Page 1

MP/EMP Post Debugger

User’s Guide

Page 2

Page 3

Mastercam X3

MP-EMP Post

Debugger User’s

Guide

[Preliminary Review Version]

July 2008

Page 4

ii • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Mastercam® MP-EMP Post Debugger User’s Guide

Date: July 2008

Copyright © 2008 CNC Software, Inc. — All rights reserved.

Software: Mastercam X3

ISBN: 1-883310-86-5

IMPORTANT NOTICE!

Software License

PLEASE READ THIS STATEMENT AND THE SOFTWARE LICENSE AGREEMENT

COMPLETELY BEFORE USING THIS SOFTWARE. YOU MUST ACCEPT THE TERMS

OF THIS LICENSE BEFORE YOU CAN OPERATE THE SOFTWARE PROGRAM.

BY CONTINUING TO USE THIS SOFTWARE, YOU (EITHER AN INDIVIDUAL OR A

SINGLE ENTITY) INDICATE YOUR INTENTION TO BE BOUND BY AND ACCEPT

THE TERMS AND CONDITIONS OF THIS SOFTWARE LICENSE. IF YOU DO NOT

AGREE TO THESE TERMS AND CONDITIONS, YOU MAY NOT ACCESS OR

OTHERWISE USE THIS SOFTWARE AND WILL IN FACT BE PROHIBITED FROM

DOING SO. THIS COMPUTER SOFTWARE MAY BE USED ONLY PURSUANT TO

THE TERMS AND CONDITIONS SET FORTH BELOW, AND SOLELY IN

CONJUNCTION WITH THE ACCOMPANYING SECURITY MECHANISM (UNLESS

OTHERWISE SPECIFIED IN THE "EXCEPTIONS TO SECURITY MECHANISM

REQUIREMENTS" SECTION OF SUCH TERMS AND CONDITIONS) WHICH MUST

BE PRESENT ON YOUR COMPUTER (OR NETWORK AS APPLICABLE) AT ALL

TIMES DURING SUCH USE.

Please Note:

regarding the use of this Software that are in addition to those found within this

Software License. If you have any questions or concerns as to the existence of any

such additional restrictions or guidelines, you should consult with your supervisor

or your IT Department before using this Software.

Read This If You Have Received This Software From A Third Party:

this Software from someone other than an authorized CNC Software, Inc. reseller,

you do not have a legal software license. (For example, if you acquired this Software

simply by buying a machine or Software from the former owner or from an auction,

you do not have a valid license.) You should contact CNC Software, Inc. (860-875-

5006) in order to obtain a new and valid license. Use of this Software without a

valid software license is unlawful, a violation of the Copyright Act and may expose

you to criminal liability under 17 United States Code Sec. 506, including fines and

damages.

If you have paid a license fee, CNC Software, Inc. ("CNC") a Connecticut

corporation with its principal place of business at 671 Old Post Road, Tolland,

Connecticut, 06084 hereby grants to you a non-exclusive, non-transferable license

(the "License") to use this software program and its accompanying documentation

(and, if applicable, to permit your authorized employees to use them), solely in

accordance with the terms and conditions of this Software License Agreement. You

may use the Software solely for your internal business purposes and solely in

conjunction with the accompanying hardware or software device, method, scheme

or other security measure provided by CNC which allows a user to access the

Software and prevents unauthorized access to the Software (the "Security

Mechanism"). The Software, any updates to the Software through purchase or due

to enrollment in an authorized software Maintenance program (including any that

you download through the Internet), and the Documentation in printed or

electronic form shall hereinafter collectively be referred to as the "Software" and are

all governed by this License.

Your company may have additional restrictions and guidelines in place

If you received

Page 5

iii

Restrictions

Copying Restrictions

Non Transferable

Intellectual Property Rights

Confidentiality

You may not use the Software without a Security Mechanism provided by CNC or

CNC's suppliers. When CNC or CNC's resellers provide you with a single-user

Security Mechanism, the Software may only be used (in executable code form

only) on a single computer to which the Security Mechanism is physically

attached. In the event CNC or CNC's resellers provide you with a multiple-user

Security Mechanism for use over an internal network (a "Network Security

Mechanism"), the Software may be used: (a) in executable code form only; (b) only

on end-user computers that are connected to the internal network to which the

Network Security Mechanism is attached; and (c) only by the number of users and

accessed by the number of end-user computers for which licenses were purchased

and as further allowed by the Network Security Mechanism. You may physically

transfer the Software from one computer equipped with a single-user Security

Mechanism to another only if the Security Mechanism is included in the transfer

and is installed with the new computer.

You shall not: (a) copy (except as provided below), adapt, modify the Software; (b)

publish, display, disclose or create a derivative work from the Software or any part

thereof; (c) de-compile or translate, disassemble, create or attempt to create, by

reverse engineering or otherwise, the source code form of the Software from the

executable code of the Software; (d) remove any proprietary notices, labels or

marks from the Software; (e) sell, rent, lease, distribute or otherwise transfer or

provide all or any part of the Software to any person or entity without the prior

written consent of CNC; (f) use the Software to provide outsourcing, service

bureau, time sharing or other services to any third party; or (g) sublicense, assign,

delegate or otherwise transfer your rights in the Software, under the Software

License Agreement or any of the related rights or obligations for any reason

without the prior written consent of CNC. You shall not circumvent, bypass,

modify, reverse engineer, disassemble, disable, alter, enhance or replicate the

function of the Security Mechanism in any manner whatsoever. Any attempt to do

so shall result in automatic termination of this License without prejudice to all

other legal rights and remedies of CNC.

