Page 1

Refrigeration

Systems

Installation

Manual

7/16 Rev. A 57-02510

Page 2

Table of Contents

Tools Required 3

General Information 4-7

Unpacking & Inspection for Ceiling Mount 4

Unpacking & Inspection for Remote 5

Latch and Diffuser Installation 6-7

General Installation Instructions 8-11

Ceiling Mount Refrigeration Systems 8-9

Wall Mount Refrigeration Systems 10

Freezer Models 100 & 150 or Cooler Model 075 11

Remote Refrigeration Systems 12-13

With Electric Vaporizer 12

With Optional Electric Condensate Vaporizer 13

Instructions for Pre-Charged Lines 14-15

Instructions for Wire Harness 16

Outdoor Systems 17-18

Membrane Roofing Material 17-18

Operation 19-21

Standard Temperature (Cooler) Systems 19

Low Temperature (Freezer) Systems 20-21

Maintenance 22

Maintenance Analysis 23

Page 3

3

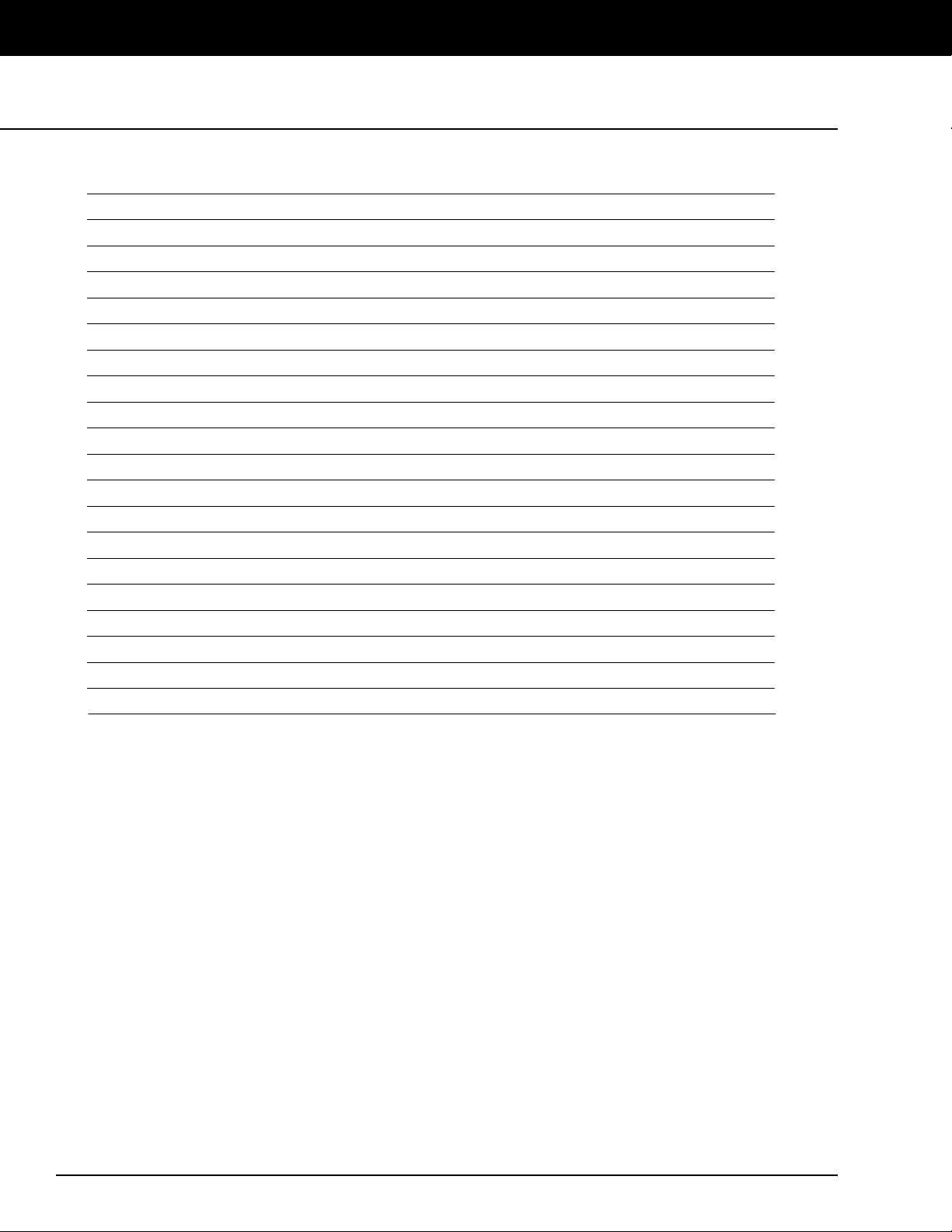

Tools Required fof Uncrating and Installation of the Refrigeration System

Tools Required

•

Safety Glasses

•

Metal Snips

•

Pry bar

•

Hammer

•

Adjustable open end wrench (2)

•

Drill driver

•

Pencil

Page 4

4

Refrigeration Systems-General Information

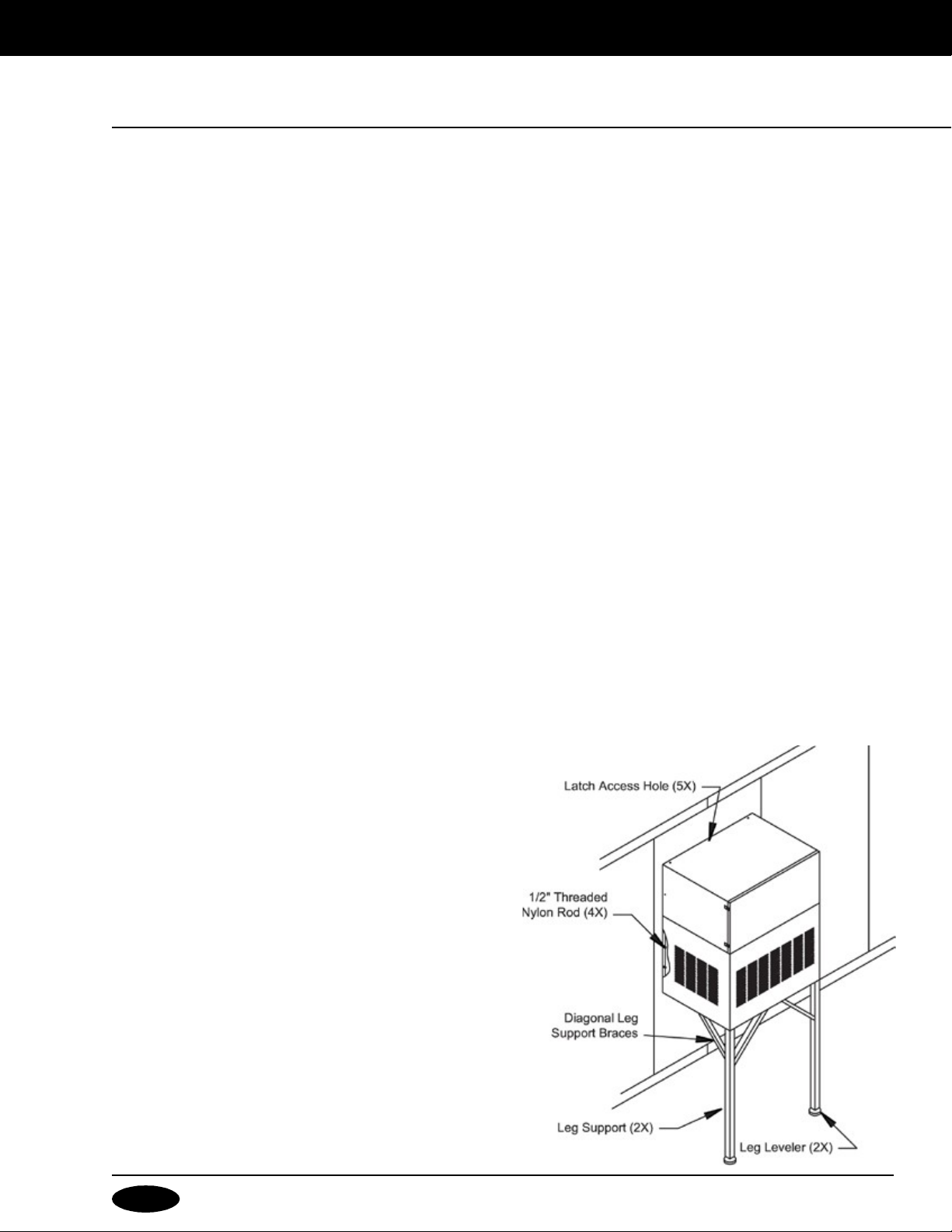

CEILING MOUNTED REFRIGERATION SYSTEM

GENERAL INFORMATION

This Refrigeration System was produced utilizing the latest in manufacturing technology, the highest quality

materials available, along with innovations that make it a distinctive product in its field. Despite rigid controls in

the production of the product, there is no substitute for thoroughly reading and UNDERSTANDING the instructions

that follow. The result will be an orderly and efficient installation. Please take the time to follow the steps explicitly!

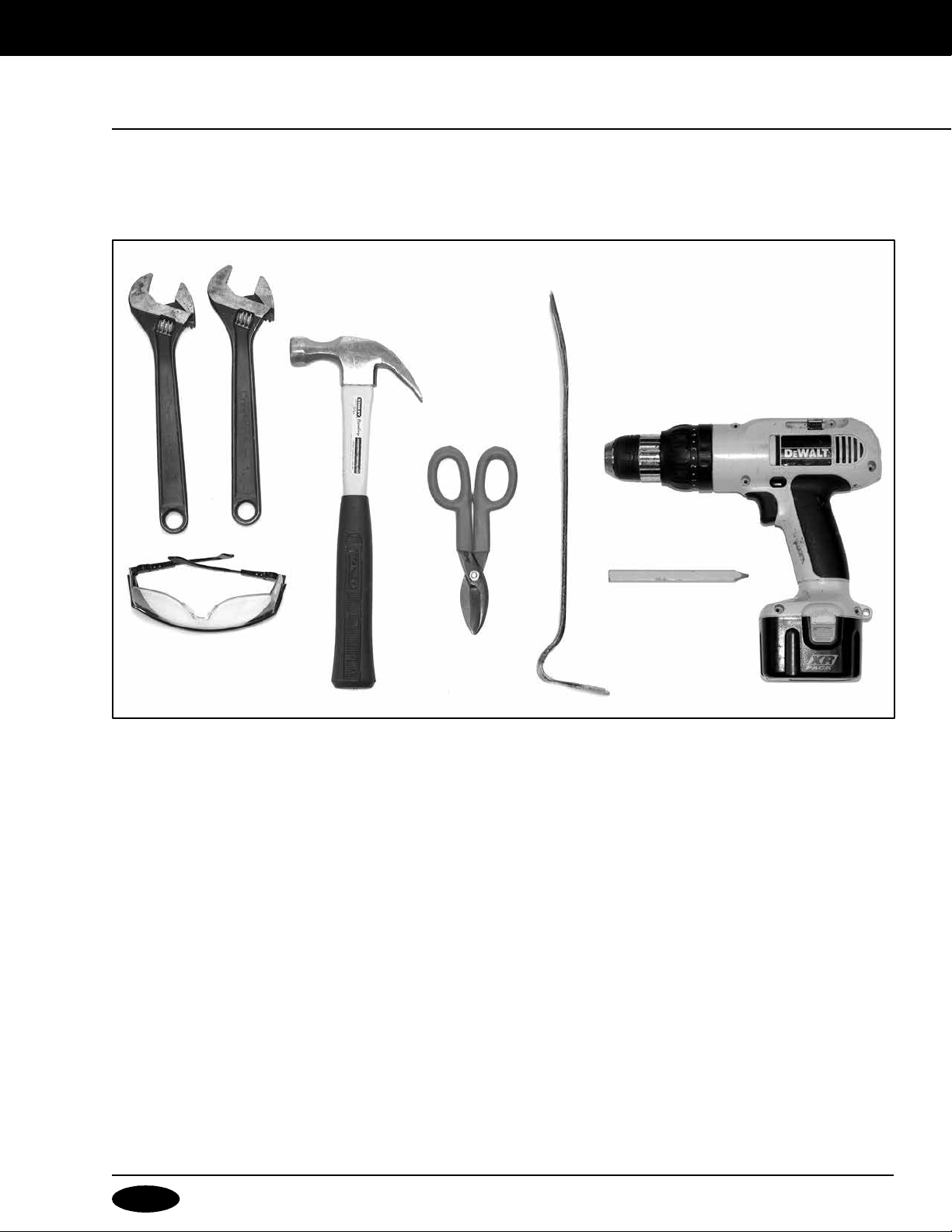

UNPACKING & INSPECTION--CEILING MOUNT SYSTEM

Check the Delivery Receipt for the number of pieces that made up the shipment and make sure that the number

of pallets, boxes or crates agrees with that number. Each piece should be clearly marked with the same five-digit

order number that appears on the Delivery Receipt as the shipper's number.

