USER’S MANUAL

INSTRUKCJA OBSŁUGI

РУКОВОДСТВО ПО ПРИЕМЕНЕНИЮ

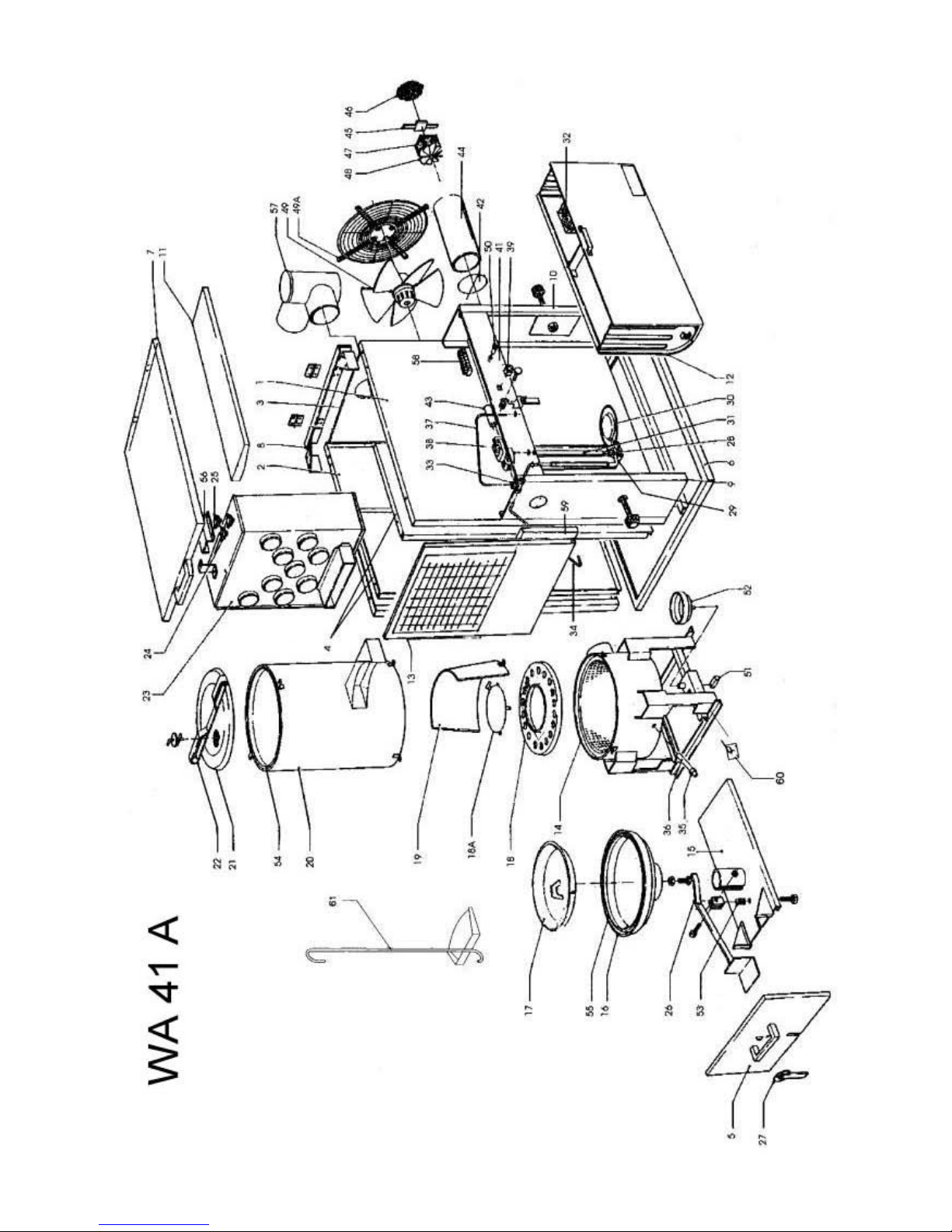

WA 41 A

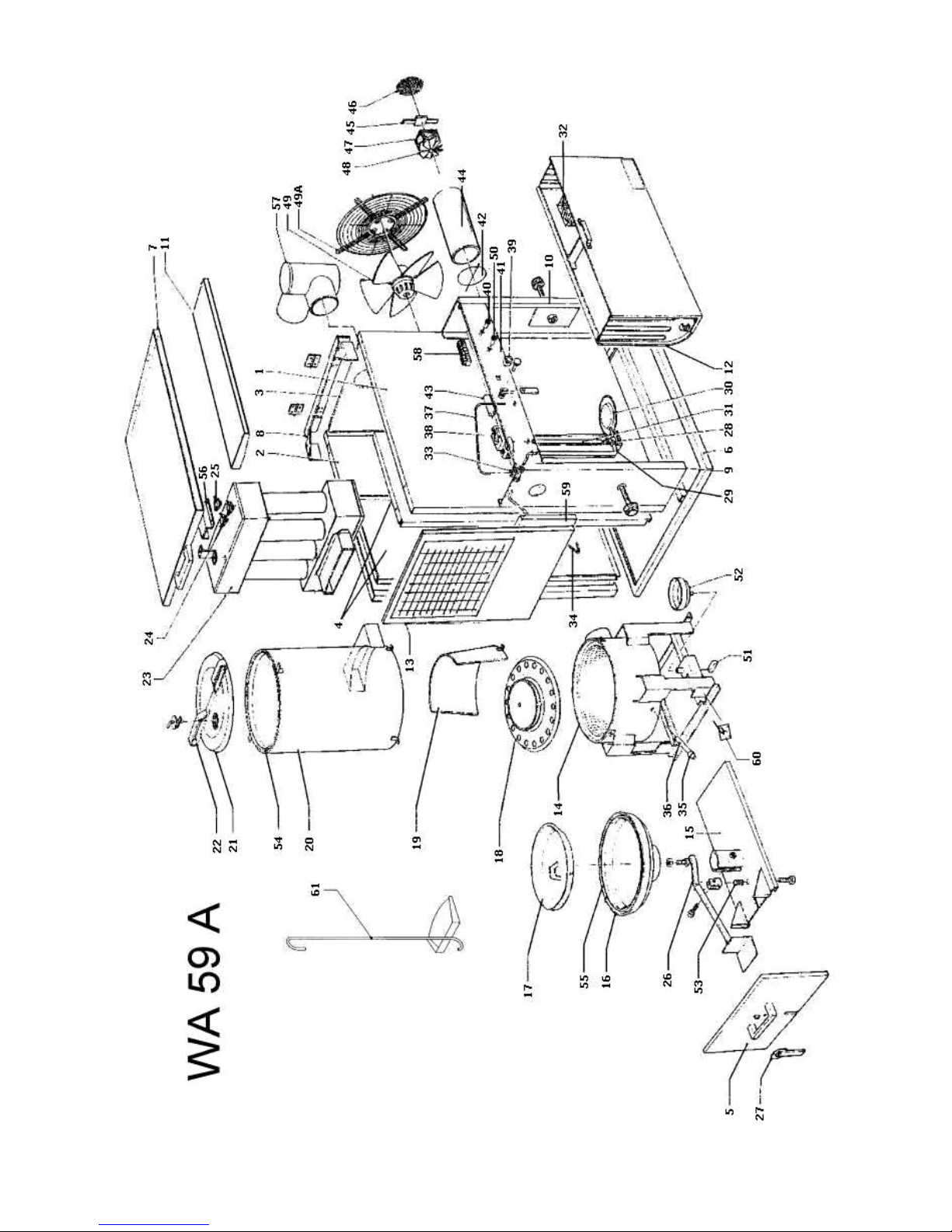

WA 59 A

UNIVERSAL OIL HEATERS

NAGRZEWNICE NA OLEJ UNIWERSALNY

НАГРЕВАТЕЛИ НА УНИВЕРСАЛЬНОЕ

МАСЛО

Installation must be made in accordance with local regulations which may differ from this installation manual.

Montażu należy dokonać zgodnie z lokalnymi przepisami, które mogą się odbiegać od zaleceń w poniższej

instrukcji obsługi.

Сборку следует провести в согласии с местными законами, которые могут отличаться от этого

руководства.

CONTENTS PAGE

SPIS TREŚCI STRONA

СОДЕРЖАНИЕ СТРАНИЦА

*

Description, warnings and installation

Opis, ostrzeżenia i montaż

Описание, предупреждения, сборка

*

Combustion chamber, ignition procedire and safeguards

Komora spalania, uruchamianie i zabezpieczenia

Камера сгорания, порядок запуска, предохранительные устройства

*

Maintenance, taking out of operation,

and draught test indicator

Konserwacja, wyłączanie i tester przewodu kominowego

поддержка, oкончание процесса и указатель проверки тяги

*

Drawing

Schemat urządzenia

Схема нагревателя

*

Spare parts list

Lista części zamiennych

Список запасных частей

*

Faults

Usuwanie usterek

Устранение неисправностей

*

Technical details

Dane techniczne

Технические данные

Electric wiring diagram

Schemat elektryczny

Электрическая схема

40.020.040

-NLC-

ENGLISH

To obtain full benefit from the WA 41 A and

trouble free operation, read the following instructions and information carefully.

DESCRIPTION AND FUNCTION

* The control panel incorporates a

switch, a locking device for the fuel and a

pilot light.

