Page 1

Pizza Prep Table Refrigerator

Installation and Operation Manual

Please read this manual completely before attempting to install or operate this equipment!

Full Stainless Steel Visible Exterior

PPT-67

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지2

Page 2

SPECIFICATIONS

............................................................................................

2

SERIAL NUMBER

............................................................................................

2

CUTTING BOARD & BRACKETS Installation Schematic Diagram.................. 3

INSTALLATION OF CASTORS ........................................................................ 4

INSTALLATION OF HOOD LID........................................................................ 4

HOW TO CLEAN THE PAN AIR DUCT PANEL ............................................... 6

HOW TO OPEN AND CLOSE THE HOOD LID ................................................6

INSTALLATION

.................................................................................................

7

CLEANING & CAUTION

...................................................................................

8

BASIC OPERATION

.........................................................................................

9

BEFORE REQUESTING SERVICE

...............................................................

10

WARRANTY

.............................................................................................

11~13

Pizza Prep Table

2

Master bilt

CONTENTS

SPECIFICATIONS

PAGE

MODEL COMP H.P. V/Hz REFRIGERANT AMPS WEIGHT

PPT-67

5/8 115V/60Hz R-134a 10.4A 395lbs

The serial number is located on the rating label which is on the left interior

wall.

Please retain the unit’s serial number for service purpose.

