Master MH-40-GFA, MH-125V-GFA-A, MH-150V-GFA-A, MH-60V-GFA-A User Manual

T

I

F

DANGER

WARNING

PROPANE FORCED AIR HEATER

User’s Manual &

Operating Instructions

MODEL NUMBERS:

MH-40-GFA / MH-60V-GFA-A / MH-125V-GFA-A / MH-150V-GFA-A

CONSUMER: READ AND SAVE THESE INSTRUCTIONS

Locating Your Serial Number:

Your serial number can be found on a white label on the right side cover of your heater. It will begin

with the letter “G” followed by 9 digits. For Example: G123456789. Have your Serial Number ready

before calling customer service at 800-641-6996.

GENERAL HAZARD WARNING:

FAILURE TO COMPLY WITH THE PRECAUTIONS AND INSTRUCTIONS

PROVIDED WITH THIS HEATER, CAN RESULT IN DEATH, SERIOUS

BODILY INJURY AND PROPERTY LOSS OR DAMAGE FROM HAZARDS OF FIRE, EXPLOSION, BURN.

ASPHYXIATION, CARBON MONOXIDE POISONING AND / OR ELECTRIC SHOCK.

ONLY PERSONS WHO CAN UNDERSTAND AND FOLLOW THE INSTRUCTIONS SHOULD USE OR

SERVICE THIS HEATER. IF YOU NEED ASSISTANCE OR HEATER INFORMATION SUCH AS AN INSTRUCTIONS MANUAL, LABEL, ETC. CONTACT THE MANUFACTURER.

FIRE, BURN, INHALATION, AND EXPLOSION

HAZARD. KEEP SOLID COMBUSTIBLES, SUCH

AS BUILDING MATERIALS, PAPER OR CARD-

BOARD, A SAFE DISTANCE AWAY FROM THE HEATER AS RECOMMENDED

Factory ID: 001

BY THESE INSTRUCTIONS. NEVER USE THE HEATER IN SPACES WHICH

DO OR MAY CONTAIN VOLATILE OR AIRBORNE COMBUSTIBLES, OR

PRODUCTS SUCH AS GASOLINE, SOLVENTS, PAINT THINNERS, DUST

PARTICLES OR UNKNOWN CHEMICALS.

C

D

E

E

R

I

Fax: 320-251-2922 • Web: www.masterindustrialproducts.com • Email: info@pinnacleclimate.com

1 Industrial Blvd #101, Sauk Rapids, MN 56379 USA • Toll Free (800) 641-6996

© 2018 Pinnacle Climate Technologies, Inc.

MAGB-413

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

DANGER

DANGER

DANGER

WARNING

WARNING

WARNING

WARNING

TABLE OF CONTENTS

Safety Information.......................................................2-4

Unpacking.........................................................................4

Specifications...................................................................5

Features..

What’s in the Box.............................................................5

Operation......................................................................6-8

Ventilation......................................................................

.........................................................................

Storage/Maintenance.....................................................8

Wiring Diagrams..............................................................9

Troubleshooting Guide.................................................10

Exploded View

5

Parts List............................................................................11

Limited Warranty.............................................................12

..8

...........................................................

SAFETY INFORMATION

Carbon Monoxide Hazard This heater produces carbon monoxide, which

has no odor. Burning the heater in an enclosed space can kill you. Never

use the heater in enclosed spaces such as a tent, a camper, any vehicle

or recreational vehicle (RV), enclosed shelter, or any other enclosed areas.

If the information in this manual is not followed exactly, a fire or explosion

may result causing property damage, personal injury or loss of life.

.....11

Not for use in residential living areas or in non-adequately ventilated enclosed spaces. Never bring or store a propane cylinder indoors.

NOT FOR HOME OR RECREATIONAL VEHICLE USE.

DO NOT OPERATE THIS HEATER UNTIL YOU HAVE READ AND

THOROUGHLY UNDERSTAND THESE SAFETY AND OPERATING

INSTRUCTIONS.

Failure to comply with the precautions and instructions provided with this heater can result in death,

serious bodily injury, property loss or damage from the hazards of fire, explosions, burns, asphyxiation

or carbon monoxide poisoning. Only persons who can read and understand these instructions should

use or service this heater.

This is an unvented portable heater. It uses air (oxygen) from the area in

which it is used. Adequate combustion and ventilation air must be provided. Refer to VENTILATION on Page 8.

This product contains chemicals, including lead, which are known to the

State of California to cause cancer and birth defects or other reproductive

harm. For more information go to www.P65Warnings.ca.gov.

This heater is designed and approved for use as a construction heater in accordance with Standard

ANSI Z83.7-2011/CSA 2.14-2011. CHECK WITH YOUR LOCAL FIRE SAFETY AUTHORITY IF YOU HAVE

ANY QUESTIONS ABOUT APPLICATIONS. Other standards govern the use of fuel gasses and heating

products for specific uses. Your local authority can advise you about these.

2

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

WARNING

DANGER

DANGER

WARNING

WARNING

SAFETY INFORMATION CONT.

RISK OF INDOOR

AIR POLLUTION!

PROPANE IS AN

EXPLOSIVE GAS.

The products described in this manual are propane direct-fired, forced air heaters. Propane

forced air heaters are primarily intended for use

for temporary heating of buildings under construction, alteration or repair. Direct-fired means that

all of the combustion products of the heater enter

the heated space. This appliance is rated at 98%

combustion eciency, but does produce small

amounts of carbon monoxide.

CARBON MONOXIDE

POISONING MAY

LEAD TO DEATH!

Carbon monoxide is toxic. Humans can tolerate

only small amounts of carbon monoxide and so

precautions should be taken to provide proper

ventilation. Failure to provide proper ventilation

in accordance with the instructions in this manual

can result in death.

People with breathing problems should consult

a physician before using this heater. Early signs

of carbon monoxide poisoning resemble the flu.

Symptoms of improper ventilation / carbon monoxide poisoning are:

Headache • Dizziness • Nausea • Dry Mouth Sore

Throat • Burning of Nose and Eyes

If you experience any of these symptoms:

GET FRESH AIR AT ONCE! Have your heater

serviced and check for proper ventilation. Some

people are more aected by carbon monoxide

than others. These include: pregnant women,

those with heart or lung problems, anemia or

those under the influence of alcohol or at high

altitudes.

