Page 1

IMPORTANT: Read and understand this manual before

assembling, starting or servicing heater. Improper use

of heater can cause serious injury. Keep this manual for

future reference.

GENERAL HAZARD WARNING:

Failure to comply with the precautions and instructions

provided with this heater, can result in death, serious

bodily injury and property loss or damage from hazards

of re, explosion, burn, asphyxiation, carbon monoxide

poisoning and/or electrical shock.

Only persons who can understand and follow the instruc-

tions should use or service this heater.

If you need assistance or heater information such as an in-

structions manual, labels, etc. contact the manufacturer.

Save this manual for future reference.

For more information, visit www.desatech.com

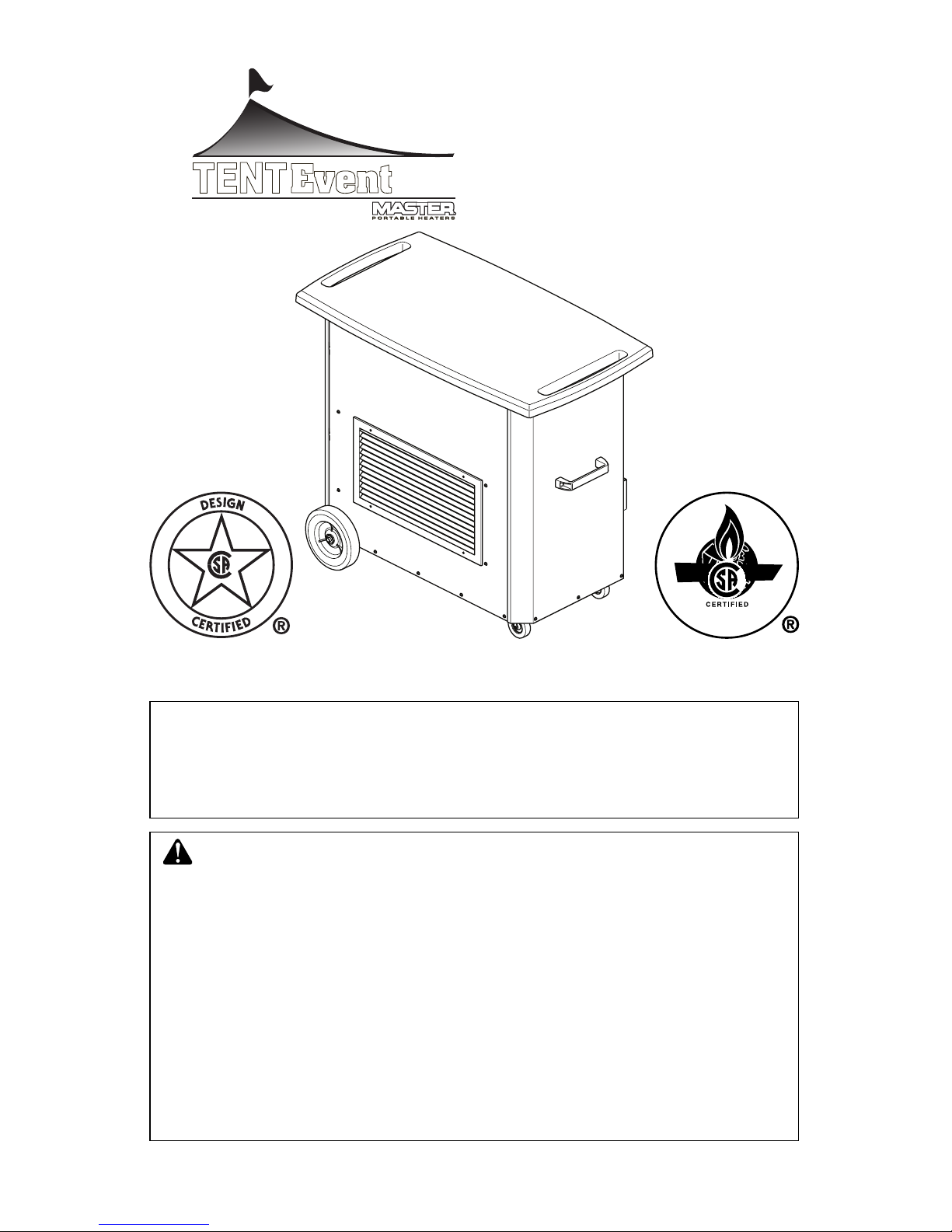

PROPANE TENT EVENT

FORCED AIR HEATER

OWNER’S MANUAL

MODELS TB116, TB117 AND TB118

125,000 BTU/HR

125

TENT

Event

by

Page 2

www.desatech.com

120193-01A2

WARNING: If the information in this manual is not

followed exactly, a re or explosion may result causing

property damage, personal injury or loss of life.

— Do not store or use gasoline or other ammable va-

pors and liquids in the vicinity of this or any other

appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a neighbor’s

phone. Follow the gas supplier’s instructions.

• If you cannot reach your gas supplier, call the re

department.

— Installation and service must be performed by a quali-

ed installer, service agency or the gas supplier.

This is an unvented gas red tent heater. It uses air (oxy-

gen) from the tent in which it is installed. Provisions for

adequate combustion and ventilation air must be provided. Provide at least 42 square inches of opening.

TABLE OF CONTENTS

Safety .................................................................. 3

Ventilation ............................................................ 5

Product Identication ........................................... 6

Propane Supply ................................................... 6

Unpacking............................................................ 7

Theory of Operation............................................. 7

Assembly ............................................................. 8

Installation ......................................................... 10

Operation ............................................................11

Storage .............................................................. 12

Maintenance ...................................................... 12

Service............................................................... 12

Specications .................................................... 16

Troubleshooting ................................................. 17

Technical Service............................................... 18

Wiring Diagram .................................................. 19

Replacement Parts ............................................ 21

Accessory .......................................................... 21

Parts .................................................................. 22

Warranty ............................................................ 28

Page 3

www.desatech.com

120193-01A 3

SAFETY

General

ANSI/NFPA 102

Standard for Grandstands, Folding and

telescopic Seating, Tents and Mem-

brane Structures

ANSI/NFPA 58

Standard for Storage and Handling of

Liquieed Petroleum Gas Latest Edition

ANSI Z223.1/NFPA 54

National Fuel Gas Code Latest Edition

ANSI/NFPA 70

National Electric Code Latest Edition

CSA C22.1 Canadian Electrical Code

Part 1

The primary purpose of construction heaters

is to provide temporary heating of buildings

under construction, alteration or repair.

Properly used, the heater provides safe economical heating. Products of combustion are

vented into the area being heated.

We cannot foresee every use which may be

made of our heaters. Check with your local

re safety authority if you have questions

about heater use.

Other standards govern the use of fuel gases

and heat producing products for specific

uses. Your local authorities can advise you

about these.

WARNING: When used without adequate combustion and

ventilation air, heater may give

off excessive carbon monoxide,

an odorless, poisonous gas.

Do not install heater until all necessary provisions are made for combustion and ventilation

air. Consult the written instructions provided

with the heater for information concerning

combustion and ventilation air. In the absence

of instructions, refer to the national fuel gas

code, ANS Z223.1, Section 5.3 or applicable

local codes.

This heater is equipped with a an Oxygen

Depletion Sensing (ODS) safety shutoff

system designed to turn off the heater if not

enough fresh air is available.

Do not tamper with oxygen

depletion safety system!

WARNING: This product

contains and/or generates

chemicals known to the State

of California to cause cancer or

birth defects or other reproductive harm.

WARNING: Fire, burn, inhala-

tion and explosion hazard. Keep

solid combustibles, such as

tables, chairs, building materials, paper or cardboard, a safe

distance away from the heater

as recommended by the instructions. Never use the heater in

spaces which do or may contain

volatile or airborne combustibles

or products such as gasoline,

solvents, paint thinner, dust particles or unknown chemicals.

WARNING: Not for home or

recreational vehicle use.

The heater is designed and approved for use

as a tent heater in accordance with these

instructions. CHECK WITH YOUR LOCAL

FIRE SAFETY AUTHORITY IF YOU HAVE

QUESTIONS ABOUT APPLICATIONS.

The heater is designed for use as a construction heater and as a vent-free tent heater. The

heater is designed for use in the space being

heated. The heater uses the air from within

the space being heated for combustion and

ventilation.

Applicable Standards:

For USA applications

ANSI Z83.7 - 2000

Gas Fired Construction Heaters

CGA 2.14 - 2000

Gas Fired Construction Heaters

CSA 3.06 - 2006

Portable Gas Fired Unvented Tent Heaters

For Canadian applications

ANSI Z83.7 - 2000

Gas Fired Construction Heaters

CGA 2.14 - 2000

Gas Fired Construction Heaters

Page 4

www.desatech.com

120193-01A4

SAFETY

Continued

If heater shuts off, do not relight until you

provide fresh air. If heater keeps shutting off,

have it serviced. Keep burner and control

compartment clean.

DANGER: Carbon monoxide

poisoning may lead to death!

Carbon Monoxide Poisoning: Early signs

of carbon monoxide poisoning resemble the

u, with headaches, dizziness, and/or nausea.

If you have these signs, the heater may not

be working properly. Get fresh air at once!

Check for proper ventilation and have heater

serviced. Some people are more affected by

carbon monoxide than others. These include

pregnant women, people with heart or lung

disease or anemia, those under the inuence

of alcohol, and those at high altitudes.

Propane/LP Gas: Propane/LP gas is odorless.

An odor-making agent is added to propane/LP

gas. The odor helps you detect a propane/LP

gas leak. However, the odor added to Propane/

LP gas can fade. propane gas may be present

even though no odor exists.

Make certain you read and understand all

warnings. Keep this manual for reference. It

is your guide to safe and proper operation of

this heater.

WARNING: Do not place

clothing or other ammable material on or near the appliance.

WARNING: Due to high temperatures, the appliance should

be located out of trafc and away

from furniture.

WARNING: Young children

should be carefully supervised

when they are in the same room

with the appliance.

WARNING: Children and

adults should be alerted to the

hazard of high surface temperature and should stay away to avoid

burns or clothing ignition.

CAUTION: Any safety screen

or guard removed for servicing

an appliance must be replaced

prior to operating the heater.

1. Install and use heater with care. Follow all

local ordinances and codes. In the absence

of local ordinances and codes, refer to

the Standard for Storage and Handling of

Liqueed Petroleum Gas, ANSI/NFPA 58,

the Natural Gas and Propane Installation

Code, CSA B149.1, and ANSI/NFPA 102

Standard for Grandstands, Folding and

telescopic Seating, Tents and Membrane

Structures. This instructs on the safe stor-

age and handling of propane/LP gases.

2. Use only the electrical voltage and fre-

quency specied on model plate. The

electrical connections and grounding of

the heater shall follow the National Electric

Code, ANSI/NFPA 70 or the Canadian

Electrical Code, Part 1, CSA C22.1.

3. Electrical Grounding Instructions - This

appliance is equipped with a three-prong

(grounding) plug for your protection against

shock hazard and should be plugged directly into a properly grounded three-prong

GFI receptacle or extension cord.

4. Use only the hose and factory preset

regulator provided with the heater.

5. Use only propane/LP gas set up for vapor

withdrawal.

6.

This is an unvented gas-red tent heater.

It uses air (oxygen) from the tent in which

it is installed. Provide adequate ventilation.

Before using heater, provide at least a 42 in2

(271 cm2) opening of fresh, outside air.

7. For indoor and outdoor use.

8. Do not use heater in occupied dwellings

or in living or sleeping quarters.

9. Do not use heater in basement or below

ground level. Propane/LP gas is heavier

than air. If a leak occurs, propane/LP gas

will sink to the lowest possible level.

10. Keep appliance area clear and free from

combustible materials, gasoline, paint

thinner, and other ammable vapors and

liquids. Dust is combustible. Do not use

heater in areas with high dust content.

Page 5

www.desatech.com

120193-01A 5

29. The heater must be installed so that the

location of the heater does not obstruct or

interfere with normal or emergency exits

and doors or walkways in the structure.

VENTILATION

WARNING: Follow the minimum fresh, outside air ventilation requirements. If proper

fresh, outside air ventilation is

not provided, carbon monoxide

poisoning can occur. Provide

proper fresh, outside air ventilation before running heater.

Provide a fresh air opening of at least 42 in

2

(271 cm2) opening of fresh, outside air.

Example: 3" high x 14" long = 42 in2. Provide

extra fresh air if more heaters are being used.

Determining Correct Heater Size

1. Determine volume of space to heat:

Length x Width x Height

50 feet x 30 feet x 15 feet = 22,500 ft

3

2. Determine desired temperature rise:

Desired temperature 65° - 25° outside

temperature = 40° rise

3.

Multiply volume x rise: 22,500 x 40 = 900,000

4.

To determine how many BTU’s are needed

multiply by 0.133

900,000 x 0.133 = 119,000 Btu

The heater thermostat will cycle on and off to

maintain the desired room temperature more

often if the BTU/hr is oversized for the space

being heated. The air inltration and leakage

of heated air through cracks, passageway

openings, etc., will adjust the required BTU’s

needed for the desired temperature.

Ventilation Air Requirements - National

Fuel Gas Code ANSI Z223.1/NFPA 54

1 inch2 of opening per 3,000 BTU with

outside air

1 inch2 of opening per 1,000 BTU with non-

outside air

Determine fresh air needed

Input Max. divided by 3,000

125,000 BTU/hr ÷ 3,000 = 41.66

Provide 42 inch2 of opening to fresh, outside air

3" high x 14" long - 42 inches

2

11. Minimum heater clearances from combustible materials: Outlet: 8 ft. (2.40 m),

Sides: 1 ft. (30 cm), Top: 3 ft. (0.91 m),

Rear: 1 ft. (30 cm)

12. Keep heater at least 6 ft. (1.83 m) from

propane/LP tank(s). Do not point heater

at propane/LP tank(s) within 20 ft. (6 m).

In Canada keep heater at least 10 ft. (3

m) from propane/LP tank(s).

13. Keep propane/LP tank(s) below 100° F

(38˚ C).

14. The minimum surrounding air temperature

rating for this heater is -20º F (-29º C).

15. Check heater for damage before each

use. Do not use a damaged heater.

16. Check hose before each use of heater.

If highly worn or cut, replace with hose

specied by manufacturer before using

heater.

17. Locate heater on stable and level surface

if heater is hot or operating.

18. Never block air inlet (rear) or air outlet

(front) of heater.

19. Keep heater away from strong drafts, wind,

water spray, rain, or dripping water.

20. Keep children and animals away from

heater.

21. Never move, handle, or service a hot

or operating heater. Severe burns may

result. You must wait 15 minutes after

turning heater off.

22. To prevent injury, wear gloves when handling heater.

23. Never attach duct work to heater.

24. Space heaters used in the vicinity of

tarpaulins, canvas or similar enclosure

materials shall be located a safe distance

from such materials. These enclosure

materials shall be of a re retardant nature. These enclosure materials shall be

securely fastened to prevent them from

igniting or from upsetting the space heater

due to wind action.

25. Do not alter heater. Keep heater in its

original state.

26. Do not use heater if altered.

27. Turn off propane/LP supply to heater and

unplug when not in use.

28. Use only original replacement parts. This

heater must use design-specic parts.

Do not substitute or use generic parts.

Improper replacement parts could cause

serious or fatal injuries.

