Page 1

EWS 115

EWS 125-S

EWS 125-ES

EWS 14-125 S

EWS 14-150 S

Bedienungsanleitung

Operating instructions

Istruzioni d’uso

Instructions d’emploi

Instrucciones de servicio

Manual de instruções

Gebruiksaanwijzing

Betjeningsvejledning

Brukerveiledningen

Käyttöohje

Bruksanvisning

Οδηγία χειρισμού

Kullanım kılavuzu

Instrukcja obsługi

Használati utasítás

Návod k obsluze

Návod na používanie

Instrucţiuni de folosire

Navodilo za uporabo

Ръководство за

експлоатация

Kasutusjuhend

Naudojimo instrukcija

Lietošanas pamācība

Руководство по

эксплуатации

Page 2

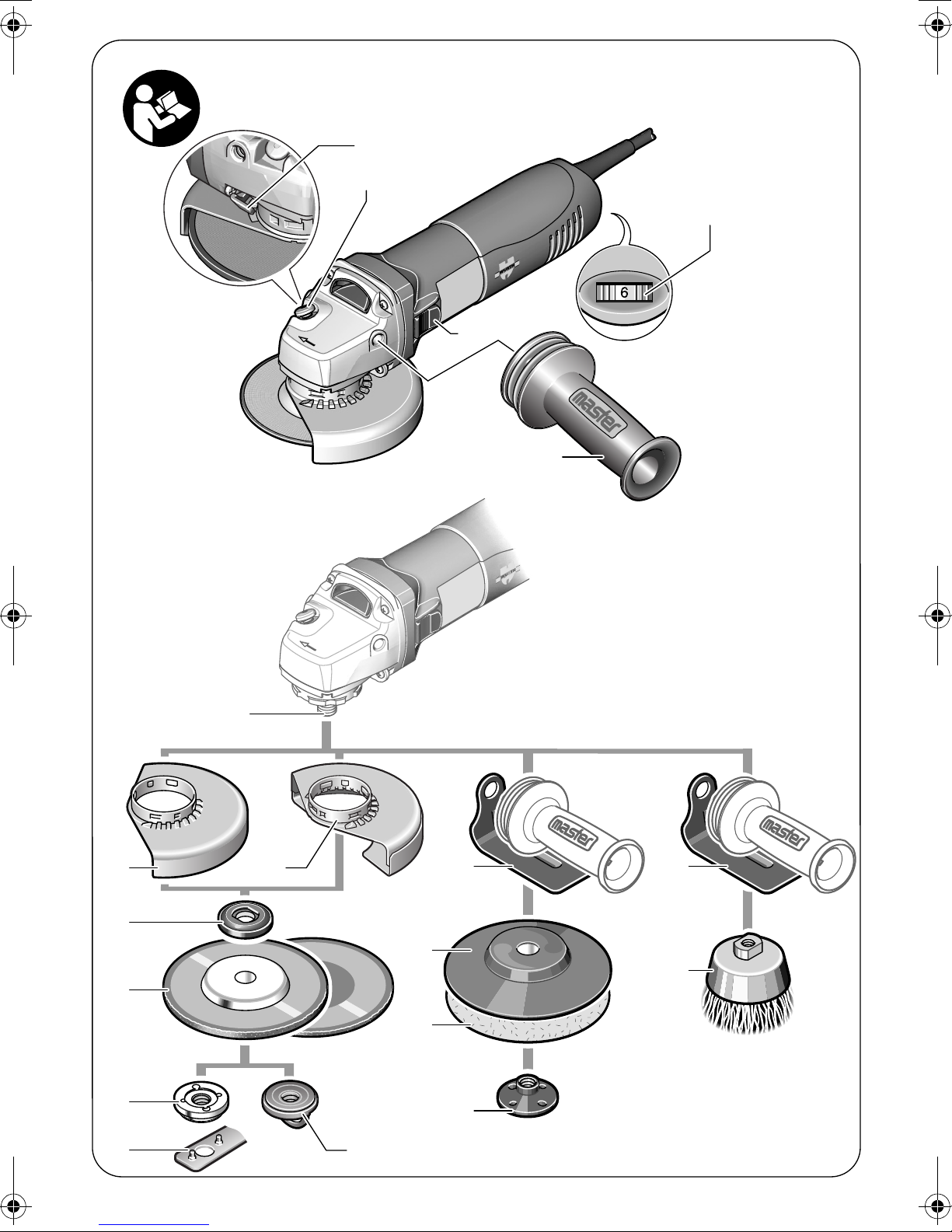

1

2

3

4

5

6

78

9

10

11

12

13

14 14

15

18

16

17

1 609 929 L48 • 15.6.07

Page 3

For Your Safety

Read all safety warnings and all

instructions. Failure to follow the

warnings and instructions may result in

electric shock, fire and/or serious

injury.

❏ See data sheet for further safety warnings

and instructions.

Safety warnings that are common

for grinding, sanding, wire brush-

ing or abrasive cutting off opera-

tions

❏ This power tool is intended to function as

a grinder, sander, wire brush or cut-off

tool. Read all safety warnings, instructions, illustrations and specifications provided with this power tool. Failure to follow

all instructions listed below may result in electric

shock, fire and/or serious injury.

❏ This power tool is not recommended for

poslishing. Operations for which the power tool

was not designed may create a hazard and cause

personal injury.

❏ Do not use accessories which are not spe-

cifically designed and recommended by

the tool manufacturer. Just because the

accessory can be attached to your power tool, it

does not assure safe operation.

❏ The rated speed of the accessory must be

at least equal to the maximum speed

marked on the power tool. Accessories run-

ning faster than their rated speed can fly apart.

❏ The outside diameter and the thickness of

your accessory must be within the capacity

rating of your power tool. Incorrectly sized

accessories cannot be adequately guarded or

controlled.

❏ The arbor size of wheels, flanges, backing

pads or any other accessory must properly

fit the spindle of the power tool. Accessories

with arbor holes that do not match the mounting

hardware of the power tool will run out of balance, vibrate excessively and may cause loss of

control.

❏ Do not use a damaged accessory. Before

each use, inspect the accessory such as

abrasive wheels for chips and cracks,

backing pads for cracks, tears or excess

wear, wire brushes for loose or cracked

wires. If power tool or accessory is

dropped, inspect for damage or install an

undamaged accessory. After inspecting

and installing an accessory, position your-

self and bystanders away from the plane

of the rotating accessory and run the

power tool at maximum no-load speed for

one minute. Damaged accessories will nor-

mally break apart during this test time.

❏ Wear personal protective equipment.

Depending on application, use face

shield, safety goggles or safety glasses. As

appropriate, wear dust mask, hearing

protectors, gloves and shop apron capable of stopping small abrasive or workpiece fragments. The eye protection must be

capable of stopping flying debris generated by

various operations. The dust mask or respirator

must be capable of filtrating particles generated

by your operation. Prolonged exposure to high

intensity noise may cause hearing loss.

❏ Keep bystanders a safe distance away

from the work area. Anyone entering the

work area must wear personal protective

equipment. Fragments of workpiece or of a

broken accessory may fly away and cause injury

beyond immediate area of operation.

❏ Hold the power tool only by the insulated

gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring or its own power cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and shock the

operator.

❏ Position the cord clear of the spinning

accessory. If you lose control of the power tool,

the cord may be cut or snagged and your hand

or arm may be pulled into the spinning accessory.

❏ Never lay the power tool down until the

accessory has come to a complete stop. The

spinning accessory may grab the surface and pull

the power tool out of your control.

❏ Do not run the power tool while carrying it

at your side. Accidental contact with the spin-

ning accessory could snag your clothing, pulling

the accessory into your body.

❏ Regularly clean the power tool’s air vents.

The motor’s fan will draw the dust inside the

housing and excessive accumulation of powdered metal may cause electrical hazards.

❏ Do not operate the power tool near flam-

mable materials. Sparks could ignite these

materials.

❏ Do not use accessories that require liquid

coolants. Using water or other liquid coolants

may result in electrocution or shock.