FOR OUTDOOR USE. INDOOR USE PERMITTED

ONLY FOR: The temporary heating of adequately

ventilated buildings or structures under construction,

alteration or repair! Provide at least a three square

foot (2,800 sq. cm) opening of outside air for every

100,000 Btu / Hr (29 kW) heater rating. Refer to

“Ventilation” on page 8 for further instructions.

WHAT TO DO IF THE SMELL OF GAS IS PRESENT:

– DO NOT attempt to light the heater.

– Extinguish any open flame.

– Shut o gas to heater.

– If odor continues, contact your local gas supplier

or fire department.

– DO NOT touch or use any electric switch or any

electric device that can cause a spark.

– Immediately call your gas supplier from a

neighbors phone. Follow the gas suppliers

instructions.

– If you can not reach your gas supplier, call the

fire department.

– Service must be done by a qualified service

agency.

RISK OF BURNS,

FIRE AND EXPLOSION!

NEVER store or use gasoline or other flammable vapors and liquids in the vicinity of this heater.

NEVER store a propane (LP) cylinder not connected to

this heater in the vicinity of this heater.

NEVER connect heater to an unregulated gas supply.

NEVER obstruct the flow of combustion and ventilation

air. (The front and rear of heater).

NEVER use duct work in front or rear of heater.

NEVER modify this heater or operate a heater that has

been modified.

NEVER service, move or handle heater while still hot or

operating

Keep all combustible materials away from this heater.

Minimum Clearance From Combustibles

Sides Top Front Rear

24 in. 36 in. 72 in. 24 in.

61 cm 92 cm 183 cm 61 cm

ALWAYS use the electrical power (voltage and frequency) specified on the model plate of the heater.

ALWAYS use only 14 AWG or better extension cord.

ALWAYS unplug the heater when not in use.

CAUTION! HOT

WHILE IN OP-

ERATION. DO NOT

TOUCH. KEEP CHILDREN, ANIMALS, CLOTHING

AND COMBUSTIBLES AWAY FROM HEATER.

3

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

SAFETY INFORMATION CONT.

RISK OF ELECTRIC

SHOCK!

Electrical Grounding

Instructions: This ap-

pliance is equipped

with a three-prong (grounding) plug for your

protection against shock hazard and should

be plugged directly into a properly grounded

three-prong receptacle.

– Gas supply connections should be checked by

using a 50/50 soap and water solution. Never use a

flame to check for gas leaks.

– Locate LP cylinder at least 6 ft. (183 cm) (10 ft./305

cm in Canada) from the heater, and do not direct

heater discharge towards the LP cylinder unless it

is at least 20 feet (610 cm) from the heater.

– Use only the regulator and hose assembly provided

with this heater. Inspect the regulator/hose

assembly prior to each use of the heater. If there

is excessive abrasion or wear, or if the hose is cut,

replace it with the proper assembly shown in the

parts list, prior to using the heater.

For use with propane

(LP) gas only.

ALWAYS install the heater so that it is not directly exposed

to water spray, rain, dripping water, or wind.

– Use heater in accordance with all local codes. In

the absence of local codes, refer to The National

Fuel Code, ANSI A223.1/NFPA 54.

– This heater is shipped from the factory for use

with propane (LP) gas only. Do not convert to

any other gas. Installation must conform to local

codes, or in their absence, with the standard for

the Storage and Handling of Liquefied Petroleum

Gases ANSI/NFPA 58 and the Natural Gas and

Propane Installation Code CSA B149.1.

RISK OF FIRE! DO NOT POSITION HEATER IN A DOWNWARD ANGLE.

ALWAYS LOCATE HEATER ON A STABLE AND LEVEL SURFACE (SEE

FIGURE 1)!

