Page 1

1

Deluxe Ice Cream Dipping/Display Merchandisers

Installation & Operations Manual

ControlTec TLY25

Master-Bilt Products

908 Highway 15 North

New Albany, MS 38652

Phone: (800) 684-8988

Rev 6-10-11

Page 2

2

Page 3

3

TABLE OF CONTENTS

INTRODUCTION………………………………….…………………………………………………………………... 4

STORE CONDITIONS…………………………….……………….…..…………………………………………….. 4

WARNING LABELS AND SAFETY INSTRUCTIONS………..…..……………………………………………… 5

PRE-INSTALLATION INSTRUCTIONS………………………..…..……………………………… ….…………… 5

Inspection for Shipping Damage…………………………………………………………….…………….. 5

INSTALLATION INSTRUCTIONS………………………………………………………………………………….. 6

General Instructions…………………………………………………………………………………………. 6

Electrical…..………………………………………………………………………………………………….. 6

Mechanical…………………………………………………………………………………………………… 7

Startup………………………………………………………………………………………………………. 7

ControlTec Electronic CONTROL.…………………………………………………………………………… …8-9

CLEANING INSTRUCTIONS……………………………………………………………………………………..…10

Can Holder Cleaning………………………………………………………………………………………...10

Frost Shield Cleaning……………………………….……………………………………………………….10

OPERATION CONDITIONS AND PRESSURES …………………………………………………………………11

SERVICE INSTRUCTIONS (Trouble Shooting )………………………………………………………………….11

MASTER-BILT PART NUMBERS………………………………………………………………………………….. 12

ACCESSORIES………………………………………………………………………………………………………...13

SALE AND DISPOSAL……………………………………………………………………………… ………………. 13

WIRING DIAGRAMS.……………………………………………………………………………………………...14-15

Page 4

4

INTRODUCTION

Thank you for purchasing a Master-Bilt cabinet. This manual contains important instructions for installing, using and

servicing a Master-Bilt DD_LCG case. A parts list is included in with this manual. Read all these documents carefully

before installing or servicing your equipment.

STORE CONDITIONS

The Master-Bilt DD_LCG cases are designed to operate in the controlled environment of an air-conditioned store. The

store temperature should be at or below 75°F and a relative humidity of 55% or less. At higher temperature or humidity

conditions, the performance of these cases may be affected and the capacity diminished. It is not uncommon in a newly

constructed store for the temperature and humidity to be above design conditions. These excessive conditions may

produce sweating in the case until the store is operational and the ambient environment is more desirable.

The Master-Bilt DD_LCG should not be positioned where it is directly exposed to rays of sun or near a direct source of

radiant heat or airflow. This will adversely affect the case and will result in poor performance.

NOTICE

Read this manual before installing your cabinet. Keep the manual and refer to it before doing any service on

the equipment. Failure to do so could result in personal in jury or damage to the cabinet.

DANGER

Improper or faulty hook-up of electrical components of the refrigeration units can result in severe injury or

death.

All electrical wiring hook-ups must be done in accordance with all applicable local, regional or national

standards.

NOTICE

Installation and service of the refrigeration and electrical components of the cabinet must be performed by a

refrigeration mechanic and/or a licensed electrician

The portions of this manual covering refrigeration and electrical components contain technical instructions intended only

for persons qualified to perform refrigeration and electrical work.

This manual cannot cover every installation, use or service situation. If you need additional information have the serial

number at hand and call or write us:

Customer Service Department

Master-Bilt Products

Highway 15 North

New Albany, MS 38652

Phone (800) 684-8988

Fax (800) 684-8988

Page 5

5

CAUTION!

GROUND REQUIRED

FOR SAFE OPERATION

WARNING LABELS AND SAFETY INSTRUCTIONS

This symbol is the safety-alert symbol. When you see this symbol on your cabinet or in this

manual, be alert to the potential for personal injury or damage to your equipment.

Be sure you understand all safety messages and always follow recommended precautions and safe operating practices.

NOTICE TO EMPLOYERS

You must make sure that everyone who installs, uses or services your cabinet is thoroughly familiar with all

safety information and procedures.

Important safety information is presented in this section and throughout this section and throughout the manual. The

following signal words are used in the warnings and safety messages:

DANGER: Severe injury or death will occur if you ignore the message.

WARNING: Severe injury or death can occur if you ignore the message.

CAUTION: Minor injury or damage to your cabinet can occur if you ignore the message.

NOTICE: This is important installation, operation or service information. If you ignore the

message, you may damage your cabinet.