* The electric pump motor drives the fuel

pump, which is positioned in the tank.

* The fuel pump delivers fuel to the com-

bustion dish and is controlled by means of

the button above the control panel,

At position low, the consumption is approx.

2,5 l/h. At position high, the consumption

is approx. 4,3 l/h.

One and another depends on viscosity.

* The main fan is controlled by a thermostat.

As soon as the combustion chamber has warmed

up sufficiently, the fan starts to operate.

* The burner is equipped with an air intake

fan to supply air for combustion. This air

combustion fan stops when the flame has

extinguished. Pipes φ 200 mm can be

connected to this fan so that the combustion

air can be sucked from outside the area to

be heated.

* Most types of waste oil can be used, such as

gearbox oil, gas oil, diesel oil, hydraulic

oil, HBO 1, 2 and 3, but not those with a

high viscosity, such as SAE90.

DO NOT USE TRANSFORMER OIL WHICH MIGHT

CONTAIN SUBSTANCES DETRIMENTAL TO THE

PERFORMANCE OF THE BURNER (PCB)

* When the pump motor stops, the flame will

extinguish once the fuel in the burner dish

is exhausted.

WARNINGS

1 There could be a possible danger of

explosion if the burner is reignited while

it is still warm.

2 There must be sufficient air for combustion;

make sure that the combustion air intake fan

is never blocked.

3 Modifications made to the burner by dealer

or end user, invalidate the manufacturer's

warranty.

INSTALLATION

* For installation, consult the local

prescriptions.

* The burner must be installed on a completely

level, concrete floor.

* Check that the chose position presents no

problem for:

- electrical supply 230V/2Amp.;

- flue pipe installation;

- combustion air supply.

* Open the top cover of the burner and remove

the cover of the combsution

chamber.

* The following items are packed within the

combustion chamber:

1x T-piece with built-in draught stabiliser

for flue pipe connection

1x cleaning shovel

1x scraping tool to remove residue from

combustion dish

1x combustion dish

2x burner ring

1x spare card to seal the bottom of com-

bustion chamber

2x handle with bolts

1x pedal

FLUE PIPE

For clean and trouble free combustion, it is

essential that the flue pipe is installed correctly.

a. minimum diameter of flue pipe: 150mm

b. check that flue connections are well sea-

led

c. minimum flue height: 5 m

d. the wind must be able to reach the top of

the flue from all directions (e.g.: it may

be necessary to extend flue above roof

apex)

e. all pipes should be vertical if possible,

keep horizontal pipes to the absolute

minimum

f. avoid bends in the flue installation if

possible but if unavoidable e.g. if flue

has two bends because of installation

through a wall or window, then:

1. the pipe should be as high as

possible within the building

2. flue pipe outside the building

should be insulated (double

walled)

3. the minimum height of the flue

has to be increased to 7.5 m to

compensate.

use a raincap

-GBB-

COMBUSTION CHAMBER (see figure 1)

* Place burner ring (1) in the burner pot and

replace combustion chamber cover.

* Unlock the sliding bottom drawer (2) by

means of pedal (3) and safety catch (6) and

open.

* The bottom of the combustion chamber and

combustion dish are now accessible, see

figure 2.

Ignition and cleaning can now be dealt with

easily.

IGNITION PROCEDURE

1. Fill the tank with fuel. Slide the locking

button on the control panel vertically to

open the tank, which hinges forward.

2. Switch to "0"; connect plug to electricity

sypply and switch on at socket.

3. Put capacity regulator in low position.

4. Pour apporx. 1/3 litre of paraffin in the

combustion dish. Crumple some paper into a

ball, light it and drop into the dish to

ignite the oil. Close and lock the sliding

drawer. Check through the top cover that the

sealing around the bottom of the combustion

chamber is visible.

5. Switch to "1". After about 5 minutes the

combustion chamber will be warmed up

sufficiently for the main fan and pump motor

to come into operation. The orange pilot

light will illuminate.

6. After approx. 30 minutes, make any necessary

adjustments to the draught stabiliser.

7. During initial commissioning burn, there

will be some fumes from the heat resistant

paint finish and because the combustion

chamber has been oiled against corrosion.

These fumes will cease after about 30 to 40

minutes.

SAFEGUARDS

* The burner is equipped with a thermostat

controlling the flame. Should the flame be

extinguished for any reason, this thermostat

will stop the fuel pump as well as the main

fan. For causes, see chapter "Location of

faults".

* An overheating thermostat which shuts off

the fuel supply completely is reset by means

of a push button in the

burner. For causes, see chapter

"Location of faults".

* The fuel supply system is equipped with an

"overflow tube", through which the oil flows

back into the tank incase the pipe to the

burner becomes obstructed. After the flame

has extinguished, the flame control

thermostat will switch off the burner. For

causes, see chapter "Location of faults".

