Page 1

DG307

1

DG307

OPERATING INSTRUCTION MANUAL

DO NOT OPERATE THE DG307 TOOL UNTIL

YOU HAVE READ THIS MANUAL AND RECEIVED THE PROPER TRAINING

ACCORDING TO ANSI STANDARD A 10.3-1995.

™

PRIOR TO OPERATING THE DG307 TOOL,

STUDY THIS MANUAL CAREFULLY AND DEVELOP A THOROUGH

UNDERSTANDING OF THE CONTENTS.

PROPER TRAINING ACCORDING TO THE CURRENT ANSI

STANDARD A 10.3, SAFETY REQUIREMENTS FOR POWDER

ACTUATED FASTENING SYSTEMS MUST BE COMPLETED AND

A MASTER QUALIFIED OPERATOR CARD MUST BE OBTAINED

PRIOR TO OPERATION OF THE TOOL. STATE, LOCAL, OR

OTHER REGULATIONS SHOULD ALSO BE FOLLOWED. LAWS,

REGULATIONS, AND STANDARDS REGARDING THE USE

OF POWDER ACTUATED TOOLS MAY PERIODICALLY BE

REVISED. ANY SUCH REVISIONS MAY CHANGE THE SAFETY

AND OPERATING PROCEDURES DESCRIBED IN THIS MANUAL.

MASTER, INC. IS NOT RESPONSIBLE FOR ANY SUCH REVISIONS

WHICH OCCUR AFTER PUBLICATION OF THIS MANUAL. IT IS THE

RESPONSIBILITY OF THE USER TO MAINTAIN FAMILIARITY WITH

THE CURRENT LAWS, REGULATIONS, AND STANDARDS THAT

APPLY TO THE POWDER ACTUATED TOOL.

TO AVOID SERIOUS INJURY OR DEATH:

NEVER CLOSE TOOL WITH ANY PART OF HAND OVER MUZZLE END.

OPERATORS AND BYSTANDERS MUST WEAR

EYE AND HEARING PROTECTION.

R2200

R2200

ALWAYS

ASSUME

TOOL IS LOADED.

DO NOT PLACE A

FINGER ON THE

TRIGGER

OF LOADED TOOL UNTIL MUZZLE END IS AGAINST WORK

SURFACE AND YOU ARE READY TO MAKE A FASTENING. NEVER

PLACE YOUR HAND OVER THE MUZZLE WITH A POWDER LOAD IN

THE TOOL. IF THE TOOL ACCIDENTALLY DISCHARGES THE PISTON

OR FASTENER MAY PENETRATE YOUR HAND RESULTING IN

SERIOUS INJURY.

TOOL OPERATION MUST READ AND UNDERSTAND

THE ENTIRE TOOL MANUAL AND MUST COMPLETE

THE OPERATOR’S EXAM ON THE LAST PAGE. THE

TOOL WARRANTY WILL NOT BE VALID UNTIL THE TEST IS

RECEIVED, WITH A COPY OF YOUR RECEIPT, AND REVIEWED

BY MASTER, INC.

Warranty

Three Year Limited Warranty

MASTER will repair, without charge, any defects due to faulty

materials or workmanship for three years from the date of

purchase. This warranty does not cover part failure due to

normal wear or tool abuse. This warranty does not apply to

accessories or damage caused where repairs have been

made or attempted by others. This warranty gives you

specific legal rights any you may have other rights which vary

in certain states or provinces.

In addition to the warranty, MASTER tools are covered by our:

1 YEAR FREE SERVICE

MASTER will maintain the tool and replace worn parts caused

by normal use, for free, any time during the first year after

purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of

your MASTER Powder Actuated Tool for any reason, you can

return it within 90 days from the date of purchase with a

receipt for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT:

If your warning labels become illegible or are missing call

us for a free replacement.

Introduction

Thank you for purchasing the MASTER DG307 low velocity

powder actuated tool. This tool will provide you with excellent

performance provided the steps for proper operation and

maintenance are followed. Powder actuated fastening

systems can provide a cost effective method of attaching

fixtures for light duty, static load conditions. The systems

provided by MASTER consist of specially designed fasteners,

installation tools, and powder loads which are designed to

function in combination to provide optimum performance.

While powder actuated tools can provide one of the fastest

and economical means of fastening, they can also be

dangerous if they are not operated properly.

Prior to operating the DG307 tool, you must be properly

trained in the operation and maintenance of this tool and be

issued a MASTER Qualified Operator Card. When using the

tool, you must have this card in your possession. As part

of the training process, you should read and understand

the contents of this instruction manual especially the safety

Low Velocity Powder

Actuated Fastening Tool

DG307

MASTER

! warning

Page 2

DG307

2

precautions.

Powder actuated tools may be operated only by properly

trained operators as described in ANSI Standard A 10.3,

Safety Requirements for Powder Actuated Fastening

Systems. For complete tool operation details, contact your

local MASTER Branch office or distributor for training.

Remember, safety begins with you! It is your primary

responsibility when operating this tool. Failure to follow the

proper operating, maintenance, and safety procedures can

result in serious injury or death to yourself or bystanders.

In addition to the training provided, you should be familiar

with any local, state, and federal regulations. If you have any

questions which are not covered in this manual, contact your

local MASTER Branch office or distributor.

Size Range

1/2” to 3” pin lengths, .22 caliber

Tool Description

The DG307 is a low velocity, single shot, .22 caliber

tool which can be used to install .300 head drive pins,

8mm

head drive pins and 1/4”-20 threaded studs, up to 3” in total

length. The DG307 is designed for maintenance or

residential contractors.

