Page 1

No. 60089

ATENCIÓN

ATTENTION

CAUTION

Master Cut

7 in. Portable Tile Saw

OWNER’S MANUAL

Scie portatif à carreaux de 180 mm

MANUEL D’UTILISATION

Sierra portátil para cortar loseta de 180 mm

MANUAL DE OPERACIÓN

™

Read and follow all safety and operating

instructions before using this saw.

Lire et suivre toutes les directives de sécurité

et d’opération avant d’utiliser cette scie.

Lea y siga todas las instrucciones de funcionamiento

y seguridad antes de usar esta sierra.

E154499

TC180

Page 2

Master Cut

WARNING AVERTISSEMENT ADVERTENCIA

For your own safety, read

instruction manual before

operating saw.

1. Always wear safety goggles

when cutting.

2. Use splash hood for every

operation for which it can

be used.

3. Disconnect saw before

cleaning or changing blade.

4. Do not use any cutting blade

with openings and grooves.

Use only continuous rim blades.

5. Replace damaged blade

before operating.

6. Do not expose to rain or use

in damp locations.

Pour assurer votre securite, lisez le moide

d'emploi avant d'utiliser le coupeur.

1. Toujours porter des lunettes protectrices

pendant la coupe.

2. Utiliser le pare-éclaboussure pour chaque

opération dont il peutêtre utiliser.

3. Débrancher l'outil avant de la nettoyer ou

de changer les roues.

4. Ne pas utiliser des roues à couper avec

des trous ou creux.Utiliser seulement des

roues à couper lisses.

5. Remplacer les roues à couper endommagés avant de faire fonctionner l'outil.

6. Ne pas exposer à la pluie ou utiliser dans

des endroits humides

Lee esta instuccion manual antes

de usa la sierra para tu bien.

1. Siempre utilice gafas de protección

al cortar.

2. Utilice una capota de protección

para cada operación en la cual la

puede utilizar.

3. Desconectar la sierra antes de limpiarla

o antes de cambiar el disco de corte.

4. No utilice ningún disco de corte que

tenga aperturas o ranuras. Solamente

utilice discos de corte lisos.

5. Reemplace el disco de corte cuando

esté dañado.

6. No la exponga a la lluvia o no la

utilice en áreas húmedas.

™

7 in. Portable Tile Saw

Scie portatif à carreaux de 180 mm

Sierra portátil para cortar loseta de 180 mm

No. 60089

TABLE OF CONTENTS

General Safety Instructions.............................3

Electrical Requirements ..................................4

Warning...............................................................5

Extension Cords.................................................5

Specific Operation Guide ................................6

Set Up and Operation ...................................6–8

Diamond Blades ................................................8

Diamond Blade Do’s and Don’ts.................8–9

Saw Maintenance.............................................9

Troubleshooting .................................................9

Accessories Included with Saw ....................9

State-of-the-Art Features of this Saw ...........9

Parts List ...........................................................10

Specifications..................................................10

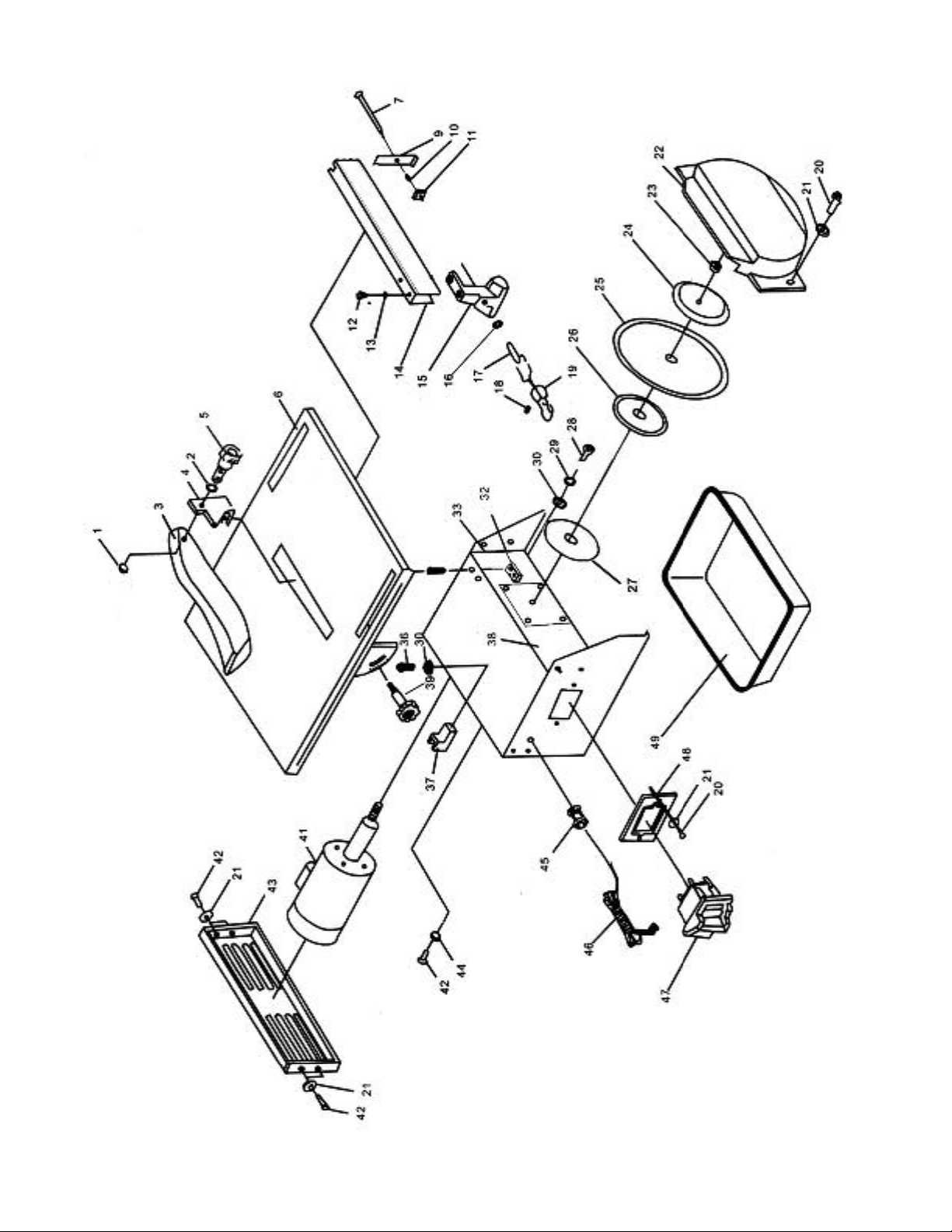

Exploded Parts Diagram ................................11

TABLE DES MATIÈRES

Instructions générales de sécurité..............12

Exigences électriques .............................13–14

Avertissement ..................................................14

Rallonges....................................................14–15

Guide de fonctionnement spécifique ..........15

Installation et fonctionnement ...............15–17

Lames diamantées ..........................................18

Ce qu’il faut faire et ne pas faire

pour les lames diamantées ...........................18

Entretien de la scie .........................................18

Dépannage........................................................19

Accessoires inclus avec la scie ..................19

Caractéristiques de pointe

de cette scie.....................................................19

Liste des pièces...............................................20

Spécifications..................................................20

Pièces éclatées ...............................................21

CONTENIDO

Instrucciones generales de seguridad . . . 22

Requerimientos eléctricos. . . . . . . . . . . 23–24

Advertencia . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cables de extensión . . . . . . . . . . . . . . . . . . . 25

Guía específica de uso . . . . . . . . . . . . . . 25–26

Puesta a punto y funcionamiento . . . . . 26–27

Discos de diamante . . . . . . . . . . . . . . . . . . . . 28

Qué hacer y qué no hacer

con el disco de diamante . . . . . . . . . . . . . . . 28

Mantenimiento de la sierra . . . . . . . . . . . . . 29

Localización de averías . . . . . . . . . . . . . . . . 29

Accesorios incluidos con la sierra . . . . . . 29

Características de avanzada

de esta sierra . . . . . . . . . . . . . . . . . . . . . . . . . 29

Lista de piezas . . . . . . . . . . . . . . . . . . . . . . . . 30

Especificaciones. . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrama de las piezas. . . . . . . . . . . . . . . . . 31

30

LIMITED WARRANTY

Refer to warranty card.

GARANTIE LIMITÉE

Faire référence à la carte de guarantie.

- 2-

GARANTIA LIMITADA

Referirse a la tarjeta de guarantia.

Page 3

GENERAL SAFETY INSTRUCTIONS

Read this owner's manual completely and make sure you understand all of it's safety guidelines.

. KEEP GUARDS IN PLACE and in working order.

1

2. REMOVE ADJUSTING KEYS & WRENCHES. Before turning on the tile saw, make sure the keys and adjusting

wrenches have been removed.

3. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

4. ALWAYS REMAIN ALERTWHEN THE SAW IS IN USE. Inattention on the part of the operator may lead to

serious injury.

5. DON’T USE IN A DANGEROUS ENVIRONMENT. Don’t use power tools in damp or wet locations or expose

them to rain. Keep work area well lit.

6. KEEP CHILDREN AWAY. All visitors should remain at a safe distance from work area.

7. MAKE WORKSHOP CHILD-PROOF with padlocks, master switches or by removing starter keys.

8. USE THE RIGHT TOOL. Don’t force a tool or attachment to do a job for which it was not designed.

9. USE THE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry the current your product will draw. An undersized

cord will cause a drop in line voltage resulting in loss of power and overheating. Table (see Table 1) shows

the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier the cord.

10. DON’T FORCE THE TOOL. It has been designed to operate at maximum safety and performance levels.

11. DO NOT FORCETHE MATERIAL BEING CUT. Always let the blade cut at its own speed.

12. WEAR PROPER APPAREL. Do not wear loose clothing, neckties, rings, bracelets or other jewelry which may

get caught in moving parts. Non-slip foot wear is recommended. Wear protective hair covering if you have

long hair.

13. ALWAYS USE SAFETY GLASSES. Also use face or dust mask for commercial cutting operations. Everyday

eyeglasses only have impact-resistant lenses, they are NOT safety glasses.

14. SECURE WORK. Use clamps or a vise instead of your hand to hold work when practical. This safety

precaution allows for proper tool operation using both hands.

15. DON’T OVERREACH. Keep proper footing and balance at all times.

16. MAINTAIN TOOLS WITH CARE. Keep tools clean and in good working condition for maximum safety

performance. Follow instructions for lubricating and changing accessories.

17. DISCONNECTTOOLS BEFORE SERVICING – when changing accessories, such as blades, bits, cutters, etc.

18. REDUCETHE RISK OF UNINTENTIONAL STARTING. Make sure switch is in OFF position before plugging in.

19. USE RECOMMENDED ACCESSORIES. Consult the owner’s manual for recommended accessories. The use of

improper accessories may increase risk of injury.

20. DO NOT DRY CUT WITH BLADES DESIGNED FOR WET CUTS.

21. MAKE SURE YOU USETHE CORRECT BLADE for the job you are doing.

22. NEVER STAND ON TOOL. Serious injury could occur if the wet saw is tipped or if the cutting tool is

unintentionally contacted.

23. CHECK DAMAGED PARTS. Before further use of the tool, damaged part(s), (i.e., guard) should be carefully

checked to determine that it will operate properly and perform its intended function. Check for alignment of

moving parts, binding of moving parts, breakage of parts, mounting and any other condition that may affect

the saw’s operation. A guard or other part that is damaged should be properly repaired or replaced.

24. ENSURETHATTHERE IS A CONTINUOUS FLOW OF WATER to both sides of blade during operation.

25. CHECK DIAMOND BLADES CAREFULLY FOR CRACKS, NICKS, MISSING DIAMOND MATRIX OR

OUT-OF-ALIGNMENT CONDITION. Replace damaged blades immediately. DO NOT USE DAMAGED BLADES.

They may cause bodily injury.

26. DIRECTION OF FEED. Feed work into the blade against the direction of rotation of the blade only.

27. DO NOT ALTERTHE PLUG OR USE A 2-PRONG RECEPTACLE. This saw is equipped with a 3-prong

electrical plug.

28. NEVER LEAVE TOOL RUNNING UNATTENDED. Turn power off. Don’t leave tool until it comes to a

complete stop.

