Page 1

Welcome to the family. Let’s get started.

MPS 330G, MPS 340G

PROPANE SMOKER

Manual applies to the following model number(s)

MB20053718, MB20053818, MB20053918, MB20054018,

MB20054118, MB20054218

Your model number

Mfg. Date - Serial Number

These numbers are located on the rating label of the unit.

IMPORTANT

Please record this information immediately and keep in a safe place for future use.

Manual Code: 9805180020 180830-GSB

AGA certificate No. 8687 G

Master it. Masterbuilt.

Page 2

CARBON MONOXIDE

HAZARD

DANGER

Burning wood chips gives o carbon monoxide,

which has no odor and can cause death.

DO NOT burn wood chips inside homes,

vehicles, tents,

garages or any enclosed areas.

USE ONLY OUTDOORS where it is well

ventilated.

IF YOU SMELL GAS:

1. Shut o gas to the appliance.

2. Extinguish any open ame.

3. Open/remove door.

4. If odor continues, keep away from the

appliance and immediately call your Fire

Department.

WARNING

This manual contains important information necessary for the proper assembly

and safe use of the appliance.

Read and follow all warnings and instructions before assembling and using the appliance.

Follow all warnings and instructions when using the appliance.

Keep this manual for future reference.

Failure to follow these instructions could result in re, explosion or burn hazard

which could cause property damage, personal injury, or death.

DANGER

1. Never operate this appliance unattended.

2. Never operate this appliance within 10 feet (3.0m) of any structure, combustible material

or other gas cylinder.

3. Never operate this appliance within 25 feet (7.5m) of any ammable liquid.

4. If re should occur, keep away from appliance and immediately call your re department.

Do not attempt to extinguish an oil/grease re with water.

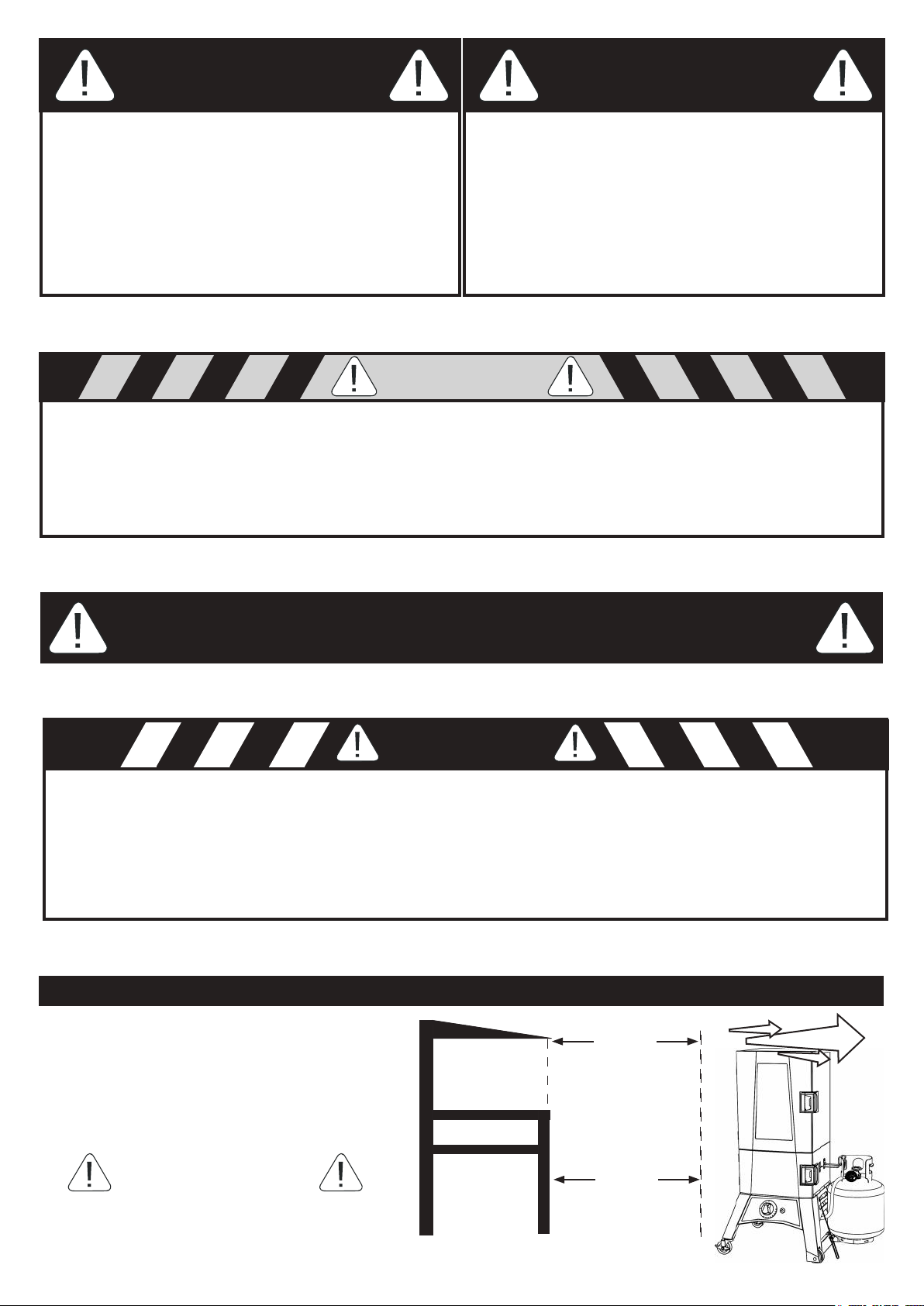

STRUCTURAL PROXIMITY AND SAFETY USAGE RECOMMENDATIONS

Before using smoker check wind direction

and place cylinder DOWNWIND. This is

necessary so that cylinder supply system

is arranged for vapor withdrawal.

