость для мытья посуды.

Кухонная плита оборудована электронным •

программатором. После подсоединения

устройства к сети, следует установить текучее

время. Описание программаторов находиться в

отдельных инструкциях.

Перед первым использованием кухонной •

плиты следует закрыть дверь духового шкафа

и включить его на приблизительно 30 минут.

Духовой шкаф должен быт пустой. Ручку

выбора функции установить на позиции

или

, а ручку регулятора установить

на 250°С. Возникающие при этом дым и

запах – незначительны, если позаботиться

о соответствующей вентиляции помещения,

например, открывая окна. После того, как

духовой шкаф остынет, очистить согласно

рекомендациям, представленным в разделе

«уход и очистка».

10.1 Газовые конфорки (10.1.1)

А – розжиг

В – наконечник термопары (система газконтроля)

10.2 Ручки.

Подача газа в конфорках регулируется ручками

газовых вентилей. Перед включением конфорки

следует убедиться, что ручка, которую мы

собираемся покрутить, соответствует конфорке,

которую мы хотим зажечь. Принадлежность

конфорок к ручкам указано на рисунке (10.2.1).

10.3 Выбор пламени.

Пламя не должно выходить за пределы дна

посуды. Величина пламени зависит от позиции

ручки (10.3.1, 10.3.2,10.3.3)

0 – конфорка погашена (подача газа перекрыта)

- большое пламя

- маленькое пламя

10.4 Большое пламя

(10.3.2) следует использовать до кипения блюда, а для дальнейшего

приготовления его следует уменьшить и лучше

всего установить на позиции «маленькое пламя»

(10.3.3). Величину пламени следует регулировать

только в диапазоне между

и (10.4.1)

10.5 Розжиг конфорок

Кухонные плиты оснащены в предохранительное

устройство, отсекающее подачу газа к конфорке

после угасания пламени, например при заливании

конфорки блюдом.

Ручку выбранной конфорки повернуть против –

движения часовой стрелки, нажать на нее

и держать в этом положении до момента

загорания газа (10.5.1),

После загорания газа, держать нажатой ручку –

дo упора еще около 5 сек, чтобы активировать

устройство,

Отпустить ручку и установить желаемую –

интенсивность пламени.

В случае случайного угасания пламени,

закрыть вентиль конфорки и не возобновлять

попытки зажжения конфорки на протяжении

1 минуты.

10.6 Гашение конфорок

Повернуть ручку по движению часовой стрелки и

установить ее в позиции „0”.

10.7 Розжиг конфорок при использовании

сжиженного баллонного газа

Перед розжигом первой конфорки, открыть

вентиль на баллоне, а затем разжечь конфорку,

как это описано выше.

При отсекании подачи газа, перед гашением

последней конфорки следует:

закрыть вентиль на газовом баллоне, –

24

RU

после угасания пламени закрыть вентиль –

этой конфорки.

Если газовая плита не используется, вентиль на

газовом баллоне должен быть закрыт.

10.8 Подбор посуды

Диаметр дна посуды должен быть в 2,5 – 3 раза •

больше рассекателя конфорки (10.8.1). Посуда

не должна выступать за решетку, а пламя

не должно выходить за пределы дна посуды

(10.8.2).

Посуда должна всегда быть чистой и сухой, •

поскольку при таких условиях посуда хорошо

проводит и удерживает тепло.

Во время приготовления пищи посуда должна •

быть накрыта крышками, что позволит избежать

накопления избыточного количества пара в

кухонном помещении.

Минимальные размеры посуды:

Для маленькой конфорки – Ø 90 мм•

Для средней конфорки – Ø 160 мм•

Для большой конфорки – Ø 200 мм•

11.1 Компоненты духового шкафа (11.1.1)

[1], [2], [3], [4], [5] – уровни направляющих

1 – верхняя спираль

2 – спираль гриля

3 – нижняя спираль

4 – лампочка подсветки камеры

5 – перфорированная крышка

6 – датчик температуры

11.2 Ручка выбора функций (11.2.1)

Ручка выбора функций позволяет выбрать самую

подходящую функцию для данного блюда. Ее

можно поворачивать в обоих направлениях. Ниже

описаны функции для духового

шкафа.

Нижний подогрев

Тепло отдает нижняя спираль, установленная

под полом камеры духового шкафа. Эта функция

используется, когда необходимо дожарить блюдо

снизу. Рекомендуется использовать в течении

последних 10-15 минут запекания.