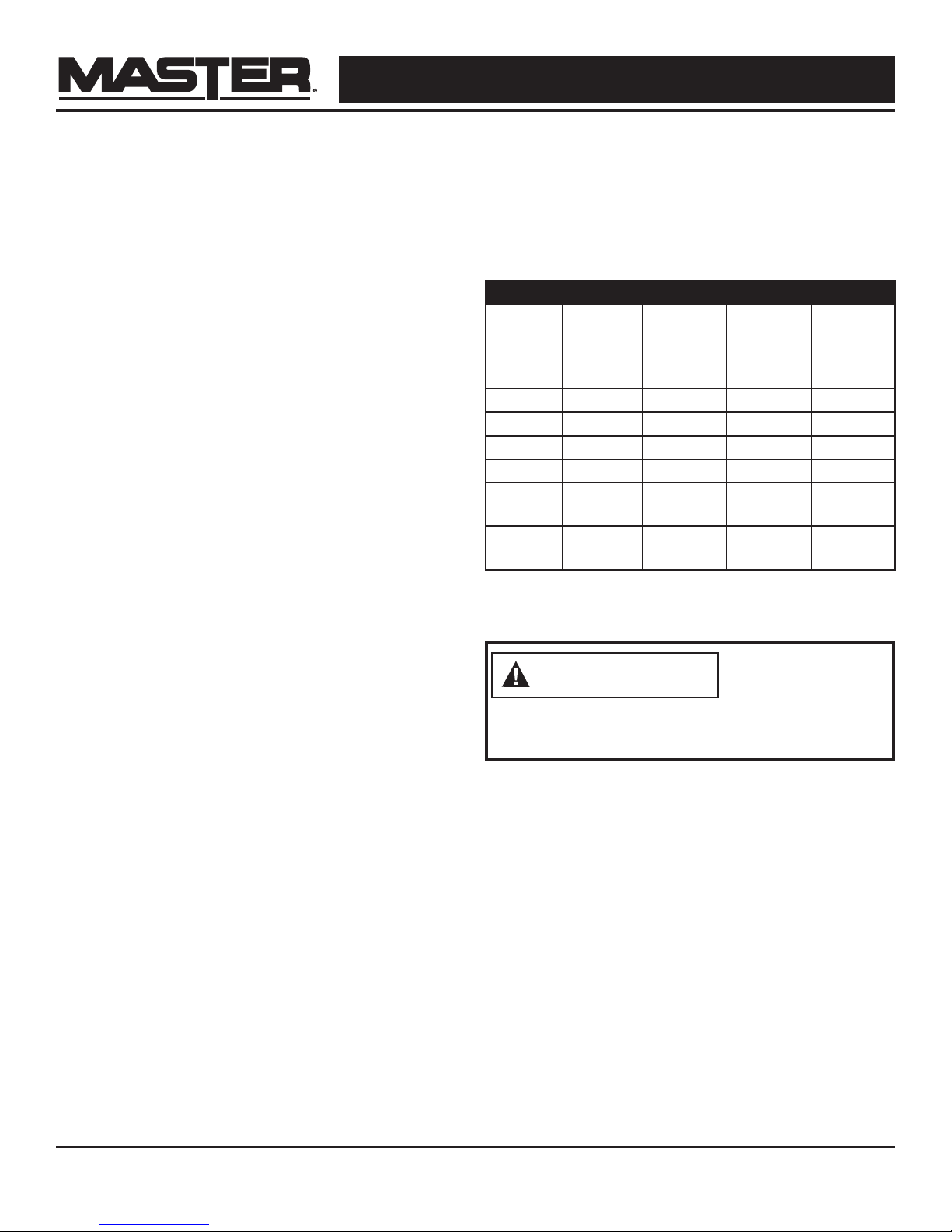

Manifold, Minimum, and Maximum Inlet Pressure

40-GFA 60V-GFA

Man.

Min. 5 PSI (34.5 kPa)

Max. Bottle Pressure

ing material and contact with hot surfaces both

during use and while in storage.

11" (279

mm) W.C.

11" (279

mm) W.C.

125V-GFA 150V-GFA

8.3" (211

mm) W.C.

The hose assembly

shall be pro tected

from trac, build-

8" (203

mm) W.C.

Figure 1

UNPACKING

1. Remove all packing items applied to heater for

shipment. Keep plastic cover caps attached to inlet

connector and hose / regulator assembly for storage.

2. Remove all items from carton

3. Check all items for shipping damage. If the heater

is damaged, promptly inform dealer where you

purchased the heater.

sembly supplied with the heater must be used

without alteration.

4

The Propane (LP)

gas pressure regulator and hose as-

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

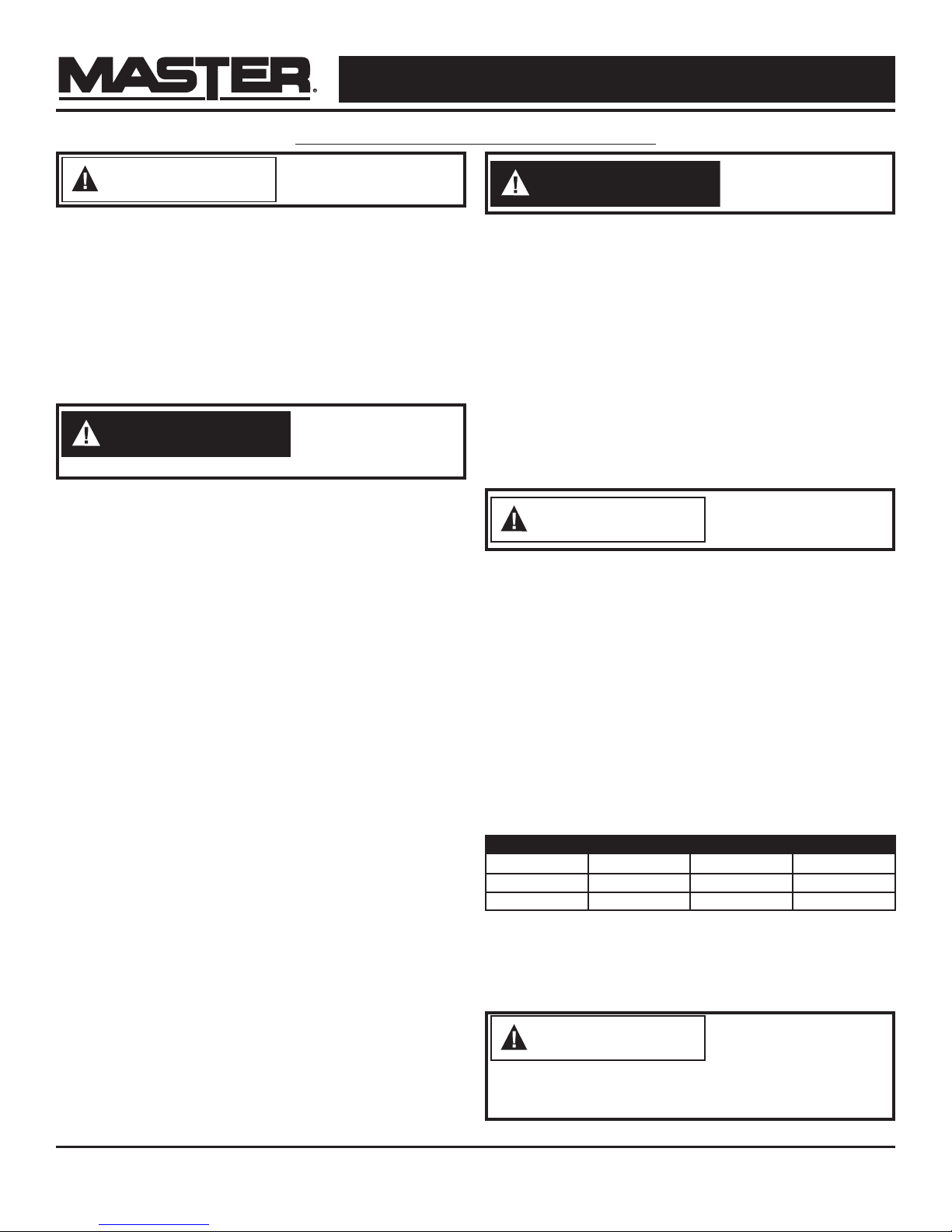

SPECIFICATIONS

Model # 40-GFA

BTU 40,000 40 / 50 / 60,000 95 / 110 / 125,000 120 / 135 / 150,000

Fuel Consumption - Lb./hr (kg/hr)

Maximum Operating Hours 11 10.5 22 18

Required Cylinder - Lb. (kg) 20 (9) 20 (9) 100 (45) 100 (45)

Fuel Type Propane Propane Propane Propane

2

Heating Area - Ft.

Air Flow (CFM) 300 300 400 400

Max Outlet Temp - ºF (ºC) 477 (247) 491 (255) 500 (260) 622 (328)

Volts: AC/Hz 120V / 60Hz 120V / 60Hz 120V / 60Hz 120V / 60Hz

Amps 0.6 A 0.6 A 1.02 A 1.02 A

(m2) 1000 (93) 1500 (139) 3125 (290) 3800 (353)

1.9

(0.9)

Specifications subject to change without notice.