- 3-

Page 4

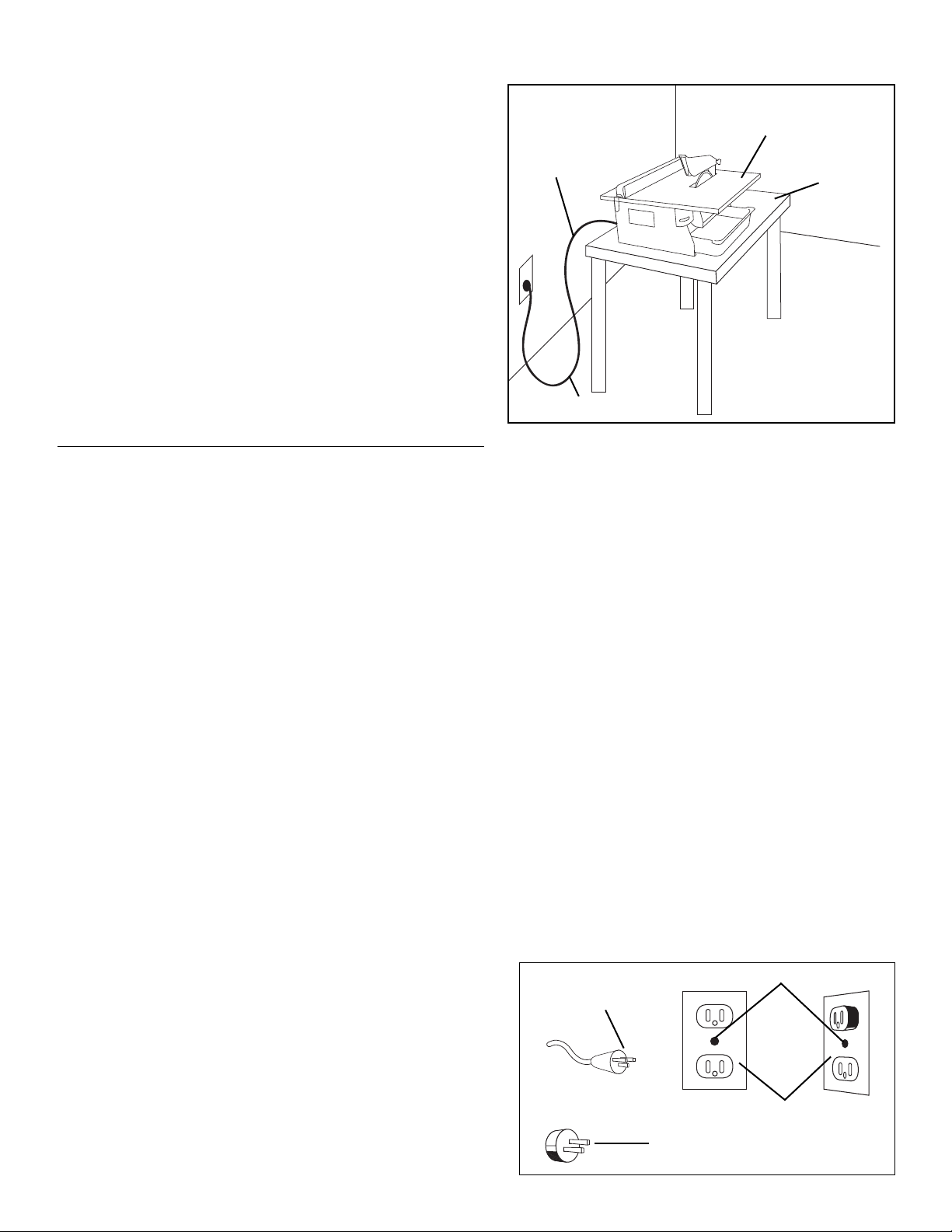

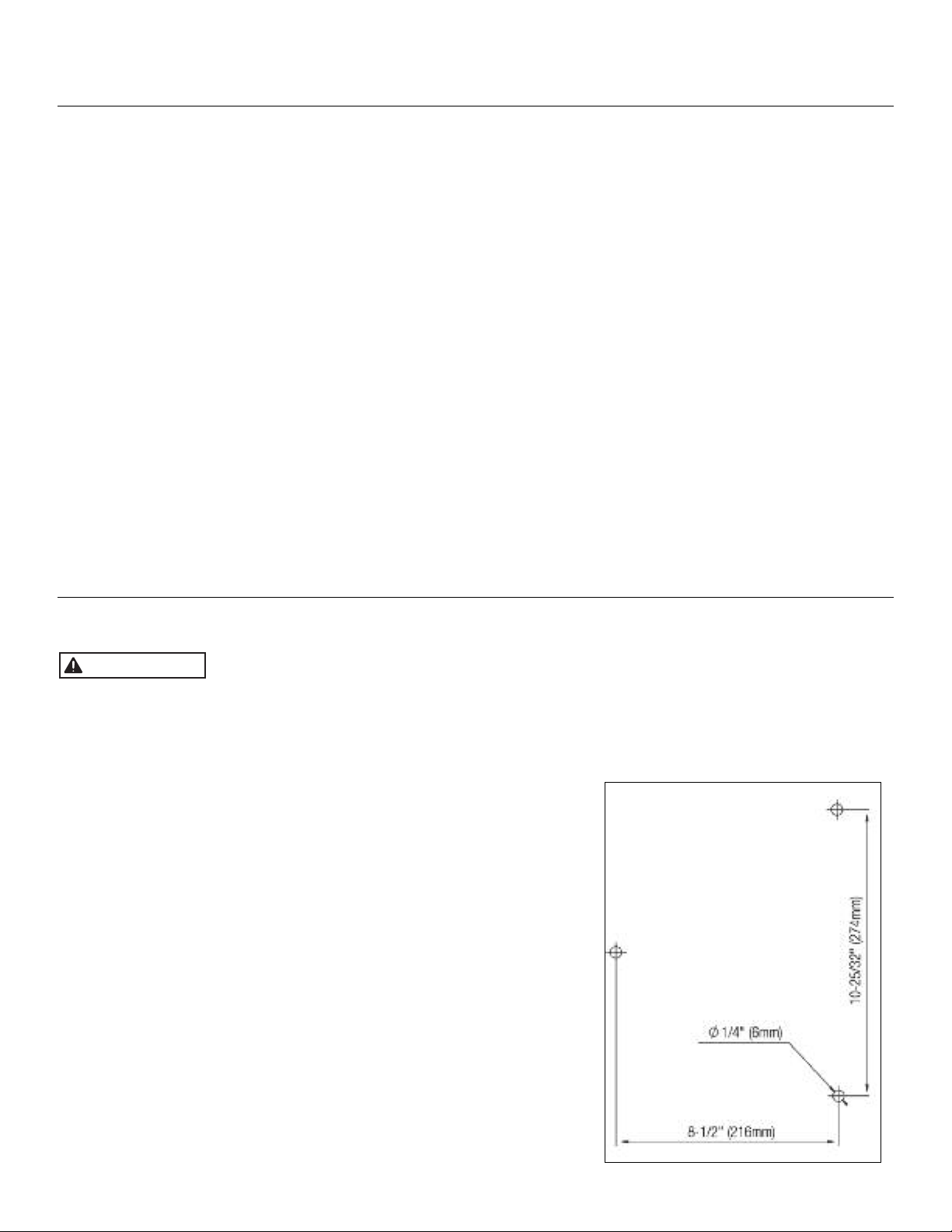

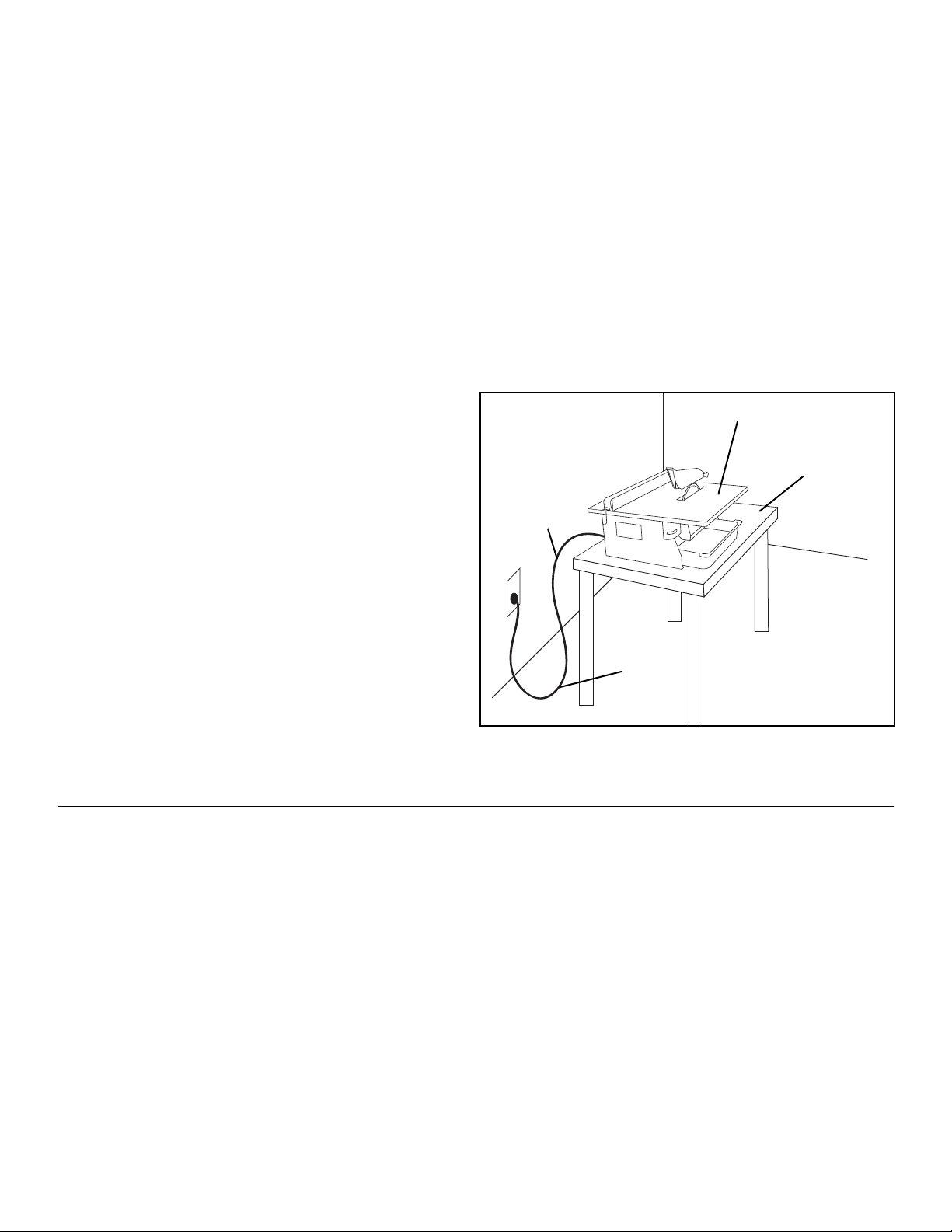

29. POSITIONING OF TILE SAW See FIGURE 1

FIGURE 1

A. To avoid the possibility of the appliance plug or

eceptacle getting wet, position the tile saw to

r

one side of a wall-mounted receptacle to prevent

water from dripping onto the receptacle or plug.

The user should arrange a “drip loop” in the cord

connecting the saw to a receptacle. The “drip

oop” is that part of the cord below the level of

l

POWER SUPPLY

CORD

TILE SAW

SUPPORTING

SURFACE

the receptacle, or connector if an extension cord

is used, to prevent water traveling along the cord

and coming in contact with the receptacle.

B. If the plug or receptacle does get wet, DO NOT

unplug the cord. Disconnect the fuse or circuit

breaker that supplies power to the tool. Then,

unplug and examine for presence of water in

the receptacle.

30. CHECK DIAMOND BLADES CAREFULLY for cracks,

nicks, missing diamond matrix, or out-of-alignment.

Replace blades immmediately. DO NOT use damaged

DRIP LOOP

blades. They may cause bodily injury.

ELECTRICAL REQUIREMENTS

• THIS TILE SAW MUST BE CONNECTED TO A GROUNDED POWER SOURCE while in use to protect the

operator from electrical shock.

• IN THE EVENT OF A MALFUNCTION OR BREAKDOWN, grounding provides a path of least resistance for

electrical current to reduce the risk of electrical shock. The tile saw is equipped with an electrical cord with a

grounding conductor and a grounding plug. Insert the 3-prong electrical plug into a 3-pole receptacle that is

properly installed and grounded in accordance with all local codes and ordinances.

• DO NOT MODIFY THE PLUG provided if it will not fit the outlet. Have the proper outlet installed by a

qualified electrician.