Overhead Construction

Rails

10 Feet

Wind Flow

WARNING: HOSE IS A

TRIP HAZARD THAT

COULD CAUSE SUPPLY

CYLINDER TO TIP

2

Walls

10 Feet

Page 3

GENERAL WARNINGS AND SAFETY INFORMATION

READ ALL INSTRUCTIONS

• Always use unit in accordance with all applicable local, state and federal re codes.

• Before each use check all nuts, screws and bolts to make sure they are tight and secure.

• Never operate unit under overhead construction such as roof coverings, carports, awnings, or overhangs.

• Unit is for OUTDOOR HOUSEHOLD USE ONLY.

• Never use inside enclosed areas such as patios, garages, buildings or tents.

• Never use inside or on recreational vehicles or boats.

• Maintain a minimum distance of 10ft (3m) from overhead construction, walls, rails or other structures.

• Keep a minimum 10ft (3m) clearance of all combustible materials such as wood, dry plants, grass, brush,

paper, or canvas.

• Never use unit for anything other than its intended use. This unit is NOT for commercial use.

• Accessory attachments not supplied by Masterbuilt Manufacturing, LLC are NOT recommended and may

cause injury.

• Use of alcohol, prescription or non-prescription drugs may impair user’s ability to properly assemble or

safely operate unit.

• Keep a re extinguisher accessible at all times while operating unit.

• When cooking with oil or grease, have a type BC or ABC re extinguisher readily available.

• In the event of an oil or grease re do not attempt to extinguish with water. Immediately call the re

department. A Type BC or ABC re extinguisher may, in some circumstances contain the re.

• Use unit on a level, non-combustible, stable surface such as dirt, concrete, brick or rock. An asphalt

surface (blacktop) may not be acceptable for this purpose.

• Unit MUST be on the ground. Do not place unit on tables or counters. Do NOT move unit across uneven

surfaces.

• Do not use unit on wooden or ammable surfaces.

• Keep unit clear and free from combustible materials such as gasoline and other ammable vapors and

liquids.

• Do not leave unit unattended.

• Keep children and pets away from unit at all times. Do NOT allow children to use unit. Close supervision is

necessary should children or pets be in area where unit is being used.

• Do NOT allow anyone to conduct activities around unit during or following its use until it has cooled.

• Never use glass, plastic or ceramic cookware in unit. Never place empty cookware in unit while in use.

• Never move unit when in use. Allow unit to cool completely (below 115°F (45°C)) before moving or storing.

• Store only when re is completely out and all surfaces are cold.

• Never use unit as a heater (READ CARBON MONOXIDE HAZARD).

• The unit is HOT while in use and will remain HOT for a period of time afterwards and during cooling

process. Use CAUTION. Wear protective gloves/mitts.

• Be careful when removing food from unit. All surfaces are HOT and may cause burns. Use protective

gloves/mitts or long, sturdy cooking tools for protection from hot surfaces or splatter from cooking

liquids.

• DO NOT bump or impact the unit to prevent personal harm, damage to unit or spillage/splashing of hot

cooking liquid.

• Do not touch HOT surfaces

• Unit is hot during use. To avoid burns, keep face and body away from door, lid and vents. Steam and hot

air are expelled during use.

• Air dampers are HOT while the unit is in use and during cooling; wear protective gloves when adjusting.

• Unit has an open ame. Keep hands, hair, and face away from burner ame. Do NOT lean over burner

when lighting. Loose hair and clothing may catch re.

• DO NOT obstruct ow of combustion and ventilation.

• Do not cover cooking racks with metal foil. This will trap heat and may cause damage to the unit.

• The installation of this appliance shall comply with the requirement of AS/NZS 5601 and the local authority

- gas.

• Before each use inspect gas hose for signs of damage.

• Keep fuel supply hose away from any heated surface.

• Keep fuel supply hose away from unit while in operation.

• Regulator and hose assembly supplied with unit MUST be used. For replacement parts, if needed, contact

Customer Service at 1300 174 876.

• Use 20LB (9kgs) gas cylinder that has protective collar (cylinder not included with unit).

• Keep ventilation openings of cylinder enclosure free and clear of debris.

WARNINGS & IMPORTANT SAFEGUARDS CONTINUED ON PAGE 4

3

Page 4

GENERAL WARNINGS AND SAFETY INFORMATION

WARNINGS & IMPORTANT SAFEGUARDS

CONTINUED FROM PAGE 3

• LP gas cylinder being used must be constructed and marked in accordance with specications for LP gas

cylinders of the US Department of Transportation (DOT) or the Standard for Cylinders, Spheres and Tubes

for the Transportation for Dangerous Goods, CAN/CSA-B339.

• Never use gas cylinder if there is evidence of dents, gouges, bulges, re damage, erosion, leakage,

excessive rust, or other forms of visible external damage. This may be hazardous and cylinder should be

taken to a liquid propane supplier to be checked.

• Never attach/disconnect gas cylinder, move or alter gas ttings when unit is in operation.

• Always disconnect gas cylinder from unit when not in use.