SAFETY

Continued

Page 6

www.desatech.com

120193-01A6

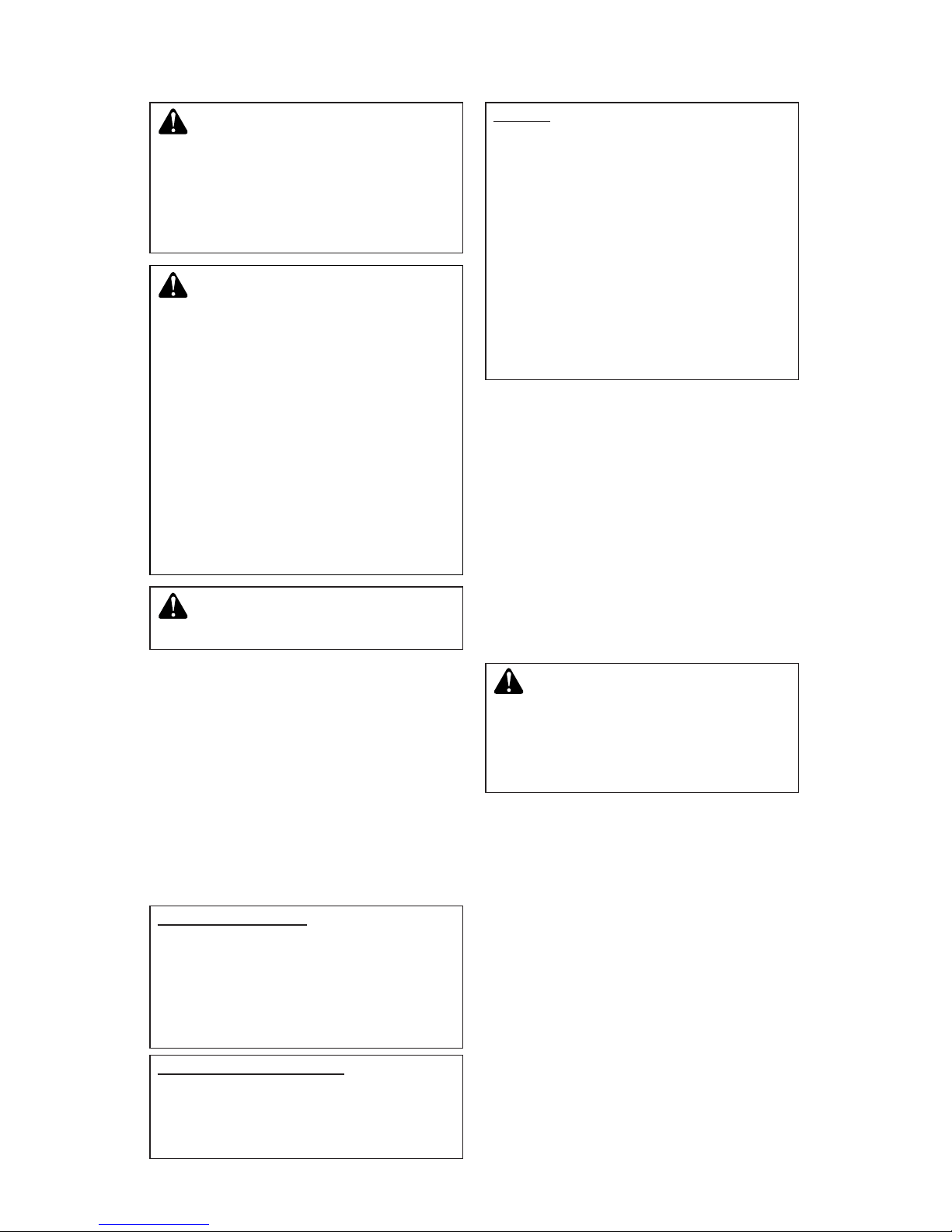

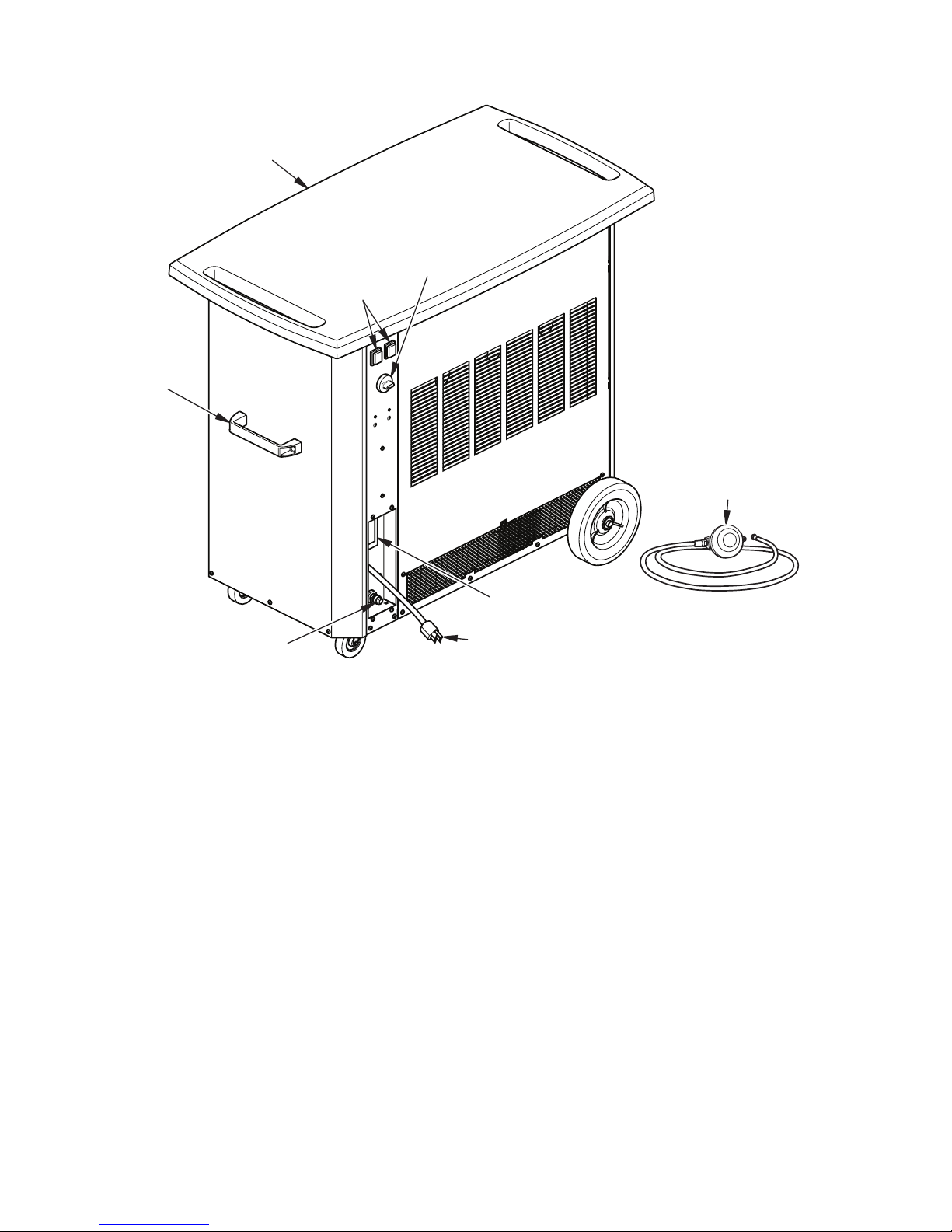

Figure 1 - Tent Heater

Top

Power Cord

Hose and

Regulator

Assembly

Gas Inlet

Handle

Thermostat

Knob

ON/OFF

Switches

Receptacle

PROPANE SUPPLY

PRODUCT IDENTIFICATION

1. The amount of propane gas in tank(s)

2. The temperature of tank(s)

The following chart shows the number of

100 lb. (45 kg) tanks needed to run this

heater.

Smaller tanks can be used for limited run

times but it is recommended to use larger

tanks for optimum performance.

Average Temperature Number Of Tanks

At Tank (100 lb/45 kg)

Above 20° F (-6.7° C) 2

20° F (-6.7° C) to 0° F (-18° C) 3

Below 0° F (-18° C) Use larger tank

Less gas is vaporized at lower temperatures.

You may need two or more 100 lb. (45 kg)

tanks or one larger tank in colder weather.

Your local propane gas dealer will help you

select the proper supply system. The minimum surrounding air temperature rating for

each heater is -20° F (-29° C).

Propane/LP gas and propane tank(s) are to

be furnished by the user.

Use this heater only with a propane vapor

withdrawal supply system. See Chapter 5

of the Standard for Storage and Handling

of Liqueed Petroleum Gas, ANSI/NFPA 58

and the Natural Gas and Propane Installation

Code CSA B149.1. Your local library or re

department will have this booklet.

Keep propane/LP tank(s) at least 5 ft away

from the side of the tent.

The propane/LP tank(s) shall be protected

from vehicles and secured in accordance

with the Standard for Grandstands, Folding

and Telescopic Seating, Tents and Membrane

Structures NFPA 102 and the Standard for

Storage and Handling of Liquieed Petroleum

Gases ANSI/NFPA 58.

The amount of propane gas ready for use

from propane tanks varies. Two factors decide

this amount:

Page 7

www.desatech.com

120193-01A 7

UNPACKING

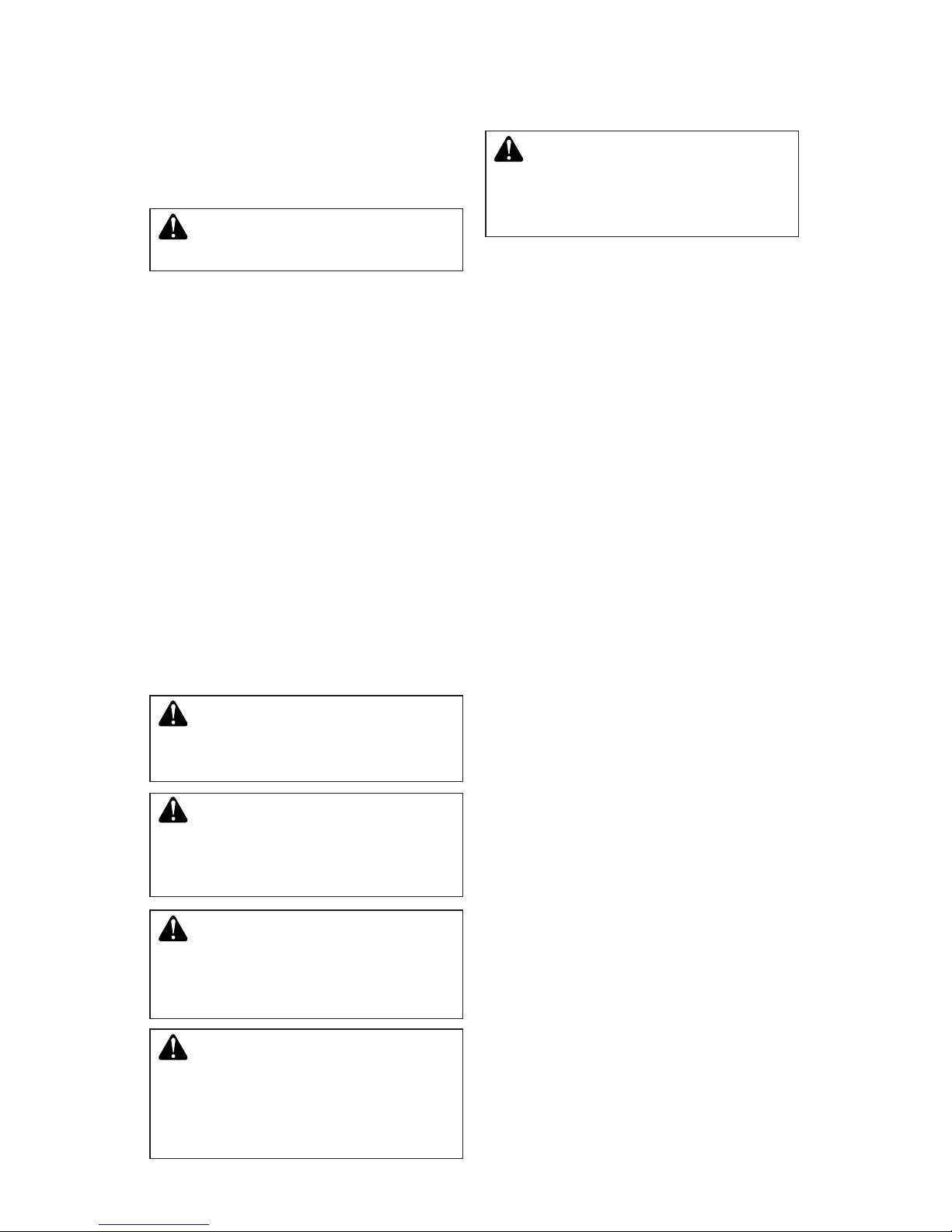

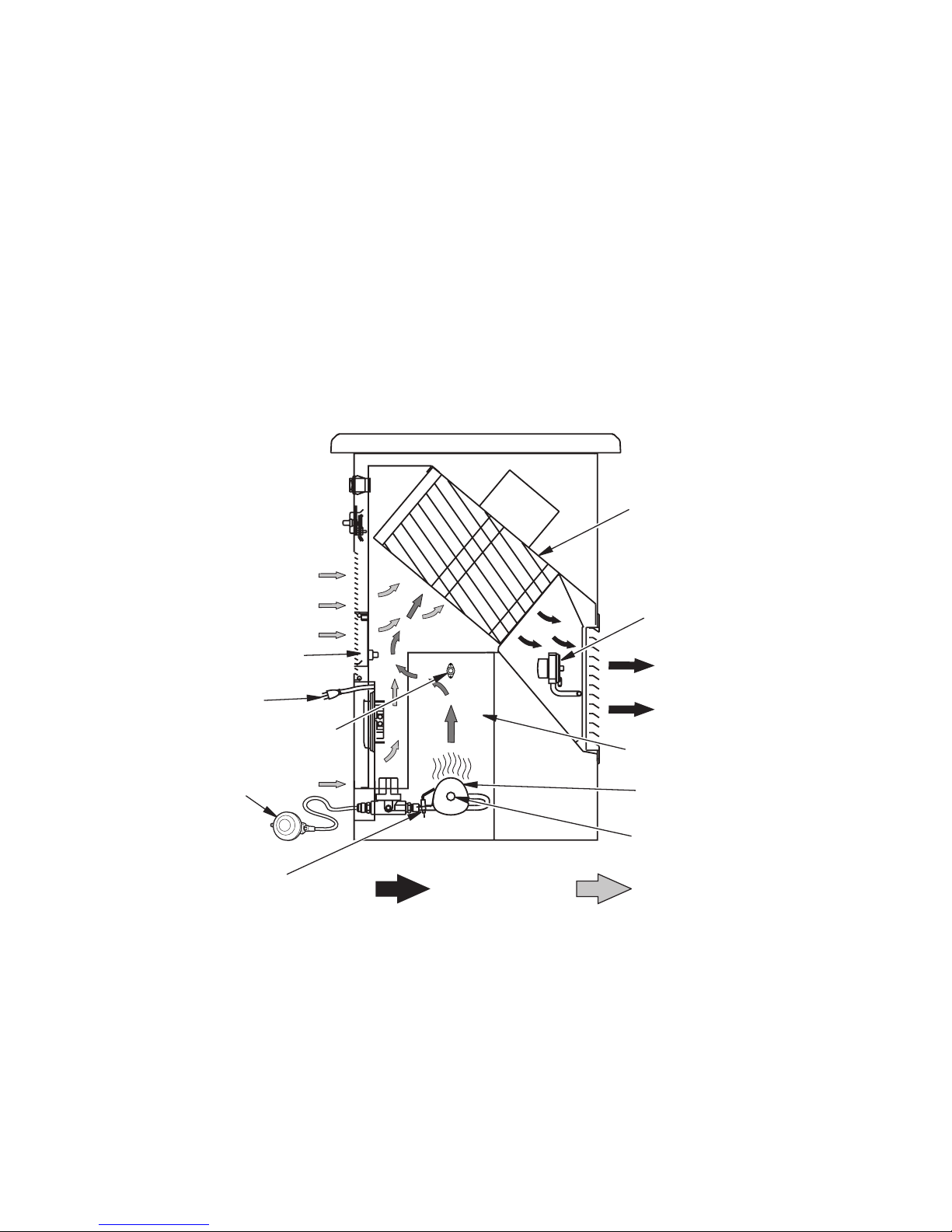

Figure 2 - Cross Section Operational View

Clean

Heated

Air Out

(Front)

Combustion Chamber

Hose/Regulator

Assembly

Injector

Motor and

Blower

Assembly

Cool

Air In

(Back)

Power Cord

Fuel

DSI

Air for Fuel

System

Thermal Switch

Ignitor, Flame

Sensor and ODS

Burner

Air Pressure Switch

1. Remove all packing items applied to

heater for shipment. Keep plastic cover

caps (attached to inlet connector and

hose/regulator assembly) for storage.

2. Remove all items from carton.

3. Check all items for shipping damage. If

heater is damaged, promptly inform dealer

where you bought heater.

THEORY OF OPERATION

The Fuel System: The hose/regulator assembly attaches to the propane gas supply. The

propane gas moves through the automatic control valve and out the injector.

The Air System: The motor turns the fan. The fan pulls air into and around the combustion

chamber. This air is heated and provides a stream of clean, hot air.

The Ignition System: The direct spark ignitor (DSI) sends voltage to the spark ignitor. The

spark ignitor ignites the fuel and air mixture.

The Safety Control System: There are 4 independent systems:

1. Flame Sensor: This system causes the heater to shut down if the ame goes out.

2. Thermal Switch: This system causes the heater to shut down if the heater gets too hot

(blocked openings).

3. Air Pressure Switch: The system will not allow the heater to start if there is not adequate

air ow.

4. ODS - Oxygen Depletion System: This system shuts down the heater if the oxygen level

drops below the specied level (18%).

