Page 1

What’s New

Page 2

Mastercam® X6 What’s New

Date: October 2011

Copyright © 2011 CNC Software, Inc.— All rights reserved.

First Printing: October 2011

Software: Mastercam X6

TERMS OF USE

Use of this document is subject to the Mastercam End User License Agreement. A copy

of the Mastercam End User License Agreement is included with the Mastercam product

package of which this document is part. The Mastercam End User License Agreement

can also be found at:

www.mastercam.com/legal/licenseagreement/

Page 3

What’s New in Mastercam X6

General System Enhancements

64-bit Support

Mastercam X6 is available as a 64-bit application, which lets you take full advantage of your 64-bit hardware and

operating systems.

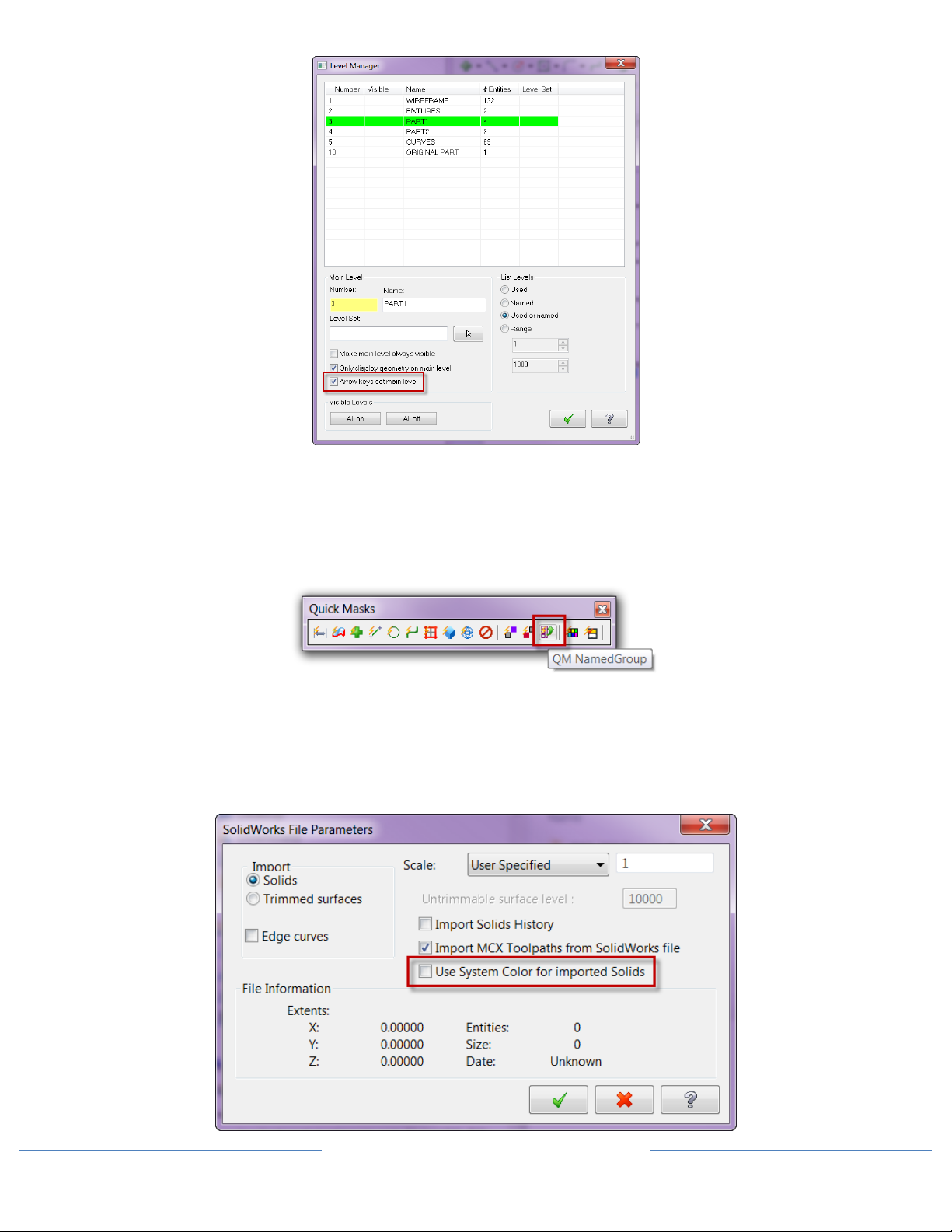

Level Manager Improvements

These improvements focus on level manipulations that are especially useful on parts imported from other

systems where levels were not used. These enhancements will assist you in organizing the data so you can

create toolpaths or perform other edits to the model.

On the Change Levels and Attributes dialog boxes, you now have control over the visibility of new levels you

create for geometry. You can force new levels to be visible or invisible once the geometry is moved or copied.

In addition, you can control which level is the Main level using the arrow keys in the Level Manager. Select the

Arrow keys set main level checkbox and use the arrow keys to move through the level list and change your

Main level.

What’s New in Mastercam X6 - Page 1

Page 4

Quick Mask for Groups

This new Quick Mask provides a shortcut to the Groups Manager dialog box for geometry selection. Instead of

selecting All, Group Manager, you can simply click this toolbar button and then double-click to quickly select all

geometry assigned to a group.