• IMPROPER CONNECTION OF THE EQUIPMENT-GROUNDING CONDUCTOR CAN RESULT IN A RISK OF

ELECTRIC SHOCK. The conductor with insulation that is green on the outside (with or without yellow stripes)

is the equipment-grounding conductor. If repair or replacement of the electrical cord or plug is necessary, do

not connect the equipment-grounding conductor to a live terminal.

• CHECK WITH A QUALIFIED ELECTRICIAN or service personnel if the grounding instructions are not

completely understood, or if in doubt as to whether the tool is properly grounded.

• USE ONLY 3-WIRE EXTENSION CORDS that have 3-prong grounding plugs and 3-pole receptacles that

accept the tile saw’s plug.

• REPAIR OR REPLACE DAMAGED OR WORN CORD IMMEDIATELY.

• IF THE PLUG OR RECEPTACLE DOES GET WET, DO NOT UNPLUG THE CORD. Disconnect the fuse or circuit

breaker that supplies power to the tool. Then, unplug and examine for presence of water in the receptacle.

• ONLY UL-LISTED EXTENSION CORDS SHOULD BE USED WITH THIS PRODUCT.

• IMPROPER USE OF EXTENSION CORDS MAY CAUSE INEFFICIENT OPERATION OF YOUR TOOL, which can

result in overheating. Be sure your extension cord is

rated to allow sufficient current flow to the motor. For

the proper gauge for this tile saw, please refer to

TABLE 1.

• DO NOT LET YOUR FINGERSTOUCH THE TERMINALS

of plug when installing or removing the plug to or from

the outlet.

• THIS TILE SAW MUST BE PROPERLY GROUNDED. The

risk of electric shock and bodily injury are greatly

increased if it is not, particularly when used in damp

locations or in proximity to plumbing.

NOTE: This tool is intended for use on a circuit that has an

- 4-

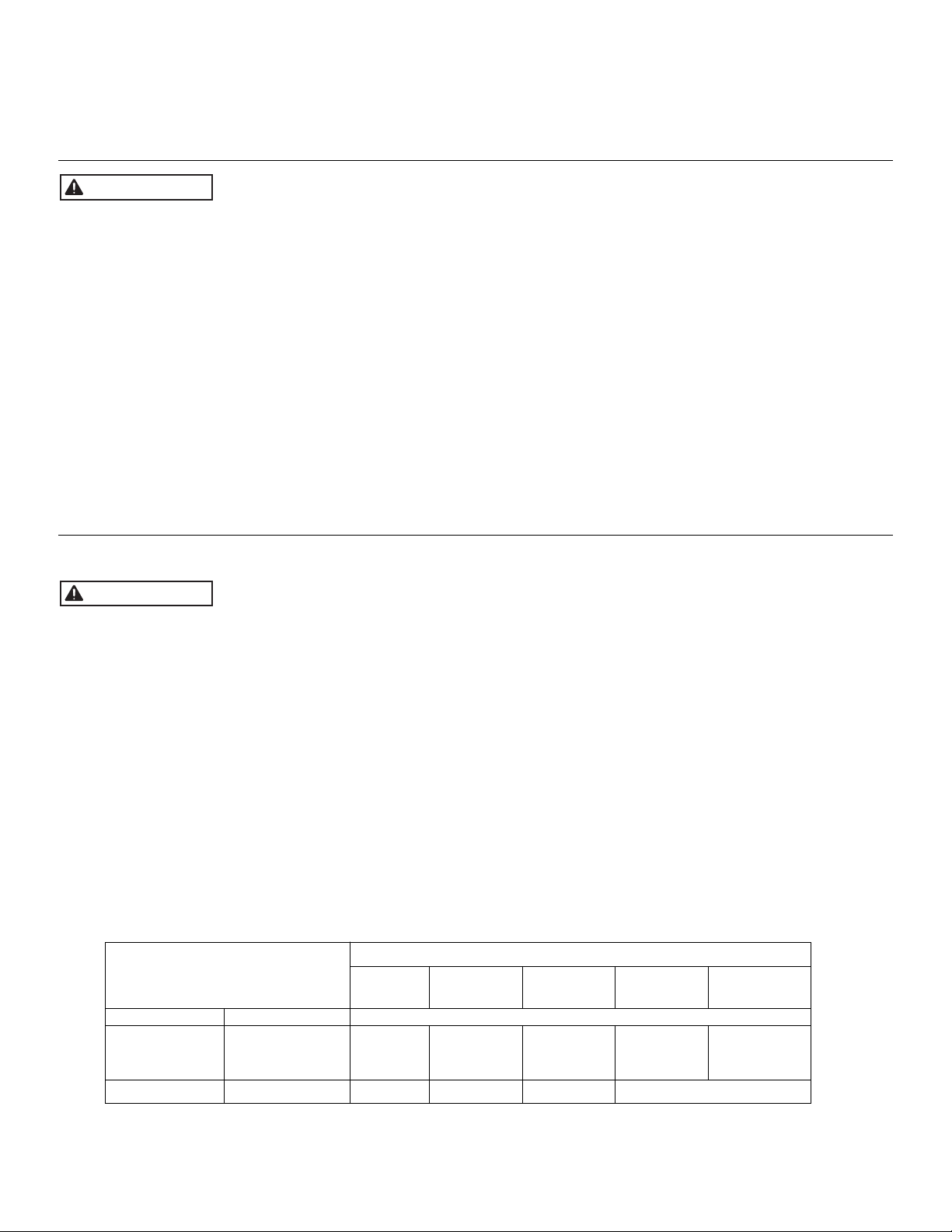

FIGURE 2

METAL SCREW

(A) GROUNDING PIN

(B) GROUNDED OUTLET BOX

(C) GROUNDING ADAPTER

(Not Permitted In Canada)

Page 5

outlet that looks like the one illustrated in FIGURE 2 (A). The tool has a grounding plug that looks like the plug

WARNING

WARNING

llustrated in FIGURE 2 (A). A temporary adapter, which looks like the adapter illustrated in FIGURE 2 (B) AND

i

(C), may be used to connect this plug to a 2-pole receptacle as shown in FIGURE 2 (B) if a properly grounded

outlet can be installed by a qualified electrician. The green-colored rigid prongs extending from the adapter

must be connected to a permanent ground such as a properly grounded outlet box.

PERSONAL INJURY CAN OCCUR IF OPERATED IMPROPERLY.

• Keep fingers and loose clothing away from rotating blade.

• Use extreme caution when cutting tile. Make sure hands and fingers are clear from the blade groove in the

sliding table. Severe abrasion, cuts , or pinching of hands or fingers can occur as the table is advanced,

particulary at the end of its travel.

• Electrical shock can occur if operating instructions are not followed.

FOR YOUR OWN SAFETY READ INSTRUCTION MANUAL BEFORE OPERATING SAW.

• Wear eye protection.

• Use splash hood for every operation for which it can be used.

• Unplug saw before servicing, when changing cutting wheels, and cleaning.

• Use tool only with smooth-edge cutting wheels free of openings and grooves.

• Replace damaged cutting wheel before operating.

• Do not fill water tray above water fill line.

EXTENSION CORDS

TO REDUCE THE RISK OF ELECTROCUTION, KEEP ALL CONNECTIONS DRY AND OFF THE GOUND. DO NOT TOUCH PLUG

WITH WET HANDS.

1. Use only extension cords that are intended for outdoor use. These extension cords are identified by a

marking “Acceptable for use with outdoor appliances: store indoors while not in use.” Use only extension

cords having an electrical rating not less than the rating of the product. Do not use damaged extension

cords. Examine extension cord before using and replace if damaged. Do not abuse extension cords and do

not yank on any cord to disconnect. Keep cord away from heat and sharp edges. Always disconnect the

extension cord from the receptacle before disconnecting the product from the extension cord.

2. Gound Fault circuit Interrupter (GFCI) protection should be provided on the circuit(s) or outlet(s) to be used

for the tile saw. Receptacles are available having built-in GFCI protection and may be used for this measure

of safety.

3. USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an

extension cord, be sure to use a cord heavy enough to carry the current your product will draw. An

undersized cord will cause a drop in line voltage, resulting in loss power and overheating. TABLE 1 below

shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the

next heavier gauge. The smaller the gauge number, the heavier the cord.

TABLE 1

Total length of cord in feet

AWG

Not Recommended

Ampere Rating

More Than Not More Than

06

6 10

10 12

12 16

Volts

120 V 25 ft. 50 ft. 100 ft. 150 ft.

240V 50ft. 100 ft. 200 ft. 300 ft.

18 16 16 14

18 16 14 12

16 16 14 12

14 12

NOTE: When using an extension cord, ensure all cords are no smaller than #12 gauge, rated at a 20-amp

minimum, and equipped with 3-prong plugs. Use of anything smaller may result in overheating or burn out of

- 5-

Page 6

the motor. It is recommended to have an electrician check the voltage at the saw motor to ensure proper voltage

CAUTION

to run the saw efficiently and safely.

SPECIFIC OPERATION GUIDE

. Ensure that the directional arrow marked on the blade corresponds with the rotational direction of the motor.

1

2. With the saw disconnected from the power supply, rotate the blade by hand to ensure it is free

from obstruction.

3. Always keep the blade-securing arbor and collars clean.

4. Ensure that the blade-securing bolt is securely tightened.

5. Never try to cut freehand. Always ensure that the tile to be cut is pressed firmly against the rip fence.

6. Ensure that the workpiece that will be cut off has sufficient room to move sideways. Failure to do so may

result in the off-cut binding against the blade.

7. Never cut more than one tile at a time.

8. Never cut pieces too small that are not held securely against the rip fence, and provide enough space for the

hand to be a safe distance from the blade.

9. Ensure that the table and surrounding area are clear with the exception of the tile to be cut.

10. Before cutting a tile piece, let the saw blade run freely for a few seconds. If it makes an unfamiliar sound or

vibrates excessively, switch it off immediately and disconnect it from the power supply.

11. Let the blade reach full speed before commencing the cut.

12. Let the blade come to a complete stop before removing any jammed material from around the

blade area.

13. Never allow the blade to run dry. Failure to keep the water tray at the recommended level will result in

possible over-heating of the diamond blade.

SET UP AND OPERATION

Follow all of the Assembly & Installation Instructions completely before connecting

the saw to a power source or turning the motor on.

Carefully open the container and remove all saw components and

packing materials. Ensure that you have checked each item with the

exploded view before discarding the container or packing materials.

The contents of the container are as follows:

• Water Tank • Blade Guard Support

• Spanner A • Blade Guard

• Spanner B • Parallel Guide

• 7 in. (180 mm) • Angle Gauge

Continuous Rim

Diamond Blade

The following pages illustrate the step-by-step installation of

various components and operation of this saw. Read instructions

completely before operating this saw!

ATTACHINGTHE TILE CUTTER ON AWORKBENCH:

1. Drill three holes in the workbench the same as dimensions

in FIGURE 3.