ODS Operation: Burner porting "blows" out causing ame sensor to cool, shutting down heater.

Page 8

www.desatech.com

120193-01A8

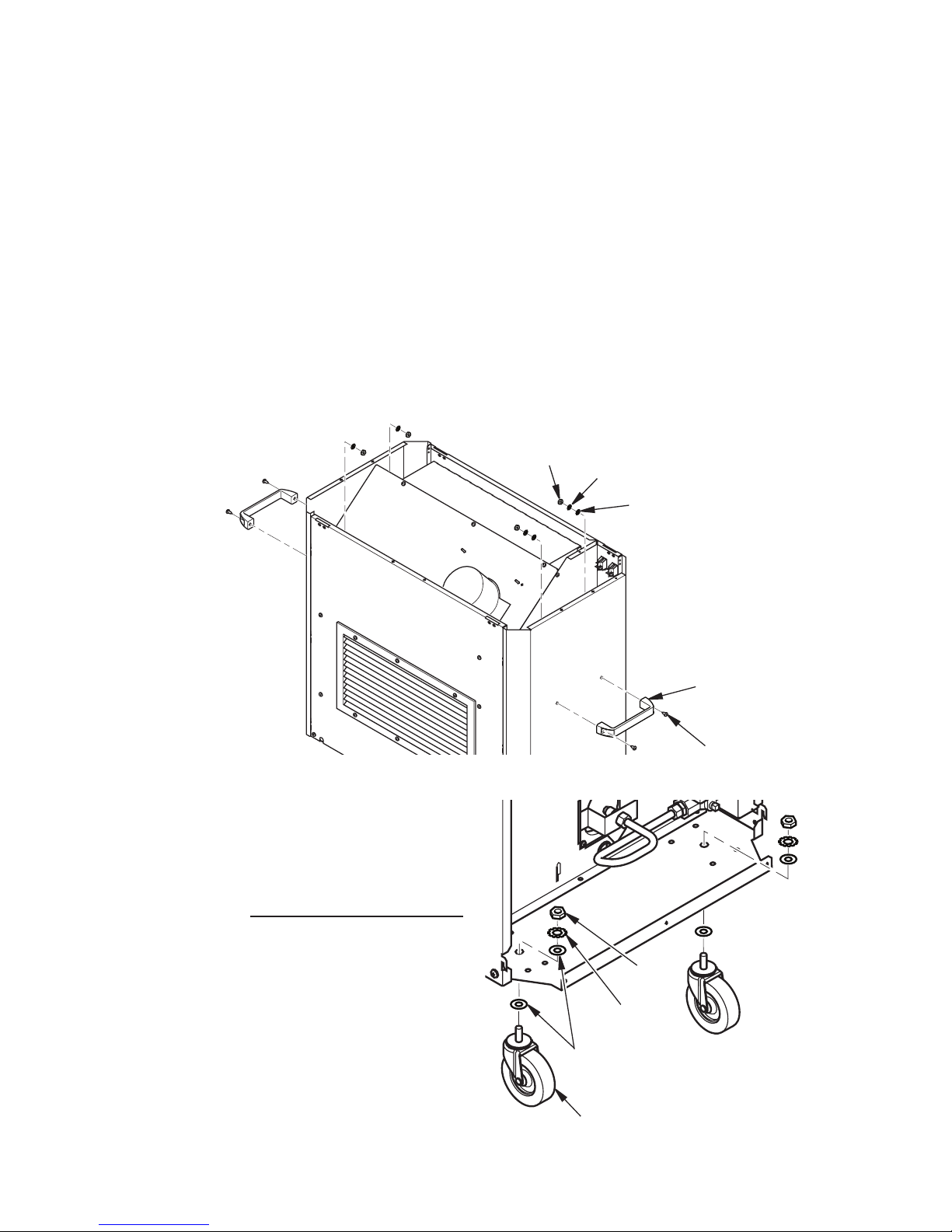

ASSEMBLY

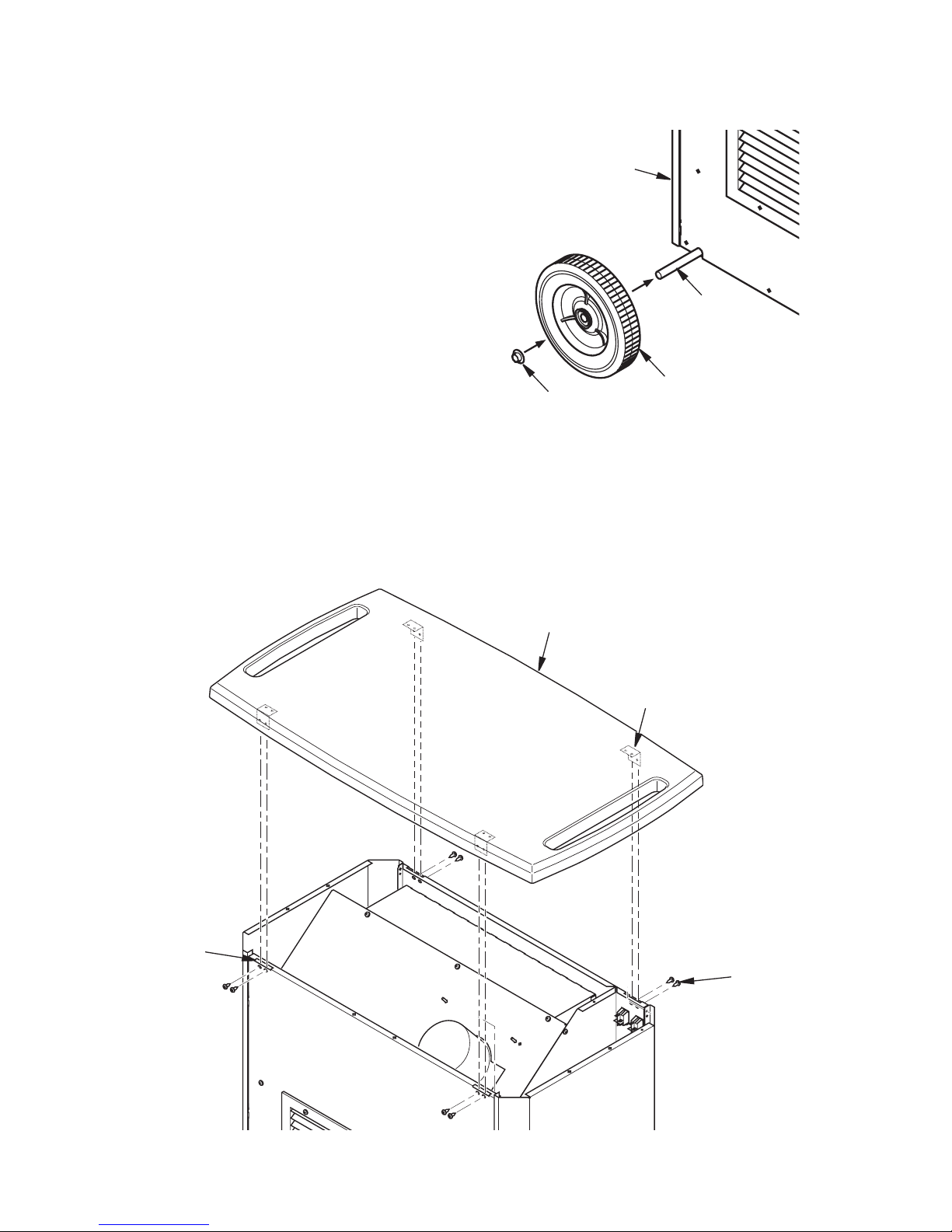

Figure 3 - Attaching Handles

Handle

Screw

Nut

Lock Washer

Figure 4 - Installing Casters

Nut

Flat Washer

Caster

ASSEMBLY ITEMS

Before assembling heater, make sure you have the items listen below.

• Phillips head screwdriver

• Wrench

• Hardware packet

Handles (2), 3/4" Screws (4), 1/4-20 Nuts (4), 1/4 Flat washers (4), 1/4 Lock washers (4)

Casters (2), 3/8" Nut (2), 3/8 Lock washers (2), 3/8 Flat Washers (4)

Wheels (2), Push Caps (2)

Brackets (4), 1/2" black screws (8), 3/8" screws (8)

Note: Place metal parts on packaging during assembly to protect from scratches.

Casters

1. Remove casters, 3/8 at washers, 3/8

lock washers and 3/8 nuts from hardware

packet.

2. You may wish to remove side panel from

heater to make installing casters easier.

If so, see Top and Side Panel Removal

on page 13. Figure 4 shows side panel

removed for clarity.

3. Use a spacer to prop end of heater up

so holes in base can be accessed (the 2

wheels stacked on top of each other will

accomplish this).

4. Place a at washer onto threaded stem of

caster. Insert caster stem through hole in

cabinet base as shown in Figure 4.

5. Attach each caster to base with a at

washer, a lock washer and a nut as shown

in Figure 4.

Side Handles

1. Remove handles, 3/4" screws, 1/4-20

nuts, 1/4 at washers and 1/4 lock washers from hardware packet.

2. Attach each handle to side panels with 2

screws, 2 nuts, 2 at washers and 2 lock

washers. Insert screw from outside of

heater and through handle. From inside

of heater, attach a at washer, then a lock

washer then a nut as shown in Figure 3.

Flat Washer

Lock Washer

Page 9

www.desatech.com

120193-01A 9

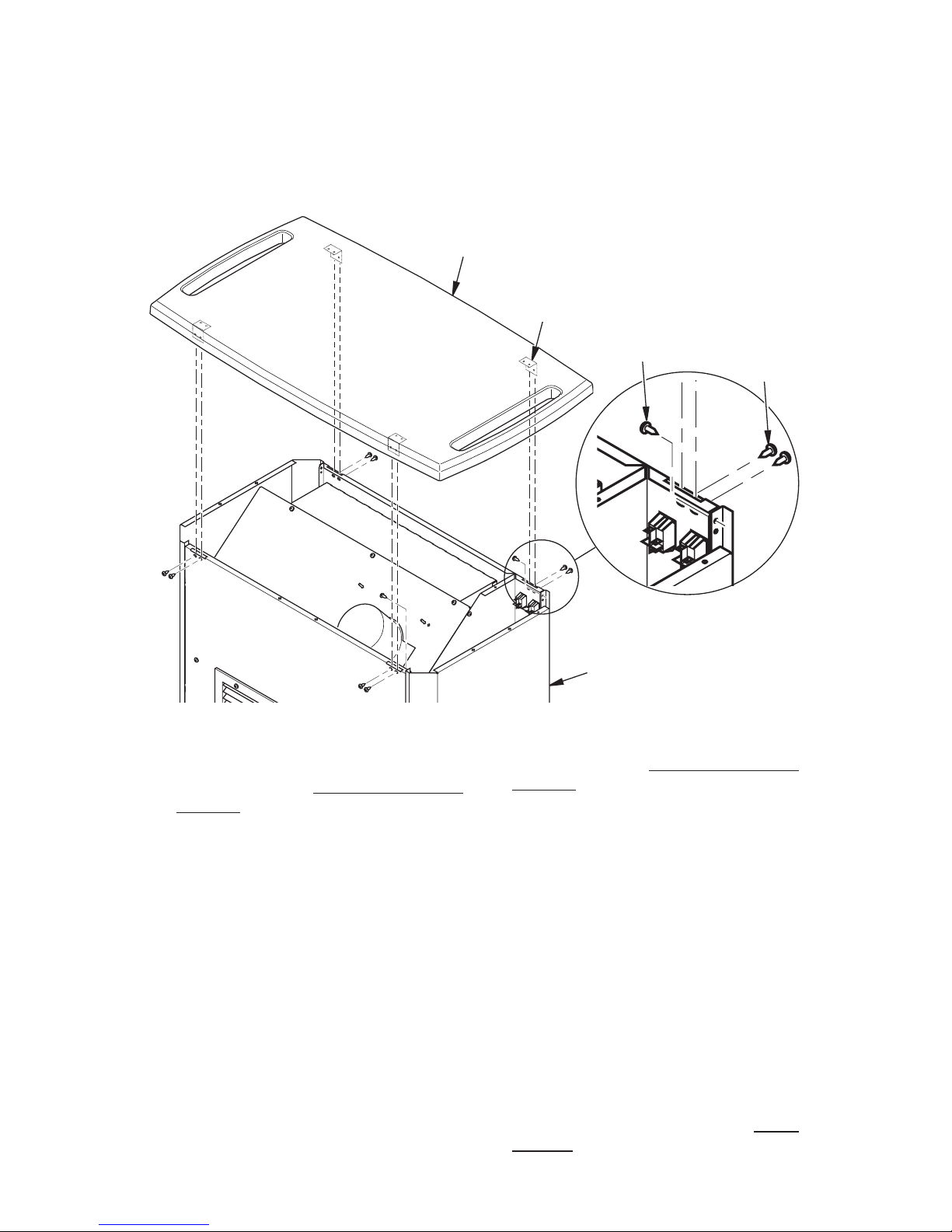

Bracket

Top

Bracket

Screws

Figure 6 - Attaching Top

ASSEMBLY

Continued

Figure 5 - Installing Axle and Wheels

Heater

Front

Axle

Wheel

Push Cap

Wheels and Axle

1. Locate wheels and axle in packaging.

Remove 2 push caps from hardware

packet.

2. Stand axle upright placing one end on the

oor. Gently tap one push cap onto end

of axle.

3. Slide one wheel onto axle then carefully

slide axle through heater body as shown

in Figure 5.

4. Slide second wheel onto axle from opposite side of heater.

5. Have another person secure wheel and

axle from other side of heater while gently

tapping second push cap onto end of

axle.

Top

1. Remove 4 brackets, (8) 1/2" black screws

and (8) 3/8" screws from hardware

packet.

2. Lay top upside down on a clean surface.

Attach 4 brackets to top with 1/2" black

screws.

3. Turn top over and carefully place over

heater, positioning brackets through slots

in heater front and rear panels.

4.

Attach brackets to heater with 3/8" screws.

Bracket

Slots

Page 10

www.desatech.com

120193-01A10

INSTALLATION

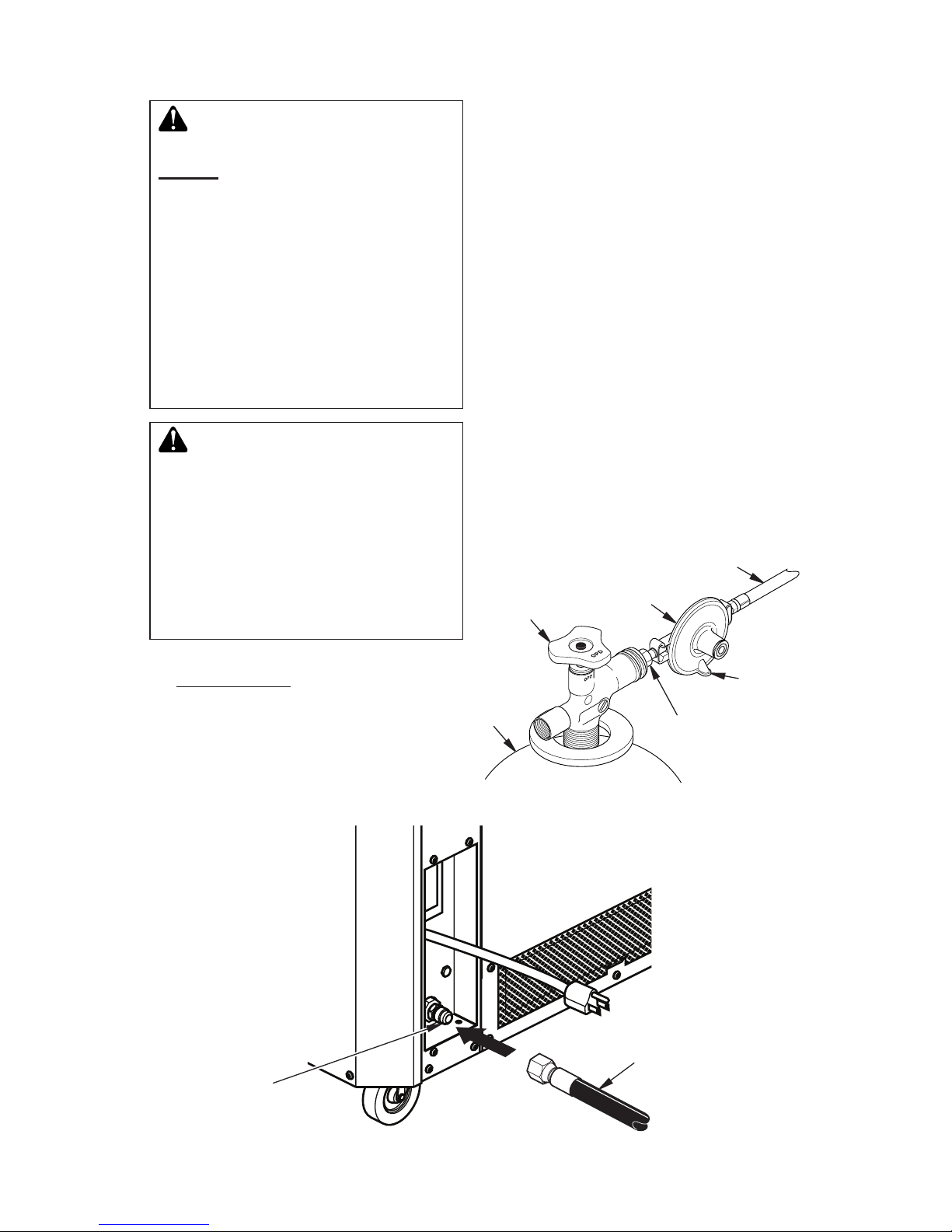

2. Connect fuel gas connector fitting on

hose/regulator assembly to propane

tank(s) (see Figure 7). Turn counterclockwise into threads on tank valve. Tighten

rmly using wrench.

