Page 1

MP-CLR UF Top Mount Water

Installation and Operation Manual

Softeners

June 2015 Version

Page 2

Table of Contents

No.

1

Model # and Packaging

Packaging Information

Component Packaging Description

Packaging Description

System Media

Media Packaging

2

Softening System

System Positioning

Water Softener Tank Loading

Filling with Media

MP-Clear Reflections Control Valve

Attaching Valve to Tank

3

MP-Clear Reflections Control Valve

Attaching Valve, cont’d

4

Service & Drain Piping,

Drain Piping

5

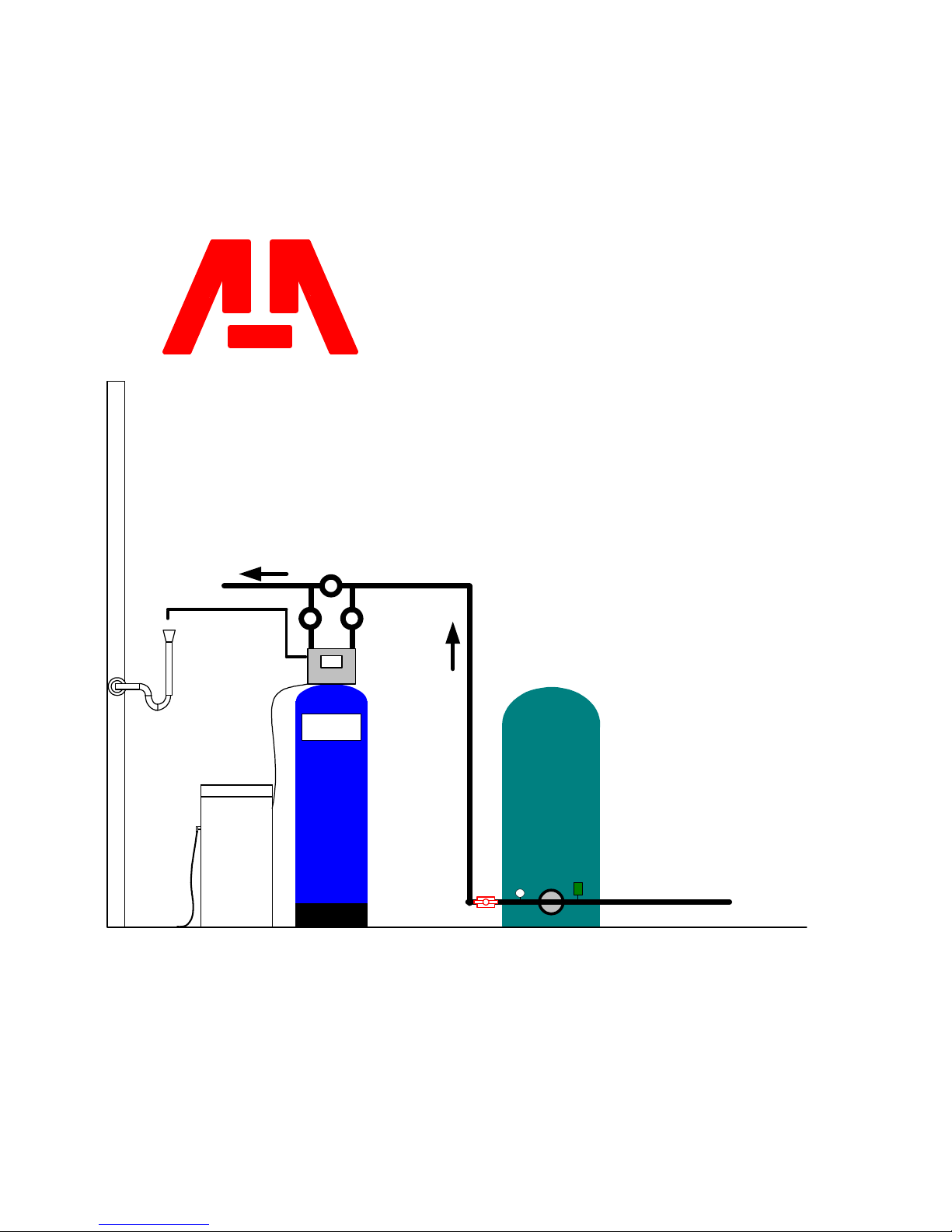

System Schematic

Piping Layout

6

Electrical Supply

Electrical Requirements

Brine Tank / Brine Tubing

Brine tank w/shut off

7

Filling Softener with Water

Details for Filling Softener Tank with

8

MP-Clear Reflections Control Valve

Setting the timer

9

Final Check

Final Install ati on Chec k

10

Manual Regeneration

Instructions for Manual Regeneration

Power loss/ Error codes

“What if” Instructions

11

Bypass

Bypass Operation

12

Troubleshooting

Problem/ Cause / Solution

13

Troubleshooting

Problem/ Cause / Solution

14

Troubleshooting

Problem/ Cause / Solution

15

Troubleshooting

Problem/ Cause / Solution

16

Troubleshooting

Problem/ Cause / Solution

17

Error Code Troublesho oti ng

Problem/ Cause / Solution

18

Error Code Troublesho oti ng , cont’d

Problem/ Cause / Solution, cont’d

19

Valve Parts List

Part Numbers List

20

Valve Parts List

Part Numbers List

21

Valve Parts List

Part Numbers List

22

Valve Parts List

Part Numbers List

23

Valve Parts List

Part Numbers List

24

Warranty

Warranty

Page

Topic Description

General Installation Layout

Timer

Water

Page 3

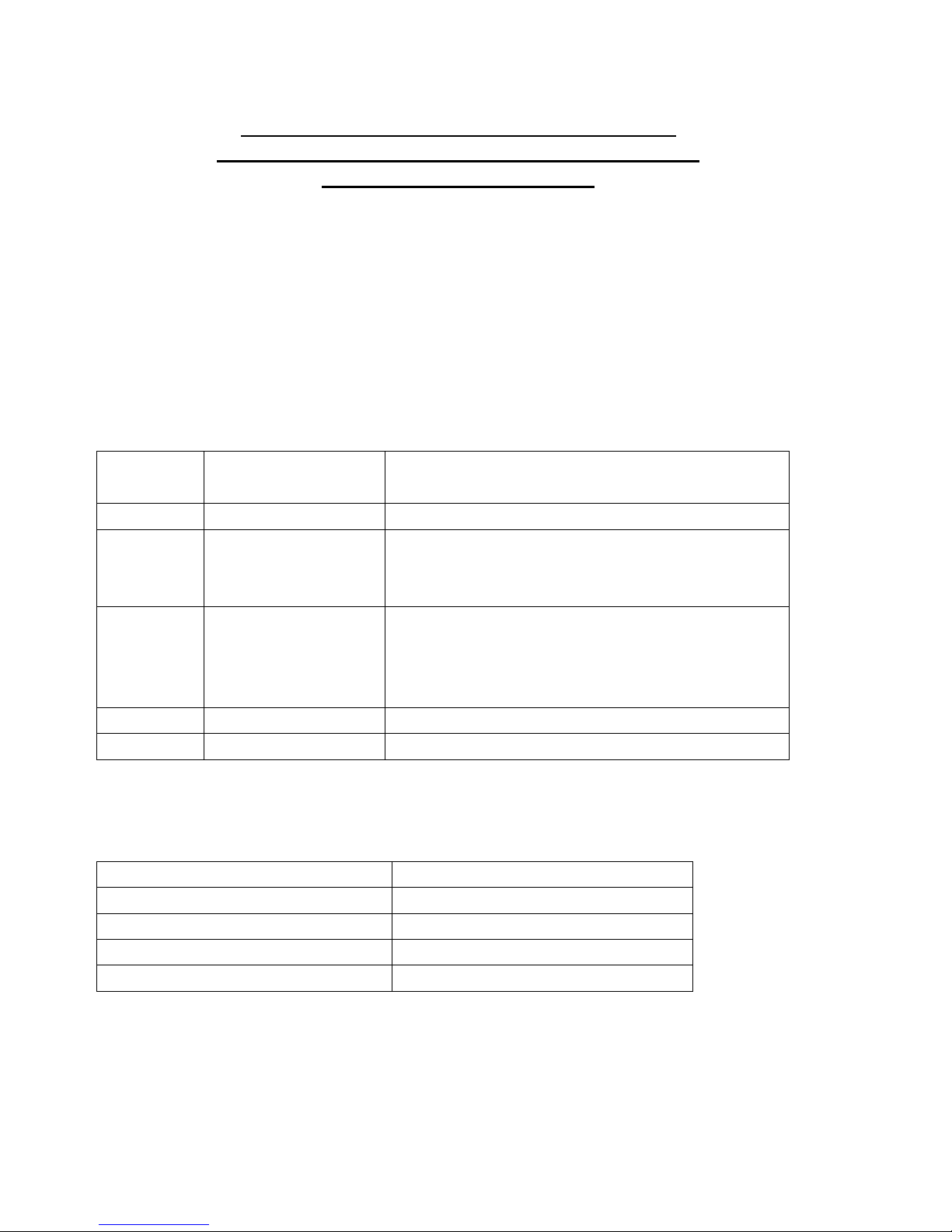

Installation and Operating Instructions for

