Page 1

Basic 2D

Machining

Page 2

Page 3

mastercam x getting started series tutorials

Basic 2D

Machining

October 2010

Be sure you have the latest information!

Information might have been changed or added since this document was

published. Contact your local Reseller for the latest information.

Page 4

II • BASIC 2D MACHINING

Mastercam® X5 Basic 2D Machining

Date: October 2010

Copyright © 2010 CNC Software, Inc.— All rights reserved.

First Printing: October 2010

Software: Mastercam X5

Part Number: X5-PDF-TUT-2M

TERMS OF USE Use of this document is subject to the Mastercam End User License Agreement. A

copy of the Mastercam End User License Agreement is included with the

Mastercam product package of which this document is part. The Mastercam End

User License Agreement can also be found at:

www.mastercam.com/legal/licenseagreement/

Page 5

Contents

Introduction ...................................................................... 1

1. Drilling Holes............................................................... 5

III

Tutorial Goals................................................................................... 2

Before You Begin............................................................................. 2

If You Need More Help.................................................................... 3

Additional Documentation.............................................................. 4

Lesson Goals.................................................................................... 5

Exercise 1: Assigning a Machine Definition.............................. 5

Exercise 2: Setting Up Stock ....................................................6

Exercise 3: Drilling Four Holes ..................................................8

2. Roughing Outside the Part ......................................... 15

Lesson Goals..................................................................................15

Exercise 1: Creating a Dynamic Mill Toolpath......................... 15

Exercise 2: Viewing Your Toolpaths........................................ 23

Exercise 3: Creating a Contour Toolpath................................. 23

3. Machining Inside the Part.......................................... 29

Lesson Goals..................................................................................29

Exercise 1: Creating a Dynamic Mill Toolpath......................... 29

Exercise 2: Creating a Slot Mill Toolpath ................................ 34

4. Previewing Toolpaths ................................................ 39

Lesson Goals..................................................................................39

Exercise 1: Backplotting All Toolpaths.................................... 39

Exercise 2: Verifying All Toolpaths.......................................... 42

5. Posting Toolpaths ...................................................... 45

Lesson Goals..................................................................................45

Exercise 1: Posting All Toolpath Operations ........................... 45

Page 6

IV • BASIC 2D MACHINING

Conclusion...............................................................................................48

Post Processing Summary: Sending NC Files to Machine ....... 48

Page 7

INTRODUCTION

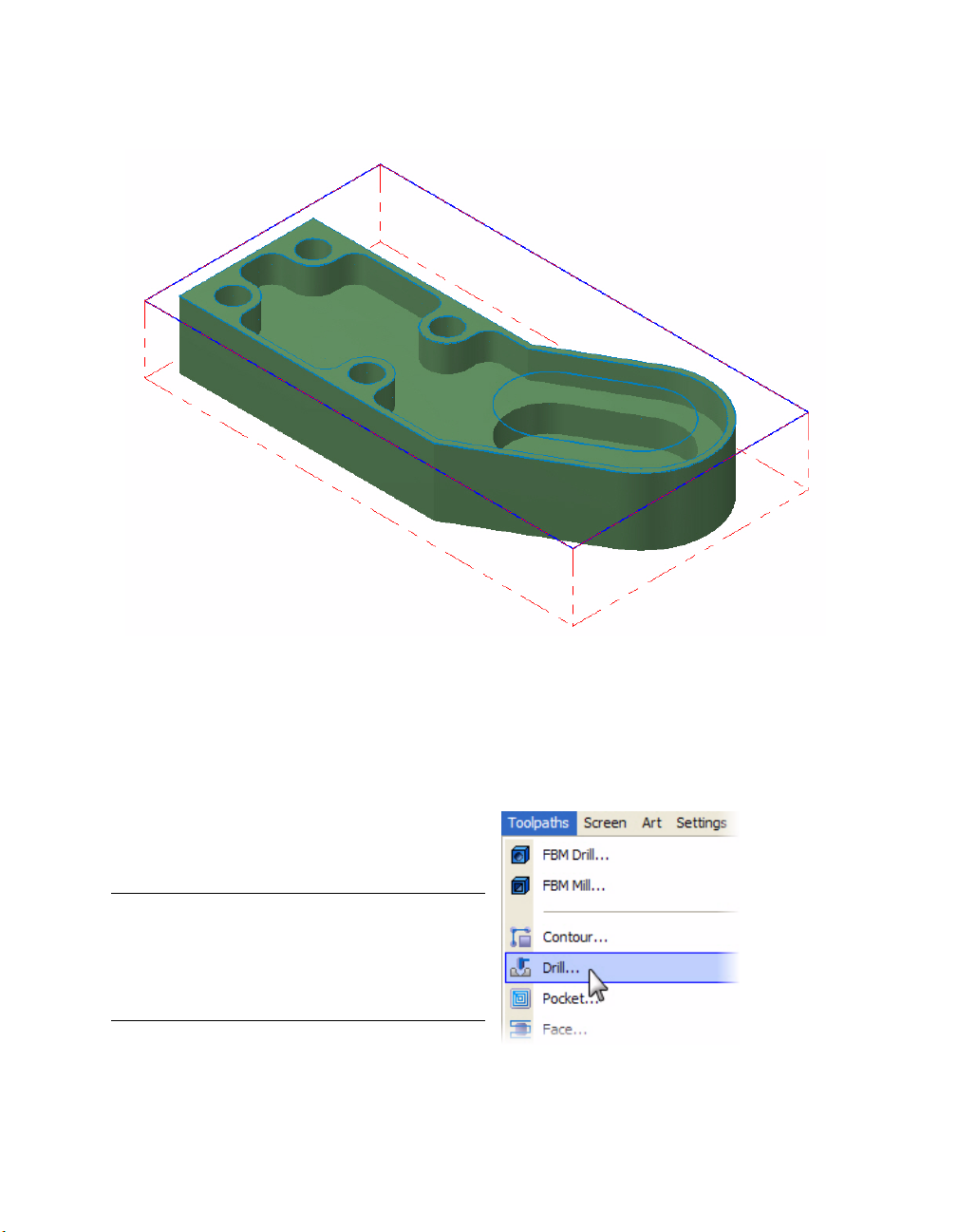

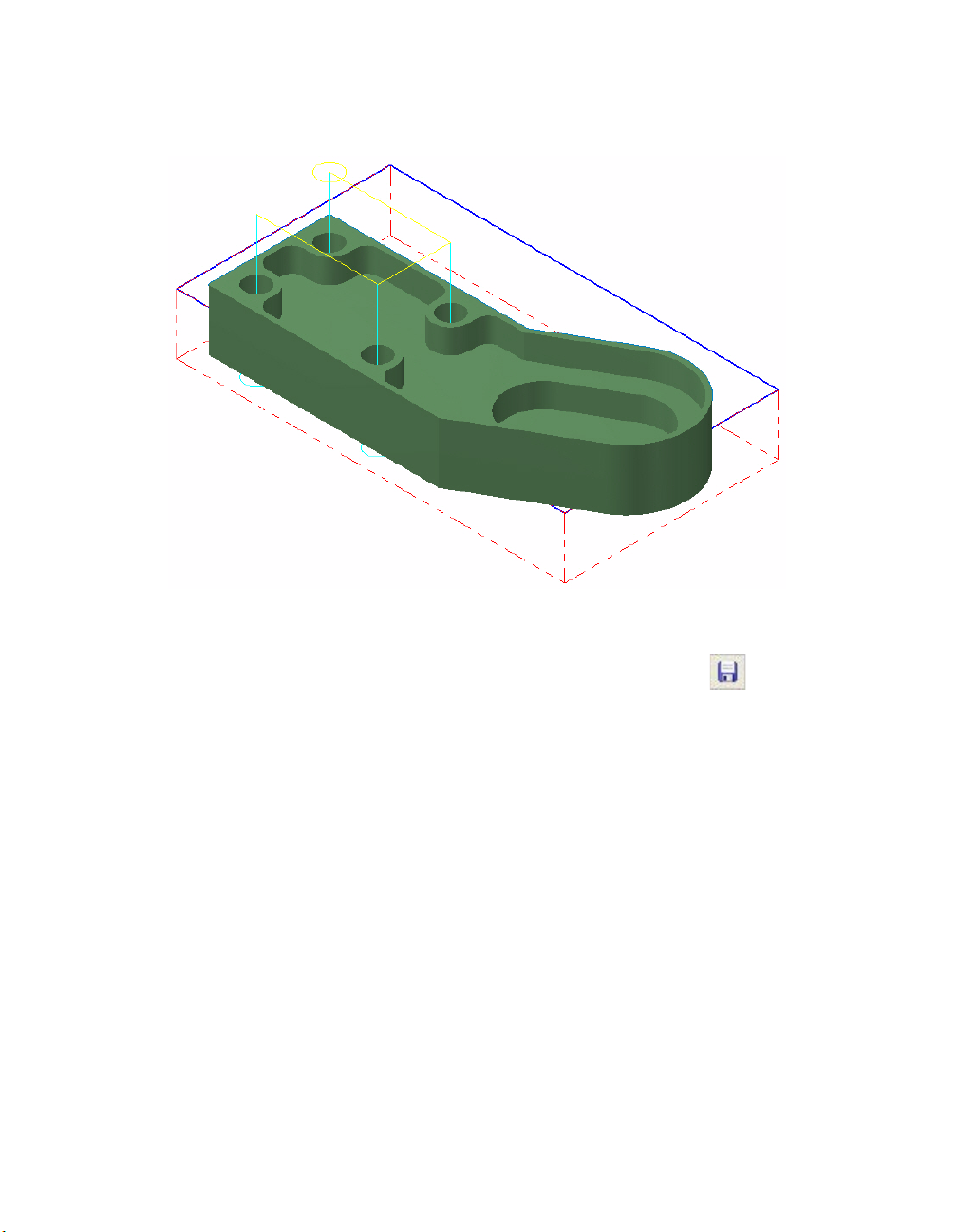

This tutorial focuses on applying several mill toolpaths to a part previously designed in Mastercam.

The tutorial then guides you through the steps to take that toolpath data and create NC code to

machine the part.