IMPORTANT: Tighten regulator with vent

pointing down. Pointing vent down protects regulator from weather damage.

3. Connect hose to inlet connector (see

Figure 8). Tighten rmly using a wrench.

IMPORTANT: Extra hose or piping may be

used if needed. Install extra hose or piping

between hose/regulator assembly and

propane tank. You must use the regulator

supplied with heater.

4. Open propane supply valve on propane

tank(s) slowly.

Note: If not opened slowly, excess ow

check valve on propane tank will stop gas

ow. If this happens, close propane supply

valve and open again slowly.

5. Check all connections for leaks. Correct

all leaks.

Figure 7 - Regulator With Vent Pointing

Down

Hose

Regulator

Vent

(pointing

down)

Fuel Gas

Connector

Supply Valve

Propane

Tank

Figure 8 - Hose and Inlet Connector

Hose

Inlet

Connector

WARNING: Review and un-

derstand the warnings in the

Safety section, page 2. They are

needed to safely operate this

heater. Follow all local codes or

in the absence of local codes,

with the Standard for Grand-

stands, Folding and Telescopic

Seating, Tents and Membrane

Structures NFPA 102 and the

Standard for Storage and Han-

dling of Liquieed Petroleum

Gases ANSI/NFPA 58.

WARNING: Test all gas piping

and connections for leaks after

installation or servicing. Never

use an open ame to check for a

leak. Apply a noncorrosive leak

detection uid to all joints (available at local plumbing supply

stores). Bubbles forming show a

leak. Correct all leaks at once.

1. Provide propane supply system (see

Propane Supply, page 6).

Page 11

www.desatech.com

120193-01A 11

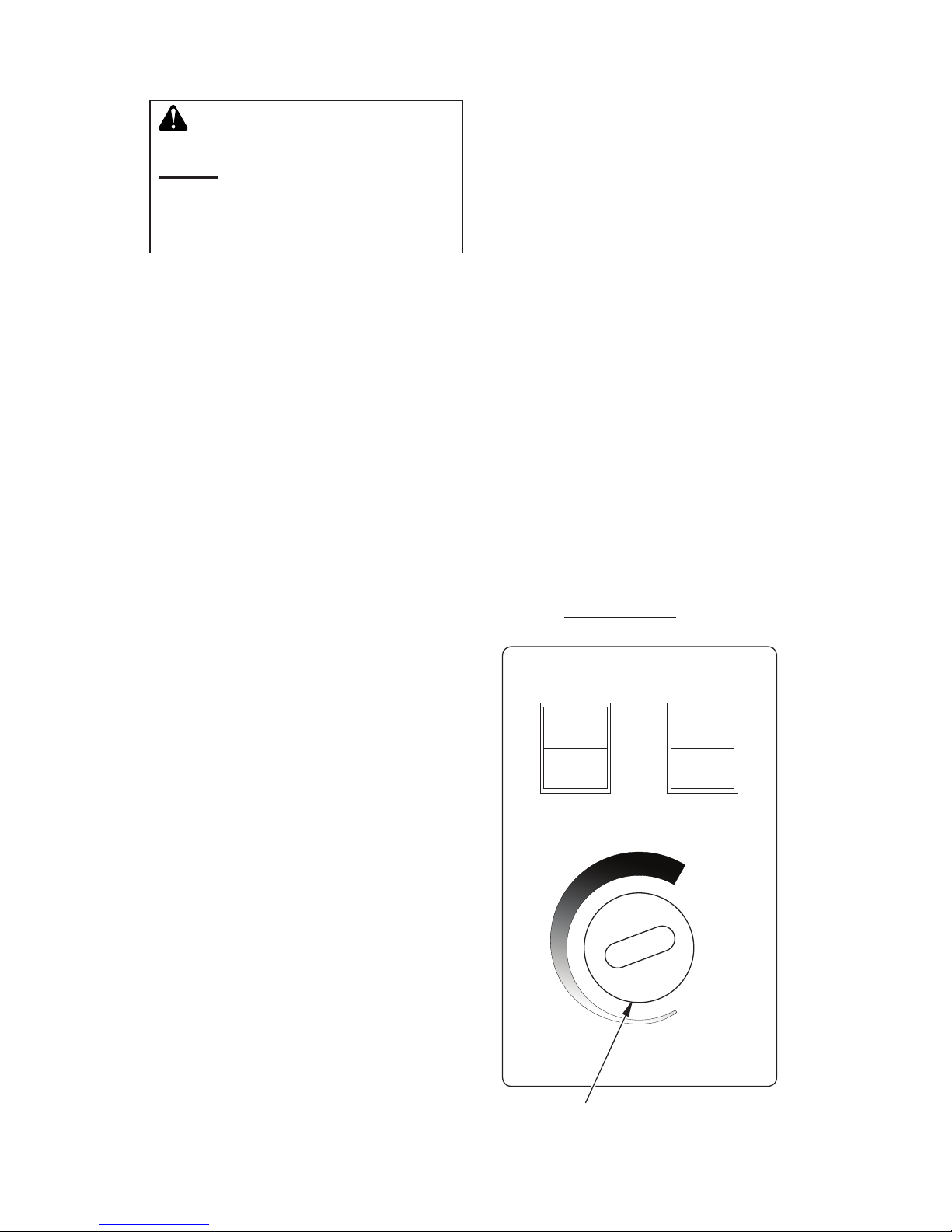

OPERATION

CONTINUOUS FAN WITH HEAT

1. Press Switch 1 to ON.

2. Press Switch 2 to ON.

3. Adjust thermostat knob to desired

comfort level.

Note: Fan will stay on when burner cycles off.

FAN ONLY WITH NO HEAT

1. Turn gas supply off.

2. Press Switch 1 to OFF.

3. Press Switch 2 to ON.

4. Adjust thermostat knob to Fan Only

position.

TO STOP HEATER

1. Tightly close propane/LP supply valve on

propane tank(s).

2. Wait a few seconds. Heater will burn gas

left in supply hose.

3. Press on/off switches to the OFF position.

4. Unplug heater.

TO RESTART HEATER

1. Press on/off switches to the OFF position.

2. Reconnect extension cord.

3. Turn on gas supply valve.

4. Follow To Start Heater instructions, col-

umn 1.

Thermostat

Fan Cycle

ON

OFF

Switch 1

Fan

Continuous

ON

THERMOSTAT

CYCLE

LOW

Fan Only

HIGH

OFF

Switch 2

8

1

2

3

4

5

6

7

Thermostat Knob

Figure 9 - Control Panel

WARNING: Review and un-

derstand the warnings in the

Safety section, page 2. They are

needed to safely operate this

heater. Follow all local codes

when using this heater.

TO START HEATER

1. Follow all installation, ventilation and

safety information.

2. Connect regulator/hose assembly to gas

supply.

3. Check for leaks using a noncorrosive leak

detection uid. Bubbles forming indicate a

gas leak. Correct all leaks before attempting to operate heater.

4. Locate heater on a stable and level surface. Make sure strong drafts do not blow

into front or rear of heater.

5. Plug power cord of heater into a three

prong, grounded extension cord. Extension cord must be at least 6 feet (1.83 m)

long, CSA listed and of proper size.

Extension Cord Size Requirement

Up to 100 ft. (30 m) long, use 16 AWG

rated cord.

101 to 200 ft. (31 to 60 m) long, use 14

AWG rated cord.

6. Plug extension cord into a 120v/60 hz,

three hole, grounded GFI outlet.

7. Open gas supply valve slowly.

Note: If heater burner does not ignite,

turn gas supply off and open slowly. The

hose/regulator assembly is equipped with

an excess ow safety valve. An audible

"click" is heard when opened too fast.

8. Choose desired function:

THERMOSTAT OPERATION WITH HEAT

1. Press Switch 1 to ON.

2. Press Switch 2 to OFF.

3. Adjust thermostat knob to desired

comfort level.

Note: Fan will cycle on and off with burner.

Page 12

www.desatech.com

120193-01A12

STORAGE

2. Place plastic cover caps over brass ttings

on inlet connector and hose/regulator assembly.

3. Store in dry, clean, and safe place.

4. When taking heater out of storage, always

check inside of heater. Insects and small

animals may place foreign objects in

heater. Keep inside of heater free from

combustible and foreign objects.

CAUTION: Disconnect heater

from propane supply tank(s).

1. Store propane tank(s) in safe manner. See

Chapter 5 of Standard for Storage and

Handling of Liqueed Petroleum Gases,

ANSI/NFPA 58 and the Natural Gas and

Propane Installation Code CSA B149.1.

Follow all local codes. Always store propane tanks outdoors.

MAINTENANCE

WARNINGS

• Never service heater while it

is plugged in, connected to

propane supply, operating, or

hot. Severe burns and electrical shock can occur.

• Keep heater clear and free

from combustible materials,

gasoline, and other ammable

vapors and liquids.

• Do not block the ow of combustion or ventilation air.

1. Keep heater clean. Clean heater annually

or as needed to remove dust and debris. If

heater is dirty or dusty, clean heater with

a damp cloth. Use household cleaners on

difcult spots.

2. Inspect heater before each use. Check

connections for leaks. Apply a noncor-

rosive leak detection uid to connections.

Bubbles forming show a leak. Correct all

leaks at once.

3. Inspect hose/regulator assembly before

each use. If hose is highly worn or cut,

replace with one specied by manufacturer.

4. Have heater inspected yearly by a quali-

ed service agency.

5. Keep inside of heater free from combus-

tible and foreign objects. Remove motor

and other internal parts if needed to clean

inside of heater (see Service, below).

Burner

Check burner air inlet after every 300 hours

of operation to ensure burner air inlet is free

of dust or debris. Use compressed air (30 PSI

or less) to clean out burner air inlet.

SERVICE

WARNING: Never service

heater while it is plugged in,

connected to propane supply,

operating, or hot. Severe burns

and electrical shock can occur.

IMPORTANT: CHECK FOR GAS LEAKS. Test

all gas piping and connections for leaks after

installation or servicing. Never use an open

ame to check for a leak. Apply a noncorrosive

leak detection uid to all joints (available at local plumbing supply stores). Bubbles forming

show a leak. Correct all leaks at once.

Page 13

www.desatech.com

120193-01A 13

SERVICE

Continued

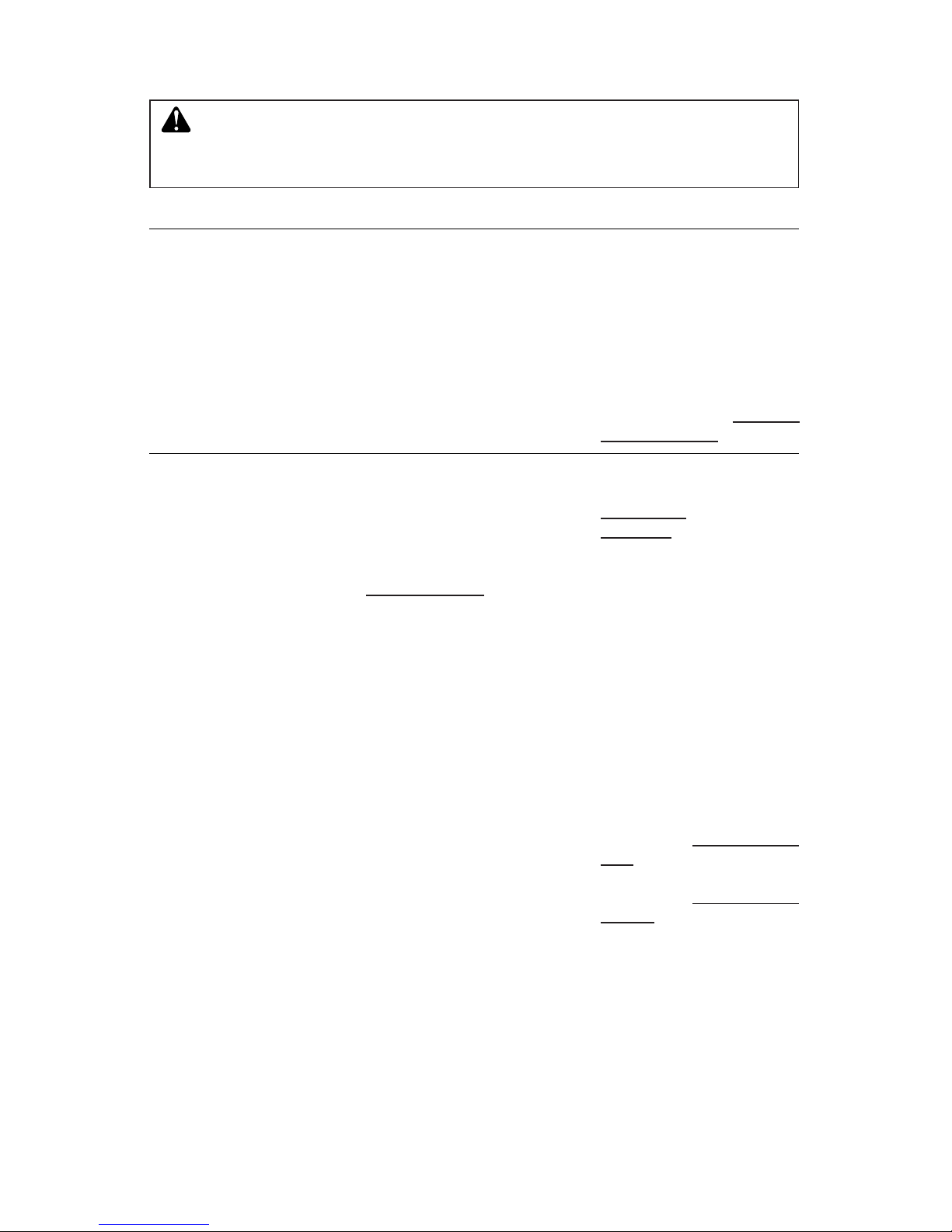

ELECTRICAL AND GAS TRAIN

COMPONENT ACCESS

1. Remove top (see Top and Side Panel

Removal, above).

2. Locate wiring diagram on inside of side

panel or go to page 19.

3. Check that all wiring terminals are securely connected.

4. Check for gas leaks around ttings and

tubing of plumbing connections. See

page 10.

TOP AND SIDE PANEL REMOVAL

1. Remove 8 screws securing top brackets

to body panels. Remove top and set aside

(see Figure 10).

Brackets

Located

Underneath

Figure 10 - Removing Top and Side Panel

Side

Panel

Top

Bracket

Screws

Side Panel

Screw

2. Remove 2 screws securing side panel

at top edge. Remove 3 screws at lower

outside edge (see Figure 10). Push down

and lift out side panel.