* The burner is equipped with an

"overflow security", located underneath

the bottom of the combustion chamber. This

will come into operation if, over a

period, the fuel is not burnt completely.

The excess fuel will flow from the

combustion dish, via an inlet tube, into a

small container. This container is

positioned on a spring-loaded micro

switch. As soon as this container is half

full, the fuel pump is switched off automatically. For causes, see chapter "Location of faults".

* The air combustion fan is equipped with a

thermostat.

Figure 1

MAINTENANCE

The heater requires very little maintenance and the

regularity of such maintenance will depend greatly on

the type(s) of waste oil being burnt. The cleaner the

fuel, the less maintenance is required.

In general:

* clean combustion dish and overflow tube daily;

* clean burner pot, burner ring and combustion

chamber at least once a week. Ensure that the

air intake holes of combustion chamber and

lower side (3) at bottem connection are not

obstructed;

* clean heat exchanger, fuel supply pipe, tank

and filter once per heating season;

* combustion chamber bottom: as soon as the seal

around the bottom of the combustion chamber is

no longer visible, it is essential that it is

replaced, normally this is once per heating

season.

* Clean filling sieve, fuel tank and filter

regularly.

* The water in the tank can be drained by means

of a tap at the bottom of the tank.

TAKING OUT OF OPERATION

* Switch to position "0". The fuel pump will

stop and the flame will be extinguished once

the oil in the combustion chamber is burnt.

* Remove the plug from the wall socket after the

air intake fan has cooled down.

* If the burner is not to be used for a long

period, combustion chamber, combustion dish,

heat exchanger and tank should be cleaned

carefully and protected against corrosion.

The heater is delivered with a spare seal. If this

seal is not replaced at the appropriate

time, leakages causing soot formation may occur. The

pedal assembly is equipped with an adjusting

screw (2).

If leakages occur or replacement of the seal is

necessary, adjust this screw so that the bottom of the

combustion chamber is set at more pres-sure against

the chamber.

┌────────────────────────────────────────────────┬─────────────────────────────────────────────────────────────┐

│ LOCATION OF FAULTS │ │

├──────┬──────┬──────┬──────┬──────┬──────┬──────┤ │

│ A │ B │ C │ D │ E │ F │ │ │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┤ │

│Flame │Flame │Soot │Heater│Heater│Over- │ │ │

│extin-│extin-│forma-│stops │heats │flow │ │ │

│gui- │gui- │tion │after │insuf-│secu- │ │

│

│shed │shes │in │15 min│fi- │rity │ │ CHECK: │

│imme- │after │burner│or │cient-│is │ │ │

│diate-│the │pot │longer│ly │filled│ │ A. Electrical connection. │

│ly af-│main │and │period│ │with │ │ B. Positioning of burner pan and burner ring. │

│ter │fan │combus│ │ │oil │ │ C. Flue installation, see page 1. │

│igni- │has │tion │

│ │ │ │ │

│tion │star- │cham- │ │ │ │ ├─────────────────────┬───────────────────────────────────────┤

│ │ted │ber │ │ │ │ │ CAUSE │ SOLUTION │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ 1 │ │ 7 │ 5 │ │ │Fuel tank is empty or│ Clean filter. │

│ │ │ │ │ │ │ │filter is obstructed.│ │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ 2 │

│ 2 │ │ │ │ │Combustion air fan │ Check: if plug is in socket. │

│ │ │ │ │ │ │ │does not work. │ Check: if fan motor is blocked. │

│ │ │ │ │ │ │ │ │ Check: electrical connections and │

│ │ │ │ │ │ │ │ │ thermostat. │

│ │ │ │ │ │ │ │ │ Check: air supply to the fan. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│

│ 3 │ │ 5 │ 3 │ │ │Supply tube is ob- │ Fuel flows into tank via return pipe, │

│ │ │ │ │ │ │ │structed. │ clean fuel supply tube. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ 4 │ │ 4 │ │ │ │Pump motor is not │ Check if pump shaft can be turned by │

│ │ │ │ │ │ │ │working. │ hand. if not, remove and clean pump. │

│ │ │ │ │ │ │ │ │ Check if oil is too viscously: turn │

│ │ │ │ │ │ │ │ │ capacity regulator to position high. │

│ │ │ │ │ │ │ │ │ Check overflow security switch by mo- │

│ │ │ │ │ │ │ │ │ ving the overflow tray a few times up │

│ │ │ │ │ │ │ │ │ and down. │

│ │ │ │ │ │ │ │ │ Control switch is not pushed in or │

│

│ │ │ │ │ │ │ │ drawn out well. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ 3 │ 5 │ │ 1 │ │ │ │Overheating security │ Too much oil has been used for the │