You may make one (1) copy of the Software for backup or archival purposes,

provided that you reproduce all proprietary notices of CNC on any such copy.

You may not transfer or assign the Software or this Software License Agreement or

any rights or obligations hereunder. Any attempt to do so will automatically

terminate this License without the need for notice. This termination is without

prejudice to all other legal rights and remedies of CNC.

The Software is and includes intellectual property of CNC. All associated

intellectual property rights, including, without limitation, worldwide patent,

trademark, copyright and trade secret rights, are reserved by CNC. CNC retains all

right, title and interest in and copyrights to the Software, regardless of the form or

media in or on which the original or other copies may subsequently exist. This

Software License Agreement shall not constitute a sale of the Software and no title

or proprietary rights to the Software are transferred to you hereby. You

acknowledge that the Software is a unique, confidential and valuable asset of CNC,

and CNC shall have the right to seek all equitable and legal redress which may be

available to it for the breach or threatened breach of this Software License

Agreement including, without limitation, injunctive relief. Unauthorized copying

of the Software or failure to comply with the above restrictions shall result in

automatic termination of this License and this Software License Agreement

without prejudice to all other legal rights and remedies of CNC.

You acknowledge that the Software contains proprietary trade secrets of CNC and

you hereby agree to maintain the confidentiality of the Software using at least as

great a degree of care as you use to maintain the confidentiality of your own most

11

12

13

14

15

16

17

18

19

110

Page 6

iv • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

confidential information. You agree to promptly communicate the terms and

conditions of this Software License Agreement to those persons employed by you

who come into contact with the Software, and to use your best efforts to ensure

their compliance with such terms and conditions, including, without limitation,

absolutely preventing such persons to use any portion of the Software for the

purpose of deriving the source code of the Software or defeating the Security

Mechanism.

Enforcement

Obligations

Limited Warranties

Disclaimer of

Consequential

Damages and

Limitation of Liability

In the event you become aware that any person or entity in your employ or under

your control is using the Software in a manner not authorized by this Software

License Agreement, you shall immediately take all steps necessary to stop such

unauthorized use of the Software. You shall promptly notify CNC in writing of any

unauthorized use of the Software of which you become aware.

CNC WARRANTS THAT THE MEDIA ON WHICH THE SOFTWARE IS DISTRIBUTED

WILL BE FREE OF DEFECTS IN MATERIAL OR WORKMANSHIP FOR A PERIOD OF

THIRTY (30) DAYS AFTER PURCHASE. THE FOREGOING LIMITED WARRANTY

EXCLUDES DEFECTS ARISING OUT OF ACCIDENT, NEGLECT, MISUSE, FAILURE

OF ELECTRIC POWER AND CAUSES OTHER THAN ORDINARY AND AUTHORIZED

USE. EXCEPT FOR THE FOREGOING LIMITED WARRANTY, THE SOFTWARE IS

PROVIDED "AS IS, WITH ALL FAULTS." THIS LIMITED WARRANTY IS THE ONLY

WARRANTY PROVIDED BY CNC REGARDING THE SOFTWARE. TO THE

MAXIMUM EXTENT PERMITTED BY LAW, CNC DISCLAIMS ALL OTHER

WARRANTIES OF ANY KIND, EITHER EXPRESSED OR IMPLIED, INCLUDING,

WITHOUT LIMITATION, IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE. CNC IS NOT OBLIGATED TO PROVIDE

ANY UPDATES TO THE SOFTWARE.

Sole and Exclusive Remedy for Breach of Warranty: YOUR SOLE EXCLUSIVE

REMEDY AND CNC'S SOLE OBLIGATION HEREUNDER SHALL BE, AT CNC'S SOLE

OPTION (i) REPLACEMENT OF THE DEFECTIVE MEDIA; OR (ii) REFUND OF THE

PURCHASE PRICE OF THE SOFTWARE. CNC SHALL HAVE NO OTHER

OBLIGATION OR LIABILITY TO YOU ARISING FROM OR RELATED TO THIS

LICENSE OR YOUR USE OF THE SOFTWARE. ANY USE BY YOU OF THE

SOFTWARE IS AT YOUR OWN RISK.

Note on Documentation: While CNC makes every effort to ensure that its

Documentation for the Software is accurate and up-to-date, it cannot guarantee the

Documentation at all times represents the latest operation and functionality of the

Software. The content of all documentation, in electronic or printed form, for the

Software is provided for informational purposes only. The content of the

Documentation may be changed without notice to you. CNC expressly disclaims

any warranty or representation that the Documentation is an accurate and/or

current reflection of the Software's operation and performance.