SERIAL NUMBER

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지2

Page 3

3

Master bilt

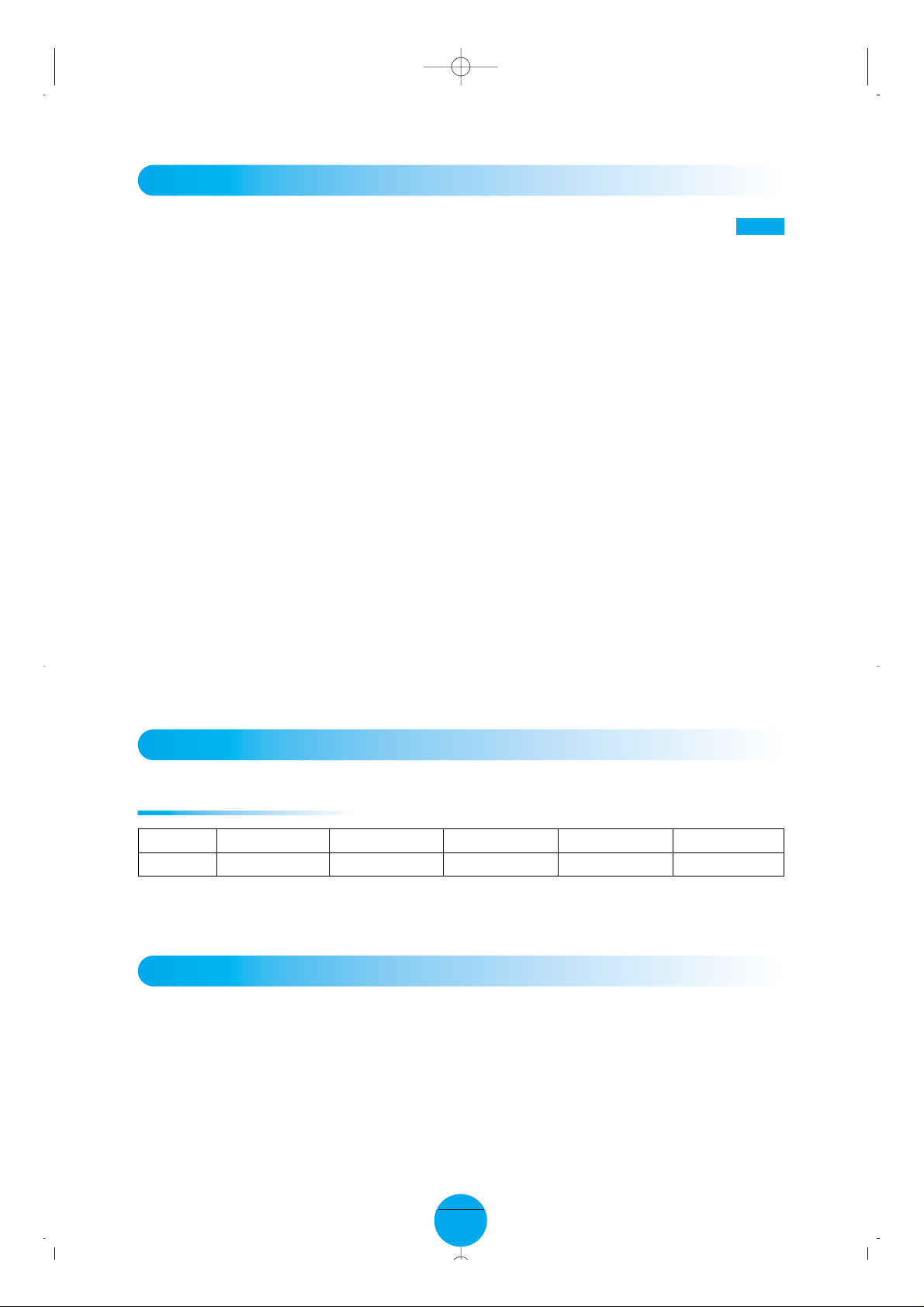

Part List

* Assemble CUTTING BOARD and BRACKETS as above drawing.