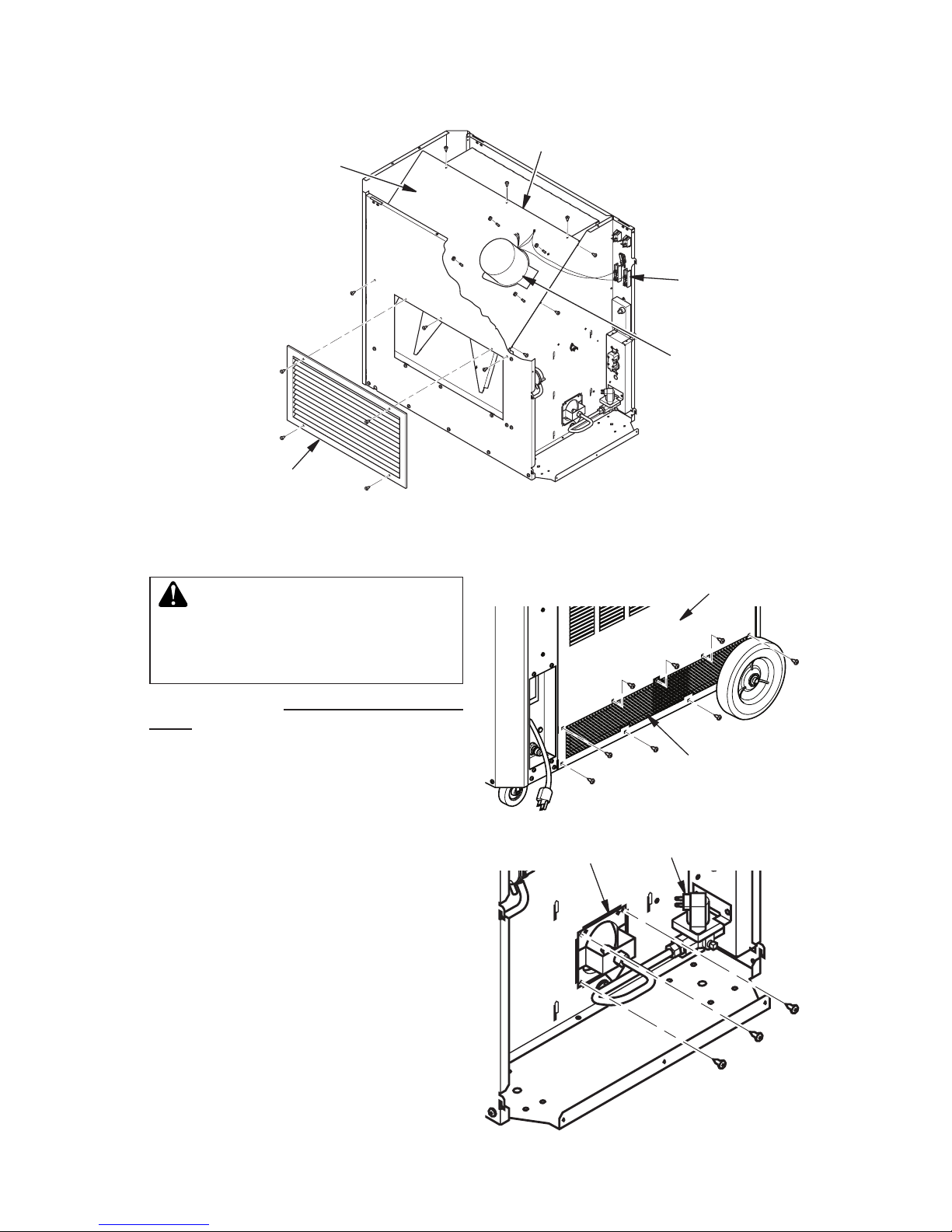

MOTOR AND BLOWER ASSEMBLY

1. Remove top (see Top and Side Panel

Removal, above).

2. Remove 4 screws securing outlet louver

to front panel (see Figure 11, page 14).

3. Follow wires from blower/motor and disconnect from terminal blocks. Pull wires

out and coil excess to prevent damage to

insulation.

4. Remove 9 screws securing blower mount-

ing panel (see Figure 11, page 14). Bend

bafe top up and carefully lift entire as-

sembly out of heater.

5. Remove 4 nuts securing blower/motor to

mounting panel.

6. Attach new blower/motor to mounting

panel and reinstall in reverse order. Use

care when removing or installing blower

to mounting panel to avoid damage to

wiring. Reattach wiring referring to Wiring

Diagram on page 19.

Page 14

www.desatech.com

120193-01A14

Outlet Louver

Figure 11 - Removing Blower/Motor Assembly

Terminal

Blocks

Blower/Motor

Blower

Mounting

Panel

Bafe Top

Figure 12 - Back Panel and Screen

Figure 13 - Removing Burner

Burner

Solenoid Valve

Back Panel

Screen

BURNER, IGNITOR AND GAS

ORIFICE

WARNING: Make sure heater

is disconnected from propane and

electrical supply. Heater could

ignite causing severe burns.

Remove top (see Top and Side Panel Removal, see page 13).

Replacing Burner

1. Remove all visible screws from lower section of back panel and screen (see Figure

12). Pull back panel out to gain access to

screen. Push screen up and over ange,

then slide out.

2. Disconnect orange ignitor wire from ignitor. Ignitor is attached to back of burner.

3. Disconnect gas line at solenoid valve

and at orice using a 5/8" wrench. Avoid

bending and set aside.

4. Remove 3 screws securing burner to

partition (see Figure 13). Rotate burner

clockwise and pull out of chamber.

Note: There is a cutout on the partition

that allows the ignitor and bracket to slide

out as a complete assembly. Use caution

when removing or installing burner to avoid

damaging or dislocating ignitor electrode.

5. After all service is complete, reinstall

burner in reverse order. Support burner

SERVICE

Continued

while inserting burner locator pin into hole

in chamber end panel. Replace screen

and back panel.

Page 15

www.desatech.com

120193-01A 15

Replacing Ignitor

1. To loosen back panel and gain access

to ignitor, follow step 1 under Replacing

Burner, page 14.

2. Remove ignitor bracket screw and lift

ignitor.

3. Attach new ignitor with ignitor mounting

screw removed in step 2.

4. Install new ignitor. Ignitor gap between

ignitor electrode and burner deck is

0.13"/0.15" (3.3/3.8 mm).

5. Test for spark. Plug into extension cord

and watch for spark between ignitor

electrode and burner deck.

SERVICE

Continued

Ignitor Gap

Figure 14 - Ignitor Gap

Replacing Gas Orice

1. Hold burner flange and rotate orifice

counterclockwise to remove.

2. Install new orice

IMPORTANT: CHECK FOR GAS LEAKS. Test

all gas piping and connections for leaks after

installation or servicing. Never use an open

ame to check for a leak. Apply a noncorrosive

leak detection uid to all joints (available at local plumbing supply stores). Bubbles forming

show a leak. Correct all leaks at once.

REPLACING DSI CONTROL

1. Remove top (see Top Panel Removal,

page 13).

2. Disconnect orange ignitor wire.

3. Remove white wire connector.

4. Remove 2 screws and nuts securing DSI

control.

5. Install new DSI control. Reconnect wiring.

REPLACING GAS VALVE

1. Remove top (see Top and Side Panel

Removal, page 13).

2. Disconnect 2 blue wires.

3. Remove gas line.

4. Remove 2 screws and nuts holding valve

to mounting plate.

5. Remove brass ttings from old gas valve.

If damaged replace with new fittings.

Install ttings into new gas valve. Use

pipe joint sealant that is resistant to liquid

petroleum (LP) gas. Tighten all ttings.

6. Install new gas valve using screws and

nuts from step 4.

7. Connect blue wires to new gas valve.

8. Reconnect gas line.

IMPORTANT: CHECK FOR GAS LEAKS. Test

all gas piping and connections for leaks after

installation or servicing. Never use an open

ame to check for a leak. Apply a noncorrosive

leak detection uid to all joints (available at local plumbing supply stores). Bubbles forming

show a leak. Correct all leaks at once.

CHECKING REGULATOR

PRESSURE

1. Remove top (see Top Panel Removal,

page 13).

2. Locate pressure tap on solenoid valve and

remove (retain plug for later installation).

See Figure 15, page 16.

3. Install 1/8 NPT barb tting with sealant on

threads into solenoid valve.

4. Connect to manometer or pressure gauge

that measures in inches of water.

5. Connect hose and regulator to heater and

tank.

6. Plug in and turn on.

Page 16

www.desatech.com

120193-01A16

SPECIFICATIONS

• Output Rating - 125,000 Btu/Hr (131,882 kJ/Hr)

• Fuel Consumption - 1.4 Gal/Hr (5.2 Liters/Hr), 5.8 lb/Hr (2.6 kg/Hr)

• Propane Vapor Fuel Only

• Manifold Pressure - 10" (25.4 cm) WC

• Supply Pressure To Regulator: Minimum (for purposes of input adjustment) 10 psi (69 kPa),

Maximum - Tank Pressure

• Regulator Outlet Pressure - 11" wc

• Electric Input - 120 V/60 Hz

• Amperage - Start 7, Run 3.5

• Load - 10 amps on receptacle

• Hot Air Output (Approx) - 1000 CFM (28.3 m3/min)

• Motor - 1,100 RPM, 1/4 HP

• Ignition - Electronic Direct Spark Ignition (D.S.I.)

• Ignitor Gap - 0.12"/0.15" (3.1/3.8 mm)

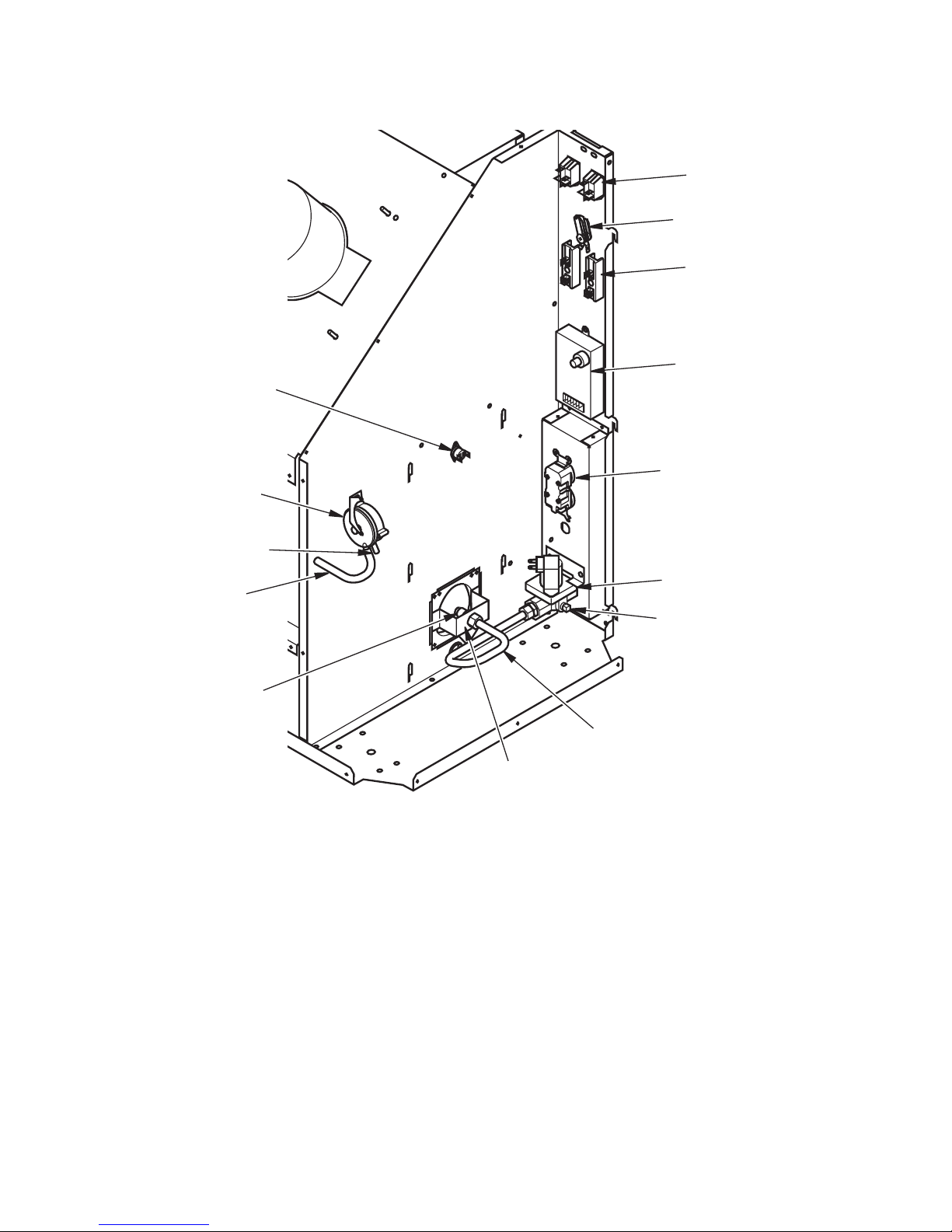

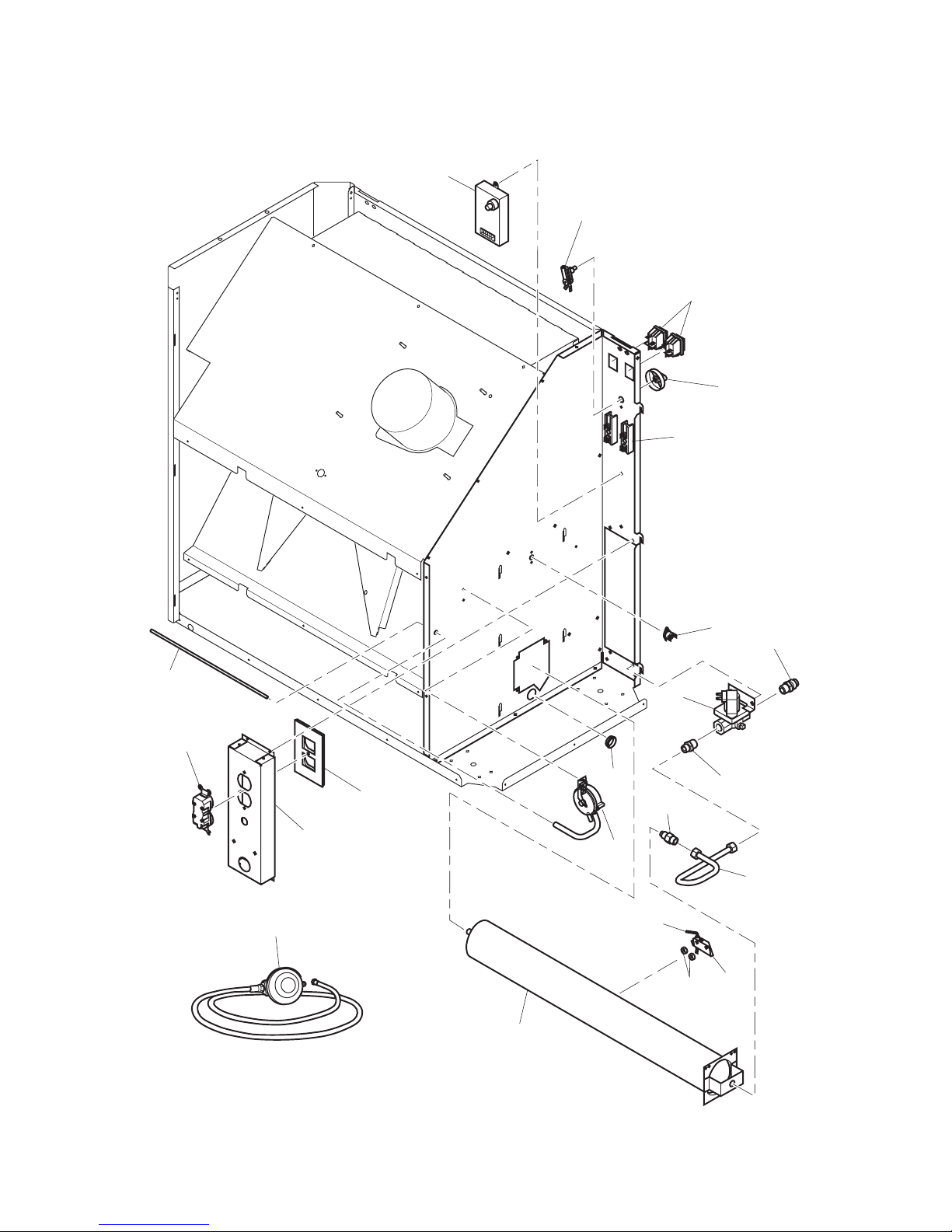

Figure 15 - Tent Heater Parts

Solenoid

Valve

Receptacle

DSI

Terminal

Boards

Thermostat

Switches

Gas Line

Burner

Pressure

Switch

SERVICE

Continued

Vacuum

Pressure

Pressure

Tap

Thermal

Limit Switch

Injector

Page 17

www.desatech.com

120193-01A 17

REMEDY

1. Check voltage to electrical

outlet. If voltage is good,

check heater power cord for

breaks

2. Adjust thermostat to higher

setting

3. Wait for ambient temperature

to decrease

4. Replace motor. See Motor and

Blower Assembly, page 13

1. Repeat installation and operation instructions. See

Installation, page 10 and

Operation, page 11

2.

A) Check ignitor wire. Tighten

or reattach loose ignitor wire.