The warning and safety labels shown throughout this manual are placed on your Master-Bilt Products cabinet

at the factory. Follow all warning label instructions. If any warning or safety labels become lost or damaged,

call your customer service department at (800) 684-8988 for replacements.

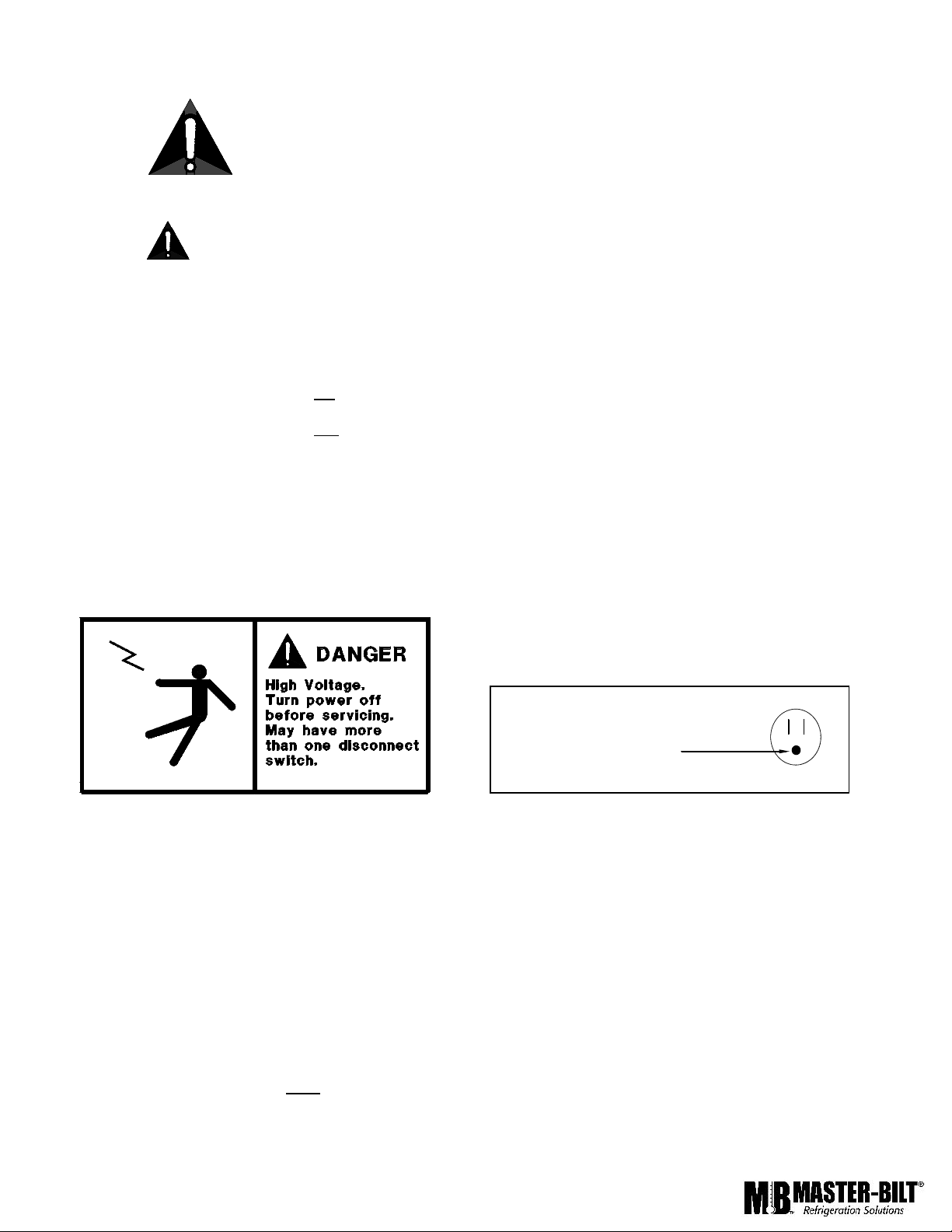

This label is located on top of the electrical control This label is attached to the cabinet power cord

label and on the wiring channel. on models with a power cord.

PRE-INSTALLATION INSTRUCTIONS

INSPECTION FOR SHIPPING DAMAGE

You are responsible for filing all freight claims with the delivering truck line. Inspect all cartons and crates for damage as

soon as they arrive. If damage is noted to shipping crates or cartons or if a shortage is found, note this on the b ill of

lading (all copies) prior to signing.