Technical Data

TOOL BODY PIN LENGTH TOOL LENGTH

Engineered Plastic 1/2” to 3” Total Length 12-1/2”

LOAD TYPE TOOL WEIGHT POWER LEVEL

.22 Caliber in 4.3 lbs. Gray (1), Brown (2)

Crimped “A” Load Green (3), Yellow (4)

PIN TYPE

Ballistic Point Drive Pin, .300 Head Drive Pin, 8mm Head Drive Pin,

1/4”-20 Threaded Stud

DG307 Selection Guide

CAT NO. DESCRIPTION STD CTN.

DG307 Tool (Blister Pack) 1

52522 Piston 1

52510 Nose Piece 1

52512 Piston Reset Pin 1

Fastener Functioning

Prior to learning the safe operating

procedures for this tool, it is important

to understand how a powder actuated

fastener works. A powder actuated

fastener is considered to be a direct

drive or forced entry type of fastener

because it is driven directly into the

base material. The driving action causes tremendous forces

to be applied to the fastener. MASTER powder actuated

fasteners are specially designed and manufactured using

an austempering process to withstand the forces imposed

during the driving operation. Only fasteners manufactured or

supplied by MASTER should be used in this tool.

Functioning In Concrete

The performance of a powder actuated fastener when

installed into concrete or masonry base materials is based on

the following factors:

1. Strength of the base material

2. Hardness and concentration of the aggregate

3. Shank diameter of the fastener

4. Depth of embedment into the base material

5. Fastener spacing and edge distance

In addition to these factors, installation

tool accessories such as a stop

spall which reduces the tendency of

the concrete surface to spall during

the driving action can increase the

performance of the fastener.

When a powder actuated fastener

is driven into concrete, it displaces the

volume of concrete around the embedded

area of the fastener shank. As this

occurs, the concrete directly surrounding

the fastener is compressed and in turn

presses back against the shank of the

fastener. Additionally, the driving action

generates heat which causes particles within the concrete

to fuse to the shank of the fastener. This combination of

compression and fusion holds the fastener in the concrete

base material. A similar action occurs when fastening into

block masonry.

Generally, the performance of the fastener in a given

concrete strength will increase with greater embedment

depths in a certain range. Depending on the fastener style

and base material strength, embedment depths range from

5/8” to 1-1/2”. For depths greater than this range, there is

the possibility of fastener bending or fishhooking which may

decrease expected load capacities and create a safety hazard.

During the driving action, some localized surface spalling

of the

concrete may occur. Normally, this is a surface effect which

does not effect the performance of the fastener. However,

it may pose an aesthetic problem for exposed applications

where a fixture is not used. In cases such as this, two

methods can be used to improve the appearance of the

fastening. A stop spall adapter mounted on the powder

actuated tool can help to reduce surface spalling. Another

method used is to drive the fastener through a steel washer

to improve the appearance of the application.

Functioning In Steel

The load performance of a powder

actuated fastener when installed into

steel base materials is based on the

following factors:

1. Thickness of the steel

2. Tensile strength of the steel

3. Shank diameter of the fastener

4. Depth of point penetration through the steel

5. Fastener spacing and edge distance.

When a powder actuated fastener is driven into steel, it

displaces the steel laterally 360˚ around the shank of the

fastener. Since steel is an elastic material, it presses back

against the shank of the fastener to hold it in place. As the

diameter of the fastener shank is increased, the load capacity

obtained will generally increase provided the steel thickness

is sufficient to accept the fastener. To further increase

fastener performance in steel, some fasteners have a knurled

shank which allows the steel to form a key lock into the

grooves to provide higher capacities than those obtained with

a smooth shank. For optimum performance, the fastener

point should completely penetrate the steel. Normally, a

minimum of 1/4” is allowed for the point length. An increase

in performance can be expected until the fastener no longer

completely penetrates through the steel. At this point, the

elastic properties of the steel cause a compression force to

be developed at an angle against the fastener point which

Stop

Spall

Washer

Stop

Spall

1

2

Model DG307

MASTER

Page 3

DG307

3

reduces load capacity. In thicker steel base materials,

adequate load capacities may be obtained for applications in

which the point of the fastener does not fully penetrate the

steel.

Job site performance tests are recommended.

Fasteners should not be used in areas that have been

welded or cut with a torch as these procedures may have

caused local hardening of the steel. Over driving of the fastener should be avoided as the rebound created may reduce

the load capacity or cause damage to the fastener. When

fastening into unsupported long steel members, it may be

necessary to provide support in the area of the fastening to

prevent spring action which can cause inconsistent penetration and a reduction in load capacity.

Suitable Base Material

While powder actuated fasteners can be used successfully in

concrete, certain masonry materials, and A 36 steel, some

materials are completely unsuitable. Fasteners should never

be fired into hard or brittle materials such as cast iron, tile,

glass, or rock. These materials can shatter easily resulting in

a potential safety hazard. In addition, soft base materials

Surface

Shatters

Material

Cracks

Fastener Sinks in

with Average

Hammer Blow

Point

Flattens

No

Indent

such as wallboard, plaster, or wood are

not appropriate as the fastener could

pass completely through these

materials. The user should never guess

when fastening into any base material.

Failure to follow the recommended

installation and safety guidelines can

result in severe injury or death to the

tool operator and/or bystanders.

Center Punch Test

A center punch test should always be

performed to determine the suitability

of the base material for a powder

actuated fastening. This test is relatively

simple and can help to insure a safe,

successful fastening.

Be sure to wear

the appropriate eye protection when

performing this test. To begin, select

the fastener to be used for the job.

Then, place the point of the fastener

against the proposed base material.

Strike the fastener with a single

hammer blow, then examine the point.

If the point of the fastener is not blunted and the base

material has a clear point indentation, it is acceptable to

proceed with the first test installation.

Use of a powder actuated system is not recommended if

the following occurs during the center punch test:

1. The fastener point has been blunted. This indicates that the

base material is too hard.

2. The base material cracks or shatters. This indicates that

the base material is too brittle.