• Propane only, 15.48MJ/h, inlet pressure 2.75kpa, injector orice 1.1mm.

• This product will NOT operate with natural gas.

• When use is complete, always, rst turn the smoker control knob OFF, then turn the gas cylinder valve OFF,

and nally disconnect the cylinder.

• Gas MUST be turned o at the supply cylinder when not in use.

• Cylinder MUST be stored outdoors, out of children’s reach and must NOT be stored in a building, garage, or

any other enclosed area.

• Do NOT store spare LP gas cylinder under or near unit. Gas cylinder safety relief valve may overheat

allowing gas to release causing re which may cause death or serious injury.

• Never ll cylinder over 80% full or cylinder may release gas causing re which may cause death or serious

injury.

• Place a dust cap on cylinder valve outlet whenever cylinder is not in use. Only install dust cap provided with

cylinder. Other caps or plugs may cause leaks.

• If you smell, hear or see gas escaping, immediately get away from gas cylinder and call the Fire Department.

Fire may cause death or serious injury.

• Reference ignition steps before use.

• Never use lighter uid with propane.

• Wood chips or wood chunks must be used in order to produce smoke and create the smoke avor.

• Flame disk bowl/ wood chip tray/bowl is HOT when unit is in use. Use caution when adding wood.

• Check grease tray often during cooking. Empty grease tray before it gets full. Grease tray may need to be

emptied periodically during cooking.

• Do not open upper smoker door(s) unless necessary. Opening smoker door(s) causes heat to escape, which

may cause extended cooking time and may cause wood to are up. Closing the door(s) will re-stabilize the

temperature and stop are up.

• This is a smoker. There will be a lot of smoke produced when using wood chips. Smoke will escape through

seams and turn the inside of smoker black. This is normal. To minimize smoke loss around door(s), door

latch(s) can be adjusted to further tighten door seal against body.

• To adjust door handle/latch, loosen the two screws that mount the door hook to the smoker body. Slide the

door hook forward or rearward as needed to achieve the desired door seal. Then retighten the two door hook

screws. Be sure not to set the door handle/latch too tight as it could cause damage to the unit and make it

dicult to operate. The door should be adjusted so that it closes completely.

• When outside temperature is cooler than 65°F (18°C) and/or altitude is above 3,500 feet (1067m), additional

cooking time may be required. To insure that meat is completely cooked use a meat thermometer to test

internal temperature.

• Do not use wood pellets.

• Food needs to be in the center of smoking racks. This allows food drippings to go into the water bowl.

• Do not leave old wood or ashes in the ame disk bowl/woodchip tray/bowl. Once ashes are cold, empty

bowl/tray. Bowl/tray should be cleaned out prior to, and after each use to prevent ash and residue buildup.

• Dispose of cold ashes by placing them in aluminum foil, soaking with water and discarding in a noncombustible container.

• Do not store unit with HOT ashes inside unit.

• DO NOT SPRAY AEROSOLS IN THE VICINITY OF THIS APPLIANCE WHILE IT IS IN OPERATION.

• DO NOT USE OR STORE FLAMMABLE MATERIALS IN OR NEAR THIS APPLIANCE.

• DO NOT PLACE ARTICLES ON OR AGAINST THIS APPLIANCE.

• DO NOT MODIFY THIS APPLIANCE.

• SERVICING SHALL BE CARRIED OUT ONLY BY AUTHORIZED PERSONNEL, AND THAT THE APPLIANCE

SHALL NOT BE MODIFIED.

SAVE THESE INSTRUCTIONS

4

Page 5

SMOKER OPERATION - READ & FOLLOW ALL INSTRUCTIONS CAREFULLY

GETTING STARTED

• Pre-season unit prior to rst use. See PRE-SEASON INSTRUCTIONS.

• Before starting the unit, see ADDING WOOD CHIPS OR ADDING WOOD CHUNKS.

• This smoker is equipped with door stops that will hold the door open during loading and unloading of food.

• This smoker is calibrated to be within +/- 25°F of each set point. Depending on the amount of food in the smoker and the outside

environment a slight adjustment may be needed to reach the exact temperature desired.

CAUTION - All surfaces are HOT and may cause burns. Use protective gloves or long, sturdy cooking tools when loading/

unloading food or racks, and when adding wood chips or water.

PRE-SEASON INSTRUCTIONS

Curing your smoker will rid the unit of chemicals and oils left over by the manufacturing process allowing them to burn o.

PRE-SEASON SMOKER PRIOR TO FIRST USE.

1. Perform soapy water test, see SOAPY WATER TEST WARNINGS AND PROCEDURES.

2. Using a napkin or cloth, rub a light coat of cooking oil on smoking racks and inside smoker door. Make sure water pan is in place with

NO WATER.

3. Start smoker, set to 350°F (177°C) and let the smoker burn for about 1 hour.

4. Allow unit to cool COMPLETELY.

5. Reapply light coat of cooking oil on smoking racks and inside of smoker door.

6. Restart smoker and burn for 20 minutes.

• Cure your smoker periodically to prevent excessive rust.

OPERATING INSTRUCTIONS

1. To start smoker see IGNITION INSTRUCTIONS.

2. With protective gloves on, place water bowl in position. Pour 1 inch of water, juice, or vinegar into water bowl. This will add avor and

moisture to food and prevent it from drying out.