60V-GFA

1.9 / 2.3 / 2.8

(0.9 / 1.04 / 1.27)

125V-GFA 150V-GFA

4.4 / 5.1 / 5.8

(2.00 / 2.31 / 2.63)

5.5 / 6.2 / 6.9

(2.50 / 2.81 / 3.13)

FEATURES

Handle

Outer Shell

Guard

Inner Shell

Power Cord

Height Controller Gas Valve Knob

Base

WHAT’S IN THE BOX

Hose & Regulator Assembly (1)

Heater (1)

5

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

CAUTION

OPERATION

Propane Supply / Information:

Propane (LP)

This heater is not supplied with a propane cylinder.

Use only an approved propane cylinder.

LP Characteristics

– Flammable, explosive under pressure, heavier

than air and pools in low areas.

– In its natural state, propane has no odor, but

for your safety an odor that smells like rotten

cabbage has been added.

– Contact of propane (LP) gas with the skin can

cause freeze burns.

– Heater is manufactured for use with propane

gas only. DO NOT attempt to convert to any

other gas. Such modifications are dangerous

and will void the warranty.

– When heater is not in use, LP Cylinder must be

turned OFF.

– Be sure that the LP Cylinder is located on a level

and stable surface.

– DO NOT use this heater in a basement or below

ground level. Propane is heavier than air and

will always seek the lowest level. If you suspect

a leak, shut o the valve at the LP Cylinder

immediately.

The Propane (LP) cylinder must also be equipped

with the following:

– A collar to protect the gas valve.

– A shut-o valve terminating a LP cylinder valve

outlet as specified in the American National

Standard for Compressed Gas Cylinder Valve

Outlets and Inlets Connections.

– A safety relief valve having direct

communications with the vapor space of the LP

cylinder.

– The heater must operate on vapor withdrawal

from the operating cylinder.

The amount of Propane (LP) used with this heater

varies. Both factors are:

– The amount of gas in the cylinder of LP.

– The temperature of the LP tank and its

surroundings.

Minimum Number of LP Cylinders

Average

Temp

(ºF / ºC)

32º / 0º 1 1 2 2

20º / -7º 1 1 2 2

10º / -12º 1 1 3 3

0º / -18º 1 1 3 3

-10º / -23º 2 2

-20º /

-29º

The table above shows the minimum number of 100 lb.

(45 kg) LP cylinders required in cold weather. Your local LP

dealer will help you select the proper LP supply system.

40-GFA

100 lb.

(45 kg)

cylinder

2 2

60V-GFA

100 lb.

(45 kg)

cylinder

125V-GFA

100 lb.

(45 kg)

cylinder

Use Larger

Tank

Use Larger

Tank

150V-GFA

100 lb.

(45 kg)

cylinder

Use Larger

Tank

Use Larger

Tank

Propane is safe to

use when properly

handled. Careless

handling of the LP cylinder could result in a fire

and or an explosion.

– Always keep LP cylinder fastened and upright.

– Avoid tipping the LP cylinder on its side when

connected to a regulator, since this may cause

damage to diaphragm in the regulator.

– Handle valves with care.

– Never connect an unregulated LP cylinder to a

construction heater.

– DO NOT subject LP cylinder to excessive heat.

– Tightly close the gas shuto valve on the LP

cylinder after each use.

– All fittings must be protected when

disconnected from the LP cylinder.

6

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

WARNING

CAUTION

OPERATION CONT.

– Never store an LP cylinder inside a building or

in the vicinity of an gas burning appliances.

The disconnected

tank must never be

stored in a build-

ing, garage or any other enclosed area.

Pre-Lighting Instructions:

Purging and filling

of the LP cylinders

must be performed

by personnel who

have been thoroughly trained in accepted LP

gas industry procedures. Failure to follow these

instructions may result in explosion, fire, severe

personal injury or death.