If damage is discovered when the cabinet is uncrated, immediately call the delivering truck line and follow up the call with

a written report indicating concealed damage to your shipment. Ask for an immediate inspection of your concealed

damage item. Crating material must be retained to show the inspector from the truck line.

Page 6

6

INSTALLATION INSTRUCTIONS

GENERAL INSTRUCTIONS

1. Be sure the equipment is properly installed by competent service people.

2. Keep the equipment clean and sanitary so it will meet your local sanitation codes.

3. Rotate your stock so that older stock does not accumulate. This is especially important for ice

cream. A "First-In, First-Out" rotation practice will keep the products in good salable condition.

4. Do not place product in the case when it is soft or partially thawed. Also, product should not be put in the case for at

least 6 hours after it is started.

5. Stock cases as quickly as possible, exposing only small quantities to store temperatures for short periods of time.

6. When replacing burned out fluorescent tubes, be sure that the electrical power to the lighting circuit is turned off.

NOTICE TO STORE OWNERS / MANAGERS

Moisture or liquid around or under the cabinet is a potential slip/fall hazard for persons walking by or working

in the general area of the cabinet. Any cabinet malfunction or housekeeping problem that creates a slip/fall

hazard around or under the cabinet should be corrected immediately.

If moisture or liquid is observed around or under a Master-Bilt cabinet, an immediate investigation should be made by

qualified personnel to determine the source of the moisture or liquid. The investigation should determine if the cabinet is

malfunctioning or if there is a drainpipe leaking.

ELECTRICAL

WARNING

Before servicing electrical components in the case, make sure all power to case is off. Always use a qualified

technician.

Page 7

7

MECHANICAL

Remove grille and check refrigeration lines to see that they are free (not touching each other or compressor).

Spin condenser fan blade to see that it is free.

Check that all service valves are open.The picture below is Master-Bilt’s standard DD-Unit. The compressor is hermetic,

it is internally spring mounted and ready to run.

Hermetic Compressors

Remove cabinet from crate base and slide into location. Cabinet must be level from side to side and front to back.

To comply with Sanitation requirements the cabinet must be mounted on legs (6” high min.) or casters or the base must

be sealed to the floor with an N.S.F. listed silicone sealant.

STARTUP

Uncoil the lead cord and pass it through the hole provided in the grill. While the cabinet is in operation, check the

voltage draw and the amperage draw versus this rating on the nameplate. Voltage should be checked at the

compressor terminals while the compressor is initially starting. The unit is designed to operate at +/- 10% of 115 volts,

60 cycle, single phase. This means that the voltage should be between 103 and 126.5 volts.

A separate 20 amp. fuse circuit for each cabinet is recommended to avoid the possibility of other appliances on a circuit

from overloading and causing a malfunction. Make sure that the electrical service is grounded upon installation.

Page 8

8

712 1365 11 8

9

10

3

4

1

2

Aux

-

OK

+

Fan AuxDefOut

AL

TLY 25

MASTER-BILT ELECTRONIC REFRIGERATION CONTROL (TLY25/Y39)

GENERAL DESCRIPTION

The model TLY25/Y39 is a digital controller with microprocessor that is typically used in cooling applications that have

temperature control with ON/OFF regulation.

The instrument has 3 relay outputs, two inputs for PTC or NTC temperature probes and a digital input, that can all be

configured.

The 2 outputs can be used for controlling the compressor or the temperature control device (OUT1), and the Light switch

fuction (OUT2)

The input for the PTC and NTC temperature probes (which can be selected by parameter) can be used to measure the

wall temperature (Pr1)

TLY25 Y39

1 - Key P: Used for setting the Set point and for programming the function parameters

2 - Key DOWN/Aux: Used for decreasing the values to be set and for selecting the parameters. It can also be an Auxiliary output to

turn the lights on. For DD-LCG this Button serves as the light switch.

3 – UP Key: Used for increasing the set point value

4 - Key U: Used for visualising the temperatures taken by the cell probes and evaporator (Pr1 and Pr2) . Also used for turning the

Condensing unit On/Off, buy push and hold U button for 5 seconds.

5 - Led OUT: Indicates the compressor output status (or the temperature control device) on (on), off (off) or inh ibited (flashing)

6 - Led DEF: Indicates defrosting in progress (on) or dripping (flashing) .

7 - Led FAN: Indicates fan output status on (on), off (off) or delayed after defrosting (flashing)

8 - Led AUX: Indicates AUX output status on (on), off (off) or inhibited (flashing)

9 - Led AL: Indicates the alarm status (on), (off) and silenced or memorized (flashing)

10 - Led SET: Indicates the input in programming mode and the programming level of the parameters. It also serves to indicate

the Stand-by status.