MP-CLEAR REFLECTONS UPFLOW CONTROL

Top Mount Water Softener

Model #:

_______ MP-CLR-30 UF 1.0 CF Water Softener

_______ MP-CLR-45 UF 1.5 CF Water Softener

_______ MP-CLR-60 UF 2.0 CF Water Softener

_______ MP-CLR-75 UF 2.5 CF Water Softener

Shipping Carton Description / unit:

# of

Contents Description

cartons

1 Mineral tank Distributor pipe installed

1 Brine tank

464 shutoff valve assembly. *NOTE:

MP-Clear Reflections valve is shipped

in brine tank.

1 MP-Clear

Reflections

Upflow control

MP-Clear Reflections timer and

backwash flow control and bypass with

1” copper or pvc connection

valve

C-800 1-cubic foot boxes

C-800 ½- cubic foot boxes

Filter Media is Packaged as Follows:

Model # Media

MP-CLR-30 UF BY Preloaded at Factory

MP-CLR-45 UF BY Preloaded at Factory

MP-CLR-60 UF BY Preloaded at Factory

MP-CLR-75 UF BY 2-1/2 CF C-800

NOTE: THIS SOFTENER IS NOT INTENDED TO BE USED FOR TREATING WATER THAT

IS MICROBIOLOGICALLY UNSAFE OR OF UNKNOWN QUALITY WITHOUT

ADEQUATE DISINFECTION WHETHER BEFORE OR AFTER THE SYSTEM.

Page 4

Water Softener Positioning:

1. Place water softener in desired position, far enough from walls and

other obstructions to allow for servicing the unit.

2. Place the water softener within reasonable access to a grounded

115V/60 HZ circuit and a legal drain line connection.

Water Softener Tank Loading:

(Only the MP-CLR-75 needs to be loaded))

1. Remove yellow caplug from top of tank. DO NOT CUT white riser

tube. Tube was prefitted at the factory.

2. Check the riser to ensure that it is seated securely in the bottom

plate. The top of the distributor pipe will be flush with the top of the

tank (this was prefitted at the factory).

3. Cover the top opening of the distributor pipe before filling the tank

with media (if necessary).