2. Fasten the machine with bolts on to the workbench.

FIGURE 3

- 6-

Page 7

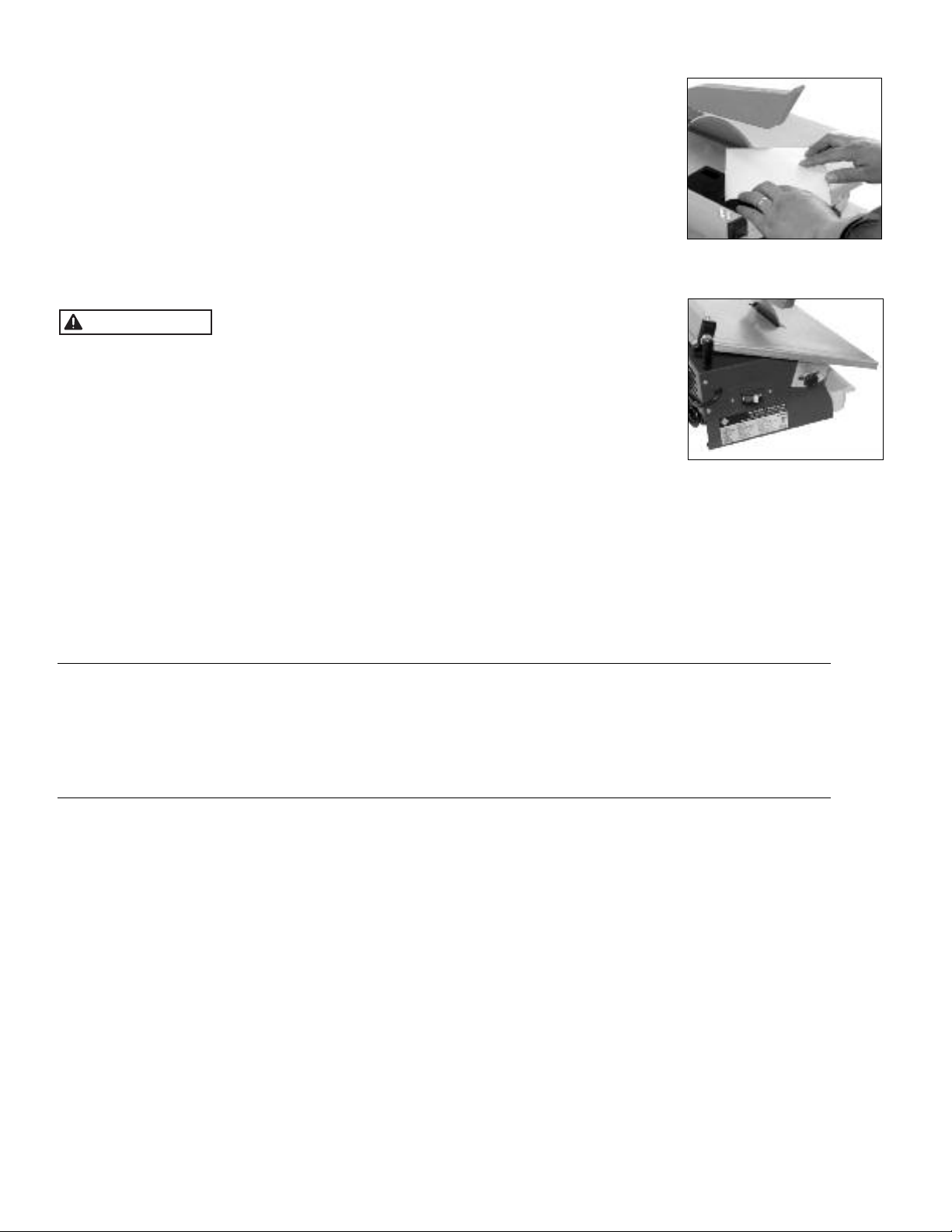

BLADE AND BLADE GUARD INSTALLATION:

WARNING

WARNING

Use with 7 in. Continuous Rim Diamond Blade.

1. Unplug the machine from the power source.

2. Remove the water tank from underneath the machine.

. Remove the lower blade guard by removing the screws on each side of

3

the lower blade guard FIGURE 4.

4. Use Spanner A and Spanner B to loosen and remove the arbor nut from

the motor spindle as shown in FIGURE 5.

5. Slide the outer flange FIGURE 5 and the diamond blade off the end of

the motor spindle.

6. Slide the new diamond blade and the outer flange over the end of

the motor spindle. Note: Make sure the directional arrow printed on the

diamond blade is pointing in a counter-clockwise direction

when viewing the machine facing the arbor nut.

7. Thread and tighten the arbor nut onto the motor spindle to secure

the diamond blade.

8. Re-install the lower blade guard.

FILLING AND DRAININGTHE WATER TRAY:

1. Fill the tray with water to cool blade during operation of the tile saw.

2. Remove the tray and pour the water out.

FIGURE 4

FIGURE 5

STARTING AND STOPPING THE MOTOR:

This machine has a magnetic switch for safer operation.

1. Connect the unit to a power supply of the correct voltage and frequency (120V–60HZ).

2. To turn the machine on, push the switch to “ON.”

3. To turn the machine off, push the switch to “OFF.”

For your own safety, always position the switch to the “OFF” position when the saw is not in use. In the event of a

power failure, blown fuse or tripped circuit breaker, press switch to the “OFF” position. This will prevent the tool

from starting up again when the power comes back on.

Only use this machine after it has been assembled completely and it has been screwed onto the workbench.

STEPS FOR MAKING A STRAIGHT CUT:

1. Using a marking pencil, mark the cut line on a piece of tile.

2. Unlock the parallel guide FIGURE 6 and slide it to the edge

of the table.

3. Line up the cut line on the tile with the diamond blade.

4. Adjust the parallel guide against the edge of the tile and

lock the parallel guide into position.

5. Turn the machine on by pushing the switch to the “ON” position,

and then allow it to reach full speed. Be sure the blade runs smoothly.

The blade should also be wet from the water tank below the machine

before beginning use.

6. Keeping fingers out of the cutting path, slowly slide the tile into the

moving blade. Note: DO NOT feed the tile into the blade too fast.

FIGURE 6

- 7-

Page 8

STEPS FOR MAKING A DIAGONAL CUT:

WARNING

Diagonal cuts can be made on rectangular tiles using the supplied angle gauge.

IGURE 7 shows a typical set up for cutting the corner off a square tile.

F

STEPS FOR MAKING MITER OR 45 DEGREE CUTS:

The work table can be tilted up to 45 degrees to accommodate bevel cutting.

Loosen the knob on the front of the tile cutter as shown in FIGURE 8. Use the scale

n the front of the tile cutter to set the desired table tilt angle. Re-tighten the knob

o

to secure the table.

FIGURE 7

CHANGING THE BLADE:

FIGURE 8

Disconnect the power supply before making adjustments,

maintenance, cleaning or replacing the blade!

1. Unplug the machine from the power source.

2. Remove the water tank from underneath the machine.

3. Remove the lower blade guard by removing the screws on each side of the

lower blade guard FIGURE 4.

4. Use Spanner A and Spanner B to loosen and remove the arbor nut from the

motor spindle as shown in FIGURE 5.

5. Slide the outer flange FIGURE 5 and the diamond blade off the end of the motor spindle.

6. Slide the new diamond blade and the outer flange over the end of the motor spindle. Note: Make

sure the directional arrow printed on the diamond blade is pointing in a counter-clockwise direction

when viewing the machine facing the arbor nut.

7. Thread and tighten the arbor nut onto the motor spindle to secure the diamond blade.

8. Re-install the lower blade guard.

DIAMOND BLADES

1. Use only 7 in. (180 mm) Continuous Rim Diamond blades in this saw.

2. This saw uses Continuous Rim Wet Diamond blades with a 5/8 in. (15.88 mm) diameter arbor.

3. This tile saw is to be used with only Continuous Rim Diamond Blades. Failure to do so may result in

severe bodily injury and damage to the saw.

DIAMOND BLADE DO’s & DON’Ts

DO’s

1. Inspect blades daily for cracks or uneven wear. Discard cracked, chipped or bent blades!

2. Always use manufacturer’s recommendation for matching the right blade with the right material

being cut.

3. Inspect the arbor shaft for uneven wear before mounting the blade.

4. Always use blades with the correct arbor size on a compatible arbor shaft.

5. Ensure the blade is mounted with the rotation arrow in the proper direction and is securely

tightened with a wrench.

6. Always wear proper safety equipment at all times when operating the saw. Wear goggles and dust

mask at all times when operating saw.

7. Periodically check the blade for cracks or bond fatigue.

8. Always ensure a continuous flow of water on both sides of the blade before cutting any material.

- 8-

Page 9

DON’Ts

WARNING

1. Do not operate the saw without all safety guards in position.

2. Do not operate the saw with blades larger or smaller than recommended.

. Do not cut dry with blades marked “Use Wet.”

3

. Do not exceed maximum RPMs recommended by the blade manufacturer.

4

5. Do not force the material into the blade. Let the blade cut at its own speed.

6. Do not cut material not recommended by the blade manufacturer.

SAW MAINTENANCE

Do not service, clean or maintain the saw without first turning off the motor and unplugging the saw from it's power

source. Failure to do so may result in serious injury to the operator.

1. “Truing” the cutting table may be required occasionally. The saw blade must be 90˚ to the “tile stop” on the

cutting table to prevent blade “binding” while cutting tile.

a. Use a carpenter’s square, held against the blade and against the “tile stop”, at the back of the

cutting table.

b. If the two are not square (90˚), loosen the wing nut on the left guide rail, and move the guide rail until the

blade and cutting table are exactly square.

c. Tighten the wing nut on the guide rail securely.

2. For longest life and best performance, clean the saw after every use.

3. Wipe off all exterior surfaces and keep the cutting table clean and free of tile chips and debris.

4. Wipe off both the guide bars and the rollers on the cutting table.

5. Place light machine oil on the guide bar to facilitate smooth travel of the linear guide assembly.

TROUBLESHOOTING

OVERHEATING OF SAW:

A. Turn saw off and let it rest until motor is cool to the touch.

B. Check and clean the ventilation slots, removing blockage and dirt.

THE SAW DOES NOT START:

A. Check that power cord is properly plugged in.

B. No power from outlet.

C. Switch is damaged.

ACCESSORIES INCLUDED WITH SAW

• Spanner A

• Spanner B

• 7 in. (180 mm) Continuous Rim Diamond Blade

• Angle Gauge

• Parallel Guide

STATE-OF-THE-ART FEATURES OF THIS SAW

• Lightweight and portable

• Adjustable cutting table allows for precision 45 degree cuts

• Direct drive, 3/5 HP motor, 3,600 RPM

• Automatic thermal overload protection protects saw from power surges and motor overheating

• Lightweight for easy setup and maintenance

- 9-

Page 10

PARTS LIST

PART # DESCRIPTION

60089-1-N Nut

60089-2-N Washer

60089-3-N Blade Guard

60089-4-N Riving Knife

60089-5-N Bolt

60089-6-N Table

60089-7-N Clamp Rod

60089-9-N Moving Clamp

60089-10-N Spring

60089-11-N Square Spacer

60089-12-N Hex Screw

60089-13-N Washer

60089-14-N Fence

60089-15-N Fixed Clamp

60089-16-N Flat Washer

60089-17-N Connection Bolt

60089-18-N Cotter Pin

60089-19-N Clamp Lever

60089-20-N Screw

60089-21-N Washer

60089-22-N Lower Blade Guard

PART # DESCRIPTION

60089-23-N Nut

60089-24-N Outer Flange

60089-25-N Blade

60089-26-N Inner Flange

60089-27-N Lower Blade Plate

60089-28-N Screw

60089-29-N Spring Washer

60089-30-N Washer

60089-32-N Nut

60089-33-N Frame

60089-36-N Screw

60089-37-N Cord Storage

60089-39-N Knob

60089-41-N Motor

60089-42-N Screw

60089-44-N Star Washer

60089-45-N Strain Relief

60089-46-N Cable and Plug

60089-47-N Key Safety Switch

60089-48-N Plate

60089-49-N Water Tank

Page 11

EXPLODED PARTS

Page 12

RÈGLES GÉNÉRALES SUR LA SÉCURITÉ

Lire ce manuel d'utilisation au complet et s'assurer de bien comprendre toutes les consignes de sécurité.

1. LAISSER LES ACCESSOIRES DE PROTECTION EN PLACE et en état de marche.

. ENLEVER LES CLÉS DE RÉGLAGE ET LES CLÉS. Prendre l’habitude de vérifier si elles sont bien enlevées

2

avant de faire démarrer la scie.

3. GARDER VOTRE ZONE DE TRAVAIL PROPRE. Les accidents sont souvent dus à des endroits encombrés et au

désordre sur un établi.

4. TOUJOURS DEMEURER ALERTE LORS DE L’UTILISATION DE LA SCIE. Un moment d’inattention de la part de

l’opérateur peut entraîner des blessures graves.

5. NE PASTRAVAILLER DANS UN ENVIRONNEMENT DANGEREUX. Éviter d’utiliser des outils électriques dans

des endroits humides ou mouillés, et encore moins sous la pluie. Veillez à bien éclairer votre zone de travail.

6. GARDER LES ENFANTS HORS DE PORTÉE. Les visiteurs doivent se tenir suffisamment à l’écart de votre

zone de travail.

7. RENDRE VOTRE ATELIER À L’ÉPREUVE DES ENFANTS au moyen de cadenas, d’interrupteurs généraux ou en

enlevant les clés de contact des appareils.

8. UTILISER L’OUTIL APPROPRIÉ. Ne pas forcer l’outil ou l’accessoire à faire un travail pour lequel ils ne sont

pas conçus.

9. UTILISER UNE RALLONGE APPROPRIÉE. S’assurer que votre rallonge soit en bon état et qu’elle soit d’un

calibre suffisant pour supporter le courant que votre appareil soutirera. Une rallonge de calibre insuffisant

causera une perte de tension et provoquera ainsi une panne électrique et un surchauffage. Le tableau (se

reporter au TABLEAU 1) indique les calibres à utiliser selon la longueur de la rallonge et la puissance

nominale en ampères. En cas de doute, utiliser le calibre supérieur. Plus le numéro de jauge est petit, plus le

calibre est élevé.

