Page 1

AC 24

Installation manual

Rev. 1.0

EN

Rev. 1.0

Page 2

Declaration of Conformity

Dantherm S.p.A

Marienlystvej 65

DK - 7800 Skive

Tel.: +45 96 14 37 00

Fax: +45 96 14 38 00

Declaration of following product:

Product name: AC 24

Product no.: 323043

EN

Dehumidication

The product is in conformity with the following directives:

2006/42/EC Machinery Directive

2014/35/EU Low Voltage Directive

2014/30/EU EMC Directive

2014/68/EU Pressure Equipment Directive

2011/65/EU RoHS Directive

1907/2006/EC REACH Regulation

- and is manufactured in conformity with the following harmonised standards:

DS/EN ISO 12100-1:2011 Safety of machinery - General principles for design

EN 60204-1 Safety of machinery - Electrical equipment of machines - Part 1

EN 60 335-1:2012 Household and similar electrical appliances - Safety - Part 1:

EN 60 335-2-40:2003 Household and similar electrical appliances - Safety - Part 2-40

DS/EN 61000-6-2:2005 Electromagnetic compatibility (EMC) - Part 6

DS/EN 61000-6-3:2007 Electromagnetic compatibility (EMC) - Part 6

Skive, 20/08-2018

Product manager

Lars Brodersen

VP Sales

Page 3

22.08.2018

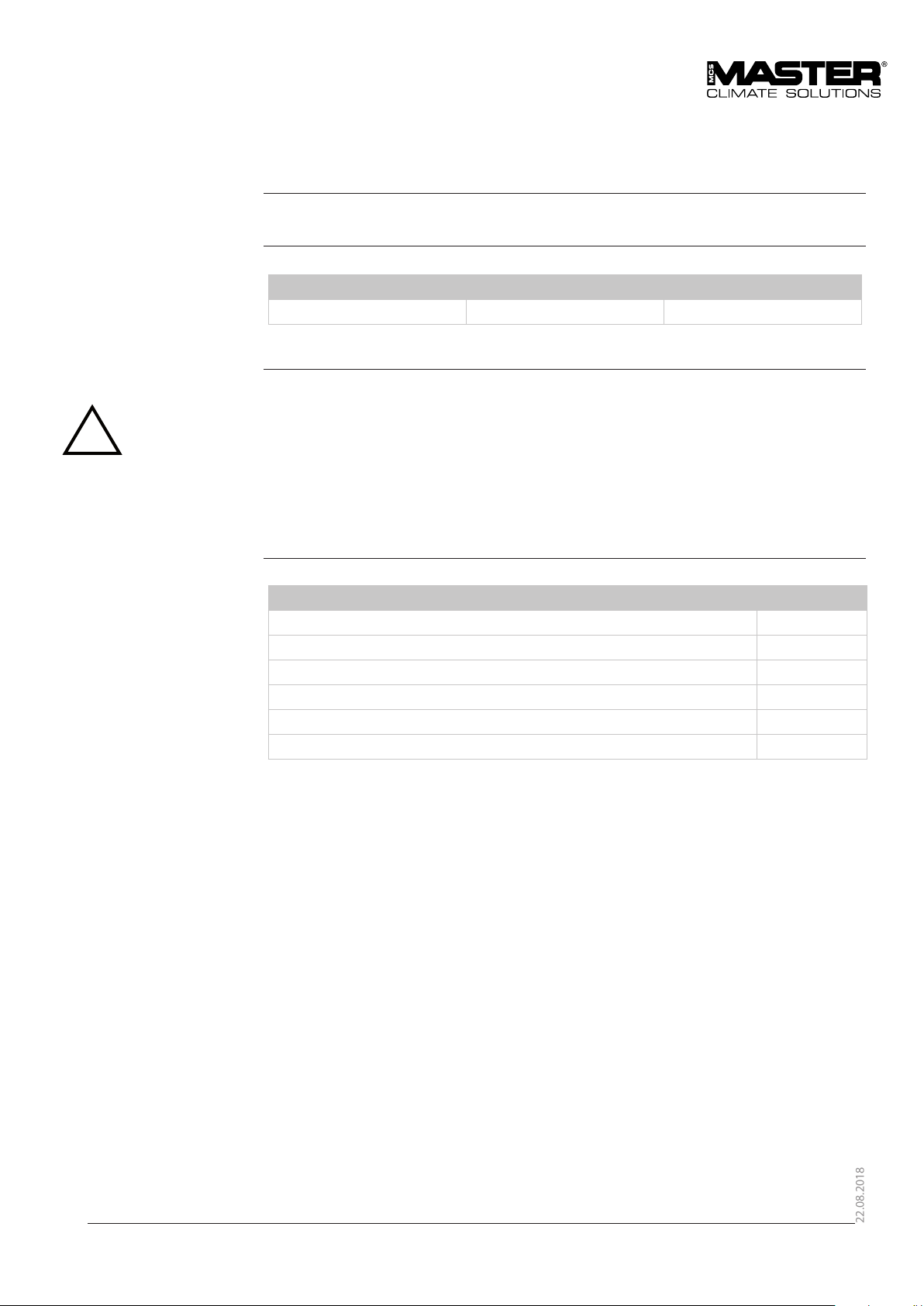

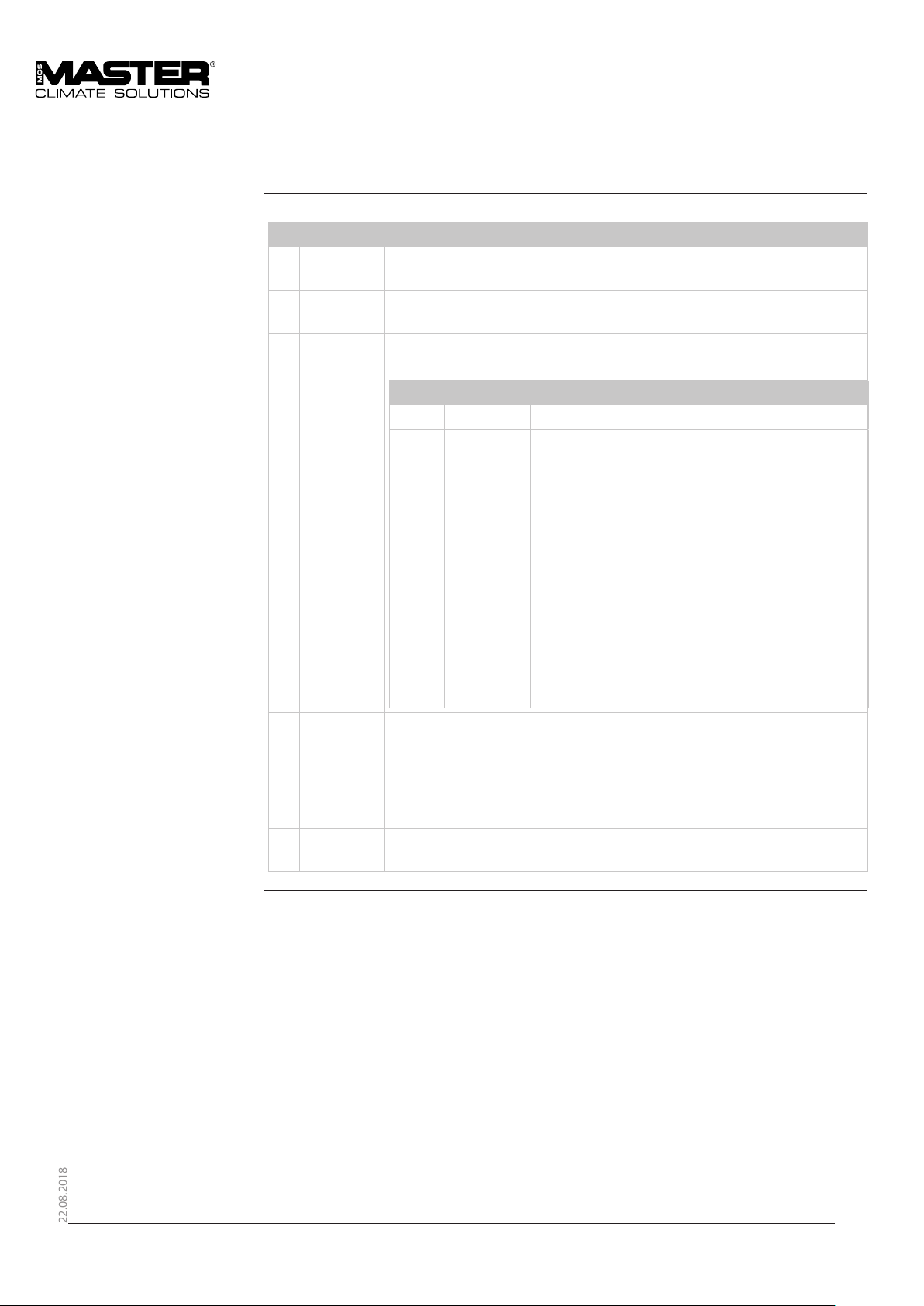

Overview

Introduction This is the service manual for the Master AC-24 unit.

The below table of contents gives an overview of the main sections.

This manual is for the unit AC 24

Dantherm Number Code NSN

323043 AC-24-B-305-R9010 * 4120-22-631-1514

*) The code is specied on the data plate, which is placed on the control panel.

See the explanation of the syntax code on page 8

WARNING It is the responsibility of the operator to read and understand this service manual and other

information provided and to use the correct operating procedures.

Air conditioners should only be operated by qualied (trained) personnel and the repair of

!