4. Pour the C-800 provided with the unit into the top of the tank. See

page one for your specific model number unit to determine the

amount of media to load into the mineral tank.

5. Remove the material used to cover the top opening of the distributor

pipe.

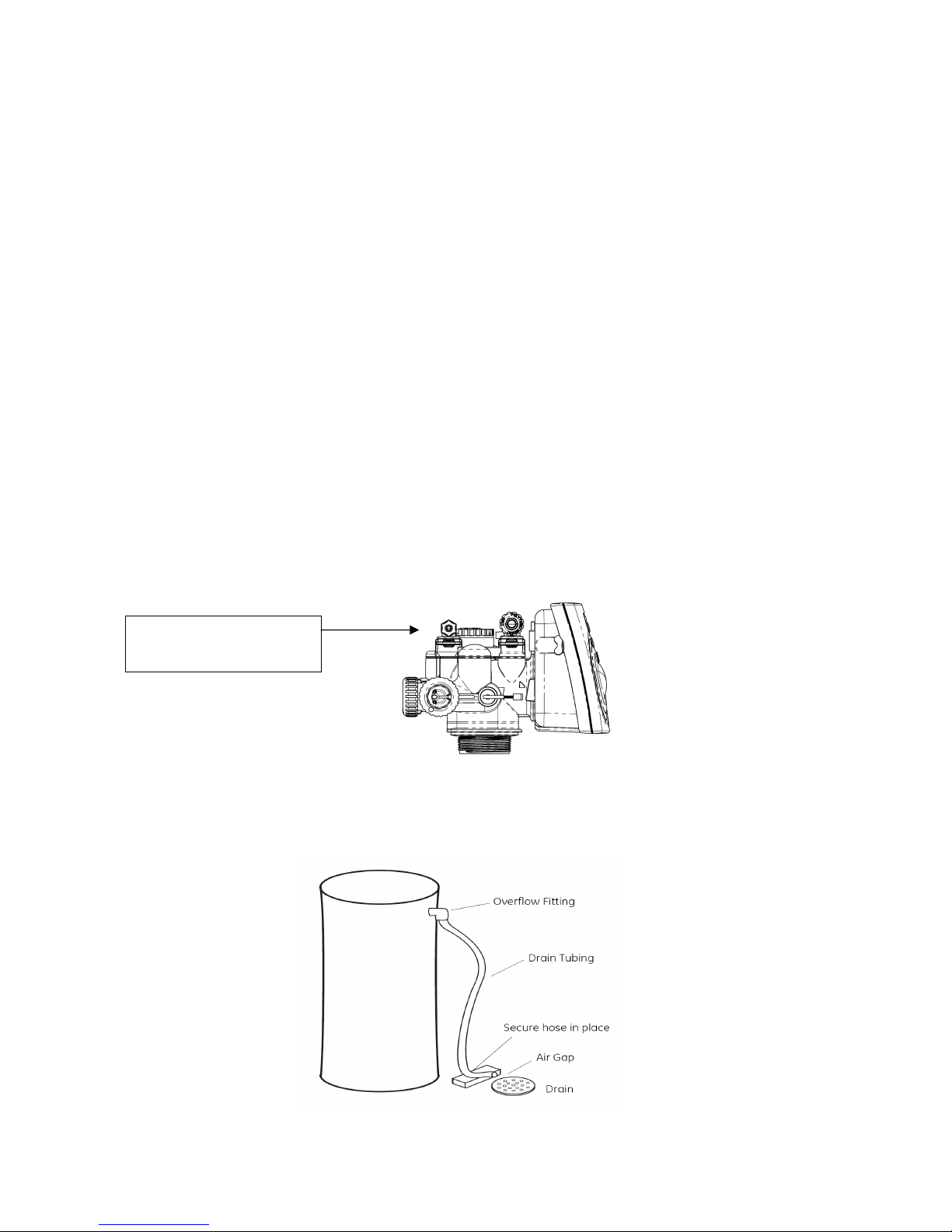

MP-Clear Reflections Control Valve:

1. When facing the front of the MP-Clear Reflections timer, the inlet

connection is located on the right and the outlet connection is on the

left. The control valve's inlet and outlet connections are either 1”

copper or PVC equipped with split ring and nut.