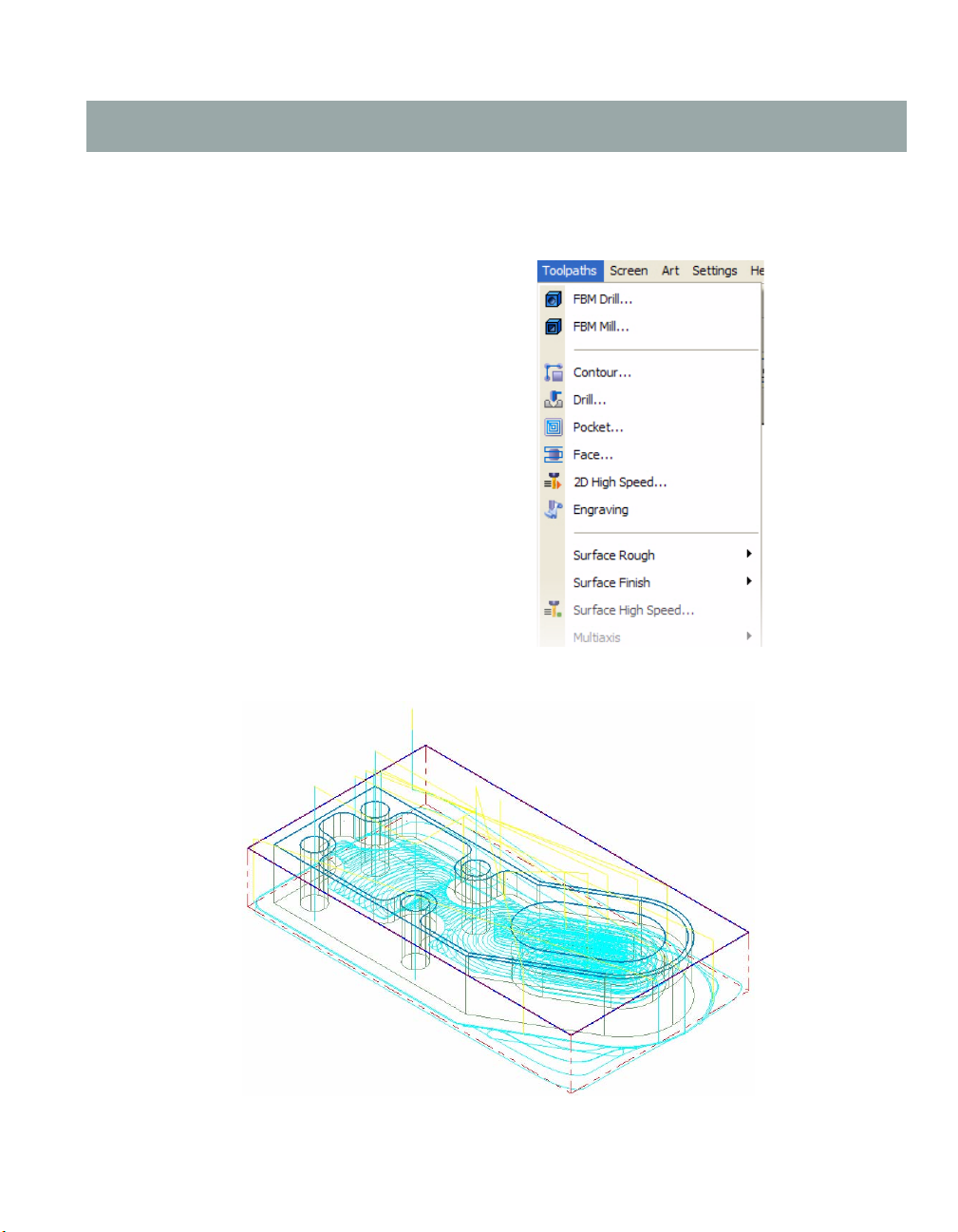

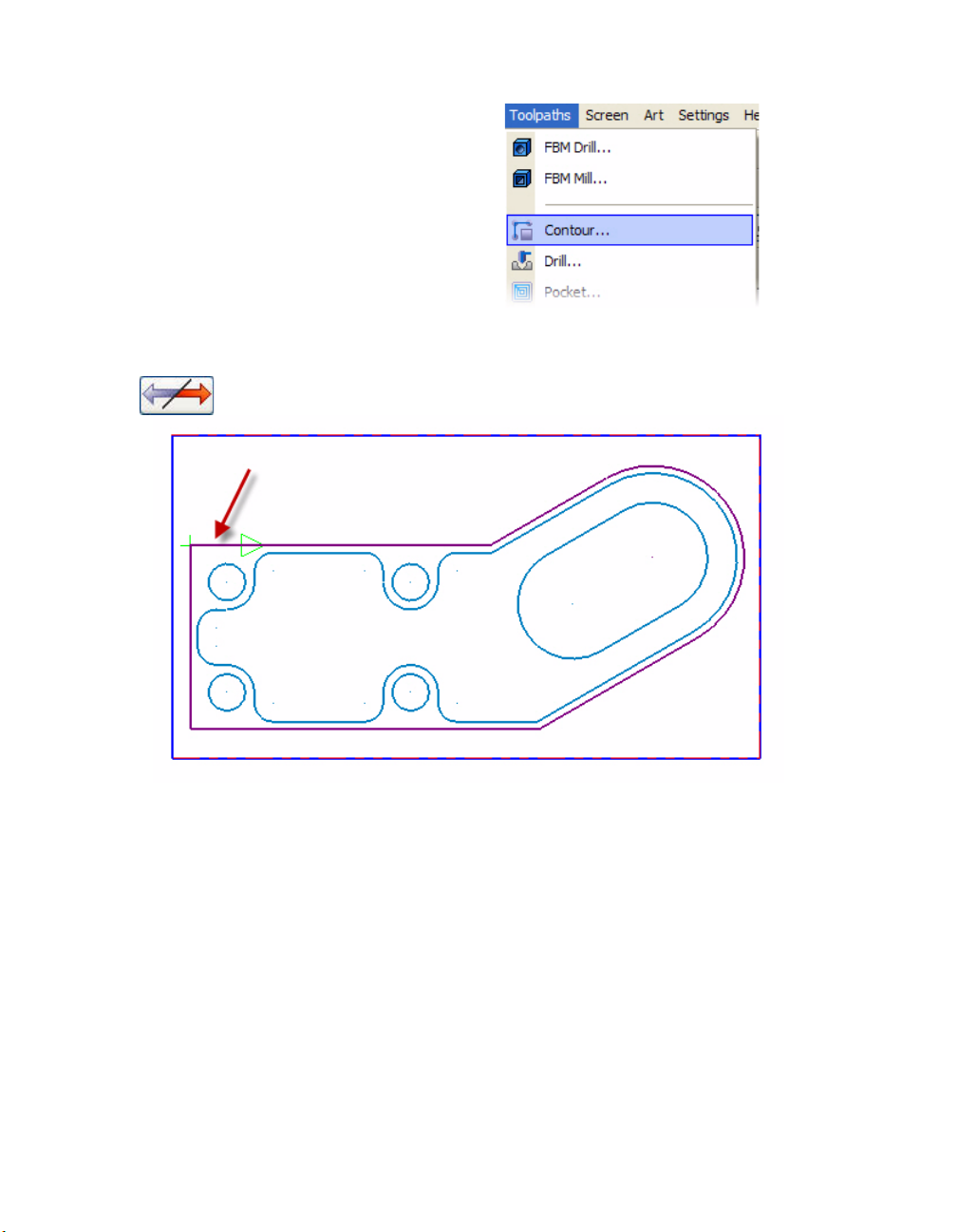

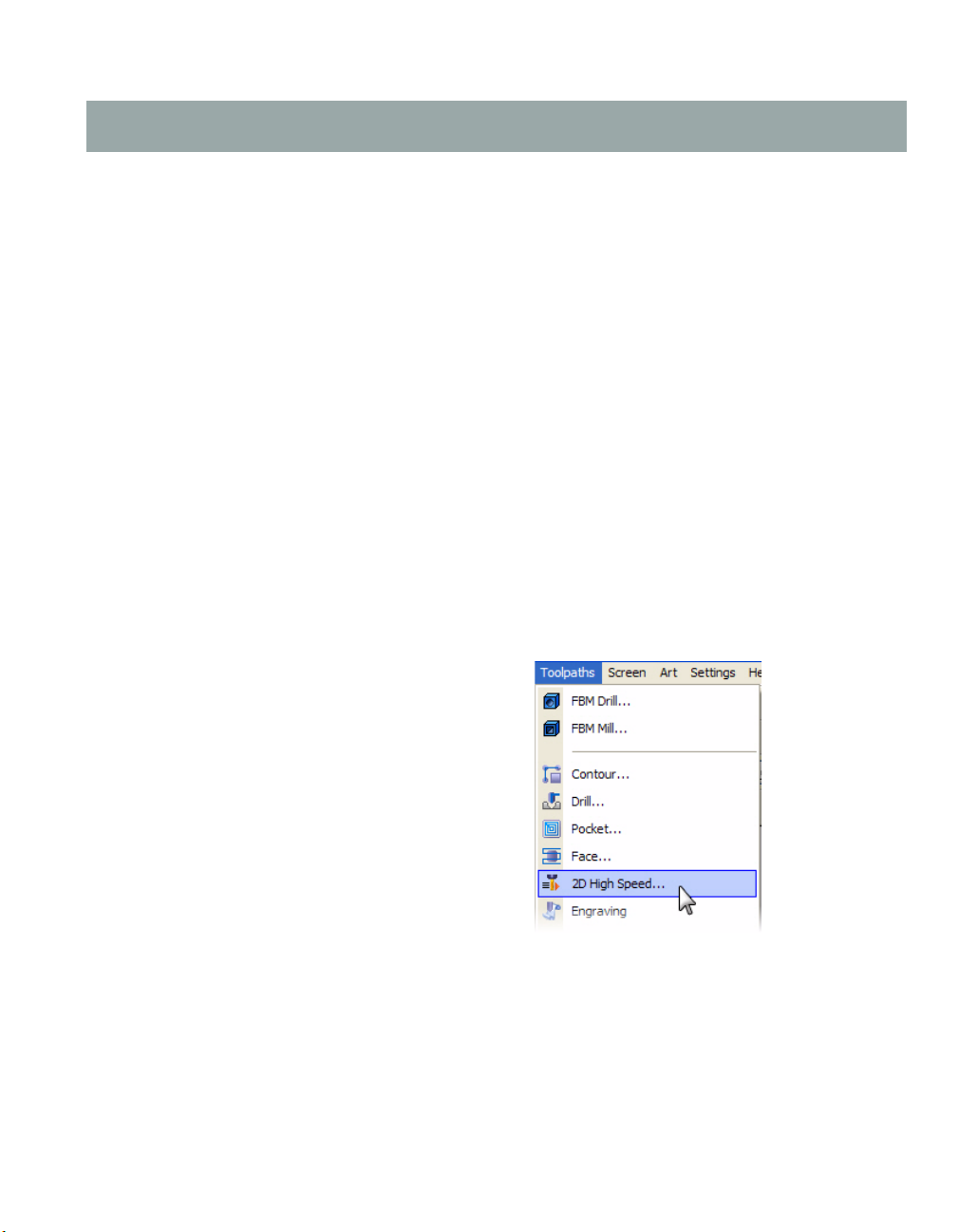

Mastercam offers a variety of toolpath types that let

you quickly build toolpaths for specific

applications. You access these toolpaths, such as

the mill toolpaths shown here, through the

Toolpa th s menu.

After you create a toolpath, you can use

Mastercam's backplot feature to preview its

operation on the screen. Once you are satisfied

with it, post it from the Toolpath Manager to

generate the NC code for a specific machine tool.

When you first begin this tutorial, you will be

prompted to assign a machine definition to the

part. This tutorial does not go into any depth on

machine and control definitions. However, the

Help and other documentation installed with

Mastercam provide comprehensive information

regarding these Mastercam features.

When you finish this tutorial, your part will look like this:

If you would like to design (create) the part before you begin this tutorial, please follow the Basic 2D

Design tutorial procedures (published separately in document #X5-PDF-TUT-2D).

Page 8

2 • BASIC 2D MACHINING

Tutorial Goals

Open a part file, assign a default machine definition, and set up stock.

Create four drill holes with one toolpath (including selecting a drill point, choosing tooling,

using tool tip compensation, and setting machining values).

Rough the outside of the part (including chaining entities, selecting tooling, and setting

machining values).

Clean out the inside of the part (including chaining entities, choosing tooling, and setting

machining values).

View all toolpaths in the graphics window.

View a specific toolpath by temporarily turning off the display of selected toolpaths.

Backplot (view the path the tools take to cut the part) all toolpaths.

Customize your backplot display.

Simulate (verify) the machining of the part from a stock model display.

Post all toolpath operations to an NC file, review/edit the code as necessary, and save the

NC file.

Before You Begin

This is a module of the Mastercam Getting Started Series Tutorial Series. The series introduces

general Mastercam functions and teaches basic skills for getting started with Mastercam. Other

tutorial series include:

Focus Series: Focuses on a specific Mastercam feature—for example, Setup Sheets or FBM

Drill, and teaches basic and advanced skills.

Exploring Series: Explores a single Mastercam product—for example, Mill, Solids, or Wire,

and teaches in-depth skills for working with the product.

The Mastercam tutorial series is in continual development, and we will add modules as we

complete them. For information and availability, please contact your local Mastercam Reseller.

IMPORTANT: Screen colors in the tutorial pictures were modified to enhance image

quality; they may not match your Mastercam settings or the tutorial results. These color

differences do not affect the lesson or the exercise results.

General Tutorial Requirements

All Mastercam tutorials have the following general requirements:

You must be comfortable using the Windows

The tutorials cannot be used with Mastercam Demo/Home Learning Edition (HLE). The

Demo/HLE file format (EMCX) is different from Mastercam (MCX), and basic Mastercam

functions, such as file conversions and posting, are unavailable.

®

operating system.

Page 9

INTRODUCTION • 3

Each lesson in the tutorial builds on the mastery of preceding lesson’s skills. We

recommend that you complete them in order.

Focus Series and Exploring Series tutorials require, at minimum, a mastery of the basic

Mastercam skills taught in the Getting Started Series modules. A general knowledge of

machining principals and practices is also required.

You must have a seat of Mastercam X5 Design or higher to complete most of the tutorials in

the Getting Started Series.

The Basic 2D Machining module in the Getting Started Series requires, at minimum, a seat

of Mill Entry or Router Entry.

The Basic 3D Machining module in the Getting Started Series requires Mill Level 3 or Router

Pro.

Additional files may accompany a tutorial. Unless the tutorial provides specific

instructions on where to place these files, store them in a folder that can be accessed from

the Mastercam workstation, either with the tutorial or in any location that you prefer.

The Getting Started Series tutorials are available in an Adobe

format. Additional tutorial videos may also be available. Contact your local Mastercam

Reseller for more information.

®

Flash® compatible video

You must install Adobe Flash Player to display tutorial videos. You can download Adobe

Flash Player from www.adobe.com.

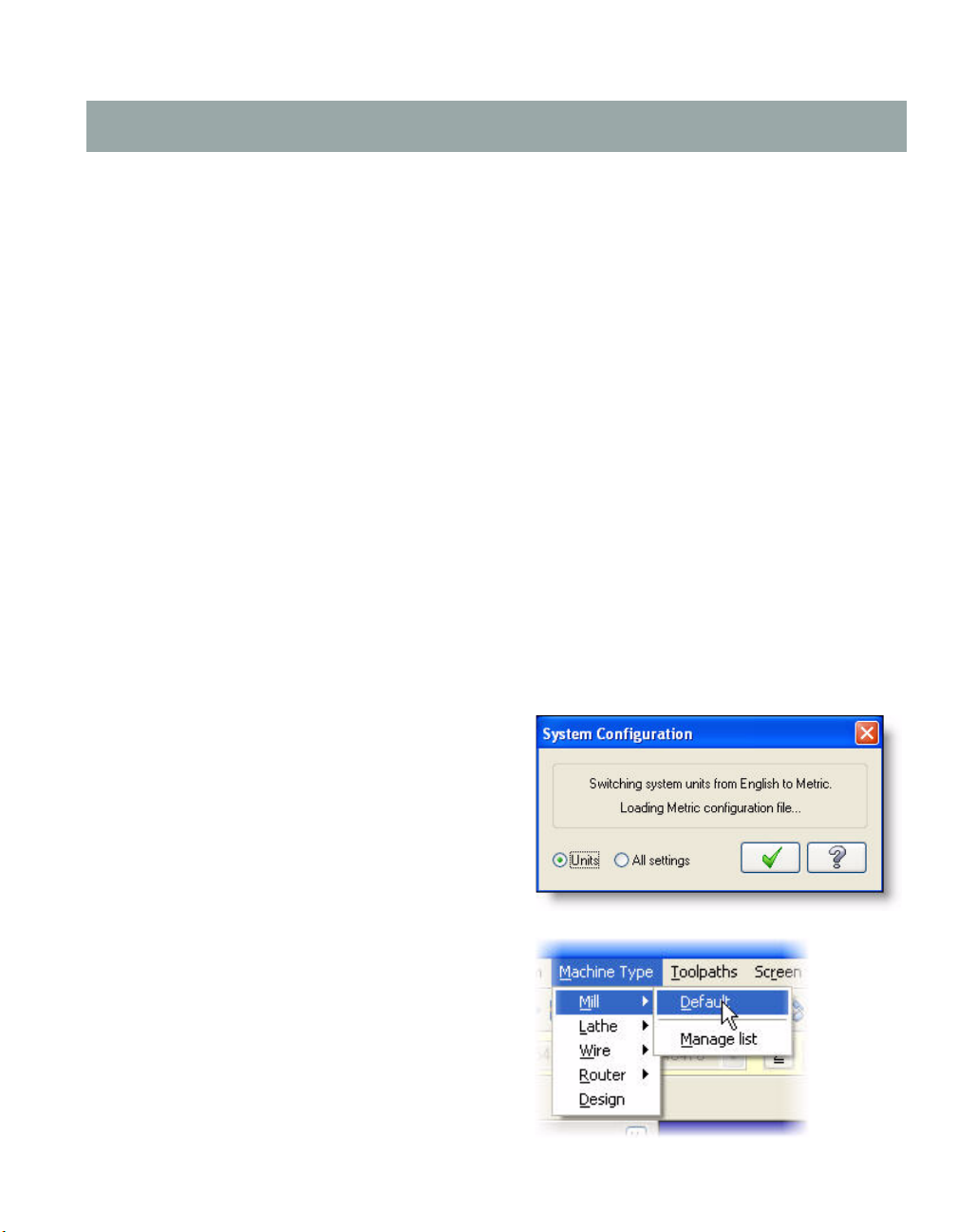

You must configure Mastercam to work in metric units. Complete the instructions in the

following section Preparing for a Tutorial to set Mastercam to metric.

Preparing for a Tutorial

Before you start a tutorial, be sure you have completed the following tasks:

1 Start Mastercam using your preferred method:

Double-click Mastercam’s desktop icon.

Or

Launch Mastercam from the Windows Start menu.

2 Select the metric configuration file:

a Select Settings, Configuration from

Mastercam’s menu.

b Choose ...\mcamxm.config <Metric>

from the Current drop-down list.

c Click OK.

If You Need More Help

There are many ways to get help with Mastercam, including the following:

Page 10

4 • BASIC 2D MACHINING

Mastercam Help—Access Mastercam Help by selecting Help, Contents from Mastercam’s

menu bar or by pressing [Alt+H] on your keyboard. Also, most dialog boxes and ribbon

bars feature a Help button that opens Mastercam Help directly to related information.

Online help—You can search for information or ask questions on the Mastercam Web

forum, located at www.emastercam.com. You can also find a wealth of information,

including many videos, at www.mastercam.com and www.mastercamedu.com.

Mastercam Reseller—Your local Mastercam Reseller can help with most questions about

Mastercam.

Technical Support—CNC Software’s Technical Support department (860-875-5006 or

support@mastercam.com) is open Monday through Friday from 8:00 a.m. to 5:30 p.m. USA

Eastern Standard Time.

Documentation feedback—For questions about this or other Mastercam documentation,

contact the Technical Documentation department by email at techdocs@mastercam.com.

Mastercam University—CNC Software sponsors Mastercam University, an affordable

online learning platform that gives you 24/7 access to Mastercam training materials. Take

advantage of more than 180 videos to master your skills at your own pace and help prepare

yourself for Mastercam Certification. For more information on Mastercam University,

please contact your Authorized Mastercam Reseller, visit www.mastercamu.com, or email

training@mastercam.com.

Additional Documentation

You can find more information on using Mastercam in the following materials, located in the

\Documentation folder of your Mastercam installation:

Mastercam X5 Installation Guide

Mastercam X5 Administrator Guide

Mastercam X5 Quick Start

Mastercam X5 Reference Guide

Mastercam X5 Transition Guide

Mastercam X5 Quick Reference Card

Mastercam X5 Wire Getting Started Guide

Version 9 to X Function Map

Mastercam X5 NCI & Parameter Reference

Mastercam X5 Post Debugger User’s Guide

Page 11

LESSON 1

1Drilling Holes

The first step to machining the tutorial part is to drill the four holes. By beginning with drilling, you

can then use the holes to fixture the part on the machine tool.

Lesson Goals

Open a part file and assign a machine definition.

Define stock.

Create a drill toolpath (including selecting drill points, choosing tooling, and setting

machining values).

Use tool tip compensation.

Exercise 1: Assigning a Machine Definition

In this exercise, you open an existing part, assign a machine definition to the part, and save it under

a new file name.

1 Start Mastercam.

2 From the Mastercam menu bar, choose File, Open.

3 Open BASIC_2D_MACHINING_START.MCX-5, which was provided with this tutorial.

4 Click OK if prompted to switch to a metric

configuration.

5 Press [Alt +S] to shade the part for easier

viewing.

6 From the Mastercam menu, choose

Machine Type, Mill, Default to open the

default Mill machine definition.

In Mastercam, you select a machine

definition before creating any toolpaths.

The machine definition is a model of your

machine tool's capabilities and features

and acts like a template for setting up

machining jobs.

Page 12

6 • BASIC 2D MACHINING

Note: Parts that have previously been saved with a machine definition automatically load the

associated machine definition.

7 Choose File, Save As and save the part under a different file name than the original file.

This will protect the original tutorial file from being overwritten.

Exercise 2: Setting Up Stock

In this exercise, you define the stock model from which your part is cut. Stock models help you

visualize your toolpaths more realistically. The stock model you define can be displayed with the

part geometry when viewing the file or toolpaths, during backplot, or while verifying toolpaths.

1 In the Operations Manager, click on the

plus sign (+) next to Properties - Mill

Default MM.

It changes to a minus sign (-) and displays

the machine group properties. Machine

groups are created automatically and

displayed in the Toolpaths Manager when

you select a machine from the Machine

Type menu. They include job setup

information for toolpaths, such as tool

numbering, stock models, material

selection, and toolpath defaults and

libraries.

2 Click the Stock Setup icon to display the

Stock Setup tab in the Machine Group

Properties dialog box.

Page 13

DRILLING HOLES • 7

3 Click the Select corners button near the bottom of the dialog box. Mastercam brings you

back to the graphics window to select the two opposite stock corners.

4 Click the two opposite corners as shown in the following picture. The Stock Setup tab

displays again with X and Y coordinate values from the selected corners.

5 Enter 25 for the Z coordinate in the stock diagram to provide some depth for your stock.

6 Select the Display check box to see the stock model boundaries in the graphics window.

Page 14

8 • BASIC 2D MACHINING

7 Click OK to complete the stock setup. The stock displays as dashed red lines around the

part.

Exercise 3: Drilling Four Holes

In this exercise, you create a drill toolpath that drills all four holes of the part.

Selecting the Drill Holes

1 From the Mastercam menu, choose

Toolpaths, Drill. The Drill Point Selection

dialog box opens.

Note: You may be prompted for an NC file

name. If prompted, click OK to confirm the

default NC file name, or overwrite the file

name and click OK to modify the default file

name.

Page 15

DRILLING HOLES • 9

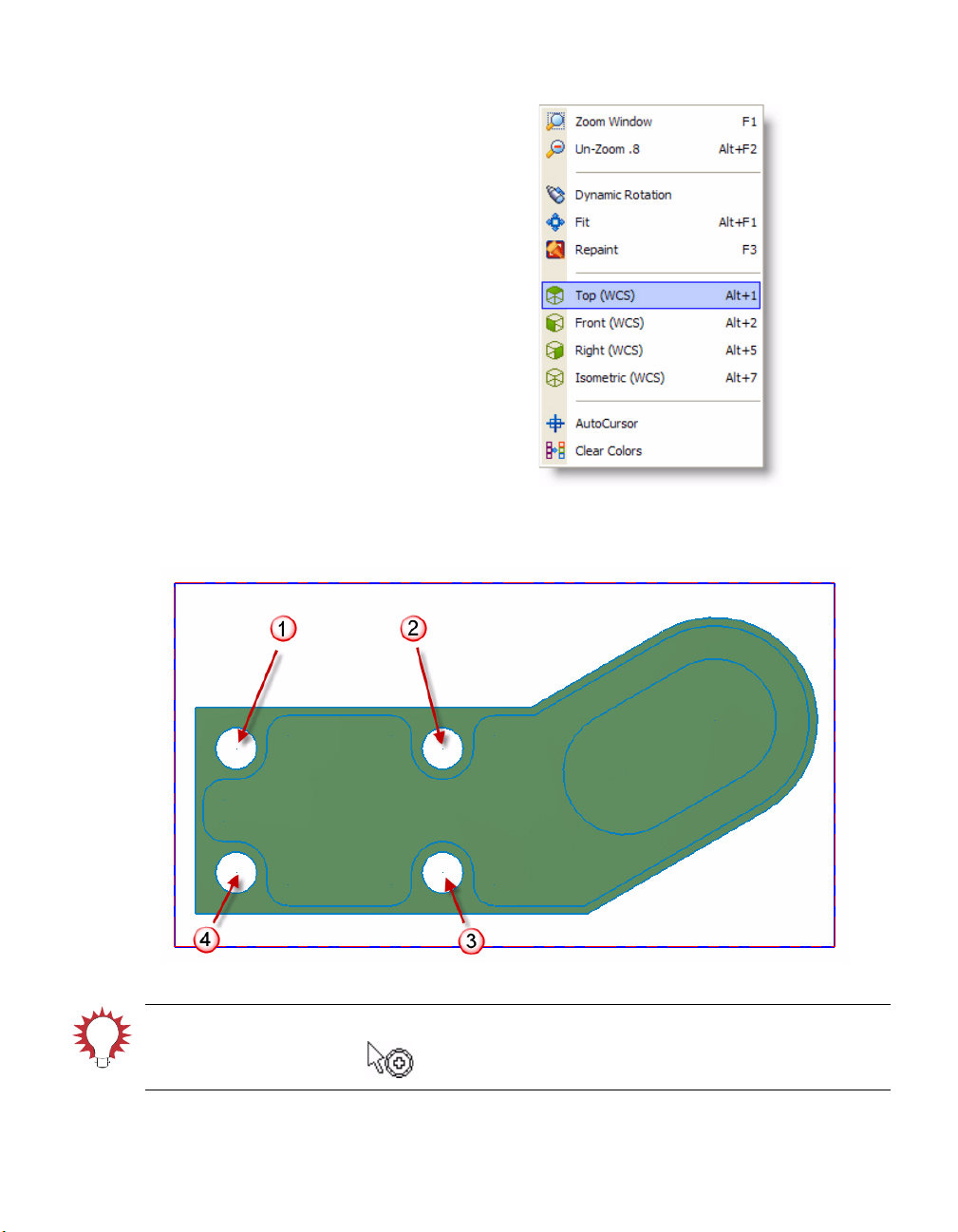

2 Right-click in the graphics window and

choose To p ( W C S ) to switch to a Top

graphics view. This will make it easier to

select the drill holes.