NO PART NAME SPECIFICATION QUANTITIES

1 CUTTING BOARD 67’* 19 5/16’* 1/2’ 1

2 CUTTING BOARD BRACKET SUS304 2

3 LID BRACKET LEFT SUS304 1

4 LID BRACKET CENTER SUS304 1

5 LID BRACKET RIGHT SUS304 1

6 CUTTING BOARD KEY SCREW M5*L6.5 2

7 SCREW M4*10 10

6

3

4

5

7

2

1

CUTTING BO ARD & BRA CKETS Installation Schematic Diagram

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지3

Page 4

4

Master bilt

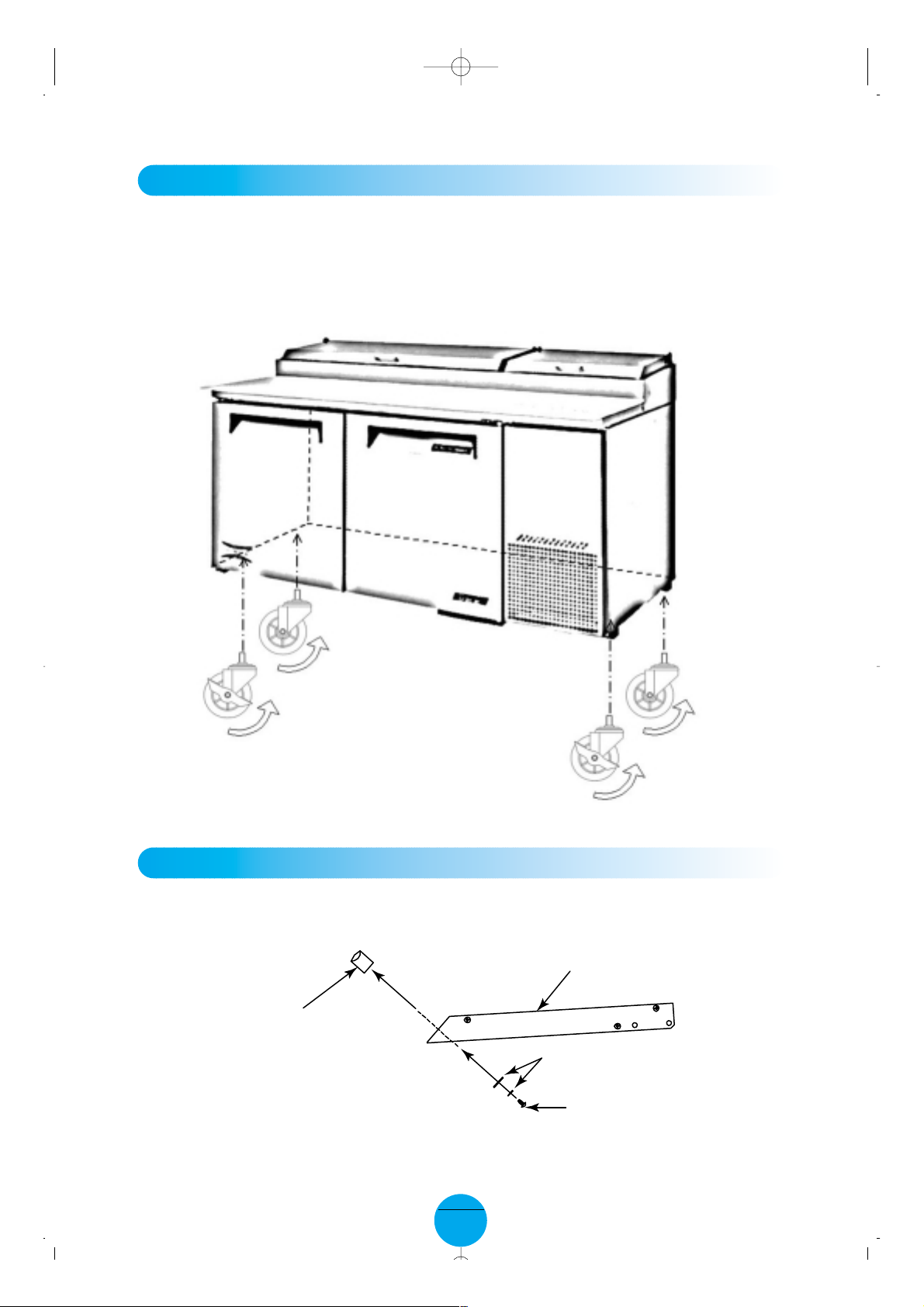

1) HANDLE ASSEMBLY

* Assemble the handle with washers and screws as above drawing.

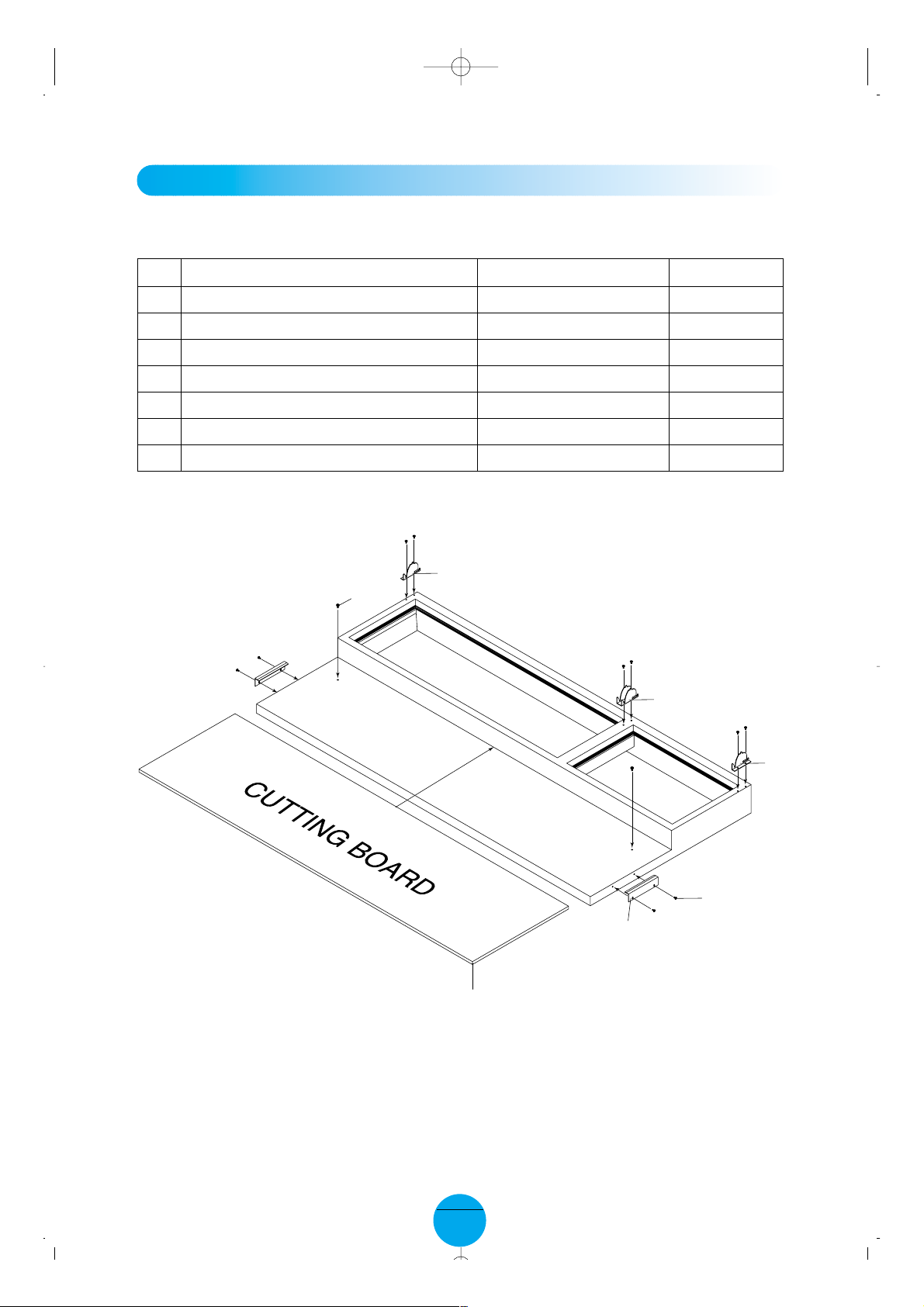

1) Screw the castor (in rear side) and the castor brakes (in front side) by using

castor wrench.