Control Valve

Front View Top View

2

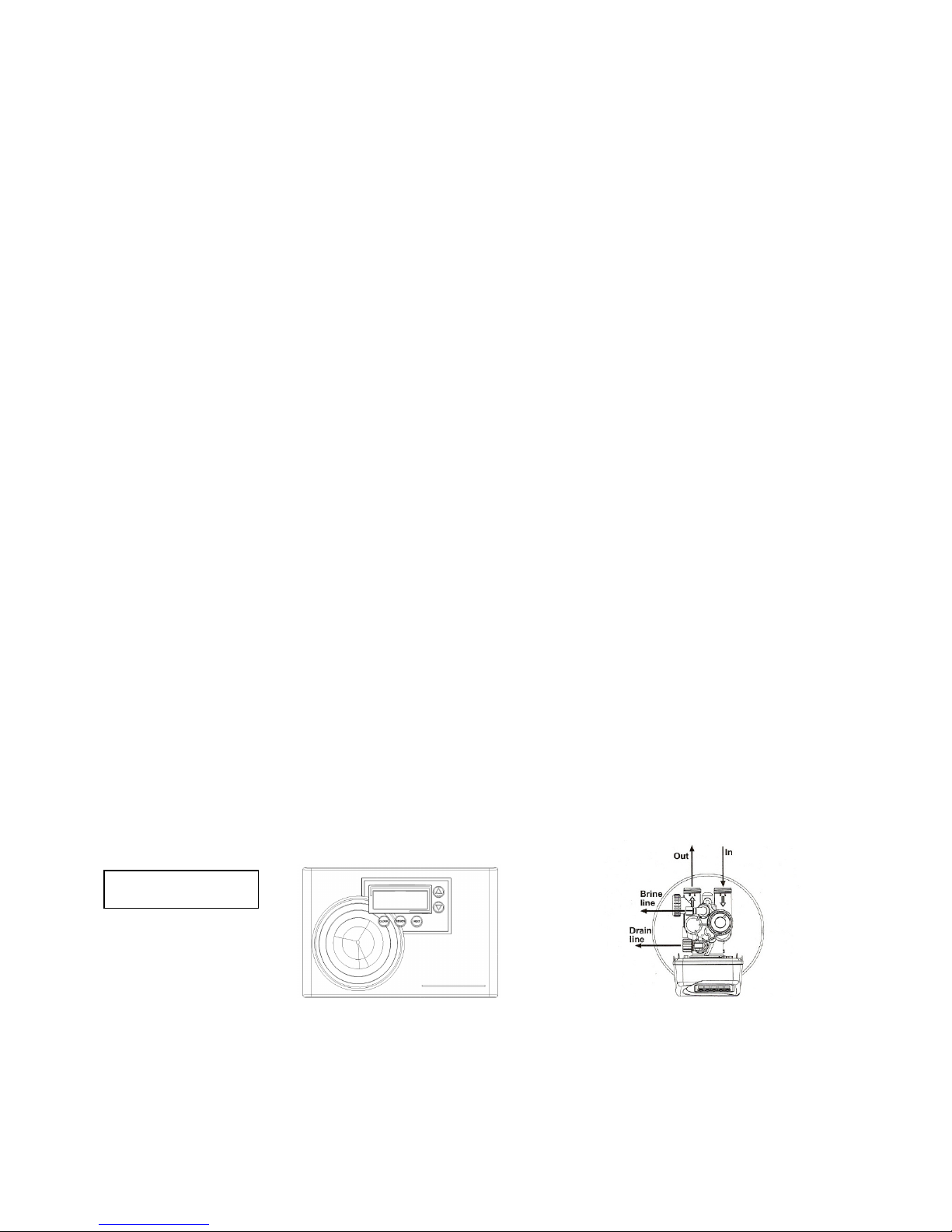

Page 5

1. Turn the control valve upside down and ensure that the control valve

distributor o’ring is in place. Use silicone lubricant on the o'ring.

**DO NOT USE PETROLEUM!**

**USE ONLY SILICONE **

2. Place the control valve onto the distributor pipe and into the tank

opening.

3. Thread the control valve hand tight . Do not overtighten.

4. Locate the bypass valve assembly that is packaged with the

control valve. The bypass valve has two red handles that

indicate flow direction, two threaded connections for the tail

piece kit and two o’ring seal connections with nuts for the control

valve. Align the insert connection ends with o’ring seals and

nuts to the inlet and outlet connections of the control valve.

Hand tighten the nuts. DO NOT OVERTIGHTEN THE NUT!

Bypass Valve

5. Locate the tail piece kit that is packaged with the control valve.

The standard tail piece kit is 1” copper with optional 1”/ 3/4” PVC or

¾” copper kits available as a special order. Each tail piece,

o’ring, split ring and nut is presassembled at the factory. Align a

tail piece assembly to the bypass valve threaded inlet and insert

until the nut can be tightened. Hand tighten the nut because

excessive tightening will damage the assembly. REPEAT THE

PROCEDURE FOR THE OUTLET CONNECTION.