3 Click each of the center points of the four holes of the part. Choose them in a clockwise

order from top left to bottom left as shown in the numbered sequence below.

TIP: When you get close to each hole’s center point, Mastercam displays a Visual Cue that

indicates the center point.

4 Click OK. The 2D Toolpaths - Drill/Circles dialog box opens.

Page 16

10 • BASIC 2D MACHINING

Page viewTree view area

Quick

View

Settings

area

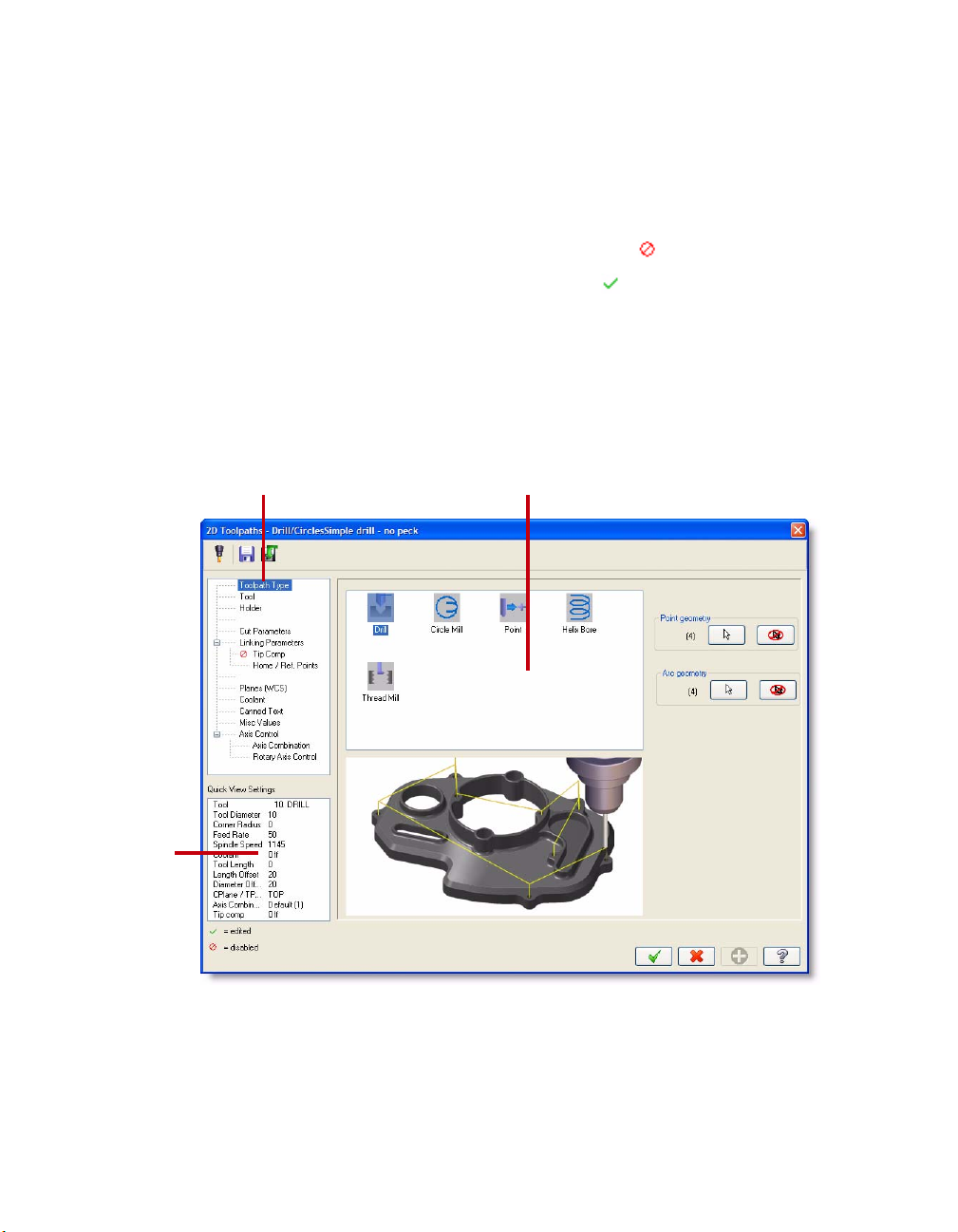

Exploring the Toolpath Dialog Boxes

Many Mastercam toolpaths, including Drill, use a tree-style dialog interface made up of

three distinct areas:

Tree View - Displays a list of all the available dialog box property pages.

Inactive pages are marked with a red circle and a slash.

Edited pages are marked with a green check mark.

Some pages may have a plus or minus symbol, indicating that the page has subpages

and can expand and contract to either display or hide the subpages.

Page View - Changes with each selection you make in the Tree View area.

Quick View Settings - Summarizes key toolpath information from parameters you set on

the different pages. It updates automatically as you make changes in the pages, and is

always visible.

Page 17

DRILLING HOLES • 11

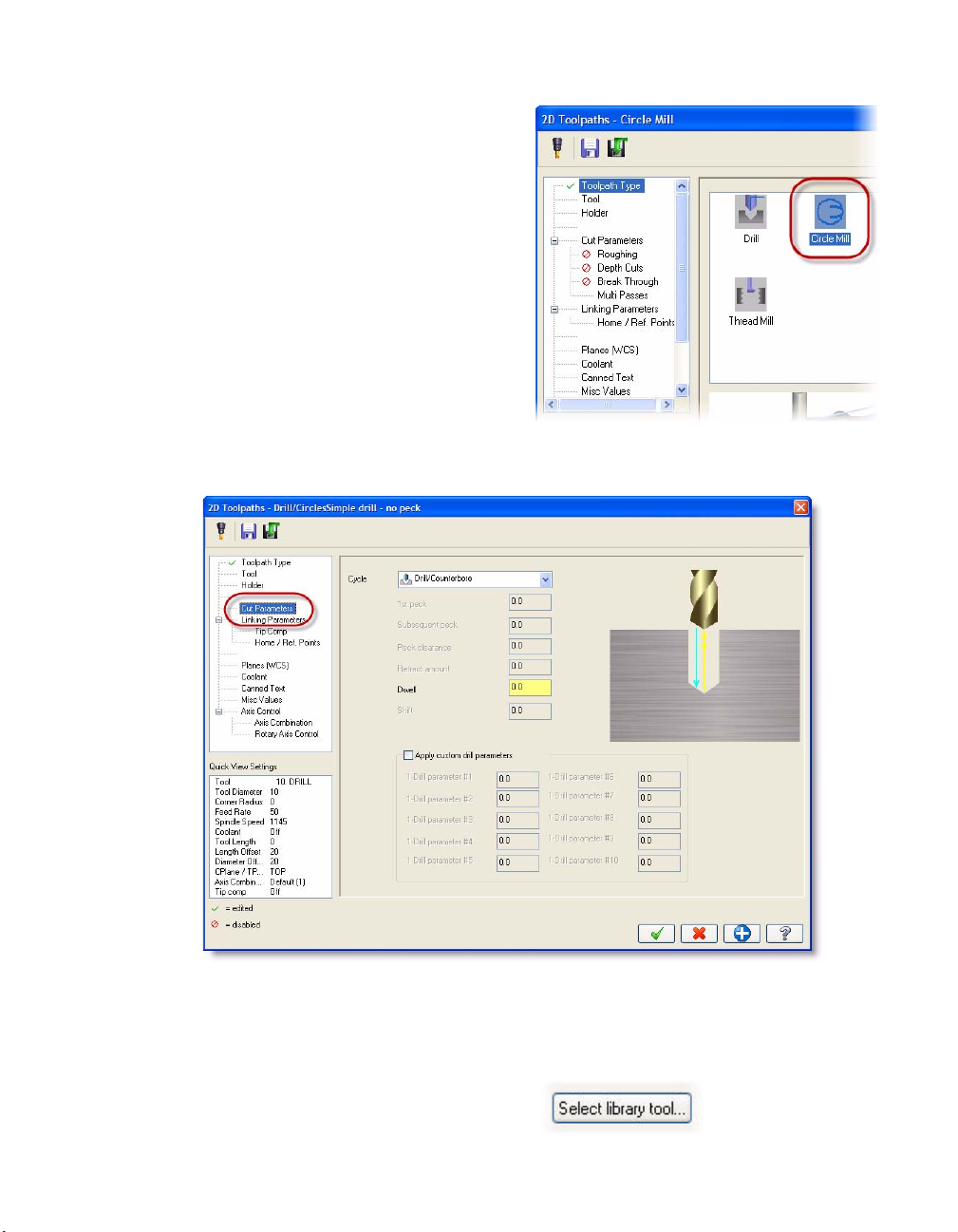

1 Click on the Circle Mill toolpath type icon.

This changes the toolpath to a circle mill

toolpath and changes the pages listed in

the Tree View area.

Notice that the Toolpath Type page in the

Tree View area now has a green check

beside it, indicating that you made a

change on that page.

2 Click the Drill toolpath type icon to change

back to a drill toolpath.

3 Click the Cut Parameters page in the Tree View list. The Page area changes to list cut

parameters for the toolpath.

Setting Drilling Parameters

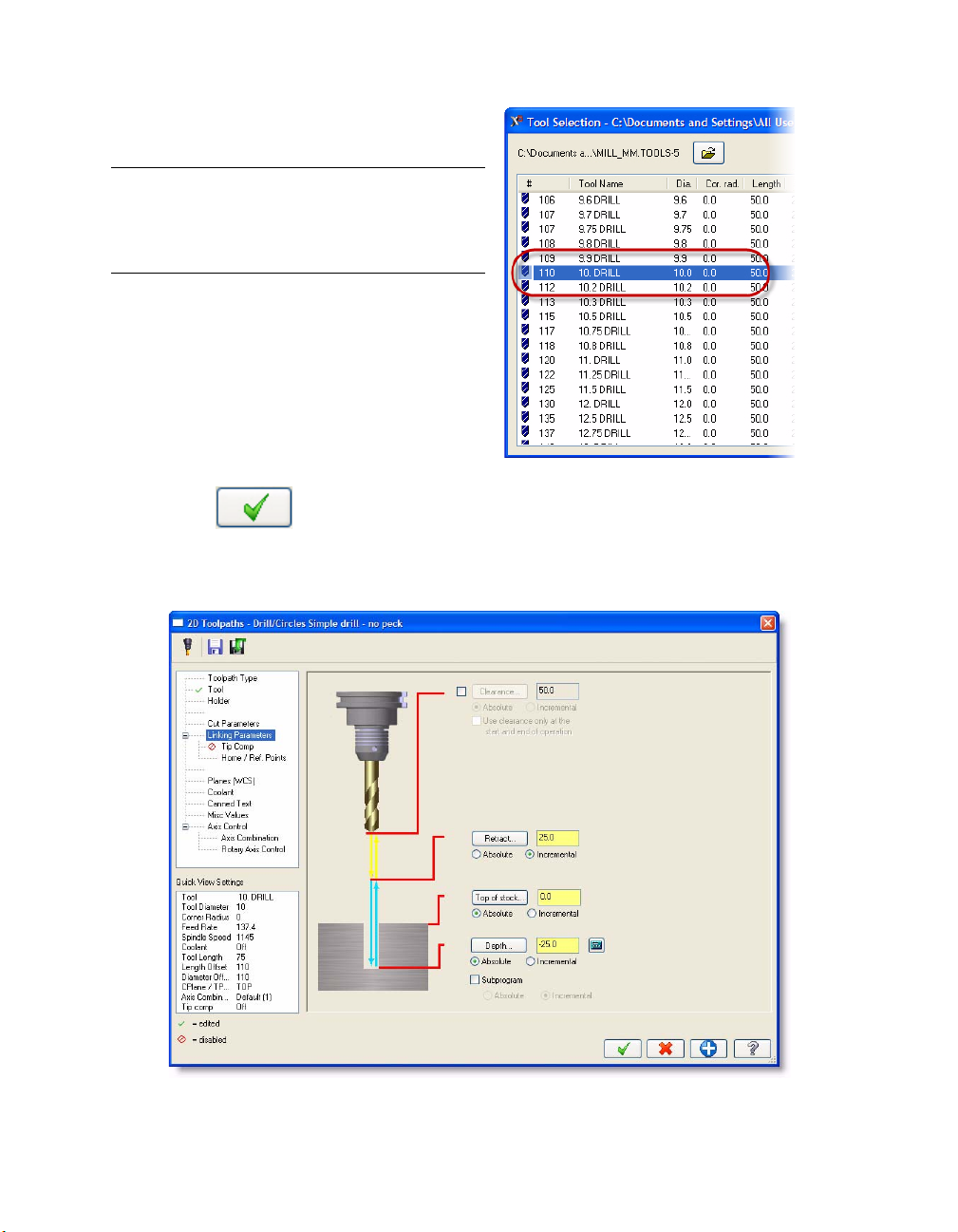

1 Click the To o l page in the Tree View list to pick a tool for the drill toolpath.

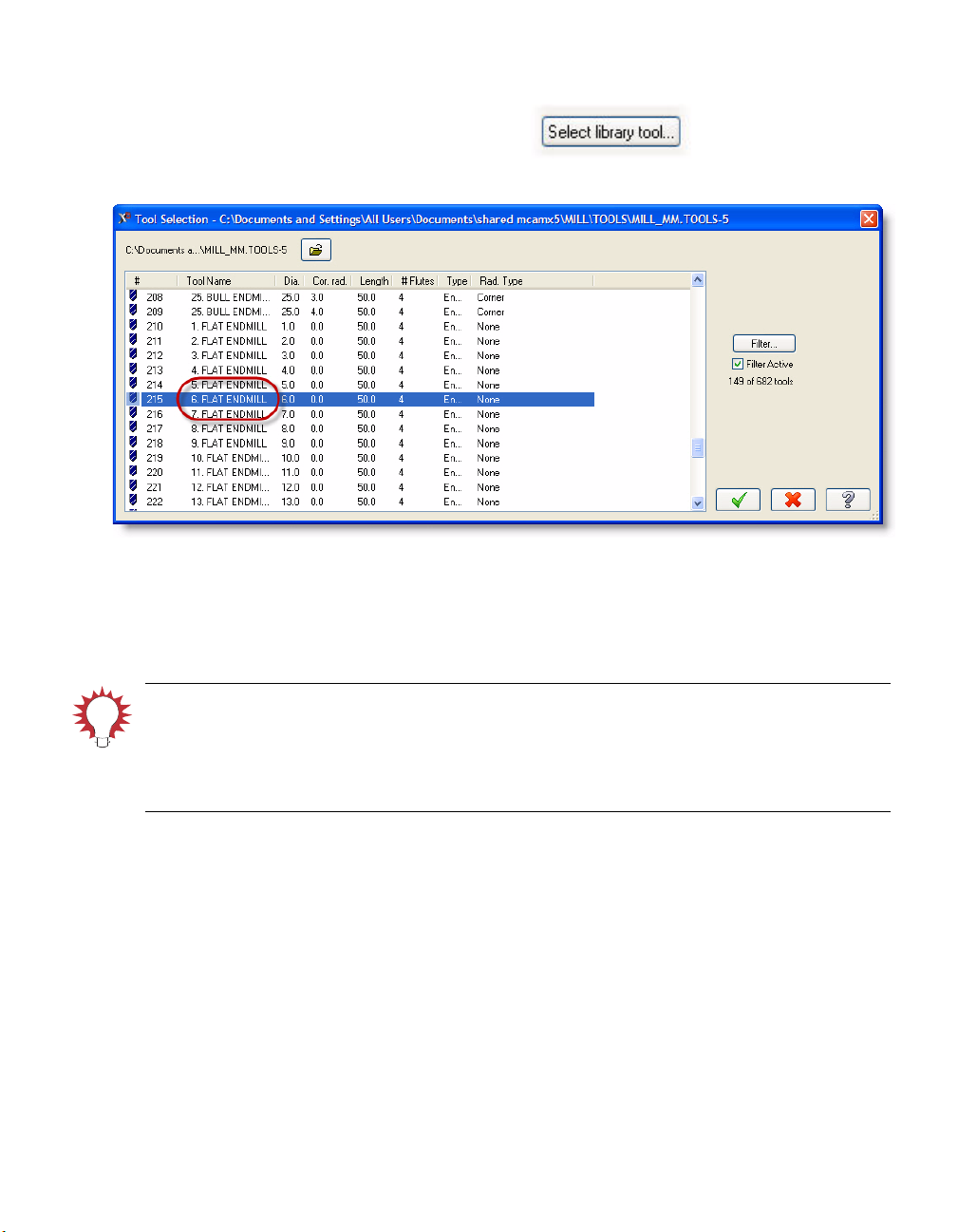

2 Click the Select library tool button to pick

a tool from one of Mastercam’s tool

libraries.

The Tool Selection dialog box opens.

Page 18

12 • BASIC 2D MACHINING

3 Select the 10mm diameter drill from the

tool list.

Note: Make sure that the Mill_MM.TOOLS

tool library is selected at the top of the dialog

box. If not, click the drop-down arrow and

select it from the tool library list.

4 Click OK to return to the Tool page.

5 Click the Linking Parameters page in the Tree View list.

6 Enter -25.0 in the Depth field.

7 Click the Tip Comp page in the Tree View list. Notice that this page is off by default.

Page 19

DRILLING HOLES • 13

8 Select the Tip Comp check box to turn on this feature and enter 5.0 in the Breakthrough

amount field.

TIP: The drill tip compensation tells Mastercam how far to drill past the final depth to break

through the stock. Enter a positive number only. Entering a negative value results in the drill

retracting before the desired depth is reached.

9 Click OK to generate the drill toolpath for the four holes.

10 Right-click in the graphics window and

choose Isometric (WCS) from the menu to

view the part and toolpath in the isometric

view.