14–English

1 609 929 L48 • 15.6.07

Page 4

Kickback and related warnings

❏ Kickback is a sudden reaction to a pinched or

snagged rotating wheel, backing pad, brush or

any other accessory. Pinching or snagging

causes rapid stalling of the rotating accessory

which in turn causes the uncontrolled power tool

to be forced in the direction opposite of the

accessory’s rotation at the point of the binding.

For example, if an abrasive wheel is snagged or

pinched by the workpiece, the edge of the wheel

that is entering into the pinch point can dig into

the surface of the material causing the wheel to

climb out or kick out. The wheel may either jump

toward or away from the operator, depending on

direction of the wheel’s movement at the point of

pinching. Abrasive wheels may also break under

these conditions.

Kickback is the result of power tool misuse

and/or incorrect operating procedures or conditions and can be avoided by taking proper precautions as given below.

❏ Maintain a firm grip on the power tool

and position your body and arm to allow

you to resist kickback forces. Always use

auxiliary handle, if provided, for maximum control over kickback or torque

reaction during start-up. The operator can

control torque reactions or kickback forces, if

proper precautions are taken.

❏ Never place your hand near the rotating

accessory. The accessory may kickback over

your hand.

❏ Do not position your body in the area

where the power tool will move if kickback

occurs. Kickback will propel the tool in the direc-

tion opposite to the wheel’s movement at the

point of snagging.

❏ Use special care when working corners,

sharp edges, etc. Avoid bouncing and

snagging the accessory. Corners, sharp

edges or bouncing have a tendency to snag the

rotating accessory and cause loss of control or

kickback.

❏ Do not attach a saw chain woodcarving

blade or toothed saw blade. Such blades

create frequent kickback and loss of control over

the power tool.

Additional safety instructions for

grinding and cutting off opera-

tions

❏ Always use guard designed for the type of

wheel you are using. The guard must be

securely attached to the power tool and

positioned for maximum safety, so the

least amount of wheel is exposed towards

the operator. The guard helps to protect oper-

ator from broken wheel fragments and accidental contact with wheel.

❏ Use only wheel types that are recom-

mended for your power tool and the specific guard designed for the selected

wheel. Wheels for which the power tool was not

designed cannot be adequately guarded and are

unsafe.

❏ Wheels must be used only for recom-

mended applications. For example: do not

grind with the side of the cut-off wheel. Abrasive

cut-off wheels are intended for peripheral grinding; side forces applied to these wheels may

cause them to shatter.

❏ Always use undamaged wheel flanges

that are of correct size and shape for your

selected wheel. Proper wheel flanges support

the wheel thus reducing the possibility of wheel

breakage. Flanges for cut-off wheels may be different from grinding wheel flanges.

❏ Do not use worn down wheels from larger

power tools. Wheels intended for larger power

tools are not suitable for the higher speed of a

smaller tool and may burst.

Additional safety warnings specific

for abrasive cutting off operations

❏ Do not “jam” the cut-off wheel or apply

excessive pressure. Do not attempt to

make an excessive depth of cut. Overstress-

ing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut

and the possibility of kickback or wheel breakage.

❏ Do not position your body in line with and

behind the rotating wheel. When the wheel,

at the point of operation, is moving away from

your body, the possible kickback may propel the

spinning wheel and the power tool directly at

you.

1 609 929 L48 • 15.6.07

English–15

Page 5

❏ When wheel is binding or when interrupt-

ing a cut for any reason, switch off the

power tool and hold the power tool

motionless until the wheel comes to a

complete stop. Never attempt to remove

the cut-off wheel from the cut while the

wheel is in motion, otherwise kickback

may occur. Investigate and take corrective

action to eliminate the cause of wheel binding.

❏ Do not restart the cutting operation in the

workpiece. Let the wheel reach full speed

and carefully reenter the cut. The wheel may

bind, walk up or kickback if the power tool is

restarted in the workpiece.

❏ Support panels or any oversized work-

piece to minimize the risk of wheel pinching and kickback. Large workpieces tend to

sag under their own weight. Supports must be

placed under the workpiece near the line of cut

and near the edge of the workpiece on both sides

of the wheel.

❏ Use extra caution when making a “pocket

cut” into existing walls or other blind

areas. The protruding wheel may cut gas or

water pipes, electrical wiring or objects that can

cause kickback.

Safety warnings specific for sand-

ing operations

❏ When sanding, do not use excessively

oversized sanding disc paper. Follow

manufacturers recommendations, when

selecting sanding paper. Larger sanding

paper extending beyond the sanding pad

presents a laceration hazard and may cause

snagging, tearing of the disc, or kickback.

Safety warnings specific for wire

brushing operations

❏ Be aware that wire bristles are thrown by

the brush even during ordinary operation.

Do not overstress the wires by applying

excessive load to the brush. The wire bristles

can easily penetrate light clothing and/or skin.

❏ If the use of a guard is recommended for

wire brushing, do not allow any interference of the wire wheel or brush with the

guard. Wire wheel or brush may expand in

diameter due to work load and centrifugal

forces.

Additional safety warnings

Wear safety goggles.

❏ Use suitable detectors to determine if util-

ity lines are hidden in the work area or

call the local utility company for assistance. Contact with electric lines can lead to fire

and electric shock. Damaging a gas line can lead

to explosion. Penetrating a water line causes

property damage or may cause an electric shock.

❏ When working stone, use dust extraction.

The vacuum cleaner must be approved for

the extraction of stone dust. Using this

equipment reduces dust-related hazards.

❏ Use a cutting guide when cutting stone.

Without sideward guidance, the cutting disc can

jam and cause kickback.

❏ When working with the machine, always

hold it firmly with both hands and provide

for a secure stance. The power tool is guided

more secure with both hands.

❏ Secure the workpiece. A workpiece clamped

with clamping devices or in a vice is held more

secure than by hand.

❏ Do not work materials containing asbes-

tos. Asbestos is considered carcinogenic.

❏ Take protective measures when dust can

develop during working that is harmful to

one’s health, combustible or explosive.

Example: Some dusts are regarded as carcinogenic. Wear a dust mask and work with dust/chip

extraction when connectable.

❏ Keep your workplace clean. Blends of mate-

rials are particularly dangerous. Dust from light

alloys can burn or explode.

❏ Never use the machine with a damaged

cable. Do not touch the damaged cable

and pull the mains plug when the cable is

damaged while working. Damaged cables

increase the risk of an electric shock.

❏ Use only original Würth accessories.

16–English

1 609 929 L48 • 15.6.07

Page 6

Intended Use

Product Features

The machine is intended for cutting, roughing, and

brushing metal and stone materials without using

water.

For cutting metal, a special protection guard for cutting (accessory) must be used.

With approved sanding tools, the machine can be

used for sanding with sanding discs.

For damage caused by usage other than intended,

the user is responsible.

While reading the operating instructions, unfold the

graphics page for the machine and leave it open.

The numbering of the product features refers to the

illustration of the power tool on the graphics page.

1 Release lever for protection guard

2 Spindle lock button

3 Thumbwheel for speed preselection

(EWS 125-ES)

4 On/Off switch

5 Auxiliary handle

6 Grinder spindle

7 Protection guard for sanding

8 Protection guard for cutting*

9 Mounting flange with O-ring

10 Grinding/cutting disc*

11 Clamping nut

12 Two-pin spanner

13 Quick-clamping nut**

14 Hand guard*

15 Rubber sanding plate*

16 Sanding sheet*

17 Round nut*

18 Cup brush*

*The accessories illustrated or described are not

included as standard delivery.

**Depending on version

1 609 929 L48 • 15.6.07

English–17

Page 7

Technical Data

Angle Grinder EWS

115

EWS

125-S

EWS

125-ES

EWS

14-125 S*

EWS

14-150 S*

Art. No. 0 702 ... 471 X.. 472 X.. 473 X.. 476 X.. 477 X..

Rated power input W 800 1100 1100 1400 1400

Output power W 500 660 660 820 820

No-load speed rpm 11000 11000 2800

11000 9300

–11000

Grinding disc diameter, max. mm 115 125 125 125 150

Thread of grinder spindle M 14 M 14 M 14 M 14 M 14

Kickback stop – z z z z

Restarting protection – zzzz

Reduced starting current – z z z z

Constant electronic control – zzzz

Speed preselection – – z – –

Weight according to

EPTA-Procedure 01/2003 kg 1.9 2.0 2.0 2.2 2.3

Protection class /II /II /II /II /II

The values given apply for nominal voltages [U] of 230/240 V.