IN NO EVENT WHATSOEVER WILL CNC, OR ITS EMPLOYEES, SHAREHOLDERS,

DISTRIBUTORS OR RESELLERS BE LIABLE TO YOU FOR ANY INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN

CONNECTION WITH THIS SOFTWARE LICENSE AGREEMENT OR THE USE OF

THE SOFTWARE, EVEN IF CNC HAS BEEN ADVISED OF THE POSSIBILITY OF

SUCH DAMAGES. WITHOUT LIMITING THE FOREGOING, CONSEQUENTIAL

DAMAGES SHALL INCLUDE, WITHOUT LIMITATION, SPECIAL, PUNITIVE OR

EXEMPLARY DAMAGES, DAMAGES FOR LOSS OF BUSINESS, LOSS OF PROFITS,

BUSINESS INTERRUPTION, LOSS OF BUSINESS INFORMATION, AND LOSS OF

OR DAMAGE TO ANY PRODUCTS THAT THE SOFTWARE IS USED IN

CONJUNCTION WITH.

Page 7

Indemnification

Educational Pricing

Ter mi na ti on

General

CNC'S ENTIRE LIABILITY WITH RESPECT TO ITS OBLIGATIONS UNDER THIS

SOFTWARE LICENSE AGREEMENT OR OTHERWISE SHALL NOT EXCEED THE

AMOUNT OF THE LICENSE FEE PAID BY YOU FOR THE SOFTWARE. SOME

JURISDICTIONS DO NOT ALLOW THE EXCLUSION OR LIMITATION OF IMPLIED

WARRANTIES OR LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES,

SO THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT APPLY TO YOU.

You shall indemnify and hold harmless CNC, its officers, directors, employees,

resellers and agents (the "Indemnified Parties") from and against all losses,

settlements, claims, actions, suits, proceedings, judgments, awards, damages,

liabilities, costs and expenses including, without limitation, reasonable attorneys'

fees (collectively "Losses") which arise out of or are related to any breach of this

Software License Agreement by you or your employees, agents, resellers, dealers or

sub-dealers, and shall reimburse the Indemnified Parties for any and all legal,

accounting and other fees, costs and expenses reasonably incurred by any of them

in connection with investigating, mitigating or defending any such Losses.

If this Software was obtained through or in accordance with a CNC "Educational

Pricing" plan, option, grant, schedule or program, it may not be used by anyone,

including you, to conduct any computer aided design, computer aided drafting,

computer aided machining, or training activities that, directly or indirectly,

generate or otherwise result in monetary revenues for the benefit of any individual

or any entity, other than the school that originally received this Software.

This Software License Agreement is effective until terminated. You may terminate

this Software License Agreement at any time by returning to CNC all copies of the

Software under your control and by returning the Security Mechanism to CNC.

CNC may terminate this Software License Agreement if CNC determines, in its sole

discretion, that you have violated the terms of this Software License Agreement.

Upon termination of this Software License Agreement, you agree to immediately

return to CNC all copies of the Software, return the Security Mechanism to CNC,

and certify to CNC in writing that all known copies, including backup copies, have

been returned. All provisions relating to confidentiality, proprietary rights,

indemnification and non-disclosure shall survive the termination of this Software

License Agreement. You may not transfer this Software to the purchaser of any

equipment on which the Software may be resident. You may not transfer this

Software via liquidation, bankruptcy, auction, close of business, or any other

method that does not involve an authorized Mastercam reseller. This License is

for you alone. In the event you breach the provisions of this Section, CNC shall be

entitled to liquidated damages in the amount of Fifteen Thousand Dollars

($15,000), plus its reasonable attorney's fees and court costs.

This Software License Agreement shall be governed by and construed in

accordance with the laws of the state of Connecticut, USA without regard for

Connecticut's conflicts of law principles. The sole and exclusive jurisdiction and

venue for any litigation arising from or related to this Software License Agreement

or the subject matter hereof shall be in an appropriate state or federal court located

in Hartford, Connecticut. You hereby submit to the personal jurisdiction of the US

District Court for the District of Connecticut and the Superior Court of the State of

Connecticut. This Software License Agreement shall constitute the entire

agreement between you and CNC with respect to the subject matter hereof. Any

waiver or modification of this Software License Agreement shall be valid only if it is

in writing and signed by both parties hereto. If any part of this Agreement is found

invalid or unenforceable by a court of competent jurisdiction, the remainder of

this Agreement shall be interpreted so as to reasonably affect the intention of the

parties.

v

11

12

13

14

15

16

17

18

19

110

Page 8

vi • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Attorneys Fees

U.S. Government

Restricted Rights

Export Restrictions

Exceptions to Security

Mechanism

Requirements

Survival

Reservation of Rights

Trademarks

In the event that CNC is required to take legal action to enforce its rights under this

License Agreement and obtains a ruling or settlement in its favor, you shall be liable

to CNC for its reasonable attorney's fee incurred in investigating and prosecuting its

claim.

The Software provided hereunder is a "commercial item," as that term is defined in

48 C.F.R. 2.101, consisting of "commercial computer software" and "commercial

computer software documentation," as such terms are used in 48 C.F.R. 12.212.