3. When using an average hammer blow, the fastener

penetrates the base material easily. This indicates that the

base material is too soft.

Fastener Installation Requirements

It is important to understand the required minimum base

material thickness requirements along with the minimum

spacing and edge distance requirements. Failure to follow

these requirements can result in an unsuccessful fastening

and create a safety hazard.

Base Material Thickness

Concrete base material should be at

least three (3) times as thick as the

fastener embedment penetration. If the

concrete is too thin, the compressive

forces forming at the fasteners point can

cause the free face of the concrete to

break away. This can create a dangerous

condition from flying concrete and/

or the fastener and also results in a reduction of fastener

holding power.

For applications in the face shell of concrete

masonry block, select a fastener length which will not

exceed the thickness of the face shell.

Fastener Penetration Guide

The following table lists typical embedment or penetration

depths expected in the base materials listed. The

penetration will vary depending on the density of the

material. This table should be used as a guide since the

consistency of these materials varies. When in doubt, a job

site performance test should be conducted.

DENSITY TYPICAL BASE MATERIAL PENETRATION

Soft Masonry Concrete block 1” -1-1/4”

Average Concrete Poured concrete 3/4” - 1”

Dense Concrete Pre-stressed/ 5/8” - 3/4”

pre-cast concrete

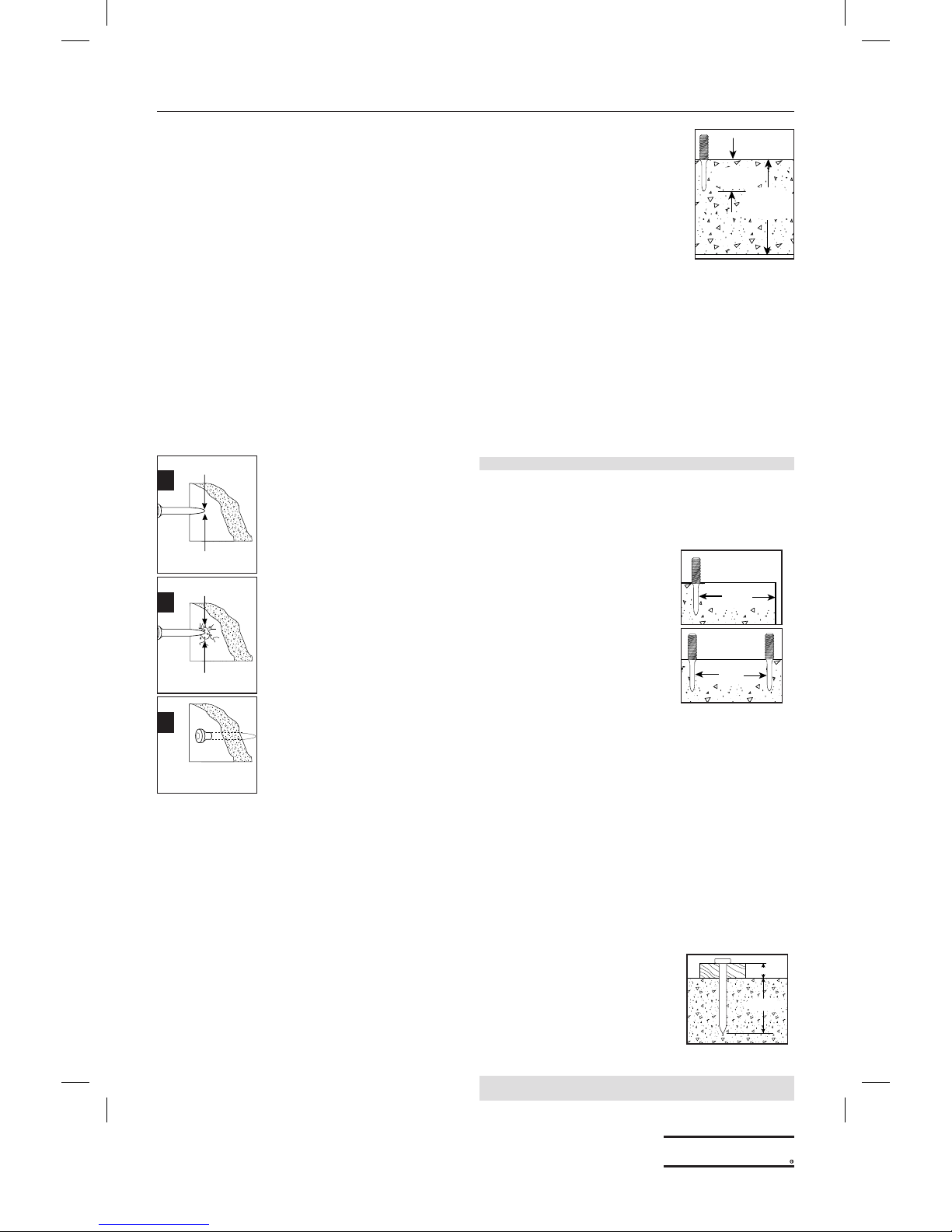

Edge Distance

3"

3"

Do not fasten closer than 3” from

the edge of concrete. If the concrete

cracks, the fastener may not hold.

Closer edge distances for applications

such as sill plates may be permitted

if specific fastener testing has been

conducted.

Spacing

Setting fasteners too close together

in concrete or masonry can cause

cracking. The recommended minimum

distance between fasteners is 3” center to center.

Fastener Length Selection In Concrete

For permanent applications using pins in concrete, first

determine the thickness of the fixture to be fastened. To this,

add the required embedment or penetration into the base

material. This will be the fastener shank length required.

For applications in the face shell of masonry block, select a

fastener length which will not exceed the thickness of the

face shell.

For removable applications with threaded studs, the

shank length required is equal to the embedment depth

required. To determine the minimum threaded length, add

the thickness of the fixture and the nut / washer thickness.