*Not available in all countries.

Noise/Vibration Information

Measured values determined according to EN 60745. 0 702 ... 471 X.. 472 X..

477 X..

473 X..

476 X..

Typically the A-weighted noise levels of the product are:

Sound pressure level

Sound power level

Uncertainty K=

dB(A)

dB(A)

dB

91

102

91

102

3

3

91

102

Wear hearing protection!

Vibration total values (triax vector sum) determined according to

EN 60745:

Surface grinding:

Vibration emission value a

Uncertainty K=

Disk sanding:

Vibration emission value a

Uncertainty K=

WARNING

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN 60745 and may be used to compare one tool

h

h

m/s

m/s

m/s

m/s

2

2

2

2

5.5

2.0

3.0

1.5

8.5

2.0

3.0

1.5

7.0

2,0

3.0

1.5

with another.

The vibration emission level will vary because of the ways in which a power tool can be used and may

increase above the level given in this information sheet. This could lead to a significant underestimate of

exposure when the tool is used regularly in such a way.

Note: To be accurate, an estimation of the level of exposure to vibration experienced during a given period

of work should also take into account the times when the tool is switched off and when it is running but not

actually doing the job. This may significantly reduce the exposure level over the total working period.

3

18–English

1 609 929 L48 • 15.6.07

Page 8

Declaration of Conformity

We declare under our sole responsibility that the

product described under “Technical Data” is in conformity with the following standards or standardization documents: EN 60745 according to the

provisions of the directives 89/336/EEC, 98/37/EC

(until Dec. 28, 2009), 2006/42/EG (from Dec. 29,

2009 on).

07

Adolf Würth GmbH & Co. KG

P. Zürn R. Bauer

Mounting the Protective Devices

❏ Before any work on the machine itself,

pull the mains plug.

Protection Guard for Sanding

Place the protection guard 7

onto the spindle collar as

shown in the illustration. The

triangle marks on the protection guard must correspond

with the respective marks on

the gear case.

Press the protection guard 7

onto the spindle collar until

the shoulder of the protection

guard is seated against the

flange of the machine, and

turn the protection guard

until it can clearly be heard to

engage.

Adjust the position of the protection guard 7 to the

requirements of the work process. For this, press the

release lever 1 upward and turn the protection

guard 7 to the required position.

❏ Adjust the protection guard 7 in such a

manner that sparking is prevented in the

direction of the operator.

❏ The protection guard 7 may be turned

only upon actuation of the release lever 1!

Otherwise the power tool may not continue to be used under any circumstances

and must be taken to an after-sales service agent.

Note: The encoding keys on the protection guard 7

ensure that only a protection guard that fits the

machine type can be mounted.

Protection Guard for Cutting

❏ For cutting metal, always work with the

protection guard for cutting 8.

The protection guard for cutting 8 is mounted in the

same manner as the protection guard for sanding 7.

Auxiliary Handle

❏ Operate your machine only with the auxil-

iary handle 5.

Screw the auxiliary handle 5 on the right or left of the

machine head depending on the working method.

Vibration-dampening Auxiliary

Handle

The vibration-dampening auxiliary handle reduces

the vibrations, making operation more comfortable

and secure.

❏ Do not make any alterations to the auxil-

iary handle.

Do not continue to use an auxiliary handle if

it is damaged.

Hand Guard

❏ For operations with the rubber sanding

plate 15 or with the cup brush/wheel

brush/flap disc, always mount the hand

guard 14.

The hand guard 14 is fastened with the auxiliary

handle 5.

Mounting the Grinding Tools

❏ Before any work on the machine itself,

pull the mains plug.

❏ Grinding and cutting discs become very

hot while working; do not touch until they

have cooled.

Clean the grinder spindle 6 and all parts to be

mounted.

For clamping and loosening the grinding tools, lock

the grinder spindle with the spindle lock button 2.

❏ Actuate the spindle lock button only when

the grinder spindle is at a standstill. Oth-

erwise, the machine may become damaged.

Grinding/Cutting Disc

Pay attention to the dimensions of the grinding tools.

The mounting hole diameter must fit the mounting

flange without play. Do not use reducers or adapters.

1 609 929 L48 • 15.6.07

English–19

Page 9

When using diamond cutting discs, pay attention

that the direction-of-rotation arrow on the diamond

cutting disc and the direction of rotation of the

machine (see direction-of-rotation arrow on the

machine head) agree.

See graphics page for the mounting sequence.

To fasten the grinding/cutting disc, screw on the

clamping nut 11 / 13 and tighten with the two-pin

spanner; see Section “

❏ After mounting the grinding tool and

before switching on, check that the grinding tool is correctly mounted and that it

can turn freely. Make sure that the grinding tool does not graze against the protection guard or other parts.

Quick-clamping Nut

An O-ring (plastic part) is inserted

in the mounting flange 9 around

the centring collar. If the O-ring

is missing or is damaged, it

must in all cases be replaced

before the mounting flange 9 is

mounted.

”.

Flap Disc

❏ For operations with the rubber sanding

plate 15 or with the cup brush/wheel

brush/flap disc, always mount the hand

guard 14.

Rubber Sanding Plate

❏ For operations with the rubber sanding

plate 15 or with the cup brush/wheel

brush/flap disc, always mount the hand

guard 14.

See graphics page for the mounting sequence.

Screw on the round nut 17 and tighten with the two-

pin spanner.

Cup Brush/Disc Brush

❏ For operations with the rubber sanding

plate 15 or with the cup brush/wheel

brush/flap disc, always mount the hand

guard 14.

See graphics page for the mounting sequence.

The cup brush/disc brush must be able to be

screwed onto the grinder spindle until it rests firmly

against the grinder spindle flange at the end of the

grinder spindle threads. Tighten the cup brush/disc

brush with an open-end spanner.

Quick-clamping Nut

❏ Use the quick-clamping nut only for grind-

ing/cutting discs with a diameter of up to

125 mm (max.).

X

After mounting the mounting flange and grinding/cutting disc, the clear thread length “X of the

grinding spindle” must be at least 4 mm.

Lock the grinding spindle with the spindle lock button 2. Fold up the clip of the quick-clamping nut 13

and manually screw the nut onto the grinding spindle in clockwise direction 6 until firmly seated on the

grinding/cutting disc. Fold the clip down again.

To release, fold up the clip of the quick-clamping nut

13 and manually unscrew the nut off of the locked

spindle in anticlockwise direction. If necessary, the

quick-clamping nut 13 can also be loosened with

the corresponding two-pin spanner 12 after folding

up the clip.

Approved Grinding Tools

All grinding tools mentioned in these operating

instructions can be used.

The permissible speed [rpm] or the circumferential

speed [m/s] of the grinding tools used must at least

match the values given in the table.

Therefore, observe the permissible rotational/cir-

cumferential speed on the label of the grinding

tool.

max.

[mm] [mm]

Dbd[rpm][m/s]

d

b

D

d

b

D

115

125

D

150

115

125

75 30 M 14 11000 45

6

22.2

6

22.2

6

22.2

––

11000

11000

9300

11000

110008080

80

80

80

20–English

1 609 929 L48 • 15.6.07

Page 10

Rotating the Machine Head

❏ Before any work on the machine itself,

pull the mains plug.

The machine head

can be rotated with

respect to the

machine housing in

90° steps. In this

manner, the On/Off

switch can be brought

into a more convenient position for special working

situations, e.g. for

left-handed persons.

Completely unscrew the four screws. Rotate the

machine head carefully, without removing it

from the housing, to the new position. Screw in

and tighten the four screws again.

Starting Operation

❏ Observe correct mains voltage! The volt-

age of the power source must agree with

the voltage specified on the nameplate of

the machine. Power tools marked with

230 V can also be operated with 220 V.

When operating the machine with power from

mobile generators that do not have sufficient reserve

capacity or are not equipped with suitable voltage

control with starting current amplification, loss of

performance or untypical behavior can occur upon

switching on.

Please observe the suitability of the power generator

being used.