3

Control Valve

Tail piece assembly

Page 6

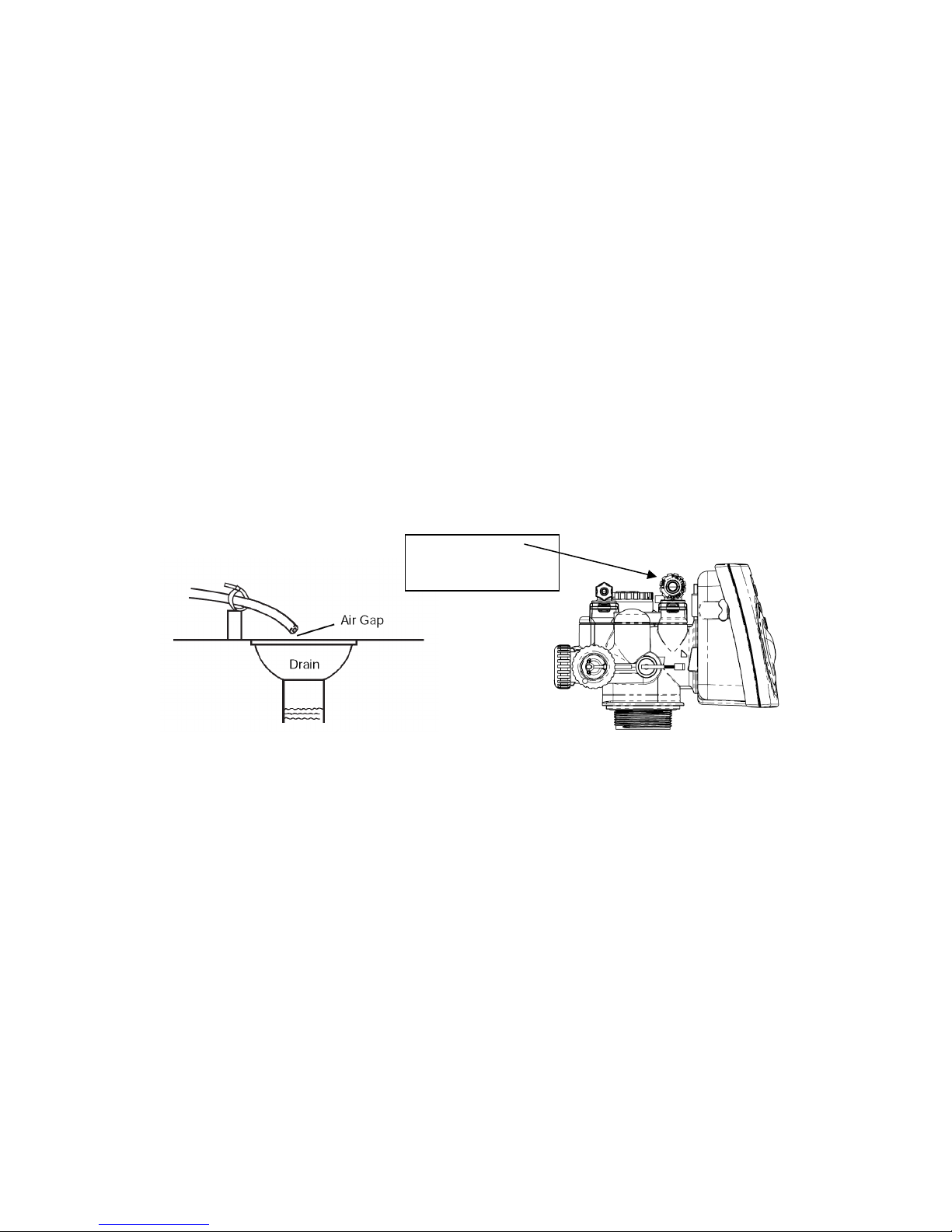

Service and Drain Piping:

1. Pipe water softener into the service lines. The inlet and outlet

connections of the control valve are 1” copper or PVC and are

located on the back of the valve body. As you face the timer the

inlet is on the right and the outlet is on the left. Always follow local

plumbing codes when installing our water treatment equipment.

2. If sweat fittings are used, be sure soldering is done in such a manner

as not to allow heat to reach the control valve or bypass. (If

Schedule 80 PVC is used make sure to follow the proper primer and

solvent instructions.)

3. The drain line connection is 5/8” OD or ¾” npt and is located on the

top left of the valve as you face the timer. It is recommended you

install a ¾” union on the drain line for servicing if not using 5/8 OD.

The drain line must be of adequate size to allow for full regeneration

flow.

DRAIN LINE

CONNECTION

• The control valve drain connection is 3/4" npt.

• Never decrease the drain piping size to below the

drain connection size.

• Maximum drain line length is 30 feet with proper

sloping the entire length.

• Maximum drain line height is 6 feet above the control

valve.

• The drain line must be piped to an open air gap (See

Figure above)

• Always follow local plumbing codes.

UNDER NO CIRCUMSTANCES SHOULD THERE BE A DIRECT

CONNECTION WITH SANITARY SEWAGE FACILITIES.

4

Page 7

Treated

Air Gap Drain

MASTER

Water Conditioning Corp.

Water Conditioning Corp.

Water Conditioning Corp.Water Conditioning Corp.

TYPICAL PIPING LAYOUT FOR

MP-CLR SE RIES SOFTENER

Untreated

Master Water

Conditioner

Overflow

fitting to

floor drain

gravity

Brine tank

NOTE: All Master Water Conditioners must be

installed after the well tank or water meter if its

5

public water supply.

Well Tank

Page 8

Electrical Requirements:

Always follow all local electrical codes when installing our water

treatment equipment.

1. Provide an 115v/60Hz properly grounded dedicated electrical

Outlet. (It’s very important that the polarity be correct)

Avoid using outlets that are switch controlled.

2. Maximum amperage required is 5 amps.

3. Make sure the electrical service provides power 24 hours per day.

We recommend installing a surge protector to protect unit from

power surges, which are not covered by warranty.

Brine Tank:

1. The brine tank should be located directly beside the water softener

mineral tank.

2. Connect the 3/8" poly tubing to the 3/8” black elbow compression

fitting located on the top left side of the MCA control valve.

See Figure Below.

3/8” BRINE LINE

CONNECTION

The brine tank is equipped with a shutoff valve, the float height

was preset at the factory.

6

Page 9

Filling Water Softener with Water:

1. Connect the MP-MCA control valve transformer into the electrical

outlet provided.

2. Press and hold the REGEN button until the drive motor starts. When

the drive motor stops, the display will read “RINSE” position.

3. Press the REGEN again until the drive motor starts. When the drive

motor stops, the display will read “BRINE” position.

4. Press the REGEN again until the drive motor starts. When the drive

motor stops, the display will read “RINSE” position. The fast rinse

position will rinse the softener tank.

5. Open the inlet ball valve a ¼ turn of its full open position to allow

water to enter the water softener mineral tank slowly. The water is

going to enter the tank from the bottom of the distributor pipe and

leave the tank from the top. This will slowly purge all the air from the

tank.

IF WATER ENTERS THE TANK TOO FAST, ALL THE CATION

RESIN WILL BE FLUSHED TO DRAIN DURING START UP.

6. When only water is running to the drain, open the inlet and outlet ball

valves fully.

7. Press and hold the REGEN button until the drive motor starts. When

the drive motor stops, the display will read “FILL” position. The brine

tank will fill with the proper amount of water.

NOTE: THE TIMER WILL AUTOMATICALLY ADVANCE TO THE

SERVICE POSITION AND THE DISPLAY WILL READ THE CAPACITY

REMAINING, IN GALLONS.