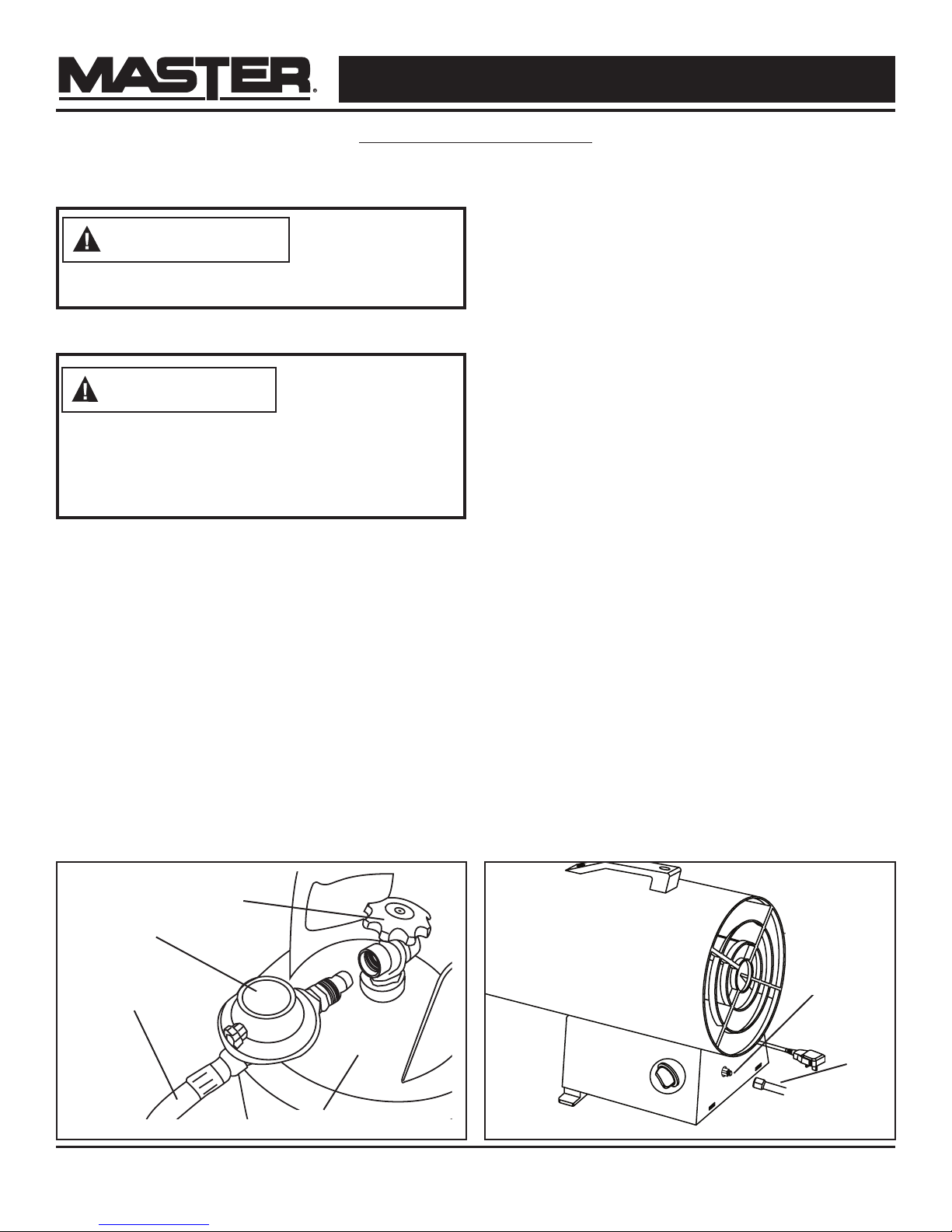

Connecting the LP Cylinder

ALL NEW LP CYLINDERS MUST BE PURGED

BEFORE THE FIRST FILLING.

– Turn heater gas valve knob and LP cylinder valve

to OFF position.

– LP cylinder valve equipped with old style fitting has

LEFT HANDED THREADS. Turn fitting CLOCKWISE

to loosen. Protect this fitting when disconnected

from LP cylinder.

– Have your LP cylinder filled by your local propane

gas supplier.

– Some LP cylinders have a bleed-OFF valve. This

valve should be inspected for leaks after each

filling of the LP cylinder. Turn the valve clockwise to

close.

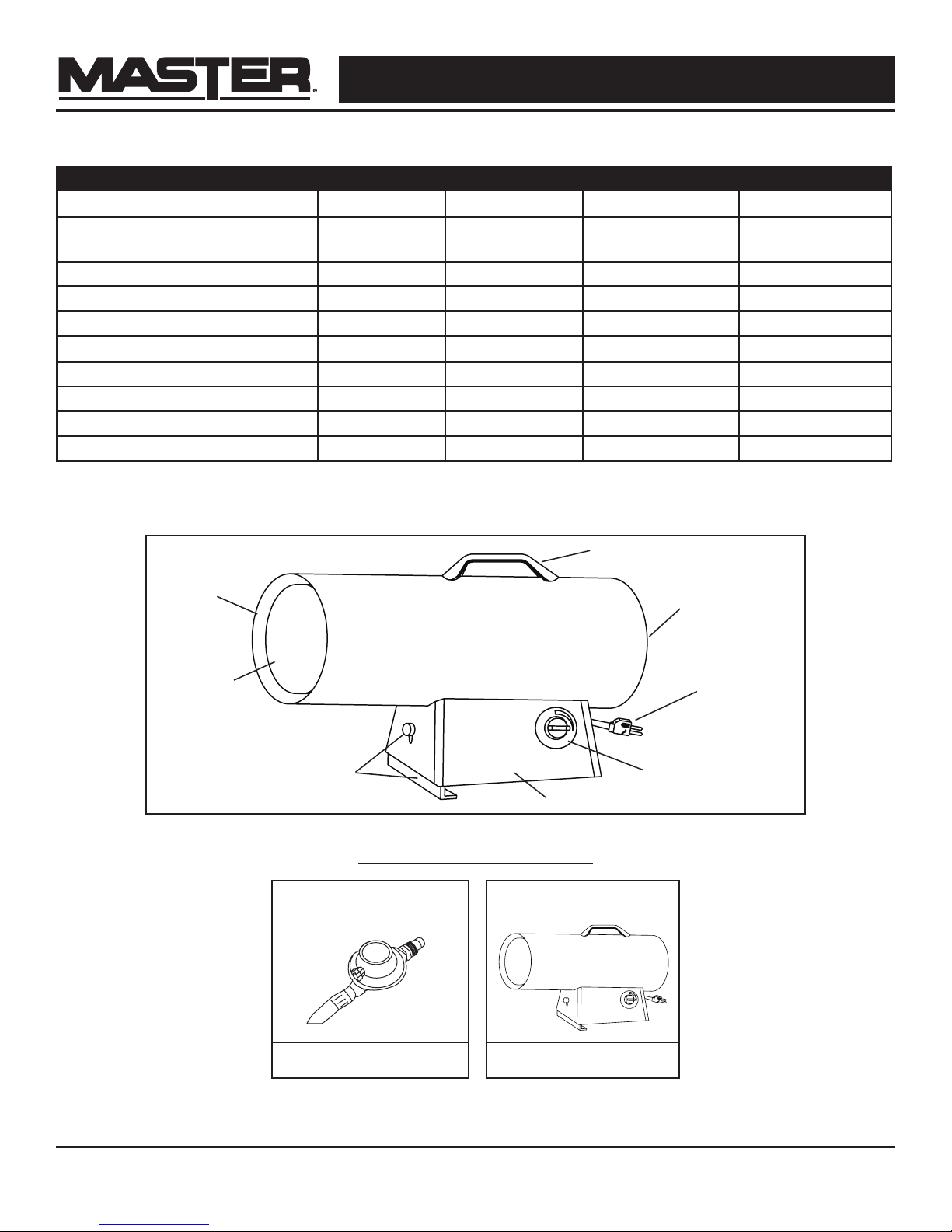

– Fasten full propane tank and connect proper

fitting to LP cylinder valve by turning COUNTERCLOCKWISE (See Figure 2 & 3).

– With heater gas valve knob still in OFF position

turn ON the LP cylinder valve and check for leaks

with soap solution.

Checking For Leaks

– To check for leaks, make up a 50/50 solution of

dish soap and water. Apply this solution to all gas

connections. If bubbles appear, there is a leak. If

a leak is found, turn o the gas supply, and reconnect the leaking connection. If the leak persists

after several tries, contact Pinnacle Customer

Service at 800-641-6996.

– The installation of this heater must meet all local

codes and/or gas utility requirements. In the

absence of local codes, the National Fuel Code

ANSI Z223.1/NFPA 54 should be followed.

– The minimum clearances to any combustible

construction materials must be maintained at all

times (See Page 3).