Examine the general condition of the shipment and, as soon as unpacking is completed, carefully inspect all parts

for possible shipping damage. If damaged parts are discovered, contact the supplier immediately.

Delivery Receipt

Page 5

Refrigeration Systems-General Information

5

UNPACKING & INSPECTION--REMOTE REFRIGERATION SYSTEMS

Check the Delivery Receipt for the number of pieces that made up the shipment and make sure that the number

of pallets, boxes or crates agrees with that number. Each piece should be clearly marked with the same five-digit

order number that appears on the Delivery Receipt as the shipper's number.

Examine the general condition of the shipment and, as soon as unpacking is completed, carefully inspect all parts

for possible shipping damage. If damaged parts are discovered, contact the supplier immediately.

It is recommended the condensing unit be elevated from the deck a minimium of 12"-18" to ensure the condenser

fan is not drawing or pulling heat reflected off the building roof or pavement in a grade level installation in which

the summer heat may exceed 120°°°°F.

Page 6

Refrigeration Systems-General Information

6

CAPSULE PAK™ LATCH AND DIFFUSER INSTALLATION INSTRUCTIONS

CAUTION: REMOVE DIFFUSER PRIOR TO CEILING PANEL INSTALLATION!

1. Remove diffuser from ceiling panel before installing ceiling panel.

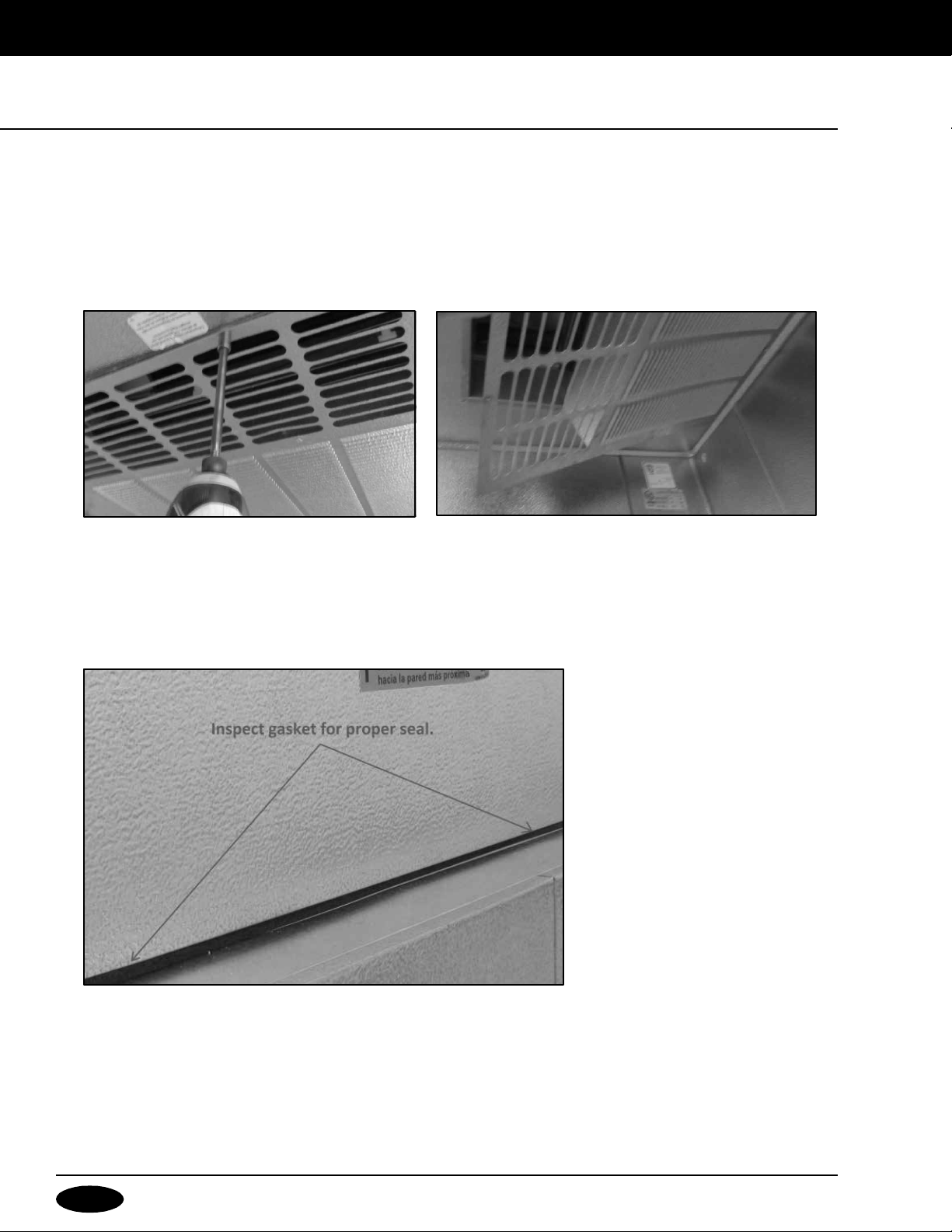

Figure 1

2. Lift Capsule Pak™ into position on top of walk-in. Note: Do not slide Capsule Pak™ into position as cowl

gasket damage will occur. If the Capsule Pak™ must be slid into position, place Capsule Pak™ on a piece of

cardboard prior to moving to prevent gasket damage.

Figure 2

3. Inspect cowl gasket to ensure proper placement.

Figure 3

Page 7

Refrigeration Systems-General Information

7

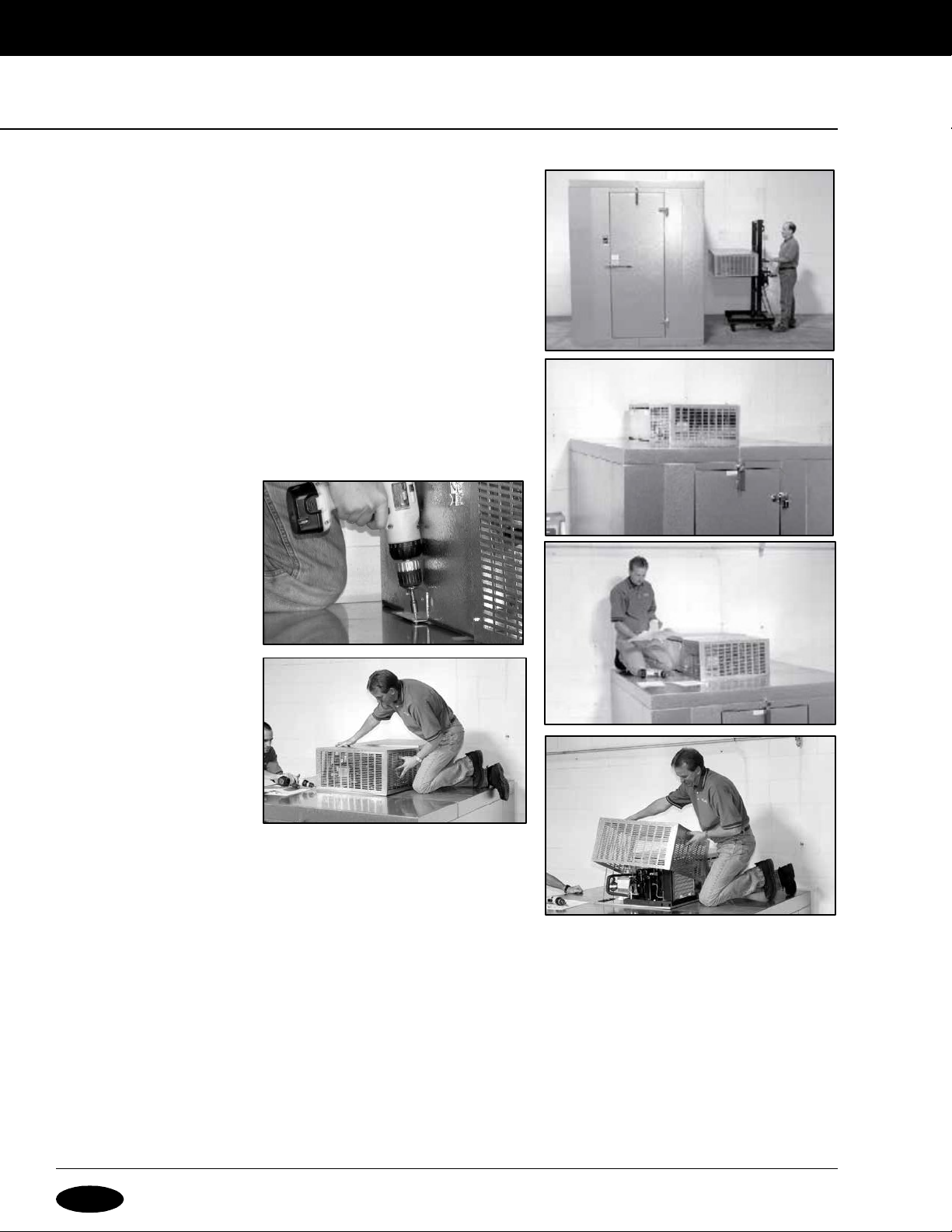

4. Secure interior latches.

Figure 4

5. Seal cowl to ceiling at gasket seam above diffuser panel using provided silicone.

Figure 6

Figure 5

6. Replace diffuser panel removed in step 1.

Page 8

8

General Installation Instructions

GENERAL INSTALLATION INSTRUCTIONS

This section has the general instructions for installing the ceiling

mounted Refrigeration System. Before proceeding, also see the

following section on mounting "Remote Systems with Electric

Vaporizer", if applicable.

Note: Proper "temporary" interior support must be added during the

installation of the refrigeration.

Note: Due to the weight of these systems, it is highly recommended

that proper lifting equipment, such as a fork lift or scissor lift, be utilized

during installation. Also, be sure to allow for sufficient airflow around

the condenser. Model numbers ending with the letter "A" require

a minimum clearance of two feet for proper unit operation. Model

numbers ending with the letter "B" require a minimum of five inches

behind the unit and open to

the front for proper operation.

If multiple units are located

in the same area, be sure

they do not exhaust hot air

into one another. In addition

to allowing for proper airflow,

consideration should be

given to the final mounting

location of the refrigeration

system relative to the

customer location to avoid

any possible risk of noise

impacting the customer

experience.

Position the insulated

evaporator section of the

Refrigeration System over

the hole in the walk-in ceiling

section.

Align the tabs on the side of the insulated evaporator section with the

predrilled holes in the ceiling section. Fasten latches and seal perimeter

as described in the Latch and Diffuser Installation Instructions found

on pages 6 and 7. When reinstalling the diffuser panel, make sure the ceiling section divider on the panel seals

against the black gasket. Some adjustment may be required by simply bending the ceiling section divider slightly

forward or backward. This will prevent any short cycling of discharge and return air.

Fasten the insulated evaporator section down to the ceiling using the provided drive screws, which can be

found attached to the side of the refrigeration system. CAUTION! This must be done to prevent the entire

refrigeration system from moving during operation.

Note: On smaller refrigeration systems, you may elect to install the system on the ceiling section while the section

is still on the floor. CAUTION! Make sure to fasten down the system to the ceiling panel. The ceiling section and

the refrigeration system may then be erected together in the normal sequence of assembly as shown in the Kold

Locker™ Walk-in Installation Instructions. This method is not practical and should not be used with larger systems

of 100 series or above, such as a 100, 150 or 151 model.

Page 9

General Installation Instructions

9

Note: The process above is the same when locating/installing the insulated evaporator section of a Remote

Refrigeration System.