7

Page 10

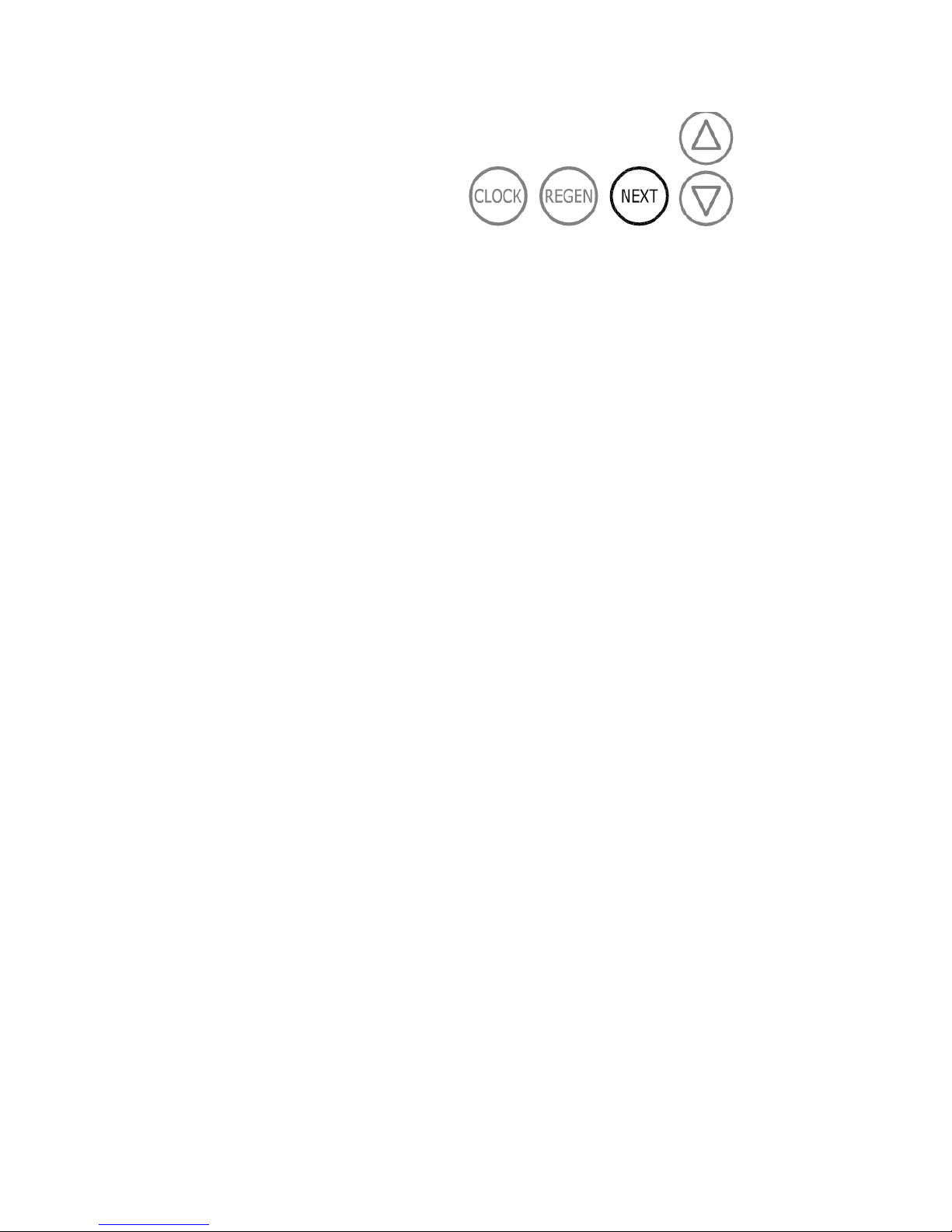

MP-Clear Reflections Control Valve Timer Settings:

Note: The control valve is set at the factory. You only need to set the

time of day , hardness and regeneration time if required, which is preset

at 2 am.

Time of Day Setting

1) Press the CLOCK button. The screen will show the Time of Day

in blinking numbers.

2) To change the Time of Day, use the UP and DOWN arrows to set

the Hour.

3) To change the Minutes, press CLOCK, use the UP and DOWN

arrows to set the Minutes

4) Press the CLOCK button.

Hardness Setting (the factory default is 10)

1) Press the NEXT and UP arrow , hold for 3 seconds. The screen

will show the Hardness as grains per gallon in blinking numbers.

2) To change the number, use the UP or DOWN arrows.

3) Press the NEXT button.

If water was tested by Master Water Conditioning, follow

recommendations on water analysis, for hardness setting.

Regeneration Day Override Setting (the factory default is OFF)

1) Press the NEXT button. The screen will show the Regeneration

Day Override in blinking numbers.

2) To change the number, use the UP or DOWN arrows.

3) Press the NEXT button.

Time of Regeneration Setting (the factory default is 2 AM)

1) The screen will show the Time of Regeneration in blinking

numbers.

2) If Regeneration time change is desired, use the UP or DOWN

arrows to adjust the hour.

3) Press the NEXT button. Use the UP or DOWN arrows to adjust

the minutes.

4) Press the NEXT button. The display will show the time of day.

NOTE: SALT SETTING AND CAPACITY ARE PRESET AT THE

FACTORY.

8

Page 11

Final Check:

1. Fill the brine tank with Solar Salt and the Res-Up Feeders with ResUp (one quart is provided).

2. Make sure the drain line connection meets all plumbing codes and

that the drain line size can handle the backwash flow rate of the

softener.

3. Make sure the Inlet and Outlet on bypass valve are open.

4. Make sure the control valve timer is plugged into an electrical outlet

with power 24 hours per day.

5. Check all piping for leaks.

9

Page 12

Manual Regeneration:

Note: For softeners, if brine tank does not contain salt, fill with salt

and wait at least 2 hours before regeneration.

To initiate manual regeneration immediately, press and hold the

“REGEN” button for three seconds. The system will begin to regenerate

immediately. The request cannot be cancelled.