Consistent with 48 C.F.R. 12.212 and 48 C.F.R. 227.7202-1 through 227.7202-4, the

Software made available to the United States of America, its agencies and/or

instrumentalities, is provided with only those rights set forth in this Agreement. Use,

duplication or disclosure of the Software by the government is subject to the

restrictions as set forth in subparagraph (c) (1) and (2) of the Commercial Computer

Software-Restricted Rights clause at 48 C.F.R. 52.227-19, as amended, or any

successor regulations thereto.

You represent and warrant that you will not, without obtaining prior written

authorization from CNC and, if required, of the Bureau of Export Administration of

the United States Department of Commerce or other relevant agency of the United

States Government, export or re-export, directly or indirectly, the Software from the

United States to (i) any country destination or entity to which export is restricted by

the Export Administration Regulations of the United States Department of

Commerce; (ii) any country or entity subject to sanctions administered by the Office

of Foreign Assets Control, United States Department of the Treasury; or (iii) such

other countries or entities to which export is restricted by any other United States

government agency. You further agree that you are solely responsible for

compliance with any import laws and regulations of the country of destination of a

permitted export or re-export, and any other import requirement related to a

permitted export or re-export.

CNC software programs Mastercam Design LT and Mastercam Demo as well as

printed and electronic documentation do not require the use of Security

Mechanisms, and the provisions in this Software License Agreement relating to

Security Mechanisms do not apply to your use of such programs, provided,

however, that such provisions shall apply to your use of all other Software and

documentation provided hereunder.

All provisions of this Software License Agreement relating to confidentiality, nondisclosure, CNC's proprietary rights, disclaimers, and limits of liability, or

indemnification by Customer shall survive termination of this License for any

reason.

All rights not expressly granted are reserved by CNC.

Mastercam® is a registered trademark of CNC.

Windows, Windows 2000, Windows XP, and Windows Vista are registered

trademarks of Microsoft Corporation. Mastercam Verify is created in conjunction

with MachineWorks Ltd. Mastercam Backplot includes Copyrighted intellectual

property rights owned by NWD.

Printed in the United States of America.

Printed on recycled paper.

Page 9

Contents

1. The Post Debugger Interface ......................................... 1

2. Using the Post Debugger.................................................. 7

vii

X The Main Window................................................................ 2

The Menu Bar......................................................................... 4

The Toolbar............................................................................ 5

Keyboard Shortcuts................................................................ 6

X Enabling the Debugger ......................................................... 8

X Running the Debugger........................................................ 11

X Running a Post.................................................................... 13

X Tracing through a Post....................................................... 14

X Using Breakpoints .............................................................. 18

X Watching Variables ............................................................ 21

3. The Debugger Windows................................................. 25

X The PST Output Window ................................................... 26

X The NCI Output Window.................................................... 27

X The NC Output Window..................................................... 28

X The Error Output Window.................................................. 30

X The Watches Window ....................................................... 31

X The Stack History Window................................................ 32

X The Post Lists Window...................................................... 33

Page 10

viii • Mastercam X3 / MP-EMP Post Debugger User’s Guide

Page 11

chapter 1

The Post Debugger Interface

This chapter covers the following topics:

The Main Window . . . . . . . . . . . . . . . . . . . . . . . page 2

The Menu Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . page 4

The Toolbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 5

Keyboard Shortcuts . . . . . . . . . . . . . . . . . . . . . . page 6

Mastercam’s MP/EMP Post Debugger helps you find and

correct errors in your posts. Using the debugger, you can step

through the posting process a line at a time, while watching the

post produce the NC code. As you manipulate the posting

process, you can watch how variables change value and view a

stack trace of the post execution. In this chapter, you explore

the MP/EMP Post Debugger’s interface.