Override Solid Face Color on Import

This new option, located in File, Open, Options or Settings, Configuration, Converters, forces the colors of

imported solids to take on the current system color. This overrides any face or feature colors that have already

been applied to a solid.

What’s New in Mastercam X6 - Page 2

Page 5

DWFx Import

Mastercam X6 now supports the .DWFx file format, which is an Autodesk file format based on the XML Paper

Specification (XPS) format from Microsoft. DWFx files can also be opened directly within Microsoft’s XPS Viewer.

File Translator Updates

• ACIS: R22

• Autocad: Can now take .DWFX files

• CATIA V5: R21

• KeyCreator: 2011

• Parasolids: 23

• ProE/Creo: Wildfire5/Creo 1.0

• SolidEdge: ST4

• SolidWorks: 2012

Design Enhancements

Intersecting and Trimming Solid Edges

Mastercam’s AutoCursor now recognizes intersections between wireframe geometry and solid edges without

creating additional geometry first.

You can also trim or extend wireframe geometry to solid edges using the existing Mastercam trimming

functions. Some examples include:

• Using Edit, Trim/Break, Trim/Break/Extend to trim the wireframe to one, two, or three solid edge

entities.

• Selecting Edit, Trim Many to use a solid edge as the trim boundary

• Using Edit, Trim/Break, Break at Intersection to break wireframe where it intersects solid edges.

Solid Trim to Surface

The Trim Solid dialog box includes two new options for trimming solids to surfaces. These options give you

more control over your trimming results.

What’s New in Mastercam X6 - Page 3

Page 6

Remove Solid History

The functionality from the NoHist C-Hook is now incorporated into the main Mastercam product. This function

strips the list of operations or features from a solid model, leaving it as a "brick" in the Solids Manager. You can

use this to prevent changes and protect your model. You can access this function by choosing Solids, Remove all

solid history operations

Xform Fit

Xform Fit is a new function in Mastercam X6 that “nests” geometry along a vector, making it easier for you to

make multiple copies between two defined points without knowing the exact distance between the points. This

can be helpful when fitting parts between clamps and fixtures.

Trim/Divide Support for Splines

Mastercam X6 includes support for splines in Xform Divide for trimming curves or curves to be trimmed.

All and Only Mask – Arc Sweep

The All and Only masks now include the option to select arcs and circles with a sweep angle in mind. This is

another way to speed up your geometry selection. For example, selecting a 0.5” diameter can be limited to only

circles when diameter and arc sweep are used together. You can set these options on the Miscellaneous page of

the Select All and Select Only dialog boxes.

What’s New in Mastercam X6 - Page 4

Page 7

Analyze Point or Area Using Feet/Inches

In the following Analyze functions, you can now see results in inches, feet/inches decimal, feet/inches fractional,

millimeters, centimeters, or meters:

• Position

• Volume/Area, 2D Area

• Volume/Area, Surface Area

• Volume/Area, Solid Properties

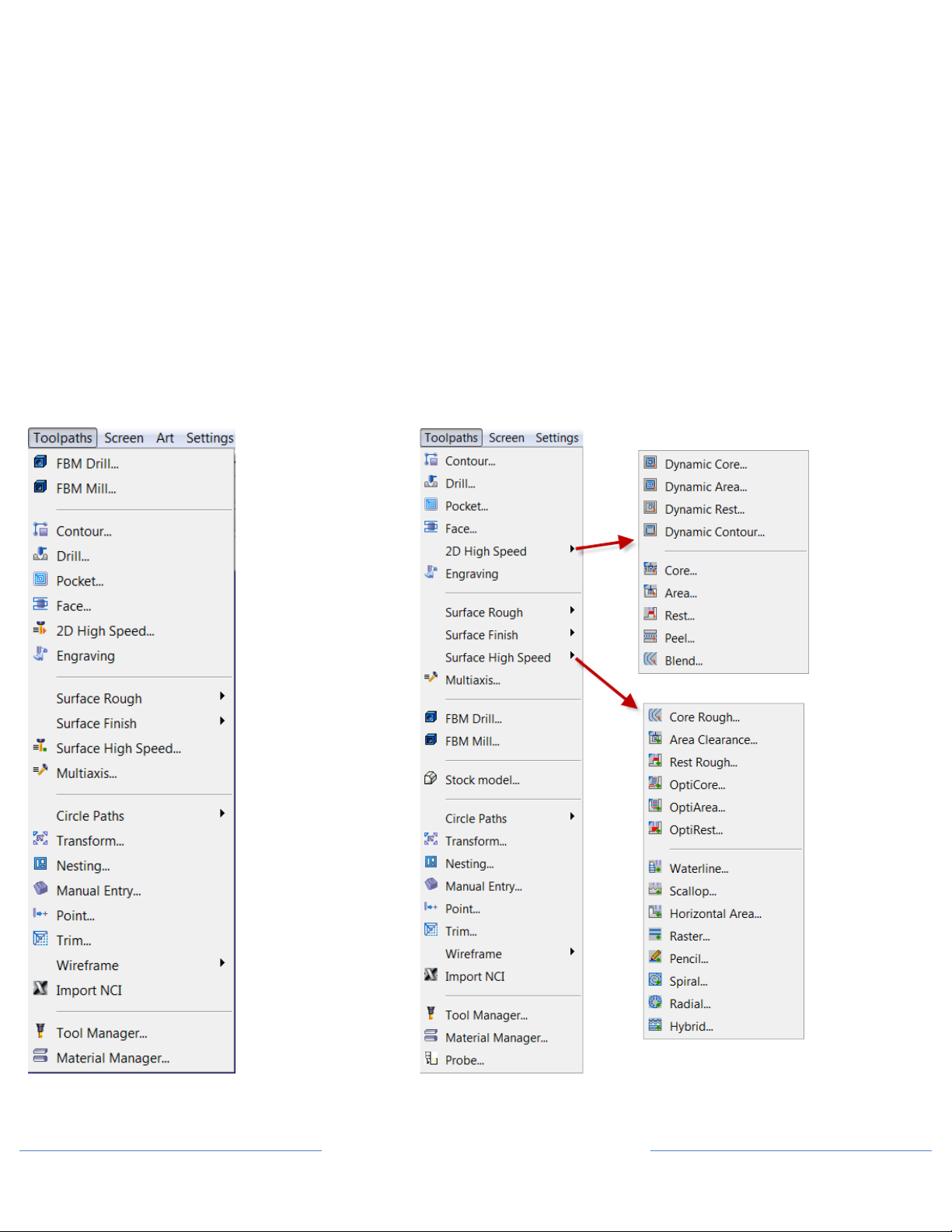

General Mill/Router Enhancements

Mill/Router Toolpath Menu Reorganization

By restructuring the Mill and Router toolpath menus, you now have easier, faster access to all 2D and 3D high

speed toolpaths.