B) Assure gap between ignitor

electrode and burner deck is

0.13"/0.15" (3.3/3.8 mm). Do

not bend electrode. Doing so

may cause it to break

C) Replace ignitor elec-

trode. See Replacing Ig-

nitor, page 15

D) Replace spark trans-

former. See Replacing DSI

Control, page 15

3. Clean tubing

POSSIBLE CAUSE

1. No electrical power to heater

2. Thermostat set too low

3. Ambient temperature is too

high. Thermostat is satis-

ed

4. Defective motor

1. User did not follow installation or operation instructions

properly

2. No spark at ignitor. To test

for spark, follow step 5 under

Replacing Ignitor, page 15. If

you see spark at ignitor, have

heater serviced by qualied

service person. If no spark

seen:

A) Loose or disconnected

ignitor wire

B) Wrong spark gap

C) Bad ignitor electrode

D) Bad spark DSI

3. Air proving switch blocked

OBSERVED FAULT

Fan does not turn when

switch(s) 1 or 2 are pressed

to ON

Heater will not ignite

TROUBLESHOOTING

WARNING: Never service heater while it is plugged in, connected

to propane supply, operating, or hot. Severe burns and electrical

shock can occur.

Page 18

www.desatech.com

120193-01A18

WARNING: Use only in areas

free of high dust content.

TROUBLESHOOTING

Continued

REMEDY

1. A) Rell tank

B) Provide additional and/or

larger tanks. See Propane

Supply, page 6

2. This can happen when running

heater in temperatures above

85° F (29˚ C). Run heater in

cooler temperatures

3. Check heater inlet and outlet.

Remove any obstructions

4.

Replace motor and blower assembly. See page 13

5. Clean heater. See Mainte-

nance, page 12

1. Check all connections for

leaks. Apply noncorrosive leak

detection uid to gas joints.

Bubbles forming show a leak

that must be corrected

2. To obtain correct mixture of

propane/LP gas and air, use

a larger cylinder size, i.e.

100 lb. See Propane Supply,

page 6

3. Use a larger supply cylinder

size, i.e. 100 lb.

POSSIBLE CAUSE

1. Propane supply may be

inadequate

2. High surrounding air temperature causing thermal

limit device to shut down

heater

3. Restricted air ow

4. Damaged fan

5. Excessive dust or debris in

surrounding area

1. Gas leak

2. Heater operating on a 20 lb.

propane/LP cylinder. Insuf-

cient propane/LP gas will be

supplied by a 20 lb. cylinder

resulting in odor

3. Propane/LP supply tank is

"freezing up". Evaporation

and consumption rate of

propane/LP from supply tank

is to great for the size of the

tank and air temperature

OBSERVED FAULT

Heater shuts down while

running

Heater producing odor

TECHNICAL SERVICE

You may have further questions about

this heater. If so, contact DESA Heating

Products’ Technical Service Department

at 1-866-672-6040. When calling, please

have your model and serial numbers of your

heater ready.

You can also visit DESA Heating Products’

Technical Service web site at

www.desatech.com.

Page 19

www.desatech.com

120193-01A 19

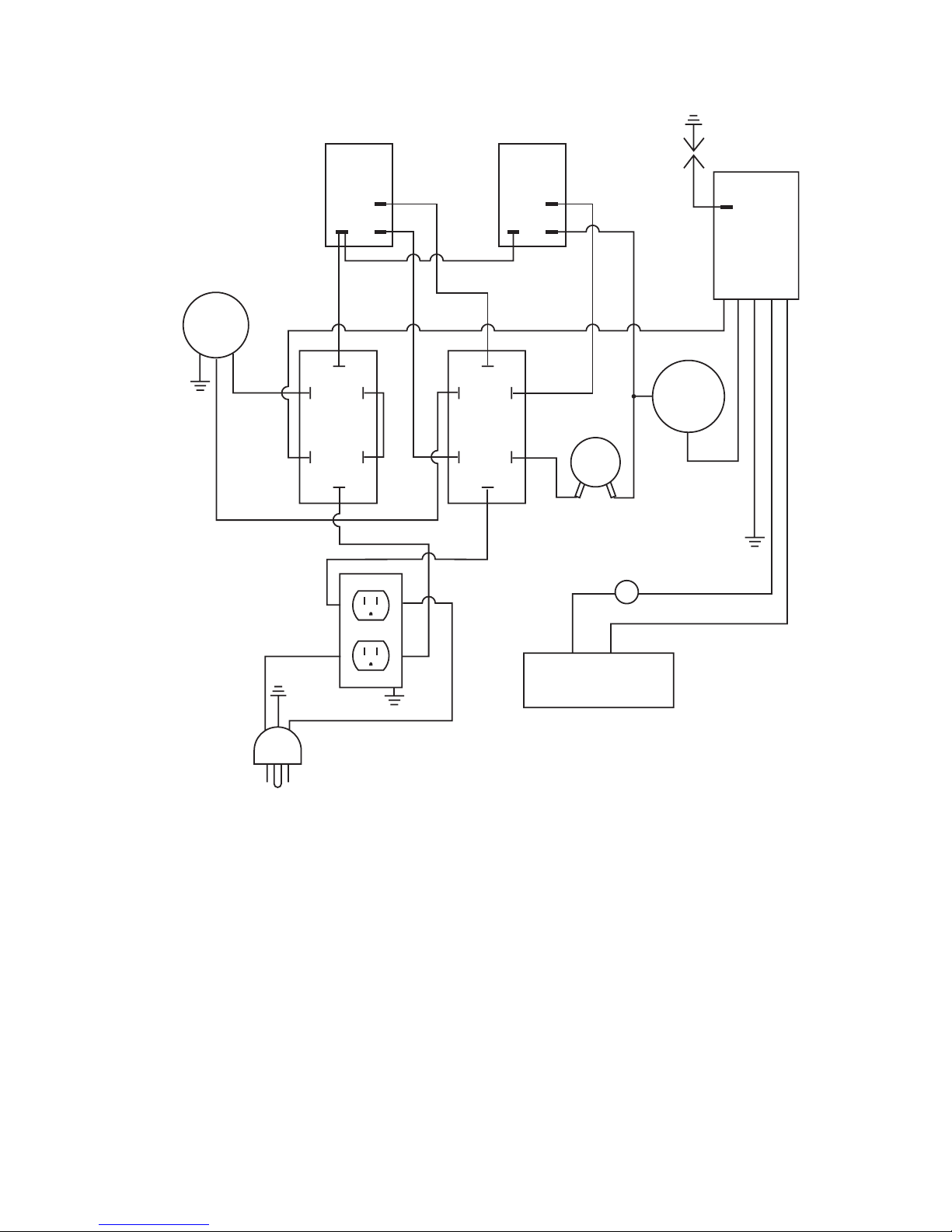

WIRING DIAGRAM

Electrical Connection Diagram

Motor

Moteur

VAC

Switch

(4)

Thermostat

Termostato

Receptacle

(6)

Switch 1

Cycle

(1)

White

Blanco/Blanc

White

Blanco/Blanc

White

Blanco

Blanc

White

Blanco

Blanc

White/Blanco/Blanc

White

Blanco

Blanc

White/Blanco/Blanc

Solenoid Valve/

Válvula de solenoide/

Électrovanne

DSI

(encendedor

de chispa

directa)

AED

Black

Negro

Noir

Black

Negro

Noir

Black

Negro

Noir

Black

Negro

Noir

Black

Negro

Noir

Orange

Naranja

Black

Negro

Noir

Green

Verde

Vert

Green

Verde

Vert

Green

Verde

Vert

Green

Verde

Vert

Blue

Azul

Bleu

Blue/Azul/Bleu

Blue/Azul/Bleu

Red/Rojo/Rouge

Red

Rojo

Rouge

Red

Rojo

Rouge

Terminal Block

(3)

Terminal Block

(3)

Switch 2

Continuous

(2)

(1) Interruptor 1 ciclo automático/

Interrupteur 1 en cycle

(2) Interruptor 2 continuo/

Interrupteur 2 en continu

(3) Bloque de terminales/Bornier

(4) Interruptor de VCA/

Interrupteur V c.a.

(5) Interruptor térmico/

Interrupteur thermique

(6) Receptáculo/Prise

Power Cord/

Cable de alimentación/

Cordon électrique

Thermal Switch

(5)

S1 = Switch 1

(1)

S2 = Switch 2

(2)

VAC = VAC Switch

(4)

T/S = Thermal Switch

T = Thermostat

Black

Negro/Noir

Black

Negro/Noir

Black

Negro/Noir

Black

Negro

Noir

T

L1

Page 20

www.desatech.com

120193-01A20

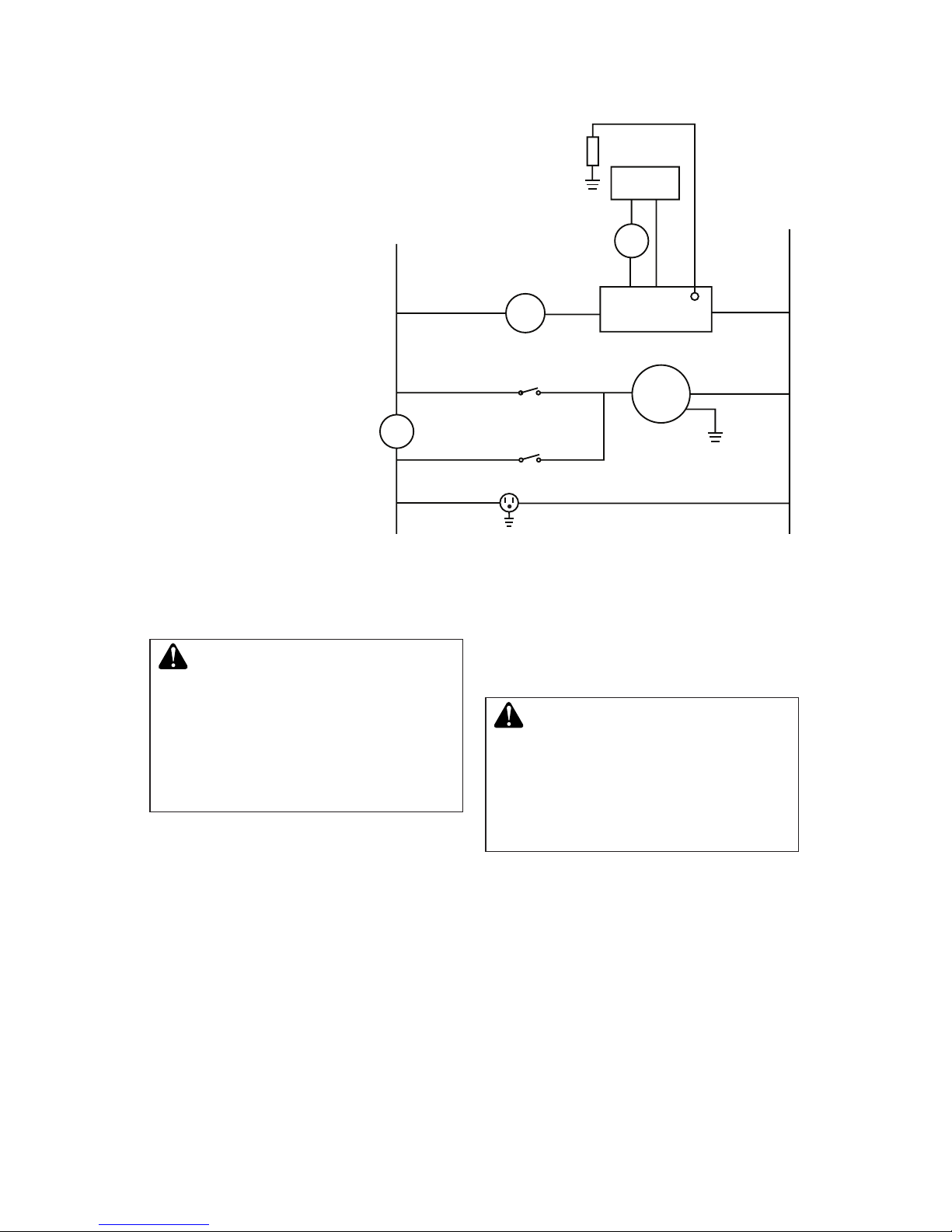

Ladder Diagram

WARNING: Never attempt

to service heater while it is

plugged in, operating, or hot.

Burns and electrical shock could

result. Only a qualied service

person should service or repair

heater.

WIRING DIAGRAM

Continued

If any of the original wire as supplied with

the appliance must be replaced, it must be

replaced with 105° C wire or it’s equivalent.

WARNING: Label all wires

prior to disconnection when

servicing controls. Wiring errors

can cause improper and dangerous operation. Verify proper

operation after servicing.

(1) Interruptor 1 ciclo automático/

Interrupteur 1 en cycle

(2) Interruptor 2 continuo/

Interrupteur 2 en continu

(3) Bloque de terminales/Bornier

(4) Interruptor de VCA/

Interrupteur V c.a.

(5) Interruptor térmico/

Interrupteur thermique

(6) Receptáculo/Prise

Motor

Moteur

White

Blanco/Blanc

White/Blanco/Blanc

S1 = Switch 1

(1)

S2 = Switch 2

(2)

VAC = VAC Switch

(4)

T/S = Thermal Switch

(5)

T = Thermostat

Neutral

Neutro

Neutre

White

Blanco

Blanc

Black

Negro/Noir

Black

Negro/Noir

Black

Negro/Noir

Black

Negro

Noir

Black

Negro

Noir

Blue

Azul

Bleu

Blue/Azul/Bleu

Blue/Azul/Bleu

T

L1

DSI

VAC

S2

Receptacle

(6)

S1

Solenoid

Valve

Ignitor

Encendedor

Allumeur

Orange

Naranja

T/S

L2

Red/Rojo

Rouge

Red

Rojo

Rouge

Page 21

www.desatech.com

120193-01A 21

REPLACEMENT PARTS

WARNING: Use only original

replacement parts. This heater

must use design-specic parts.

Do not substitute or use generic

parts. Improper replacement

parts could cause serious or fatal injuries. This will also protect

your warranty coverage for parts

replaced under warranty.

PARTS UNDER WARRANTY

Contact authorized dealers of this product.

If they can’t supply original replacement

part(s), call DESA Heating Products at

1-866-672-6040.

When calling DESA Heating Products, have

ready

• your name

• your address

• model number of your heater

• how heater was malfunctioning

• purchase date

In most cases, we will ask you to return the

part to the factory.

PARTS NOT UNDER WARRANTY

Contact authorized dealers of this product.

If they can’t supply original replacement

part(s), call DESA Heating Products at

1-866-672-6040.

When calling DESA Heating Products, have

ready:

• model number of your heater

• the replacement part number

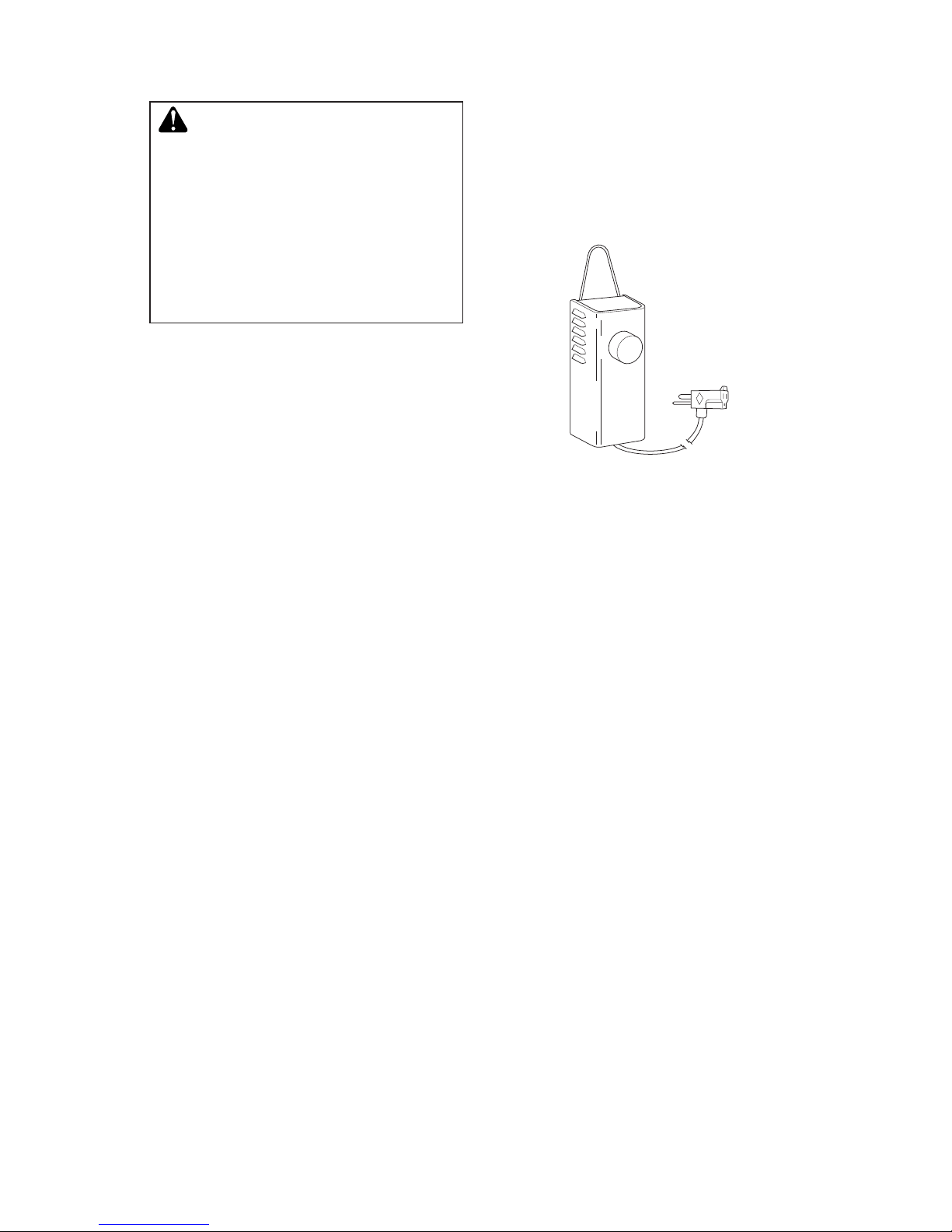

ACCESSORY

Purchase accessories and parts from your

nearest dealer or service center. If your dealer

or service center can not supply an accessory

or part, call DESA Heating Products’ Parts

Department at 1-866-672-6040. You can also

write to the address listed on the back page

of this manual.