│ │ │ │ │ │ │ │has switched off │ ignition procedure. │

│ │ │ │ │ │ │ │heater. │ Check if main fan is not blocked and │

│ │ │ │ │ │ │ │(Reset this security │ working. │

│ │ │ │ │ │ │ │by pushing the button│ Check fan and electric connections. │

│ │ │ │ │ │ │ │in the heater) │ Capacitor in switch box may be faulty.│

│ │ │ │ │ │ │ │ │ Overflow security is filled with oil, │

│ │ │ │ │ │ │ │ │ see F. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ │ 1 │ │ │ 1 │ │Burner pan, burner │

Clean burner pan daily. │

│ │ │ │ │ │ │ │ring and burner pot │ Clean burner pot and burner ring at │

│ │ │ │ │ │ │ │have not been cleaned│ least once a week. │

│ │ │ │ │ │ │ │regularly. │ │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ │ 4 │ │ │ │ │Poor connection be- │ Check packing and slide construction. │

│ │ │ │ │ │ │ │

tween sliding panel │ Replace packing if necessary. │

│ │ │ │ │ │ │ │with bottom and bur- │ Adjust set screw for spring pressure. │

│ │ │ │ │ │ │ │ner pot. │ │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ 4 │ │ │ │ │ │ │Flame control thermo-│ Connect the two wires to the thermo- │

│ │ │ │ │ │ │ │stat is defective. │ stat (attention, 220V) on nr. 5 and 12│

│ │ │ │ │ │ │

│ │ If main blower starts to rotate, this │

│ │ │ │ │ │ │ │ │ indicates a defective thermostat. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ 1 │ │ 3 │ 3 │ 2 │ 2 │ │Insufficient chimney │ Check flue for leakages. │

│ │ │ │ │ │ │ │draught. │ Check if draught stabiliser is in │

│ │ │ │ │ │ │ │Min. draught = 2 mmwk│ closed position. │

│ │ │ │ │ │

│ │ │ Check flue for obstruction. │

│ │ │ │ │ │ │ │ │ Check flue height. Min. height is 5 m.│

│ │ │ │ │ │ │ │ │ If there is more than 1 elbow or hori-│

│ │ │ │ │ │ │ │ │ zontal pipe, the flue height must be │

│ │ │ │ │ │ │ │ │ extended. │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ │ │ 2 │

1 │ 3 │ │Fuel does not vapo- │ Viscosity of oil is too high. Mix with│

│ │ │ │ │ │ │ │rise sufficiently. │ paraffin or diesel oil. │

│ │ │ │ │ │ │ │After some time the │ │

│ │ │ │ │ │ │ │overflow security │ │

│ │ │ │ │ │ │ │switches off heater. │ │

├──────┼──────┼──────┼──────┼──────┼──────┼──────┼─────────────────────┼───────────────────────────────────────┤

│ │ 2 │ │

6 │ 4 │ │ │Tank contains water. │ Clean tank. Drain by means of drain │

│ │ │ │ │ │ │ │ │ plug beneath the tank. │

└──────┴──────┴──────┴──────┴──────┴──────┴──────┴─────────────────────┴───────────────────────────────────────┘

Technical Data / Dane Techniczne / Технические данные

Jednostka WA 41 A WA 59 A

Capacity min. bruto *

Wydajność minimalna brutto

Тепловая мощность мин. брутто

BTU/h

kW

82.000

24

123.000

36

Capacity max. bruto *

Wydajność maksymalna brutto

Тепловая мощность макс. брутто

BTU/h

kW

140.000

41

202.000

59

Fuel Consumption min.

Zużycie paliwa min.

Расход топлива мин.

l/h

2,5 3,8

Fuel Consumption max.

Zużycie paliwa max.

Расход топлива макс

l/h

4,3 6,2

Burning duration with full tank min.

Czas pracy na pełnym zbiorniku paliwa –

wydajność min.

Время работы с полным топливным баком –

мин.мощность

h

Burning duration with full tank max.

Czas pracy na pełnym zbiorniku paliwa –

wydajność max.