Kickback stop (EWS 125-S/

EWS 125-ES/ EWS 14-125 S/

EWS 14-150 S)

In case of a sudden drop in speed, e.g. jamming

while carrying out a separating cut, the power supply

to the motor is interrupted.

To restart the operation, switch the On/Off

switch 4 to the Off position and start the machine

again.

Restarting protection (EWS 125-S/

EWS 125-ES/ EWS 14-125 S/

EWS 14-150 S)

The restarting protection feature prevents uncontrolled restarting of the machine after an interruption

in the power supply.

To restart the operation, switch the On/Off

switch 4 to the Off position and start the machine

again.

Reduced starting current

(EWS 125-S/EWS 125-ES/

EWS 14-125 S/EWS 14-150 S)

The electronic reduced starting current limits the

power consumption when switching the tool on and

enables operation from a 13 ampere fuse.

Constant Electronic Control

(EWS 125-S/EWS 125-ES/

EWS 14-125 S/EWS 14-150 S)

Constant electronic control holds the speed constant

at no-load and under load, and ensures uniform

working performance.

Switching On and Off

To start the power tool, push the On/Off switch 4

forwards.

To lock the On/Off switch 4, press the On/Off

switch 4 down at the front until it latches.

To switch off the power tool, release the On/Off

switch 4 or, if it is locked, briefly push down the back

of the On/Off switch 4 and then release it.

❏ Check grinding tools before using. The

grinding tool must be mounted properly

and be able to move freely. Carry out a

test run for at least one minute with no

load. Do not use damaged, out-of-centre

or vibrating grinding tools. Damaged grind-

ing tools can burst and cause injuries.

1 609 929 L48 • 15.6.07

English–21

Page 11

Speed preselection (EWS 125-ES)

The required speed can be preselected with the thumbwheel 3 (also while running).

The data in the following table are recommended values.

Material Application Accessory Thumbwheel 3

Metal Removing paint Sanding disc 2 – 3

Wood, metall Brushing, rust removal Cup brush, sanding disc 3

Metal, masonry Sanding Sanding disc 4– 6

Metal Rough grinding Sanding disc 6

Operating Instructions

❏ Exercise caution when cutting slots in

structural walls; see Section “Information

on Structures ”.

❏ Clamp the workpiece if it does not remain

stationary due to its own weight.

❏ Do not strain the machine so heavily that

it comes to a standstill.

❏ Grinding and cutting discs become very

hot while working; do not touch until they

have cooled.

Rough Grinding

❏ Never use a cutting disc for roughing.

The best roughing results are achieved when setting

the machine at an angle of 30° to 40°. Move the

machine back and forth with moderate pressure. In

this manner, the workpiece will not become too hot,

does not discolour and no grooves are formed.

Flap Disc

With the flap disc (accessory), curved surfaces and

profiles can be worked.

Flap discs have a considerably higher service life,

lower noise levels and lower sanding temperatures

than conventional sanding sheets.

Cutting Metal

❏ For cutting metal, always work with the

protection guard for cutting 8.

When cutting, work with moderate feed, adapted to

the material being cut. Do not exert pressure onto

the cutting disc, tilt or oscillate the machine.

Do not reduce the speed of running down cutting

discs by applying sideward pressure.

The machine must

always work in an upgrinding motion.

Otherwise, the danger exists of it being

pushed uncon-

trolled out of the cut.

When cutting profiles

and square bar, it is

best to start at the

smallest cross section.

Information on Structures

Slots in structural walls are subject to the Standard

DIN 1053 Part 1, or country-specific regulations.

These regulations are to be observed under all circumstances. Before beginning work, consult the

responsible structural engineer, architect or the construction supervisor.

Maintenance and Cleaning

❏ Before any work on the machine itself,

pull the mains plug.

❏ For safe and proper working, always keep

the machine and ventilation slots clean.

❏ In extreme working conditions, conductive

dust can accumulate in the interior of the

machine when working with metal. The

protective insulation of the machine can

be degraded. The use of a stationary

extraction system is recommended in such

cases as well as frequently blowing out the

ventilation slots and installing a residual

current device (RCD).

If the machine should fail despite the care taken in

manufacturing and testing procedures, repair

should be carried out by a Würth master-Service.

22–English

1 609 929 L48 • 15.6.07

Page 12

In all correspondence and spare parts orders, please

always include the article number given on the type

plate of the machine.

The current spare parts list for this power tool can be

viewed in the Internet under

“http://www.wuerth.com/partsmanager”

or be requested from your next Würth branch office.

Guarantee

For this Würth power tool, we provide a guarantee

in accordance with the legal/country-specific regulations from the date of purchase (verified by invoice

or delivery document). Damage that has occurred

will be corrected by replacement or repair.

Damage caused by normal wear, overloading or

improper handling is excluded from the guarantee.

Claims can only be accepted if the power tool is sent

undisassembled to a Würth branch office, your

Würth sales representative or a customer service

agent for Würth power tools.

Disposal

The machine, accessories and packaging should be

sorted for environmental-friendly recycling.

Only for EC countries:

Do not dispose of power tools into household waste!

According to the European Guideline

2002/96/EC for Waste Electrical and

Electronic Equipment and its implementation into national right, power tools that are no

longer usable must be collected separately and disposed of in an environmentally correct manner.

Subject to change without notice.

1 609 929 L48 • 15.6.07

English–23

Page 13

Würth worldwide:

Würth Albania Ltd.

Rr. Asim Vokshi

Pall 49/1 Ap. 9

AL-Tirana

Albania

Tel. ++355/42/29748

Fax ++355/42/29748

wuerthal@icc.al.eu.org

Würth Armenia Co. Ltd.

63 Tigran Mets Ave.

AM-375005 Yerevan

Armenia

Tel. ++3741/559970

Fax ++3741/559972

wuerth@arminco.com

Würth Handelsges.m.b.H.

Würth Strasse 1

AT-3071 Böheimkirchen

Austria

Tel. ++43/2743/70700

Fax ++43/2743/70703333

info@wuerth.at

Würth Australia Pty Ltd

4 Redwood Drive

AU-Dingley VIC 3172

Australia

Tel. ++61/3/95517244

Fax ++61/3/955 12994

info@wurth.com.au

Wurth Aztur Ltd

Mir Galal Str.63.

AZ-370134 Baku

Azerbaijan

Tel. ++994/12/601934

Fax ++994/12/601934

wurth@azdata.net

Wurth BH d.j.l.

Dzemal Biedia 162

BA-71000 Sarajevo,BIH

Bosnia

Tel. ++387/33/461770

Fax ++387/33/461825

Würth Belux N.V.

Everdongenlaan 29

BE-2300 Turnhout

Belgium

Tel. ++32/14/445566

Fax ++32/14/423077

info@wurth.be

Wuerth Bulgaria EOOD

Iskarsko Chaussee Boul. 12

BG-1592 Sofia

Bulgaria

Tel. ++359/2/9659955

Fax ++359/2/9659966

wuerth_bg@ibm.net

Würth Belarus Ltd.

Botanitscheskaja Str. 5a-603

BY-220038 Minsk

Belarus

Tel. ++375/172/363919

Fax ++375/172/852512

wuerthbel@open.by

Würth AG

Dornwydenweg 11

CH-4144 Arlesheim

Switzerland

Tel. ++41/61/7059111

Fax ++41/61/7059494

infos@wuerth-ag.ch

Würth Guangzhou

International Trading Co., Ltd.

Room 601, North Tower,

Nantian Building,

3 Jiangong Road

Tianhe High and New Technology

Industry Development Zone

CN-510665 Guangzhou

China

Tel. ++86/20/85552840

Fax ++86/20/855550245

wurthgz@public.guangzhou.gd.cn

Würth Hong Kong Co. Ltd.

Unit B 6/f Prince Ind Bidg

106 King Fuk St.,

San Po Kong, Kowloon

CN-Hong Kong

China

Tel. ++8/52/27508118

Fax ++8/52/27530084

info@wuerth-hk.com

Wuerth China-Shanghai

Langsheng Trading Co., Ltd.

2nd Floor (West)

No. 18 Factory Site

No. 481 Gui Ping Road

CN-200233 Shanghai

China

Tel. ++86/21/64951418

Fax ++86/21/64848610

wuerthcn@public3.sta.net.cn

Würth Tianjin International

Trade Co., Ltd.