Mastercam X5 Mill Mastercam X6 Mill

What’s New in Mastercam X6 - Page 5

Page 8

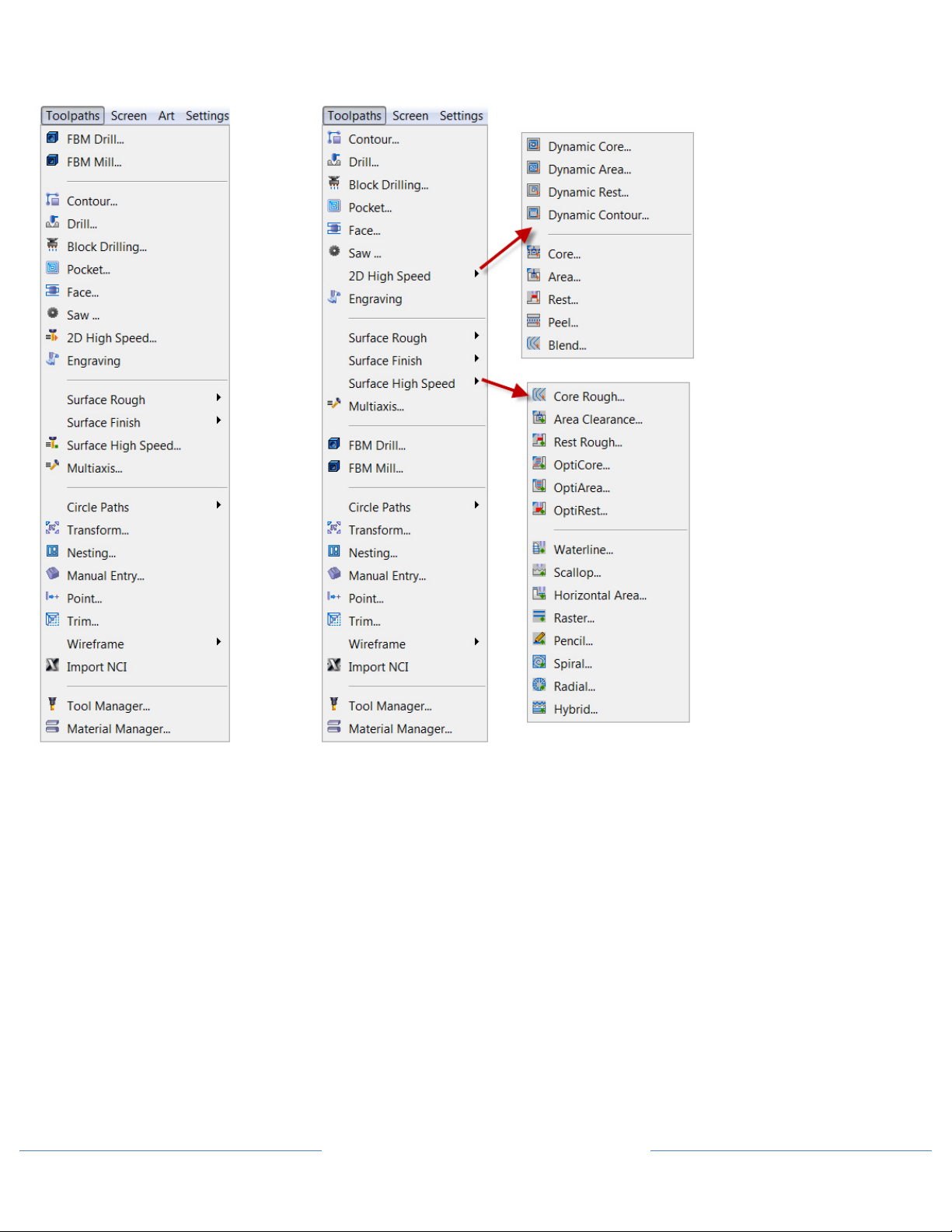

Mastercam X5 Router Mastercam X6 Router

What’s New in Mastercam X6 - Page 6

Page 9

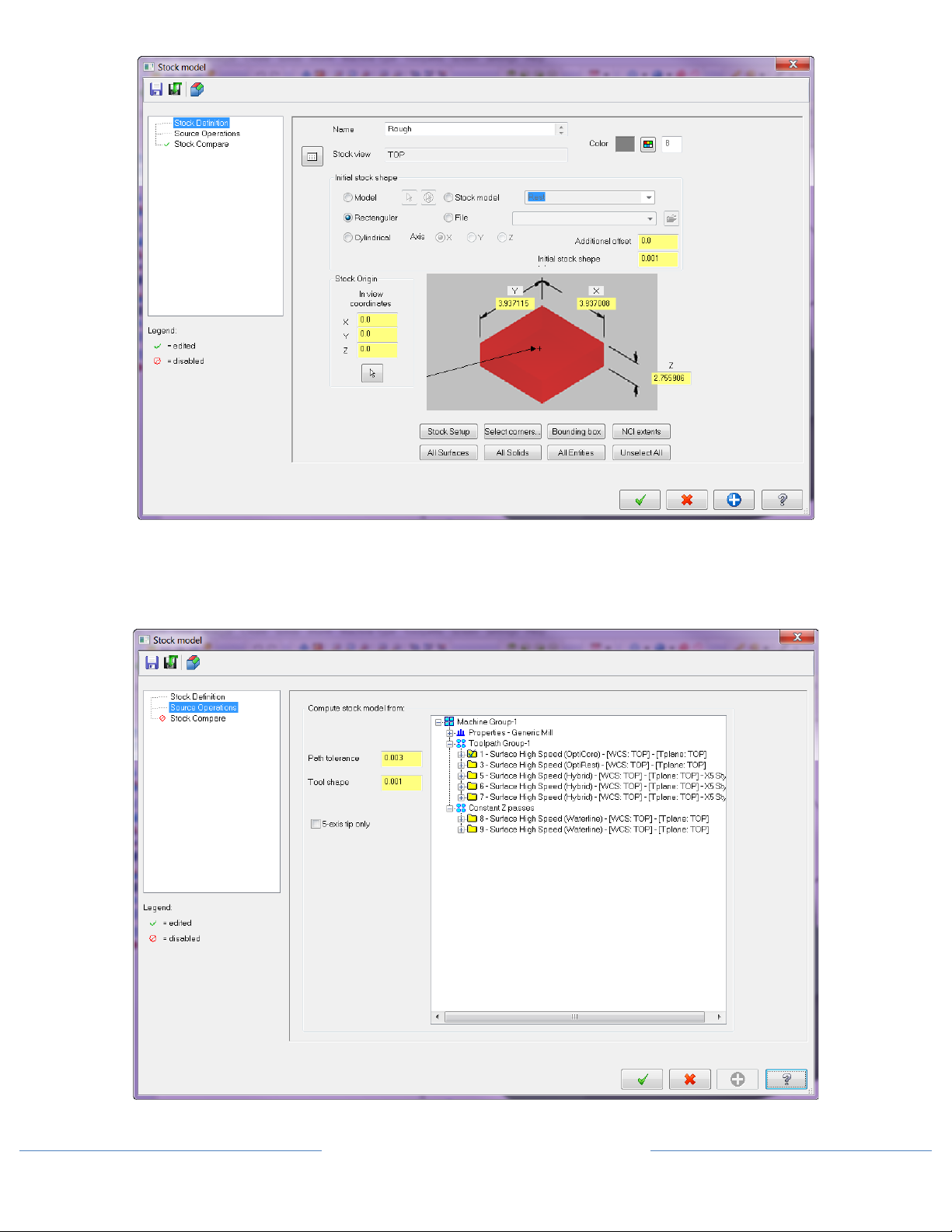

Stock Model

In Mastercam X6, the stock model for Mill 2-axis through 5-axis toolpaths is now a separate entity in the

Toolpath Manager with more power and flexibility than ever before.

You can generate an initial stock model by choosing Toolpaths, Stock model from the Mastercam menu. The

stock model is fully associative and has parameters that can be edited at any time similar to toolpath or solid

operations. The stock model operation is marked dirty and requires a regen if you make changes to the stock

model parameters or any toolpath the stock model is referencing.

Once created, you can use stock model operations to:

• Verify stock

• Define stock for rest machining

• Visualize stock

• Generate stock model compares

Note: If you have activated multi-threaded processing for your configuration, Mastercam generates stock model

operations as multi-threaded processes.