Время работы с полным топливным баком –

мин.мощность

h

Heated Airflow

Przepływ powietrza

Нагретый воздушный поток

m3/h

3000 3000

Voltage

Zasilanie sieciowe

Электрическое снабжение

V/Hz

220-240 / 50 220-240 / 50

Power Consumption

Pobór mocy

Потребляемый ток

A

1,1 1,2

Flue Diameter

Średnica rury kominowej

Диаметр патрубка для отвода отработанных

газов

mm

150 200

Width

Szerokość

Ширина

cm

820 820

Length

Długość

Длина

cm

880 880

Weight

Waga

Вес

kg

135 175

Height

Wysokość

Высота

cm

1.080 1.290

* Depending on viscosity

* W zależności od lepkości

* В зависимости от вязкости

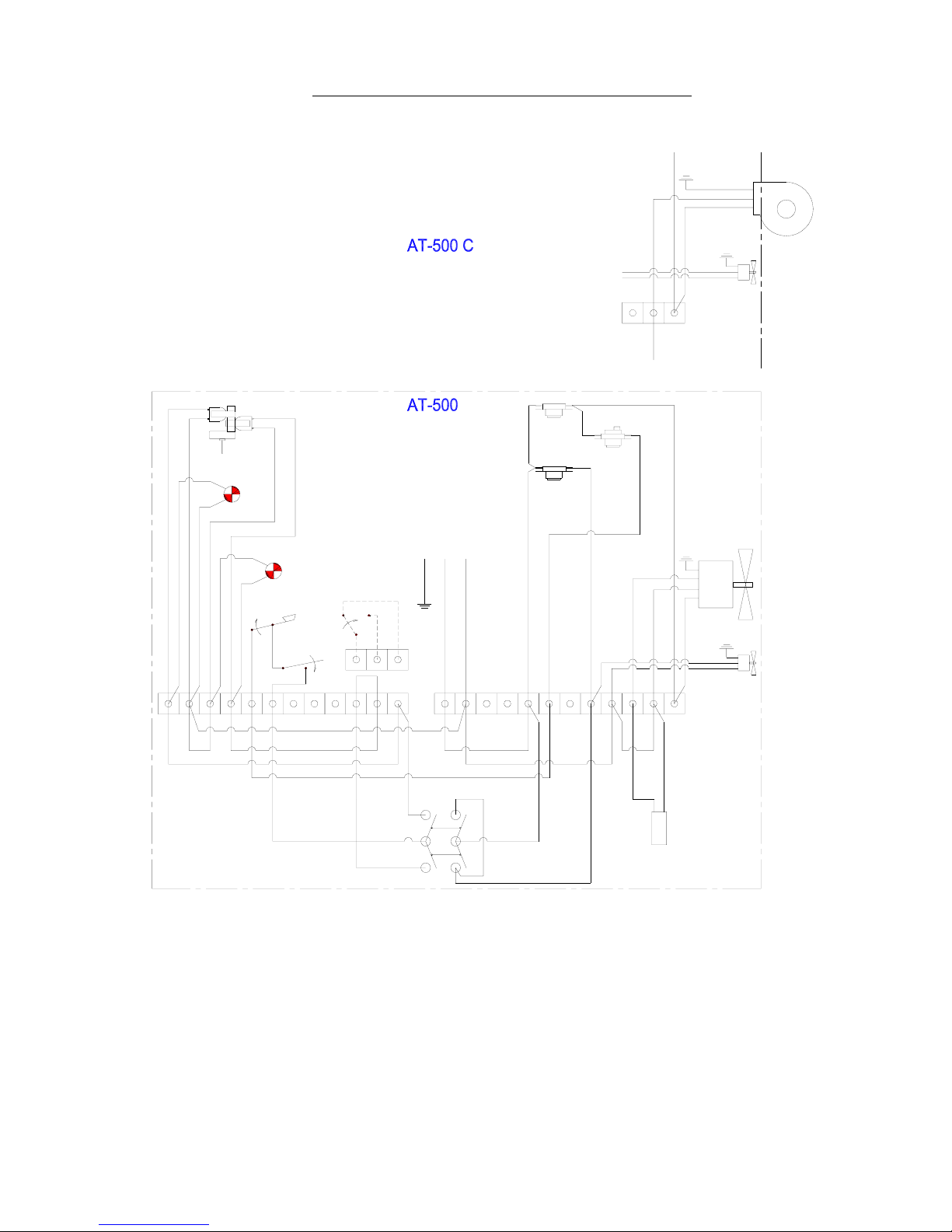

WIRING DIAGRAM / SCHEMAT ELEKTRYCZNY / ЭЛЕКТРИЧЕСКАЯ СХЕМА

WA 41 A

FL Flashlight /Lamka kontrolna / Сигнальный свет

MS Microswitch / Mikrowyłącznik / Микропереключатель

MB Main fan / Wentylator główny / Главный вентилятор

PM Pump motor / Silnik pompy / Двигатель насоса

LT Overheating thermostat / Termostat przegrzania /Термостат перегрева

T Thermostat / Termostat / Термостат

CB Combustion air intake fan / Wentylator komory spalania /Вентилятор камеры сгорания