THERMOSTAT KIT - PP235

Keeps your building at the temperature you

select day and night. Helps economize on

fuel. Includes 25 ft. cord.

Page 22

www.desatech.com

120193-01A22

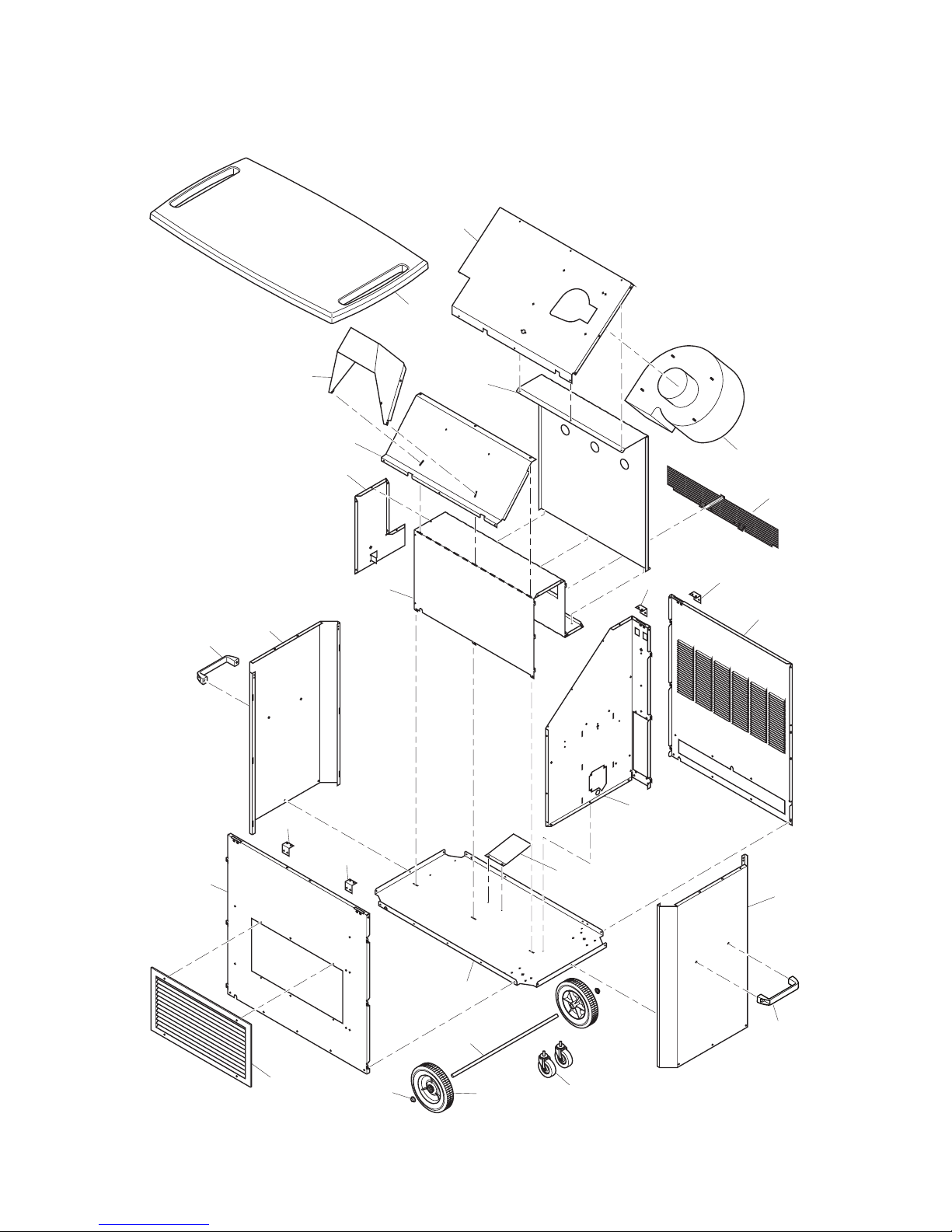

PARTS

CABINET

MODELS TB116, TB117 AND TB118

16

17

18

14

15

7

2

6

5

9

13

19

22

20

21

8

4

3

11

1

12

14

15

10

10

10

10

Page 23

www.desatech.com

120193-01A 23

KEY

NO. PART NO. DESCRIPTION QTY

1 119551-01 Cabinet Top, White • 1

119551-02 Cabinet Top, Black • 1

119551-03 Cabinet Top, Tan • 1

2 119555-01 Blower Mounting Panel • • • 1

3 119753-01 Motor and Blower Assembly • • • 1

4 119640-01 Bafe • • • 1

5 118295-01 Outlet Duct • • • 1

6 119558-01 Lower Bafe • • • 1

7 120043-01 Chamber End Panel • • • 1

8 120042-01 Top Chamber • • • 1

9 120123-01 Screen • • • 1

10 120116-01 Bracket • • • 4

11 118287-01AC Back Panel, White • • 1

118287-02DG Back Panel, Tan • 1

12 118289-01 Partition Panel • • • 1

13 120126-01 Ignitor Reector • • • 1

14 119926-01AC End Panel, White • • 2

119926-02DG End Panel, Tan • 2

15 120111-01 Handle • • • 2

16 118286-01 Cabinet Base • • • 1

17 118294-01AC Front Panel, White • • 1

118294-02DG Front Panel, Tan • 1

18 119553-01 Louvered Outlet Duct • • • 1

19 M16801-12 Plated Axle • • • 1

20 120469-01 Wheel • • • 2

21 M28526 Push cap • • • 2

22 120201-01 Caster • • • 2

PARTS AVAILABLE - NOT SHOWN

Decals Available • • •

120425-01 Hardware Bag • • • 1

110267-01 D.S.I. Wire Harness • • • 1

120173-01 Wire Assembly • • • 1

120173-02 Wire Assembly • • • 1

097806-04 Ignitor Cable • • • 1

098219-44 Power Cord • • • 1

** Not a eld replaceable part.

PARTS

CABINET

This list contains replaceable parts used in your heater. When ordering parts, follow the

instructions listed under Replacement Parts on page 21 of this manual.

TB116

TB117

TB118

Page 24

www.desatech.com

120193-01A24

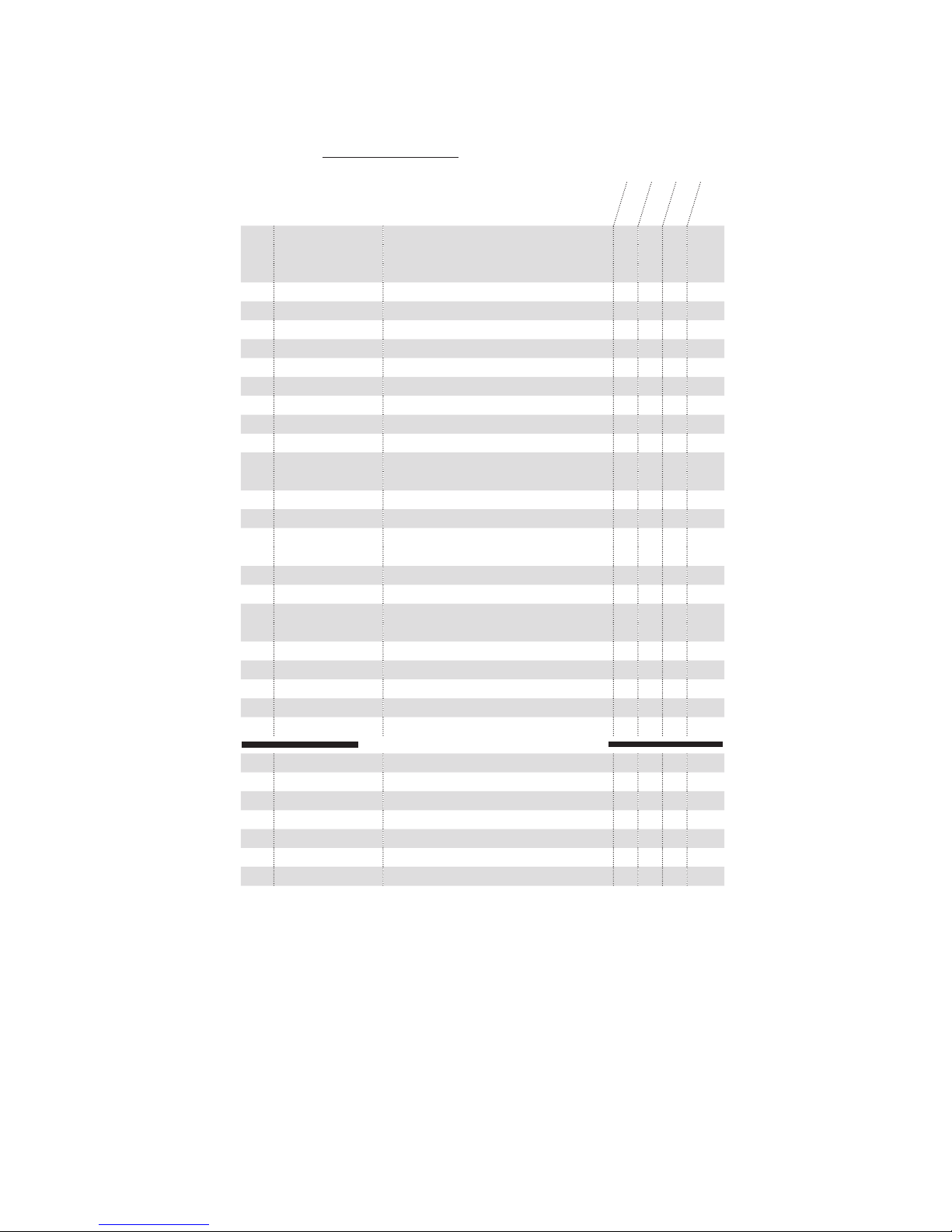

PARTS

MODELS TB116, TB117 AND TB118

17

21

11

10

16

13

12

14

9

8

7

22

2

4

3

19

1

18

20

5

15

6

Page 25

www.desatech.com

120193-01A 25

KEY

NO. PART NO. DESCRIPTION QTY

1 M51605-05 D.S.I. Control • • • 1

2 104458-01 Thermostat • • • 1

3 108394-01 ON/Off Switch • • • 2

4 104460-01 Thermostat Knob • • • 1

5 099125-01 Terminal Board • • • 2

6 101481-12 Thermal Limit Switch • • • 1

7 M51572-02 Male Connector • • • 1

8 103015-01 Solenoid Valve • • • 1

9 098264-02 Male Connector • • • 1

10 103845-15 Injector • • • 1

11 120127-01 Fuel Tube • • • 1

12 103934-01 Ignitor • • • 1

13 119884-01 Ignitor Bracket • • • 1

14 098249-01 ODS Nut • • • 2

15 118254-01 Burner • • • 1

16 M50104-02 Shorty Bushing • • • 2

17 120095-01 Pressure Switch Assembly • • • 1

18 120276-01 Duplex Cover • • • 1

19 119618-01 Recessed Valve Plate • • • 1

20 103769-01 Duplex Outlet • • • 1

21 120096-01 Air Switch Tube • • • 1

22 078923-04 Regulator and Hose Assembly • • • 1

** Not a eld replaceable part.

PARTS

MODELS TB116, TB117 AND TB118

This list contains replaceable parts used in your heater. When ordering parts, follow the

instructions listed under Replacement Parts on page 21 of this manual.

TB116

TB117

TB118

Page 26

www.desatech.com

120193-01A26

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

NOTES

Page 27

www.desatech.com

120193-01A 27

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

_____________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

______________________________________________________

NOTES

Page 28

2701 Industrial Drive

P.O. Box 90004

Bowling Green, KY 42102-9004

1-866-672-6040

WARRANTY

KEEP THIS WARRANTY

LIMITED WARRANTIES FOR NEW AND FACTORY

RECONDITIONED PRODUCTS

New Products: DESA Heating, LLC warrants this heater and any parts thereof, to be free of defects

in materials and workmanship for one (1) year from the date of rst purchase, when operated and

maintained in accordance with the manufacturer's instructions. These warranties are extended only to

the original retail purchaser, when proof of purchase is provided.

Factory Reconditioned Heaters: DESA Heating, LLC warrants this factory reconditioned heater and

any parts thereof, to be free of defects in materials and workmanship for thirty (30) days from the date of

rst purchase, when operated and maintained in accordance with the manufacturer's instructions. These

warranties are extended only to the original retail purchaser, when proof of purchase is provided.

This warranty covers only the cost of parts and labor required to restore the product to proper operating

condition. Transportation and incidental costs associated with warranty repairs are not reimbursable

under this warranty.

Warranty service is available only through authorized dealers and service centers.

This warranty does not cover defects resulting from misuse, abuse, negligence, accidents, lack of

proper maintenance, alteration, modication, tampering, contaminated fuels, repair using improper

parts, or repair by anyone other than an authorized dealer or service center. Routine maintenance is

the responsibility of the owner.

THIS EXPRESS WARRANTY IS GIVEN IN LIEU OF ANY OTHER WARRANTY EITHER EXPRESSED

OR IMPLIED, INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

DESA Heating, LLC assumes no responsibility for indirect, incidental or consequential damages. Some

states do not allow the exclusion or limitation of incidental or consequential damages, or limitations or

exclusions may not apply to you. This Limited Warranty gives you specic legal rights and you may also

have other rights which vary from state to state.

Model _____________________________________

Serial No. __________________________________

Date of Purchase ____________________________

82 Akron Road

Toronto, Canada M8W 1T2

416-255-5333

The only warranty applicable is our standard written warranty. We make no other warranty, expressed or implied.

WARRANTY SERVICE

Should your heater require service, return it to your nearest authorized service center. Proof of purchase

must be presented with the heater. The heater will be inspected. A defect may be caused by faulty materials

or workmanship. If so, DESA Heating, LLC will repair or replace the heater without charge.

REPAIR SERVICE

Return your heater to your nearest authorized service center. Repairs not covered by the warranty will be

billed at standard prices. Each Service Center is independently owned and operated. We reserve the right

to amend these specications at any time without notice.

120193-01

Rev. A

11/06

Patent Pending

Page 29

IMPORTANTE: lea y comprenda este manual antes de

ensamblar, encender o dar servicio al calentador. El uso

inadecuado del calentador puede causar lesiones graves. Conserve este manual para referencias futuras.

ADVERTENCIA GENERAL DE PELIGRO:

El incumplimiento de las precauciones e instrucciones

proporcionadas con este calentador puede causar la

muerte, lesiones físicas graves y pérdidas o daños a

propiedades ocasionados por incendios, explosiones,

quemaduras, asfixia, intoxicación con monóxido de carbono y/o electrocución.

Únicamente las personas que puedan entender y seguir

las instrucciones deberán usar o dar servicio a este

calentador.

Si necesita ayuda o información sobre el calentador, por

ejemplo, un manual de instrucciones, etiquetas, etc., comuníquese con el fabricante.