2) Use the castor shims to level the cabinet, if necessary, by inser ting them to

stems of the castors.

INSTALLA TION OF CASTOR AND CAST OR BRAKE

INSTALLA TION OF HOOD LID

Rotation

CASTOR (2EA)

DOOR(L)

DOOR(R)

CABINET

CASTOR (WITH BRAKE) (2EA)

WASHER

SIDE VIEW OF

HOOD LID

SCREW

HANDLE

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지4

Page 5

5

Master bilt

2) Assemble HOOD LID BRACKET like drawing below.

3) Insert HOOD LID SHAFT like drawing below.

* Insert shaft and pull hood lid with parallel like arrow direction.

INSTALLA TION OF HOOD LID

LEFT LID

RIGHT LID

FRONT VIEW OF THE UNIT

There are 3 kinds of bracket. They are for left, middle, right position.

LEFT BRACKET’S

BENDING DIRECTION

IS LEFT.

RIGHT BRACKET’S

BENDING DIRECTION

IS RIGHT.

HOOD

LID

SHAFT

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지5

Page 6

6

Master bilt

HO W T O CLEAN THE PAN AIR DUCT PANEL

HO W T O OPEN AND CLOSE THE HOOD LID

1) Remove all pans.

2) Clean the PANEL with cloth and warm water.

❈ When cleaning where pans are located or putting and removing food, be

careful that hood lid is in lid brackets correctly so it will not fall.

MODEL: PPT-67

The Pan Air Duct Panel is

located under pans.

PAN (6+3EA)

HOOD LID

1) When opening HOOD LID, push

forward away from you till locked

in place at lid bracket.

2) When closing HOOD LID, lift

handle and pull up, and close

slowly.

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지6

Page 7

7

Master bilt

1. GOOD AIR CIRCULATION

- Do not place any object that will restrict air flow in front or back grills.

- Turbo air highly recommends that there is ample space in rear of unit. 3 inches or more

is best.

2. PLACE ON STRONG GR OUND

- Be sure the location chosen has a floor strong enough to suppor t the total weight of

the cabinet and contents.

3. DO NOT PLA CE NEAR HEAT

- Be sure to avoid hot corners and locations near stoves .

- High ambient temperature will make cooling efficiency lower .

4. INDOOR USAGE ONLY

- Be sure to install this unit indoor, so it will not get wet from the rain.

5. STABILIZING

- Make sure the unit is installed in a stable condition with the front wheels lock ed

while in use.

6. LEVELING

- Be sure that the unit is level from front to bac k and side to side.

INSTALLA TION

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지7

Page 8

8

Master bilt

CLEANING

1. POWER CORD

- Be sure the power cord is connected to the proper voltage.

- A protected circuit of the correct voltage and amper age must be run for connection of

the line cord.

- Turn ‘off’ the power switch bef ore disconnecting the pow er cord, whene v er perf orming

maintenance functions or cleaning the refrigerated cabinet.

- Compressor warranties are void if compressor b urns out due to low voltage .

2. RE-STARTING

- If disconnected, wait 5 minutes before re-starting.

3. POSITIONING FOOD

- Do not obstruct the air inlet which is located at the right inside of the unit.

- Check the gap between the air inlet and food (etc.) whether abo ve 3 inch or not.

CA UTION

Before cleaning, turn unit off at power switch.

1. CLEANING THE INTERIOR AND EXTERIOR

- The interior and exterior of the unit can be cleaned using warm water with soap.

- Do not use an abrasive cleaner because it will scratch the surf ace.

2. CLEANING THE CONDENSER FINS

- To maintain proper refrigeration performace, the Condenser coil must be free of dust,

dirt, and grease.

This will require periodic cleaning. Condenser fins should be cleaned at least every

three months (90 days) or as needed.

- To clean condenser, unplug at power cord. Condenser can be cleaned with vaccum,

brush, or CO2 (high pressure air).