PL Pilot light / Lamka kontrolna /Контрольный свет

OS Overflow security / Zabezpieczenie przed przelewem / Защита от перелива

S Switch / Przełącznik / Переключатель

C Condensor / Kondensator /Конденсатор

123456789101112 2134657 1089 1112

W

H

I

T

E

YELLOW

GREEN

RED

1

S

4

2

5

PURPLE

G

R

E

E

N

BLUE

B

R

O

W

N

BROWN

BLACK

ORANGE

C

Y

E

L

L

O

W

Y

E

L

L

O

W

CB

MB

LT

PT

VT

B

R

O

W

N

B

L

U

E

B

R

O

W

N

B

R

O

W

N

BLACK

BLACK

230V / 50Hz

SUPPLY

PM

PL - yellow

Y

E

L

L

O

W

Y

E

L

L

O

W

40.020.674/02

B

R

O

W

N

B

L

A

C

K

B

L

U

E

BROWN

BLUE

B

L

A

C

K

B

L

A

C

K

B

R

O

W

N

BLUE

OP

MS

B

R

O

W

N

(remove C!)

B

R

O

W

N

10 11 12

CB

BLUE

BROWN

B

R

O

W

N

B

L

U

E

B

L

A

C

K

MBc

MBc : Main fan radial for C-kit (Ancillary)

CB : Combustion air intake fan

PL : Pilot light

OP : microswitch for Overflow Protection

S : Switch

C : Capacitor

MS : Microswitch for pump stop security

MB : Main fan

PM : Pump motor

LT : Limit thermostat

PT : Pump thermostat

VT : Combustion air thermostat

BROWN

WIRING DIAGRAM / SCHEMAT ELEKTRYCZNY / ЭЛЕКТРИЧЕСКАЯ СХЕМА

WA 59 A

CB : Combustion air intake fan

PL : Pilot light

OP : microswitch for Overflow Protection

S : Switch

C : Capacitor

MS : Microswitch for pump stop security

MB : Main fan

PM : Pump motor

LT : Limit thermostat

PT : Pump thermostat

VT : Combustion air thermostat

MBc : Main fan radial for C-kit (Ancillary)

PURPLE

W

H

I

T

E

1234

YELLOW

GREEN

7

56 89

RED

2

1

S

5

BLACK

ORANGE

4

1

G

R

E

E

N

10 11 12

BLUE

2345

40.020.592/03

Y

E

L

L

O

W

Y

E

L

L

O

W

C

BROWN

768910

B

R

O

W

N

11 12

BLUE

CB

RT

B

L

A

C

K

B

L

A

C

K

B

R

O

W

N

B

R

O

W

N

MS

OP

B

L

U

E

230V / 50Hz

SUPPLY

PL - yellow

Y

E

L

L

O

W

Y

E

L

L

O

W

PM

B

R

O

W

N

B

R

O

W

N

B

R

O

W

N

B

L

A

C

K

B

L

U

E

BROWN

MB

BLACK

BLACK

LT

VT

B

R

O

W

N

PT

6

3

W

H

I

T

E

GREY

10 11 12

PL - red

B

L

A

C

K

B

L

A

C

K

LOW

HIGH

R

E

D

R

E

D

BLUE

RT : Room thermostat (Accessory for AT-500)

10

B

R

O

W

N

1211

BROWN

BLUE

B

L

U

E

B

R

O

W

N

CB

MBc

B

L

A

C

K

(remove C!)

BROWN

FL Flashlight /Lamka kontrolna / Сигнальный свет

MS Microswitch / Mikrowyłącznik / Микропереключатель

MB Main fan / Wentylator główny / Главный вентилятор

PM Pump motor / Silnik pompy / Двигатель насоса

LT Overheating thermostat / Termostat przegrzania /Термостат перегрева

T Thermostat / Termostat / Термостат

CB Combustion air intake fan / Wentylator komory spalania /Вентилятор камеры сгорания