Page 12

2 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

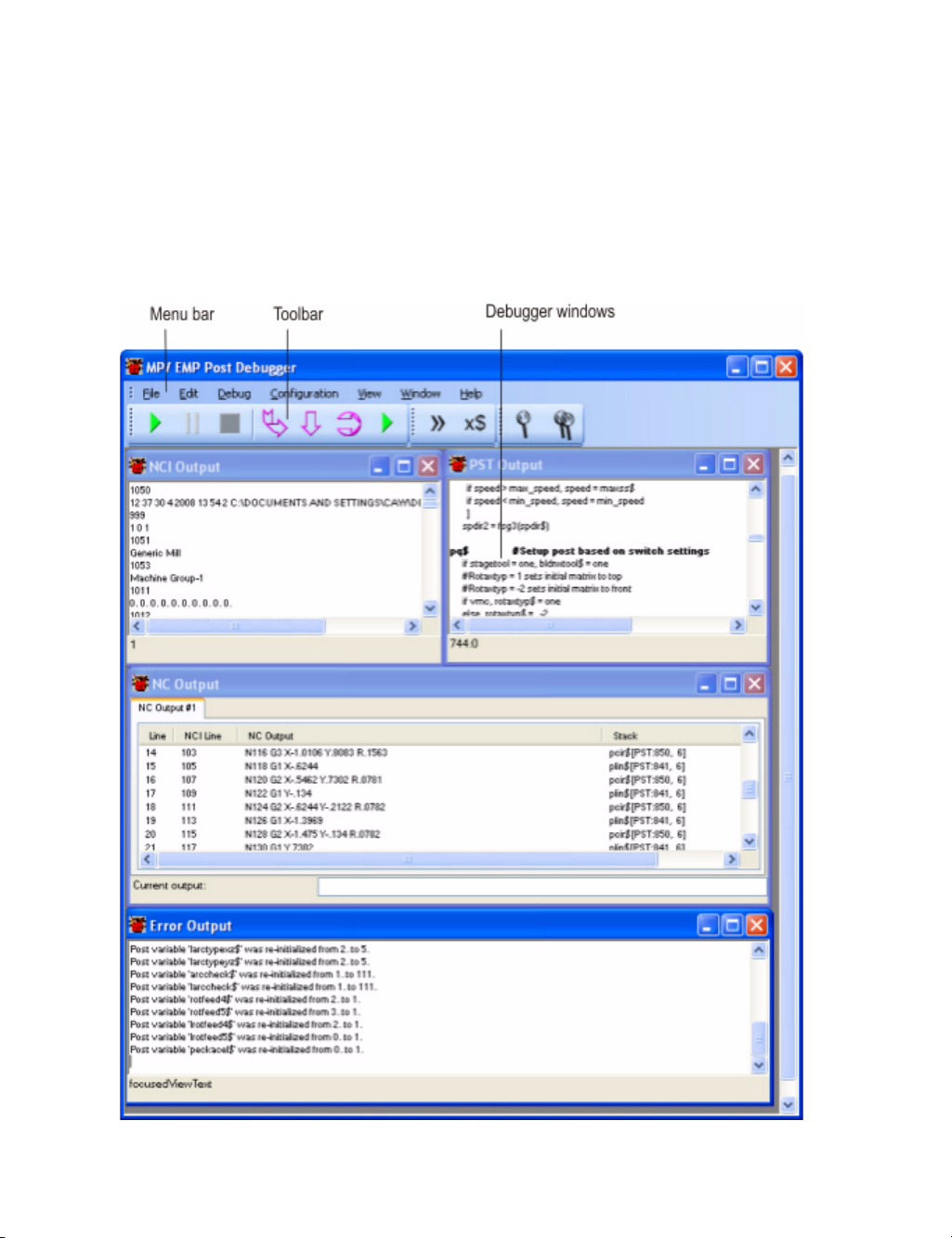

The Main Window

The MP/EMP Post Debugger’s main window hosts a menu bar and

toolbar, as well as the debugger windows.

Figure 1-1: The Post Debugger’s main window

Page 13

THE POST DEBUGGER INTERFACE / The Main Window • 3

The PST Output, NCI Output, NC Output, and Error Output debugger

windows are housed within the main window, and although they can

be sized and positioned individually, they cannot be dragged outside

of the main window.