11 - Led -: Indicates that a low temperature alarm is in progress (lit) or that a low temperature alarm has been memorised

(flashing).

12 - Led OK: Indicates that no alarms are in progress

13 - Led +: Indicates that a high temperature alarm is in progress (lit) or that a high temperature alarm has been memorised

(flashing)

Page 9

9

OPERATION

HOW TO CHANGE SET POINTS

1. Press the P until sp-1 is displayed.

2. Push UP ▲ or DOWN▼ arrows to change the value.

3. To Exit: wait 20 seconds without pressing a key.

NOTE 1: The set value is stored even when the procedure is exited by waiting the time-out to expire.

NOTE 2: Master-Bilt’s SETPOINT is set at a recommended -5 to -10F at the factory.

NOTE 3: If power is turned off to the unit, wailt for at least 2 minutes before power the case back up to prevent from

short cycle.

PARAMTERS SET POINTS

DISPLAY

SYMBOL

PARAMETER

MASTER-

BILT

SETTING

SP

Set point

-5°F

D

Differential

5

LS

Low limit Set point

-15°F

HS

High limit set point

+30°F

HA

Hight Temperature Alarm

32°F

ALARM SIGNALS

MESSAGE

CAUSE

OUTPUT

E1

Sensor

Bad Sensor or Sensor got disconected from the

controller.

od

Delay on in progress

Wait for delay cycle end.

HI

Maximum temperature alarm in

progress

Output temperature unchanged. Cabinet too warm!

LO

Minimum temperature alarm in

progress

Output Unchanged. Cabinet Too cold

AL

Digital input alarm in progress

Lights

Page 10

10

CLEANING

WARNING: DO NOT REMOVE FROST WITH A KNIFE, PICK, OR SHARP OBJECTS. DO NOT USE ABRASIVE

CLEANERS OR CAUSTIC CLEANERS OR SCOURING PADS

Every 30 to 60 days (depending on frost accumulation), the cabinet should be emptied, warmed up, and wiped down

using a solution of 1 teaspoon of baking soda with 1 quart of water. This solution will help eliminate odors. Do not use

strong soaps or detergents as they leave odors that can contaminate your product. The DD line cabinets are equipped

with a floor drain that exits out the lower rear of the cabinet. This exit has a convenient garden hose fitting.

If it is not convenient to turn the power off the cabinet, lay a piece of plastic sheeting on the floor of the cabinet and

scrape the frost off walls using a plastic scraper. Do not use metal scrapers. This will damage the interior paint of the

cabinet.

Lid Removal and Cleaning

The lid can be remove by lifting up and out (see picture). The

lid is a high-impact plastic. Wash with warm soapy

water or non-abrasive detergent to avoid scratching.

Can Holder Assembly Removal and Cleaning (Optional)

Remove plastic can clamp by screwing knob off the threaded shaft.

Wash the can holder and can clamp with a non-abrasive detergent to

maintain sanitary gloss. Remove the shaft by loosening the wing nut

and unscrewing the shaft from the shelf. Wash the shaft and shelf

using a non-metallic brush.

Frost-Shield Removal and Cleaning (optional)

When the frost-shields accumulate approximately ½ to 1

inch of frost (about two to three days), remove it by lifting

up to disengage from the keyhole slot. Remove the frost

by holding under running water until clean. Dry and

replace the frost-shield by engaging screws at the big end

of the keyhole and push down.

Page 11

11

OPERATION CONDITIONS AND PRESSURES

With room ambient temperature of +80oF and cold cabinet (unit cycling on control):

DD-66 & DD-88 with R-404a

Suction pressure – 6 to 8 psig.

Head pressure – 240 to 260 psig.

If room ambient is low, 60 oF or lower, then the suction pressure could be as low as 4 psig. Temporary block the

condenser coil to raise head pressure to 240 psig in order to verify proper charge and a suction pressure of 6psig to 8

psig. Remove blockage after pressure check.

SERVICE INSTRUCTIONS (Trouble Shooting Guide)

1. High head pressure and high back

pressure:

A. Condenser coil clogged or

restricted.