3 DO NOT cover racks with aluminum foil as this will not allow heat to circulate properly.

4. ADDING WOOD CHIPS: Pre-heat smoker to desired temperature for approximately 20 minutes. After unit has reached desired

temperature, place up to 1 cup (0.24l) of wood chips in wood chip tray.

ADDING WOOD CHUNKS: Before pre-heating smoker, place up to 1 cup (0.24l) of wood chunks in wood chip tray, then pre-heat

smoker to desired temperature for approximately 20 minutes. Wood chip tray may not close fully when using wood chunks.

• You may use dry or pre-soaked wood chips or chunks in your smoker. Dry chips or chunks will burn faster and produce more intense

smoke. Chips or chunks pre-soaked in water (for approximately 30 minutes) will burn slower and produce a less intense smoke.

• DO NOT ADD MORE THAN 1 CUP (0.24l) OF WOOD CHIPS OR CHUNKS AT A TIME. Never use wood pellets.

• Place additional wood chips or chunks in smoker as needed to achieve desired smoke avor.

• Wood chips or chunks must be used in order to produce smoke and create the smoke avor.

5. Place food in the smoker, position on the center of the smoking rack.

6. DO NOT overload smoker with food. Extra large amounts of food may trap heat, extend cooking time and cause uneven cooking. Leave

space between food on racks and smoker sides to ensure proper heat circulation. If utilizing cooking pans, be sure pans do not cover

more than 75% of the rack space and place pans on center of rack to ensure even cooking.

7. When smoking one or two items, use top two racks for best results.

8. Adjust smoker settings, control knob and air damper, to desired cooking temperature.

• Close air damper on unit to retain moisture and heat. If cooking foods such as sh or jerky, open air damper to release moisture.

9. If wood chips or chunks do not smoke on low setting, open bottom door slightly for approximately 2 minutes. This will allow the cabinet

temperature to fall which will cause the burner to adjust to a larger ame and will begin the smoking process.

10. Use caution when cooking on windy days to ensure the ame does not blow out. If you suspect or experience a ame blow out, rst

open the door to check the ame and follow the IGNITION INSTRUCTIONS to re-ignite the burner if needed. Adjust the smoker control

knob setting for a higher ame to prevent further blow outs. Never ignite smoker with the door closed.

11. Extreme cold temperatures may extend cooking times.

12. Once cooking is complete turn unit OFF, see IGNITION INSTRUCTIONS for turning o unit, remove the gas cylinder and then follow

CLEANING and STORING INSTRUCTIONS. CLEAN AFTER EVERY USE. This will extend the life of your smoker and prevent mold

and mildew.

CLEANING and STORING INSTRUCTIONS

• ALWAYS MAKE SURE UNIT IS COOL TO THE TOUCH BEFORE CLEANING AND STORING.

• Be sure to clean smoker after each use. Make sure the gas cylinder has been turned o and removed.

• For rack supports, racks, water bowl, and drip pan use a mild dish detergent. Rinse and dry thoroughly.

• For wood chip tray clean frequently to remove ash build up, residue and dust.

• Dispose of cold ashes by placing them in aluminum foil, soaking with water and discarding in a non-combustible container.

• For the interior, exterior and door seal of the unit simply wipe down with a damp cloth after each use to keep unit in proper working

condition. Do not use a cleaning agent. Make sure to dry thoroughly.

• After cleaning, store smoker in a covered and DRY AREA.

• Store only when re is completely out and all surfaces are cold.

• When not in frequent use and using a cover, remember to check your smoker periodically to avoid possible rust and corrosion due to

moisture buildup.

CHECK OUT MASTERBUILT.COM FOR MORE TIPS AND RECIPE VIDEOS.

5

Page 6

WARNING

PERFORM “SOAPY WATER TEST” BEFORE EACH USE. SEE “SOAPY WATER TEST”

SECTION IN MANUAL.

REGULATOR TO GAS CYLINDER. TURN GAS OFF AFTER EACH USE.