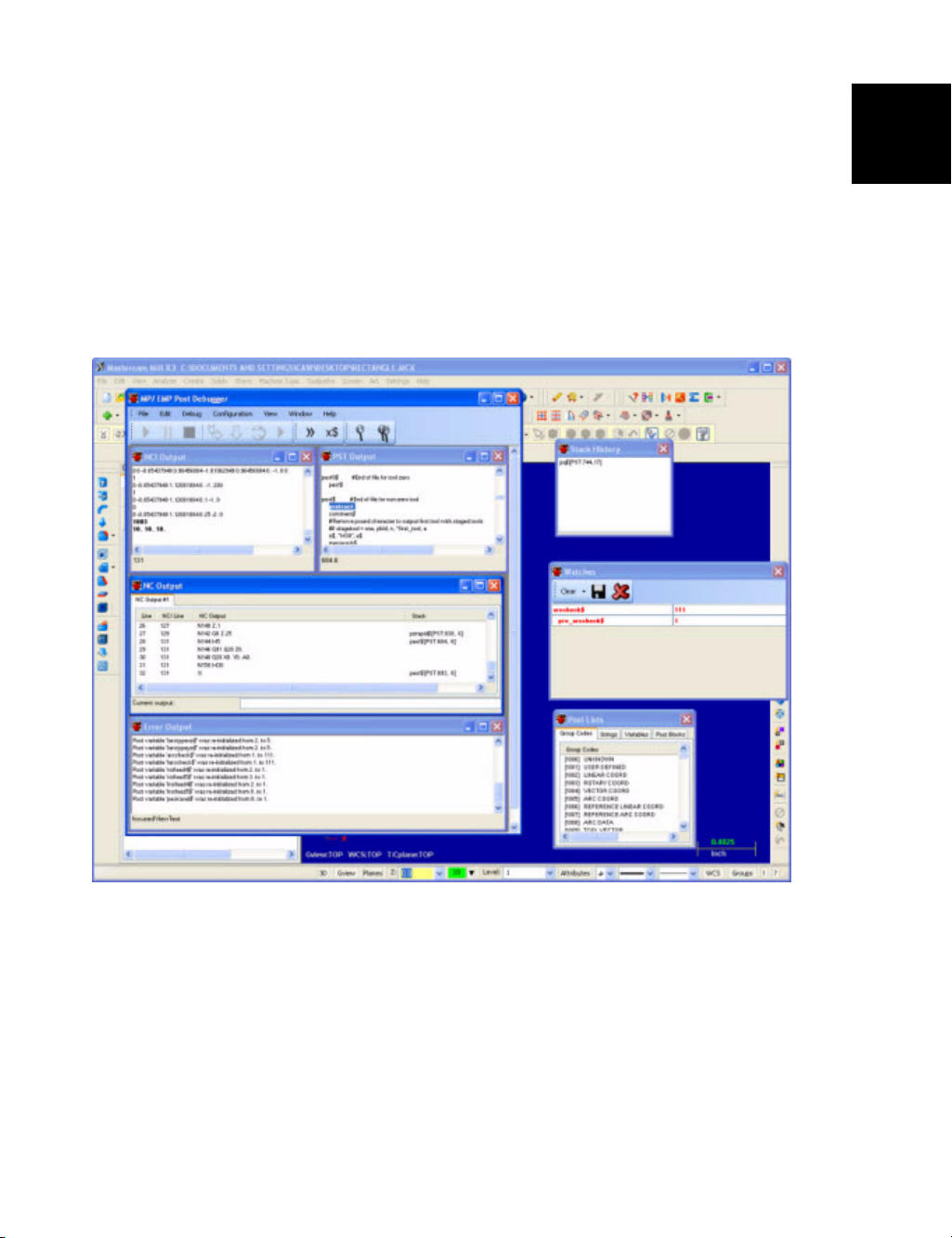

The Stack History, Watches, and Post Lists windows, however, can be

moved to any convenient location on your screen (Figure 1-2) or even

to a second monitor.

Figure 1-2: Arranging the debugger ’s windows

1

Page 14

4 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

The Menu Bar

The Post Debugger’s menu bar contains the commands you need to

work with the debugger. Table 1 describes each command.

Table 1: The menu bar commands

Menu Command Description

File Quit Terminates the current session, but

Exit Terminates the current session, and

Edit Find Searches for occurrences of a given

Find Again Searches for the next occurrence of

Debug Run Runs quickly through the post,

Run Step Runs through the post, while

Break Pauses the debugger’s processing

Stop Stops the debugger’s processing

Step Into Enters the currently highlighted

Step Over Executes all of the commands that

Step Statement Moves forward through the post one

Toggle

Breakpoint

Add Watch Adds the currently highlighted

Configuration Displays the Configuration dialog

View Wat ch Turns the Watches window on or off

Stack Turns the Stack History window on

Post Lists Turns the Post Lists window on or

leaves the debugger open

closes the debugger

text string

the previously searched text string

without building a stack history

building the stack history (much

slower than the Run command)

post block, or, if not on a post block,

executes the current line

are part of the highlighted post

block, or, if not on a post block,

executes the current line

statement at a time

Adds or removes a breakpoint from

the currently selected line

variable to the Watches window

box

or off

off

Page 15

THE POST DEBUGGER INTERFACE / The Main Window • 5

Table 1: The menu bar commands (Continued)

Menu Command Description

Window Cascade Positions the PST Output, NCI

Output, NC Output, and Error

Output windows so that they

diagonally overlap

Horizontal Positions the PST Output, NCI

Output, NC Output, and Error

Output windows horizontally

Vertical Vertically stacks the PST Output,

NCI Output, NC Output, and Error

Output windows

[Window List] Activates the window selected in the

list

Help PDF Displays this document

About Displays the About dialog box

The Toolbar

The toolbar (Figure 1-3) contains a subset of the commands in the

menu bar. Table 2 describes each command.

Figure 1-3: The Post Debugger’s toolbar

1

Table 2: The toolbar commands

Command Description

Run Runs quickly through the post, without

building a stack history

Pause Pauses the debugger’s processing

Stop Stops the debugger’s processing

Page 16

6 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Table 2: The toolbar commands (Continued)

Command Description

Step Into Enters the currently highlighted post block,

Step Over Executes all of the commands that are part of

Step Statement Moves forward through the post one

Run Step Runs through the post, while building the

Break Point Adds or removes a breakpoint from the

Add Watch Adds the currently highlighted variable to

Find Searches for occurrences of a given text

Find Next Searches for the next occurrence of the

or, if not on a post block, executes the

current line

the highlighted post block, or, if not on a

post block, executes the current line

statement at a time

stack history (much slower than the Run

command)

currently selected line

the Watches window

string

previously searched text string

Keyboard Shortcuts

For many of the debugger’s commands, you can use the keyboard

shortcuts shown in Table 1-3.

Table 3: Keyboard shortcuts

Command Keystroke

Add Watch Ctrl+W

Break F12

Run F5

Find Ctrl+F

Find Next F3

Select All Ctrl+A

Step Into F11

Step Over F10

Step Statement Ctrl+F11

Stop Shift+F5

Toggle Breakpoint F9

Page 17

chapter 2

Using the Post Debugger

In this chapter, you will learn about:

Enabling the Debugger . . . . . . . . . . . . . . . . . . . page 8

Running the Debugger . . . . . . . . . . . . . . . . . . page 11

Running a Post . . . . . . . . . . . . . . . . . . . . . . . . . page 13

Tracing through a Post. . . . . . . . . . . . . . . . . . . page 14

Using Breakpoints . . . . . . . . . . . . . . . . . . . . . . page 18

Watchin g Variables . . . . . . . . . . . . . . . . . . . . . . page 21

The MP/EMP Post Debugger intercepts Mastercam’s posting

process, letting you take control and analyze, step by step,

what’s happening as the post processor reads your part’s NCI

file and outputs the NC code. In this chapter, you learn how to

start the debugger, as well as explore ways to use the debugger

to find errors in your posts.