B. Condenser fan motor defective.

C. Air in the system.

D. Refrigeration overcharge.

2. Low back pressure and low head pressure:

A. Capillary tube restriction.

B. Refrigerant undercharged.

C. Leak in system.

D. Moisture in system.

3. Pressures normal – cabinet warm:

A. Refrigerant undercharged.

B. Thermostat set too warm.

4. Compressor starts and runs – but cycles

on overload:

A. Low voltage.

B. Overload protector defective.

C. High head pressure (see#1).

5. Compressor will not start – hums, but

cycles on overload:

A. Low voltage.

B. Relay defective.

C. Overload defective.

D. High head pressure (see #1).

6. Cabinet sweating:

A. High ambient humidity.

7. Special service situations

If moisture or liquid is observed around or under a Master-Bilt cabinet, an immediate investigation should be made

by qualified personnel to determine the source of moisture or liquid. The investigation made should determine if

the cabinet is malfunctioning or if there is a simple housekeeping problem.

Moisture or liquid around or under a cabinet is a potential slip/fall hazard for persons walking by or working

in the general area of the cabinet.

Any cabinet malfunction or housekeeping problem that creates a slip/fall hazard around or under a cabinet

should be corrected immediately.

Page 12

MASTER-BILT PART NUMBERS

Description

DD-46LCG

DD-66LCG

DD-88LCG

LED Lighting kit

23-01740

23-01739

23-01738

Capillary Tube

11-01306

11-01450 (2 REQ)

11-01450 (2 REQ)

Compressor

03-14761

03-14902

03-14902

Condenser Coil

07-13253

07-13296

07-13296

Condenser Fan Blade

15-13093

15-13093

15-13093

Condenser Fan Motor

13-00311

13-00311

13-00311

Condenser Fan Motor Bracket

13-00754

13-00754

13-00754

Condensing Unit

Drier

09-09171

09-09171

09-09171

Fluorescent Lamp, 18”

23-00329

Fluorescent Lamp, 36”

23-00325

23-00325

23-00325

Gasket

37-00497

37-00498

37-00499

Glass, Tempered (Curved Glass)

31-02927

31-02926

31-02925

Lid Assembly

062-145A

060-145A

061-145A

Power Switch

19-01090

19-01090

19-01090

Shelf, Wire

33-01413

33-01413

33-01413

Electronic Temperature Control

19-13952 (TLY-25)

19-14205 (Y-39)

19-13952 (TLY-25)

19-14205 (Y-39)

19-13952 (TLY-25)

19-14205 (Y-39)

Wire Harness (126” Power Cord)

21-00524

21-00524

21-00524

The table below gives Master-Bilt part numbers. Use this chart when ordering replacement parts for your

12

Page 13

Accessories

Description

DD-26(CG)(-L)

DD-46(CG)(-L)

DD-66(CG)(-L)

DD-88(CG)(-L)

Can Holders –Includes

White Can Covers

A059-200300

A062-20300

A060-20300

A061-20300

Can Covers

Clear

White

44-00984

44-00973

44-00984

44-00973

44-00984

44-00973

44-00984

44-00973

Casters

Set (4), 3” Dia.

Set (6), 3” Dia.

A062-11140

A062-11140

A061-11140

A061-11140

Condiment Holders and

Food Pan Display

A059-10650

A062-10650

A060-10650

A061-10650

Individual Containers for

Condiment Holders (Clear)

44-01020

44-01020

44-01020

44-01020

Dipper Well

w/Installation Kit

A060-20400

A060-20400

A060-20400

A060-20400

Frost Shield (Patented)

Master-Bilt Exclusive

A059-11150

A062-11150

A060-11150

A061-11150

Legs

6” leg kit

A062-11170

A062-11170

A061-11170

A061-11170

Lid Locking Kits –

Less Locks

A059-11129

A059-11129

A060-11129

A060-11129

DDN Flavor Tags

A062-20225

A062-20225

A062-20225

A062-20225

SALE AND DISPOSAL

OWNER RESPONSIBILITY

If you sell or give away your Master-Bilt cabinet you must make sure that all safety labels and the Installation Service Manual are included with it. If you need replacement labels or manuals, Master-Bilt will provide them free.

Contact the customer service department at Master-Bilt at (800) 684-8988.

The customer service department at Master-Bilt should be contacted at the time of sale or disposal of your cabinet

so records may be kept of its new location.

If you sell or give away your Master-Bilt cabinet and you evacuate the refrigerant charge before shipment, MasterBilt recommends that the refrigerant charge be properly recovered in compliance with section 608 of the Clean Air

Act effective November 1995 and in accordance with all applicable local, regional, or national standards.

13

Page 14

14

Page 15

15

Loading...

Loading...