– Inspect the heater before each use, and at least

annually by a qualified service person.

Supply Valve

Regulator

Inlet

Connector

Hose

Figure 2 Figure 3

Propane Tank

7

Hose

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

1

O

1

3

2

O

DANGER

DANGER

Lighting Instructions:

Starting the Heater (Ignition

1. Connect the heater to a three prong (grounded)

power source. You must use a three prong (grounded)

extension cord that is at least 6 feet long is a minimum

of 14 AWG rating.

2. Connect heater to a proper LP cylinder.

3. Turn gas control knob CLOCKWISE to o position.

4. Wait five (5) minutes for any gas to clear. Smell for

gas, if you do not smell gas, go to step 5.

5. Turn gas supply ON by turning the LP cylinder valve

COUNTERCLOCKWISE to OPEN.

6. Push in and turn gas control knob

COUNTERCLOCKWISE to 1 position. This will light the

burner. If needed, keep pressing control knob until

the burner lights, and keep pressing and turning from

“O” (OFF) to 1 on Piezo electric spark models (40GFA) (See Figure 4).

7. Keep the gas control knob depressed for at least 30

seconds after lighting the burner. After 30 seconds,

release the control knob.

8. If the burner doesn’t stay lit, repeat lighting procedures.

)

OPERATION CONT.

9. When burner stays lit, turn gas control knob

COUNTERCLOCKWISE to desired setting (all models

except 40-GFA).

Shutdown Instructions

To Shut Off the Heater:

1. Turn gas control knob CLOCKWISE to

“O” (OFF) position (See Figure 4).

2. Turn gas supply OFF by turning the LP cylinder valve

CLOCKWISE to close.

3. Disconnect the power cord.

Test Firing the Heater

Test fire your construction heater following the lighting

instructions applicable to the gas control system

employed.

Leak test all gas connections with 50/50 soap and water

solution prior to start-up. Soap bubbles indicate a gas

leak. DO NOT use a match or flame to test for gas leaks.

NOTE: Heater surface temperature must be cold before

initiating service, cleaning or storage.

Figure 4

40-GFA

Valve Knob

Ignition Ignition

OFF

60V-GFA / 125V-GFA /

150V-GFA Valve Knob

VENTILATION

– Risk of indoor air pollution and Carbon

Monoxide Poisoning. Use heater only in well

ventilated areas.

– Refer to Safety Information on pages 2-3

for information about Carbon Monoxide

Poisoning.

– ALWAYS provide a fresh air opening in the

heated space of at least three square feet

(2,800 sq. cm) for each 100,000 BTU / Hr (29

kW). of heater output. Provide a larger opening

if more heaters are being used.

OFF

CARBON MONOXIDE POISONING MAY LEAD TO

DEATH!

Not for use in

residential living

areas or in non-

adequately ventilated enclosed spaces.

Minimum Ventilation Opening Needed

40-GFA 60V-GFA

1.2 ft.

2

1.8 ft.

2

1110 cm21670 cm

125V-GFA 150V-GFA

2

3.8 ft.

2

3530 cm

2

4180 cm

4.5 ft.

2

2

8

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

DANGER

STORAGE / MAINTENANCE

Always disconnect the heater from the LP cylinder

before putting the heater into storage. If for any

reason the heater is to be stored indoors, the tank

MUST be disconnected from the LP cylinder, and

the cylinder stored outdoors in a well-ventilated

area, out of the reach of children, and in accordance with the Standard for Storage and Handling

of Petroleum Gases, ANSI/NFPA 58 - latest edition

and Natural Gas and Propane Installation Code,

CSA B149.1. The plastic valve plug or valve cover

supplied with the cylinder must be re-installed on

the valve to protect the fitting from damage.