Page 18

8 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Enabling the Debugger

Before you can access the debugger, you must activate it in

Mastercam.

X To Enable the debugger

1 On your Windows Start menu, choose All Programs.

Page 19

USING THE POST DEBUGGER / Enabling the Debugger • 9

2 In the Mastercam X3 folder, choose MCAMX Control Panel

Applet.

3 In the Mastercam X Utility window, select Enable Post

Debugger.

2

Page 20

10 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

After you have activated the debugger, its button appears in the Post

processing dialog box:

Page 21

USING THE POST DEBUGGER / Running the Debugger • 11

Running the Debugger

The following procedure describes how to run the Post Debugger.

X To run the MP/EMP Post Debugger

1 In Mastercam, open a part that contains toolpaths.

2 In the Operations Manager, click the Post selected

operations button.

3 In the Post Processing dialog, select the NC file check box.

2

4 Click the Debugger button. The debugger intercepts

Mastercam’s post processing and displays its main window.

Page 22

12 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

5 Use the Debug menu (or the toolbar) commands to control

and watch the posting process.

Page 23

Running a Post

USING THE POST DEBUGGER / Running a Post • 13

How you use the debugger depends on what you are looking for in

your post. As you use the debugger, you will discover different ways to

find the information you need. To get you started, the following

sections describe some basic ways to use the debugger.

The simplest way to use the debugger is to click the Run button, which

causes the debugger to run the post at its fastest speed, populating the

various debugger windows with output. When the post finishes, you

can examine the contents of the windows, which provide a convenient

way to view the following files:

The NCI file that Mastercam generated for your part’s

operations—Mastercam generates this file before the

debugger takes control of the posting process.

The PST instructions that processed the NCI file into the NC

file—The code in the PST file, which was probably supplied by

your Mastercam Reseller, is specific to the machine that will

cut the part.

The NC file, which is the final code that cuts your part—

Mastercam creates this file by interpreting the NCI file as

directed by the PST file.

After running a post, you can also see errors that occurred. Such errors

provide clues to what may be wrong with a malfunctioning post. You

may be able to resolve post issues with the error information alone.

2

Page 24

14 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Tracing through a Post

Instead of just running the post and examining the output, you will

often want to trace through a post step by step. When you do this, as

each instruction executes, you see the resulting output (if any). During

tracing, you can also verify the post’s logic, which is the path that the

debugger takes through the post.

When it comes to tracing a post, you have many options. The following

procedures describe some common ways to trace.

X To trace with Step Into

The debugger’s Step Into command lets you watch the post execute

one line at a time. Each time you click Step Into, the debugger

executes a line and updates its window to show the results. The

debugger then waits for you to issue another command. This

procedure demonstrates Step Into tracing.

1 Start the debugger. The debugger’s NCI Output and PST

Output windows display the intermediate NCI instructions

and the PST file, respectively. The current PST line displays in

bold.

Page 25

USING THE POST DEBUGGER / Tracing through a Post • 15

2 Click the Step Into button. The debugger moves to the first

code line inside of the current post block.

3 Click Step Into again. If the current line is an instruction, the

debugger executes the instruction and moves to the next line,

as shown in the following figure. If the current line calls a post

block or function, the debugger jumps to that post block or

function (thus the name Step Into).

2

Page 26

16 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

4 Keep pressing Step Into to trace deeper and deeper into the

post, watching to see that the instructions execute in the order

that you expect.

X To trace with Run Step

The Run Step command Lets you watch the post processing as it

happens, without your having to continually click a button.

1 Start the debugger. The debugger’s NCI Output and PST

Output windows display the intermediate NCI instructions

and the PST file, respectively. The current PST line displays in

bold.

2 Click the Run Step button. The debugger starts executing the

post, displaying the process as it converts the NCI file to NC

output.

3 Watch the NCI Output window to see the current line the post

is processing.

Page 27

USING THE POST DEBUGGER / Tracing through a Post • 17

4 Watch the PST Output window to see the debugger quickly

processing post lines.

5 Watch the NC Output window to see the post as it builds each

NC line. The window’s main pane shows the previously output

lines. The Current output box shows the current line being

built.

2

Page 28

18 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Using Breakpoints

Often, you don’t want to debug an entire post from the beginning.

More likely, you want to trace from a specific location in your post.

Breakpoints make this type of debugging possible.

X To trace with breakpoints

1 Start the debugger. The debugger’s NCI Output and PST

Output windows display the intermediate NCI instructions

and the PST file, respectively. The current PST line displays in

bold.

2 Click the Run button to execute the entire post and populate

the debugger’s windows with output.