Jie Fang Nan Lu Str. 518-1

CN-300221 Tianjin

China

Tel. ++86/22/88242263

Fax ++86/22/88243813

tjwuerth@public.tpt.tj.cn

Wuerth Cyprus LTD

Strovolos industrial estate

P.O. Box 8899

CY-2083 Nicosia

Cyprus

Tel. ++357/2/512086

Fax ++357/2/512091

wuerthcy@cytanet.com.cy

Würth, spol. s r.o.

Sazecská 2

CZ-10800 Praha 10

Czech Republic

Tel. ++420/2/72106111

Fax ++420/2/72106119

info@wuerth.cz

Adolf Würth GmbH & Co. KG

Postfach

D-74650 Künzelsau

Reinhold-Würth-Str. 12-16

DE-74653 Künzelsau

Germany

Tel. ++49/7940/15-0

Fax ++49/7940/15-1000

info@wuerth.com

Würth Danmark A/S

Montagevej 6

DK-6000 Kolding

Denmark

Tel. ++45/79/323232

Fax ++45/75/517250

Würth Estonia AS

Liimi 3 A

EE-10621 Tallinn

Estonia

Tel. ++372/6563509

Fax ++372/6563494

wuerth@wuerth.ee

Würth Egypt for Trading S.A.E.

27th. Km Alexandria Cairo Desert

Road, Behind Mercedes

EG-Amriya Alexandria

Egypt

Tel. ++2/03/4700432

Fax ++2/03/4700432

wurth@wurthegypt.com

Würth España S.A.

Poligono Riera de Caldes

Carrer Dels Joiers 21-23

ES-08184 Palau de Plegamans

Barcelona

Spain

Tel. ++34/93/8629500

Fax ++34/93/8646203

webmaster@wurth.es

Würth Oy

Herajoki

FI-11710 Riihimäki

Finland

Tel. ++358/19/7701

Fax ++358/19/729010

Würth France S.A.

Z.I. Ouest

Rue Georges Besse

FR-67158 Erstein Cedex

France

Tel. ++33/3/88645300

Fax ++33/3/88646200

Wurth U.K. Ltd.

1 Centurion Way

Erith

GB-Kent DA 18 4 AE

Great Britain

Tel. ++44/208/3196000

Fax ++44/208/3196400

info@wurth.co.uk

Würth Georgia Ltd.

Marshal Gelovani Avenue 36

GE-380059 Tbilisi

Georgia

Tel. ++995/32/530610

Fax ++995/32/250610

gewuerth@caucasus.net

Würth Hellas S.A.

23. Klm. National Road

Athens-Lamia

145 68 Krioneri Attikis

P.O. Box 51877

Attikis

GR-145 02 Agios Stefanos Attikis

Greece

Tel. ++30/1/6290800

Fax ++30/1/8134756

info@wurth.gr

Würth-Hrvatska d.o.o.

Franje Lucica 23/III

HR-10000 Zagreb

Croatia

Tel. ++385/1/3498784

Fax ++385/1/3498783

wurth.hrvatska@zg.hinet.hr

Würth Szereléstechnika KFT

Gyár utca 2

HU-2040 Budaörs

Hungary

Tel. ++36/23/418130

Fax ++36/23/421777

wuerth@wuerth.hu

PT Wuerth Indah

JI. Meruya Ilir Raya No. 82 A-B

ID-Jakarta 11360

Indonesia

Tel. ++62/21/5860036

Fax ++62/21/5861043

wuerth@idola.net.id

Würth Ireland Ltd.

Monaclinoe Industrial Estate

Ballysimon Road

IR-Limerick

Ireland

Tel. ++353/61/412911

Fax ++353/61/412428

Würth Israel Ltd.

Alon Hatavor 2

Zone 1

IL-Caesarea Industrial Park

P.O. Box 3585

IL-Caesarea Industrial Park

Zip 38900

Israel

Tel. ++972/4/6273939

Fax ++972/4/6270999

Wuerth India Pvt. Ltd.

33, Santosh Building,

Marol Co-operative Industrial

Estate,

M V Road, Andheri (East)

IN-Mumbai 400 059

India

Tel. ++91/22/8507023

Fax ++91/22/8507020

wuerth@bom4.vsnl.net.in

Würth Teheran Ltd.

Pasdaran St.-Corner of Negarestane 5-No.183

IR-16619 Teheran-Iran

Iran

Tel. ++98/21/2842828

Fax ++98/21/2856171

wuerthtehran@irost.com

Würth á Íslandi ehf.

Veslurhraun 5

IS-210 Garðabær

Iceland

Tel. ++354/5302000

Fax ++354/5302001

ebse@wurth.is

Würth S.r.l. - GmbH

Via Stazione, 51

I - 39044 Egna (BZ)

Tel. ++39/0471/828111

Fax ++39/0471/828600

vendite@wuerth.com

Wurth – Jordan Co. Ltd.

Al-yadoudeh

P.O. Box 951

JO-Amman-11592

Jordan

Tel. ++962/6/4122512

Fax ++962/6/4122510

wurthjor@go.com.jo

Würth Japan Co., Ltd.

MT Building

33 Sanmaicho, Kanagawa-ku

JP-Yokohama 221-0862

Japan

Tel. ++81/45/4884186

Fax ++81/45/4884187

sat_ueda@wuerth.co.jp

jun_ando@wuerth.co.jp

Würth Nippon GmbH & Co. KG

6F Tsuruga Bldg., 1-29-15

Shinyokohama, Kohoku-Ku

JP-Yokohama 222-0033

Japan

Tel. ++81/45/4704633

Fax ++81/45/4704621

jj.wn@poem.ocn.ne.jp

Wuerth Kenya Ltd.

P.O. BOX 16751

Meru Road

KE-Mombasa

Kenya

Tel. ++254/11/312403

Fax ++254/11/312437

wuerth@africaonline.co.ke

Würth Foreign Swiss

Company Ltd.

3 Erkindik Boulevard

KG-Bishkek, 720040

Kyrgyzstan

Tel. ++996/312/227976

Fax ++996/312/661025

wurth@imfiko.bishkek.su

Page 14

Würth Kosova

No. 36 Pashe Dibra

Bregu i diellit

Prishtina

Tel. ++377/44/186514

wurthkosova@hotmail.com

Wurth Korea Co. Ltd.

128-1, O-Keum Dong,

KR-Song Pa-Gu, Seoul,

Korea (138-859)

South Korea

Tel. ++82/2/4009311

Fax ++82/2/4009315

wurth-kr@wurth.co.kr

Wuerth Kazakhstan Ltd.

Abai 125, 2nd floor

KZ-480008, Almaty

Kazakhstan

Tel. ++7/3272/622432

Fax ++7/3272/622495

wurthkaz@kaznet.kz

Würth Lietuva

Dariaus ir Gireno 21

LT-2038 Vilnius

Lithuania

Tel. ++370/2/263045

Fax ++370/2/264108

info@wurth.lt

Würth Reinsurance

Company, S.A.

B.P. 2217

L-1022 Luxembourg

Siège social

65, Avenue de la gare

LU-1611 Luxembourg

Tel. ++352/494177

Fax ++352/494188

Würth Maroc SARL

48 Avenue Pasteur

MA-Casablanca 20150

Marocco

Tel. ++212/2/2405700

Fax ++212/2/2405706

Würth Moldova Ltd.

b-dul Stefan cel Mare, nr 4

Hotel National

MD-Chisinau

Moldavia

Tel. ++373/2/540398

Fax ++373/2/540398

Würth Makedonien GmbH

ul. Gorce Petrov 108a

MK-91000 Skopje

Macedonia

Tel. ++389/233/2230

Fax ++389/233/2083

wurthmak@unet.com.mk

Würth Caraibes Sarl

Z.I. Cocotte Canal

MQ-97224 Ducos-Martinique

Tel. ++596/560701

Fax ++596/564369

wurth.caraibes@wanadoo.fr

Würth Limited

Würth House

Triq il-Masgar

MT-Qormi QRM09

Malta

Tel. ++356/494604

Fax ++356/441081

wuerth@maltanet.net

Wuerth (Malaysia) Sdn. Bhd.