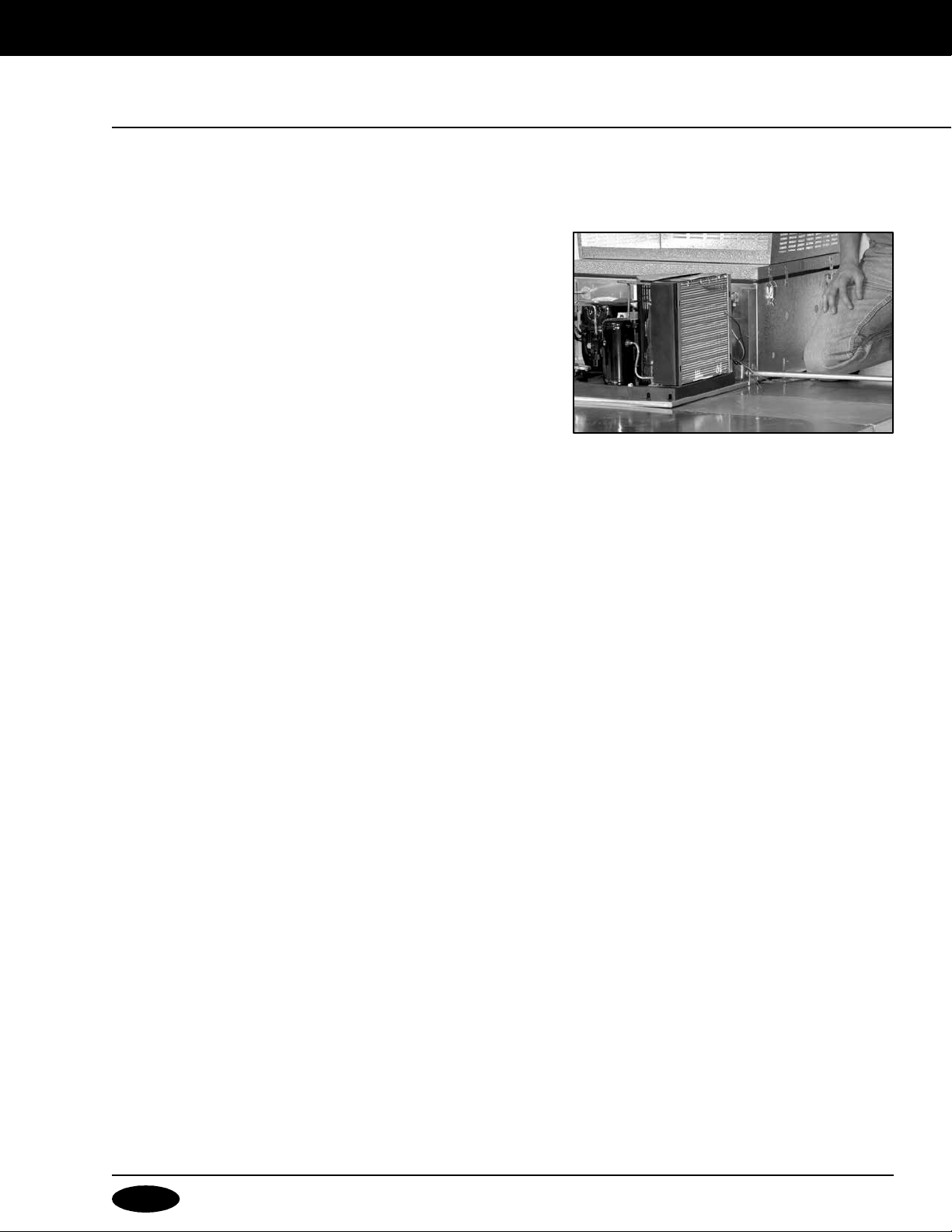

After the system is in place, make sure that the bolts fastening

the condensing unit section to the evaporator section are

loose enough so that the two sections can adjust to the ceiling

surfaces. Note: On large systems, 100 series and above, the

units are placed on a rack assembly and do not have these

bolts connecting the two sections together. No adjustment is

necessary.

Note: Some motor compressors are openly spring mounted to

absorb vibration. Be sure that these bolts are loosened to permit

the compressor to float freely on the springs. A reminder label

is applied to systems where this procedure applies.

Some systems require a permanent connection to an electrical service and a connection at the junction box located

within the condensing unit housing. Refer to the serial tag for all pertinent electrical data. These systems must

be connected to a power supply disconnect switch and wired according to local and national electric codes. No

plumbing drain is required, under normal conditions, since the condensate moisture is dissipated automatically by

a built-in hot gas vaporizer.

Page 10

General Installation Instructions

10

WALL MOUNTED REFRIGERATION SYSTEMS

INSTALLATION INSTRUCTIONS

Note: If the system to be wall mounted is a freezer model 100 or 150 or cooler model 075, please see the next

section with special instructions on mounting these units.

Carefully raise the entire refrigeration system and insert the projecting sleeve of the evaporator section into the

opening of the walk-in wall. While supporting the system, lock it into position by turning the locks exactly as you

did when locking the walk-in sections together. Make sure that the locks are positively engaged and insert the plug

buttons into the lock access holes when finished. Refer to Figure 1.

Note: Some motor compressors are openly spring mounted to absorb vibration. Be sure that these bolts are

loosened to permit the compressor to float freely on the springs. A reminder label is applied to systems where this

procedure applies.

Some systems require a permanent connection to an electrical service and a connection at the junction box located

within the condensing unit housing. Refer to the serial tag for all pertinent electrical data. These systems must be

connected to a power supply disconnect switch and wired according to local and national electric codes.

Figure 1.

Wall Mounted Refrigeration System

No plumbing drain is required, under normal conditions, for indoor installations. A built-in hot gas vaporizer

dissipates the condensate moisture automatically. In outdoor installations, the condensate should be plumbed to

the nearest drain. Check local building codes. Outside drain lines must also be wrapped with a suitable heater wire

if they are ever subjected to below freezing temperatures. Outdoor installations also require the attachment of the

rain hood that will divert rainfall from the upper surface of the evaporator housing. See Figure 1 for an illustration.

Be sure to allow for sufficient airflow around the condenser. A minimum clearance of six inches is required for

installation and a minimum of two feet is required for service consideration. Ambient temperature around the

system should be less than 90°°°°F and 50% RH. If multiple units are located in the same area, be sure they do not

exhaust hot air flows into one another. In addition to allowing for proper airflow, consideration should be given to

the final mounting location of the refrigeration system relative to the customer location to avoid any possible risk

of noise impacting the customer experience.

Please see the section “Instructions for Pre-Charged Lines” if the installation of this system involves the use of

pre-charged lines to connect the evaporator and condenser sections.

Page 11

General Installation Instructions

11

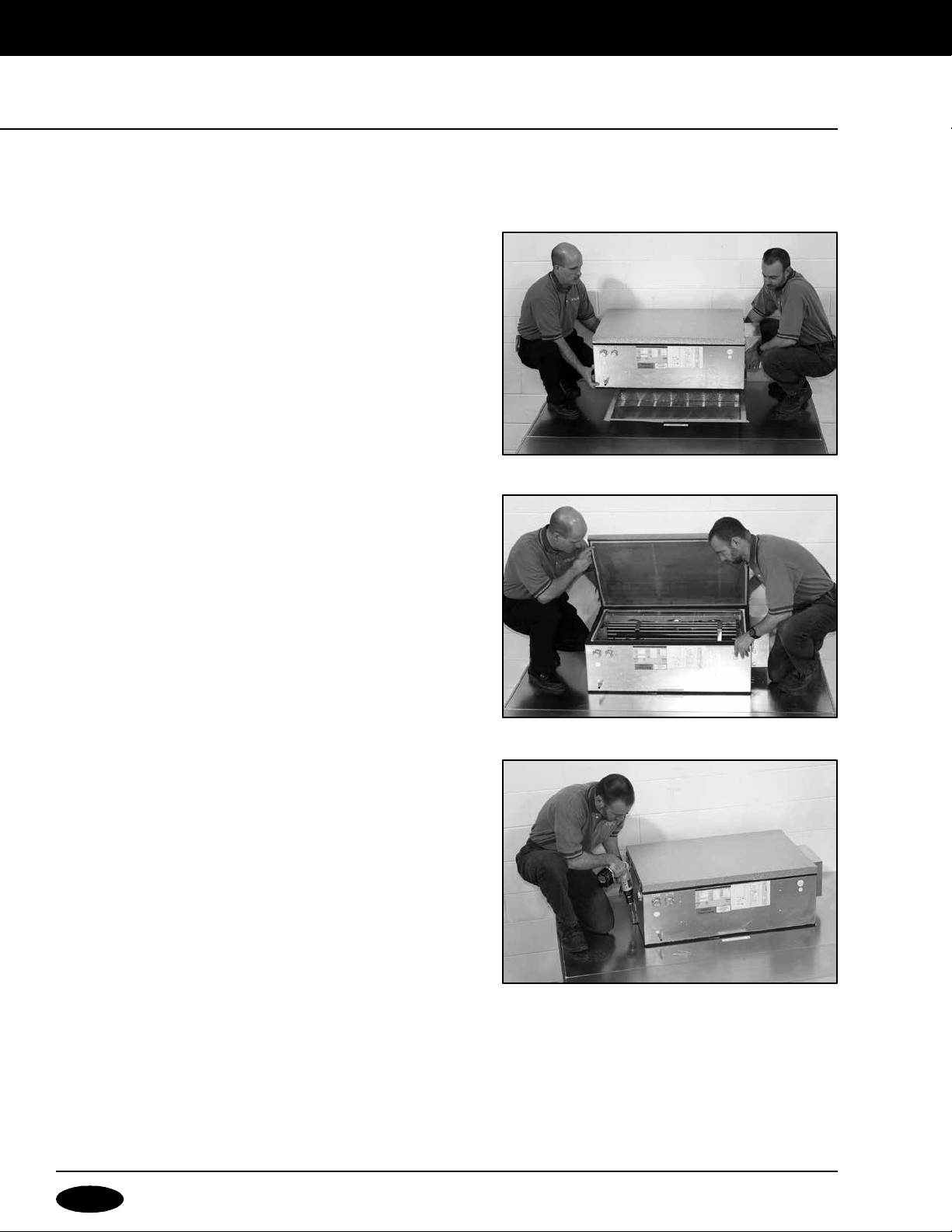

Freezer Models 100 and 150 or Cooler Model 075

1. After uncrating, before attempting to attach the refrigeration system to the walk-in, a substantial temporary

support should be built. The support should be approximately 28 inches high and placed directly below the wall

opening of the walk-in.

Note: Due to the weight of these systems it is highly recommended that proper lifting equipment, such as a fork

truck, be utilized during installation.

2. Lift the refrigeration system onto the temporary support. Determine whether the coil section sleeve is positioned

properly so that it can be inserted into the opening without being bent or damaged. Shim the system appropriately

so that this can be accomplished.

3. Carefully slide the entire system so that the coil section sleeve enters the opening without disturbing the

temporary support below the refrigeration system. Continue until the gasket around the coil section contacts and

seals around the entire perimeter of the coil section. Shim the system and adjust it accordingly so that the gasket

seal will be uniform on all four sides.

4. Using the section-latching wrench provided for the erection of the walk-in, insert the wrench into the latch access

holes of the coil section. Turn each of the locks clockwise until the latches engage the strikes in the walk-in. Turn

the lock until a full stop is encountered. DO NOT REMOVE THE TEMPORARY SUPPORT!

5. Remove the louver assembly and drill four 9/16” diameter holes through the two upright angles of the condensing

unit section. Drill completely through the walk-in wall and insert the 1/2" threaded nylon rods. Secure with the flat

washers and nuts provided. Refer to Figure 2.

6. With the leveling screws threaded completely into the leg support, insert the leg support into the leg retainers

at the outer corners of the condensing unit section. Unscrew the leg leveling screws until they contact the floor or

other supporting surface. Note: If the supporting surface is extremely uneven, suitable shimming material must be

provided under one or both of the leg supports.

7. Attach the diagonal leg support braces using the

threaded fasteners provided. Make the final adjustments

to the leg leveling screws so that they serve as

supporting devices to the outer edge of the refrigeration

system.

8. Insert plug buttons into each of the latch access holes.

9. Remove the temporary support assembly that was

provided in Step 1.

Page 12

12

Remote Refrigeration Systems

REMOTE SYSTEMS WITH ELECTRIC VAPORIZER

Set the Refrigeration System evaporator section over the

hole in the ceiling section. Align the tabs on the side of the

insulated evaporator section with the pre-drilled holes in the

ceiling section. Remove the Diffuser Panel from the ceiling

inside the walk-in to gain access to four latches located along

the perimeter of the cowl. Refer to the Latch and Diffuser

Installation Instructions found on pages 6 and 7. Seal the

seam as described in the instructions. When reinstalling the

Diffuser Panel, make sure that the ceiling section divider

located on the panel seals against the black gasket. Some

adjustment may be required by simply bending the ceiling

section divider slightly forward or backward. This will prevent

any short cycling of discharge and return air.

Fasten the evaporator section down to the ceiling using the

provided drive screws, which can be found taped to the side

of the insulated evaporator section.

CAUTION! This must be done to prevent the entire

refrigeration system from moving during operation.

Page 13

Remote Refrigeration Systems

13

OPTIONAL FEATURE - ELECTRIC CONDENSATE VAPORIZER

Note the location of the condensate drain line coming

from the evaporator. Locate the electric vaporizer so

the condensate will run into it. If the vaporizer cannot

be located at the drain line, use the supplied plastic

tubing, copper elbow, and hose clamp(s) as required to

extend the drain line. Cut the plastic tubing to length as

required.

Provide power to the electric vaporizer per local and

national electric codes.