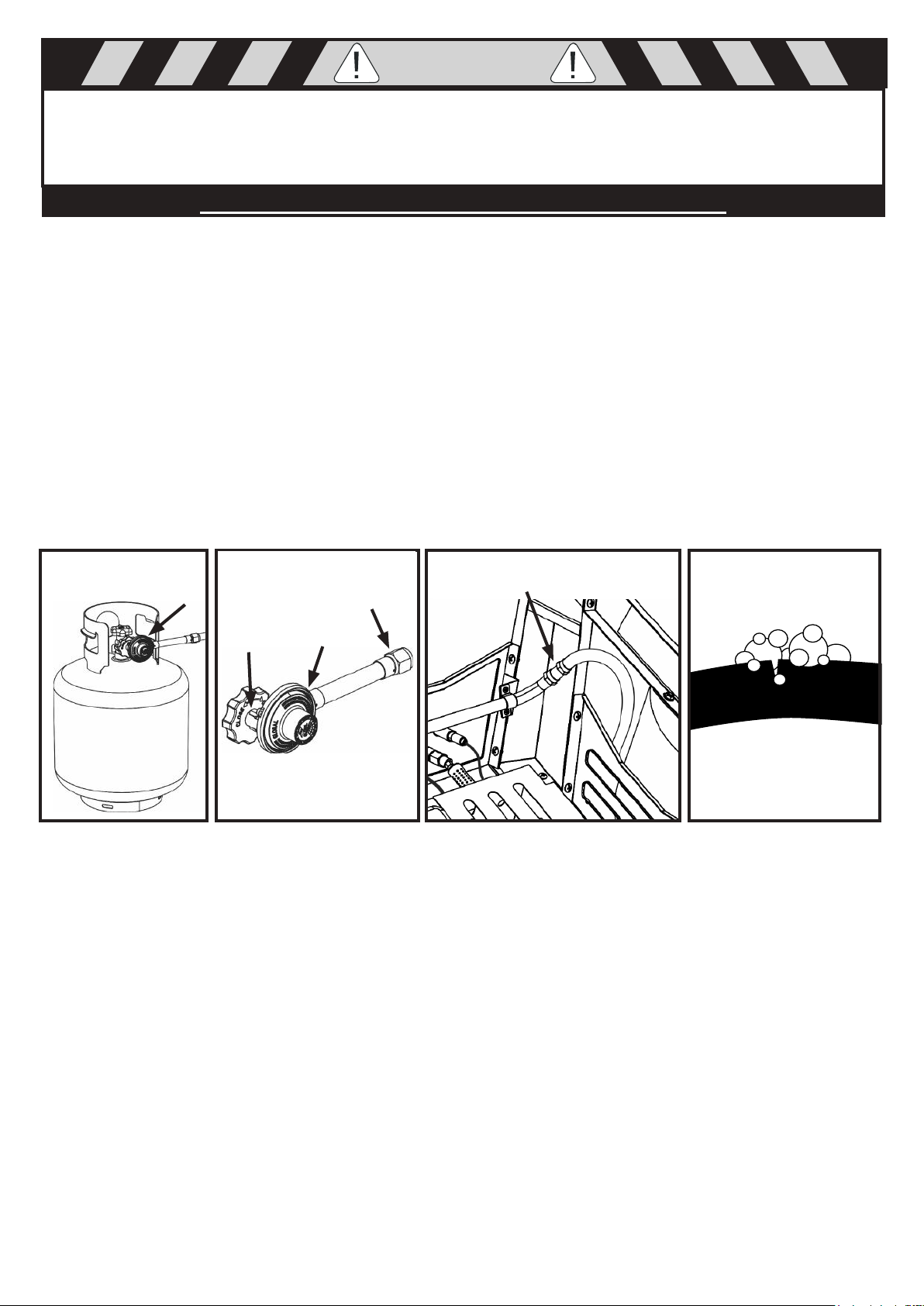

SOAPY WATER TEST WARNINGS & PROCEDURES

WARNINGS

• Soapy Water Test MUST be performed each time gas cylinder is connected to burner/hose or each time it is

used.

• Soapy Water Test MUST be performed outdoors in well ventilated area.

• When performing Soapy Water Test keep unit away from open ames, sparks or lit cigarettes.

• Never use an open ame to test for gas leaks.

PREPARATION:

• Remove any cookware and accessories from unit.

• Make sure gas cylinder valve and control knob are turned to the OFF position.

• Prepare soapy water solution: (1) part dish washing liquid (or more if desired), (3) parts water.

• Apply soapy water solution to gas cylinder valve, regulator and hose length up to burner control valve.

EXTINGUISH ALL OPEN FLAMES BEFORE CONNECTING

Apply solution to

gas cylinder valve

Apply solution to hose regulator

and the full length of the hose

Apply solution underneath control panel

where burner and hose are connected

Failed test will present

bubbles as shown below.

TESTING GAS CYLINDER VALVE:

• Turn gas cylinder valve ON and watch for bubbles. DO NOT LEAVE GAS ON MORE THAN 12 SECONDS. If

bubbles appear, stop, turn gas cylinder valve OFF and retighten tting. Repeat test.

TESTING REGULATOR AND HOSE:

• AFTER gas cylinder valve has passed Soapy Water Test, turn gas cylinder valve ON and check for bubbles at

regulator location, along full length of hose and at burner control valve. DO NOT LEAVE GAS ON MORE THAN

12 SECONDS. If bubbles appear, stop, turn gas cylinder valve OFF and retighten the connection that is leaking

gas. If hose is source of leak, STOP, do not use unit. Hose must be replaced.

• WHEN TEST IS COMPLETE, AND THERE ARE NO LEAKS, WAIT MINIMUM OF 5 MINUTES FOR GAS

FUMES TO DIMINISH BEFORE LIGHTING SMOKER.

DURING ANY PORTION OF SOAPY WATER TEST IF BUBBLES CONTINUE TO

APPEAR, STOP, DO NOT USE UNIT. CONTACT LOCAL PROPANE DEALER OR

CUSTOMER SERVICE AT 1300 174 876.

Note: Use 20LB (9kgs) gas cylinder that has a protective collar with this unit. Cylinder NOT included with this unit.

6

Page 7

IGNITION INSTRUCTIONS

REGULATOR, BURNER AND GAS VALVE CONNECTION & OPERATION

CLOCKWISE

12.25” (45cm)

APPROX.

COUNTER

CLOCKWISE

Fig. 1

17.75”

(45cm)

APPROX.

Fig. 2

1/4"

• Inspect hose before each use. If there are signs of abrasion, wear, cuts, or leaks, the hose must be

replaced. DO NOT USE.

• Inspect burner before each use. Check burner and burner venturi tube for insects and insect nests.

A clogged tube can lead to a re beneath unit.

• Check to ensure the orice is centered inside the venturi tube. Failure to properly assemble the

valve orice to the venture tube can result in gas leak or potential re at connection. See assembly

steps for proper assembly method.