10. NE PAS FORCER L’OUTIL. Il fonctionnera mieux et il y aura moins de risques s’il est utilisé selon ses normes.

11. NE PAS FORCER LE MATÉRIAU À COUPER. Toujours laisser la lame couper à son propre rythme.

12. PORTER LES VÊTEMENTS APPROPRIÉS. Évitez de porter des vêtements amples, des cravates, des bagues,

des bracelets ou des bijoux qui risquent de s’accrocher dans les éléments mobiles. Il est recommandé de

porter des chaussures à semelles antidérapantes. Si vous avez des cheveux longs, couvrez les pour les

protéger.

13. TOUJOURS PORTER DES LUNETTES DE SÉCURITÉ. Portez également un masque facial ou anti-poussières

lors des opérations de coupe commerciales. Les lunettes de tous les jours ne sont munies que de lentilles

résistantes aux chocs; ce ne sont PAS des lunettes de protection.

14. SECURISEZ VOTRE PLAN DE TRAVAIL. Autant que possible, utiliser des pinces ou un étau au lieu de vos

mains pour tenir les pieces. Cette mesure de sécurité vous permettra de faire fonctionner l’outil

correctement avec vos deux mains.

15. NE PAS UTILISER LA SCIE À BOUT DE BRAS. Gardez les pieds fermement au sol et un bon équilibre en

permanence.

16. ENTRETENIR LES OUTILS AVEC SOINS. Garder les outils propres et en bon état pour obtenir un rendement

sécuritaire maximal. Respecter les instructions de graissage et de remplacement des accessoires.

17. DÉBRANCHER L’OUTIL AVANT D’EFFECTUER L’ENTRETIEN, de remplacer des accessoires tels que les lames,

les forets, les coupoirs, etc.

18. RÉDUIRE LES RISQUES DE DÉMARRAGE ACCIDENTEL. Vérifier que l’interrupteur soit bien à la position OFF

(éteint) avant de le brancher.

19. UTILISER LES ACCESSOIRES RECOMMANDÉS. Consulter le manuel d’utilisation pour la liste des accessoires

recommandés. L’utilisation d’accessoires inappropriés peut augmenter les risques de blessure.

20. NE PAS COUPER À SEC AVEC DES LAMES CONÇUES POUR LES COUPES AU MOUILLÉ.

21. S’ASSURER D’UTILISER LES LAMES APPROPRIÉES pour le travail à effectuer.

22. NE JAMAIS SE TENIR DEBOUT SUR L’OUTIL. Cela risque de causer des blessures graves si l’outil bascule ou

entre accidentellement en contact avec la personne.

- 12 -

Page 13

23. VÉRIFIER LES PIÈCES ENDOMMAGÉES. Avant d’utiliser l’outil, vérifier s'il y a des pièces endommagées (un

protecteur, par exemple) avec soin pour s’assurer qu’elles fonctionneront correctement et qu’elles

effectueront la fonction pour laquelle elles ont été conçues. Vérifier l’alignement des pièces mobiles, leurs

ixations, les risques de rupture, leur montage et tout autre élément pouvant affecter le fonctionnement de la

f

scie. Réparer ou remplacer tout protecteur ou pièce endommagée.

24. S’ASSURER QU’IL Y AIT UN DÉBIT D’EAU CONTINU des deux côtés du disque lors du fonctionnement.

25. EXAMINER LES LAMES À TRANCHANT AU DIAMANT AVEC SOINS POUR S’ASSURER QU’ELLES N’AIENT

AS DE FISSURES, D’ENTAILLES, QUETOUTES LES MATRICES AU DIAMANT SOIENT PRÉSENTES ET

P

QU’ELLES SOIENT OU BIEN ALIGNÉES. Remplacer les lames endommagées immédiatement. NE PAS

UTILISER UNE LAME ENDOMMAGÉE. Elle risque de causer des blessures.

26. SENS DE L’ALIMENTATION. Alimenter la pièce à découper en direction opposée à la rotation du disque.

27. NE PAS MODIFIER LA FICHE OU UTILISER UNE PRISE DE COURANT BIPOLAIRE. Cette scie est munie d’une

fiche électrique à 3 broches.

28. NE JAMAIS LAISSER L’OUTIL FONCTIONNER SANS SURVEILLANCE. Éteindre l’outil et ne pas le laisser

avant qu’il ne se soit arrêté complètement.

29. COMMENT PLACER LA SCIE À CARREAUX (Voir

FIGURE 1)

A. Afin d’éviter de mouiller la fiche de l’appareil ou

FIGURE 1

SCIE À CARREAUX

la prise de courant, placer la scie à carreau du

côté d’une prise de courant murale afin

d’empêcher l’eau de s’égoutter dans la prise ou

SURFACE DE

SUPPORT

la fiche. L’utilisateur doit arranger une boucle

d’égouttement dans le cordon reliant la scie à la

prise de courant. La boucle d’égouttement est la

CORDON

ÉLECTRIQUE

partie du cordon qui se trouve sous le niveau de

la prise, ou du connecteur dans le cae

d’utilisation d’une rallonge, pour empêcher l’eau

de s’égoutter le long du cordon et d’entrer en

contact avec la prise.

B. Si la fiche ou la prise entrent en contact avec de

l’eau, NE PAS débrancher le cordon. Débrancher

le fusible ou le disjoncteur qui alimentent l’outil.

BOUCLE

Ensuite, débrancher l'appareil et vérifier s’il y a

de l’eau dans la prise.

30. EXAMINER LES LAMES À TRANCHANT AU

DIAMANT AVEC SOINS pour s’assurer qu’elles n’aient pas de fissures ou d’entailles, que toutes les matrices

au diamant soient présentes et qu’elles soient bien alignées. Remplacer les lames endommagées

immédiatement. NE PAS utiliser une lame endommagée. Elle risque de causer des blessures.

INSTALLATIONS ÉLECTRIQUES

• BRANCHER L’APPAREIL À LA SOURCE D’ÉNERGIE. Pour protéger l’utilisateur contre toute possibilité et tout

risque d’électrocution, cet outil doit être branché dans une prise mise à la terre.

• Dans le cas d’un mauvais fonctionnement ou d’une panne, la mise à la terre fournit un chemin de moindre

résistance au courant électrique et réduit le risque de choc électrique. Cet outil est équipé d’un cordon

électrique avec conducteur de terre et fiche de masse. Brancher la fiche électrique à 3 broches dans une prise

tripolaire installée adéquatement et mise à la terre conformément aux règles et ordonnances locales.

• Ne pas modifier la fiche fournie si elle ne convient pas à votre prise. Faire installer la prise nécessaire par un

électricien qualifié.

• Une connexion incorrecte du conducteur de terre peut créer un risque d’électrocution. Le fil isolé de couleur

verte (avec ou sans rayures jaunes) est le conducteur de terre de l’appareil. Si le cordon électrique ou la fiche

doivent être réparés, ne pas relier le conducteur de terre de l’appareil à une borne positive.

• Vérifier auprès d’un électricien ou d’un employé de maintenance qualifiés si les directives de mise à la terre

ne sont pas bien comprises ou en cas de doute quant à la mise à la terre de l’outil.

• N’utiliser que des rallonges à 3 fils avec un fil de mise à la terre et des prises tripolaires qui correspondent à

la fiche de l’outil.

- 13 -

Page 14

• Réparer ou remplacer immédiatement les cordons électriques endommagés ou usés.

AVERTISSEMENT

AVERTISSEMENT

• Si la prise entrent en contact avec de l’eau, ne pas débrancher le cordon. Débrancher le fusible ou le

disjoncteur qui alimentent l’outil. Ensuite, débrancher l'appareil et vérifier s’il y a de l’eau dans la prise.

N’utiliser que les rallonges électriques classées UL.

•

• L’utilisation des rallonges électriques de capacité insuffisante risque de mal faire fonctionner l’outil et

provoquer une surchauffe. S’assurer que le calibre de la rallonge électrique soit suffisant pour alimenter le

moteur. Pour connaître le calibre nécessaire pour cette scie à eau, se reporter au TABLEAU 1.

• Ne jamais laisser vos doigts entrer en contact avec les

broches de la prise lorsque vous branchez ou

débranchez l'alimentation.

• Cette scie à eau doit être mise à la terre correctement,

sinon les risques d’électrocution et de blessures

augmentent énormément, particulièrement lorsque

l’outil est utilisé dans des endroits humides ou près

de la tuyauterie.

NOTE: Cet outil est conçu pour être branché sur un circuit

doté d’une prise ressemblant à celle représentée au

FIGURE 2 (A). Sa fiche de terre ressemble aussi à celle

représentée au FIGURE 2 (A). Un adaptateur temporaire,

qui ressemble à celui représenté par les FIGURE 2 (B) ET

(C), peut être utilisé pour brancher cette fiche sur une prise

murale bipolaire (tel que montré dans le FIGURE 2 (B) si

une prise correctement mise à la terre peut être installée par un électricien qualifié. Les broches rigides de

couleur verte qui dépassent de l’adaptateur doivent être reliées à une prise de terre permanente, comme celle

d’une prise murale mise à la terre.

FIGURE 2

A) BROCHE DE MISE À

(

LA TERRE

VIS MÉTALLIQUE

(B) SORTIE MISE À LA TERRE

(C) ADAPTATEUR DE MISE À LA TERRE

(Interdit au Canada)

IL Y A DES RISQUES DE BLESSURE SI L’OUTIL N’EST PAS UTILISÉ CORRECTEMENT.

• Garder les doigts et les vêtements amples loin de la lame rotative.

• Faire extrêmement attention lors de la coupe de carreaux. S’assurer de bien éloigner les mains et les doigts

de l’encoche de fixation de la lame dans la table coulissante. Des risques d’abrasions, de coupures ou de

pincement graves existent lorsque la table avance, particulièrement à la fin de son déplacement.

• Il y a des risques d’électrocution si le mode d’emploi n’est pas respecté

POUR VOTRE PROPRE SÉCURITÉ, LIRE CE MANUEL D’ENTRETIEN AVANT D’UTILISER LA SCIE.

• Porter des lunettes de sécurité.

• Utiliser l’écran anti-éclaboussures autant que possible.

• Débrancher la scie avant d’en effectuer l’entretien, de changer les disques de coupe ou de la nettoyer.

• Utiliser l’outil seulement avec des disques lisses sans fentes et encoches.

• Remplacer les disques endommagés avant d’utiliser l’appareil.

• Ne pas remplir le plateau d’eau au-dessus du niveau indiqué

RALLONGES ÉLECTRIQUES

AFIN DE RÉDUIRE LES RISQUES D’ÉLECTROCUTION, GARDER TOUTES LES CONNEXIONS SÈCHES ET DÉGAGÉES DU

SOL. NE PAS TOUCHER À LA FICHE LORSQUE LES MAINS SONT MOUILLÉES.

1. N’utiliser que des rallonges électriques conçues pour être utilisées à l’extérieur. Ces rallonges sont identifiées

par une étiquette “Peut être utilisée avec des appareils de plein air. Ranger à l’intérieur lorsqu’elle n’est pas

utilisée.” N’utiliser que des rallonges qui possèdent un calibre électrique équivalent ou supérieur au calibre

de l’appareil. Ne pas utiliser de rallonges endommagées. Examiner la rallonge avant de l’utiliser et la

remplacer si elle est endommagée. Ne pas maltraiter les rallonges électriques et ne pas les tirer

- 14 -

Page 15

brusquement pour les débrancher. Garder les rallonges loin de toute source de chaleur et d’arêtes vives.

Toujours débrancher la rallonge de la prise de courant avant de débrancher l’appareil de la rallonge.

. Un interrupteur de défaut à la terre doit être présent sur le(s) circuit(s) ou la(les) sortie(s) en vue d’être utilisé

2

avec la scie à carreaux. Il existe des prises de courant munies d’un interrupteur de défaut à la terre intégré

qui peuvent être utilisées pour cette mesure de sécurité.

3. UTILISER UNE RALLONGE APPROPRIÉE. S’assurer que la rallonge soit en bon état et qu’elle soit de calibre

suffisant pour supporter le courant que votre appareil soutirera. Une rallonge de calibre insuffisant causera

ne perte de tension et provoquera ainsi une panne électrique et une surchauffe. Le tableau ci-dessous

u

indique les calibres à utiliser, selon la longueur de la rallonge, ainsi que la puissance nominale en ampères.