Page 14

Remote Refrigeration Systems

14

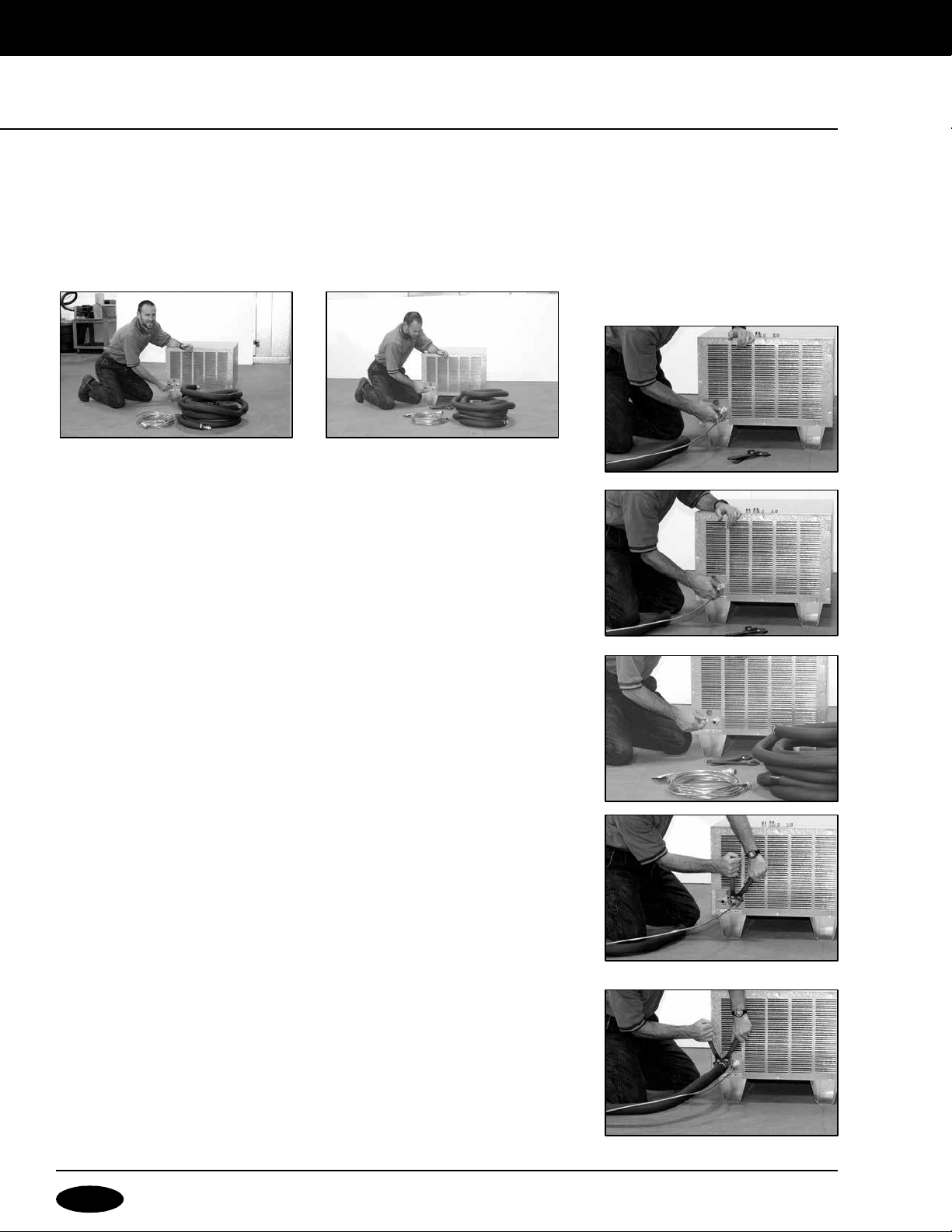

INSTRUCTIONS FOR PRE-CHARGED LINES - REMOTE SYSTEMS

By employing self-sealing refrigeration couplings, the condensing unit section, evaporator section, and the

connecting tubing are separately pre-charged with refrigerant and leak tested at the factory before shipment.

Follow steps 1-8 below to install the connecting tubing at both the condensing unit and the evaporator section.

1. Carefully uncoil the suction line. This is the line covered with a continuous

length of sponge rubber insulation.

2. Carefully uncoil the liquid line. The liquid line is the smaller diameter, bare

copper tube.

3. Before making any connections, determine the routing of both lines and

carefully hand bend them to suit the situation. Keep any bend radius rather

large to prevent kinking the tubing. It is a general practice to route the suction

and liquid line parallel and close together in the installation.

4. Remove the dust caps and plugs from the couplings and inspect them to

see if the synthetic seals are intact.

5. Using a clean cloth, wipe the coupling seals and threaded surfaces to

prevent the inclusion of any dirt or foreign material in the system.

6. LUBRICATE the synthetic seal in the male half of the couplings with

refrigeration oil and thread the two coupling halves together BY HAND to

ensure proper mating of the threads. Note: Make certain that the insulated

suction line is connected to the coupling half marked "Suction Line" and that

the bare tube liquid line is connected to the coupling half marked "Liquid Line".

Note: Always use two wrenches on the coupling body hex nut and on the union

to prevent twisting of the tube while tightening the connections as described in

the next step.

7. Using the proper size wrench on the union nut, tighten until the coupling

bodies bottom, or until a definite resistance is felt. Tighten an additional 1/6 to

1/4 turn. This final turn is necessary to ensure the knife edge metal seal bites

into the brass seat of the coupling halves, forming a leak proof joint.

Note: legs shown in photos are not standard but instead, an optional item.

Connecting to the Condensing Unit Side

Page 15

Remote Refrigeration Systems

15

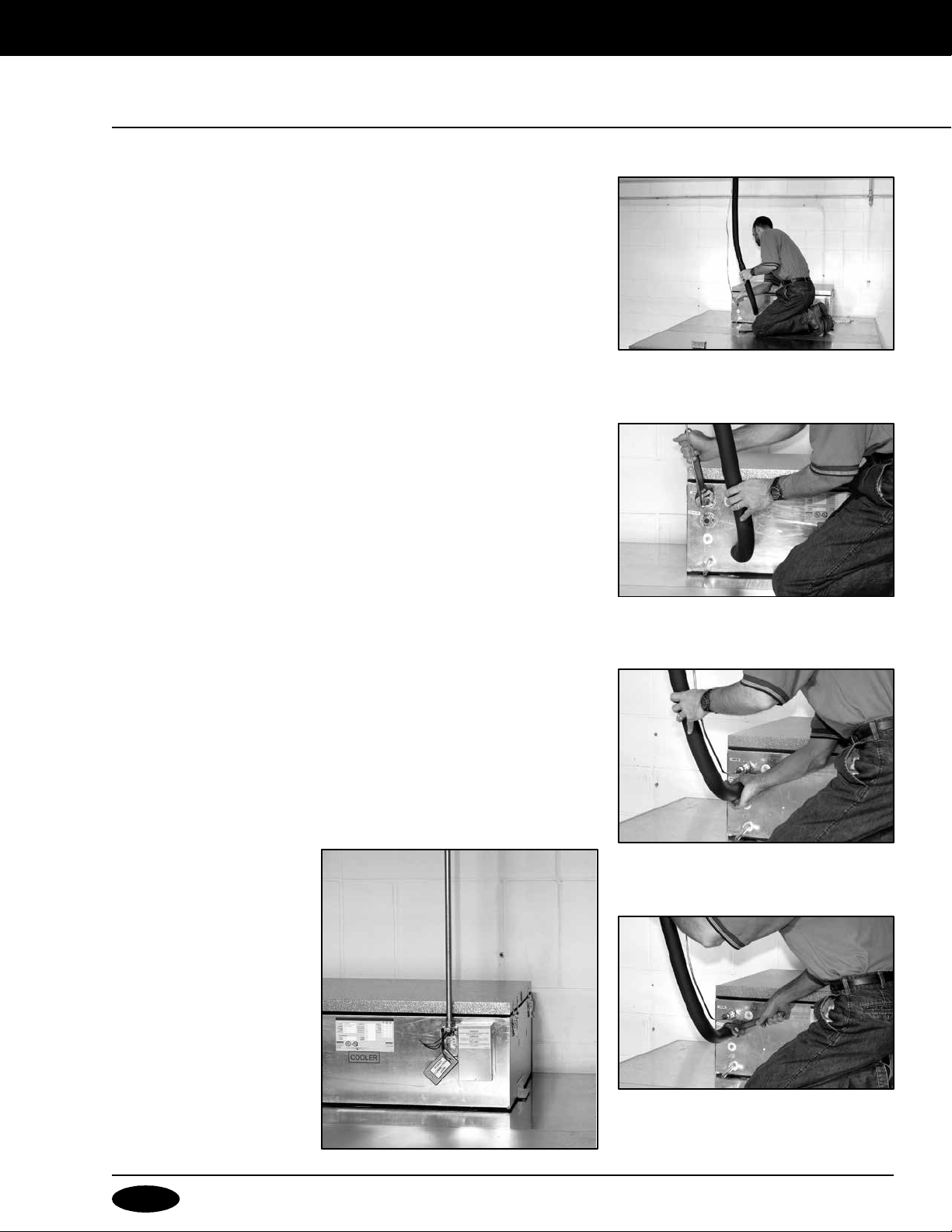

8. Once the suction line is connected, the sponge insulation must be

pulled up to cover the quick connects. Tie or tape off the insulation to

prevent air infiltration and reduce water/ice formation on the suction

line.

All valves are open and the system is ready for operation. Remember,

the refrigeration couplings on this system are self sealing and, if the

need ever arises, the couplings may be disconnected without any loss

of refrigerant.

IMPORTANT: Since this system is equipped with pre-charged

refrigerant lines, it is the installing contractor’s responsibility to ensure

that the quick connect refrigerant couplings are properly mated and

are leak free. It is also their responsibility upon start-up to check the

system for proper operation and make any necessary temperature

control or thermal expansion valve adjustments.

Note: A drain line is required to be run by the contractor for this type

of installation.

CAUTION: Line set must not exceed 3 feet longer than required length

to complete connection or improper oil return may result in compressor

failure. Contact the Service Department with model and serial number

for further assistance.This information is also included on a tag

attached to the line set.

Some systems require a permanent connection to an electrical

service and a connection at the junction box located within the

condensing unit housing. Refer to the serial tag for all pertinent

electrical data. These systems must be connected to a power

supply disconnect switch and wired according to local and

national electric codes.

Connecting to the Evaporator Section Side

Page 16

16

Remote Refrigeration Systems With Wire Harness

1. All systems with a wire harness will have a “K” at or near the end of the model number.

Example: RCPB100DC-A-50K.

2. These systems will come with the wire harness already wired to the condensing unit section of the refrigeration

system.

3. These wire harnesses will have approved seal tight conduit and connectors.

4. Before power is connected to the condensing unit section it should first be wired to the evaporator section with

the wire harness provided.

5. Remove the control box cover on the evaporator section.

6. Make the proper connections inside the control box on the evaporator section as shown in the wiring diagram

provided with the system.

7. Replace the cover on the control box when wiring is completed.

8. Now power can be brought to the condensing unit section of the refrigeration system.

Page 17

Outdoor Systems

17

OUTDOOR SYSTEMS UTILIZING A MEMBRANE ROOFING MATERIAL

1. After the walk-in is completely assembled,

place the curb face down on top of

the ceiling sections (curb is fastened

to crate base during shipping and

must be removed and installed prior to

membrance roof installation). To ensure

proper opening alignment, mark the

outside portion of the curb on the ceiling

sections with a marking pencil.

2. Remove the paper from the gasket and

position the curb, gasket side down, on

the pencil line. Press down firmly. Note:

Movement of the curb is very difficult

after the gasket adheres to the ceiling

section. Refer to Figure 1.

Walk-In

Curb

Alignment Marks

Ceiling Sections

Figure 1

Cutout Line

Fasten to Edge

of Curb Frame

Membrane

Roofing

Opening

3. Lay the membrane roofing material

over the walk-in ceiling sections and

curb leaving a six inch overhang

on all four sides of the walk-in.

Using an utility knife, cut a hole in

the membrane roof approximately

1-1/2” in from the edge of the

opening. (The resulting hole in the

membrane will be smaller than the

ceiling opening). Fold the 1-1/2”

membrane flaps into the opening,

notching the membrane around

the locators and divider. Use either

sheet metal screws, caulk, glue,

etc. to fasten the membrane roofing

material to the inside edge of the

curb frame. Refer to Figure 2.

Walk-In

Figure 2

Page 18

18

Outdoor Systems

Membrane

4. Set the Refrigeration System over the

opening in the curb. Remove Diffuser

Panel from the ceiling inside the walkin to gain access to four latches

located along the inner perimeter of the

cowl. Refer to the Latch and Diffuser

Installation Instructions found on pages

6 and 7. Use the Lock Extensions

supplied with the curb to bridge the

distance between the latches and

strikes. Seal the latched seam as

described in the instructions. When

reinstalling the Diffuser Panel, make

sure that the ceiling section divider

located on the panel seals against the

black gasket. Some adjustment may

be required by simply bending the

ceiling section divider slightly forward

or backward. This will prevent any

short cycling of discharge and return

air. Remove the enclosure from the

condensing unit portion of the system

and drill two 9/16” holes through the

condensing unit base plate, membrane roof material and the foamed

ceiling section. The holes should be located on opposite sides of the

unit. Insert one 1/2” threaded nylon rod into each hole. Apply silicone

sealant around each nylon rod and hole and place one washer and

nut on the condensing unit end of each threaded nylon rod. Place

a second washer and nut on the inside of the walk-in and tighten

securely. Replace the enclosure and attach the outdoor hood with the

drive screws provided. Refer to Figure 3. The nylon rods, washers,

and nuts are provided.