You may need to center the part in the

graphics window to see it. The easiest way

to do this is to use the graphics window

right-click menu and select Fit to fit the

part in the graphics window, then unzoom

by pressing [Alt+F2]. You can also use the

fit/zoom/unzoom buttons in the View

Manipulation toolbar.

Page 20

14 • BASIC 2D MACHINING

Your toolpath should look like this. The cyan lines are feed motion and the yellow lines are

rapid motion.

11 Right-click in the graphics window again, and choose Top (W C S ) .

12 Choose File, Save from the Mastercam menu or click the Save button to save your

part.

Now that the holes are drilled, you can move forward with removing stock from the outer area of

the part.

Page 21

LESSON 2

2Roughing Outside the Part

The next step to machining the tutorial part is to remove the bulk of the stock from the outside. You

will use a couple of toolpaths to machine this area.

Lesson Goals

Create a dynamic mill toolpath (including chaining entities, choosing tooling, and setting

machining values).

View a specific toolpath by temporarily turning off the display of selected toolpaths.

Create a contour toolpath (including chaining entities, choosing tooling, and setting

machining values).

Exercise 1: Creating a Dynamic Mill Toolpath

In this exercise, you create a dynamic mill 2D toolpath to clear away much of the stock from the

outside of the tutorial part. Dynamic mill toolpaths, part of the 2D High Speed toolpath suite, utilize

the entire flute length of their cutting tools to produce the smoothest, most efficient tool motion for

high speed pocketing and core milling.

1 From the Mastercam menu, choose

Toolpaths, 2D High Speed. The Chaining

dialog box opens.

Chaining is the process of selecting one or

more entities and linking them together in

a specific order and direction. The entities

must have adjoining endpoints and may

be open or closed shapes.

2 Press [Alt+S] to turn off shading and make it easier to select the chains.

Page 22

16 • BASIC 2D MACHINING

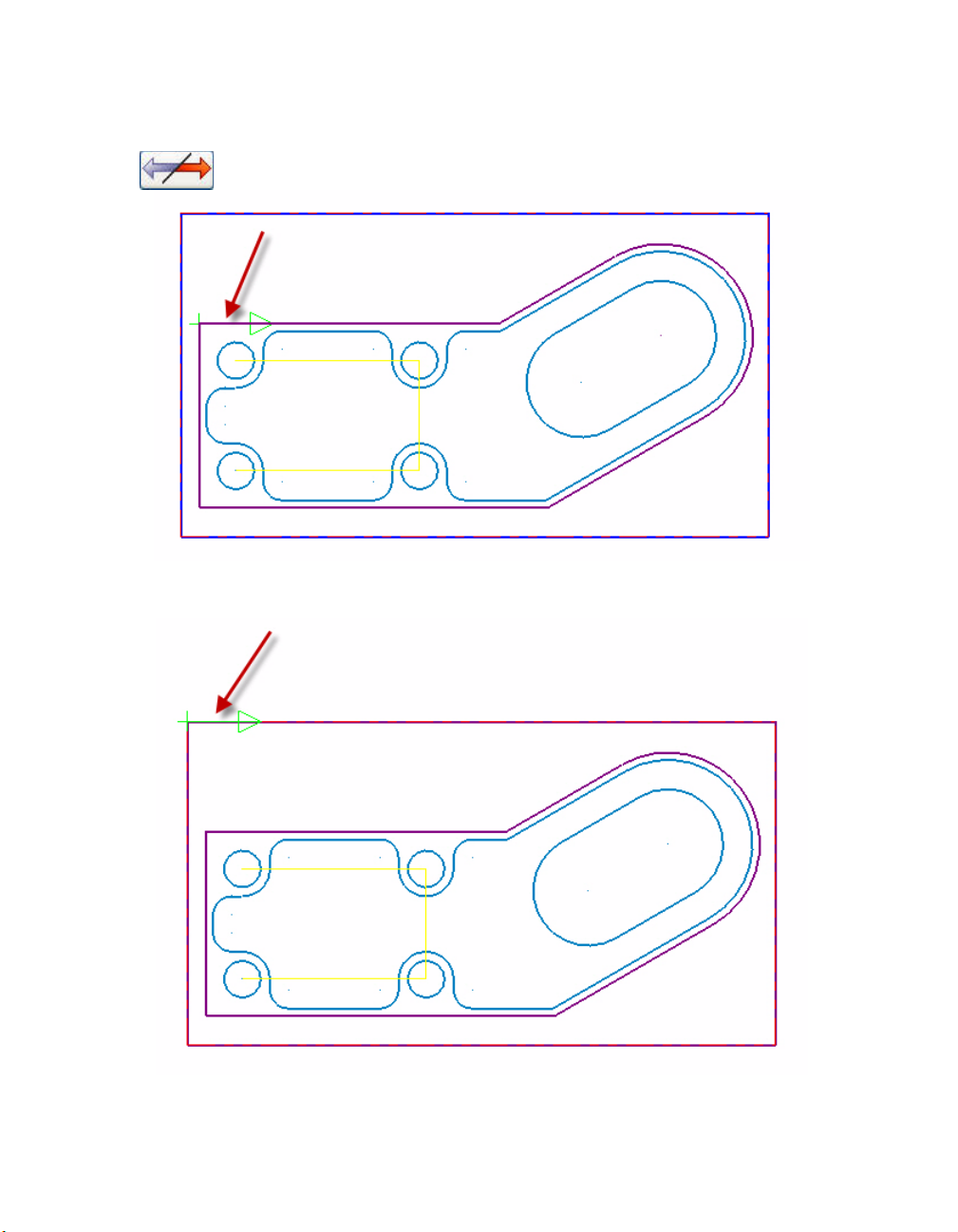

3 Click the outside contour of the part to chain it. The chaining arrow should point

clockwise. If the chaining direction arrow is pointing counterclockwise, click the Reverse

button on the Chaining dialog box.

4 Click the top of the stock boundary as the second chain. This second chain represents the

size of the stock material. The chaining arrow should again point clockwise.

5 Click OK on the Chaining dialog box to chain the part. The Chaining dialog box closes and

the 2D High Speed Toolpath dialog box opens.

Page 23

ROUGHING OUTSIDE THE PART • 17

6 Select the Dynamic Core Mill toolpath type. The Tree View area updates with a list of

parameters for dynamic mill toolpaths.

7 Click the To o l page in the Tree View list to select a tool for this toolpath.

8 Click the Select library tool button. The

default metric tool library opens.

9 Select the 12mm diameter flat endmill, and click OK.

Page 24

18 • BASIC 2D MACHINING

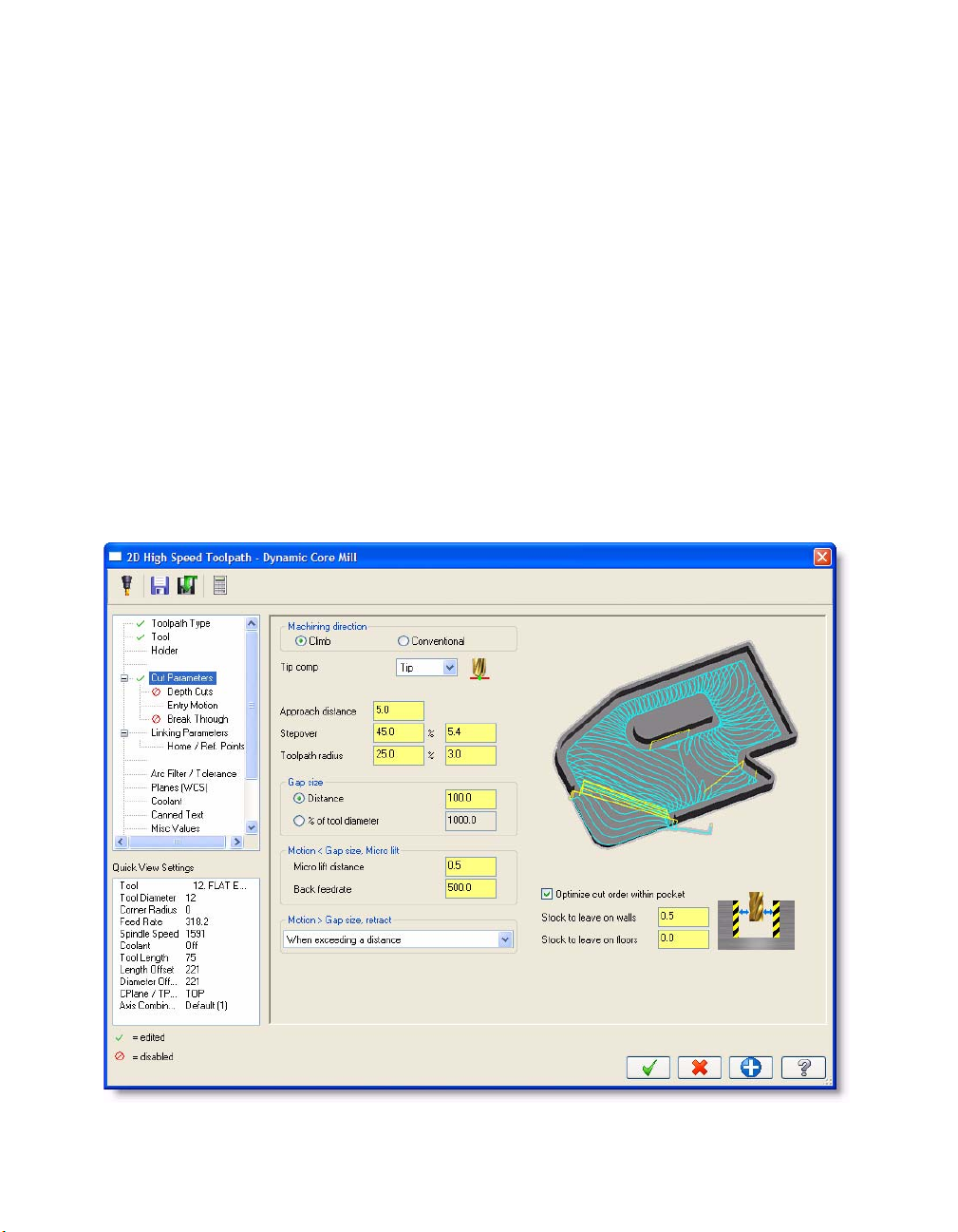

Setting the Dynamic Mill Toolpath Parameters

1 Click the Cut Parameters page in the Tree View area to enter values for different cutting

parameters and compensation options.

2 Set the following parameters:.

Enter 5.0 for the Approach distance, which adds the specified absolute distance to

the beginning of the toolpath’s first cut.

Enter 25% for the Toolpath radius. This parameter is used to calculate 3D arc moves

and reduce sharp corner motion between passes.

Enter 0.5 for the Micro lift distance. Microlifts are slight lifts during back moves that

help clear chips and minimize excessive tool heating.

Select When exceeding a distance from the Retract drop-down list, select the

Distance radio button in the Gap size group box, and enter 100.0. Mastercam adds

retract motion when the next cut begins at a distance greater than the distance you

define.

Enter 0.5 for the Stock to leave on walls.This leaves 0.5mm of stock on the outer

walls.

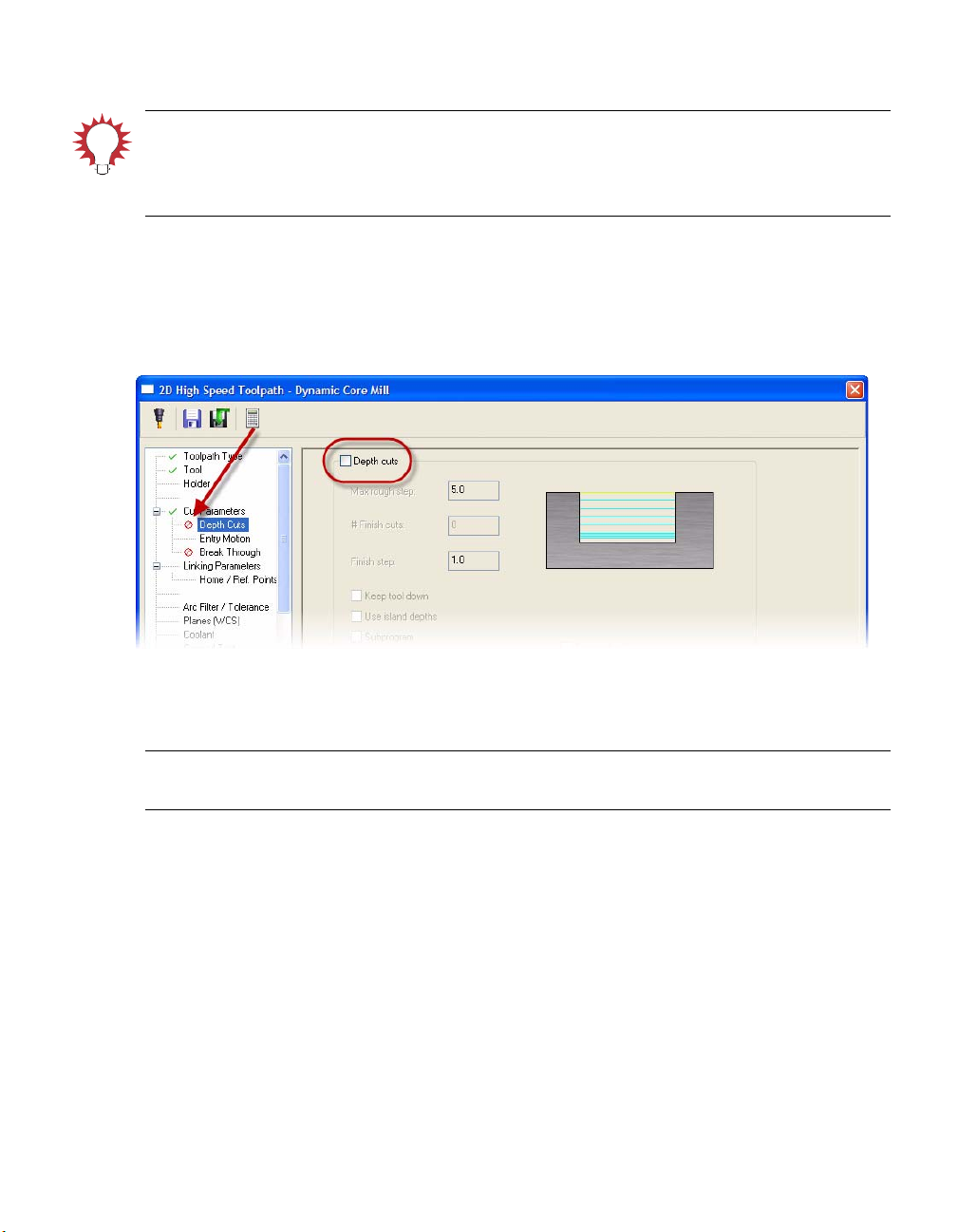

3 Click the Depth cuts page in the Tree View area.

Page 25

ROUGHING OUTSIDE THE PART • 19

TIP: Depth cuts divide the total depth of a toolpath into smaller Z-axis cuts to reduce tool

wear. You can enter a maximum rough step, and Mastercam divides the total depth into

equal steps. Or you can enter the exact number of finish steps and the size of each finish

step. For more details, please refer to the Mastercam Help.

4 Deselect the Depth cuts check box to turn off depth cuts for this toolpath. Notice the red

circle and a slash that displays next to the Depth Cuts page, indicating that the options on

this page are all turned off.

Dynamic mill toolpaths utilize the full flute length of your tool, so dividing the toolpath

into smaller cuts is not necessary.

5 Click the Entry Motion page in the Tree View list to set how and where the tool enters the

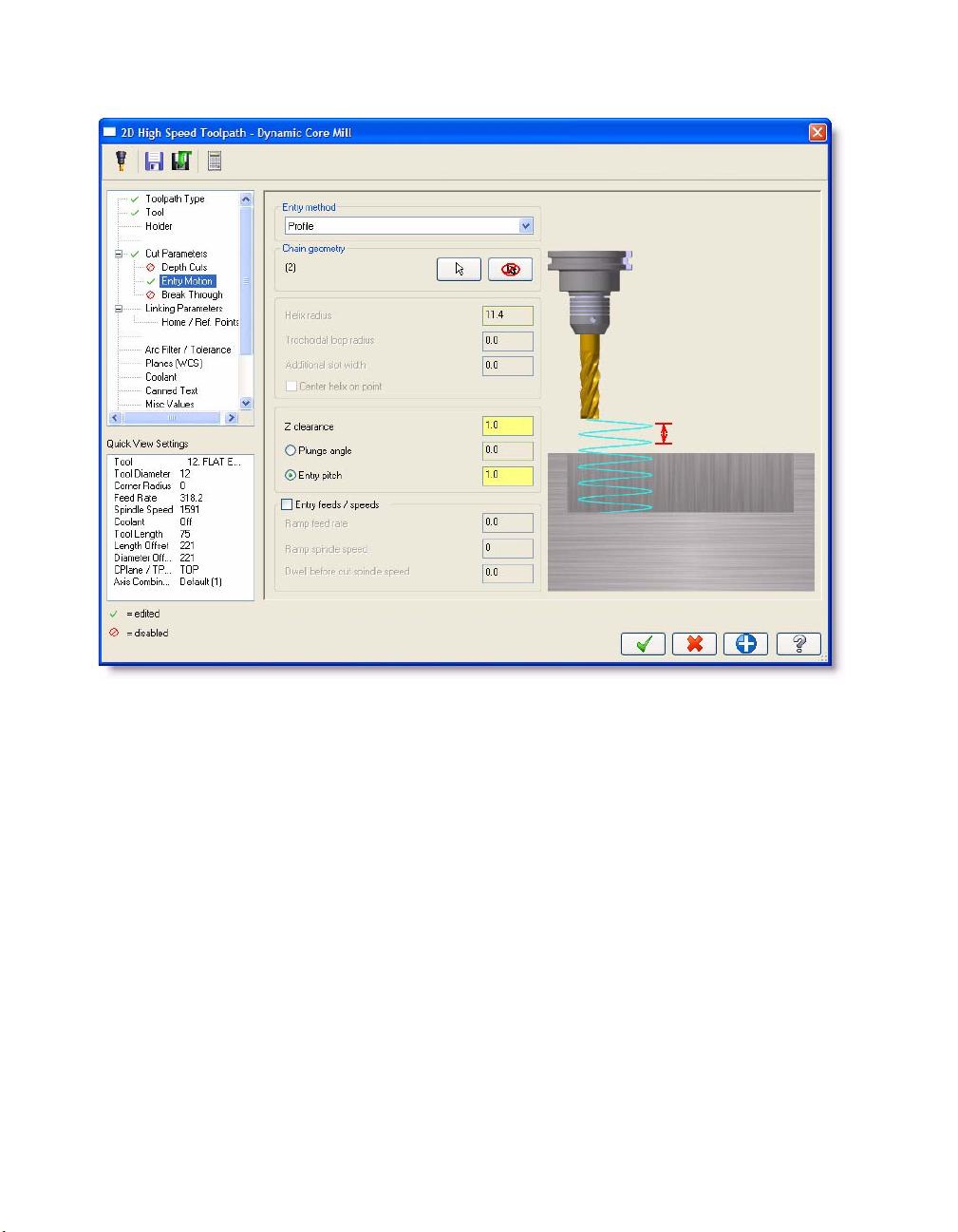

stock.