3. CLEAN THE GASKET

- The door gasket should be cleaned frequently to maintain proper sealing.

4. CLEAN THE DRAIN PAN

- Empty the Drain Pan which is located under the unit, periodically.

- When reinstalling Drain Pan, mak e sure Drain Hose is placed back in pan.

5. CHECK AFTER CLEANING

- Plug unit back in and turn on power switch.

- Check that the unit is operating properly.

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지8

Page 9

9

Master bilt

BASIC OPERATION

PPT-67

1. The controller(thermostat) is located at the right inside of the unit.

2. The factory setting for the control is ‘Normal’, and maintains about 38˚F (3˚C) inside.

3. Set toward “Cool” for higher temperature and “Cold” f or lo wer temperature .

4. The thermostat controls compressor’s cycling b y sensing inside temperature.

5. When unit will not be used for a long time , turn the power switch off located under the

thermostat knob.

REFRIGERAT ORS

OFF

COOL

COLD

NORMAL

T emperature Controller

(Thermostat)

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지9

Page 10

10

Master bilt

BEFORE REQUESTING SER VICE

SYMPTOMS CAUSES SOLUTIONS

Refrigerator(Freezer)

is freezing(melting)

food.

The unit does not

refrigerate at all.

The unit does not

refrigerate well.

There is a loud noise.

There are dew-drops

on the unit exterior .

There are dew-drops

on the unit interior.

The door does not

close tightly.

• The setting temperature is too

low(high) to maintain food

freshness.

• There is a power connection

failure problem.

• The unit is in sunlight or near a

heating device.

• The unit contains hot food or too

much food.

• The unit door is opened too

frequently or left open too long.

• The temp . dial is not on the

correct position.

• The condenser is clogged.

• The floor is too weak or the

leveling f eet are set incorrectly.

• The backside of the unit is too

close to the wall.

• The tra y is not in the correct

position.

• High-moisture air can produce

dewdrops during rainy seasons.

• The door is opened too

frequently or left open too long.

• Damp food is stored.

• The door is bent.

• The unit is not lev el.

• The door gasket has come out.

• Turn the temperature dial to a

warmer(colder) setting.

•

Check the power cord to mak e sure

the unit is pluged in it correctly

.

• Mov e out of sunlight or aw a y

from heater.

• Check the condition of stored

food.

• Check the position of the temp

control dial.

• Check the installation and

adjust the tray position.

• Wipe with a dry cloth.

• K eep the door closed to

remove dewdrops .

• Lev el the unit again.

• Reposition the gasket.

The following points are not malfunctions:

• A water-flowing sound can be heard when the compressor stops.

This is the sound of REFRIGERANT flowing.

• The compressor does not run during the defrost cycle.

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지10

Page 11

11

Master bilt

Warranty Claims

All claims for labor or parts must be made directly through Turbo Air. If unit was manufactured more than one year,

proof of purchase must be faxed in or sent with claim. All claims should include: model number of the unit, the serial

number of the cabinet, and all pertinent information supporting the existence of the alleged defect.

If compressor is replaced under warranty, Turbo Air will either request the compressor or compressor tag be returned.

Compressor or tag must be returned with all information related to the unit. Any action or breach of these warranty

provisions must be commenced within one year after said cause of action has occurred.

One Y ear Parts & Labor Warranty

Turbo Air warrants to the original purchaser of every new Turbo Air refrigerated unit, the cabinet and all parts thereof,

to be free from defects in material or workmanship, under normal and proper use and maintenance service as

specified by Turbo Air and upon proper installation and start-up in accordance with the instruction packet supplied

with each Turbo Air unit. Turbo Air’s obligation under this warranty is limited to a period of one (1) year from the date

of original installation or 15 months after shipment date from Turbo Air, whichever occurs first.

Any parts, covered under this warranty, that are determined by Turbo Air to have been defective within one (1) year

of original installation or fifteen (15) months after shipment date from manufacturer, whichever occurs first, is limited to

the repair or replacement, including labor charges, of defective parts or assemblies. The labor warranty shall include

standard straight time labor charges only and reasonable travel time, as determined by Turbo Air.

Additional Four Year Compressor W arranty

In addition to the one (1) year warranty stated above, Turbo Air warrants its hermetically sealed compressor to be free

from defects in both material and workmanship under normal and proper use and maintenance service for a period of

four (4) additional years from the date of original installation, but not to exceed five (5) years and three (3) months

after shipment from the manufacturer.