Note: Seal gasket at top of curb with silicone.

Figure 5

be plumbed to the nearest drain. Check local building codes. Outside drain lines must also be wrapped with a suitable heater

wire if they are ever subjected to below freezing temperatures.

Roofing Material

5. Fold all four corners of the membrane roofing

material over the walk-in corners as shown in

Figure 4.

6. Attach the trim and door hood by using the

provided hex head sheet metal screws. All pieces

should be held down 3-1/8” from the ceiling top as

shown in Figure 5. Ensure the trim and membrane

roof material cover the joint between the ceiling

and wall panels. Note: The trim may have to be

cut to fit.

NOTE: In outdoor installations, the condensate should

Figure 3

Fold Membrane

7. Trim off all excess membrane roofing material

from under the terminatin bar with a utility knife

Do not allow the knife to cut the metal panel, as

this will damage the coating and cause rust.

Walk-In

Figure 4

Capsule Pak™

With Hood

Membrane

Roofing

Opening

Page 19

Operation

19

OPERATION

STANDARD TEMPERATURE (COOLER) SYSTEMS

The automatic air defrost Capsule Pak™ Refrigeration System for coolers is a basic, unitized refrigeration system.

The system is designed to provide normal storage temperatures in a Kold Locker™ Walk-in with a minimum of

effort during initial installation. The system consists of a complete condensing unit, an evaporator coil, a method

for controlling the temperature, and a time switch for setting "off cycle" defrost.

Important: It is the installing contractor’s responsibility to check the operation upon start-up and make necessary

temperature control or thermal expansion valve adjustments as required for proper operation.

Note: Capsule Pak™ Refrigeration Systems that are designed for outdoor installation will be fitted with electric

crankcase heaters, electrically heated condensate drain tubes, automatic head pressure control valve, and the

"pump-down cycle".

Refrigeration Controller

Capsule Pak™ refrigeration systems may be equipped with either a conventional temperature thermostat or an

electronic programmable temperature control. See page 19 for the operation of a conventional control or see

separate instructions on the operation of the electronic temperature control.

Defrost Cycle (Cooler System)

The purpose of the defrost cycle is to allow time for any frost formed on the evaporator to melt and clear from the

surface. The time clock stops the condensing unit. During this time, the evaporator fans continue to run, blowing

+35-38˚F air over the fins. This process will warm the evaporator above

+32˚F. After 15 minutes, the condensing unit should restart.

Note: Some models may have a programmable controller used in place of the Time

Clock. This unit is used to control the time and duration of the defrost. Please see the

separate instructions that are included for the operation of this control.

Time Clock

The time clock used to control the defrost cycle has been factory preset. However,

please refer to the following instructions on the operation of the time clock if an

adjustment is ever needed. Note: The cooler time clock is factory set for a 15 minute

defrost every 3 hours.

Time Clock Adjustment

The 24-hour dial has quarter-hour divisions and AM/PM indications. The time switch is set by pushing the

captive trippers to the outer ring position for the entire period that the load is to be turned "on", i.e. fifteen minutes

for each tripper on the 24-hour dial. When the tripper is pushed to the inside, the switch is in the "off" position. (It

is not recommended for the cooler to have defrosts longer than 15 minutes.)

Page 20

20

Operation

LOW TEMPERATURE (FREEZER) SYSTEMS

The low temperature, automatic electric defrost Capsule Pak™ Refrigeration System is the most dependable and

readily understood equipment available. It employs a basic refrigeration system with electric elements to

provide heat for defrosting.

Important: It is the installing contractor’s responsibility to check the operation upon start-up and make necessary

temperature control or thermal expansion valve adjustments as required for proper operation.

Note: Capsule Pak™ Refrigeration Systems that are designed for outdoor installation will be fitted with electric

crankcase heaters, electrically heated condensate drain tubes, automatic head pressure control valve, and the

"pump-down cycle".

Defrost Cycle

Under low temperature conditions, the air being forced through the evaporator coil is well below freezing at all

times, even during each compressor "off" cycle. Therefore, a source of heat

must be supplied to melt the accumulated frost. To achieve a complete

defrost, electric heater elements are attached to the evaporator coil and

to the drain pan. An electric time switch initiates a predetermined number

of regular defrost periods per day. When a defrost period occurs, the time

switch stops the evaporator fan(s) and the condensing unit, and energizes

the electric heaters in the evaporator coil and in the drain pan beneath it.

Note: Some models may have a programmable control used in place of

the time switch. This unit is used to control the temperature and the defrost

settings. Please see the separate instructions that are included on the

operation of this control.

Defrost Cycle Termination

As the defrost cycle progresses and the frost accumulation melts from the fins

of the evaporator coil, the temperature of the finned surfaces of the evaporator

coil will rise proportionately with the removal of the frost. When this temperature

reaches about 50°F, a point where the evaporator coil should be completely

free of frost, a defrost termination thermostat attached to the evaporator coil

will energize a solenoid coil in the defrost time switch which will revert the system to the cooling cycle. The fan(s)

in the evaporator housing will not start, however, until the fan delay cycle has expired. See the "Fan Delay" below.

Fan Delay

When a defrost cycle is terminated through the action of the defrost termination thermostat as described in the

section "Defrost Cycle Termination", the electric defrost heaters are de-energized, the compressor starts, and

evaporation resumes in the coil. The evaporator fan(s), however, will not start until the evaporator coil temperature

is reduced to about +20°F. Once this temperature is reached, the fan delay switch action of the defrost termination

thermostat energizes the evaporator fan(s) and they begin operating.

The fan delay feature is an important part of defrosting. If the fan(s) was permitted to start immediately following

a defrost period, the heat that accumulated in the evaporator housing would be circulated throughout the walk-in,

raising the temperature considerably. In addition, any droplets of moisture that remained clinging to the fins of the

evaporator coil would be blown into the storage space. The fan delay feature provides for a short refrigeration cycle

WITHOUT the evaporator fan(s) to prevent these conditions.

Note: During the initial startup of a Capsule Pak™ Refrigeration System on warm Kold Locker™ Walk-in, the

evaporator fan(s) will not start until the evaporator coil reaches and maintains +20°F. Further, the evaporator fans

may cycle "on" and "off" several times until the evaporator coil reaches and maintains +20°F.

Page 21

Operation

21

Time Clock Adjustments:

Setting the correct time of day: Simply rotate the minute hand clockwise until the correct time of day on the outer

dial is aligned with the triangle marker on the inner dial. In referring to the illustration, the correct time of day shown

is 8:00 a.m.

Number of defrosts per day: The time switch is factory set to provide four defrosts per day. If more defrosts are

required, move additional white tabs at the desired time. No more than two consecutive tabs should be set

at any one time. Each white tab constitutes 15 minutes of defrost time. If the four defrost periods provided are

more than necessary, push white tabs back toward the center of the dial.

Fail-Safe feature: The fail-safe of the timer is factory set at 30 minutes. The function of this device is to terminate

the defrost cycle and revert back to the cooling cycle if a system malfunction occurs during defrost. No adjustment

of this device should ever be necessary. Lengthening the fail-safe time will not lengthen the defrost cycle.

Note: The defrost times are factory set at 10:00 a.m., 4:00 p.m., 10:00 p.m., and 4:00 a.m. This setting will provide

adequate defrosting for a normal installation.

Refrigeration Controller

Some Capsule Pak™ Refrigeration Systems are equipped with

conventional temperature thermostats that sense the "cut-in" and

"cut-out" temperatures of the return air to the evaporator coil.

These thermostats are adjustable and require a turn of the dial to

change the interior storage temperature. Note: The control can

be reached through the interior louver for adjustment, with a

6” long shaft flat blade screwdriver. Make adjustments in small

increments until the desired temperature is reached.

Indoor Capsule Pak™ Refrigeration Systems may be equipped

with either a conventional temperature thermostat or an electronic

programmable temperature control. See separate instructions on the

operation of the electronic temperature control.

All outdoor Capsule Pak™ Refrigeration Systems and some indoor

systems employ a "pump-down cycle" which permits the compressor to pump most of the refrigerant from the

evaporator into its receiver after each "on" cycle. In this application, the refrigeration controller regulates the

operation of a solenoid valve in the liquid line. A low-pressure control is installed in the low side of the system that

shuts down the compressor due to low pressure, which results when the solenoid valve closes the liquid line. The

temperature thermostat is adjustable and requires a turn of the dial to change the interior storage temperature.

Drain Tube Heater

Low temperature ceiling mounted Capsule Pak™ Refrigeration Systems may employ a low wattage, electric

heater strip. This heater is spirally wound around the condensate drain tube that extends from the drain pan below

the evaporator coil to the evaporator section housing wall. This heater is energized continually to provide positive

discharge of the condensate moisture to the hot gas vaporizer. The heater and drain tube are covered with an

insulated tape.

Page 22

22

Maintenance

MAINTENANCE

WARNING: When servicing any Capsule Pak™ Refrigeration System or performing any maintenance

procedure, always disconnect the main power supply.

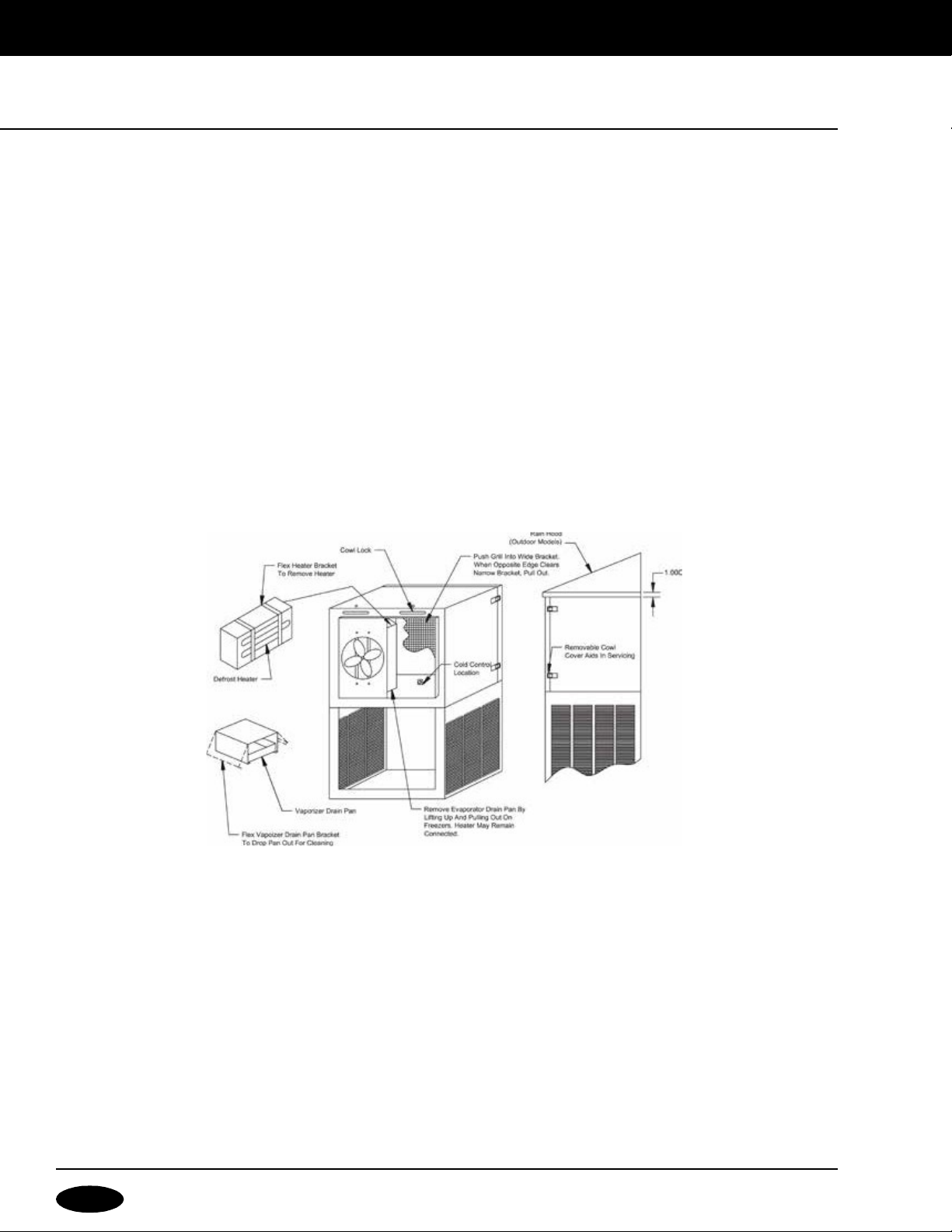

The condensing unit, condensate vaporizer, and the control box on low temperature models are all accessible

by removing the grills or louvers on the condensing unit housing. The evaporator coil section is accessible by

unlatching and removing the evaporator section housing cover. For access to the fan blade(s) and for oiling the

fan motor on some models, remove the louver on the walk-in ceiling.