The nut and washer thickness is equal to the nominal thread

diameter. Do not over tighten threaded

parts. Maximum tightening torque

values are listed in the table below.

Use of a nut setter is recommended to

reduce the possibility of over tightening

the fasteners. For critical applications,

perform a job site test.

MAXIMUM TORQUE FOR 1/4” STUD MAXIMUM TORQUE FOR 3/8” STUD

(

FT.-LBS.) (FT.-LBS)

2 4

2

3

1

Penetration

3x

Penetration

Fixture

Embedment

Model DG307

MASTER

Page 4

DG307

4

Installation In Steel

The following guidelines are based on the installation of a

fastener in ASTM A 36 structural steel with the point fully

penetrating the steel member. Recommended steel material

thickness ranges from a minimum of 1/8” to a maximum of

3/8”. For use in higher strength structural steel, applications

where the point does not penetrate the steel member, or a

thickness of steel greater than 3/8”, job site performance

tests are recommended.

Base Material Thickness

Steel base materials should be a

minimum of 1/8” in thickness.

Edge Distance

For installations in A 36 steel, 1/2”

is the recommended minimum edge

distance.

Spacing

The recommended minimum distance

between fastenings is 1-1/2” center

to center for installations in ASTM A

36 steel.

Fastener Length Selection In Steel

For permanent applications when using pins in steel, first

determine the thickness of the fixture to be fastened. To this,

add the thickness of the steel base material plus a minimum

of 1/4” to allow for proper point penetration. This will be the

minimum fastener shank length required. Do not select a

fastener length longer than that required for the application.

An excessively long shank can burnish or polish the hole

created in the steel resulting in a reduction in load capacity.

For removable applications with threaded studs, the

shank length required is equal to the thickness of the steel

base material plus a minimum of 1/4” to allow for proper

point penetration. This will be the minimum fastener shank

length required. Do not select a shank length longer than

that required for the application. An excessively long shank

can burnish or polish the hole created in the steel resulting

in a reduction in load capacity. To determine the minimum

threaded length, add the thickness of the fixture and the nut

/ washer thickness. The nut and washer thickness is equal to

the nominal thread diameter.

Do not over tighten threaded studs, the maximum

tightening torque is listed in the table below. Use of a nut

setter is recommended to reduce the possibility of over

tightening the fasteners. For critical applications, perform a

job site test.

Fastener Selection Guide

.300 Head Diameter Drive Pins

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PD3011000

1/2” K 100 5000 .300 .143 .5

PD3011050

5/8” K 100 5000 .300 .143 .5

PD3001100

3/4” 100 5000 .300 .143 .5

PD3001150

1” 100 5000 .300 .143 .6

PD3001200

1-1/8” 100 1000 .300 .143 .7

PD3001250

1-1/4” 100 1000 .300 .143 .8

PD3001300

1-1/2” 100 1000 .300 .143 .9

PD3001350

1-3/4” 100 1000 .300 .143 1.1

PD3001400

2” 100 1000 .300 .143 1.2

PD3001450

2-1/4” 100 1000 .300 .143 1.2

PD3001500

2-3/8” 100 1000 .300 .143 1.3

PD3001550

2-1/2” 100 1000 .300 .143 1.4

PD3001600

2-3/4” 100 1000 .300 .143 1.6

PD3001650

3” 100 1000 .300 .143 1.9

.300 Head Diameter Drive Pins with Top Hat

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PDT3031000

1/2” K 100 5000 .300 .143 .5

PDT3031050

5/8” K 100 5000 .300 .143 .5

PDT3031100

3/4” 100 5000 .300 .143 .5

PDT3031150

1” 100 5000 .300 .143 .6

.300 Head Diameter Step Shank Pins

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

SPD3041000

3/4” Step Shank 100 1000 .300 .143/130 .5

SPD3041050

1” Step Shank 100 1000 .300 .143/130 .6

.300 Head Diameter Drive Pins - Master Pack

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PD301100M

1/2” K 1000 5000 .300 .143 .5

PD301105M

5/8” K 1000 5000 .300 .143 .5

PD300110M

3/4” 1000 5000 .300 .143 .5

PD300115M

1” 1000 5000 .300 .143 .6

PD300125M

1-1/4” 1000 5000 .300 .143 .8

PD303100M

1/2” K TH 1000 5000 .300 .143 .5

PD303105M

5/8” K TH 1000 5000 .300 .143 .5

PD303110M

3/4” TH 1000 5000 .300 .143 .5

PD303115M

1” TH 1000 5000 .300 .143 .6

.300 Head Diameter Drive Pins with 3/4” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PDW3051100

3/4” 100 1000 .300 .143 1.6

PDW3051200

2-1/2” 100 1000 .300 .143 2.5

.300 Head Diameter Drive Pins with 7/8” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PDW3061150

1” 100 1000 .300 .143 1.9

PDW3061250

1-1/4” 100 1000 .300 .143 2.0

PDW3061300

1-1/2” 100 1000 .300 .143 2.1

PDW3061400

2” 100 1000 .300 .143 2.4

PDW3061550

2-1/2” 100 1000 .300 .143 2.7

PDW3061650

3” 100 1000 .300 .143 3.0

.300 Head Diameter Drive Pins with 1” Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PDW3071000

1-1/4” 100 1000 .300 .143 2.2

PDW3071050

1-1/2” 100 1000 .300 .143 2.3

PDW3071250

2” 100 1000 .300 .143 2.6

PDW3071150

2-1/2” 100 1000 .300 .143 2.9

PDW3071200

3” 100 1000 .300 .143 3.2

1/8"

1/2"

1-1/2"

Model DG307

MASTER

Page 5

DG307

5

.300 Head Diameter Drive Pins with 1-7/8” Insulation Washer

CAT. SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH BOX CTN. DIA. DIA. 100