• Check to ensure the igniter pin is properly spaced and aligned to the burner. Igniter pin should be

approximately 1/4” from the burner and aligned to the top of a burner port (Fig. 2). Conrm spacing

is correct by pressing the igniter button and ensuring spark occurs between igniter pin and burner.

• Connect hose regulator to LP Gas Cylinder

1. Make sure gas cylinder valve is closed. Turn valve clockwise until it stops.

2. Make sure control knob on smoker is in the OFF position.

3. Remove protective cap from gas cylinder and coupling nut if applicable.

4. Center and insert regulator nipple into valve outlet on gas cylinder (Fig. 1). Turn regulator

coupling nut counter clockwise until it stops. DO NOT OVER TIGHTEN.

• Perform Soapy Water Test.

• Before starting lighting procedure make sure the smoker door(s) are open.

• When lighting burner remove all parts inside or on unit to prevent explosion from gas build up.

Fig. 3

• To use, turn gas cylinder valve ON, push control knob in, hold and and turn counter-clockwise to

desired temperature setting. Push ignitor button to light, after ignition continue holding control knob

in for 5 seconds to activate the ame sensor.

• If ignition does not take place within ve seconds, turn control knob to OFF position and wait ve

minutes and repeat lighting procedures. If ignition still does not occur, see match light instructions.

• Always ensure that smoker door(s) are open before igniting. Gas can accumulate in smoker.

• If ame goes out during cooking, turn control knob OFF, turn gas cylinder valve OFF, wait 5

minutes, then open door(s) and wait 5 additional minutes before repeating ignition instructions

above.

• Control knob sets the smoker to a desired temperature. Push control knob in and turn clockwise to

shut ame o.

• Visually check burner ame (Fig. 3). A CORRECT FLAME should be blue with a small amount of

yellow at the tip. An INCORRECT FLAME is excessively yellow and irregular. If an incorrect ame

occurs, turn control knob to OFF position, turn OFF gas cylinder valve, allow unit to cool and then

clean burner. Let burner completely dry before re-lighting.

• After use turn control knob OFF, then turn gas cylinder valve OFF and disconnect tank.

7

Page 8

MATCH LIGHT INSTRUCTIONS

1. Read all instructions and warnings before lighting.

2. Check control knob and gas cylinder valve to be certain it is in OFF position before connecting to

gas cylinder.

3. Perform soapy water test before each use.

4. Open door(s) during lighting and/or remove all accessories and cooking vessels from in/or on unit.

5. Turn gas cylinder valve ON, push control knob in, hold and and turn counter-clockwise to desired

temperature setting, after ignition continue holding control knob in for 5 seconds to activate the

ame sensor.

6. Place a long, lit replace match stick close enough to burner to ignite.

7. If ignition does not take place within ve seconds, turn control knob to OFF position and wait ve

minutes and repeat match light instructions.

8. After each use, rst turn control knob o, then gas cylinder valve o. Always allow unit to cool

completely before touching, moving or storing.

In the event of a gas leak that cannot be stopped, or if a

WARNING

re occurs due to a gas leak, contact the re department.

TROUBLESHOOTING GUIDE

Symptom Cause Possible Solution

Gas leaking from cracked, cut or burned hose Damaged hose Turn o gas at LP cylinder.

Replace hose.

Contact Masterbuilt at 1.800.489.1581.

Gas leaking from LP cylinder Failure due to rust or mishandled equipment Replace LP cylinder.

Gas leaking from gas cylinder valve Failure of valve due to rust, mechanical failure or mishandled

equipment

Gas leaking between LP cylinder and regulator connection Improper installation, connection not tight enough, damaged

threads or bad rubber seal

Fire under control panel Fire in tube of burner due to burner blockage Turn o both smoker control knob and gas cylinder valve. Once the re is

Grease re or excessive/continuous ame Grease build up on or around burner area Turn o both smoker control knob and gas cylinder valve. Allow ames

Flame does not remain lit after igniting* Flame sensor wire is loose Turn o gas. Disconnect LP cylinder. Tighten ame sensor wire to valve.

Low ame output* Out of fuel Rell or replace with full LP cylinder.

Flames blow out* Low on LP gas Rell LP cylinder.

Flare-up Excessive grease buildup Clean burner and inside unit.

Excessive fat on meat Trim fat o of meat.

Cooking temperature too high Adjust or lower temperature accordingly.

Persistent grease re Grease trapped by food buildup around burner system Turn smoker control knob and gas cylinder valve o. Allow re to

Flashback (re in burner tube) Burner and/or burner tube has blockage Turn smoker control knob and gas cylinder valve o. Clean burner and/

Slower than expected cooking times* Valve not properly aligned to burner Check to see if valve is centered in burner tube.

Turn o gas cylinder valve and return cylinder to gas provider/supplier.

Turn o gas cylinder valve, then re-attach regulator to cylinder.

Turn o gas cylinder valve and return cylinder to gas provider/supplier.

Visually inspect rubber seal for damage.

out and burner has cooled, remove and inspect burner for spiders, nests,

rust or other debris.

to extinguish and time for unit to cool down. Clean grease/food particles

from/around burner or burner area and surrounding surfaces.

extinguish and the unit to cool down. Once cool, remove and clean parts.

or burner tube.

*

Also seeTroubleshooting solutions: “Causes” Low or No Flow/Vapor lock/Excess on the next page.

8

Page 9

TROUBLESHOOTING SOLUTIONS: “CAUSES” LOW OR NO FLOW/VAPOR LOCK/EXCESS FLOW

Symptom Cause Possible Solution

Burner doesn’t light after pressing ignitor button Low/no gas ow 1. Turn smoker control knob to “O” position.