En cas de doute, utiliser le calibre supérieur suivant. Plus le numéro de jauge est petit, plus le calibre

est élevé.

TABLEAU 1

Voltage

120 V 7.62 m 15.24 m 30.5 m 61 m

Ampérage

Plus de Jusqu’a

0A 6A

6A 10 A

10 A 12 A

12 A 16 A

NOTE: Lors de l’utilisation d’une rallonge, s’assurer que cette dernière ne soit pas d’un calibre inférieur à 12,

qu’elle possède un ampérage nominale d’au moins 20 ampères et qu’elle soit équipée de prises à 3 broches.

L’utilisation de toute rallonge de capacité inférieure peut provoquer une surchauffe ou l’usure prématurée du

moteur. Il est recommandé de faire vérifier la tension du moteur de la scie par un électricien professionnel afin

d’assurer la sécurité de l’utilisateur et du fonctionnement de l’outil.

240 V 15.24 m 30.5 m 61 m 91.5 m

Rallonge - Longueur en Mêtres

AWG

18 16 16 14

18 16 14 12

16 16 14 12

14 12

Non Recommandé

GUIDE DE FONCTIONNEMENT SPÉCIFIQUE

1. Assurez-vous que la flèche directionnelle sur la lame corresponde à la direction rotative du moteur.

2. Lorsque la scie est hors tension, tournez la lame à la main pour lui permettre de tourner librement

sans obstruction.

3. Gardez toujours l’arbre et les collets fixant la lame propres.

4. Assurez-vous que le boulon fixant la lame soit bien resserré avec une clef.

5. N’essayez jamais de couper à main levée. Assurez-vous toujours que le carreau à couper soit pressé

fermement contre la butée.

6. Assurez-vous que la pièce à couper ait suffisamment d’espace pour bouger de côté. Dans le cas contraire

la chute pourrait coller à la lame.

7. Ne coupez jamais plus d’un carreau à la fois.

8. Ne coupez jamais de pièces trop petites qui ne sont pas bien retenues en place contre la butée et prévoyez

suffisamment d’espace pour que votre main soit à bonne distance de la lame.

9. Assurez-vous que la table et que l’espace environnant soient libres de tout sauf du carreau à couper.

10. Avant de couper le carreau, laissez la lame de scie fonctionner librement pendant quelques secondes. Si

vous entendez un son inhabituel ou si elle vibre trop, arrêtez-la et débranchez la scie.

11. Laissez la lame arriver à sa pleine vitesse avant de commencer la coupe.

12. Laissez la lame s’arrêter complètement avant de retirer tout matériel coincé autour de la lame.

13. Ne laissez jamais la lame tourner à sec. Ne pas garder le plateau d’eau au niveau recommandé mènera

à la surchauffe de la lame à tranchant au diamant.

- 15 -

Page 16

INSTALLATION ET FONCTIONNEMENT

ATTENTION

Suivez bien toutes les instructions d’assemblage et d’installation avant de brancher

la scie à carreaux à toute source de courant ou avant de la mettre en marche.

Ouvrez prudemment le carton et retirez toutes les composantes de la

scie et le matériel d’emballage. Assurez-vous d’avoir vérifié chaque

article avec la vue éclatée avant de jeter le contenant ou le matériel

d’emballage. Elements inclus dans l’emballage:

• Réservoir d’eau • Couteau à déchirer

• Clef A • Capot de lame

• Clef B • Guide de parallélisme

• Lame de coupe • Guide de coupe en angle

diamantée à bord

continu 180 mm

Les pages suivantes illustrent la démarche détaillée d’installation des

différents composants et le fonctionnement de la scie. Veuillez lire

toutes les instructions avant d’utiliser la scie!

ATTACHER LE COUPE CARREAU SUR UN ÉTABLI:

1. Percez trois trous comme avec les dimensions indiquées sur

la FIGURE 3.

2. Fixez la machine avec des boulons sur l’établi.

FIGURE 3

FIGURE 4

INSTALLATION DE LA LAME ET DU CAPOT DE PROTECTION

DE LAME:

Utilisez uniquement des Lame de coupe diamantée à bord

continu 180 mm ou des lames diamantées Turbo.

1. Débranchez la machine de la source de courrant éléctrique.

2. Retirez le réservoir d’eau en dessous de la machine

3. Retirez le capot de lame inférieur en dévissant les vis de chaque

coté du capot de lame inférieur FIGURE 4.

4. Utilisez les clefs A et B pour retirer l’écrou de mandrin de l’axe du

moteur (voir FIGURE 5).

5. Retirez la bride extérieure FIGURE 5 et la lame diamantée à

remplacer de l’axe du moteur.

6. Installez la nouvelle lame diamantée et la bride extérieure sur l’axe

du moteur. Note: Assurez vous que la flèche directionnelle

imprimée sur la lame diamantée indique une direction inverse du

sens des aiguilles d’une montre en regardant la machine du coté

de l’écrou de mandrin.

7. Replacez et serrez l’écrou de mandrin sur l’axe du moteur pour fixer en place la lame diamantée.

8. Réinstallez le capot de protection de lame inférieur.

REMPLIR ET DRAINER LE PLATEAU D’EAU:

1. Remplissez le réservoir d’eau pour pouvoir refroidir la lame pendant son utilisation.

2. Retirez le réservoir pour pouvoir déverser l’eau.

FIGURE 5

- 16 -

Page 17

DÉMARRER ET ARRÊTER LE MOTEUR:

AVERTISSEMENT

. Branchez la scie à une source de courrant éléctrique de voltage et fréquence correcte (120 V 60 Hz)

1

2. Pour mettre en marche, appuyez sur l’interrupteur pour le mettre en position “ON.”

3. Pour arrêter la machine, appuyez sur l’interrupteur pour le mettre sur la position “OFF.”

Attention! Pour votre propre sécurité, mettez toujours l’interrupteur en position “OFF” quand la scie n’est pas utilisée.

Dans l’éventualité d’une coupure de courrant, arrêt par fusible ou coupe circuit, mettez ‘interrupteur en position “OFF.”

Cela permettrad’éviter que la scie se mette n marche un fois le courrant est rétablis.

Attention! Utilisez cette machine uniquement une fois qu’elle a été complètement assemblée sur l’établi.

ÉTAPES POUR FAIRE UNE COUPE DROITE:

1. En utilisant un crayon de marquage, marquez la ligne de coupe sur

le carreau.

2. Débloquez le guide de parallélisme FIGURE 6 et glissez le jusqu’au bord

de la table.

3. Alignez la ligne de coupe avec la lame de scie diamantée.

4. Ajustez le guide de parallélisme contre le bord du carreau et bloquez le

guide de parallélisme en position.

5. Mettez la machine en marche en mettant l’interrupteur en position “ON.”

Laissez ensuite la scie atteindre sa vitesse de fonctionnement.

Assurez-vous que la lame tourne sans entraves. La lame doit être

mouillée par l’eau du réservoir avant de pouvoir l’utiliser.

6. En gardant les doigts en dehors du chemin de coupe, glissez doucement

le carreau sous la lame en mouvement. Note: NE PAS glisser le carreau

trop rapidement sous la lame.

ÉTAPES POUR FAIRE UNE COUPE EN DIAGONALE:

Les coupes en diagonale peuvent être pratiquées sur les carreaux

rectangulaires en utilisant le guide de coupe en angle. La FIGURE 7 montre

une installation typique pour couper un coin de carreau rectangulaire.

ÉTAPES POUR FAIRE DES COUPES EN ANGLE OU À 45 DEGRÉS:

La table de travail peut se pivoter jusqu’a 45 degrés pour un découpage

biseauté. Tournez la poignée sur la face frontale du système de coupe

comme indiqué sur la FIGURE 8. Utilisez l’échelle de mesure sur la face

frontale du système de coupe pour régler l’angle de coupe désiré. Resserrez

ensuite la poignée pour bloquer la table.

FIGURE 6

FIGURE 7

FIGURE 8

CHANGER LA LAME:

Coupez le courant avant tout ajustement, entretien, nettoyage ou remplacement de la lame!

1. Débranchez la machine de la source de courrant éléctrique.

2. Retirez le réservoir d’eau en dessous de la machine.

3. Retirez le capot de lame inférieur en dévissant les vis de chaque coté

du capot de lame inférieur FIGURE 4.

4. Utilisez les clefs A et B pour retirer l’écrou de mandrin de l’axe du moteur (voir FIGURE 5).

5. Retirez la bride extérieure FIGURE 5 et la lame diamantée à remplacer de l’axe du moteur.

6. Installez la nouvelle lame diamantée et la bride extérieure sur l’axe du moteur. Note: Assurez vous que la

flèche directionnelle imprimée sur la lame diamantée indique une direction inverse du sens des aiguilles

d’une montre en regardant la machine du coté de l’écrou de mandrin.

- 17 -

Page 18

7. Replacez et serrez l’écrou de mandrin sur l’axe du moteur pour fixer en place la lame diamantée.

AVERTISSEMENT

8. Réinstallez le capot de protection de lame inférieur.

RUBANS À TRANCHANT AU DIAMANT

1. Utilisez uniquement des Lame de coupe diamantée à bord continu 180 mm pour cette scie.

2. Cette scie est prévue pour des lames de coupe diamantée à bord continu pour utilisation sous eau avec un

iamètre de mandrin de 15.88 mm.

d

3. Cette scie est prévue pour être utilisée uniquement avec des lames diamantées à bord continu. L’utilisation

d’autres types de lames pourrait provoquer des accidents corporels graves et endommager la scie.

CE QU’IL FAUT FAIRE ET NE PAS FAIRE POUR LES LAMES DIAMANTÉES

CHOSES À FAIRE

1. Examiner les disques quotidiennement pour s’assurer qu’ils n’aient pas de fissures ou qu’ils ne soient pas

usés. Jeter les disques craquelés, ébréchés ou tordus!

2. Toujours respecter les recommandations du fabricant quant à l’utilisation du disque approprié au type de

travail à accomplir.

3. S’assurer que l’arbre ne soit pas usé de façon inégale avant d’installer le disque.

4. Toujours utiliser des disques avec un mandrin de dimension adéquate sur un arbre de mandrin compatible.

5. S’assurer que le disque soit installé avec la flèche de rotation dans la bonne direction et qu’il soit bien serré

au moyen d’une clé.

6. Toujours porter l’équipement de sécurité nécessaire lors de l’utilisation de la scie. Toujours porter des

lunettes de sécurité et un masque anti-poussières lors du fonctionnement de la scie.

7. S’assurer périodiquement que le disque n’ait pas de fissures ou qu’il ne soit pas déformé.

8. Toujours s’assurer d’avoir un débit d’eau constant des deux côtés du disque avant de couper tout matériau.

CHOSES À NE PAS FAIRE

1. Ne pas utiliser la scie sans que tous les dispositifs de protection ne soient en place.

2. Ne faites pas fonctionner la scie avec des lames plus larges ou plus petites que ce qui est recommandé.

3. Ne pas couper à sec avec des disques conçus pour les coupes à eau.

4. Ne pas excéder la vitesse recommandée par le fabricant du disque.

5. Ne pas forcer le matériel à couper. Laisser le disque couper à sa propre vitesse.

6. Ne pas couper des matériaux qui ne sont pas recommandés par le fabricant du disque.

ENTRETIEN DE LA SCIE

Avant d'effectuer l'entretien, des réparations ou le nettoyage, éteindre le moteur et débrancher la scie de sa source

d'alimentation, sinon cela pourrait causer des blessures graves à l'utilisateur.

1. Il pourra s’avérer nécessaire de “centrer” la table de coupe de temps à autre. Le disque doit se trouver à un

angle de 90° de “l’arrête du carreau” sur la table de coupe afin d’empêcher le disque de se coincer lors de

la coupe.

a. Utiliser une équerre de menuisier et l’appuyer contre le disque et “l’arrête du carreau” à l’arrière de la

table de coupe.

b. Si les deux ne sont pas à un angle de 90° l’un de l’autre, desserrer le boulon à tête hexagonale situé sur

la glissière gauche et déplacer celle-ci jusqu’à ce que le disque et la table de coupe soient exactement

perpendiculaires.

c. Serrer le boulon à oreilles qui se trouve sur la glissière.

- 18 -

Page 19

2. Pour prolonger la durée de vie et obtenir un meilleur rendement, nettoyer la scie après chaque usage.

3. Essuyer toutes les surfaces extérieures et garder la table propre et libre de copeaux de carreaux et de débris.

. Essuyer les deux barres de guidage et les rouleaux sur la table de coupe.