6, Jalan Permas 9/13

Taman Permas Jaya

MY-81750 Masai Johor

Malaysia

Tel. ++60/7/3876280

++60/7/3881712

Fax ++60/7/3884391

wuerth@po.jaring.my

Würth Nederland B.V.

Moeskampweg 13

NL-5222 AW ‘s-Hertogenbosch

Postbus 344

NL-5201 AH ’s-Hertogenbosch

Netherlands

Tel. ++31/73/6291911

Fax ++31/73/613137

info@wurth.nl

Würth Norge AS

Postboks 84

NO-1483 Skytta

Morteveien 12,

Gjellerasen Naeringspark

NO-1481 Hagan

Tel. ++47/670/62500

Fax ++47/670/62711

kontakt@wuerth.no

Würth New Zealand Ltd.

42 Hobill Avenue,

P.O. Box 97079

Manukau City

NZ-South Auckland/Mail Centre

New Zealand

Tel. ++64/9/2623040

Fax ++64/9/2623030

info@wurth.co.nz

Wuerth Philippines, Inc.

Air-Rich Building

Km. 19.5 East Service Road,

South Expressway

PH-Parañaque City,

Philippines

Tel. ++63/2/8382697

Fax ++63/2/8382195

wuerthphils@pacific.net.ph

Würth Polska Sp. z o.o.

ul. Plochinska 33

PL-03-044 Warzawa

Poland

Tel. ++48/22/819041

Fax ++48/22/8117190

biuro@wurth.pl

Würth Portugal Tecnica de

Montagem, Ldo.

Estrada Nacional, 249-4

Abrunheira

P-2710-089 Sintra

Portugal

Tel. ++351/21/9157200

Fax ++351/21/9151038

wurth.portugal@mail.telepac.pt

Würth Romania S.R.L.

Zapada Mielior 16-18

Sector 1

P.O. 18-85

RO-Bucarest 71529

Romania

Tel. ++40/1/2323282

Fax ++40/1/2328933

wuerth@moon.ro

Wuerth Mittelrussland

c/o Logovaz

Transportnaja Ul. 20

RU-394043 Voronezh

Russia

Tel. ++7/0732/727065

Fax ++7/0732/727065

wurth@wurth.vrn.ru

Würth Irtysch

Ul. Dobrovolskogo 8/1

RU-644099 Omsk

Russia

Tel. ++7/3812/245291

Fax ++7/3812/245291

rus@wuerth.omsk.su

Würth Russia

Bulwar Generala

Karbyschewa, 8, Of. 504

RU-123154 Moskau

Russia

Tel. ++7/095/9468028

Fax ++7/095/9468028

sale@wurth.ru

Würth Nordkaukasus Ltd.

Krasnoarmejskaja Str. 206

RU-344010 Rostow am Don

Russia

Tel. ++7/8632/618051

Fax ++7/8632/618054

wuerthnk@icomm.ru

ZAO Wuerth-Siberia

Serebrennikovskaja, 14, of. 501

RU-630007 Novosibirsk

Russia

Tel. ++7/3832/234673

Fax ++7/3832/234673

wuerthsb@drbit.ru

Würth St. Petersburg

Prospekt Dunaiski 68

RU-192 288 St. Petersburg

Russia

Tel. ++7/812/1726166

Fax ++7/812/1726085

web@wurth.spb.ru

ZAO Wuerth-Ural

Institutskaja, 6, Of. 202

RU-620016 Ekaterinburg

Russia

Tel. ++7/3432/432393

Fax ++7/3432/432393

wurth_ur@etel.ru

ZAO Wuerth-Volga

Novosadovaja st., 221, Of. 205

RU-443011 Samara

Russia

Tel. ++7/8462/703252

Fax ++7/8462/703252

wurth_ur@etel.ru

Würth Svenska AB

Würth´s väg

Hjälmarberget

Box 1705

SE-70117 Örebro

Sweden

Tel. ++46/19/351000

Fax ++46/19/351001

Würth Singapore Pte. Ltd.

Bukit Batok central Post Office

P.O. box 365

SG-Singapore 916513

Tel. ++65/487/4238

Fax Box 1705

Würth d.o.o.

Plemljeva 86

SI-1210 Ljubljana

Slovenia

Tel. ++386/1/5128690

Fax ++386/1/5121472

wurth@siol.net

Würth s.r.o.

Pribylinská ul. c. 2

SK-83104 Bratislava

Slovakia

Tel. ++421/7/49201211

Fax ++421/7/49201299

wurth@wurth.sk

Wuerth Verbindungstechnik

Co., Ltd.

41/198 SukhontasawadRoad

TH-Ladprao Bangkok 10230

Thailand

Tel. ++66/2/9078880

Fax ++66/2/9078877

master@wuerth-th.com

Würth Otomotiv ve Montaj

San. Ürün. Paz. Ltd. Sti.

Eski Silivri Caddesi No. 22

TR-34900 Mimarsinan

Büyükcekmece

Turkey

Tel. ++90/212/8634603

Fax ++90/212/8634608

info@wurth.com.tr

Wurth Taiwan, Co., Ltd.

4th Fl., 28 Lane 80,

Sec. 3 Nan-Kang Rd.,

TW-Taipei, Taiwan,

R.O.C.

Taiwan

Tel. ++886/2/27857122

Fax ++886/2/27857027

wurthtw@gcn.net.tw

Würth Ukraine Ltd.

Maschynobudiwna, 44

UA-Kiew 03680

Ukraine

Tel. ++380/44/4465376

Fax ++380/44/4466467

wuerthua@i.kiev.ua

Würth Central Purchasing

America, Inc.

91 Grant Street

US-Ramsey, NJ 07446

USA

Tel. ++1/201/9951111

Fax ++1/201/9959908

Würth Technik

Halklar Dustligi 132-1

UZ-706800 Nawoi

Uzbekistan

Tel. ++998/79/2235207

Fax ++998/79/2235207

danijar@wuerth.com.uz

Cong ty TNHH Vu Viet

9/3 Ly Van PhucTan Dinh Ward- Dist 1

VN-Ho Chi Minh City

Vietnam

Tel. ++84/8/8205635

Fax ++84/8/8205634

vuvietct@hcm.vnn.vn

Wurth d.o.o. za trgovinu

montaznom opremom

Zrenjaninski put 153 h

YU-11211 Beograd

Yugoslavia

Tel. ++381/11/3320198

Fax ++381/11/3320242

wurth_yu@eunet.yu

Würth South Africa Co (Pty)

Ltd.

P.O. Box 616

ZA-Isando 1600

South Africa

Tel. ++27/11/9747191

Fax ++27/11/9746169

wurthsa@wurth.co.za

For more countries and

information see

http://www. wuerth.com

Page 15

Adolf Würth

GmbH & Co. KG

74650 Künzelsau

Tel. 07940 15-0

Fax 07940 15-1000

info@wuerth.com

www.wuerth.de

Würth Niederlassungen:

Aachen

Tel. 0241 56879-0

Fax 0241 56879-50

nl.aachen@wuerth.com

Aalen

Tel. 07361 9230-0

Fax 07361 9230-50

nl.aalen@wuerth.com

Alzey

Tel. 06731 99078-0

Fax 06731 99078-9

nl.alzey@wuerth.com

Aschaffenburg

Tel. 06021 449958-0

Fax 06021 449958-9

nl.aschaffenburg@wuerth.com

Augsburg

Tel. 0821 29761-0

Fax 0821 29761-50

nl.augsburg@wuerth.com

Backnang

Tel. 07191 9040-0

Fax 07191 9040-50

nl.backnang@wuerth.com

Bad Kreuznach

Tel. 0671 794617-0

Fax 0671 794617-9

nl.bad-kreuznach@wuerth.com

Bad Mergentheim

Tel. 07931 92405-0

Fax 07931 92405-9

nl.bad-mergentheim

@wuerth.com

Bad Neustadt

Tel. 09771 636998-0

Fax 09771 636998-9

nl.bad-neustadt@wuerth.com

Bamberg

Tel. 0951 70084-0

Fax 0951 70084-50

nl.bamberg@wuerth.com

Bayreuth

Tel. 0921 79205-0

Fax 0921 79205-50

nl.bayreuth@wuerth.com

Berlin-Charlottenburg

Tel. 030 32678430

Fax 030 32678351

nl.berlin-charlottenburg

@wuerth.com

Berlin-Hohenschönhausen

Tel. 030 986001-0

Fax 030 986001-55

nl.berlin-hohenschoenhausen

@wuerth.com

Berlin-Pankow

Tel. 030 45976668-0

Fax 030 45976668-9

nl.berlin-pankow@wuerth.com

Berlin-Tempelhof

Tel. 030 7568778-0

Fax 030 7568778-9

nl.berlin-tempelhof

@wuerth.com

Biberach

Tel. 07351 58798-0

Fax 07351 58798-50

nl.biberach@wuerth.com

Bielefeld

Tel. 0521 92418-0

Fax 0521 92418-27

nl.bielefeld@wuerth.com

Bochum

Tel. 0234 95543-0

Fax 0234 95543-50

nl.bochum@wuerth.com

Böblingen

Tel. 07031 21176-0

Fax 07031 21176-50

nl.boeblingen@wuerth.com

Bonn

Tel. 0228 6844989-0

Fax 0228 6844989-9

nl.bonn@wuerth.com

Braunschweig

Tel. 0531 35478-0

Fax 0531 35478-90

nl.braunschweig@wuerth.com

Bremen

Tel. 0421 39988-0

Fax 0421 39988-51

nl.bremen@wuerth.com

Bremen-Hemelingen

Tel. 0421 485208-0

Fax 0421 485208-9

nl.bremen-hemelingen

@wuerth.com

Chemnitz

Tel. 0371 27147-0

Fax 0371 27147-50

nl.chemnitz@wuerth.com

Coburg

Tel. 09561 23996-0

Fax 09561 23996-9

nl.coburg@wuerth.com

Cottbus

Tel. 0355 75661-0

Fax 0355 75661-50

nl.cottbus@wuerth.com

Crailsheim

Tel. 07951 9637-0

Fax 07951 9637-50

nl.crailsheim@wuerth.com

Darmstadt

Tel. 06151 500389-0

Fax 06151 500389-9

nl.darmstadt@wuerth.com

Dillingen

Tel. 06831 769959-0

Fax 06831 769959-9

nl.dillingen@wuerth.com

Dortmund-Dorstfeld

Tel. 0231 9580868-0

Fax 0231 9580868-9

nl.dortmund-dorstfeld

@wuerth.com

Dortmund-Holzwickede

Tel. 02301 91869-0

Fax 02301 91869-9

nl.dortmund-holzwickede

@wuerth.com

Dresden-Löbtau

Tel. 0351 43847-0

Fax 0351 43847-50

nl.dresden-loebtau

@wuerth.com

Dresden-Mickten

Tel. 0351 41453-0

Fax 0351 41453-50

nl.dresden-mick-

ten@wuerth.com

Düren

Tel. 02421 495595-0

Fax 02421 495595-9

nl.dueren@wuerth.com

Düsseldorf

Tel. 0211 97306-0

Fax 0211 97306-50

nl.duesseldorf@wuerth.com

Elmshorn

Tel. 04121 461999-0

Fax 04121 461999-9

nl.elmshorn@wuerth.com

Erfurt

Tel. 0361 42057-0

Fax 0361 42057-50

nl.erfurt@wuerth.com

Erlangen

Tel. 09131 933079-0

Fax 09131 933079-9

nl.erlangen@wuerth.com

Eschborn

Tel. 06196 777068-0

Fax 06196 777068-9

nl.eschborn@wuerth.com

Essen

Tel. 0201 86645-0

Fax 0201 86645-50

nl.essen@wuerth.com

Esslingen

Tel. 07153 9294-0

Fax 07153 9294-50

nl.esslingen@wuerth.com

Flensburg

Tel. 0461 494337-0

Fax 0461 494337-9

nl.flensburg@wuerth.com

Frankfurt/Main

Tel. 069 426938-0

Fax 069 426938-50

nl.frankfurt-main@wuerth.com

Frankfurt

Nieder-Eschbach

Tel. 069 5069868-0

Fax 069 5069868-9

nl.frankfurt-nieder-eschbach

@wuerth.com

Freiberg

Tel. 03731 203939-0

Fax 03731 203939-9

nl.freiberg@wuerth.com

Freiburg

Tel. 0761 55966-0

Fax 0761 55966-50

nl.freiburg@wuerth.com

Fulda

Tel. 0661 833488-0

Fax 0661 833488-9

nl.fulda@wuerth.com

Gelnhausen

Tel. 06051 91527-0

Fax 06051 91527-9

nl.gelnhausen@wuerth.com

Gera

Tel. 0365 43728-0

Fax 0365 43728-50

nl.gera@wuerth.com

Gießen

Tel. 0641 96236-0

Fax 0641 96236-50

nl.giessen@wuerth.com

Göppingen

Tel. 07161 60693-0

Fax 07161 60693-50

nl.goeppingen@wuerth.com

Goslar

Tel. 05321 351930-0

Fax 05321 35193-50

nl.goslar@wuerth.com

Hagen

Tel. 02331 396099-0

Fax 02331 396099-9

nl.hagen@wuerth.com

Halle/Saale

Tel. 0345 566768-0

Fax 0345 566768-9

nl.halle-saale@wuerth.com

Hamburg-Norderdstedt

Tel. 040 534361-0

Fax 040 534361-50

nl.hamburg-norderstedt

@wuerth.com

Hamburg-Oststeinbek

Tel. 040 711863-0

Fax 040 711863-50

nl.hamburg-oststeinbek

@wuerth.com

Hamburg-Seevetal

Tel. 04105 5844-0

Fax 04105 5844-50

nl.hamburg-seevetal

@wuerth.com

Hamburg-West

Tel. 040 6750369-0

Fax 040 6750369-9

nl.hamburg-west@wuerth.com

Hamm

Tel. 02381 304908-0

Fax 02381 304908-9

nl.hamm@wuerth.com

Hannover

Tel. 0511 78680-0

Fax 0511 78680-50

nl.hannover@wuerth.com

Heidelberg

Tel. 06221 58988-0

Fax 06221 58988-50

nl.heidelberg@wuerth.com

Heilbronn

Tel. 07131 9556-0

Fax 07131 9556-50

nl.heilbronn@wuerth.com

Hof

Tel. 09281 144097-0

Fax 09281 144097-9

nl.hof@wuerth.com

Hürth

Tel. 02233 96686-0

Fax 02233 96686-9

nl.huerth@wuerth.com

Ingolstadt

Tel. 0841 142828-0

Fax 0841 142828-50

nl.ingolstadt@wuerth.com

Jena

Tel. 03641 4512-0

Fax 03641 4512-50

nl.jena@wuerth.com

Kaiserslautern

Tel. 0631 357899-0

Fax 0631 357899-9

nl.kaiserslautern@wuerth.com

Karlsruhe

Tel. 0721 62522-0

Fax 0721 62522-50

nl.karlsruhe@wuerth.com

Kassel

Tel. 0561 99868-0

Fax 0561 99868-50

nl.kassel@wuerth.com

Kempten

Tel. 0831 57448-0

Fax 0831 57448-50

nl.kempten@wuerth.com

Kiel

Tel. 0431 64740-0

Fax 0431 64740-50

nl.kiel@wuerth.com

Page 16

Koblenz

Tel. 02630 9470-0

Fax 02630 9470-50

nl.koblenz@wuerth.com

Köln

Tel. 0221 956442-0

Fax 0221 956442-50

nl.koeln@wuerth.com

Kulmbach

Tel. 09221 690379-0

Fax 09221 690379-9