Note: The open pocket machining method enters from outside the material - these entry

parameters are only used if Mastercam encounters a closed pocket.

6 Set the following parameters:

Select Profile from the Entry method drop-down list. This entry method creates a

ramp entry based on the shape of the offset pocket. The slot is cleared by taking

lighter cuts in the Z axis. Subsequent cuts are properly engaged at the full cut depth.

Enter 1.0 for the Z clearance. This is an extra height used in the ramping motion

down from a top profile. It ensures that the tool has fully slowed down from rapid

speeds before touching the material, so that it enters the material smoothly at the

plunge angle.

Select the Entry pitch radio button and enter 1.0 for the distance. This controls the

entry descent by the pitch value you define. Mastercam lowers the tool by the pitch

value for every complete revolution of the entry motion, ensuring the tool is never

buried by more than the specified pitch.

Page 26

20 • BASIC 2D MACHINING

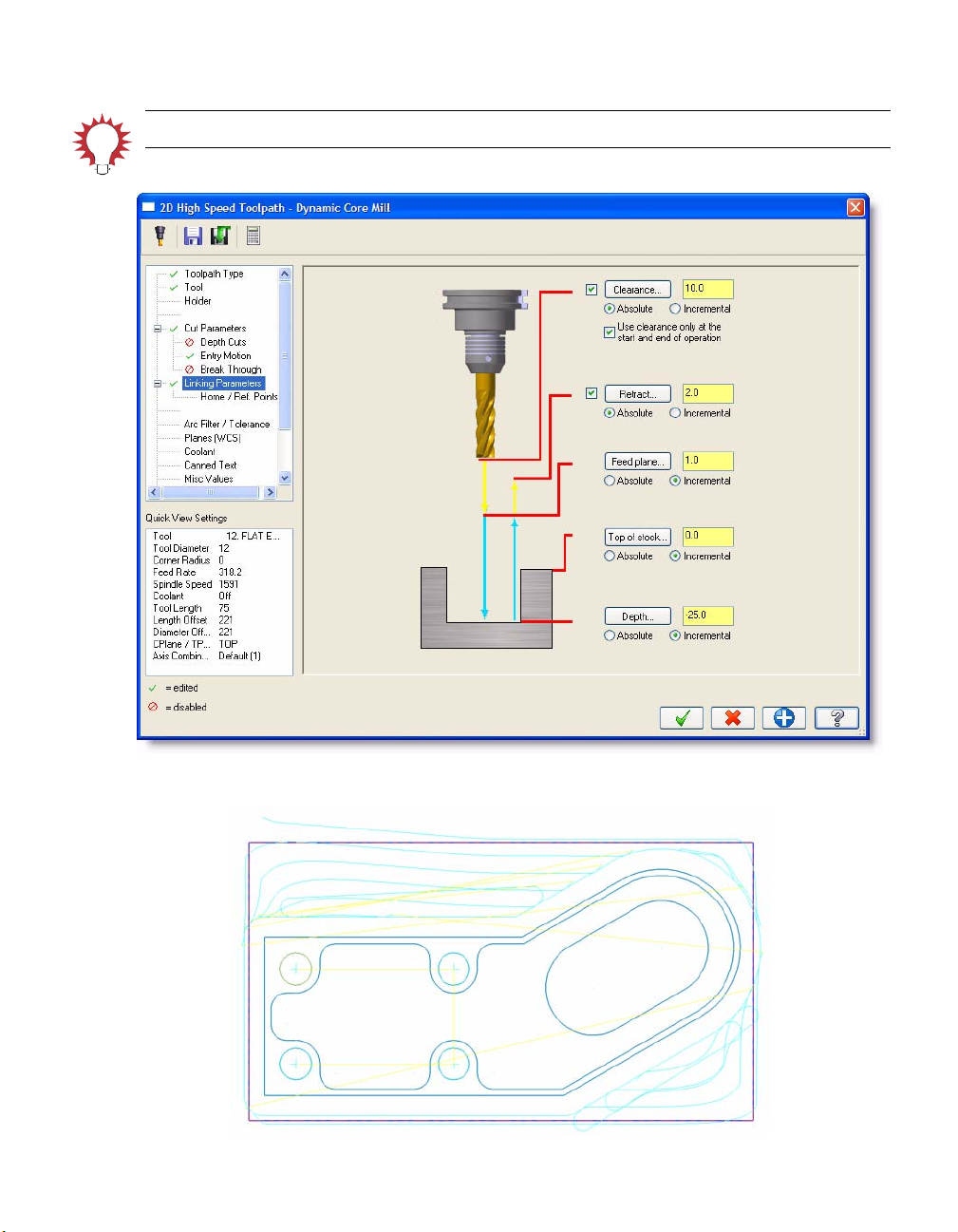

7 Click the Linking Parameters page in the Tree View list to set important heights such as

clearance, retract, and feed plane, as well as the final toolpath depth.

8 Set the following parameters:

Select the Clearance check box and enter 10.0 for the height, which is the height at

which the tool moves to and from the part.

Select the Use clearance only at the start and end of operation check box, so the

toolpath rapids to the clearance height only at the start and end of the toolpath.

Enter 2.0 for the Retract height and select the Absolute radio button. This is the

height that the tool moves up to before the next tool pass. By selecting Absolute, the

retract height is always measured from 0,0,0, not relative to any selected geometry.

Enter 1.0 for the Feed plane height, which is the height that the tool rapids to before

changing to the plunge rate to enter the part.

Enter 0 for the Top of stock height, which is the height of the material in the Z axis.

Enter -25.0 for the Depth. This value determines the final machining depth and the

lowest depth that the tool descends into the stock. In this case, the depth is -25mm,

or 25 mm below the top of the part.

Page 27

TIP: The default depth is the depth of the selected geometry.

ROUGHING OUTSIDE THE PART • 21

9 Click OK to generate the toolpath.

Page 28

22 • BASIC 2D MACHINING

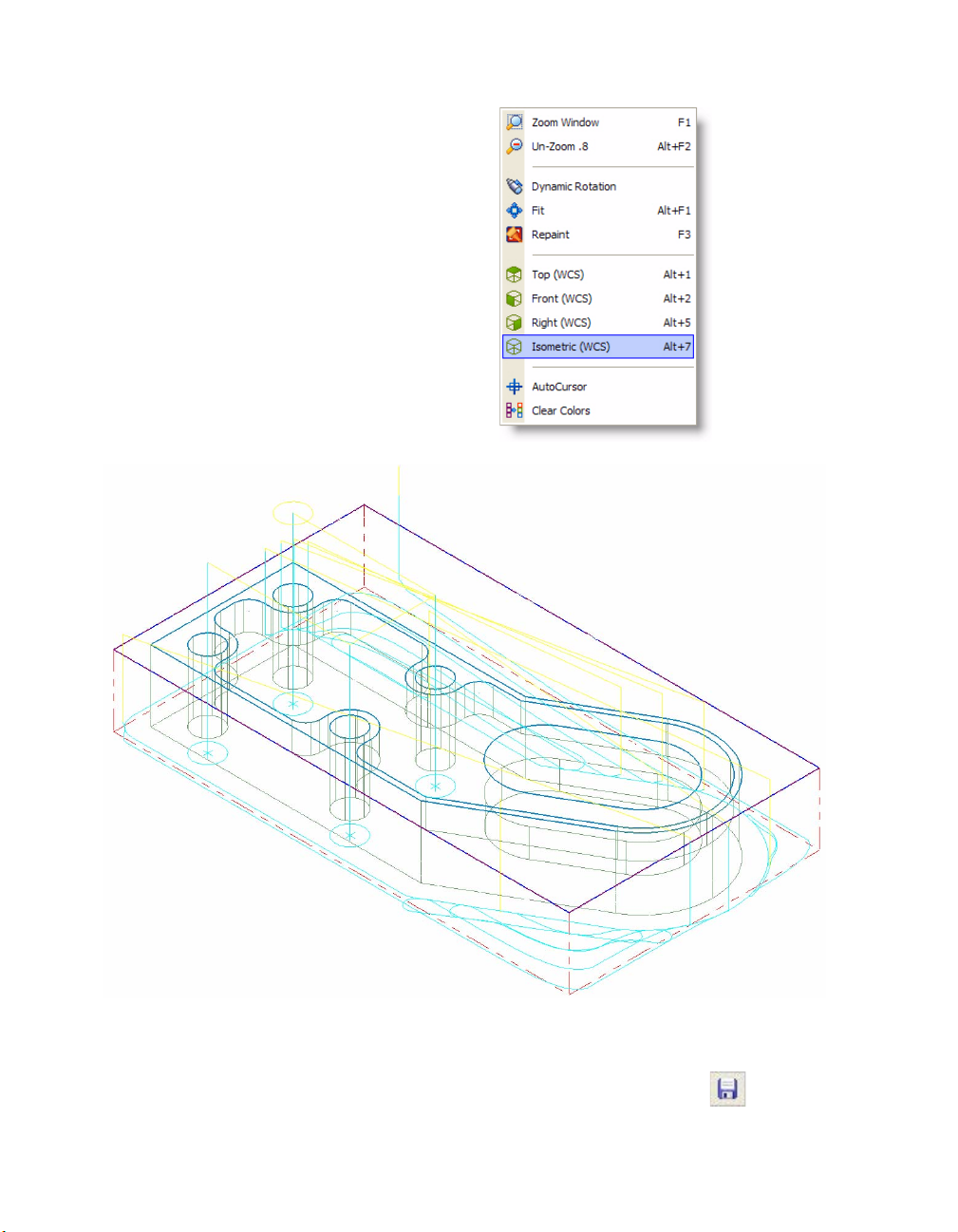

10 Right-click in the graphics window and

choose Isometric (WCS) from the menu to

view the part and toolpath in the isometric

view.

The toolpath cleans most of the material

outside the part using smooth, efficient

tool motion.

11 Right-click in the graphics window again and choose Top (W C S ) from the menu to view the

part and toolpath in the top view.

12 Choose File, Save from the Mastercam menu or click the Save button to save your

part.

Page 29

ROUGHING OUTSIDE THE PART • 23

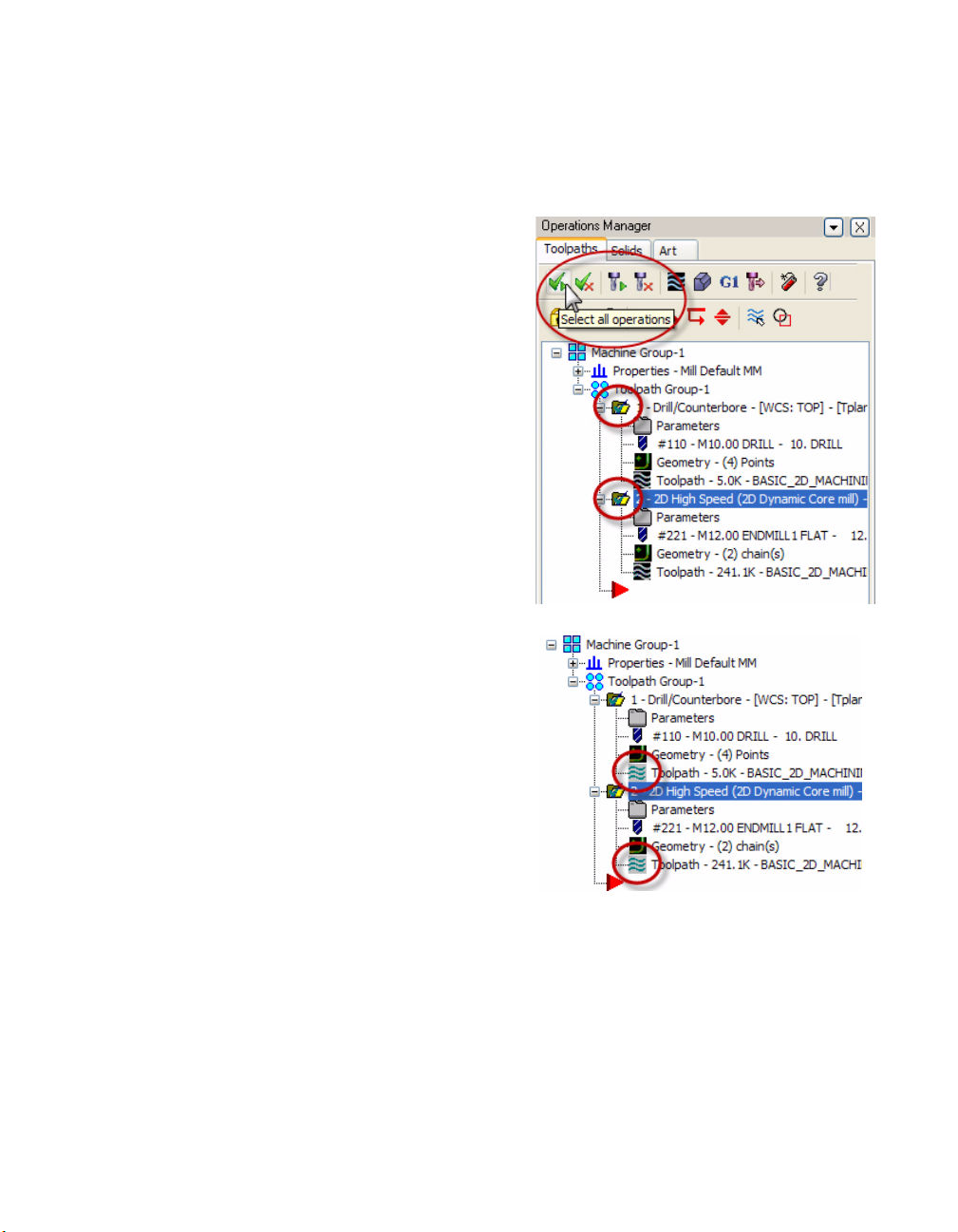

Exercise 2: Viewing Your Toolpaths

In this exercise, you will temporarily turn off the display for the drill and dynamic mill toolpaths so

that you easily see any additional toolpaths you create.

1 In the Toolpath Manager, click the Select

all operations button. Check marks

display on the yellow folders of each

toolpath, which indicates that they are

selected.

2 Press [T] to toggle off the toolpath display

of both toolpaths in the graphics window.

This function toggles the visibility of

toolpaths on and off in the graphics

window so that you can view only specific

toolpaths.

The Toolpath icon changes to gray when

the toolpath display is toggled off.

Exercise 3: Creating a Contour Toolpath

To get the final finish on the outer walls with no stock remaining, you will create a contour toolpath.

Contour toolpaths remove material along a path defined by a chain of curves. Contour toolpaths

only follow a chain; they do not clean out an enclosed area.

Page 30

24 • BASIC 2D MACHINING

1 From the Mastercam menu, choose

Toolpaths, Contour. The Chaining dialog

box opens.

2 Click the outside contour of the part to chain it. The chaining arrow should point

clockwise. If the chaining direction arrow is pointing counterclockwise, click the Reverse

button on the Chaining dialog box.

3 Click OK on the Chaining dialog box to chain the part. The Chaining dialog box closes and

the 2D Toolpaths - Contour dialog box opens.