Vapor lock at coupling nut to LP cylinder

Low ame output Excess ow valve tripped

Vapor lock at coupling nut/LP cylinder

connection

Flames blow out Excess ow valve tripped

Slower than expected cooking times Vapor lock

2. Turn gas cylinder valve knob to OFF.

3. Disconnect regulator from cylinder to relieve vapor lock.

4. Reconnect regulator to cylinder by hand turning until tight.

5. Slightly open the gas cylinder valve slowly and then open further by turning 1 full

turn.

6. You are now ready to light the smoker.

7. Turn the smoker control knob to high and light with ignitor.

FAQ

• Was the temperature setting of the unit adjusted from a higher setting to a lower setting? For example, was the unit at 275 and changed to 225?

If yes, was the unit allowed to stabilize for 5 minutes at the new temperature setting before opening/closing the door(s)? If no, allow the unit to stabilize between set point changes for 5 minutes before opening

and closing the door(s). During this transition period the ame is vulnurable to potential blow outs, under certain conditions, because the pressure inside the burner is reduced while the temperature sensor is

adjusting to the lower set point.

• Is the vent open?

If no, open the vent to allow more heat to exit the unit. This will cause the unit to require more heat input to maintain its set point which will cause the unit to increase the ame height creating a stronger ame.

• Is the water bowl lled?

If no, ll the water bowl. This will cause the unit to require more heat input to maintain its set point which will cause the unit to increase the ame height creating a stronger ame.

• Is outside wind greater than 5mph?

If yes, and all the above solutions did not improve the performance, raise the set point of the unit in order to cook in those conditions.

32

5

27

3

28

31

PARTS LIST

Actual product may dier from picture shown.

2

11

12

4

13

16

8

9

1

26

6

7

25

22

23

10

14

17

15

18

19

20

24

30

33

• Parts that are preassembled at time of purchase should be ordered separately if replacement is needed.

29

34

35

36

21

37

9

Page 10

(A)

M6x12

Qty-45

HARDWARE LIST

(B)

M5x10

Qty-4

(C)

M4.2x8

Qty-15

(D)

M4x8

Qty-6

(E)

M6 Lock

Qty-1

(F)

M6

Qty-22

(G)

M5x10

Qty-2

PARTS LIST

NO QTY DESCRIPTION

1 1 Air Damper

2 1 Top Smoker Body

3 1 Top Smoker Door

4 1 Bottom Smoker Body

5 1 Bottom Smoker Door

6 1 Top Cabinet Temperature Sensor Cover

7 1 Bottom Cabinet Temperature Sensor Cover

8 1 Top Door Handle

9 1 Bottom Door Handle

10 4 Smoking Rack

11 1 Water Bowl Rack

12 1 Water Bowl

13 1 Tank Retainer Bracket

14 1 Tank Support

15 1 Match Stick w/Chain

16 1 Control Knob

17 1 Ignitor

18 1 Cabinet Temperature Sensor Bracket

19 1 Control Panel

20 1 Cabinet Temperature Sensor

21 1 Valve Assembly

22 1 Heat Diuser

23 1 Burner Box Kit

24 1 Heat Shield

25 1 Grease Tray Bracket

26 1 Grease Tray

27 1 Wood Chip Tray Rack

28 1 Wood Chip Tray w/Lid

29 1 Right Front Leg

30 1 Left Front Leg

31 1 Right Rear Leg

32 1 Left Rear Leg

33 1 Rear Leg Brace

34 1 Left Side Leg Brace

35 1 Right Side Leg Brace

36 1 Tank Leg Brace

37 1 Gas Manifold Bracket

10

Page 11

WARNING

• Smoker should only

be rolled on smooth

surface.

• Smoker should never be

rolled up/down stairs or

uneven surface.

• Potential damage to smoker or harm to user may result from failure to follow warnings.

DO NOT RETURN TO RETAILER for assembly assistance, missing or damaged parts.

STOP!

Please contact Customer Service at 1300 174 876. Please have the model number

and serial number available. These numbers are located on the silver rating label on the unit.

• BEFORE ASSEMBLY READ ALL INSTRUCTIONS CAREFULLY.

• ASSEMBLE UNIT ON A CLEAN, FLAT SURFACE.

• TOOLS NEEDED: Adjustable Wrench, Phillips Head Screwdriver

• Approximate assembly time: 35 minutes

* Actual product may dier from picture shown

** It is possible that some assembly steps have been completed in the factory. **

11

Page 12

ASSEMBLY

Actual product may dier from picture shown.

1

2

3

2

C

x7

4

C

2

3

23

4

A

x4

4

AA

A

F

A

x2 x2

A

14

F

F

36

12

Page 13

ASSEMBLY

5

A

A

31

x12

A

FRONT

AVANT

FRENTE

A

Do not tighten all screws yet.

32

Swivel Casters

A

Swivel Casters

6

A

A

A

29

A F

x18 x16

36

35

A A

33

F

F

F

30

Tighten all screws.

A

A

34

A

A

F

F

FRONT

F

A

13

Page 14

ASSEMBLY

7

21

D

x4

D

D

37

17

19

8

F

F

A

A

FA

19

x4x4

9

Flame

Sensor Wire

Carefully attach the

ame sensor wire to the

valve as shown. Ensure

fully tightened.