To initiate a manual regeneration at the preset delayed regeneration

time, when the regeneration time option is set to “NORMAL” or

“NORMAL + on 0”, press and release “REGEN”. The words “REGEN

TODAY” will flash on the display to indicate that the system will

regenerate at the preset delayed regeneration time. If you pressed

“REGEN” in error, pressing the button again will cancel the request.

Note: If the regeneration time option is set to “on 0” there is no set

delayed regeneration time so “REGEN TODAY” will not activate if

“REGEN” button is pressed.

Power Loss

If the power goes out for less than two hours, the system will

automatically reset itself. If an extended power outage occurs, the time

of day will flash on and off which indicates the time of day should be

reset. The system will remember the rest.

Error Message

If the word “ERROR” and a number are alternately flashing on the

display, contact a service technician for help. This means the valve is

unable to function properly.

10

Page 13

11

Page 14

Troubleshooting

Problem: Water conditioner fails to regenerate. No soft water.

Possible Cause Solution

Power supply to MP-Clear

Reflections control has been

interrupted.

Water pressure lost. Restore water pressure.

Corrupted programming of MPClear Reflections timer.

Defective MP-Clear Reflections

timer.

No salt in brine tank. Add salt and regenerate.

Manual bypass valve is open. Close manual bypass valve.

Leak at riser pipe seal. Insure that riser pipe is properly

Insufficient brine. Check brine float height and clean

Plugged injector or injector screen. Inspect and clean injector and/or

Determine reason for power

interruption and correct. Reset time of

day.

Reprogram timer assembly.

Replace timer assembly.

sealed at o’ring seal. Inspect pipe for

cracks.

assembly if necessary. Check flow

rate capabilities of safety float and air

check assembly.

injector screen.

Possible Cause Solution

Plugged injector or injector screen. Inspect and clean injector and/or

Insufficient water pressure. Increase water pressure above 25

Corrupted programming of MPClear Reflections timer.

Defective MP-Clear Reflections

timer.

Obstructed drain line. Remove obstruction.

12

Problem: No Brine Draw

injector screen.

psig (172kPa) minimum.

Reprogram timer assembly.

Replace timer assembly.

Page 15

Problem: Insufficient brine draw

Possible Cause Solution

Partially clogged injector or injector

screen.

Inspect and clean injector and/or

injector screen assembly.

Restricted flow rate in brine line. Check flow rate capabilities of the

safety float/aircheck assembly.

Insufficient water pressure. Increase water pressure above 25

psig (172kPa) minimum.

Excessive back pressure on

injector due to elevated drain line.

Reduce drain line elevation to height

of valve.

Damaged valve disk. Replace all valve disks.

Partially restricted drain line. Remove restriction.

Problem: Insufficient Refill to Brine Tank

Possible Cause Solution

Brine refill control Remove and clean

Restricted flow rate in brine line. Check flow rate capabilities of the

safety float/aircheck assembly.

Problem: Excessive Water in Brine Tank

Possible Cause Solution

Plugged drain line flow control. Clean flow control.

Plugged injector and/or injector

screen

Problem: Loss of Media to Drain

Possible Cause Solution

No flow control installed in drain

line.

13

Inspect and clean injector and/or

screen.

Install drain line flow control.

Page 16

Problem: Leak to Drain

Possible Cause Solution

No flow control installed in drain

Install drain line flow control.

line.

Insufficient water pressure. Increase water pressure above 25

psig (172kPa) minimum.

Damaged valve disk or obstruction

in valve disk.

Inspect and if damaged, replace all

valve disks or remove obstruction.

Problem: Loss of Water Pressure

Possible Cause Solution

Fouled resin bed due to iron

accumulation.

Slots in riser pipe or laterals are

filled with resin fines.

Clean control valve and mineral bed

with cleaner.

Inspect and clean distributor pipe slots

as needed.

Problem: Salt in Water to Service after Regeneration

Possible Cause Solution

Injector is too small for system size. Install correct injector

Brine draw time excessively long

due to low water pressure.

Increase water pressure above 25

psig (172 kPa) minimum.

Restricted drain line. Remove drain line restriction.

Insufficient rinse volume. Increase slow rinse time, fast rinse

time, or both.

Damaged valve disk. Replace all valve disks.

Plugged injector and/or injector

screen.

Inspect and clean injector and/or

injector screen.

14

Page 17

Problem: Timer does not display time of day

Possible Cause Solution

AC Adapter unplugged Connect power

No electric power at outlet Repair outlet or use working outlet

Defective AC Adapter Replace AC Adapter

Defective PC Board Replace PC Board

Problem: Timer does not display correct time of day

Possible Cause Solution

Switched outlet Use uninterrupted outlet

Power Outage Reset time of day

Defective PC Board Replace PC Board

Problem: Control Valve regenerates at wrong time of day

Possible Cause Solution

Power Outages Reset control valve to correct time of

day

Time of day not set correctly Reset to correct time of day

Time of regeneration incorrect Reset regeneration time

Problem: Control valve stalled in regeneration

Possible Cause Solution

Motor not operating Replace motor

No electric power at outlet Repair outlet or use working outlet

Defective AC adapter Replace AC adapter

Defective PC board Replace PC board

Broken drive gear or drive cap

assembly

Replace drive gear or drive cap

assembly

Broken piston retainer Replace piston retainer

Broken main or regenerate piston Replace main or regenerate piston

15

Page 18

Problem: Control valve does not regenerate automatically when UP and

DOWN buttons are held and depressed

Possible Cause Solution

AC adapter unplugged Connect AC adapter

No electric power at outlet Repair outlet or use working outlet

Broken drive gear or drive cap

Replace drive gear assembly

assembly

Defective PC board Replace PC board

Problem: Control valve does not regenerate automatically but does

when UP and DOWN buttons are depressed and held

Possible Cause Solution

Defective PC board Replace PC board

Set-up error Check control valve set-up procedure

16

Page 19

ERROR CODES

17

Page 20

18

Page 21

CLEAR REFLECTIONS PARTS

19

Page 22

CLEAR REFLECTIONS PARTS

20

Page 23

CLEAR REFLECTIONS PARTS

21

Page 24

CLEAR REFLECTIONS PARTS

22

Page 25

23

Page 26

MASTER

Water Conditioning Corp.