PL Pilot light / Lamka kontrolna /Контрольный свет

OS Overflow security / Zabezpieczenie przed przelewem / Защита от перелива

S Switch / Przełącznik / Переключатель

C Condensor / Kondensator /Конденсатор

UNIVERSAL OIL HEATERS – WA 41

Pos. Code NR Description

1 S/R SIDE PLATE LEFT

2 S/R SIDE PLATE RIGHT

3 S/R BACK PANEL

4 S/R COOLING PLATE

5 S/R SLIDING PANEL

6 S/R BOTTOM PANEL

7 S/R TOP LID

8 S/R FRAME

9 S/R SIDE PANEL LEFT

10 S/R SIDE PANEL RIGHT

11 S/R TOP LID OF CONTROL PANEL

12 4506.137 TANK

13 S/R BLOWING GRILL

14 4506.141 VAPORIZING SECTION

15 S/R SLIDER

16 4506.138 BOTTOM

17 4506.021 COMBUSTION DISH

18 4506.043 BURNER RING

18a 4506.044 HEAT SHIELD WA 41A

19 4506.133 BAFFLE PLATE

20 4506.136 COMBUSTION CHAMBER

21 4506.130 COVER COMBUSTION CHAMBER

22 4506.125 LOCKING BAR

23 4506.140 HEAT EXCHANGER

24 4506.019 THERMOSTAT

25 4506.020 OVERHEAT THERMOSTAT

26 4506.126 LEVER

27 S/R LOCKING DEVICE

28 4506.006 FUEL PUMP

29 S/R FUEL PUMP SUPPORT

30 4506.005 FILTER

31 4506.123 DRIVE SHAFT

32 4506.134 FUEL TANK FILTER

33 S/R 3-WAY CONNECTOR

34 S/R SUPPLY PIPE

35 4506.131 CONNECTOR

36 4506.118 DRIP FEED PIPE

37 4506.122 RETURN LINE

38 4506.003 PUMP MOTOR

39 4506.121 SWITCH

40 N/A PILOT LIGHT RED

41 S/R CONTROL PANEL

42 S/R AIR INLET PLATE

43 4506.119 CAPACITOR

44 S/R FAN HOUSING

45 S/R MOTOR CLIP

46 S/R PROTECTION GRILL

47 4506.135 MOTOR

48 4506.116 COMBUSTION FAN

49 4506.139 MAIN FAN

49a 4506.132 PROTECTION GRILL

50 4506.117 PILOT LIGHT YELLOW

51 4506.202 MICRO SWITCH

52 4506.124 OVERFLOW TRAY

53 4506.128 COMPRESION SPRING

54 4506.120 SEALING CORD

55 4506.129 SEALING CORD

56 S/R THERMOSTAT BRACKET

57 4506.002 T-PIECE

58 4506.115 CROWN STRIP

59 4506.127 COOLING PLATE

60 S/R MICRO SWITCH PUMP STOP

61 S/R SHOWEL

S/R – Parts available by special request only

4

UNIVERSAL OIL HEATERS – WA 59

Pos. Code NR Description

1 S/R SIDE PLATE LEFT

2 S/R SIDE PLATE RIGHT

3 S/R BACK PANEL

4 S/R COOLING PLATE

5 S/R SLIDING PANEL

6 S/R BOTTOM PANEL

7 S/R TOP LID

8 S/R FRAME

9 S/R SIDE PANEL LEFT

10 S/R SIDE PANEL RIGHT

11 S/R TOP LID OF CONTROL PANEL

12 4506.137 TANK

13 S/R BLOWING GRILL

14 4506.148 VAPORIZING SECTION

15 S/R SLIDER

16 4506.138 BOTTOM

17 4506.021 COMBUSTION DISH

18 4506.149 BURNER RING

19 4506.133 BAFFLE PLATE

20 4506.145 COMBUSTION CHAMBER

21 4506.130 COVER COMBUSTION CHAMBER

22 4506.125 LOCKING BAR

23 4506.147 HEAT EXCHANGER

24 4506.019 THERMOSTAT

25 4506.020 OVERHEAT THERMOSTAT

26 4506.126 LEVER

27 S/R LOCKING DEVICE

28 4506.143 FUEL PUMP

29 S/R FUEL PUMP SUPPORT

30 4506.005 FILTER

31 4506.123 DRIVE SHAFT

32 4506.134 FUEL TANK FILTER

33 S/R 3-WAY CONNECTOR

34 S/R SUPPLY PIPE

35 4506.131 CONNECTOR

36 4506.118 DRIP FEED PIPE

37 4506.122 RETURN LINE

38 4506.004 PUMP MOTOR

39 4506.058 SWITCH

40 N/A PILOT LIGHT RED

41 S/R CONTROL PANEL

42 S/R AIR INLET PLATE

43 4506.119 CAPACITOR

44 S/R FAN HOUSING

45 S/R MOTOR CLIP

46 S/R PROTECTION GRILL

47 4506.135 MOTOR

48 4506.116 COMBUSTION FAN

49 4506.139 MAIN FAN

49a 4506.132 GRILL

50 4506.117 PILOT LIGHT YELLOW

51 4506.202 MICRO SWITCH

52 4506.124 OVERFLOW TRAY

53 4506.128 COMPRESION SPRING

54 4506.120 SEALING CORD

55 4506.129 SEALING CORD

56 S/R THERMOSTAT BRACKET

57 4506.144 T-PIECE

58 4506.115 CROWN STRIP

59 4506.127 COOLING PLATE

60 S/R MICRO SWITCH PUMP STOP

61 S/R SHOWEL

S/R – Parts available by special request only

6

Loading...

Loading...