nl.kulmbach@wuerth.com

Künzelsau

Tel. 07940 9350-0

Fax 07940 9350-50

nl.kuenzelsau@wuerth.com

Künzelsau-Gaisbach

Tel. 07940 15-2555

Fax 07940 15-4555

nl.gaisbach@wuerth.com

Landshut

Tel. 0871 95371-0

Fax 0871 95371-50

nl.landshut@wuerth.com

Leinfelden-Echterdingen

Tel. 0711 220629-0

Fax 0711 220629-50

nl.leinfelden-echterdingen

@wuerth.com

Leipzig-Rückmarsdorf

Tel. 0341 49014-0

Fax 0341 49014-40

nl.leipzig@wuerth.com

Leipzig Zentrum Ost

Tel. 0341 468669-0

Fax 0341 468669-9

leipzig-zentrum-ost@wuerth.com

Leonberg

Tel. 07152 92824-0

Fax 07152 92824-29

nl.leonberg@wuerth.com

Limburg

Tel. 06431 21598-0

Fax 06431 21598-9

nl.limburg@wuerth.com

Lippstadt

Tel. 02941 286891-0

Fax 02941 286891-9

nl.lippstadt@wuerth.com

Lörrach

Tel. 07621 161098-0

Fax 07621 161098-9

nl.loerrach@wuerth.com

Lübeck

Tel. 0451 87192-0

Fax 0451 87192-50

nl.luebeck@wuerth.com

Ludwigsburg

Tel. 07141 688959-0

Fax 07141 688959-9

nl.ludwigsburg@wuerth.com

Magdeburg

Tel. 0391 25587-0

Fax 0391 25587-50

nl.magdeburg@wuerth.com

Mainz

Tel. 06131 62739-0

Fax 06131 62739-50

nl.mainz@wuerth.com

Mannheim

Tel. 0621 72746-0

Fax 0621 72746-50

nl.mannheim@wuerth.com

Mannheim-Mallau

Tel. 0621 8425078-0

Fax 0621 8425078-9

nl.mannheim-mallau

@wuerth.com

Memmingen

Tel. 08331 924818-0

Fax 08331 924818-9

nl.memmingen@wuerth.com

Metzingen

Tel. 07123 97386-0

Fax 07123 97386-9

nl.metzingen@wuerth.com

Michelstadt

Tel. 06061 96729-0

Fax 06061 96729-9

nl.michelstadt@wuerth.com

Minden

Tel. 0571 388479-0

Fax 0571 388479-9

nl.minden@wuerth.com

Mönchengladbach

Tel. 02161 47769-0

Fax 02161 47769-50

nl.moenchengladbach

@wuerth.com

Mosbach

Tel. 06261 675308-0

Fax 06261 675308-9

nl.mosbach@wuerth.com

Mühldorf

Tel. 08631 184606-0

Fax 08631 184606-9

nl.muehldorf@wuerth.com

München-Ismaning

Tel. 089 960703-0

Fax 089 960703-50

nl.muenchen-ismaning

@wuerth.com

München-TÜV

Tel. 089 431972-0

Fax 089 431972-50

nl.muenchen-tuev@wuerth.com

Münster

Tel. 0251 26537-0

Fax 0251 26537-50

nl.muenster@wuerth.com

Neubrandenburg

Tel. 0395 43048-0

Fax 0395 43048-50

nl.neubrandenburg@wuerth.com

Neunkirchen

Tel. 06821 401886-0

Fax 06821 401886-9

nl.neunkirchen@wuerth.com

Nordhausen

Tel. 03631 47353-0

Fax 03631 47353-9

nl.nordhausen@wuerth.com

Nürnberg

Tel. 0911 93192-0

Fax 0911 93192-50

nl.nuernberg@wuerth.com

Offenburg

Tel. 0781 96984-0

Fax 0781 96984-50

nl.offenburg@wuerth.com

Öhringen

Tel. 07941 64868-0

Fax 07941 64868-9

nl.oehringen@wuerth.com

Oldenburg

Tel. 0441 21989-0

Fax 0441 21989-50

nl.oldenburg@wuerth.com

Olpe

Tel. 02761 941269-0

Fax 02761 941269-9

nl.olpe@wuerth.com

Osnabrück

Tel. 0541 90901-0

Fax 0541 90901-50

nl.osnabrueck@wuerth.com

Paderborn

Tel. 05251 20543-0

Fax 05251 20543-29

nl.paderborn@wuerth.com

Papenburg

Tel. 04961 664099-0

Fax 04961 664099-9

nl.papenburg@wuerth.com

Passau

Tel. 0851 95662-0

Fax 0851 95662-50

nl.passau@wuerth.com

Pforzheim

Tel. 07231 13942-0

Fax 07231 13942-29

nl.pforzheim@wuerth.com

Plauen

Tel. 03741 40694-0

Fax 03741 40694-9

nl.plauen@wuerth.com

Potsdam

Tel. 0331 88884-0

Fax 0331 88884-50

nl.potsdam@wuerth.com

Rastatt

Tel. 07222 405699-0

Fax 07222 405699-9

nl.rastatt@wuerth.com

Regensburg

Tel. 0941 78398-0

Fax 0941 78398-50

nl.regensburg@wuerth.com

Reutlingen

Tel. 07121 5695-0

Fax 07121 5695-50

nl.reutlingen@wuerth.com

Rheine

Tel. 05971 804058-0

Fax 05971 804058-9

nl.rheine@wuerth.com

Rodgau

Tel. 06106 8401-0

Fax 06106 8401-50

nl.rodgau@wuerth.com

Rosenheim

Tel. 08031 23089-0

Fax 08031 23089-50

nl.rosenheim@wuerth.com

Rostock

Tel. 038204 616-0

Fax 038204 616-50

nl.rostock@wuerth.com

Saarbrücken

Tel. 0681 94865-0

Fax 0681 94865-50

nl.saarbruecken@wuerth.com

Schwabach

Tel. 09122 693034-0

Fax 09122 693034-9

nl.schwabach@wuerth.com

Schwäbisch Gmünd

Tel. 07171 104088-0

Fax 07171 104088-9

nl.schwaebisch-gmuend

@wuerth.com

Schwäbisch Hall

Tel. 0791 40723-0

Fax 0791 40723-50

nl.schwaebisch-hall@wuerth.com

Schweinfurt

Tel. 09721 509954-0

Fax 09721 509954-9

nl.schweinfurt@wuerth.com

Siegen

Tel. 0271 66049-0

Fax 0271 66049-39

nl.siegen@wuerth.com

Sinsheim

Tel. 07261 4021-0

Fax 07261 4021-50

nl.sinsheim@wuerth.com

Soest

Tel. 02921 350986-0

Fax 02921 350986-9

nl.soest@wuerth.com

Straubing

Tel. 09421 188826-0

Fax 09421 188826-9

nl.straubing@wuerth.com

Stuttgart

Tel. 0711 95573-20

Fax 0711 95573-50

nl.stuttgart@wuerth.com

Suhl Zella-Mehlis

Tel. 03682 46922-0

Fax 03682 46922-9

nl.suhl-zella-mehlis@wuerth.com

Trier

Tel. 0651 43699-0

Fax 0651 43699-50

nl.trier@wuerth.com

Troisdorf

Tel. 02241 23402-0

Fax 02241 23402-50

nl.troisdorf@wuerth.com

Ulm/Neu-Ulm

Tel. 0731 97898-0

Fax 0731 97898-50

nl.ulm-neu-ulm@wuerth.com

Urbach

Tel. 07181 990318-0

Fax 07181 990318-9

nl.urbach@wuerth.com

Villingen-Schwenningen

Tel. 07721 8719-0

Fax 07721 8719-50

nl.villingen-schwenningen

@wuerth.com

Weingarten/Ravensburg

Tel. 0751 56104-0

Fax 0751 56104-50

nl.weingarten-ravensburg

@wuerth.com

Weißenburg

Tel. 09141 9955-0

Fax 09141 9955-50

nl.weissenburg@wuerth.com

Wiesbaden

Tel. 0611 18697-0

Fax 0611 18697-50

nl.wiesbaden@wuerth.com

Wittlich

Tel. 06571 956339-0

Fax 06571 956339-9

nl.wittlich@wuerth.com

Wuppertal

Tel. 0202 64771-0

Fax 0202 64771-25

nl.wuppertal@wuerth.com

Würzburg

Tel. 0931 27989-0

Fax 0931 27989-18

nl.wuerzburg@wuerth.com

Zwickau

Tel. 0375 2713438-0

Fax 0375 2713438-9

nl.zwickau@wuerth.com

0702 473 X BA 06.07 – Printed in Germany – Imprimé en Allemagne MWV-OSW• © by Adolf Würth & Co. KG • Nachdruck, auch auszugsweise, nur mit Genehmigung.

1 609 929 L48

Loading...

Loading...