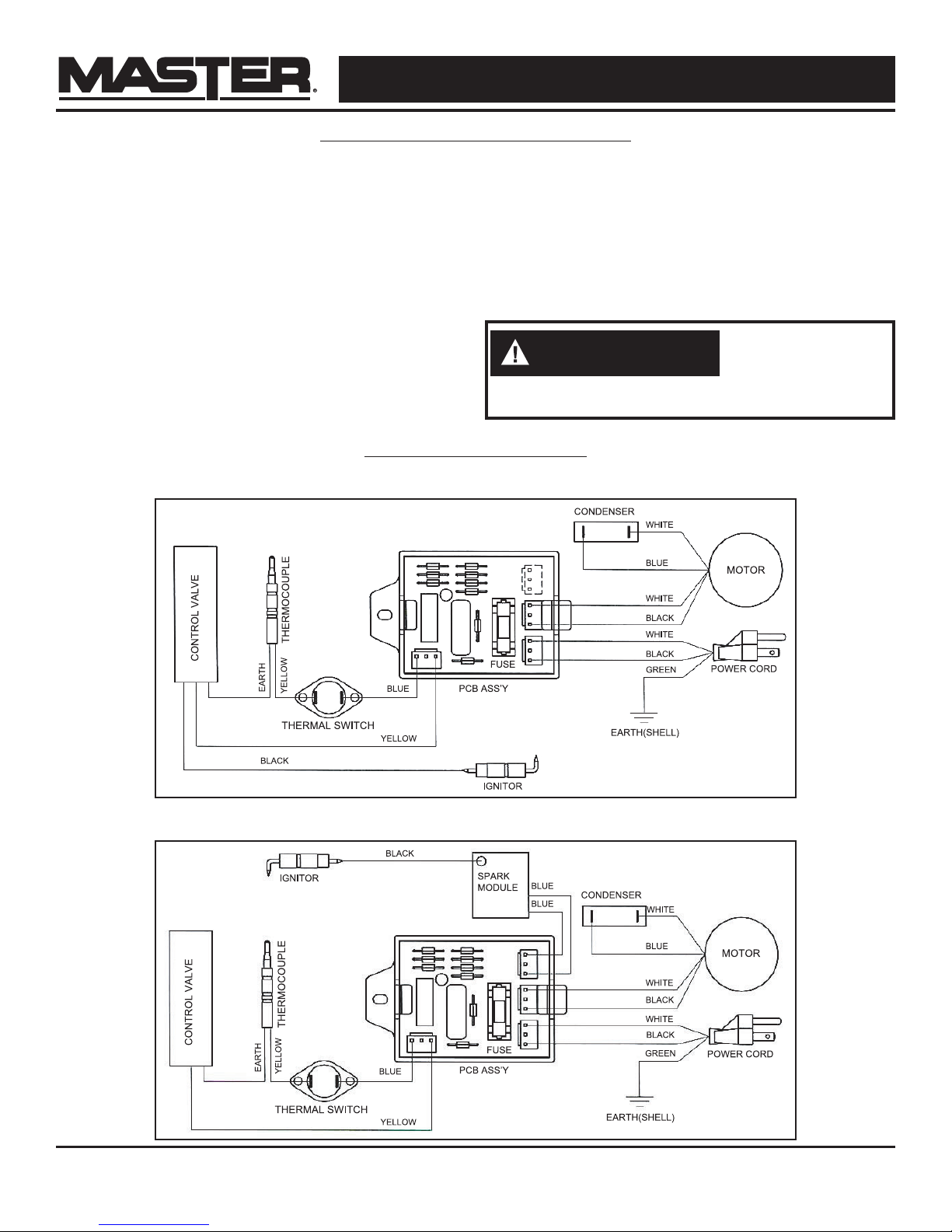

WIRING DIAGRAMS

40-GFA

Figure 6

NOTE: Installation and repair of this heater should

be done by a qualified service person.

ALWAYS be sure to follow proper maintenance

procedures. This should include cleaning the inside of the heater once a month and checking the

spark gap at least once a heating season. Re-gap

the terminals to 0.160” (4mm)

Never store an LP

cylinder inside of

a building or near

any other gas or oil burning appliances.

60V-GFA / 125V-GFA / 150V-GFA

9

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

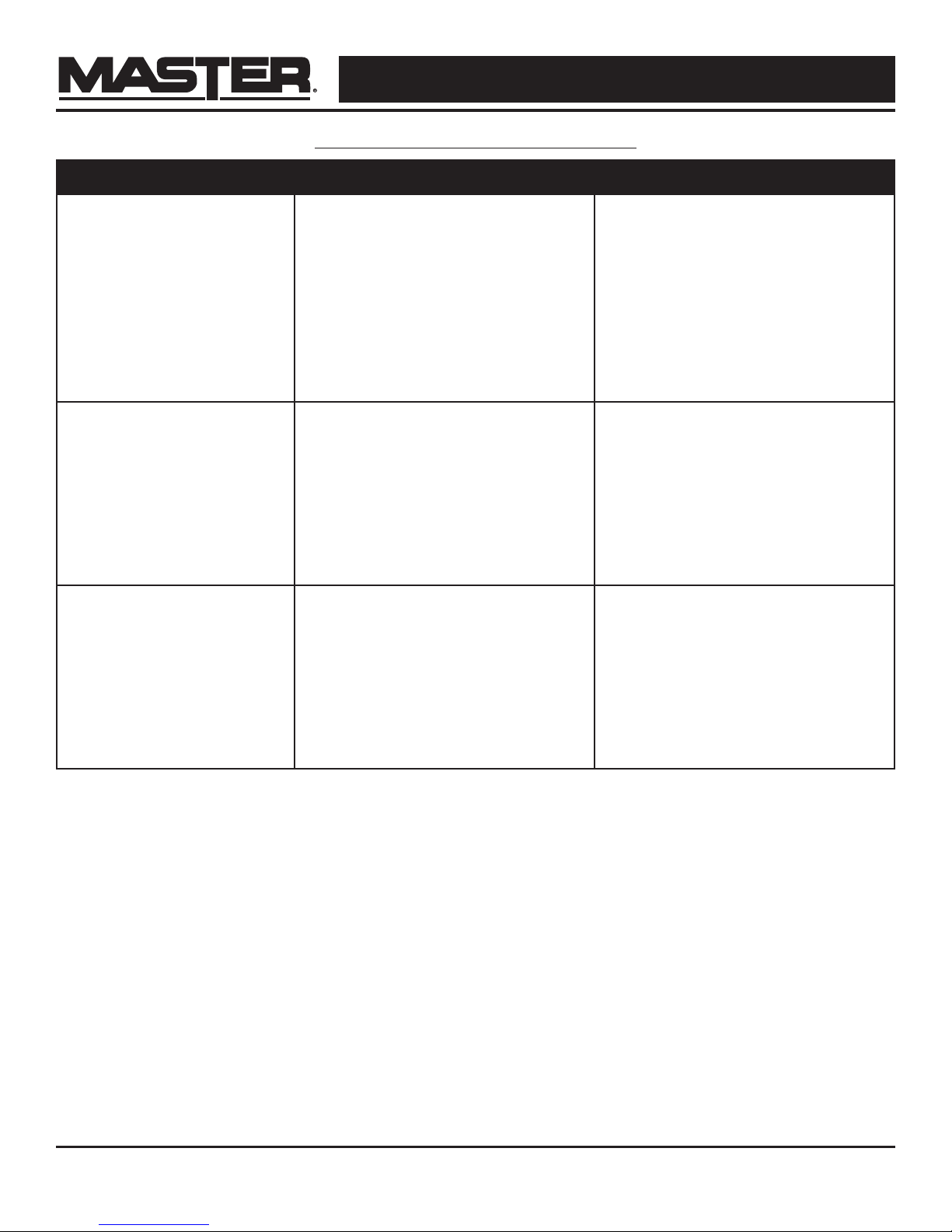

TROUBLESHOOTING GUIDE

Problem Possible Cause(s) Solution

Fan does not turn when

electricity is connected.

Heater will not fire (ignite).

Heater stops running

by itself.

1. No electric power to heater.

2. Blades of fan in contact with

heater housing.

3. Fan blades bent.

4. Fan motor defective.

1. No spark at module.

2. Incorrect spark gap.

3. Corroded electrode.

1. Temperature inside heater is too

high, causing thermal switch to

shut down operation.

2. Damaged control valve.

3. Dust or debris accumulated

in heater.

1. Check current at outlet. If voltage

is correct, inspect extension and

power cords for cuts, frays or

breaks

2. Check housing for damage. Be

sure there are no dents in the

housing obstructing the fan.

3. Straighten all fan blades.

4. Replace motor assembly.

1. Inspect module wire. Re-attach

or tighten if loose. Inspect spark

module and replace if necessary.

Inspect all other electrical

components.

2. Set plug gap to 0.16” (4 mm).

3. Replace spark plug

(multi-bracket assembly).

1. If the heater input or output is

restricted, the inside temperature

can become too hot. Keep the

areas in front and behind heater

clear of obstructions.