Cleaning the Condenser

The efficiency of the condensing unit, to a great extent, depends upon the unrestricted flow of air through the

condenser. For this reason, the condensing unit should be as clean as possible at all times and should always

have an unrestricted supply of air.

Cleaning the condenser should be done at a minimum of every 3 months.

A wire brush should be used to loosen the accumulation of dust and dirt particles that have attached to the fins

of the condenser. Once this accomplished, a vacuum cleaner can be used to remove the loosened particles. If

compressed air is used to clean the condenser, the air should be directed through the condenser from the fan

motor side. Wipe away any accumulated dust from the compressor motor and related parts.

Evaporator Drain Pan Removal - Ceiling Mounted Models

Note: Model numbers ending with the letter "A"

Remove the drain pan retainer that is located near the end of the drain pan opposite the drain tube. It is

secured by a thumbscrew. Release the drain tube stub from the drain discharge tube and remove the pan. On

freezer models, a drain pan heater is secured to the drain pan bottom by short brackets. Only a slight effort is

required to release the heater element from the brackets. When replacing the drain pan, make sure that the drain

pan stub is properly connected to the drain discharge tube. When replacing the drain pan, the drain tube must be

siliconed to prevent water leakage.

Note: Model numbers ending with the letter "B"

Remove the four screws holding the evaporator coil in place and lift out of cowl. Support coil on edge of cowl.

Remove drain tube retaining washer and push tube into pan and remove. Remove screws holding pan and

remove. If pan heater is present, open tabs and remove. Replace pan in reverse order and silicone drain tube, pan

corners and perimeter before replacing coil. Apply silicone where copper tubes exit coil.

Hot Gas Vaporizer Pan

Condensate from the evaporator pan is discharged into a hot gas vaporizer pan, which is located in the condensing

unit housing. Here the hot discharge gas from the compressor elevates the temperature of the water and it

vaporizes into the atmosphere. This pan should be cleaned periodically to remove solids that remain after the

moisture is evaporated.

Page 23

23

1.

1.

2.

2.

3.

3.

4.

4.

5.

1.

1.

2.

2.

3.

3.

4.

1.

1.

2.

2.

1.

1.

2.

2.

3.

3.

4.

4.

1.

1.

2.

2.

3.

3.

4.

4.

5.

1.

1.

2.

2.

3.

1.

1.

2.

1.

1.

2.

2.

3.

3.

4.

4.

5.

5.

1.

1.

2.

2.

1.

1.

2.

2.

3.

3.

4.

4.

MaintenanCe Analysis

MALFUNCTION POSSIBLE CAUSE SOLUTION

Compressor will not start no hum

Unplugged or power off

Fuse blown or removed

Overload tripped

Control stuck open

5. Wiring incorrect

Plug in service cord or turn power on

Replace fuse

Determine reasons and correct

Repair or replace

Check wiring against the diagram

Compressor will not start hums but trips on overload

protector

Compressor starts and runs,

but short cycles on overload

protector

Compressor operates long

or continuously

Compressor runs fine, but

short cycles

Starting capacitor open,

shorted or blown

Relay defective or burned out

Refrigerated space too warm

Improperly wired

Low voltage to unit

Starting capacitor defective

4. Relay failing to close

Low voltage to unit

Overload defective

3.

Excessive head pressure

4.

Compressor hot — warm ambient

conditions

Short of refrigerant

Control contact stuck

Evaporator coil iced

Restriction in refrigeration system

5. Dirty condenser —warm ambient

conditions

Overload protector

Cold control

Overcharge

Air in system

5. Undercharge

Relay contacts stuck

Low voltage to unit

3. Improper relay

Incorrect relay

2. Voltage too high or too low

Control setting too high

Refrigerant overcharge

Dirty condenser

Evaporator coil iced

Not operating

6.

Air flow to condenser or

evaporator blocked

Warm ambient conditions

7.

Check wiring against the diagram

Determine reason and correct

Determine reason and replace

Determine reason, correct or replace

Determine reason and correct

Check current, replace overload protector

3.

Check ventilation or restriction in

refrigeration system

4.

Check refrigerant charge, fix leak if

necessary

Fix leak, add charge

Repair or replace

Determine cause, defrost manually

Determine location and remove restriction

5. Clean condenser

Check wiring diagram

Differential too close - widen

Reduce charge

Purge and recharge

Fix leak, add refrigerant

Clean contacts or replace relay

Determine reason and correct

Replace

Check and replace

Determine reason and correct

Reset control

Purge refrigerant

Clean condenser

Determine reason and defrost

Determine reason, replace if necessary

6.

Remove obstruction for free air flow — no storage

on top of walk-in

7.

Ambient conditions should be 90° or less

Standard temperature system

freezes the product

Objectionable noise

Water overflowing from

evaporator drain pan or

condensate vaporizer pan

further information.

Control setting is too low

Control points stuck

Fan blade hitting fan shroud

Tubing rattle

Vibrating fan blade

Condenser fan motor rattles

5.

General vibration

6.

Worn fan motor bearings

1.

Air leak between refrigeration system

and walk-in panel.

2.

Drain line from evaporator drain

pan to condensate vaporizer is

blocked with foreign material.

Drain line from evaporator drain

3.

pan to condensate vaporizer is

blocked with ice.

4.

Walk-in operating in high humidity

environment (heavy door usage).

Reset the control

Replace the control

Reform or cut away small section of shroud

Locate and reform

Replace fan blade

Check motor bracket mounting, tighten

5.

Compressor suspension bolts not loosened

on applicable models - loosen them

Replace fan motor

6.

1.

Check that refrigeration system is properly set

in panel opening.

2.

Clean blockage from inside of drain line.

3.

Check that drain line heater (on freezers)

is working and repair or replace as required.

4.

Plumb drain line from evaporator to floor

drain or replace high gas vaporizer with

electric vaporizer. Consult factory for

Page 24

24

Page 25

Manual de

instalación del

Sistema de

Refrigeración

05/15 Rev. I 040086

Page 26

Tabla de Contenidos

Herramientas necesarias 3

Información General 4-7

Desembalaje e inspección para montaje en el techo 4

Desembalaje e inspección remotos 5

Instrucciones de instalación del cerrojo y difusor 6-7

Sistema de refrigeración de montaje en pared 8-11

Instrucciones de instalación 8-9

Instrucciones generales de instalación para montaje en el techo 10

Modelos de congelador 100 y 150 o modelo de enfriador 075 11

Sistemas de refrigeración remotos 12-13

Con vaporizador eléctrico 12

Con vaporizador condensado eléctrico opcional 13

Instrucciones para líneas precargadas 14-15

Instrucciones del arnés para cables 16

Sistemas para exteriores 17-18

Material para membranas para techos 17-18

Operación 19-21

Sistemas de temperatura estándar (enfriador) 19

Sistemas de baja temperatura (congelador) 20-21

Mantenimiento 22-23

Análisis de mantenimiento 24

2

Page 27

3

HerramientaS Requeridas para el desempaque e instalación del Sistema de Refrigeración

Herramientas Requeridas

•

gafas de seguridad

•

cizallas para metal

•

barra de palanca

•

martillo

•

(2)

llave

ajustable para tuercas

•

taladro

•

lápiz

Page 28

Sistemas de Refrigeración

-

4

Información General

SISTEMA DE REFRIGERACIÓN

INFORMACIÓN GENERAL

Este sistema de refrigeración fue producido utilizando tecnología de punta en su fabricación, los materiales de

más alta calidad disponibles, junto con innovaciones que lo hacen diferente en su campo. A pesar de los estrictos controles en la producción, no hay sustituto para la lectura y COMPRENSIÓN total de las instrucciones que

siguen. El resultado será una instalación eficiente y ordenada. Tómese un tiempo expresamente para seguir

los pasos.

DESEMPAQUE E INSPECCIÓN--SISTEMA DE MONTAJE SOBRE EL TECHO

Compruebe en el recibo de entrega el número de piezas que componen el envío y asegúrese que el número de

bandejas de carga, cajones o cajas estén de acuerdo con estas anotaciones. Cada pieza debe ser marcada

claramente con el mismo número de orden de cinco dígitos que aparece en el recibo de entrega como así también

el número del expedidor.

Examine las condiciones generales del envío y tan pronto como se haya completado el desempaque, inspeccione

cuidadosamente todas las piezas para determinar posibles daños producidos durante el transporte. Si descubre

partes dañadas, contáctese inmediatamente fábrica.

Recibo de entrega

Page 29

Sistemas de Refrigeración

-

5

Información General

DESEMPAQUE E INSPECCIÓN--SISTEMAS REMOTOS DE REFRIGERACIÓN

Compruebe en el recibo de entrega el número de piezas que componen el envío y asegúrese que el número

de bandejas de carga, cajones o cajas estén de acuerdo con estas anotaciones. Cada pieza debe ser marcada

claramente con el mismo número de orden de cinco dígitos que aparece en el recibo de entrega como así también

el número del expedidor.

Examine las condiciones generales del envío y tan pronto como se haya completado el desempaque, inspeccione

cuidadosamente todas las piezas para determinar posibles daños producidos durante el transporte. Si descubre

partes dañadas, contáctese inmediatamente fábrica.

Se recomienda que la condensación de ser elevada desde la plataforma un mínimo de 12 " -18" para asegurar

el ventilador del condensador no está agarrando calor reflejada en el techo del edificio o del pavimento en una

categoría instalación en la que el calor del verano puede ser superior a 120 °F.

Page 30

Sistemas de Refrigeración

-

6

Información General

INSTRUCCIONES DE INSTALACIÓN DEL CERROJO Y DIFUSOR CAPSULE PAK™

PRECAUCIÓN: ¡RETIRE EL DIFUSOR ANTES DE LA INSTALACIÓN DEL PANEL DEL TECHO!

1. Retire el difusor del panel del techo antes de instalar el panel del techo.

2. Eleve el Capsule Pak™ a su posición en la parte superior de la cámara de enfriado. Nota: No deslice el

Capsule Pak™ hasta su posición ya que pueden ocurrir daños en la junta del capó. Si debe deslizar el

Capsule Pak™ hasta su posición, coloque el Capsule Pak™ sobre un trozo de cartón antes de moverlo para

evitar daños en la junta.

Figura 1

3. Inspeccione la junta del capó para garantizar que esté correctamente colocada.

Figura 3

Figura 2

Page 31

Sistemas de Refrigeración

-

7

4. Asegure los cerrojos interiores.

Información General

Figura 4

Figura 5

5. Selle el capó al techo en la unión de la junta arriba del panel del difusor utilizando la silicona suministrada.

Figura 6

6. Vuelva a colocar el panel del difusor que extrajo en el paso 1.

Page 32

Instrucciones Generales de Instalación

8

INSTRUCCIONES GENERALES DE INSTALACIÓN

Esta sección contiene las instrucciones generales para montar sobre

el techo el Sistema de refrigeración. Antes de proceder, vea también

la siguiente sección sobre montaje "Sistemas remotos con vaporizador

eléctrico", si fuera necesario aplicarlos.

Nota: El término "temporal" interior se debe agregar la compatibilidad

durante la instalación de refrigeración.

Nota: Debido al peso de estos sistemas, se recomienda con énfasis

utilizar un equipo de elevación adecuado durante la instalación,

como una grúa de horquilla o tijeras elevadoras. Además, asegúrese

de permitir suficiente caudal de aire alrededor del condensador.

Los números de modelo que terminan en “A” requieren un espacio

mínimo de 60 cm (2 pies) para un funcionamiento correcto de la

unidad. Los números de modelo

que terminan con la letra “B”

requieren un mínimo de 12 cm

(5 pulg.) detrás de la unidad y

en la apertura delantera para un

funcionamiento correcto. Si se

ubican múltiples unidades en la

misma zona, asegúrese de que el

aire caliente de uno no se escape

en la dirección del otro. Además

de permitir un caudal de aire

correcto, debe tenerse en cuenta

la ubicación final del montaje

del sistema de refrigeración en

relación a la ubicación del cliente

para evitar cualquier riesgo

posible de ruido que impacte en

la experiencia del cliente.

Coloque en posición la sección de

aislamiento del evaporador de la sobre el agujero en la parte de techo

de la cámara frigorífica.