In the Stock Model dialog box, the Stock Definition page lets you create a name for the model, select a color, and

set the basic shape parameters. Solids, mesh entities, surfaces (even single surfaces), STL files, and other stock

models can all provide the basis for the new stock model. You can also pull in any values you entered in the

Stock Setup page of the Machine Group Properties dialog box.

What’s New in Mastercam X6 - Page 7

Page 10

The Source Operations page is where you select the source operations to process against the defined stock in the

stock model operation. Use [Ctrl+click] and [Shift+click] methods to select any combination of operations in

the tree, including those from different machine groups.

What’s New in Mastercam X6 - Page 8

Page 11

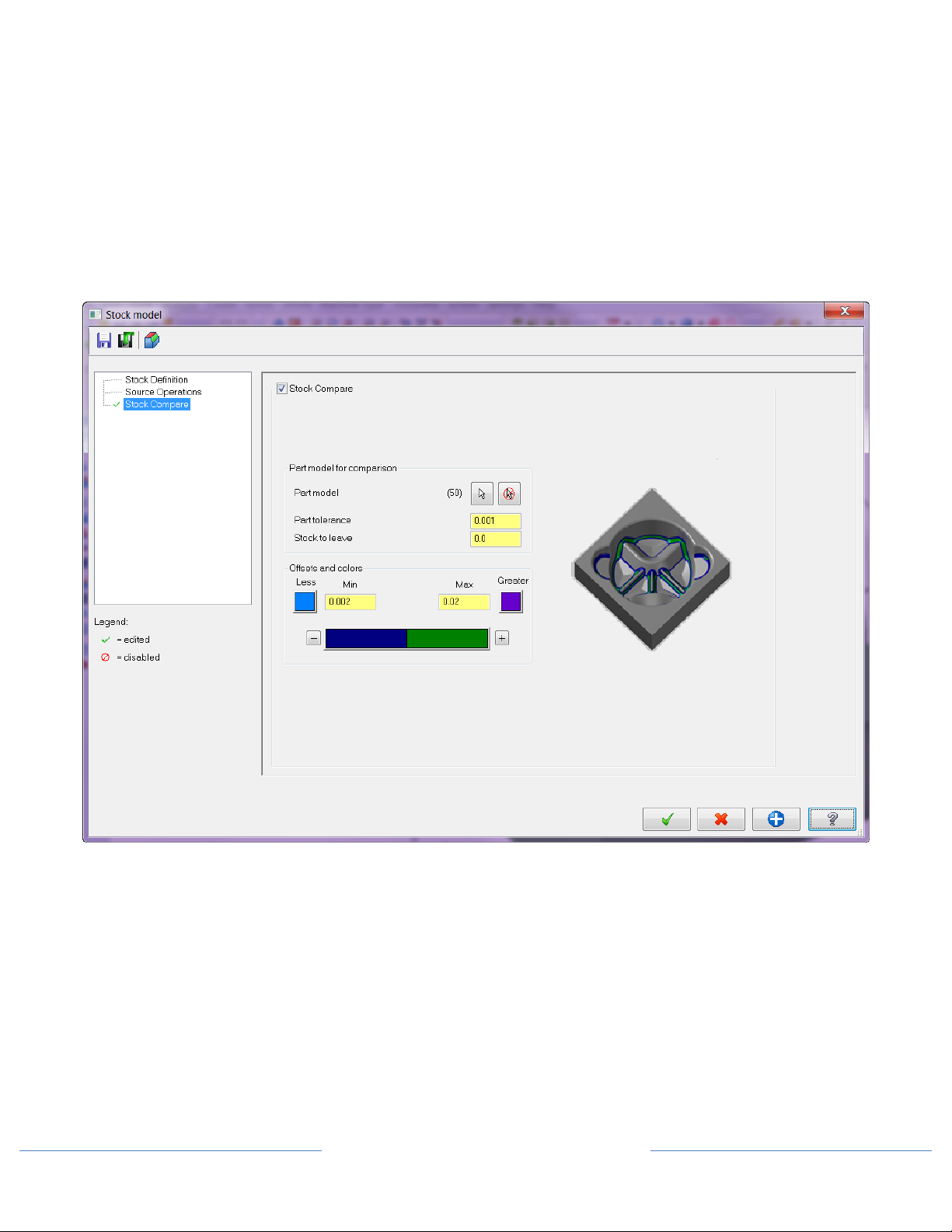

In addition, you can use the stock model to display leftover material. Using the Stock Compare page, follow these

general guidelines:

• Select the Stock Compare checkbox.

• Use the Select button to return to the graphics window and select the part model entities to use in the

comparison against the stock model.

• Define the tolerance for the stock model compare.

• Enter a value for stock to leave on the part model.

• Set the minimum/maximum offset values and colors for the compare results.

For more details on using this function, please click the Mastercam Help button at the bottom of the dialog box.

What’s New in Mastercam X6 - Page 9

Page 12

The following picture shows stock model comparison results:

Toolpath operation Stock model result from operation

Bull-Nose Tool Support in Dynamic and Optimized Roughing Toolpaths

Toolpath motion in the following Mill and Router toolpaths is now optimized for bull-nose tools as well as flat

endmills. If you select a bull-nose tool, the toolpath strategy alters the tool’s trajectory to prevent any remaining

material cusps.