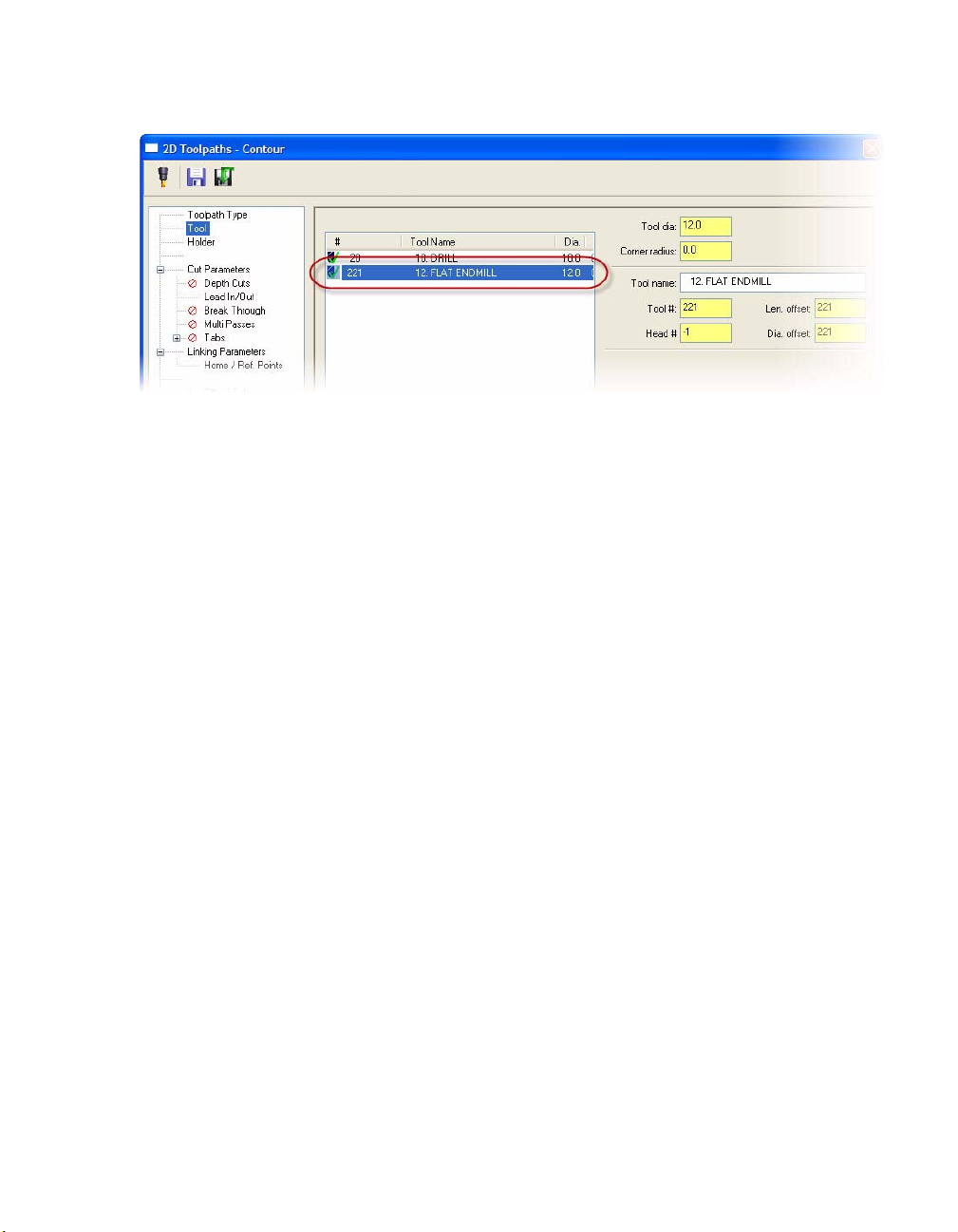

4 Click the To o l page in the Tree View list to select a tool for this toolpath.

Page 31

ROUGHING OUTSIDE THE PART • 25

5 Select the 12mm diameter flat endmill you used for the dynamic mill toolpath.

Setting the Contour Toolpath Parameters

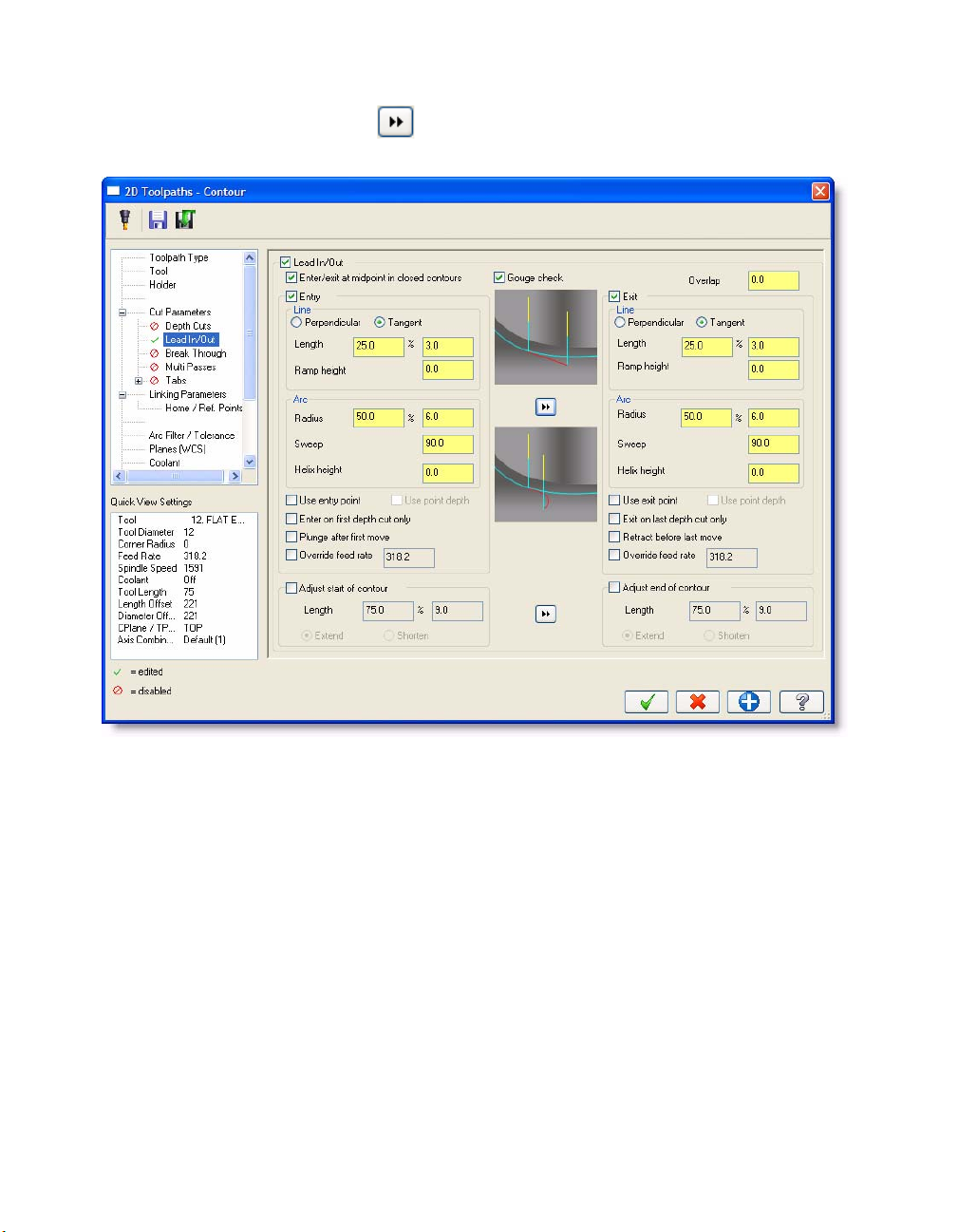

1 Click the Lead In/Out page in the Tree View area to enter values for the entry and exit

moves.

Lead in/out or entry/exit moves are a combination of lines and arcs at the beginning and

end of a 2D or 3D contour toolpath. They control how the tool approaches and pulls away

from the toolpath.

Mastercam places entry and exit lines relative to the entry and exit arcs. If both an entry

line and entry arc are defined, the line is machined first. If both an exit line and exit arc are

defined, the arc is machined first. The lead in/out entry points may differ based on where

you clicked the geometry to chain it.

2 Set the following parameters:

Enter 25% for the Entry Line Length.

Enter 50% for the Entry Arc Radius.

Page 32

26 • BASIC 2D MACHINING

Click the arrow button in the center of the page to copy the values to the Exit

parameters.

3 Click the Linking Parameters page in the Tree View list.

4 Set the following parameters:

Select the Clearance check box and enter 10.0 for the height.

Select the Use clearance only at the start and end of operation check box.

Enter 2.0 for the Retract height and select the Absolute radio button.

Enter 1.0 for the Feed plane height.

Enter 0 for the Top of stock height.

Enter -25.0 for the Depth.

Page 33

ROUGHING OUTSIDE THE PART • 27

5 Click OK to generate the toolpath.

Page 34

28 • BASIC 2D MACHINING

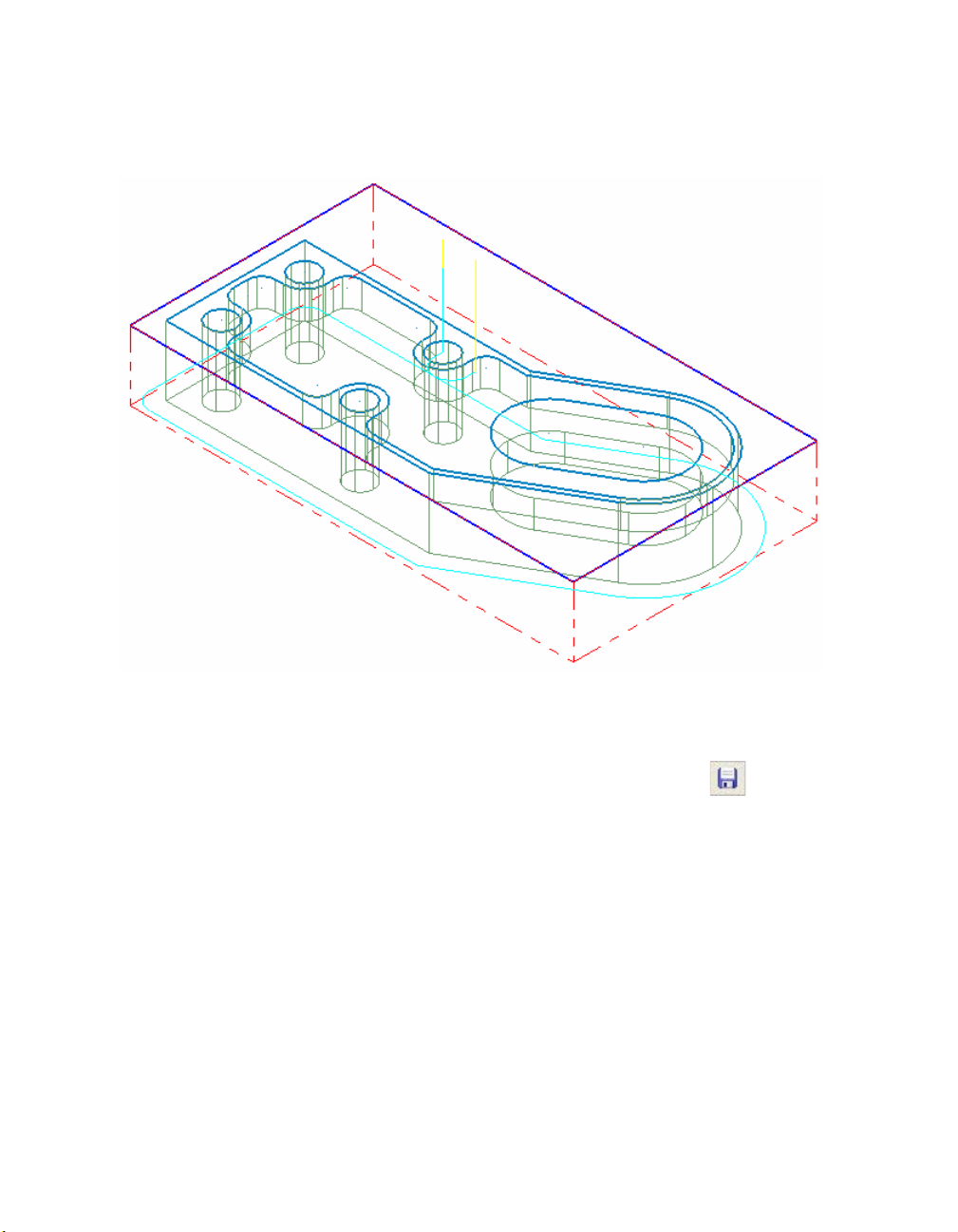

6 Right-click in the graphics window and choose Isometric (WCS) from the menu to view the

part and toolpath in the isometric view. The contour toolpath removes the 0.5mm left

behind by the dynamic mill toolpath and machines the outer wall to its final size.

7 Right-click in the graphics window again and choose Top (WCS) from the menu to view the

part and toolpath in the top view.

8 Choose File, Save from the Mastercam menu or click the Save button to save your

part.

The stock has been removed from the outer areas of the part. In the next lesson, you will remove

material from the inner areas of the part, including the slot.

Page 35

LESSON 3

3Machining Inside the Part

The next step in machining the tutorial part is to clean out material from the inside. You will use

two toolpaths specifically geared towards the areas inside the part.

Lesson Goals

Create a dynamic mill toolpath (including chaining entities, choosing tooling, and setting

machining values).

Create a slot mill toolpath (including chaining entities, choosing tooling, and setting

machining values).

Exercise 1: Creating a Dynamic Mill Toolpath

In this exercise, you create a dynamic mill toolpath to clean out the large interior shape of the

tutorial part. This toolpath type works well for all pocket shapes because the tool goes right to the

final depth, and you can cut using the whole flute length instead of stepping down.

1 Select the Contour toolpath in the Toolpath Manager and press [T] to turn off the toolpath

display. This makes it easier to see the new toolpaths you create.

2 From the Mastercam menu, choose

Toolpaths, 2D High Speed. The Chaining

dialog box opens.

Page 36

30 • BASIC 2D MACHINING

3 Click the inner contour of the part to chain it.

4 Click OK on the Chaining dialog box to chain the part. The Chaining dialog box closes and

the 2D High Speed Toolpath dialog box opens.

5 Select the Dynamic Area Mill toolpath type. The Tree View area updates with a list of

parameters for dynamic mill toolpaths.

6 Click the To o l page in the Tree View list to select a tool for this toolpath.

Page 37

7 Click the Select library tool button. The

default metric tool library opens.

8 Select the 6mm diameter flat endmill, and click OK.

Setting the Dynamic Mill Toolpath Parameters

MACHINING INSIDE THE PART • 31

1 Click the Cut Parameters page in the Tree View area to enter values for different cutting

parameters and compensation options.

TIP: Notice that the parameter values are the same as the last dynamic mill toolpath you

created. Many of the Mastercam dialog boxes retain their previous settings, saving you from

having to reenter data, reselect function buttons, or reselect options in a drop-down list. The

settings stay in their “last used” state for the remainder of the Mastercam session or until

you change them.

2 Set the following parameters:

Enter 35% for the Stepover.

Select Never from the Retract drop-down list.

Enter 0 (zero) for the Stock to leave on walls.

Page 38

32 • BASIC 2D MACHINING

Note: See Setting the Dynamic Mill Toolpath Parameters on page 18 for more information on

these parameters.

3 Click the Linking Parameters page in the Tree View list to set important heights such as

clearance, retract, and feed plane, as well as the final toolpath depth.

Page 39

4 Enter -10.0 for the Depth.

MACHINING INSIDE THE PART • 33

5 Click OK to generate the toolpath.

Page 40

34 • BASIC 2D MACHINING

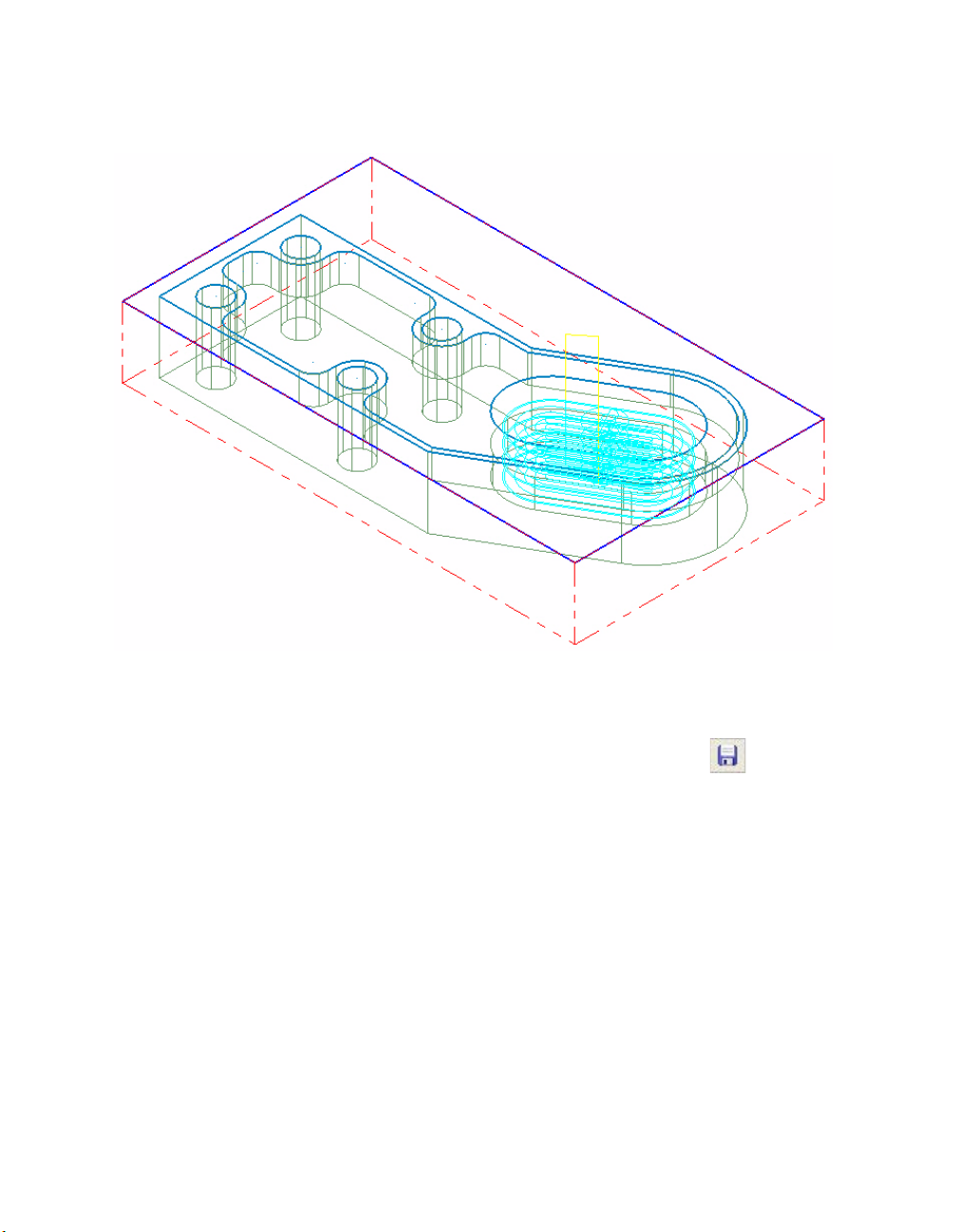

6 Right-click in the graphics window and choose Isometric (WCS) to view the part and

toolpath in the isometric view. The toolpath cleans off the floor of the part, but doesn’t

completely machine the additional slot.

7 Right-click in the graphics window again and choose Top (WCS) from the menu to view the

part and toolpath in the top view.

8 Choose File, Save from the Mastercam menu or click the Save button to save your

part.