4

5. Lubrifier légèrement les barres de guidage pour faciliter le déplacement du montage du guidage linéaire.

DÉPANNAGES

SURCHAUFFE DE LA SCIE:

A. Arrêtez la scie linéaire et laissez-la reposer jusqu’à ce que le moteur soit frais au toucher.

B. Vérifiez et nettoyez les fentes de ventilation en retirant tout blocage et toute poussière.

LA SCIE NE DÉMARRE PAS:

A. Vérifiez que le cordon est bien branché.

B. Aucun courant à la prise.

C. L’interrupteur est endommagé.

ACCESSOIRES INCLUS AVEC LA SCIE

• Clef A

• Clef B

• Lame de coupe diamantée à bord continu 180 mm

• Guide de coupe en angle

• Guide de parallélisme

CARACTÉRISTIQUES DE POINTE DE CETTE SCIE

• Légère et portable

• Table de coupe adjustable permettant des coupes à 45 degrés de précision

• Moteur en prise directe, 0.6 CV, 3600 Tours/min

• Fusible pour protection thermique automatique, protége la scie d’une montée subite de puissance ou d’une

surchauffe du moteur

• Scie Légère pour faciliter la mise en service et la maintenance

- 19 -

Page 20

LISTE DES PIÈCES

ART # DESCRIPTION

P

60089-1-N Ecrou

60089-2-N Rondelle

0089-3-N Capot de lame

6

60089-4-N Couteau à déchirer

60089-5-N Boulon

60089-6-N Table

60089-7-N Tige de fixation

0089-9-N Plaque de fixation

6

60089-10-N Ressort

60089-11-N Entretoise carrée

60089-12-N Vis à tête hexagonale

60089-13-N Rondelle

60089-14-N Barre d’appui

60089-15-N Plaque de fixation supérieure

60089-16-N Rondelle plate

60089-17-N Boulon de raccordement

60089-18-N Goupille fendue

60089-19-N Levier de fixation

60089-20-N Vis

60089-21-N Rondelle

60089-22-N Carter de lame inférieur

ART # DESCRIPTION

P

60089-23-N Ecrou

60089-24-N Bride extérieur

0089-25-N Lame

6

60089-26-N Bride intérieur

60089-27-N Plaque de lame inférieur

60089-28-N Vis

60089-29-N Rondelle de ressort

0089-30-N Rondelle

6

60089-32-N Ecrou

60089-33-N Bâti

60089-36-N Vis

60089-37-N Crochet d’enroulement du cordon

60089-39-N Poignée

60089-41-N Moteur

60089-42-N Vis

60089-44-N Rondelle en étoile

60089-45-N Bague anti-traction

60089-46-N Câble et prise

60089-47-N Interrupteur de sécurité

60089-48-N Plaque

60089-49-N Réservoir d’eau

SPÉCIFICATIONS

MOTEUR: 120V~ 60Hz

AMPÈRES: 3.8 A

RPM: n03600 Tours/min

LAME: 180 mm

ARBRE: 16 mm

ÉPAISSEUR MAX de CARREAU à 90°: 34 mm

ÉPAISSEUR MAX de CARREAU à 45°: 20 mm

DIMENSIONS: 38.4 cm x 39.5 cm

POIDS NET: 28.6lbs/ 13Kg

COUPE LES CARREAUX de: Illimité

- 20 -

Page 21

PIÈCES ÉCLATÉES

- 21 -

Page 22

INSTRUCCIONES GENERALES DE SEGURIDAD

ea este manual del usuario en su totalidad y asegúrese de entender todas las pautas de seguridad.

L

1. MANTENGA LAS PROTECCIONES EN SU LUGAR y con el orden apropiado para trabajar.

2. REMUEVA LAS LLAVES DE AJUSTE & LAS LLAVES INGLESAS. Antes de encender la sierra eléctrica para

cortar losetas asegúrese que haya quitado las llaves inglesas y las llaves de tuercas de ajuste.

3. MANTENGA LIMPIA SU ÁREA DE TRABAJO. Los accidentes suelen ser más comunes en las áreas que estén

desordenadas o por bancas en el área de trabajo.

4. MANTÉNGASE ALERTA AL UTILIZAR LA SIERRA. La falta de atención por parte del operador puede

ocasionar accidentes graves.

5. NO LA UTILICE EN AMBIENTES PELIGROSOS. No utilice herramientas eléctricas en lugares húmedos o

mojados, ni las exponga a la lluvia. Mantenga bien iluminada el área de trabajo.

6. MANTENGA A LOS NIÑOS ALEJADOS. Todos los visitantes deben mantenerse a una distancia considerable

del área de trabajo.

7. ARME SU LUGAR DE TRABAJO A PRUEBA DE NIÑOS, utilizando candados, interruptores principales, o

quitando las llaves de encendido.

8. UTILICE LA HERRAMIENTA CORRECTA. No intente utilizar herramientas o accesorios para realizar un trabajo,

en el cual la herramienta no ha sido diseñada para esa función.

9. UTILICE UN CABLE DE EXTENSIÓN ADECUADO. Asegúrese de que el cable de extensión está en buenas

condiciones. Cuando utilice un cable de extensión, asegúrese de que sea lo suficientemente pesado para

transportar la corriente que requerirá el producto. Un cable de menor tamaño al requerido causará una caída

en el voltaje de paso y dará como resultado la pérdida de energía y el recalentamiento. La tabla (ver la

TABLA 1) muestra el tamaño correcto que debe usarse, teniendo en cuenta la longitud del cable y la

clasificación de amperios de la placa de datos. Si tuviera dudas, utilice el siguiente indicador más pesado.

Cuanto menor sea el número del indicador, más pesado será el cable.

10. NO FUERCE LA HERRAMIENTA. Ha sido diseñada para funcionar a niveles de máxima seguridad

y rendimiento.

11. NO FUERCE EL MATERIAL QUE DEBE CORTAR. Siempre deje que la cuchilla corte a la velocidad para la que

fue diseñada.

12. UTILICE UNA VESTIMENTA ADECUADA. No use ropa suelta, corbatas, anillos, pulseras, u otros artículos de

joyería que pudieran quedar atrapados en las partes móviles. Se recomienda usar calzado antideslizante. Use

una cubierta protectora para el cabello si lo tuviera largo.

13. SIEMPRE USE GAFAS DE PROTECCIÓN. También use máscaras protectoras para la cara y el polvo en el caso

de operaciones de corte comercial. Las gafas comunes sólo tienen cristales resistentes a los impactos, pero

NO son gafas de seguridad.

14. SEGURIDAD AL TRABAJAR. Utilice una tenaza en lugar de la mano para sostener el trabajo cuando sea

necesario. Esta medida de seguridad le permite utilizar ambas manos para el funcionamiento adecuado de la

herramienta.

15. NOTRATE DE EXTENDERSE MÁS DE LO NECESARIO. Mantenga su posición y el equilibrio en todo

momento.

16. MANTENGA LAS HERRAMIENTAS EN BUEN ESTADO. Mantenga las herramientas limpias y en buen estado

para trabajar para obtener un máximo rendimiento de seguridad. Siga las instrucciones para lubricar y

cambiar los accesorios.

17. DESCONECTE LAS HERRAMIENTAS ANTES DE HACERLE ALGÚN ARREGLO - al cambiar accesorios, como

cuchillas, puntas, elementos cortantes, etc.

18. REDUZCA EL RIESGO DE UN ENCENDIDO INVOLUNTARIO. Asegúrese de que la herramienta se encuentra

en posición de APAGADO antes de enchufarla.

19. UTILICE LOS ACCESORIOS RECOMENDADOS. Consulte el manual del usuario para los accesorios

recomendados. El uso de accesorios inadecuados puede ocasionar accidentes.

20. NO REALICE CORTES EN SECO CON DISCOS DE DIAMANTE DISEÑADOS PARA REALIZAR CORTES CON

AGUA.

21. ASEGÚRESE DE USAR LA CUCHILLA CORRECTA para el trabajo que está realizando.

22. NUNCA SE APOYE SOBRE LA HERRAMIENTA. Puede tener un accidente grave si la herramienta se mueve o

si se toma contacto involuntario con la parte cortante.

- 22 -

Page 23

23. REVISE LAS PARTES DAÑADAS. Antes de volver a utilizar la herramienta debe revisar cuidadosamente la(s)

parte(s) dañada(s), (por ejemplo la protección), para saber si funcionará en forma adecuada y cumplirá con

su función. Revise la alineación de las partes móviles, la unión de las mismas, si se rompieron,

uperpusieron y cualquier otra condición que pueda afectar el funcionamiento de la sierra. Las protecciones

s

u otras partes que estén dañadas deben repararse o reemplazarse adecuadamente.

24. ASEGÚRESE DE QUE EXISTA UN FLUJO CONTINUO DE AGUA en ambos lados del disco de diamante

durante el funcionamiento.

5. REVISE CUIDADOSAMENTE LOS DISCOS DE DIAMANTE EN CASO DE GRIETAS, RAJADURAS, QUE LA

2

MATRIZ DE DIAMANTE FALTE O QUE ESTÉ DESALINEADO. Reemplace las cuchillas dañadas

inmediatamente. NO USE DISCOS DAÑADOS. Pueden causar accidentes graves.

26. DIRECCIÓN DE LA ALIMENTACIÓN. Solamente coloque el trabajo en la cuchilla en dirección contraria a la

rotación de la cuchilla.

27. NO ALTERE EL ENCHUFE O USE UN TOMACORRIENTE DE 2 PUNTAS. Esta sierra está equipada con un

enchufe eléctrico de 3 puntas.

28. NUNCA DEJE LA HERRAMIENTA ENCENDIDA SIN PRESTARLE ATENCIÓN. Apáguela. No deje la herramienta

hasta que se haya detenido completamente.

29. COLOCACIÓN DE LA SIERRA ELÉCTRICA PARA

LOSETAS (Ver el FIGURA 1)

A. Para evitar que el tomacorriente o enchufe del

accesorio se humedezcan, coloque la sierra

eléctrica para losetas hacia un lado del

tomacorriente que se encuentra en la pared,

FIGURA 1

CABLE DE

ALIMENTACIÓN

SIERRA PARA

BALDOSAS

SUPERFICIE

DE APOYO

para que el agua no caiga sobre éste o el

enchufe. El usuario debería realizar una

“vuelta de goteo” en el cable que conecta la

sierra al tomacorriente. La “vuelta de goteo”

es la parte del cable por debajo del nivel del

tomacorriente, o el conector si se utiliza un

cable de extensión, que evita que el agua se

deslice por el cable y entre en contacto con el

tomacorriente.

B. Si el enchufe o el tomacorriente se

VUELTA DE

GOTEO

humedecieren, no desenchufe el cable.

Desconecte el fusible o el interruptor

automático que suministra electricidad a la

herramienta. Luego desenchúfela y revise si

hay agua en el tomacorriente.

30. REVISE CUIDADOSAMENTE LOS DISCOS DE DIAMANTE en caso de roturas, rajaduras, matriz de diamante

faltante o alguna condición que le falte alineación. Reemplace las cuchillas inmediatamente. NO USE

CUCHILLAS DAÑADAS. Pueden causar accidentes graves.

REQUERIMIENTOS ELÉCTRICOS

• ESTA SIERRA ELÉCTRICA PARA LOSETAS DEBE TENER UNA CONEXIÓN POLO A TIERRA mientras está en uso

para evitar que el operador sufra una descarga eléctrica.

• EN EL CASO DE MAL FUNCIONAMIENTO O FALLA ELÉCTRICA, la conexión polo a tierra proporciona un

suministro de menor resistencia de corriente eléctrica para reducir el riesgo de una descarga eléctrica. Esta

herramienta está equipada con un cable eléctrico con un conductor con conexión polo a tierra y un enchufe

con conexión polo a tierra. Conecte el enchufe eléctrico de 3 puntas a una toma de 3 polos debidamente

instalado y con una conexión polo a tierra conforme a los códigos y regulaciones locales.

• NO MODIFIQUE EL ENCHUFE SUMINISTRADO si éste no se adapta la toma. Instale la toma adecuado con la

ayuda de un electricista profesional.

• LA CONEXIÓN INADECUADA DEL CONDUCTOR CON LA CONEXIÓN POLO A TIERRA DEL EQUIPO PUEDE

OCASIONAR UNA DESCARGA ELÉCTRICA. El conductor con aislamiento que posee una superficie externa

verde (con o sin franjas amarillas) es el conductor de conexión polo a tierra del equipo. Si fuera necesario

reparar o reemplazar el cable eléctrico o enchufe no conecte el conductor de conexión polo a tierra del

equipo a una terminal activa.