• 2D HST: Dynamic Core, Dynamic Area, Dynamic Rest

• 2D HST: OptiCore, OptiArea

Coolant Icons in Toolpath Manager

These new icons let you quickly see whether coolant is on or off for each toolpath. These icons are only used by

Mill and Lathe toolpaths. Clicking on the icons takes you to the toolpath parameters so you can make changes if

necessary.

What’s New in Mastercam X6 - Page 10

Page 13

Mill/Router Tool Improvements

Improved Tool Preview Zoom Functionality

A new Zoom button on the Define Tool dialog box quickly focuses on the tool’s cutting portion and lets you see

details on very small shaded tools. Clicking the Zoom button again returns you to the Fit view. The new preview

makes it much easier to see the cutting portion of the tool and reduces the chance of errors.

Figure 1 - The Define Tool dialog previewing a long tool with a small corner radius

Figure 2- The Define Tool dialog previewing a long tool with a small corner radius in zoom mode

What’s New in Mastercam X6 - Page 11

Page 14

New Taper Section for Lollipop Tools

The lollipop tool shape is often used for undercutting operations. In order to make better use of the tool in these

situations, it’s common to have a tapered section on the shank of the tool. Rather than creating a custom tool or

representing your tool as a short shanked tool with a tapered holder, you can now define the taper in the Define

Tool dialog box.

Holder Support Added to TOOLDB

In Mastercam X6, you can now read tool holders from the TOOLDB (tool database) file. The HOLDERS file format

is still supported for backwards compatibility. You can use the Save to library function on the Holder toolpath

parameter page to convert your HOLDERS file into a TOOLDB file. You can also save individual holders to an

existing TOOLDB file.

Besides saving individual holders to a library, one of the most important benefits is that as new TOOLDB files

become populated with holder data, you can access to them through a new library without waiting for a new

software release.

Note:

Saving individual holder components to an existing library is only supported when using the new TOOLDB

file.

What’s New in Mastercam X6 - Page 12

Page 15

Mill/Router 2D Enhancements

New 2D HST Region Chaining

The new region chaining options in Mastercam X6 give you more control over areas to machine and areas to

avoid in your 2D HST toolpaths. After you select your initial chains, the Chain Options dialog box lets you adjust

your machining areas.

2D HST Blend Mill Compensation

Cutter compensation options are now available in 2D HST Blend Mill toolpaths. The options include left, right,

inside, and outside. Tip compensation and stock to leave on walls are also supported.

What’s New in Mastercam X6 - Page 13

Page 16

2D HST Dynamic Toolpath Improvements

The 2D HST Dynamic toolpaths (Core, Area, Rest, and Contour) include several enhancements in Mastercam X6:

Variable Toolpath Radius

The 2D HST Dynamic toolpaths currently use the toolpath radius value as a hard value for both arc on/off

motion and sharp corner smoothing. At times, the tool cannot fit into narrow channels or between islands due to

the toolpath radius size. Instead of using a smaller toolpath radius to fit into these areas, which limits the

efficiency of the arc on/off motion, these toolpaths now automatically adjust the toolpath radius in these areas.

This allows the tool to fit into tight areas and mill deeper in sharp corners. You can enter a minimum toolpath

radius on the Cut Parameters page.

Without variable radius With variable radius

Zigzag Motion Support

With this new feature, you can now use zigzag toolpath motion for open passes to optimize your dynamic

toolpaths. The toolpaths use the toolpath radius to smoothly exit and enter material during direction changes.

When machining closed contours, the toolpath defaults to climb milling.

Note: This change does not apply to Dynamic Contour toolpaths.

Climb millling Zigzag milling

What’s New in Mastercam X6 - Page 14

Page 17

Outside Approach Control

Dynamic Facing, Core, and Contour toolpaths now include the ability to specify which side of the block the tool

approaches from. You can use this functionality to avoid over-travel conditions when large parts might be taking

up most of the travel in one direction.

The following pictures illustrate the approach options:

What’s New in Mastercam X6 - Page 15

Page 18

2D Contour Smoothing

In Mastercam X6, the 2D Contour toolpath now creates smooth motion in sharp corners. Removing sharp

corners reduces tool wear and makes your tool motion more efficient. You can enter an Internal corner rounding

radius on the Cut Parameters page. Corner smoothing also supports multi passes.

Without corner rounding With corner rounding

Adjust Start/End for Peel Mill and Dynamic Contour

Peel Mill and Dynamic Contour toolpaths support lead in/out for their finish passes. This additional functionality

allows the finish pass lead in/out to be extended or shortened without having to create a separate operation or

having to modify geometry. This functionality is in addition to the entry/exit extensions already supported in

the peel mill roughing motion defined on the Cut Parameters page.

What’s New in Mastercam X6 - Page 16

Page 19

Mill/Router 3D Enhancements

New OptiRest Toolpath

Mastercam’s latest 3D HST toolpath is OptiRest, which performs rest milling operations to remove remaining

material with optimized roughing motion. It is the first Mastercam toolpath to take advantage of the new stock

model functionality for defining stock removal areas. In addition, containment boundaries are required for this

toolpath.