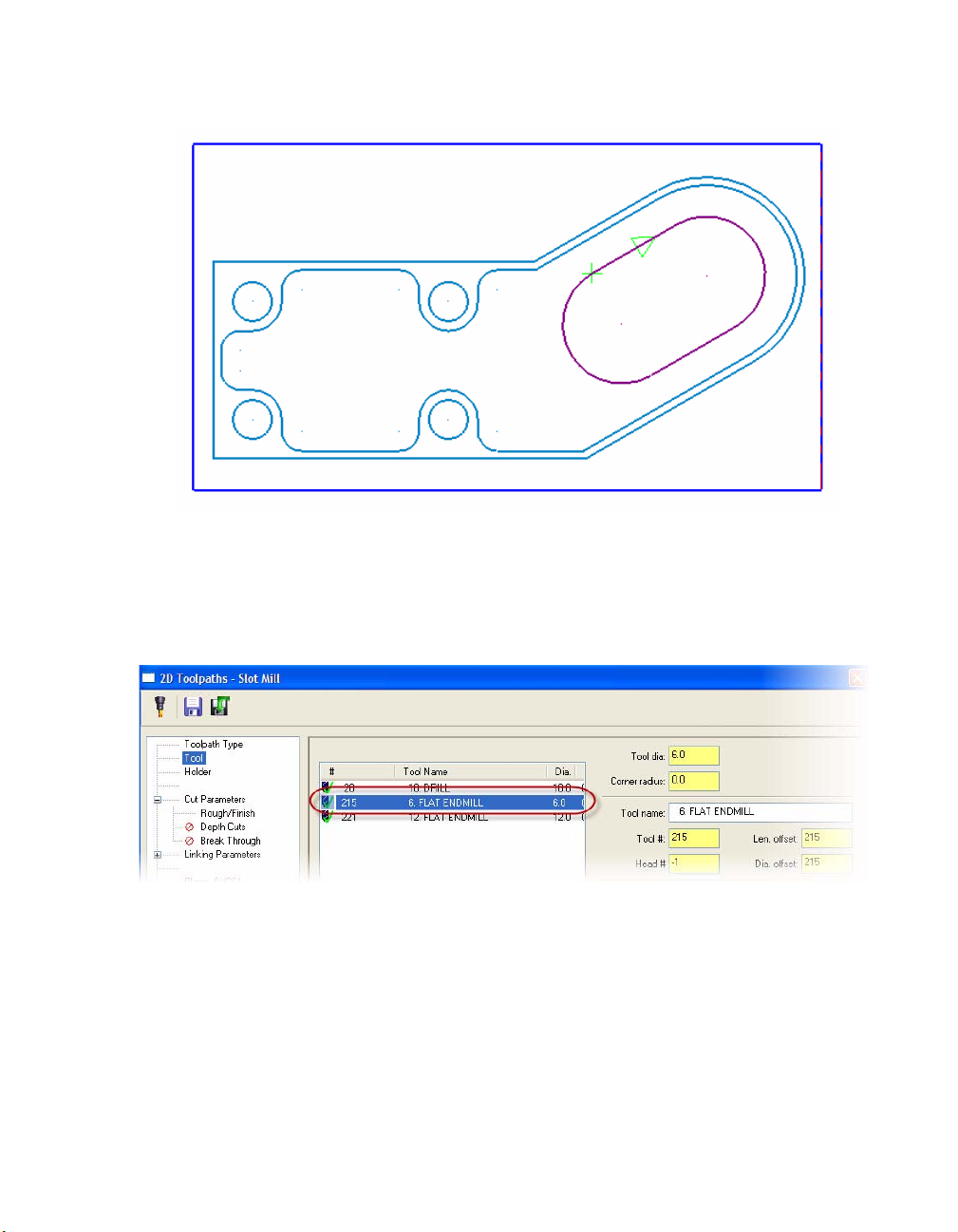

Exercise 2: Creating a Slot Mill Toolpath

Slot mill toolpaths are designed to efficiently machine obround slots. These are slots that consist of

2 straight lines and two 180-degree arcs at the ends, such as the remaining slot on your part.

1 Select the second Dynamic Mill toolpath in the Toolpath Manager and press [T] to turn off

the toolpath display. This makes it easier to see the new toolpaths you create.

2 From the Mastercam menu, choose Toolpaths, Circle Paths, Slot Mill. The Chaining dialog

box opens.

Page 41

MACHINING INSIDE THE PART • 35

3 Click the slot to chain it. The chaining arrow should point clockwise.

4 Click OK on the Chaining dialog box to chain the part. The Chaining dialog box closes and

the 2D Toolpaths - Slot Mill dialog box opens.

5 Click the To o l page in the Tree View list to select a tool for this toolpath.

6 Select the 6mm diameter flat endmill you used for the dynamic mill toolpath.

Setting the Slot Mill Toolpath Parameters

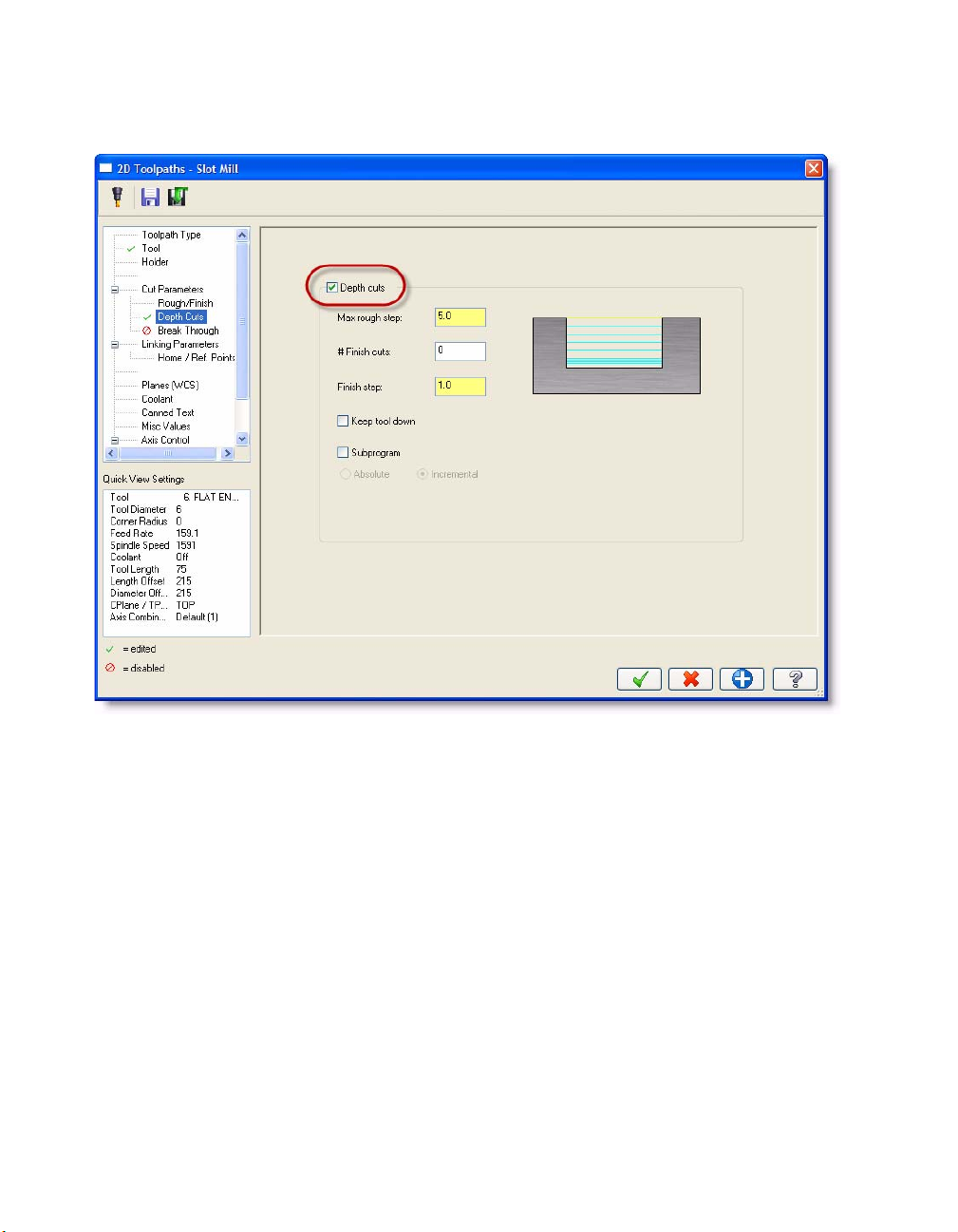

1 Click the Depth Cuts page in the Tree View area to enter values for different cutting

parameters and compensation options.

Page 42

36 • BASIC 2D MACHINING

2 Select the Depth cuts check box to turn on depth cuts. The default parameter values are

used for this toolpath.

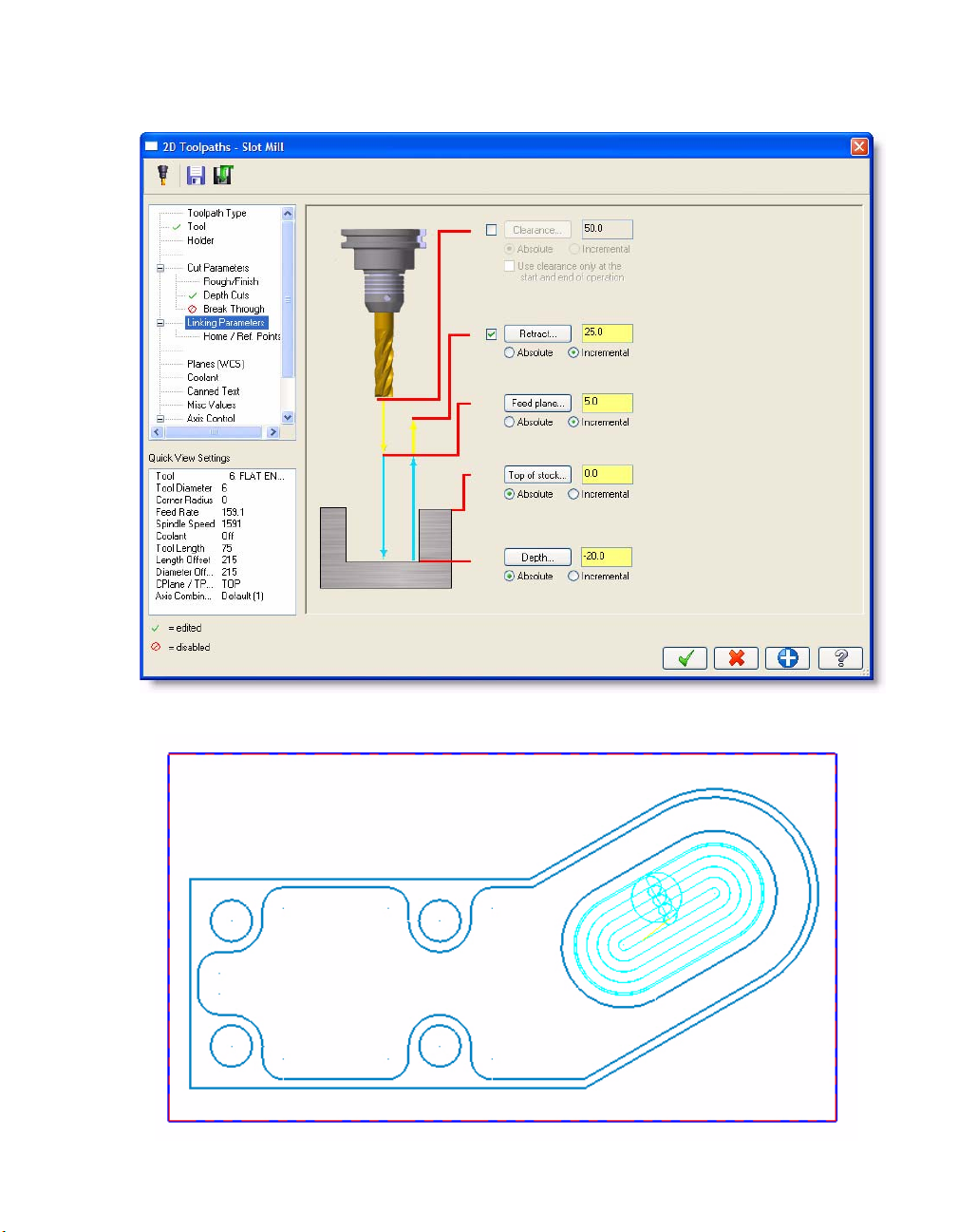

3 Click the Linking Parameters page in the Tree View list.

Page 43

4 Enter -20.0 for the Depth.

MACHINING INSIDE THE PART • 37

5 Click OK to generate the toolpath.

Page 44

38 • BASIC 2D MACHINING

6 Right-click in the graphics window and choose Isometric (WCS) to view the part and

toolpath in the isometric view. The slot is machined in four depth cuts.

7 Right-click in the graphics window again and choose Top (WCS) from the menu to view the

part and toolpath in the top view.

8 Choose File, Save from the Mastercam menu or click the Save button to save your

part.

Now that you have machined all areas of the part, you can use Mastercam’s Backplot and Verify

functions to check your toolpaths before sending them to the machine tool.

Page 45

LESSON 4

4Previewing Toolpaths

Mastercam has several ways of viewing your toolpath motion before you actually machine your

part. Visualizing the machining process for this part is an important step before sending the

program to your machine control.

Lesson Goals

Backplot all toolpaths.

Customize your backplot display.

Verify all toolpaths.

Exercise 1: Backplotting All Toolpaths

Backplot is a Mastercam function that allows you to see the path the tools take to cut the part. This

display lets you spot errors in the program before you machine the part.

Note: This lesson assumes that you have successfully completed Lessons 1 through 3 of the Basic

2D Machining tutorial and have saved the MCX file. If you have not, or if you think your

completed part file is incorrect, open the BASIC_2D_MACHINING_FINISH.MCX-5 file provided

with this tutorial.

1 If necessary, open Mastercam and your part (see note above).

2 At the top of the Toolpath Manager, click

the Select all operations button.

Page 46

40 • BASIC 2D MACHINING

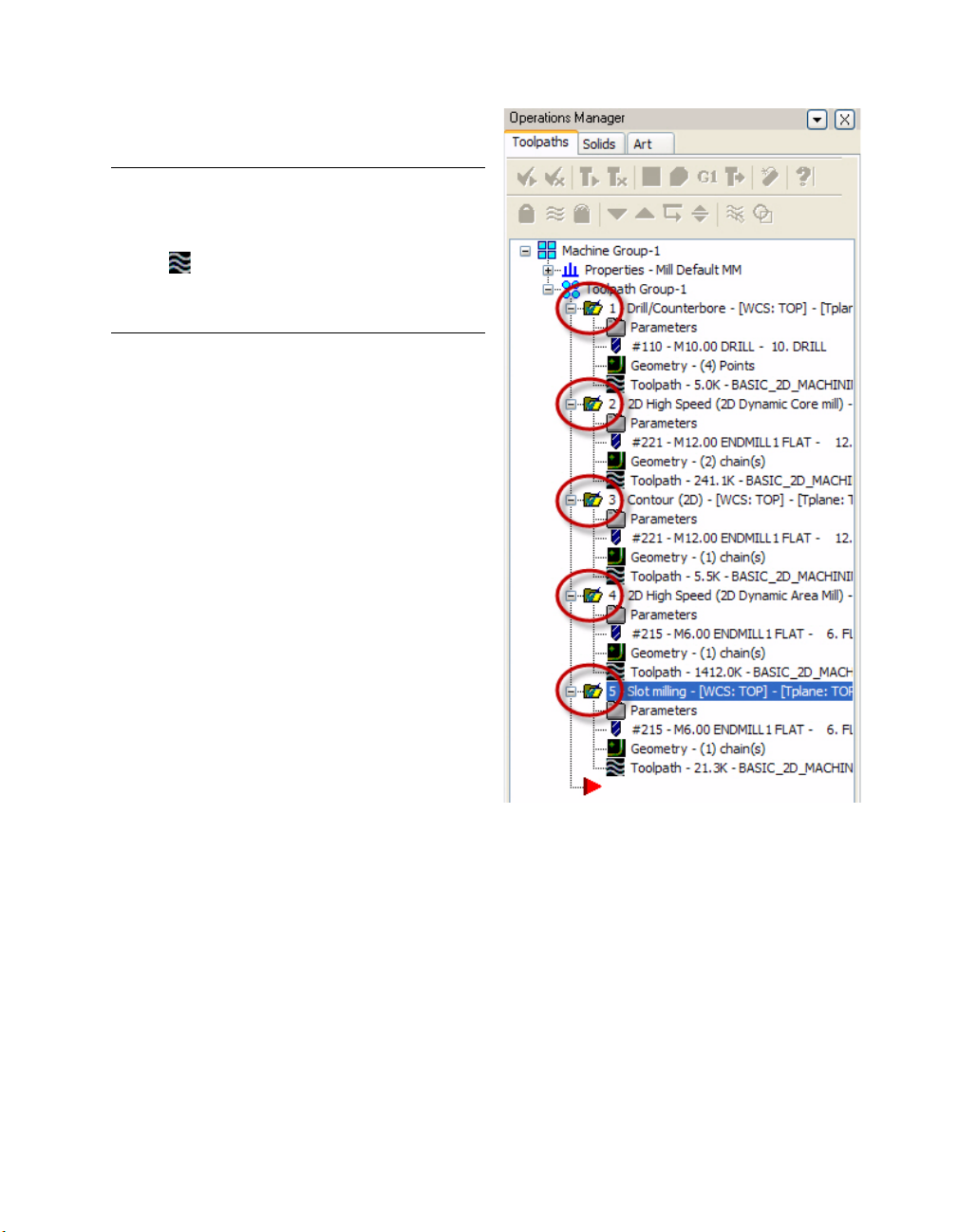

All five toolpath folders display a check

mark.

Note: Make sure that all toolpaths are set to

display in the graphics window.

The Toolpath icon for each toolpath should be

black.

If any of the toolpaths are not displayed, press

[T].

3 Right-click in the graphics window and choose Isometric (WCS) from the menu to view the

part and all toolpaths in the isometric view.