- 23 -

Page 24

• CONSULTE A UN ELECTRICISTA PROFESIONAL si no entendiera completamente las instrucciones para la

ADVERTENCIA

conexión polo a tierra; o si tuviera dudas acerca de si la herramienta está conectada correctamente polo a tierra.

UTILICE SOLAMENTE CABLES DE EXTENSIÓN DE 3 CONDUCTORES que poseen enchufes de conexión polo

•

a tierra de 3 puntas y tomacorrientes de 3 polos que aceptan el enchufe de la sierra eléctrica para

cortar losetas.

• REPARE O REEMPLACE INMEDIATAMENTE EL CABLE GASTADO O DAÑADO.

• SI EL ENCHUFE O TOMACORRIENTE SE HUMEDECIERAN, NO DESENCHUFE EL CABLE. Desconecte el

usible o el interruptor automático que suministra electricidad a la herramienta. Luego desenchúfela y revise

f

si hay agua en el tomacorriente.

• CON ESTE PRODUCTO SÓLO PUEDEN USARSE CABLES DE EXTENSIÓN CALIFICADOS POR UL.

• EL USO INADECUADO DE CABLES DE EXTENSIÓN PUEDE PRODUCIR UN FUNCIONAMIENTO DEFICIENTE

DE LA HERRAMIENTA, que puede dar como resultado el recalentamiento. Asegúrese de que el cable de

extensión tenga la potencia adecuada para suministrar una corriente eléctrica suficiente al motor. Para

calibrar su herramienta en forma adecuada consulte el siguiente cuadro (TABLA 1).

• NO TOQUE CON LOS DEDOS las terminales del

enchufe al conectar o desconectar el enchufe del toma.

• ESTA SIERRA ELÉCTRICA PARA CORTAR LOSETAS

DEBE SER INSTALADA APROPIADAMENTE POLO A

TIERRA. Si no lo estuviera aumentaría enormemente el

FIGURA 2

TORNILLO METÁLICO

(A) POLO A TIERRA

riesgo de descargas eléctricas y accidentes,

particularmente si se utilizara en lugares húmedos o

cercanos a cañerías.

NOTA: Esta herramienta está diseñada para ser usada en

un circuito que tiene un toma igual al que aparece en la

FIGURA 2 (A). La herramienta tiene un enchufe de

conexión a tierra igual al enchufe que aparece en la

(B) CAJA DE TOMA CON POLO

A TIERRA

(C) ADAPTADOR DE POLO A TIERRA

(No autorizado en Canadá)

FIGURA 2 (A). Puede utilizarse un adaptador temporal

igual al que aparece en la FIGURA 2 (B) y (C), para

conectar este enchufe a un tomacorriente de 2 polos según se muestra en la FIGURA 2 (B), si un electricista

calificado puede instalar en forma apropiada una toma adecuado con conexión polo a tierra. Las puntas rígidas

de color verde que se extienden desde el adaptador deben conectarse a una conexión a tierra permanente como

una caja de salida adecuada con conexión a tierra.

EL USO INADECUADO PUEDE OCASIONAR GRAVES ACCIDENTES.

· Mantenga los dedos y la ropa que esté suelta alejados del disco de diamante giratorio.

· Sea sumamente cuidadoso al cortar losetas. Asegúrese de que las manos y los dedos estén alejados de la

ranura de la cuchilla en la mesa corrediza. Puede rasparse, cortarse o apretarse los dedos gravemente

mientras la mesa está en movimiento, generalmente al finalizar su trayectoria.

· Si no se siguen las instrucciones de funcionamiento puede producirse una descarga eléctrica.

PARA SU SEGURIDAD LEA EL MANUAL DE INSTRUCCIONES ANTES DE PONER EN FUNCIONAMIENTO

LA SIERRA.

· Use protección para los ojos.

· Use una máscara protectora siempre que sea necesario.

· Desconecte la sierra antes de hacerle alguna reparación, cuando le cambie los discos de diamante, y antes

de limpiarla.

· Use la herramienta sólo con discos de diamantes que tengan los de bordes libres de aberturas y ranuras.

· Reemplace el disco de diamante que esté dañado antes de poner la sierra en funcionamiento.

· No llene la bandeja de agua por encima de la línea marcada para llenarlo.

- 24 -

Page 25

CABLES DE EXTENSIÓN (ALARGADORES)

. Utilice solamente los cables de extensión destinados para uso en áreas exteriores. Puede identificarlos con la

1

leyenda “Pueden usarse con dispositivos para exteriores: guardar en el interior cuando no se use.” Utilice

solamente los cables de extensión que tengan una clasificación eléctrica no menor a la clasificación del

producto. No utilice el cable de extensión si está dañado, reemplácelo. Examine el cable de extensión antes

de usarlo y suspenda el uso si está dañado. No maltrate el cable de extensión y no lo desconecte de un

irón. Mantenga el cable alejado del calor y los bordes filosos. Siempre desconecte el cable de extensión del

t

tomacorriente antes de desconectar el producto del cable de extensión.

2. ADVERTENCIA: Para reducir el riesgo de electrocución, mantenga todas las conexiones secas y lejos del

suelo. No toque el enchufe con las manos mojadas.

3. El/los circuito/s o toma/s que se usarán con la sierra para losetas/azulejos deben contener un Interruptor de

Circuito Polo a Tierra (GFCI) como protección. Se pueden obtener tomacorrientes con protección GFCI

incorporada para usarse de acuerdo con esta medida de seguridad.

4. UTILICE UN CABLE DE EXTENSIÓN ADECUADO. Asegúrese de que el cable de extensión esté en buenas

condiciones. Cuando utilice un cable de extensión, asegúrese de que sea lo suficientemente pesado para

transportar la corriente que requiera el producto. Un cable de tamaño reducido causará una caída en el

voltaje de paso, y dará como resultado la pérdida de energía y el recalentamiento. La tabla que aparece a

continuación muestra el tamaño correcto que debe usarse, teniendo en cuenta la longitud del cable y la

clasificación de amperios en la placa de datos. Si tuviera dudas, utilice el siguiente indicador más pesado.

Cuanto menor sea el número del indicador, más pesado será el cable.

TABLA 1

Longitud total del cable en pies

18 16 16 14

18 16 14 12

16 16 14 12

14 12

No recomendado

Régimen de Amperios

Más de No más de

06

6 10

10 12

12 16

Voltios

120 V 8.7 m 15.24 m 30.48 m 60.96 m

240 V 15.24 m 30.48 m 60.96 m 91.44 m

Calibre Estándar Americano (AWG)

NOTA: Cuando utilice un cable de extensión, asegúrese de que todos los cables no tengan un calibre menor al #

12, con una potencia de 20-amperios como mínimo, y estén equipados con enchufes de 3 puntas. El uso de

cualquier cable menor puede ocasionar el recalentamiento o que se queme el motor. Se recomienda que un

electricista revise el voltaje en el motor de la sierra para asegurarse de que tiene el voltaje adecuado para que la

sierra funcione de manera eficaz y segura.

GUÍA ESPECÍFICA DE USO

1. Asegúrese de que la flecha direccional marcada en el disco de diamante corresponda con la dirección de

rotación del motor.

2. Con la sierra desconectada de la fuente de energía, gire el disco de diamante manualmente para asegurarse

de que esté libre de obstrucciones.

3. Siempre mantenga limpios el mandril de sujeción del disco de diamante y los collares.

4. Asegúrese de que el perno de sujeción del disco de diamante esté bien ajustado.

5. Nunca intente cortar a mano alzada. Siempre asegúrese de que la loseta que va a cortar esté firmemente

presionada contra el tope-guía para cortar al hilo.

6. Asegúrese de que la pieza de trabajo que se cortará tenga suficiente espacio para moverse hacia los

costados. De no ser así, la pieza cortada podrá quedarse trabada en el disco.

7. Nunca corte más de una loseta por vez.

8. Nunca corte piezas demasiado pequeñas que no queden bien aseguradas contra el tope de la guía al cortar,

y deje suficiente espacio para que la mano esté a una distancia segura del disco.

9. Asegúrese de que la mesa y el área circundante estén libres, a excepción de la loseta a cortar.

10. Antes de cortar una pieza de loseta, deje que la sierra funcione libremente durante unos segundos. Si hace

un sonido extraño o vibra excesivamente, apáguela inmediatamente y desconéctela de la fuente de energía.

- 25 -

Page 26

11. Deje que el disco de diamante adquiera la máxima velocidad antes de comenzar a cortar.

ATENCIÓN

12. Deje que el disco se detenga completamente antes de quitar cualquier material atascado de alrededor del

rea del disco.

á

13. Nunca deje que el disco funcione en seco. No mantener la bandeja para agua en el nivel recomendado

puede causar el sobrecalentamiento del disco de diamante.

INSTALACIÓN Y FUNCIONAMIENTO

Siga completamente todas las instrucciones de montaje e instalación antes de conectar la sierra a una fuente de

alimentación o de encender el motor.

Abra la caja con cuidado y retire todos los componentes de la sierra y materiales de embalaje. Asegúrese de

haber verificado que ha sacado cada elemento antes de descartar el contenedor o los materiales de embalaje.

La caja contiene:

FIGURA 3

• Tanque del Agua • Protector del Disco

• Llave A • Soporte del Protector del Disco

• Llave B • Guía Paralela

• Disco de Diamante • Calibrador de Ángulos

de Banda Continua

de 180 mm

En las siguientes páginas se ilustra paso a paso la instalación de diversos

componentes y el funcionamiento de la sierra. ¡Lea detalladamente las

instrucciones antes de usar esta sierra!

SUJETANDO EL CORTADOR DE LOSETAS AL BANCO DE TABAJO:

1. Taladre tres orificios en el banco de trabajo con las mismas

dimensiones en la FIGURA 3.

2. Ajuste la maquina con los pernos al banco de trabajo.

INSTALACIÓN DEL DISCO DE DIAMANTE Y LA PROTECCIÓN DE

SEGURIDAD PARA EL DISCO:

Solamente Utilice Discos de Diamante de Banda Continua de 180 mm.

1. Desconecte la maquina de la electricidad.

2. Remueva el tanque de agua que está debajo de la maquina.

3. Remueva el protector del disco inferior, removiendo los tres

tornillos que están a cada lado del protector del disco inferior

FIGURA 4.

4. Utilice la Llave A y la Llave B para desajustar y remover la tuerca

del eje del motor como lo muestra la FIGURA 5.

5. Deslice la pestaña externa FIGURA 5 y el Disco de Diamante hacia

afuera del eje del motor.

6. Deslice el Disco de Diamante nuevo y la pestaña exterior en el eje

del motor. Nota: Asegúrese que la flecha que indica la dirección

impresa en el disco esté mirando en contra reloj, cuando está

observándola la maquina desde la tuerca del eje.

7. Inserte y ajuste el perno del eje en el eje del motor para asegurar

el disco de diamante.

8. Reinstale el protector del disco inferior.

FIGURA 4

FIGURA 5

- 26 -

Page 27

LLENADO Y DESAGUADO DE LA BANDEJA DE AGUA:

ADVERTENCIA

ADVERTENCIA

. Llene la bandeja con agua fresca durante el tiempo que esté utilizando la sierra.

1

2. Remueva la bandeja y chorree el agua.

ARRANQUE Y PARADA DEL MOTOR:

sta maquina tíene un interruptor magnético para una operación más segura.

E

1. Conecte la unidad eléctrica al nivel de voltaje y frecuencia correspondientes (120 Voltios, 60 Hertzios).

2. Para encender la maquina, presione el interruptor hacia donde dice “ON.”

3. Para pagar la maquina, presione el interruptor hacia donde dice “OFF.”

Para su propia seguridad, siempre mantenga el interruptor en “OFF” mientras no esté utilizando la sierra. En el caso

que la electricidad falle, asegúrese de colocar el interruptor en “OFF” para que cuando la electricidad regrese la

maquina no se encienda de nuevo.

Solamente utilice esta maquina después de haberla ensamblado

completamente y después que halla sido atornillada en el banco de trabajo

PASOS PARA HACER UN CORTE LINEAL:

1. Utilizando un lápiz para marcar, trace una línea sobre la loseta que

desea cortar.

2. Desatornille la guía paralela FIGURA 6 y deslícela hacia el borde

de la mesa.

3. Alinee la línea marcada con el disco de diamante.

4. Ajuste la guía paralela con el borde de la loseta y bloquee la guía

paralela en la posición deseada.

5. Encienda la maquina presionando el interruptor hacia “ON”, y