Верхний подогрев

Функция предназначена для более интенсивного

запекания блюд сверху.

Нижний подогрев с вентилятором

Вентилятор равномерно распределяет тепло,

формируемое в нижней части духового шкафа.

Конвекционная система

При этой функции тепло поступает и сверху и

снизу. Блюда следует помещать на одном уровне,

лучше в центральном месте духового шкафа.

Идеально подходит для запекания пирогов, мяса,

рыбы, хлеба, пиццы и т.п.

Традиционное запекание с вентилятором

Вентилятор вызывает циркуляцию горячего

воздуха вокруг блюда. При этом методе следует

выбрать температуру более низкую, чем при

традиционном методе запекания.

Традиционное запекание

Функция предназначена для запекания блюд

малых размеров (стейки, шашлыки, сосиски,

рыбы, тосты, гренки, запеканки и др.).

Блюдо следует поместить на подносе или решетке

на посредине.

Время запекания принимается в пределах 8-10

минут на каждый сантиметр толщины. Духовой

шкаф предварительно следует разогреть при

максимально температуре. Запекаемые порции,

по истечении половины времени следует

перевернуть на другую сторону.

Во время запекания мяса на решетке

рекомендуется установить на нижнем уровне

поднос для сбора стекающего жира и влить в него

приблизительно 0,5 л воды.

Запекание с вентилятором

Функция позволяет жарить при одновременном

равномерном распределении тепла с помощью

вентилятора.

Разморозка

При использовании этой функции включен

вентилятор, который равномерно распределяет

тепло вокруг блюда. Таким образом, одерживается

однородное размораживание пищевых продуктов.

11.3 Ручка регулировки температуры

(11.3.1)

Регулятор температуры дает возможность

устанавливать и автоматически поддерживать

температуру в духовом шкафу на требуемом

уровне.

На ручку нанесены значки, которые соответствуют

уровням температуры в духовом шкафу (после

разогрева).

Установка температуры

повернуть ручку вправо и установить на –

желаемой позиции из диапазона 50-250°С.

После окончания запекания – повернуть ручку

влево и установить ее на „•” позиции.

25

RU

11.4. Контрольные лампочки (2.6.1)

Оранжевая контрольная лампочка • обозначает

работу духового шкафа. Лампочка всегда

загорается после выбора произвольной функции

духового шкафа, а гаснет после установки ручки

выбора функции на позицию «0».

Красная контрольная лампочка• обозначает

работу регулятора температуры. Лампочка

загорается при установке произвольной

температуры и гаснет при достижении этой

температуры. Далее, она будет загораться и

гаснуть в процессе запекания, сигнализируя

о включении и выключении спиралей в целях

поддержания заданной температуры.

11.5 Электронный программатор

Программатор позволяет управлять работой

духового шкафа в автоматическом или полуавтоматическом режиме.

Использование программатора не исключает

возможности ручного управления духовым шкафом.

Описания программаторов представлены в

отдельных инструкциях.

11.6 Лампочка подсветки духового шкафа

В целях Вашей безопасности и удобства, в камере

духового шкафа во время запекания включена

подсветка. Лампочка подсветки загорается после

выбора произвольной функции духового шкафа.

После выключения духового шкафа, подсветка

гаснет.

11.7 Дополнительное оборудование

Кухонные плиты стандартно оснащены одной

или двумя поддонами (11.7.1) и решеткой для

запекания (11.7.2).

Решетка предназначена для установки на ней

различной посуды с блюдами, предназначенной

для жарки или запекания. На нее также можно

класть некоторые блюда, например мясо, сосиски,

рыбу. В таких случаях под решеткой следует

установить поддон для стекающего жира и влить

в него приблизительно 0,5 л воды, в таком случае

духовой шкаф останется чистым.

11.8 Функционирование духового шкафа

1. Разогреть духовой шкаф, а затем поместить

блюдо в посуде на соответствующем уровне

духового шкафа (11.8.1).

2. Ручкой выбора функции выбрать способ нагревания духового шкафа, например

(11.8.2)

3. Ручкой регулировки температуры установить

температуру, соответствующую блюду, например 200°С (11.8.3).

4. В кухонных плитах с программатором можно

запрограммировать работу духового шкафа.

5. После завершения запекания, ручки выбора