Page 47

PREVIEWING TOOLPATHS • 41

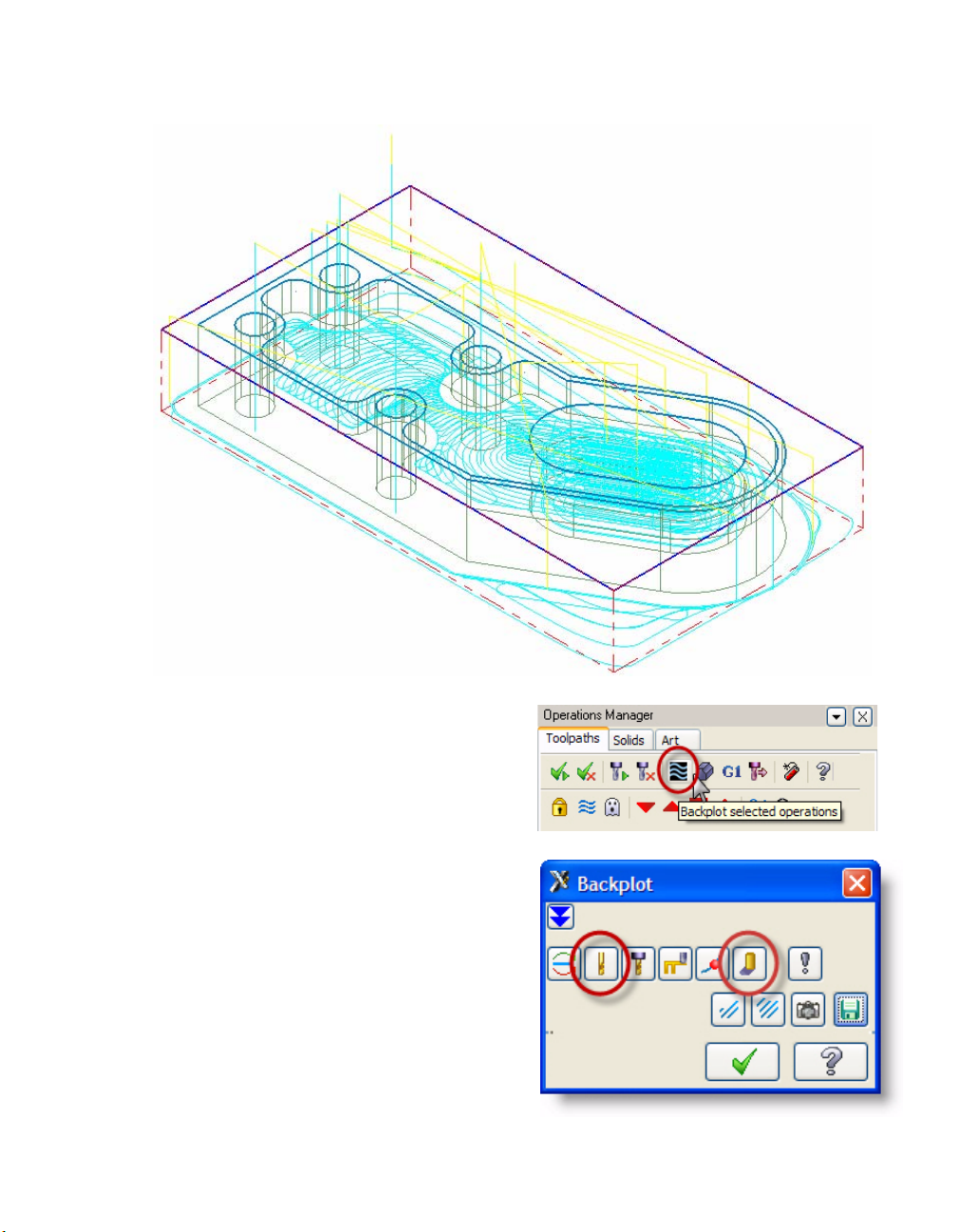

4 In the Toolpath Manager, click the

Backplot selected operations button. The

Backplot dialog box and Backplot VCR bar

open.

5 In the Backplot dialog box, select the

Display tool and Quick verify buttons.

These options will display a simulation of a

tool and shade the toolpath during

backplot.

Page 48

42 • BASIC 2D MACHINING

TIP: To further customize your backplot display, choose other buttons on the Backplot

dialog box. For example, choose the Options button to open the Backplot Options

dialog box. This dialog box lets you set various backplot parameters such as tool display,

holder display, and tool motion colors.

6 Use the buttons and sliders on the Backplot VCR bar to backplot the operations. The Play

button begins the backplotting action. Click the Help button on the VCR bar for

more information on each of the controls.

7 When finished, click OK on the Backplot dialog box to exit the backplot function.

TIP: The backplot display is easily customizable. See the Mastercam Help for details on

each of the buttons, fields, and display options in the Backplot and the Backplot Options

dialog boxes.

Exercise 2: Verifying All Toolpaths

Mastercam's Ver ify utility allows you to use solid models to simulate the machining of a part. The

model created by the verification represents the surface finish, and shows collisions, if any exist. In

this exercise, you simulate (verify) the machining of the part from a stock model display.

1 In the Toolpath Manager, make sure all

operations are selected and click the Veri fy

selected operations button. The Verify

dialog box opens.

2 In the Verify dialog box, select the Machine

button. The part, stock, and toolpaths are

simulated.

Page 49

PREVIEWING TOOLPATHS • 43

TIP: Use the buttons, fields, and controls in the Verify dialog box to customize and manage

the toolpath verification process. Click the Help button on the dialog box for details.

The following pictures shows the part after the verification is complete.

3 When finished, click OK on the Verify dialog box to exit the function.

You have verified that the toolpaths are correct, so now you can send the toolpath data to your

machine tool in preparation for machining your part.

Page 50

44 • BASIC 2D MACHINING

Page 51

LESSON 5

5Posting Toolpaths

Post processing, or posting, refers to the process by which the toolpaths in your Mastercam part

files are converted to a format that can be understood by your machine tool’s control (for example,

G-codes). A special program called a post processor, or post, reads your Mastercam file and writes

the appropriate NC code. Generally, every machine tool or control will require its own post

processor, customized to produce code formatted to meet its exact requirements.

Lesson Goals

Post all toolpaths to create NC files.

Exercise 1: Posting All Toolpath Operations

In this exercise, you post all toolpath operations for this part to an NC file, review/edit the code as

necessary, and save the NC file.

Note: This lesson assumes that you have successfully completed Lessons 1 through 3 of this Basic

2D Machining tutorial module and have saved the MCX file. If you have not, open the

BASIC_2D_MACHINING_FINISH.MCX-5 file provided with this tutorial.

1 If necessary, open Mastercam and your part (see note above).

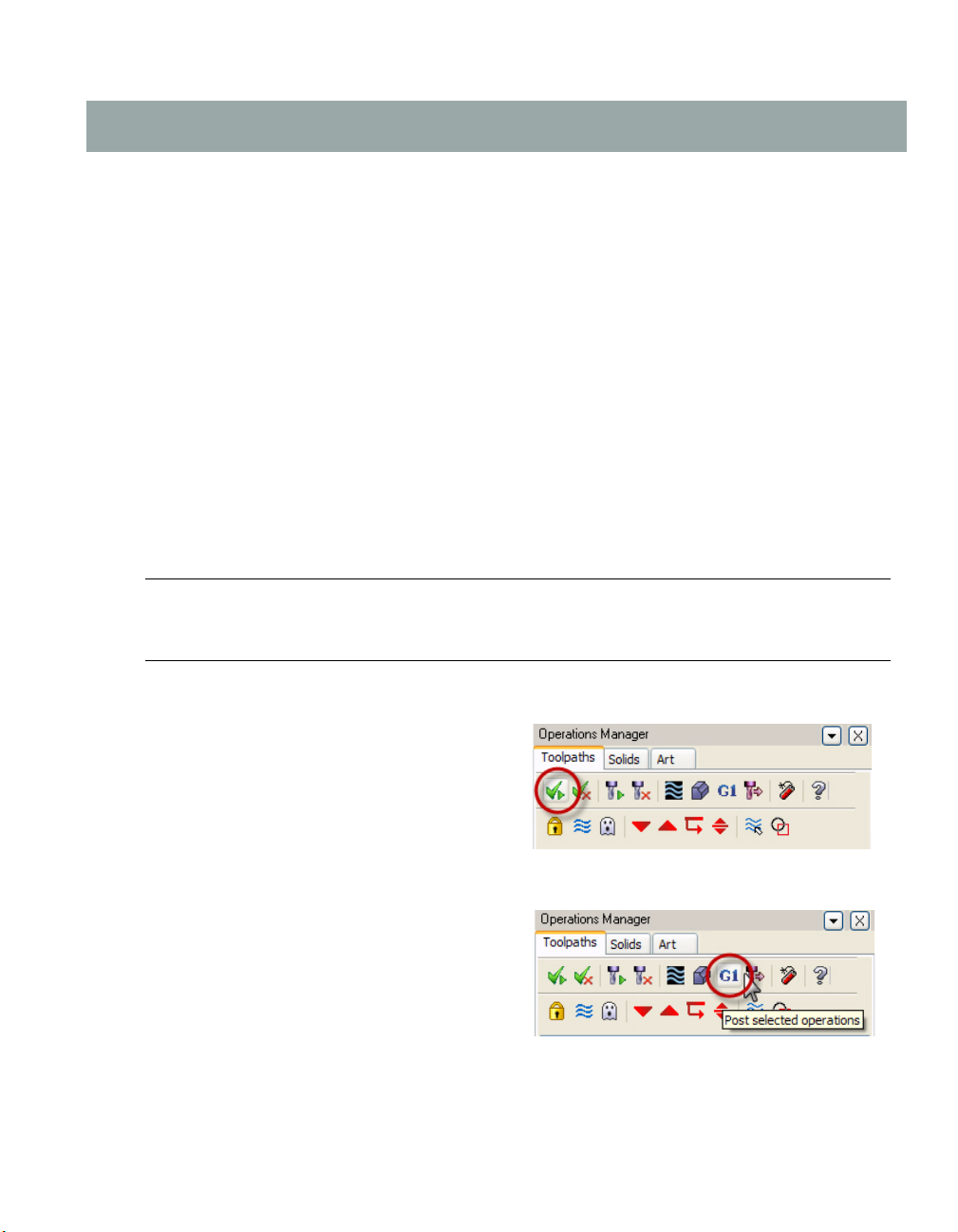

2 In the Toolpath Manager, click the Select

all operations button.

All five toolpath folders will display a check mark to indicate they are selected.

3 In the Toolpath Manager, click the Post

selected operations button. The Post

processing dialog box opens.

Page 52

46 • BASIC 2D MACHINING

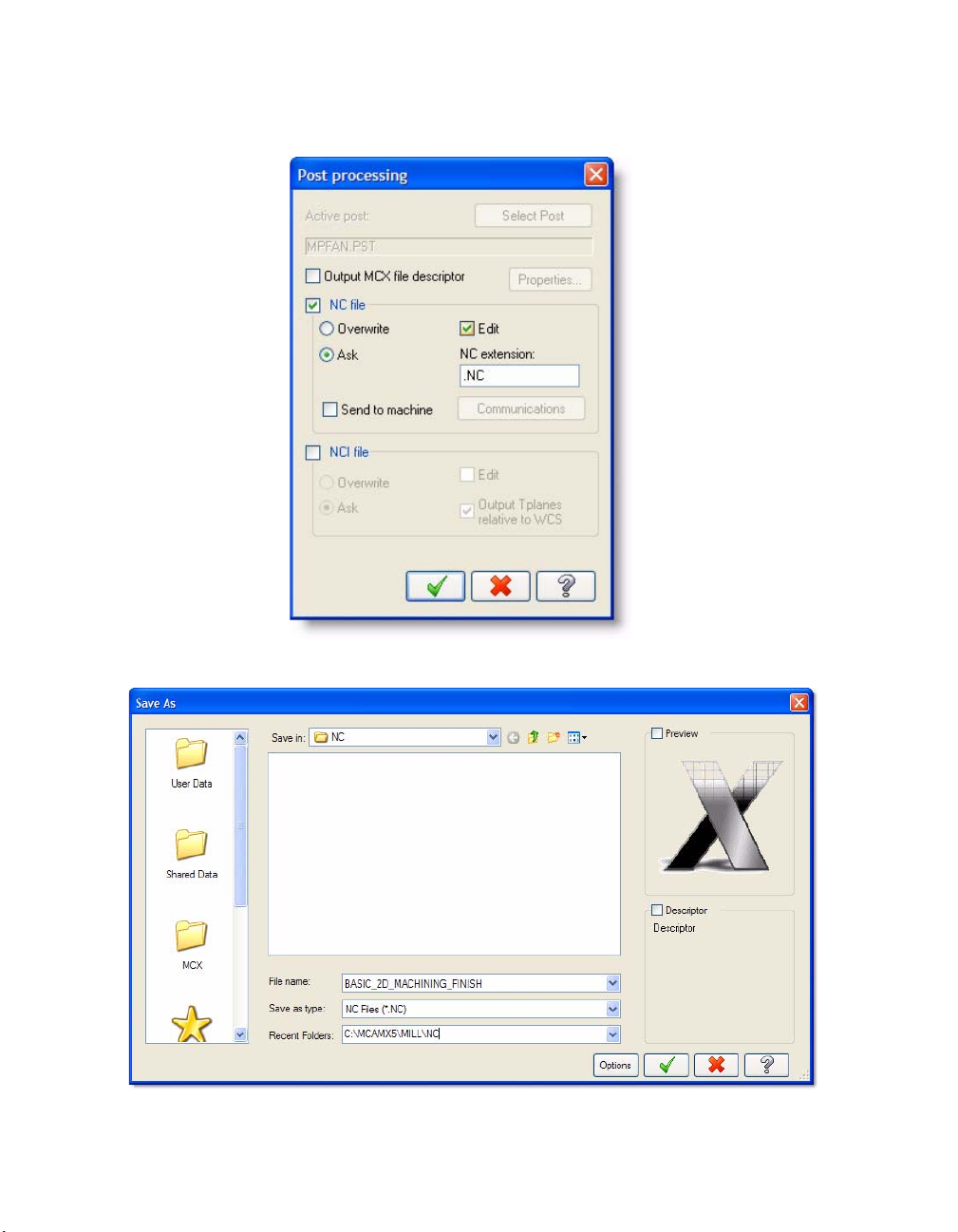

4 Set the post processing parameters as shown. These settings will ask if you want to save the

NC file and will display the resulting file in your default text editor.

5 Click OK. The Save As dialog box opens.

6 Click Save to save the NC file in the default location with the recommended file name.

Page 53

POSTING TOOLPATHS • 47

Notes:

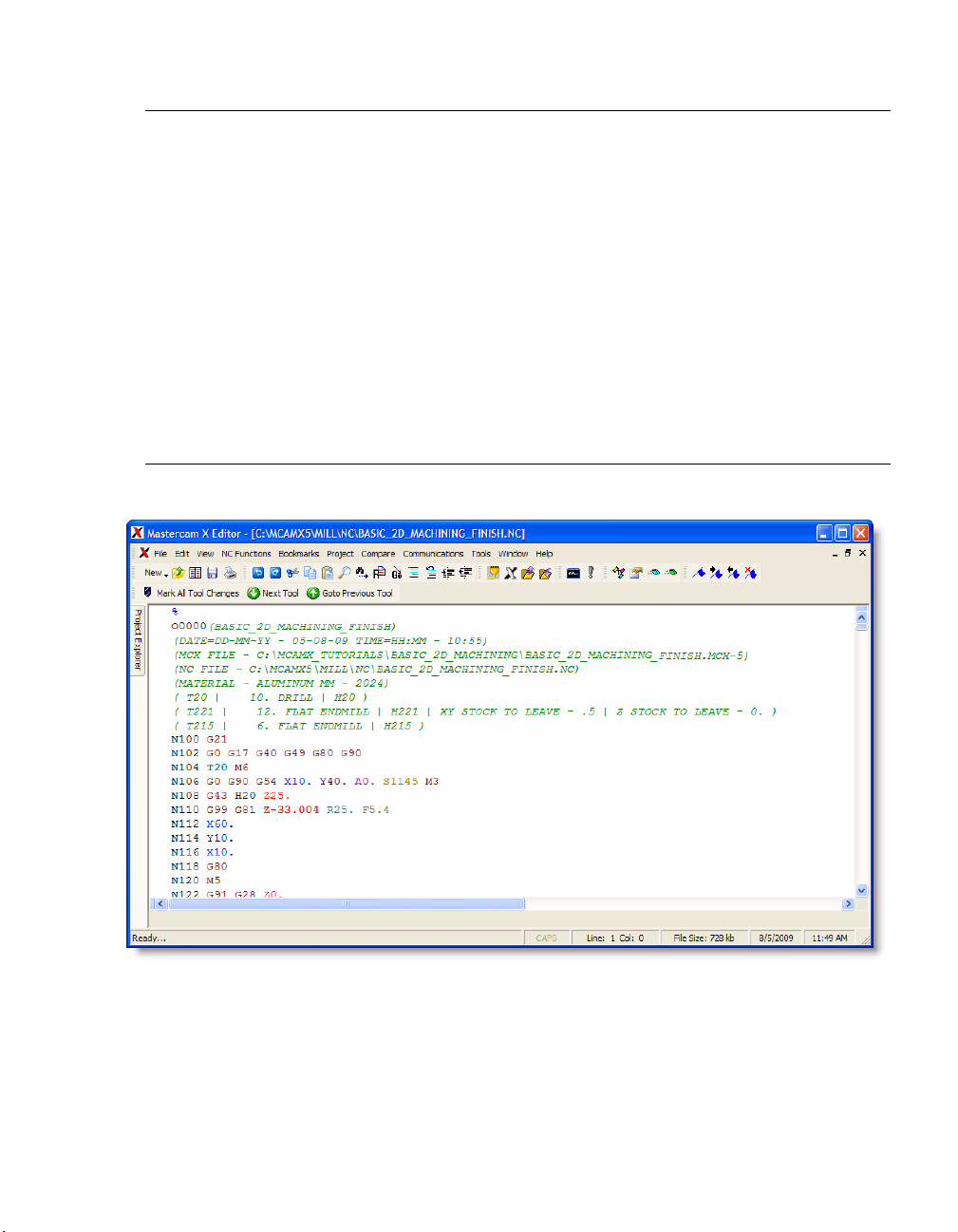

• Posting may take several minutes. When it is complete, the NC code will display in your

default editor/communicator. This tutorial uses Mastercam Editor to display the NC code.

• Producing the correct NC code for your machine and application depends on properly

configuring the machine definition, control definition, and .PST file. For detailed

information on machine definitions, control definitions, and posting, please see the

following documentation supplied with Mastercam:

Mastercam Help

Mastercam X5 Reference Guide (choose Reference Guide from the Mastercam Help

menu)

Mastercam X5 NCI & Parameter Reference (in the Documentation folder under your

Mastercam installation folder)

7 Your selected editor opens (in this case, Mastercam Editor), displaying the posted NC code.

8 Scroll through the NC code to verify that each line of code meets your expectations. Edit

and save as necessary.

Page 54

48 • BASIC 2D MACHINING

Post Processing Summary: Sending NC Files to Machine

IMPORTANT: This tutorial is based on the Mastercam Mill Default machine definition for

training purposes only. It is not possible to provide a step-by-step procedure for sending the

NC code to your machine control because machine setups are customizable and most likely

different from the machine definition used here. Following is a general description of how

the NC code is communicated to machines and their controls for machining.

After the NC file is reviewed, edited, and saved, you can set up your machine control to accept the

NC file. This is done according to your machine and control manufacturer’s procedures.

When the machine control is ready to receive the NC file, configure your preferred editor or

communications program to communicate with your machine control. Refer to your

communications program documentation for details.

Send the NC code to your machine control according to your machine and control manufacturer’s

documentation. Once you start the communication process, the send/receive data processing is

mostly managed by your machine control.

Contact your local Mastercam Reseller for customized machine/control definitions, post (PST)

files, and support.

Conclusion

Congratulations! You have completed the Basic 2D Machining tutorial. Now that you have mastered

the skills in this tutorial, we encourage you to explore Mastercam’s other features and functions.

Additional tutorials may be available in this or other series. Please contact your authorized

Mastercam Reseller for further training.

Page 55

Page 56

Attention! Updates may be available.

Go to Mastercam.com/Support for the latest downloads.

671 Old Post Road

Tolland, CT 06084 USA

www.mastercam.com

X5-PDF-TUT-2M

Loading...

Loading...