Compressor determined by Turbo Air to have been defective within this extended period will, at Turbo Air’s option, be

either repaired or replaced with a compressor or compressor parts of similar design and capacity.

The four (4) year extended compressor warranty applies only to hermetically sealed parts of the compressor and

does not apply to any other parts or components, including, but not limited to, cabinet, paint finish, temperature

control, refrigerant, metering device, driers, motor starting equipment, fan assembly or and other electrical

component, etcetera.

404A / 134A Compressor Warranty

The four-year compressor warranty detailed above will be voided if the following procedure is not carefully adhered to:

1. This system contains R404A or R134A refrigerant and polyolester lubricant. The polyol ester lubricant has

rapid moisture absorbing qualities.

2. Drier replacement is very important and must be changed when a system is opened for servicing. A 620

copper drier or better is highly recommended.

3. Micron level vacuums must be achieved to insure low moisture levels in the system. 500 microns or lower

must be obtained.

4. When compressor is grounded, suction filter drier and 620 drier or better must be replaced.

5. Compressor must be obtained through Turbo Air Inc., unless otherwise specified in writing, through Turbo

Air’s warranty department.

Warranty

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지11

Page 12

12

Master bilt

CHANGES MADE TO WARRANTY COMMENCED ON 5/1/2002

What Is Not Covered By This W arranty

Turbo Air’s sole obligation under this warranty is limited to either repair or replacement of parts, subject to the

additional limitations below. This warranty neither assumes nor authorizes any person to assume obligations other

than those expressly covered by this warranty.

NO CONSEQUENTIAL DAMAGES. TURBO AIR IS NOT RESPONSIBLE FOR ECONOMIC LOSS; PROFIT

LOSS; OR SPECIAL, INDIRECT, OR CONSEQUENTIAL DAMAGES, INCLUDING WITHOUT LIMITATION,

LOSSES, OR DAMAGES ARISING FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT

BECAUSE of REFRIGERATION FAILURE.

WARRANTY IS NOT TRANSFERABLE. This warranty is not assignable and applies only in favor of the original

purchaser / user to whom delivered. ANY SUCH ASSIGNMENT OR TRANSFER SHALL VOID THE WARRANTIES

HEREIN MADE AND SHALL VOID ALL WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

IMPROPER USAGE. TURBO AIR ASSUMES NO LIABILITY FOR PARTS OR LABOR COVERAGE FOR

COMPONENT FAILURE OR OTHER DAMAGES RESULTING FROM IMPROPER USAGE OR INSTALLATION

OR FAILURE TO CLEAN AND / OR MAINTAIN PRODUCT AS SET FORTH IN THE WARRANTY PACKET

PROVIDED WITH THE UNIT.

ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT OR INSTALLATION,

FIRE, FLOOD, ACTS OF GOD. Turbo Air is not responsible for the repair or replacement of any parts that Turbo Air

determines have been subjected after the date of manufacture to alteration, neglect, abuse, misuse, accident,

damage during transit or installation, fire, flood, or act of God.

IMPROPER ELECTRICAL CONNECTIONS. TURBO AIR IS NOT RESPONSIBLE FOR THE REPAIR OR

REPLACEMENT OF FAILED OR DAMAGED COMPONENTS RESULTING FROM ELECTRICAL POWER

FAILURE, THE USE OF EXTENSION CORDS, LOW VOLTAGE, OR VOLTAGE DROPS TO THE UNIT.

NO IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE: THERE

ARE NO OTHER WARRANTIES, EXPRESSED, IMPLIED OR STATUTORY, EXCEPT THE ONE (1) YEAR

PARTS & LABOR WARRANTY AND THE ADDITIONAL FOUR (4) YEAR COMPRESSOR WARRANTY AS

DESCRIBED ABOVE. THESE WARRANTIES ARE EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES,

INCLUDING IMPLIED WARRANTY AND MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

THERE ARE NO WARRANTIES, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF.

OUTSIDE U.S. AND CANADA: This warranty does not apply to, and Turbo Air is not responsible for, any warranty

claims made on products sold or used outside the United State and Canada.

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지12

Page 13

13

Master bilt

908 Highway 15 North • New Albany, MS 38652

Phone: (662)534-9061•Toll-Free: 800-647-1284

FAX: (662)534-6049•Toll-Free: 800-232-3966

www.master-bilt.com

PPT-67(Pizza Prep) 2003.2.8 11:57 AM 페이지13

Loading...

Loading...