Guarde este manual para referencias futuras.

Para obtener más información visite www.desatech.com

CALENTADOR DE PROPANO

DE AIRE FORZADO PARA

EVENTOS EN CARPAS

MANUAL DEL PROPIETARIO

MODELOS TB116, TB117 Y TB118

125,000 BTU/H

125

TENT

Event

by

Page 30

www.desatech.com

120193-01A2

ADVERTENCIA: si la información contenida en este

manual no se sigue al pie de la letra, se pueden producir un

incendio o una explosión que podrían ocasionar daños a

la propiedad, lesiones personales o la pérdida de la vida.

—

No guarde ni utilice gasolina u otros vapores y líquidos

inflamables cerca de este aparato ni de cualquier otro.

— QUÉ HACER SI PERCIBE OLOR A GAS

• No intente encender ningún aparato.

• No toque ningún interruptor eléctrico; no use ningún teléfono en el edificio.

• Llame inmediatamente a su proveedor de gas desde

el teléfono de algún vecino. Siga las instrucciones

del proveedor de gas.

• Si no puede localizar al proveedor de gas, llame al

departamento de bomberos.

— La instalación y el servicio deben ser realizados por

un instalador capacitado, agencia de servicio o por el

proveedor de gas.

Éste es un calentador de combustión a gas sin ventilación para carpas. Utiliza aire (oxígeno) de la carpa en la

que se instala. Se deben tomar las medidas necesarias

para asegurar que la cantidad de aire para la ventilación

y la combustión sean adecuadas. Proporcione una abertura de al menos 271 cm2 (42 pulgadas2).

TABLA DE CONTENIDO

Seguridad ............................................................ 3

Identicación del producto ................................... 6

Desempaque ....................................................... 6

Ventilación ........................................................... 6

Suministro de propano ........................................ 7

Teoría de funcionamiento .................................... 8

Ensamble............................................................. 9

Instalación ..........................................................11

Funcionamiento ................................................. 12

Almacenamiento ................................................ 13

Mantenimiento ................................................... 13

Servicio .............................................................. 13

Especicaciones ................................................ 17

Solución de problemas ...................................... 18

Servicio técnico ................................................. 19

Diagrama de cableado ...................................... 20

Piezas ................................................................ 22

Piezas de repuesto ............................................ 26

Accesorios ......................................................... 26

Garantía............................................................. 28

Page 31

www.desatech.com

120193-01A 3

SEGURIDAD

Para uso en Canadá

ANSI Z83.7 - 2000

Calentadores de combustión a gas para

construcción

CGA 2.14 - 2000

Calentadores de combustión a gas para

construcción

General

ANSI/NFPA 102

Norma para tribunas en exteriores techa-

das, gradas plegables y telescópicas,

carpas y estructuras con membranas

ANSI/NFPA 58

La edición más reciente de la Norma

para almacenamiento y manejo de gas

licuado de petróleo

ANSI Z223.1/NFPA 54

La edición más reciente del Código nacio-

nal estadounidense de gas combustible

ANSI/NFPA 70

La edición más reciente del Código

nacional estadounidense de electricidad

y el Código canadiense de electricidad,

CSA C22.1 parte 1

El propósito principal de los calentadores para

construcción es proporcionar calefacción temporal en edificios en construcción, remodelación

o reparación. Cuando se usa correctamente, el

calentador proporciona calefacción económica

y segura. Los productos de combustión se ventilan al área que se está calentando.

No podemos prever todos los usos que se les

pueden dar a nuestros calentadores. Consul-

te a las autoridades locales de seguridad

contra incendios si tiene alguna pregunta

acerca del uso de calentadores.

Otras normas rigen el uso de gases combustibles y productos que producen calor para

usos específicos. Las autoridades locales

pueden informarle acerca de éstas.

ADVERTENCIA: cuando la

combustión y la ventilación no

son adecuadas, el calentador

puede emitir cantidades excesivas de monóxido de carbono, un

gas inodoro y venenoso.

No instale el calentador sino hasta que se hayan

tomado todas las previsiones necesarias de combustión y ventilación. Consulte el instructivo impreso que se incluye con el calentador para obtener

información acerca del aire para la combustión y

ventilación. Cuando no se tengan las instrucciones, consulte el código nacional estadounidense

de gas combustible, ANS Z223.1, sección 5.3 o

los códigos locales correspondientes.

ADVERTENCIA: este producto contiene y/o genera químicos

reconocidos por el estado de California como causantes de cáncer o de defectos de nacimiento,

u otros daños reproductivos.

ADVERTENCIA: peligro de

incendio, quemaduras, inhalación

y explosión. Mantenga los combustibles sólidos como mesas,

sillas, materiales de construcción,

papel o cartón, a una distancia segura del calentador tal y como se

recomienda en las instrucciones.

Nunca use el calentador en áreas

en las que haya, o pueda haber,

combustibles volátiles o que se

acumulen en el aire, o bien, productos como gasolina, solventes,

diluyente de pintura, partículas de

polvo o químicos desconocidos.

ADVERTENCIA: no se debe

usar en residencias ni en vehículos recreativos.

El calentador está diseñado y aprobado para

su uso como calentador de carpas en conformidad con estas instrucciones. SI TIENE

PREGUNTAS SOBRE LAS APLICACIONES,

CONSULTE LAS AUTORIDADES LOCALES

DE SEGURIDAD CONTRA INCENDIOS.

El calentador está diseñado para su uso como

calentador para construcción y como calentador de

carpas sin ventilación. El calentador está diseñado

para usarse dentro del espacio que se va a calentar. El calentador utiliza el aire del espacio que está

calentando para la combustión y ventilación.

Normas aplicables:

Para uso en los EE.UU.

ANSI Z83.7 - 2000

Calentadores de combustión a gas para

construcción

CGA 2.14 - 2000

Calentadores de combustión a gas para

construcción

CSA 3.06 - 2006

Calentadores portátiles de combustión a

gas sin ventilación para carpas

Page 32

www.desatech.com

120193-01A4

SEGURIDAD Continuación

Este calentador está equipado con un sistema

de apagado de seguridad con detección de

agotamiento de oxígeno (ODS por sus siglas

en inglés) que está diseñado para apagar

el calentador cuando no hay suficiente aire

fresco.

¡No altere el sistema de segu-

ridad de detección de agota-

miento de oxígeno!

Si el calentador se apaga, no lo vuelva encender hasta que haya entrado aire fresco. Si el

calentador se sigue apagando, haga que lo

reparen. Mantenga limpios el quemador y el

compartimento de control.

PELIGRO: ¡la intoxicación

con monóxido de carbono puede

ocasionar la muerte!

Intoxicación con monóxido de carbono:

los síntomas iniciales de la intoxicación con

monóxido de carbono son semejantes a los

de la gripe, con dolores de cabeza, mareos

y/o náusea. Si usted presenta estos síntomas, es posible que el calentador no esté

funcionando correctamente. ¡Respire aire

fresco inmediatamente! Compruebe que la

ventilación sea adecuada y haga que reparen

el calentador. El monóxido de carbono afecta

más algunas personas que a otras. Las más

afectadas incluyen mujeres embarazadas,

personas con enfermedades del corazón o

de los pulmones o anemia, aquellas bajo la

influencia del alcohol y aquellas a grandes

altitudes.

Propano o gas LP: el propano o gas LP es

inodoro. Al propano o gas LP se le agrega

un agente que tiene olor. El olor le ayuda

detectar las fugas de propano o gas LP. Sin

embargo, el olor que se añade al propano o

gas LP puede desvanecerse, de manera que

puede haber gas propano aún cuando no se

perciba olor.

Asegúrese de leer y comprender todas las

advertencias. Conserve este manual como

referencia. Es su guía para la operación segura y correcta de este calentador.

ADVERTENCIA: no coloque

ropa ni otros materiales inflamables sobre el aparato o cerca

del mismo.

ADVERTENCIA: debido a las

altas temperaturas generadas

por este aparato, éste se debe

colocar fuera de las rutas de

paso y alejado de muebles.

ADVERTENCIA: los niños

pequeños deben estar bajo

estricta supervisión cuando se

encuentren en la misma habitación que el aparato.

ADVERTENCIA: se debe

advertir a niños y adultos sobre

el peligro que presenta la alta

temperatura de la superficie y

deben mantenerse a distancia

para evitar quemaduras o que

la ropa se encienda.

PRECAUCIÓN: cualquier

protección o rejilla de seguridad

que se haya retirado para el

mantenimiento del aparato deberá volverse a colocar antes de

hacer funcionar el calentador.

1. Instale y use el calentador con cuidado.

Siga todas las ordenanzas y los códigos

locales. Cuando no existan reglamentos

y códigos locales, consulte la Norma para

almacenamiento y manejo de gas licuado

de petróleo, ANSI/NFPA 58, el Código

de instalación de gas natural y propano,

CSA B149.1 y la Norma para tribunas en

exteriores techadas, gradas plegables

y telescópicas, carpas y estructuras

con membranas, ANSI/NFPA 102. Éste

proporciona instrucciones acerca del

almacenamiento y el manejo seguro del

propano o gas LP.

2. Use solamente la tensión eléctrica y la

frecuencia que se especifican en la placa

donde aparece al número de modelo. Las

conexiones eléctricas y a tierra del calentador deberán hacerse de acuerdo al

Código eléctrico nacional estadounidense, ANSI/NFPA 70 o al Código eléctrico

canadiense, parte 1, CSA C22.1.

Page 33

www.desatech.com

120193-01A 5

15. Antes de cada uso, verifique si el calentador ha sufrido algún daño. No use un

calentador dañado.

16. Revise la manguera antes de cada uso

del calentador. Si la manguera está muy

desgastada o con roturas, reemplácela

con una manguera especificada por el

fabricante antes de usar el calentador.

17. Cuando el calentador esté caliente o

funcionando póngalo en una superficie

estable y nivelada.

18. Nunca bloquee la entrada de aire (parte

posterior) ni la salida de aire (parte anterior) del calentador.

19. Mantenga el calentador alejado de corrientes fuertes de aire, viento, rocío, lluvia

y goteos de agua.

20. Evite que los niños y los animales se

acerquen al calentador.

21.

Nunca mueva, maneje o dé servicio a un calentador caliente o en funcionamiento. Podría

sufrir quemaduras graves. Debe esperar 15

minutos después de apagar el calentador.

22. Para evitar lesiones, use guantes cuando

manipule el calentador.

23. Nunca conecte tubería al calentador.

24. Los calentadores de espacios que se

usen cerca de lonas impermeables y

toldos o materiales protectores parecidos

deben colocarse a una distancia segura

con respecto a dichos materiales. Estos

materiales protectores deberán ser retardadores del fuego. Estos materiales

protectores deben estar bien asegurados

para evitar que se enciendan o que bloqueen el espacio del calentador a causa

de la acción del viento.

25. No altere el calentador. Mantenga el

calentador en su estado original.

26.

No use el calentador si éste ha sido alterado.

27. Cierre el suministro de propano o gas LP

al calentador y desconéctelo cuando no

se esté usando.

28. Use sólo piezas de repuesto originales.

Este calentador debe usar piezas diseñadas específicamente. No las sustituya ni

use piezas genéricas. El uso de piezas de

repuesto inadecuadas puede ocasionar

lesiones graves o fatales.

29. El calentador debe estar instalado de

manera que su ubicación no obstruya ni

interfiera con las salidas normales y de

emergencia, puertas o rutas de paso en

la estructura.

3. Instrucciones para la conexión eléctrica a

tierra: este aparato está equipado con una

clavija de tres patas (con conexión a tierra)

para protegerlo contra descargas eléctricas

y se tiene que conectar directamente a un

enchufe de pared con interruptor de falla

a tierra o un cable de extensión de tres

orificios conectado a tierra correctamente.

4. Use sólo la manguera y el regulador

preinstalado en la fábrica que se incluyen

con el calentador.

5. Use solamente el montaje de propano o

gas LP para la extracción de vapores.

6. Éste es un calentador de combustión a

gas sin ventilación para carpas. Utiliza aire

(oxígeno) de la carpa en la que se instala.

Proporcione ventilación adecuada. Antes

de usar el calentador, proporcione una abertura de al menos 271 cm2 (42 pulgadas2) de

aire fresco del exterior.

7. Para uso en exteriores e interiores.

8. No use el calentador en viviendas ocupadas, en estancias ni en dormitorios.

9. No use el calentador en un sótano ni

debajo del nivel del suelo. El propano o

gas LP es más pesado que el aire. Si se

produce una fuga, el propano o gas LP se

asentará en el nivel más bajo posible.

10.

El área en dónde se localiza el aparato debe

mantenerse despejada y libre de materiales

combustibles, gasolina, diluyentes para pintura y otros vapores y líquidos inflamables. El

polvo es combustible. No use el calentador

en áreas con alto contenido de polvo.

11. Distancias mínimas entre el calentador y

los materiales combustibles: a la sailda:

2.40 m (8 pies), laterales: 30 cm (1 pie),

parte superior: 0.91 m (3 pies), parte

posterior: 30 cm (1 pie)

12. Mantenga el calentador alejado de los

tanques de propano o gas LP a una distancia de por lo menos 1.83 m (6 pies).

No apunte el calentador a los tanques de

propano o gas LP que se encuentren a

menos de 6 m (20 pies). En Canadá, mantenga el calentador alejado de los tanques

de propano o gas LP a una distancia de

por lo menos 3 m (10 pies).

13. Mantenga los tanques de propano o gas

LP a menos de 38 °C (100 °F).

14. La temperatura mínima del aire circundante

de este calentador es de -29 °C (-20 °F).

SEGURIDAD Continuación

Page 34

www.desatech.com

120193-01A6

Figura 1 - Calentador de carpas

Parte superior

Cable de alimentación

Conjunto de

manguera y

regulador

Entrada

de gas

Manija

Perilla del

termostato

Interruptores

de alimentación

Enchufe

IDENTIFICACIÓN DEL PRODUCTO

DESEMPAQUE

1. Saque todos los materiales en los que

se empacó el calentador para el envío.

Conserve los tapones de plástico (colocados en el conector de entrada y en el

conjunto de manguera y regulador) para

propósitos de almacenamiento.

2. Saque todas las piezas de la caja.

3. Revise todas las piezas en busca de daños durante el transporte. Si el calentador

está dañado, infórmelo de inmediato al

distribuidor donde lo compró.

VENTILACIÓN

ADVERTENCIA: siga los

requerimientos mínimos de

ventilación de aire fresco del

exterior. Si no hay una ventilación de aire fresco del exterior

adecuada, se podría producir

una intoxicación con monóxido

de carbono. Proporcione una

ventilación adecuada de aire

fresco del exterior antes de encender el calentador.

Proporcione una abertura de al menos 271 cm2

(42 pulgadas2) para entrada de aire fresco del

exterior.

Ejemplo: 7.62 cm de alto x 35.56 cm de largo =

271 cm2 (3" x 14" = 42 pulgadas2). Proporcione

más aire fresco si se utilizan más calentadores.

Page 35

www.desatech.com

120193-01A 7

SUMINISTRO DE

PROPANO

El usuario debe proporcionar el propano o

gas LP y los tanques de propano.

Use el calentador solamente con un sistema

de suministro con extracción de vapores de

propano. Consulte el capítulo 5 de la Norma

para almacenamiento y manejo de gas licuado de petróleo, ANSI/NFPA 58 y el Código

canadiense para instalación de gas natural

y propano, CSA B149.1. La biblioteca local

o el departamento de bomberos deben tener

este folleto.

Mantenga los tanques de propano o gas LP

alejados por lo menos 1.52 m (5 pies) de las

paredes de la carpa.

Los tanques de propano o gas LP deberán

estar protegidos, alejados de vehículos y

seguros conforme a la Norma para tribunas

en exteriores techadas, gradas plegables

y telescópicas, carpas y estructuras con

membranas, NFPA 102, y la Norma para

almacenamiento y manejo de gas licuado de

petróleo, ANSI/NFPA 58.

El volumen de gas listo para usarse a partir

de tanques de propano varía. Dos factores

determinan este volumen:

1. El volumen de gas propano en el o los

tanques

2. La temperatura del o los tanques

La siguiente tabla muestra el número de tanques de 45 kg (100 libras) que se necesitan

para hacer funcionar este calentador.

Se pueden utilizar tanques pequeños durante periodos cortos, pero para obtener

un desempeño óptimo se recomienda

utilizar tanques de mayor capacidad.

Temperatura promedio Número de

en la ubicación tanques

de los tanques 45 kg (100 lb)

Superior a -6.7 °C (20 °F) 2

De -6.7 °C (20 °F) a -18 °C (0 °F) 3

Por debajo de -18 °C (0 °F) Use un tanque

más grande