3 In the NC Output window, locate the instruction where you

want to start debugging.

Page 29

USING THE POST DEBUGGER / Using Breakpoints • 19

4 Double-click the NC line. The debugger highlights the NCI

and post lines that generated the code.

5 Right-click the highlighted post line, and choose To g gl e

Breakpoint from the pop-up menu. A small arrow appears

next to the selected line.

2

6 Choose File, Quit to stop the debugging session, but leave the

debugger open.

7 In Mastercam, click the Post selected operations button, and

then click the debugger button in the Post processing dialog.

The debugger reactivates and waits for your command.

Page 30

20 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

8 Click the Run button. The debugger processes the post until it

gets to the breakpoint you set, where the debugger pauses and

waits for your command.

9 Click the Step Into button to start tracing from the

breakpoint.

Page 31

Watching Variables

USING THE POST DEBUGGER / Watching Variables • 21

Often, an invalid variable value is the cause of a post problem, so an

important part of debugging is watching to see how and where post

variable values change. The MP/EMP Debugger provides the Watches

window for monitoring variable values. When you add a variable to

this window, you can step through a post and see the variable’s value at

any point in the posting process.

X To watch a variable

1 Start the debugger.

2 If you do not see the Watches window, choose View, Watch

from the debugger’s menu.

2

Page 32

22 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

3 In the PST Output window, locate the variable that you want

to watch.

4 Right-click the variable, and select Add Watch from the pop-

up menu.

Page 33

USING THE POST DEBUGGER / Watching Variables • 23

5 Trace through your post, watching for variable values and

changes in the Watches window.

2

Page 34

24 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Page 35

chapter 3

The Debugger Windows

In this chapter, you will learn about:

The PST Output Window. . . . . . . . . . . . . . . . . page 26

The NCI Output Window . . . . . . . . . . . . . . . . page 27

The NC Output Window . . . . . . . . . . . . . . . . . page 28

The Error Output Window . . . . . . . . . . . . . . . page 30

The Watches Window . . . . . . . . . . . . . . . . . . . page 31

The Stack History Window . . . . . . . . . . . . . . . page 32

The Post Lists Window. . . . . . . . . . . . . . . . . . . page 33

The Post Debugger displays debugging information in seven

child windows. This chapter describes each of these windows.

Page 36

26 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

The PST Output Window

The PST Output window (Figure 3-1) displays the currently active PST

file. As the debugger feeds the NCI file to the post, it works through the

PST Output window’s contents, updating and building content in the

other debugger windows. For example, the NCI Output window

“bolds” the current line being processed by the post, whereas the NC

Output window displays NC code as it is output by the post.

Figure 3-1: The PST Output window

Page 37

THE DEBUGGER WINDOWS / The NCI Output Window • 27

The NCI Output Window

The NCI Output window (Figure 3-2) displays the NCI code that

Mastercam created from your part file. This is the non-machinespecific data that the post processor processes to create the machinespecific NC file. The NCI Output window uses bold text to show the

line currently being processed.

Figure 3-2: The NCI Output window

3

Page 38

28 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

The NC Output Window

The NC Output window (Figure 3-3) displays the NC code the post is

generating, along with other information such as the NC line number

and the number of the NCI code line that produced the output. The

Machine Type and Stream information is most useful with EMP posts.

Figure 3-3: The NC Output window

You can resize the columns to suit your needs or even collapse

columns to hide information. To resize a column, drag the vertical line

to the right of the column label. For example, when debugging a

traditional post, you might want to collapse the Machine Type and

Stream columns to hide that information, as shown in Figure 3-4.

Page 39

THE DEBUGGER WINDOWS / The NC Output Window • 29

Figure 3-4: Hiding columns in the NC Output window

3

Page 40

30 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

The Error Output Window

The Error Output window (Figure 3-5) shows any errors that occur

during post processing.

Figure 3-5: The Error Output window

Page 41

The Watches Window

THE DEBUGGER WINDOWS / The Watches Window • 31

The Watches window (Figure 3-6) displays the variable values that you

have selected with the Add Watch command. The window displays

both the previous and current values of a watched variable.

Figure 3-6: The Watches window

You can save a set of watch variables (called a watch set) by clicking the

Save button, or load a previously saved watch set by choosing its name

from the watch set drop-down list (Figure 3-7). You can also clear and

delete watch sets.

Figure 3-7: Saving and loading watch sets

3

Page 42

32 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

The Stack History Window

The Stack History window (Figure 3-8) shows the post’s execution

path, as the debugger goes from one post block to the next.

Figure 3-8: The Stack History window

Page 43

THE DEBUGGER WINDOWS / The Post Lists Window • 33

The Post Lists Window

The Post Lists (Figure 3-9) window contains four tabs of reference

information, including the post group codes, as well as predefined and

user-defined strings, variables, and post blocks.

Figure 3-9: The Post Lists window

3

Page 44

34 • MASTERCAM X3 / MP-EMP Post Debugger User’s Guide

Page 45

Page 46

671 Old Post Road

Tolland, CT 06084 USA

www.mastercam.com

Printed in the USA

Post Debugger Guide 1-883310-86-5

Loading...

Loading...