PD3081000

1-1/2” 100 1000 .300 .143 2.1

PD3081050

2-1/2” 50 500 .300 .143 2.7

1/4”-20 Threaded Studs

CAT. THREAD SHANK STD. STD. HEAD SHANK WT./

NO. LENGTH LENGTH BOX CTN. DIA. DIA. 100

TS3811020

1/2” 1/2”K 100 5000 1/4” .143 .8

TS3811000

3/4” 1/2”K 100 1000 1/4” .143 1.1

TS3811050

3/4” 3/4” 100 1000 1/4” .143 1.2

TS3811100

1/2” 1” 100 1000 1/4” .143 1.2

TS3811150

3/4” 1” 100 1000 1/4” .143 1.4

TS3811180

1/2” 1-1/4” 100 1000 1/4” .143 1.4

TS3811200

3/4” 1-1/4” 100 1000 1/4” .143 1.5

TS3811250

1-1/4” 1-1/4” 100 1000 1/4” .143 1.7

.300 Head Diameter Pins with Ceiling Clips

CAT. SHANK STD. STD. HEAD SHANK WIRE WT./

NO. LENGTH BOX CTN. DIA. DIA. HOLE 100

PDCA4111050

1” 100 1000 .300 .143 0.278” 3.5

PDCA4151000

1” 100 1000 .300 .143 0.278” 3.0

PDCA4111100

1-1/4” 100 1000 .300 .143 0.278” 3.7

PDCA111150

1-1/4” 100 1000 .300 .143 0.278” 3.2

.300 Head Diameter Drive Pins with

BX Cable Straps and Conduit Clips

CAT. STD. STD. HEAD SHANK WT./

NO. SHANK LENGTH BOX CTN. DIA. DIA. 100

PDCC4111150

1” 100 1000 .300 .143 3.5

P

DCC4131050

1-1/4” 100 1000 .300 .143 3.7

PDCC4121000

1/2” EMT 1” pin 100 1000 .300 .143 3.3

PDCC4121050 3/4” EMT 1-1/4”pin

100 1000 .300 .143 3.5

PDCC4121100

3/4” EMT 1” pin TH

100 500 .300 .143 3.4

PDCC4121150

3/4” EMT 1” pin 100 1000 .300 .143 3.3

PDCC4121200 1” EMT 1” pin TH

25 250 .300 143 3.2

K=Knurled TH=Top Hat

Powder Load Selection Guide

POWER LOAD STD. STD. MASTER WT./

LEVEL COLOR SIZE BOX CTN. CTN. 100

1 Grey .22A 100 1000 20000 .33

2 Brown .22A 100 1000 20000 .33

3 Green .22A 100 1000 20000 .33

4 Yellow .22A 100 1000 20000 .33 fety

InstructIons

afety InstructIons

Safety is your primary responsibility when operating

any powder actuated tool. You must read and understand

the contents of this manual. You must be familiar with all

functional and safety requirements of the tool. It is your

responsibility to obtain proper training and a MASTER operator

card prior to using this tool in compliance with the current

American National Standard A10.3 Safety Requirements

for Powder Actuated Fastening Systems and the Federal

Occupational Safety and Health Administration Standards

(OSHA). Existing state or local regulations should also be

followed. When using this tool, you must have the qualified

operators card in your possession.

Revocation of card - Failure to comply with any of the rules and

regulations for safe operation of powder actuated tools shall be

cause for the immediate revocation of your qualified operator card.

Failure to following safety instructions

can result in serious injury or death to operators or

bystanders.

Prior to Operating the Tool

1. Warning signs should always be posted within the area in

which a powder actuated tool is to be used. These signs

should be at least 8” x 10” in size with boldface type that

is not less than 1” in height. The sign should state

“Powder Actuated Tool In Use”.

2. Approved eye protection should always be worn by operator or bystander, to protect their eyes from flying particles.

Hearing protection should always be worn by the operator

and bystanders when using a powder actuated tool. Other

personal safety protection as required should also be used.

3. Never modify or fabricate parts for use in your MASTER

tool. Use only MASTER fasteners, loads, and tool parts.

4. Hands or other body parts must never be placed in front

of muzzle/barrel. Accidental discharge can cause piston

and/or fastener to pass through the operator’s hand.

5. Never compress the tool against any part of the body.

Serious injury or death may result in the event of an

accidental discharge.

6. Always point tool in a safe direction at all times.

Intended Purpose

7. Keep all other people, especially children, away from the

work area.

8. Use only in a well-lit, well-ventilated work area.

Preparation for Loading the Tool

1. Tools must be checked prior to operating to make sure

they are not fully or partially loaded with a powder load or

fastener.

2. To insure safe operation, perform the daily function test

described in this manual. Be sure the tool is not loaded

prior to performing this test.

3. Do not operate this tool unless all its parts are in place

and operating appropriately. Never attempt to use a

malfunctioning tool.

4. Never guess about the suitability of a base material. If

you are uncertain about the suitability of a base material,

perform a center punch test.

5. Do not operate the tool until you learn and understand the

color code / numbering system used to identify the power

level of powder loads.

Operating the Tool

1. Only use fasteners and powder loads designed for this

tool as supplied by MASTER.

2. Do not use powder actuated tools in the presence of

flammable fumes or vapor or an explosive atmosphere.

3. Do not fire a tool without a fastener. The piston will

Model DG307

MASTER

SAFETY INSTRUCTIONS

Page 6

DG307

6

impact the work surface possibly causing serious injury to

the operator or bystanders along with damage to the tool.

4. Do not load the tool until you are ready to make a

fastening. Check the power load level before inserting it into

the tool chamber.

5. Fastener must be loaded prior to loading the powder load,

to prevent injury to operator or bystander in the event of

an accidental discharge.