Alinee las lengüetas de los costados de la sección aislante del

evaporador con los agujeros ya perforados de la sección del techo.

Ajuste los cerrojos y el perímetro del sello como se describe en las

Instrucciones de instalación del cerrojo y difusor que se encuentran

en las páginas 6 y 7. Cuando vuelva a instalar el panel del difusor,

asegúrese que el divisor de la sección del techo del panel se selle

contra la junta negra. Puede ser necesario algún ajuste, con tan solo

doblar hacia atrás o hacia delante el separador de la sección del techo.

Esto evitará cualquier ciclado corto del aire dedescarga y retorno.

Asegure la sección aislada del evaporador al techo usando los tornillos provistos que los hallará

adosados al costado del sistema de refrigeración. ¡PRECAUCIÓN! Esto debe hacerse para evitar que el

sistema de refrigeración completo se mueva durante la operación.

Nota: En sistemas de refrigeración más pequeños, puede elegir instalar el sistema en la sección del techo

mientras esta sección está aún en el piso. ¡PRECAUCIÓN! Asegúrese de fijar correctamente el sistema al panel

de techo. La sección de techo y el sistema de refrigeración pueden ser montados juntos en la secuencia normal

de ensamblaje tal como se muestra en las instrucciones de instalación para la cámara frigorífica Kold Locker™

Page 33

Instrucciones Generales de In

stalación

9

de acceso total. Este método no es práctico y no debería ser usado con sistemas más grandes que las series

100 o superiores, como por ejemplo un modelo CPF 100, CPF150 o CPF151.

Nota: El proceso mencionado arriba es el mismo al colocar/

instalar la sección evaporadora aislada de un sistema de

refrigeración Remote.

Después de colocar el sistema, asegúrese que los bulones

que ajustan la sección de unidad condensadora a la sección

evaporadora se hallan lo suficientemente flojos para que ambas

secciones puedan ajustarse a las superficies del techo. Nota: En

sistemas grandes, series 100 y superiores, las unidades deben

ser colocadas sobre un conjunto de rejillas y no tienen estos

bulones que conectan ambas secciones. No hacen falta ajustes.

Nota: Algunos motores compresores están montados sobre

muelles para absorber las vibraciones. Asegúrese que estos bulones se aflojen para permitir que el compresor

descanse libremente sobre los muelles. Una etiqueta de aviso está colocada en los sistemas en los que este

procedimiento se aplica.

Algunos los sistemas requieren una conexión permanente a un servicio eléctrico y una conexión a la caja de

empalmes colocada dentro del alojamiento de la unidad condensadora. Consulte todos los datos eléctricos

en los rótulos correspondientes de la serie. Estos sistemas deben conectarse a un interruptor para la

fuente de suministro de poder y con un cableado conforme a los códigos eléctricos locales y nacionales. No

es necesaria ninguna cañería de drenaje, bajo condiciones normales, ya que la humedad condensada se disipa

automáticamente por medio de un vaporizador de gas caliente incorporado.

Page 34

Instrucciones Generales de Instalación

10

Bloqueo del capó

el calentador

Protector contra

la lluvia

Empuje la rejilla

hacia el soporte

ancho

Descongele el

calentador

La cubierta del

capó removible

mantenimiento

Bandeja de drenaje del

Extraiga la bandeja de

elevando y tirando de los

congeladores.

Figura 1.

Refrigeracion Para

Montar En Pared

SISTEMAS DE REFRIGERACION PARA MONTAR EN PARED

INSTRUCCIONES DE INSTALACIÓN

NOTA: Si el sistema que debe montarse a la pared es un modelo de congelador 100 o 150 o un modelo de

enfriador 075, consulte la sección siguiente con instrucciones especiales para montar estas unidades.

Eleve con cuidado todo el sistema de refrigeración e inserte la manga protectora de la sección del evaporador en la

apertura de la pared de acceso. Mientras apoya el sistema, fíjelo en posición girando las cerraduras exactamente

de la forma en que lo hizo cuando fijó las secciones de acceso en conjunto. Asegúrese que las cerraduras estén

correctamente conectadas e inserte los botones del tapón en los orificios de acceso de la cerradura cuando

finalice. Consulte la Figura 1.

NOTA: Algunos compresores de motores se montan con resortes abiertos para absorber la vibración. Asegúrese

de que estos pernos estén flojos para permitir que el compresor se mueva libremente en los resortes. Se aplica

una etiqueta recordatoria en aquellos sistemas donde se utiliza este procedimiento.

Algunos sistemas requieren una conexión permanente a un servicio eléctrico y una conexión en la caja de

conexiones ubicada dentro de la carcasa de la unidad de condensación. Para toda información pertinente

sobre electricidad, consulte la etiqueta serial. Estos sistemas deben conectarse a un disyuntor del sistema de

alimentación y cablearse según los códigos eléctricos locales y nacionales.

Bajo condiciones normales, no se requiere drenaje en la tubería para instalaciones interiores. El vaporizador de gas

calientes integrado disipa la humedad condensada automáticamente. En instalaciones exteriores, el condensado

debe dirigirse a través de la tubería al drenaje más cercano. Verifique los códigos de construcción locales. Las

líneas de drenaje exteriores también deben envolverse con un cable de calentador adecuado si se encuentran

expuestas a temperaturas de congelamiento. Las instalaciones exteriores también requieren conectar el protector

contra la lluvia que desvía el agua de la lluvia desde la superficie superior de la carcasa del evaporador. Consulte

la Figura 1 para ver una ilustración.

Asegúrese de permitir suficiente caudal de aire alrededor del condensador. Un espacio libre mínimo de seis

pulgadas es necesaria para la instalación y un mínimo de dos metros de altura es necesaria para consideración de

servicio. Temperatura ambiente alrededor del sistema debe ser inferior a 90 °F y 50% HR. Si se ubican múltiples

unidades en la misma zona, asegúrese de que el aire caliente de uno no se escape en la dirección del otro.

Doble el soporte del

calentador para extraer

vaporizador

Doble el soporte del drenaje

del vaporizador para extraer la

bandeja para la limpieza

drenaje del evaporador

ayuda en el

Sistemas De

Consulte la sección “Instrucciones para líneas precargadas” si la instalación del sistema requiere el uso de líneas

precargadas para conectar las secciones del evaporador y del condensador.

Page 35

Instrucciones Generales de In

stalación

11

Cierre con picaporte

hoyo

1/2 Enhebró

barra de nilón

(4X)

el Apoyo diagonal

de

Apoyo de pierna

(2X)

Pierna más plana

Modelos de congelador 100 y 150 o modelo de enfriador 075

1. Después de desembalar, luego de intentar conectar el sistema de refrigeración al acceso, debe construirse

un soporte sustancial temporal. El soporte debe colocarse a aproximadamente 28 pulgadas (71 cm.) de alto y

directamente por debajo de la apertura del acceso en la pared.

NOTA: Debido al peso de estos sistemas, se recomienda con énfasis utilizar un equipo de elevación adecuado

durante la instalación, como una grúa de horquilla.

2. Eleve el sistema de refrigeración hacia el soporte temporal. Determine si la manga de la sección de la bobina

está correctamente ubicada, de manera que pueda insertarse en la apertura sin doblarse o dañarse. Coloque

cuñas adecuadas en el sistema para poder lograr esto.

3. Deslice cuidadosamente todo el sistema de manera que la manga de la sección de la bobina ingrese a

la apertura sin perturbar el soporte temporal debajo del sistema de refrigeración. Continúe hasta que la junta

alrededor de la sección de la bobina haga contacto y selle alrededor de todo el perímetro de la sección de la

bobina. Coloque cuñas en el sistema y ajuste correctamente para que el sello de la junta quede uniforme en los

cuatro lados.

4. Inserte la llave en los orificios de acceso del cerrojo de la sección de la bobina utilizando la llave de cierre

de sección provista para el levantamiento del acceso. Gire todas las cerraduras hacia la derecha hasta que los

cerrojos enganchen con las intersecciones del acceso. Gire la cerradura hasta encontrar una detención total. ¡NO

EXTRAIGA EL SOPORTE TEMPORAL!

5. Retire el ensamble de la claraboya y taladre cuatro orificios de 9/16” (12 mm.) de diámetro a través de los dos

ángulos superiores de la sección de la unidad de condensación. Taladre completamente a través de la pared de

acceso e inserte las varillas de nylon enroscadas de 1/2" (12 mm.). Asegure con las arandelas planas y las tuercas

provistas. Consulte la Figura 2.

6. Con los tornillos niveladores enroscados completamente en el soporte del pie, inserte el soporte del pie en

los retenedores del pie en las esquinas externas de la sección de la unidad de condensación. Desenrosque

los tornillos de nivelado del pie hasta que hagan contacto con el suelo u otra superficie de soporte. Nota: Si la

superficie de soporte está extremadamente desnivelada, debe proporcionarse un material de cuña adecuado

debajo de uno o ambos soportes del pie.

7. Conecte las abrazaderas del soporte del pie diagonales

utilizando los sujetadores enroscados provistos. Realice los ajustes

finales en los tornillos de nivelado del pie de manera que actúen

como dispositivos de apoyo en el borde exterior del sistema de

refrigeración.

8. Inserte los botones del tapón en cada uno de los orificios de

acceso del cerrojo.

9. Retire el ensamble del soporte temporal que se proporcionó en

el Paso 1.

de acceso (5X)

la pierna refuerza

Figura 2.

(2X)

Page 36

Sistema de Refrigeración Remote

12

SISTEMAS REMOTOS CON VAPORIZADOR ELÉCTRICO

Coloque la sección evaporadora del sobre la apertura del

secciones de techo. Alinee las lengüetas sobre los costados

de la sección del evaporador aislado con los agujeros que ya

están perforados en la sección de techo. Retire el panel del

difusor del techo dentro de la cámara de frío para obtener

acceso a los cuatro cerrojos ubicados sobre el perímetro del

capó. Consulte las Instrucciones de instalación del cerrojo

y difusor que se encuentran en las páginas 6 y 7. Selle la

unión como se describe en las instrucciones. Cuando vuelva

a instalar el panel del difusor, asegúrese que el divisor de la

sección del techo ubicado en el panel se selle contra la junta

negra. Puede ser necesario algún ajuste, con tan solo doblar

hacia atrás o hacia delante el separador de la sección del

techo. Esto evitará cualquier ciclado corto del aire de descarga

y retorno.

Asegure la sección aislada del evaporador al techo usando

los tornillos provistos que los hallará adosados al costado del

sistema de refrigeración. ¡PRECAUCIÓN! Esto debe hacerse

para evitar que el sistema de refrigeración completo se mueva

durante la operación.

Page 37

Sistema de Refrigeración

Remote

13

CARACTERÍSTICAS OPCIONALES - VAPORIZADOR CONDENSADOR ELÉCTRICO

Advierta la ubicación de la línea de drenaje de la condensación

que viene desde el evaporador. Ubique el vaporizador

eléctrico de modo que la condensación caiga en él. Si el

vaporizador no puede ser ubicado en la línea de drenaje,

use la tubería plástica provista con codos de bronce y las

abrazaderas de mangueras que sean necesarias para

prolongar la línea de drenaje. Corte la tubería de plástico en

el largo necesario.

Conecte el vaporizador eléctrico a la línea de alimentación

conforme a los códigos eléctricos locales y nacionales.

Page 38

Sistema de Refrigeración Remote

14

INSTRUCCIONES PARA SISTEMAS REMOTOS DE LÍNEAS PRE-CARGADAS

Empleando uniones auto-selladoras, la sección de la unidad condensadora, la sección evaporadora y la cañería

de conexión, están pre cargadas por separado con refrigerante y comprobado en fábrica antes de su envío para

asegurarse que no hayan filtraciones. Siga los pasos de 1a 8 de más abajo, para instalar la cañería de conexión

tanto en la unidad condensadora como en la sección de evaporación.

1. Desenrolle cuidadosamente la línea de succión. Esta es la línea cubierta

con espuma de goma aisladora en todo su largo.

2. Desenrolle cuidadosamente la línea para líquido. La línea para líquido es

la de menor diámetro, cañería de cobre al descubierto.

3. Antes de hacer cualquier conexión, determine el recorrido a seguir por

ambas líneas y cuidadosamente dóblelas a mano conforme a este plan. Trate

que todo codo de la cañería sea mas bien amplio para evitar arrugas en la

cañería. Es práctica general mantener paralelas y cerca las líneas de succión

y de líquidos en la instalación.

4. Quite las tapas contra polvo y los enchufes de las conexiones e

inspecciónelas para comprobar que los sellos sintéticos estén intactos.

5. Utilizando un paño limpio, limpie los sellos de las conexiones y de las

superficies roscadas para evitar la presencia de cualquier suciedad o material

extraño dentro del sistema.