Toolpath motion Gray = stock model, purple = OptiRest machining area

What’s New in Mastercam X6 - Page 17

Page 20

3D HST Hybrid Finish Filler Passes

3D HST Hybrid toolpaths now maintain all of the Z level cuts in the steep areas of your part and fills in the

shallow areas with scallop motion. It combines the best of both worlds with waterline (constant Z) motion and

scallop where needed. In X5, shallow areas would have resulted in 3D collapse (essentially scallop) motion for

all Z cuts at that level. Now you can have both waterline and scallop motion at the same Z level so the entire part

is cut.

You can control this motion on the Cut Parameters page for Hybrid toolpaths. Use the 3D passes section to

control how the toolpath handles shallow areas. Select Preserve Z passes to keep all waterline motion in the

toolpath. Then select a method for handling the boundaries between steep and shallow areas from the dropdown.

• Closed offsets: The boundaries are treated as closed chains when calculating the 3D collapse motion.

• Upper to lower: The boundaries are treated as closed or open chains that collapse from the highest Z

value to the lowest.

• Lower to upper: The boundaries are treated as closed or open chains that collapse from the lowest Z

value to the highest.

OptiRough Toolpath Split into OptiCore and OptiArea

The current OptiRough toolpath uses a checkbox to control whether you use an area pocketing approach or a

core from outside approach. In X6, OptiRough is split into two dedicated toolpaths for areas and cores –

OptiArea and OptiCore. Both toolpaths can be found on the Surface High Speed Toolpaths menu.

What’s New in Mastercam X6 - Page 18

Page 21

Multiaxis Enhancements

Blade Expert

Multi-bladed parts are used in many industries, including marine, aeronautical, energy, and automotive.

Machining these complex shapes usually requires special multiaxis equipment, but Mastercam’s new Blade

Expert is specifically designed to generate the necessary toolpaths for many of the different multi-blade

configurations.

Blade Expert is designed to generate the toolpaths for the following segments of the multi-blade workflow:

• Roughing between the blades

• Semi-finishing the blades

• Finishing the blades

• Finishing the hub

Multi-bladed parts typically include the following key areas:

1. Hub surface - revolved floor surface that the blades sit on.

2. Blade surface - usually free-form surfaces with a double curved shape.

3. Blade leading edge - the suction side for the transported medium. For impellers and blisks, it is usually

rounded. The leading edge is usually closest to the center of the hub.

4. Blade trailing edge - the exhaust side. For an impeller, this side is not rounded. The trailing edge is

usually closest to the circumference of the hub.

5. Fillets - part of the blade. They guarantee a rounded connection between the blade and the hub. The

fillets can have a constant radius as well as a dynamic radius.

6. Splitter - found on impeller geometries. It is a shorter blade, similar to the main blades, and located

between the two main blades. The leading edge can be horizontal (as in the picture above) or tilted.

7. Shroud surface - the top surface of the blades and the splitter. It is usually an overturned surface from

the stock, but can also be a free- form surface.

Note: Blade Expert is a Mastercam add-on that must be purchased separately. You must own Mill Level 3 or

Router Pro to purchase the add-on, but you do not need to own the Multiaxis add-on.

What’s New in Mastercam X6 - Page 19

Page 22

5-axis Stock Model Toolpath Trimming

For any of the multiaxis toolpaths in the Classic toolpath family, you can trim your toolpath to the new stock

model. Trimming to stock reduces the amount of time the tool is not in contact with the material.

Lathe Enhancements

Improved Cutoff/Pickoff Operations

Mastercam X6 Lathe includes improvements to the cutoff and pickoff operations. Choose Toolpaths, Misc Ops,

Pickoff/Pull/Cutoff to access this function.

Note: You must have an updated post processor to use this function. Please contact your Mastercam Reseller for

more information.

What’s New in Mastercam X6 - Page 20

Page 23

Use this dialog box to translate geometry and create a part transfer operation from the main spindle to the sub

spindle and/or a bar pull operation prior to a cutoff toolpath. You can choose to just create the geometry

without creating any operation, or you can create the geometry and the following types of operations:

• Pickoff, Bar pull, Cutoff

• Pickoff, Cutoff

• Pickoff

• Bar pull

The following conditions must be met to use this function:

• The red Insert Arrow must be in a Lathe machine group.

• The machine group must have stock defined in a fixed spindle, or both spindles, and the chuck jaws

defined for both spindles. If both spindles can move in Z, the spindle not containing stock will be assumed

to be the pickoff spindle. If both spindles contain stock in this case, the right spindle is assumed to be the

pickoff spindle.

• A cutoff operation must exist in the currently active operation library.

For more details on using this function, please click the Mastercam Help button at the bottom of the dialog box.

Variable Depth Roughing

This new roughing parameter allows you to vary the point that the surface contacts the tool insert to prevent

notching and improve tool life. The depth can vary up to 25% of the cut depth. A positive value results in an

upward cut and a negative value results in a downward cut.

• The passes alternate between angled and straight.