12 YEAR LIMITED WARRANTY

As of Oct. 1, 1995

This Residential Water Conditioner is warranted for a period of one year from date of

purchase by first user against defects in materials and workmanship. In addition, the complete

control valve is warranted for five years. The control valve body (excluding internals and electrical

parts) is warranted for six years. The mineral tank, plastic brine tank or cabinet tank (excluding

mineral) is warranted against rust, corrosion or bursting for a period of twelve years from date of

manufacture. Except, as specifically set forth in this paragraph, Master Water Conditioning

Corporation makes no other warranties, express or implied.

This warranty shall be void if the conditioner is moved from the place of original installation,

or if damage is caused by misuse, misapplication, accident, freezing, flood, fire or if not installed in

accordance with instructions furnished by Master Water Conditioning Corporation.

This warranty shall be void in the event of damages from external sources or where the

conditioner has been operated at pressure in excess of 100 pounds per square inch or at a temperature

greater than 100 degrees F. or less than 32 degrees F. Incidental costs or consequential damages are

not covered by this warranty.

All defective parts shall be returned prepaid to Master Water Conditioning Corporation for

inspection. Master shall not be liable for labor charges other than Master factory repairs.

This warranty gives you specific legal rights, and you may have other rights which vary from

state to state. Some states do not allow limitations on duration of implied warranties or exclusion of

incidental or consequential damages, so the above limitations may not apply to you.

All claims must be submitted in writing to Master Water Conditioning Corporation at 224

Shoemaker Road, Pottstown, Pennsylvania 19464 within thirty (30) days from the discovery of the

defect. Master Water Conditioning Corporation thereafter will correct defective parts and

workmanship or rusting, corrosion or bursting within sixty (60) days.

Failure to notify Master by completing, signing and returning the registration card within

twenty (20) days of the purchase shall void the warranty.

224 Shoemaker Rd. Pottstown, Pa. 19464

Page 27

MP-CLR-XXX UF METER SOFTENER

NORMAL VIEW

NEXT

NEXT

SOFTENING

CAPACITY REMAINING

GAL

CHANGES

CAPACITY

REMAINING

IN GALLONS

TIME

SOFTENING

PM

6:35

NEXT

NEXT

0.0

CUMULATIVE

GPM

GAL

CURRENT

TIME

CURRENT

FLOW RATE

IN GALLONS

PER MINUTE

TOTAL GALLONS

SINCE START-UP*

*RESET TO “0” BY PRESSING “CLOCK” AND “REGEN” FOR 3 SECONDS

ONLY DISPLAYS IF

DAY OVERRIDE IS PROGRAMMED

OVERRIDE

REGENERATION

IN DAYS

NEXT

Page 28

NEXT AND

INSTALLER SETTINGS

HARDNESS

NEXT

REGEN TIME: HOUR

REGEN TIME: MINUTES

NEXT

CLOCK

SET TIME CLOCK

12:00

OR

TO CHANGE TIME USE

10

2:

:00

0ff

DAY OVERRIDE

(Default is OFF)

NEXT

Page 29

NEXT AND

REFERENCE ONLY

VALVE PROGRAM ING

NEXT

NEXT

Softening

SET SYSTEM

TYPE

REGENERATION

TIME

__ x 1000

NORMAL

NEXT

CALL-off

CAPACITY

X1000

SERVICE CALL

INDICATOR

NEXT

NEXT

NEXT

Post

BRINE REFILL

TIME

BRINE

2 __

3 8

BACKWASH

TIME

NEXT

F AST RINSE

TIME

4 8

NEXT

NEXT

BRINE REFILL

5 __

NEXT

NEXT

RESERVE

CAPACITY

Auto

NEXT

RELAY 1

RELAY 2

off

off

UP

SET BRINE

TYPE

NEXT

Page 30

NEXT AND

REFERENCE ONLY

VALVE PROGRAM ING

NEXT

Normal

SET SYSTEM

TYPE

NEXT

1

V ALVE SIZE

NEXT

SET 2

off

NEXT AND

Dp OFF

DELTA

PRESSURE

ONLY

SET 3

NEXT

off

SET 4

NEXT

off

Page 31

NEXT to EXIT

AND

AND

(3 SEC)

VALVE HISTORY

DAYS SINCE START-UP

REGENS SINCE START-UP

ERRORS SINCE START-UP

NEXT

NEXT

NEXT

NEXT

AND

DIAGNOSTICS

DAYS SINCE LAST

REGENERATION

GALLONS SINCE LAST

REGENERATION

NEXT

NEXT

NEXT

NEXT

MCA BOARD

RESERVE CAPACITY

CALCULATED PER DAY

IN GALLONS

USAGE PER DAY

IN GALLONS

MAXIMUM FLOW RATE

GPM

MAXIMUM FLOW RATE SINCE

START-UP IN GPM

GALLONS TREATED SINCE

START-UP (X1000)

NEXT to EXIT

Page 32

LOCK/UNLOCK:

NEXT REGEN

(IN SEQUENCE)

REGEN

PRESS ONCE FOR NEXT REGEN TIME

PRESS AGAIN T O CANCEL REGENERATION

PRESS AND HOLD FOR 3 SECONDS FOR IMMED

PRESS IN REGEN TO ADVANCE TO NEXT CYCLE

MANUAL REGENERATION

LOCKING SETTINGS

AFTER SETTING A VALUE…

Page 33

ERROR CODES

Page 34

Loading...

Loading...