6. LUBRIQUE con aceite para refrigeración los sellos sintéticos en la mitad

macho de los acoples y enrósquelos A MANO para asegurarse el correcto

apareamiento de las roscas. Nota: Asegúrese que la línea de succión aislada

está conectada a la mitad de acoplamiento marcada "Línea de succión" y que

la línea de caños descubiertos para líquidos se hallen conectados a la mitad

de acoplamiento marcada "Línea de líquidos".

Nota: Siempre use las dos llaves en el cuerpo de conexión de la tuerca

hexagonal para evitar torcer el caño mientras ajusta las conexiones como se

describe en el siguiente paso.

7. Usando el tamaño adecuado de llave de tuerca de unión, ajuste hasta llegar

al fondo de la conexión o hasta que sienta una resistencia definida. Ajuste con

una vuelta adicional de 1/6 a 1/4. Esta vuelta final es necesaria para asegurar

que el borde de filo de cuchilla del sello de metal muerda en el asiento de

metal de las mitades del acoplamiento, formando una juntura a prueba de

filtraciones.

Conexión al lado de la Unidad de condensación

Page 39

Sistema de Refrigeración

Remote

15

8. Una vez que la línea de succión esté conectada, la esponja aisladora

debe ser jalada hacia arriba para cubrir los empalmes rápidos. Ate o

pegue con cinta adhesiva la aislación para evitar filtraciones y reducir la

formación de agua/hielo en la línea de succión.

Todas las válvulas están abiertas y el sistema está listo para el

funcionamiento. Recuerde, las conexiones de refrigeración en este

sistema son auto selladoras y si surge la necesidad, las conexiones

pueden ser desconectadas sin ninguna pérdida de refrigerante.

IMPORTANTE: Como este sistema está equipado con líneas refrigerantes

pre-cargadas, es responsabilidad del contratista instalador, asegurar que

los acoplamientos refrigerantes de conexión rápida, estén correctamente

acoplados y libres de filtraciones. Es también su responsabilidad al

iniciar el funcionamiento, inspeccionar el sistema para comprobar el

funcionamiento correcto y hacer el control necesario de temperatura o

ajustes en la expansión térmica de las válvulas.

Nota: Se requiere que el contratista ponga en funcionamiento una línea

de drenaje para este tipo de instalación.

PRECAUCIÓN: El conjunto de conductos no debe exceder en más de 1

m (3 pies) de la longitud necesaria para realizar la conexión; si no podría

provocar un retorno de aceite inadecuado que a su vez podría provocar

fallas en el compresor. Póngase en contacto con el Departamento de

Servicio con sus números de modelo y de serie a mano para recibir más

ayuda. Esta información también se incluye en una etiqueta unida al

conjunto de conductos.

Algunos los sistemas

requieren una conexión

permanente a un servicio

eléctrico y a una conexión

en una caja de empalmes

colocada dentro del

alojamiento de la unidad

condensadora. Consulte

todos los datos eléctricos en

los rótulos correspondientes

de la serie. Estos sistemas

deben conectarse a un

interruptor para la fuente de

suministro de poder y con

un cableado conforme a los

códigos eléctricos locales y

nacionales.

Conexión al lado de la Sección evaporadora

Page 40

SistemaS de Refrigeración Remotos Con Arnes Para Cables

16

1. Todos los sistemas con arnés para cables tienen una “K” en o cerca del final del número del modelo.

Ejemplo: RCPB100DC-A-50K.

2. Estos sistemas vienen con un arnés para cables ya cableado en la sección de la unidad de condensación del

sistema de refrigeración.

3. Estos arnés para cables tienen un conducto con sello de ajuste y conectores aprobados.

4. Antes de conectar la alimentación a la sección de la unidad de condensación, primero debe cablearse a la

sección del evaporador con el arnés para cables suministrado.

5. Retire la cubierta de la caja de control de la sección del evaporador.

6. Realice las conexiones adecuadas dentro de la caja de control en la sección del evaporador como se muestra

en el diagrama de cableado suministrado con el sistema.

7. Vuelva a colocar la cubierta en la caja de control una vez que finalice el cableado.

8. Ahora puede llevar la alimentación a la sección de la unidad de condensación del sistema de refrigeración.

Page 41

Sistemas de Exteriores

17

SISTEMAS DE EXTERIORES QUE UTILIZAN MATERIAL DE MEMBRANA DE TECHO

1. Una vez que el acceso está completamente

armado, coloque la barbada hacia abajo

en la parte superior de las secciones del

techo (la barbada se ajusta a la base del

cajón durante el envío y debe retirarse

e instalarse antes de la instalación de la

membrana para el techo). Para asegurarse

una alineación correcta, marque con un

lápiz marcador la parte externa del cuadro

portador sobre las secciones de techo.

2. Quite el papel de la junta y ubique el cuadro

portador, el lado de la junta hacia abajo,

sobre la línea del marcador. Presione

firmemente. Nota: Los movimientos del

cuadro portador se hacen muy difíciles

después que la junta se adhiere a la

sección de techo. Vea la figura 1.

Fija material

Línea de corte

Figura 2

Cámara

Frigorifica

Cámara

Frigorifica

Membrana

de techo

Abertura

Cuadro portador

Marcas de alineación

Secciones de techo

Figura 1

3. Coloque el material de membrana

de techo sobre las secciones de

techos y cuadro portador, dejando

una saliente de aproximadamente

seis pulgadas (15 cm) en los cuatro

lados de la cámara. Usando un

cuchillo para uso general, haga un

agujero en la membrana de techo

de aproximadamente 1-1/2” (3,8 cm)

desde el borde del cuadro portador

de la abertura. (El agujero resultante

en la membrana será menor que

la abertura del techo). Doble las

solapas de 1-1/2” (3,8 cm) de la

membrana en la abertura, formando

una muesca en la membrana

alrededor de los localizadores y

divisor. Use tornillos metálicos,

masilla o pegamento, etc. para fijar

el material de membrana de techo

al interior del cuadro portador del

marco. Vea la figura 2.

Page 42

Sistemas de Exteriores

18

Costado

superior

Membrana

7,94 cm

Guamición

4. Ubique el sistema de refrigeración

sobre la abertura en el cuadro

portador. Es posible que se

requieran algunos ajustes que

consisten en doblar el divisor de

la sección del techo levemente

hacia adelante o hacia atrás.

Esto evitará cualquier ciclo corto

de descarga y devolverá el aire.

Retire el gabinete de la parte de

la unidad de condensación del

sistema y taladre dos orificios

de 9/16” (12 mm.) a través de

la placa de base de la unidad

de condensación, del material

de la membrana del techo y de

la sección del techo revestida.

Los agujeros deben estar en los

costados opuestos de la unidad.

Inserte una varilla roscada de

nylon de 1/2” (1,25 cm) en cada agujero. Aplica sellador de silicona

alrededor de cada roscada de nylon y agujero, y coloque una arandela

y una tuerca en el fin de la unidad condensadora de la varilla roscada

de nylon. Coloque una segunda arandela y tuerca en el interior de la

cámara y ajústelos firmemente. Reemplace el contenedor y asegure

la cubierta de exterior con los tornillos provistos. Vea la figura 3. Las

varillas de nylon, arandelas y tuercas están provistas.

5. Doble los cuatro ángulos del material de membrana de techo sobre

las esquinas de la cámara como se muestra en la figura 4.

6. Agregue la guarnición y la cubierta de la puerta usando los tornillos provistos de cabeza hexagonal para

lámina de metal. Todas las piezas deben ser sujetadas hacia abajo en 3-1/8 pulgadas (7,94 cm) desde la parte

superior del techo como lo muestra la figura 5. Asegúrese que la guarnición y el material de membrana de

del techo

Figura 5

temperaturas de congelamiento.

Capsule Pak™

con cubeirta

Membrana

de techo

Abertura

Cámara

Frigorifica

Figura 3

Doble la Membrana

Figura 4

techo cubran el ensamblado entre los paneles del techo

y la pared. Nota: La guarnición debe ser cortada para

de techo

encajar bien.

7. Recorte todo excesso de material de membrana de

techo debajo la barra terminación con un cuchillo

para uso general. No permite el cuchillo a cortar el

panel de metal, como esta daño la capa y causa

moho.

Nota: En instalaciones de interior, la condensación

debe ser canalizada hacia el drenaje más cercano.

Consulte los códigos locales de construcción. La parte

exterior de las líneas de drenaje deben envolverse

con un cable calentador adecuado, si soportan

Page 43

o

peración

19

OPERACIÓN

SISTEMAS DE TEMPERATURA ESTÁNDAR (ENFRIAMIENTO)

El Sistema de refrigeración Capsule Pak™ descongelador de aire automático para enfriadores es un sistema de

refrigeración básico y unificado. El sistema está diseñado para ofrecer temperaturas de almacenamiento normales

en una cámara de enfriado Kold Locker™ con un mínimo esfuerzo durante la instalación inicial. El sistema se

compone de una unidad de condensación completa, una bobina de evaporador, un método para controlar la

temperatura y un interruptor de tiempo para establecer la descongelamiento "fuera de ciclo".

Importante: Es responsabilidad del contratista de la instalación verificar el funcionamiento después del arranque

y realizar el control de temperatura necesario o los ajustes de la válvula de expansión térmica requeridos para

un funcionamiento correcto.

Nota: Los sistemas de refrigeración Capsule Pak™ que están diseñados para instalaciones exteriores están

equipados con calentadores eléctricos del cárter, tubos de drenaje condensados calentados eléctricamente,

válvula de control de carga de presión automática y "ciclo de disminución de bombeo".

Controlador de refrigeración

Los sistemas de refrigeración Capsule Pak™ están equipados con un termostato de temperatura convencional o

un control de temperatura programable electrónico. Consulte la página 19 para ver el funcionamiento de un control

convencional o vea las instrucciones separadas sobre el funcionamiento del control de temperatura electrónico.

Ciclo de descongelamiento (Sistema de enfriador)

El objetivo del ciclo de descongelamiento es permitir tiempo para que se derrita

cualquier formación de hielo en el evaporador y limpiar la superficie. El temporizador

detiene a la unidad de condensación. Durante este tiempo, los ventiladores del

evaporador continúan funcionando, soplando aire a +1,6-3,3 ˚C (+35-38 ˚F) sobre las

aletas. Este proceso calentará el evaporador por encima de los 0 °C (+32 ˚F). Después

de 15 minutos, la unidad de condensación se reiniciará.

Nota: Algunos modelos pueden tener un controlador programable que se utiliza en

lugar del temporizador. Esta unidad se utiliza para controlar el tiempo y la duración

del descongelamiento. Consulte las instrucciones separadas que se incluyen para el

funcionamiento de este control.

Temporizador

El temporizador que se utilizar para controlar el ciclo de descongelamiento está preestablecido en fábrica. Sin

embargo, consulte las instrucciones siguientes sobre el funcionamiento del temporizador si alguna vez necesita

un ajuste. Nota: El temporizador del enfriador está establecido en fábrica para un descongelamiento de 15

minutos cada 3 horas.

Ajuste del temporizador

El medidor de 24 horas posee divisiones de cuartos de hora e indicadores de a.m./p.m. El interruptor de tiempo

se establece presionando los disparadores cautivos a la posición del anillo exterior para todo el período durante

el cual estará “encendida” la carga, por ejemplo, quince minutos para cada disparador en el medidor de 24

horas. Cuando se presione el disparador hacia adentro, el interruptor estará en la posición de “apagado”. (No se

recomienda que el enfriador tenga descongelamientos de un período mayor a 15 minutos).

Page 44

o

peración

20

SISTEMAS DE BAJA TEMPERATURA (CONGELADOR)

Las bajas temperaturas, la descongelación eléctrica automática de los sistemas de refrigeración son los equipos

disponibles más confiables y fáciles de entender. Emplea un sistema básico de refrigeración con elementos

eléctricos para proveer calor para descongelar.

Importante: Es también responsabilidad del contratista instalador inspeccionar el funcionamiento y hacer el

control necesario de temperatura o ajustes en la expansión térmica de las válvulas como se requiere para un

funcionamiento correcto.

Nota: Los sistemas de refrigeración diseñados para instalaciones al aire libre se proveerán de calentadores

eléctricos de cárter, tubos de drenaje de condensación calentados eléctricamente, válvula de control automático

de presión en cabeza, en el "ciclo de bombeado"

Ajustes de cronómetros:

Establecer la hora correcta del día - Para establecer la hora correcta, simplemente

rote el dial pequeño interior en sentido contrario a las agujas del reloj hasta que la

correcta hora del día quede frente al indicador de "tiempo".

Número de descongelaciones por día - El cronómetro está programado en fábrica

para descongelar el evaporador cuatro veces por día. Si se necesitaran mas

descongelaciones, quite el tornillo de cabeza moleteada del sostén, e insértelo en la

ranura de tiempo en el dial más grande donde necesite un nuevo descongelación y

ajuste.

Ajuste de la duración del tiempo de descongelación - En el dial pequeño, en su