6. Do not close tool against work surface. The tool should be

manually closed, with hand away from muzzle/barrel to

prevent accidental discharge.

7. Hold the tool perpendicular to the work surface at all

times. Use a spall guard (part # 52166) wherever possible.

This will limit the possibility of fastener ricochet which

could cause serious injury or death to the operator or

bystanders.

8. Always perform a test fastening with the lightest load level

designed for use in the tool. If the lightest load fails to set

the fastener, try the next highest load until the proper level

is attained. Failure to follow this procedure may cause the

fastener to be overpowered. If this occurs, the fastener

may fully penetrate the base material causing serious

injury or death to someone. Overpowering the fastener can

also damage the tool, creating a safety hazard to both the

operator or bystanders.

9. Do not fasten into cast iron, tile, glass, or other types of

brittle materials. These materials can shatter and create

sharp fragments which may cause injury.

10.Do not fire tool within 3” (three inches) of the edge of a

concrete base material or within 1/2” (one-half inch) of

the edge of a steel base material.

11.Do not attempt to install a fastener closer than 3” (three

inches) to another previously inserted fastener in concrete

or 1-1/2” (one and one-half inch) in steel.

12.Do not fasten into a concrete base material less than 3

times as thick as the fastener penetration or into a steel

base material thinner than 1/8”.

13.Never attempt to install a fastener in a cracked or spalled

area in concrete. Place fastener at least 3” (three inches)

away from a spalled area to prevent the possibility of the

fastener bending and striking an operator or bystander.

14.Do not attempt to install fasteners in areas that have been

welded or cut with a torch as these procedures may have

caused local hardening of the steel.

15.Do not fasten through a pre-drilled hole unless proper

guidance is provided.

16.If you decide not to make a fastening after the tool has

been loaded, you must always remove the powder load first

followed by the fastener.

17. Never attempt to override the safety features of this tool.

18.Stay Alert, watch what you are doing, and use common

sense. Do not use tool when you are tired or under the

influence of drugs or alcohol.

19.Maintain proper footing and balance. Do not over reach.

20.Check that no one is present directly behind or below the

work surface.

Handling the Tool And Powder Loads

1. Never leave a loaded tool unattended. Once the tool is

loaded, make the fastening immediately or unload the tool.

2. Always unload the tool before work breaks, changing parts,

cleaning or servicing, and when storing.

3. To prevent accidental discharge of loads, never carry the

powder loads in the same container as the fasteners or

other hard objects.

4. Always store the powder loads in the containers provided

or in an enclosure provided for them. Never intermix the

various power levels. Keep them segregated in clearly

identified containers.

5.

Powder loads should never be used in firearms. They are normally

more powerful that the cartridges supplied with the firearms.

6.

Powder actuated tools and powder loads should always be stored

under lock and key. Tools must be unloaded when not in use.

Tool Malfunction

1. In the event that a load fails to discharge after the trigger

is pulled, the tool must be kept depressed against the

work surface for a minimum of 30 (thirty) seconds in case

of a delayed load discharge. Then carefully remove the

entire load strip. and dispose of it in a can of water or

other nonflammable liquid. Never attempt to force or pry a

load out of a tool chamber.

2. Never discard unfired powder loads into a trash container.

3. Do not attempt to unload or disassemble a jammed,

stuck or broken tool as improper handling may cause

it to discharge and strike operator and/or bystander. A

jammed tool must be pointed in a safe direction at all

times. Tag the tool and lock it up. Call your MASTER

representative for proper assistance.

Tool Operation

Be sure to read and understand all of

the safety precautions and training in this manual before

attempting to operate the tool. (Check to be sure the tool is

not loaded, the piston moves freely within the barrel, and no

foreign objects or fasteners are in the barrel.) Perform the

daily function test before using the tool.

Operation

R2200

1. Always point the tool in a safe

direction away from bystanders

and the operator. Slide the barrel

forward. This can be done by

snapping your wrist. The barrel should be pulled fully

forward to reset the piston for the next fastening. Loss of

power may result from an im properly positioned piston.

2. Always load the fastener before inserting powder load to

prevent injury to the operator or bystanders in the event of

an accidental discharge. Place the fastener, point out, into

the end of the nose piece until the fluted tip fits inside.

Do not use excessive force when inserting the fastener. If

excessive force is required, stop and determine why the

fastener can not be inserted. Correct the problem before

proceeding.

Do not use fasteners longer than 3” as

listed in the fastener selection section of this manual.

3. Make sure the breech is clear. Insert

the powder load starting with the

lowest power level. If this Load does

not fully set the fastener, try the next

higher power level until the proper

level is found.

Over driving or over powering a fastener can

cause a safety hazard.

4. Pull the barrel all the way back to

close the tool. Do not attempt to

close the tool by exerting force on

the front of the nose piece. Never

place your fingers or hands over

muzzle bushing. The safe position for hands and fingers

Model DG307

MASTER

Page 7

DG307

7

are as shown in the diagram. Hands must never be

placed in front of the tool muzzle or nose piece. In the

event of an accidental discharge, the piston and/or

fastener can pass through the operators hand.

5. Once the tool is in the closed

position, place it against the work

surface. Hold the tool firmly with

two hands and completely depress

the barrel. Then squeeze the

trigger. Always hold the tool perpendicular to the work

surface. Hold the tool firmly against the work surface to

avoid excessive recoil. Never depress the tool against

anything except the work surface.

In the event that the load does not discharge

after the trigger is pulled, continue to hold the tool depressed

against the work surface for at least 30 (thirty) seconds in

case of a delayed load discharge. Then carefully remove the

entire load strip and dispose of it in a can of water or other

non flammable liquid. Never attempt to force or pry a load

out of a tool chamber. Do not discard unfired loads into a

trash container.

6. To prepare for the next fastening, point the tool in a safe

direction. Snap the barrel forward as described in step 1.