Cabinet

Temperature

Sensor Wire

Hole for

Cabinet

Temperature

Sensor

Ignition Wire

Cabinet

Venturi

Valve

Orice

Ignition Wire

Align venturi over valve orices and attach ignition wire to piezo

ignitor on control panel.

Carefully uncoil the cabinet temperature sensor wire and locate

the hole at the back of the smoker body (shown here). USE

EXTREME CARE NOT TO CRIMP OR BREAK THE CABINET

TEMPERATURE SENSOR WIRE (oil lled).

CAUTION: Over bending the cabinet temperature sensor wire

could result in damage.

Piezo

Ignitor

Temperature

Sensor Wire

14

Page 15

ASSEMBLY

10

20

Carefully

thread cabinet

temperature

sensor wire

down through

the body of the

smoker.

11

18

20

12

C

18

x2

C

4

2

13

C

x6

7

6

C

D

C

C

D

x2

Place cabinet

temperature

sensor wire

behind the cover

before installing

it.

15

Page 16

ASSEMBLY

B

14 15

B

x4

24

B

23

4

G

x2

G

25

4

16

16

A

x4

AA

22

17

Turn smoker over onto legs.

16

Page 17

ASSEMBLY, ASSEMBLAGE, ENSAMBLAJE

Take out the racks to

clean after each use.

18

E

EA

x1x1

A

1

19

10

12

2120

2

3

5

4

11

17

Page 18

ASSEMBLY, ASSEMBLAGE, ENSAMBLAJE

Take out the grease tray

to clean after each use.

22

27

5

23

28

26

24

13

15

18

Page 19

GASMATE BARBEQUES AND ACCESSORIES PRODUCT RANGE

SITRO GROUP AUSTRALIA (S.G.A.) warrants the purchaser of this product against defects in workmanship and

materials for the following periods from the date of purchase:

For domestic use, this table applies:Stainless steel components 5 years (surface oxidization excluded)

Enamel components 5 years (chips excluded)

Powder coated components 1 year

Burners 3 years (surface rust excluded)

Cast iron cooking plates & burners 3 years (surface rust excluded)

Valves 3 years

Ignition 1 year

All other items 1 year

For commercial use :- 3 months.

This warranty is not transferable to a subsequent

purchaser if the product is sold by the original

purchaser during the warranty period.

If a warranty fault appears within the warranty period,

S.G.A. reserves the right to replace or repair the

product.

In the event that S.G.A. chooses to replace the

product, this original warranty will expire at the original

date.

If the product includes various accessories or

components, only the defective accessory or

component will be replaced or repaired.

S.G.A. reserves the right to replace defective parts of

the product with parts and components of similar

quality, grade and composition where an identical part

or component is not available.

Products presented for repair may be replaced by

refurbished products of the same type rather than

being repaired. Refurbished parts may be used to

repair the products.

To make a warranty claim, first contact S.G.A's

Customer Service Line on the contact number below.

The purchase receipt for this product is to be retained

and must be presented if making claim under the terms

of this S.G.A. warranty.

Warranty repairs are free of charge, provided the

product is delivered to our Service Department at 3335 Lionel Road, Mt Waverley, Victoria, 3149 or to one

of our Authorised Service Agents.

If a warranty fault is found the freight cost will be

credited to the owner.

If no fault is found the product will be returned and any

costs associated with the service will be charged to the

owner.

Products sent freight forward will not be accepted.

In most cases the defective accessory or component

only will need to be returned. The product or part of

the product being returned must be adequately

protected in a box.

S.G.A. will not be responsible for any in-transit loss or

damage.

This warranty does not apply to any defect,

deterioration, loss, injury or damage occasioned by or

as a result of misuse or abuse, negligent handling or

storage, normal wear and tear or if the product has not

been installed and used in accordance with S.G.A.'s

instructions, recommendations and specifications or if

the product has been subjected to abnormal

conditions. The warranty does not apply to blockages

caused by insects or living organisms.

The warranty is void if there is evidence of the product

being tampered with by unauthorised persons.

The warranty does not extend to installation or

disconnection costs.

Our goods come with guarantees that cannot be

excluded under the Australian Consumer Law. You

are entitled to a replacement or refund for a major

failure and for compensation for any other reasonably

foreseeable loss or damage. You are also entitled to

have the goods repaired or replaced if the goods fail to

be of acceptable quality and the failure does not

amount to a major failure. The benefits of this

warranty are in addition to any rights and remedies

imposed by Australian State and Federal legislation

that cannot be excluded.

Gas Products Approved For Outdoor Use Only

For warranty claims, service, spare parts or

products information in Australia, please call SITRO

GROUP AUSTRALIA Pty Ltd on the Customer

Service Line 1300 174 876

Register your Warranty online at

www.gasmate.com.au

A receipt or proof of purchase is required and must

be kept for your records.

Note: If you do not have internet access call our

customer service team on 1300 174 876

CONTACT DETAILS

Sitro Group Australia Pty Ltd

33-35 Lionel Road, Mt. Waverley

Victoria 3149, Australia.

Tel (+613) 9543 9533

Fax (+613) 9543 9839

sales@sitro.com.au

19

Page 20

Rest assured, we’re here to help.

Do not return to place of purchase.

For any queries or assistance call

Customer Service

(Australia Only)

1300 174 876

Hours of operation:

Monday to Friday 8am - 5pm EST

Keep your purchase receipt. This will be required to

make any claims under the 12 month warranty.

Loading...

Loading...