2. Replace control valve.

3. Clean inside of heater.

10

© 2018 Pinnacle Climate Technologies, Inc. Propane Forced Air Heater User’s Manual

NEVER LEAVE HEATER UNATTENDED WHILE BURNING OR

WHILE CONNECTED TO A POWER SOURCE

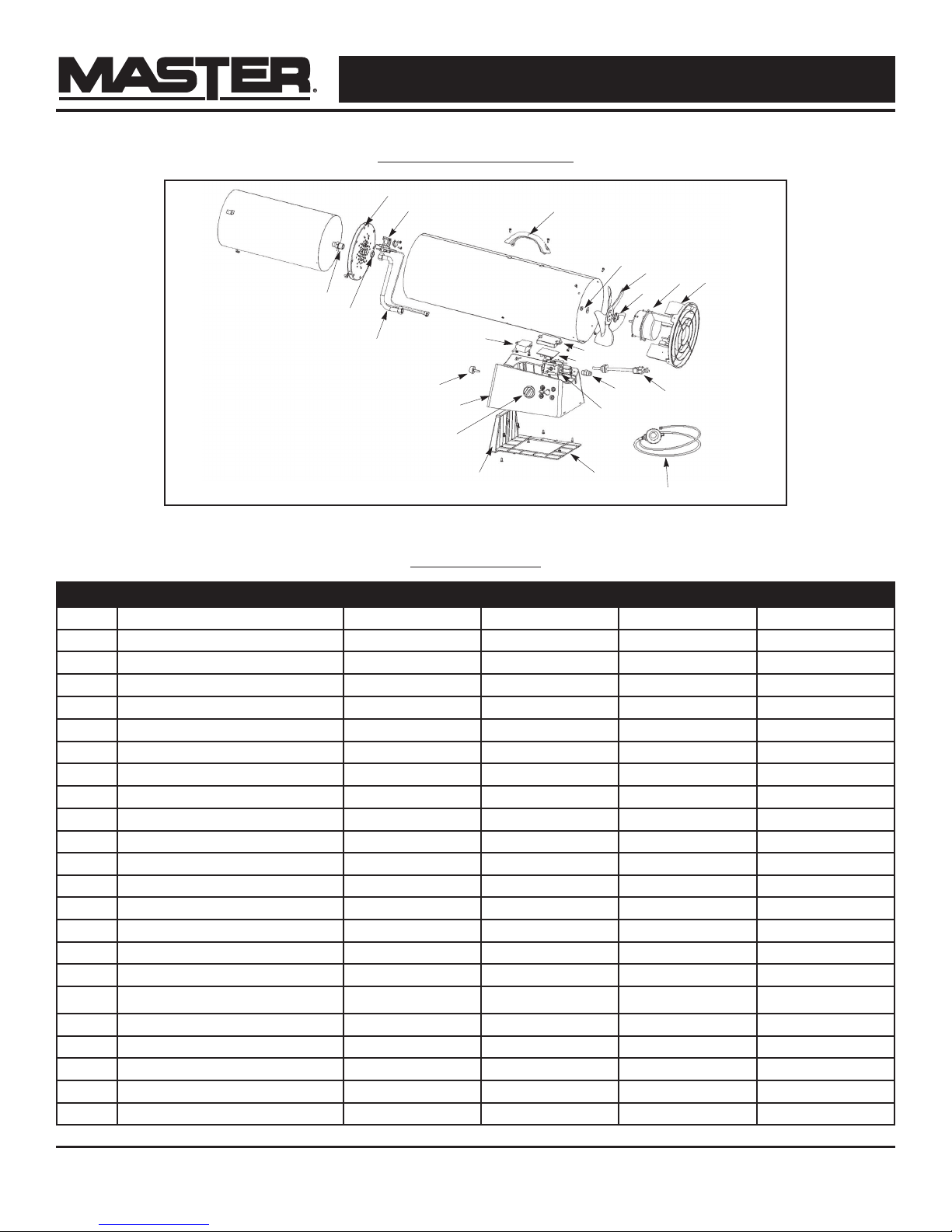

EXPLODED VIEW

4

5

7

8

6

15

18

1

21

9

10

11

12

20

19

17

16

14

13

22

2

3

23

PARTS LIST

Item # Description 40-GFA 60V-GFA 125V-GFA 150V-GFA

1 Base 22-501-0003 22-501-0003 22-501-0004 22-501-0004

2 Height Controller 22-512-0006 22-512-0006 22-512-0008 22-512-0008

3 Base Cover 22-508-0003 22-508-0003 22-508-0004 22-508-0004

4 Inner Shell Cap 22-505-0006 22-505-0010 22-505-0011 22-505-0008

5 Multi Bracket Assembly 22-504-0002 22-504-0002 22-504-0002 22-504-0002

6 Tubing Assembly 22-605-0001 22-605-0001 22-605-0002 22-605-0007

7 Nozzle 22-081-0007 22-081-0014 22-081-0015 22-081-0004

8 Nozzle Nut 22-518-0001 22-518-0001 22-518-0002 22-518-0002

9 Handle 70-001-0103 70-001-0103 70-001-0103 70-001-0103

10 Flange Hex Nut 22-518-0003 22-518-0003 22-518-0003 22-518-0003

11 Fan 22-514-0001 22-514-0001 22-514-0002 22-514-0002

12 Cushion Pad 22-509-0001 22-509-0001 22-509-0001 22-509-0001

13 Motor 22-061-0015 22-061-0015 22-061-0016 22-061-0016

14 Rear Guard 22-101-0003 22-101-0003 22-101-0004 22-101-0004

15 Round Bolt 22-503-0002 22-503-0002 22-503-0002 22-503-0002

16 Valve Assembly 22-011-0005 22-011-0017 22-011-0018 22-011-0008

17 Inlet Connector 22-507-0003 22-507-0003 22-507-0003 22-507-0003

18 Spark Module

–

19 PCB Assembly 22-521-0001 22-521-0002 22-521-0002 22-521-0002

20 PCB Case 22-506-0001 22-506-0001 22-506-0001 22-506-0001

21 Valve Knob 22-516-0001 22-516-0001 22-516-0001 22-516-0001

22 Power Cord

22-131-0001 22-131-0001 22-131-0001 22-131-0001

23 Regulator Assembly 22-041-0004 22-041-0004 22-041-0005 22-041-0005

22-604-0005 22-604-0005 22-604-0005

11

Loading...

Loading...