This action will eject the spent powder load and properly

reset the piston. Always insert a new fastener before

loading powder load in the chamber. Do not attempt to

unload or disassemble a jammed, stuck or broken tool

as improper handling may cause it to discharge and

strike operator and/or bystander. A jammed tool must be

pointed in a safe direction at all times. Tag the tool and

lock it up. Call your MASTER representative for proper

assistance.

Maintenance & Cleaning

MAKE SURE THE TOOL IS NOT LOADED.

BE SURE THE TOOL IS NOT HOT PRIOR TO ATTEMPTING

DISASSEMBLY OR CLEANING.

Daily Function Test

Check the functioning of the tool, without a powder load

or fastener in the tool, by pushing down against the work

surface, pulling the trigger, and releasing the tool from the

work surface. Function the unloaded tool several times and

insure that the breech parts and firing mechanism operate

freely before fastening with the tool.

Your MASTER Authorized representative should be asked to

assist the first time you disassemble and clean your tool.

If you ever have any trouble reassembling the tool, or have

any doubt about worn parts, call your MASTER Authorized

Powder Distributor.

Cleaning

AIl parts should be cleaned with detergent oil and the wire

brushes supplied with your tool kit. Remove heavy dirt buildup with the brush. After cleaning with oil, all parts should be

wiped thoroughly dry. Excess oil will tend to collect dirt and

dust. Wear eye protection when cleaning the tool. The piston

rod, barrel assembly, and receiver should all be cleaned of

excess dirt on a daily basis. Check the condition of the piston

for damage from wear and deformation.

To maintain this tool in good working condition, it is

necessary to disassemble and clean the entire tool if dirt

is evident in the breech face, or if the tool appears to lose

power. All parts should be cleaned with oil and wire brushes.

Remove heavy dirt. All parts should be wiped thoroughly dry

after cleaning with oil.

General tool mainte nance should be performed at six

month intervals or more frequently as required by the

frequency of tool use.

Replacing or Repairing the Piston

The piston is an expendable part and must be replaced

periodically. Typical signs of a worn out piston are: breaking,

bending or mushrooming. Prior to

servicing the tool make sure there is no

powder load in the tool. Use caution and

do not lose or damage any tool parts.

1.

Loosen the cap on the reset pin by

turning it counter clockwise. Remove the

reset pin cap.

2.

Hold the barrel in place, then remove

the reset pin spring and reset pin.

3. Slide the barrel from the receiver by

pulling it forward. If excessive dirt is built

up inside the receiver, clean it with a wire

brush.

4. Unthread the nose piece from the

barrel by turning it counter clockwise.

Pull the piston forward out of the barrel.

If a vise clamp is used

to hold the barrel, protect the bar

rel from

damage.

5. Clean the piston using a wire brush.

Inspect it for worn or damaged piston ring,

chipped end, or bending. Apply lubricant to

the piston shank to minimize piston sticking

from an overdrive con dition. Wipe the piston

dry.

6. If a piston tip is damaged, it can be

shortened a maximum of 0.20 inches.

The tip of the piston should be grooved

flat and at 90 degrees to the shank of

the piston. The cham fer of the piston

must also be reground as shown.

Piston

grinding should be performed by qualified per sonnel using

the proper equipment.

Reassembly:

7. Press the piston into the barrel.

Thread the nose piece into the barrel

and tighten it clockwise until finger tight.

Be sure the nose piece is fully seated.

8. Align the slot in the barrel with the

reset pin opening in the bottom of

the receiver. Insert the barrel into the

receiver. Insert the reset pin, and reset

pin spring. Tighten the reset pin cap

clockwise until it is finger tight and fully seated.

Upon reassembly of the tool perform the following test.

Depress the tool against a flat, hard surface and pull the

trigger. The barrel assembly should slide smoothly inside the

tool receiver. The firing pin should release after the trigger has

been pulled.

THIS TEST SHOULD BE PERFORMED

WITHOUT A PIN OR POWDER LOAD IN THE TOOL.

1

2

3

4

5

10°

0.120"

6

7

8

Model DG307

MASTER

Page 8

DG307

8

Troubleshooting

ALWAYS CHECK INSTRUCTION MANUAL FOR PROPER ASSEMBLY OF PARTS

PROBLEM POSSIBLE CAUSE SOLUTION

Fastener Overdriving Power level too high / Pin too short Use a lower powder load level number or a longer pin

Soft base material Check base material suitability section

Tool does not fire Tool not depressed completely See “Tool does not depress completely” section below

Firing pin damaged Replace damaged part(s)

Tool does not depress completely Damaged firing pin parts, ejector, etc. Parts

assembled improperly

Check the parts for damage or improper assembly

Power reduction or inconsistent

fastener penetra

tion

Barrel is not pulled fully forward when

cycling tool.

Barrel must be pulled out completely to properly reset

the piston

Worn or damaged piston Replace piston or piston ring

Load strip cannot be

inserted into tool

Improper loading Insert strip from the bottom of the tool handle

Wrong caliber strip Use proper strip

Load strip will not advance Worn advance lever guide Replace advance lever guide. This should be performed

by qualified individuals

Load will not fire when

trigger is pulled

Tool is not fully depressed Follow safety procedure for misfired load then attempt to

fully depress tool before pulling trigger

Load will not fire when tool is fully

depressed and trigger is pulled

Load is already fired Cycle tool

Load misfire Follow safety procedure

Broken firing pin Replace firing pin nut. This should be performed by

qualified individuals

Broken or missing Replace firing pin nut. This firing pin nut should be

Tool cannot be opened

or cycled

Lack of proper cleaning Clean tool thoroughly

Damaged or bent piston Remove and replace piston

Broken or damaged parts Tag tool with warning “Defective - Do Not Use” place in

locked container and contact your MASTER Authorized

representative for service

Piston stuck in the forward

position

Piston has been overdriven and is jammed

against piston reset pin

Tap the piston against a hard surface

Chipped or damaged piston Tool not held on work surface squarely.