• If the cut length is less than three times the cut depth, a straight cut is made instead of an angled cut.

• In flat areas, a straight cut is made instead of an angled cut.

• One way and zigzag cuts are both supported, as well as ID, OD, Face, Back and Angled.

What’s New in Mastercam X6 - Page 21

Page 24

Finish Toolpaths - Up/Down Cutting Strategy

Lathe finish toolpaths are now optimized by detecting and finishing up (flats) and down (walls) cut regions of

the profile using a single chain.

Note: This motion uses the following terms:

• Walls: other terms include steep, down cut and faces. Walls are cut in a vertical or downward direction.

• Flats: other terms include shallow, non-down cut and diameters. Flats are cut in a horizontal or upward

direction.

• Transition angle: the deviation from the wall angle before the geometry is considered to switch from a

Wall to a Face. A 90 degree transition angle implies that all regions of the geometry are considered Wall

geometry. A 10 degree transition when cutting OD implies that geometry with an angle between 80 and 100

or 260 and 280 degrees is considered to be Wall geometry.

What is considered a wall or flat depends on the specified transition angle and finish direction. On the Down

Cutting Parameters dialog box, you can choose from the following cutting strategies:

• Walls: Down cut Walls only using a down cut strategy.

• Flats: Machine Flat areas only in the chain direction.

• Walls then Flats: Machine all walls (wall strategy), followed by all flats (flat strategy).

• Flats then Walls: Machine all flats, followed by all walls.

What’s New in Mastercam X6 - Page 22

Page 25

Canned Rough and Finish Improvements

Mastercam X6 Lathe includes several improvements to canned rough and finish toolpaths:

• Added clearance options to the canned rough operation parameters to extend the chain for tool

clearance.

• Added parameters to shorten the start and end of the chain in the Lead in/out dialog. This is especially

useful when cutting on the OD towards the chuck. The chain can be shortened to prevent the tool from

hitting the chuck.

• Canned finish operations now use the cutter comp options from the canned rough operation. The cutter

comp options from the canned rough operation will be displayed but disabled.

• Support for Type I and Type II canned cycles

• Added a clearance value for canned finish. The start point used in canned finish is shifted above the part

by the clearance. Then at the end of canned finish, the tool moves up and away from the part on the move

to the start point.

Facing and Canned Groove Toolpaths - Optional Finish Feed/Speed

Facing toolpaths in Mastercam X6 Lathe offer additional feeds and speeds specifically for finish passes. This

functionality has also been added to Canned Groove toolpaths.

Facing Corner Break

The new Corner button on the Face parameters tab provides options for adding a chamfer or radius to the edge

of a part. The break is only allowed on the “leading” corner of the face (the first corner encountered moving in

the direction of the toolpath).

What’s New in Mastercam X6 - Page 23

Page 26

Grooving Toolpath Improvements

For groove roughing toolpaths, you now have the option to adjust the plunge and retract feed rates on the first

plunge cut.

What’s New in Mastercam X6 - Page 24

Page 27

Groove finishing toolpaths support undercut removal and negative stock to leave.

Finish Tool Inspection

Tool inspection is available in Finish toolpaths. This function had previously only been available in Rough and

Groove toolpaths. You can establish points during operations where the machine can be programmed to a

specific position and stop to allow you to perform tool inspections. You can set the conditions on which the tool

inspections are performed, such as:

• After a number of passes

• After a specified cut length

• After a specified cut duration

Additional options let you control whether a tool inspection can occur during a pass or near the start or end of a

pass. You can also use reference points to get the tool in and out of the cut, and send the tool to a selected point

or to the home position for the tool inspection position.

What’s New in Mastercam X6 - Page 25

Page 28

Rough Remaining Stock

This new option adjusts your roughing toolpaths to minimize air cuts by recognizing remaining stock. You can

then click Adjust Stock to choose your machining area.

What’s New in Mastercam X6 - Page 26

Page 29

C-Axis Face Contour and Face Drill – Support for Plane Rotation

The C-Axis Face Contour and Face Drill toolpaths now support plane rotation when using Y-axis motion.

Wire Enhancements

New AutoSync Rails

This function has been improved in Mastercam X6 Wire to create better synchronized wirepath chains from

selected solids and surfaces. Choose Create, Autosync Rails to access the new functionality.

What’s New in Mastercam X6 - Page 27

Page 30

Wirepath Editor Improvements

The Mastercam Wirepath Editor now supports 4-axis Direct wirepaths.

What’s New in Mastercam X6 - Page 28

Page 31

Control Definition Option to Force Wire Taper to Vertical

Mastercam X4 introduced a Reset Taper option on the Leads page that allowed you to force the wire back to a

vertical position when the Max lead out distance is used. In X6, a new option in the Control Definition allows for

this Reset Taper mode to be always active. Some machines require the wire to move to a vertical position on a

change-over from G41 to G42 compensation.

What’s New in Mastercam X6 - Page 29

Page 32

Page 33

Page 34

Attention! Updates may be available.

Go to Mastercam.com/Support for the latest downloads.

671 Old Post Road

Tolland, CT 06084 USA

www.mastercam.com

Loading...

Loading...