This allows the piston to slip off the head of

the pin and cause damage to the piston

Machine piston as shown on page 11. Piston regrinding

may be performed only by

qualified individuals

Piston guide will not open easily Bent shear clip Remove and replace shear clip

Excessive build-up of dirt Disassemble and clean tool

Piston stop is damaged Replace piston stop

Foreign material jammed between the

piston guide and steel liner assembly

Disassemble and remove foreign particles

Piston guide opens too easily Annular ball spring or steel annular ball

have worn

Remove and replace with a new spring and/or ball

#

Model DG307

MASTER

Page 9

DG307

9

☐

Check the correct answer

1 It is necessary to read the Operator’s Manual prior

to operating a MASTER low velocity tool.

☐

True ☐ False

2 When fastening into concrete, the base material

should be greater than the shank penetration by at

least: ☐1 time ☐2 times ☐3 times

3 When operating a powder actuated tool, your hand

should never be placed:

☐

around the tool body

☐

in front of the tool muzzle

☐

over the tool handle

4 To determine the suitability of a base material, use

the fastener as a center punch.

• Ifthefastenerisblunted,donotfasten;thematerial

is too:

☐

soft

☐

hard ☐brittle

• Ifthefastenerpenetrateseasily,donotfasten;the

material is too:

☐

soft ☐hard ☐brittle

• Ifthematerialcracksorshatters,donotfasten;the

material is too:

☐

soft ☐hard ☐brittle

5 Unsafe applications for powder actuated tools may

be caused by which of the following?

☐a soft base material

☐improper powder load

☐fastening too close to an unsupported edge

☐a malfunctioning tool

☐fastening into a spalled area

☐

fastening through a pre-existing hole

☐all of the above

6 Which one of the following building materials is not

suitable as a receiving material (base material) for

powder actuated fasteners?

☐

sheet rock ☐ wood ☐fiberglass

☐

sheet metal ☐all of the above

7 When considering the safety of a particular

application, the operator must think about:

☐

the base material

☐

the powder load power level

☐

the operator’s safety

☐

the safety of bystanders and fellow workers

☐

all of the above

8

The proper loading procedure is: insert fastener first,

powder load second. The fastener should always be

placed in the tool prior to the load.

☐

True ☐False

9

Which one of the following materials is usually

suitable for powder actuated fastenings?

☐

poured concrete ☐hollow tile

☐

surface hardened steel ☐glazed brick

10

In concrete, a fastener should be driven no closer to

an unsupported edge than:

☐

1/2” ☐1-1/2” ☐3”

11

Fishhooking is a condition which can occur when

a powder actuated fastener strikes a piece of hard

aggregate or very hard concrete, bends and comes

out of the work surface. A fishhook can cause a

serious injury or death.

☐

True ☐False

12

Placing a hand over the muzzle bushing of a

loaded tool can result in serious injury from piston

overdrive or an escaping fastener if the tool is

discharged accidentally.

☐

True ☐False

13

Piston overdrive is caused by overpowering of

the tool or by discharging the tool against a soft

surface.

☐

True ☐False

14 Malfunctioning tools cannot be used and must be

removed from service immediately.

☐

True ☐False

15 After conducting a Center Punch Test,the best

way to check the base material is to set several

fasteners using the least powerful load.

☐

True ☐False False

16 Eye protection and hearing protection should not be

worn by the operator and any necessary bystanders

when using the tool.

☐

True ☐False

17 A powder actuated tool cannot be safely used in an

explosive or flammable atmosphere.

☐

True ☐False

18 List the proper powder load level number

(1-6) next to each color listed.

Red ___ Brown ___ Green ___

Yellow ___ Gray ___ Purple ___

19 The weakest power level should be used when

making the first fastening.

☐

True ☐False

20 You can fasten into welded areas of steel.

☐

True ☐False

DG307

• Theproperprocedureifapowderloadfailstoignite

is to hold the tool against the work surface and wait

30 seconds, then proceed exactly as directed in the

Operator’s Manual.

☐

True ☐False

• MASTER powder loads for the P2100 are .22

caliber, “A” tapered, neck down, rim fire, short

crimped cartridges. No other powder load may be

used in this tool. ☐True ☐False

• Operators should never compress the DG307 or

any other powder actuated tool against any part of

their body. ☐True ☐False

• IfapistonbufferfortheDG307 becomesdeformed,

simply remove it, and use the tool without the

buffer? ☐True ☐False

OPERATOR’S NAME

HOME ADDRESS

AGE DATE OF BIRTH

COMPANY NAME

COMPANY ADDRESS

COMPANY PHONE

SIGNATURE DATE

Qualified Tool operaTor examinaTion

LICENSE AND WARRANTY ACTIVATION

THE DG307 TOOL IS WARRANTED FOR 3 YEARS FROM DATE OF PURCHASE ON MANUFACTURERS DEFECTS.

I certify that I have read and understand the DG307 Tool Operating Instruction Manual and have taken the Operator’s exam. I understand the

importance of following all safety procedures and that failure to read, comprehend, and follow the detailed rules and warnings regarding the

safe operation of powder actuated tools can result in serious injury or death to the tool operator or bystanders. I agree to conform to all the

rules and regulations regarding the use of powder actuated tools. (Please print clearly)

THE SERIAL NUMBER ON MY TOOL IS:

PLEASE SEND MY TOOL LICENSE TO:

NAME

ADDRESS

CITY STATE ZIP PHONE

MAIL TO:

3

TRIM ALONG DOTTED LINE, PLACE IN ENVELOPE, ADDRESS AS SHOWN AND AFFIX POSTAGE

#

Model DG307

MASTER

Loading...

Loading...