Table of main topics This service manual covers the following main topics:

the cooling circuit and electrical system is to be done only by skilled service people. Failure

to do so can result in personal injury or equipment damage.

Read the entire manual before the initial start-up of the air conditioner. It is important to

know the correct operating procedures for the air conditioner and all safety precautions to

prevent the possibility of property damage and/or personal injury.

Topic See page:

General information 4

Table of content 5

Product description 6

User’s guide 20

Service guide 29

Technical information 45

3

Page 4

22.08.2018

General information

Introduction This section gives the general information about this service manual and about the unit.

Target group • Users of the unit

• Technicians who install and maintain the unit

Part number Part number of this service manual is 097881

Copyright Copying of this service manual, or part of it, is forbidden without prior written permission from

Master.

Reservations Master reserves the right to make changes and improvements to the product and the service

manual at any time without prior notice or obligation.

Recycling The unit is designed to last for many years. When the time comes for the unit to be recycled, the

unit should be recycled according to national regulation to protect the environment.

Quality Management

System

Dantherm S.p.A has implemented a Quality Management System according to EN/ISO9001.

The system is supplemented with an Environmental Management System according to EN/

ISO14001. Both systems are approved by third party and certied, by Bureau Veritas Certication.

During 2005 & 2006 the Management Systems were supplemented with business routines

with regards to safety. These routines meet the requirements stated in the international

standard for Safety Management Systems OHSAS18001.

4

Page 5

22.08.2018

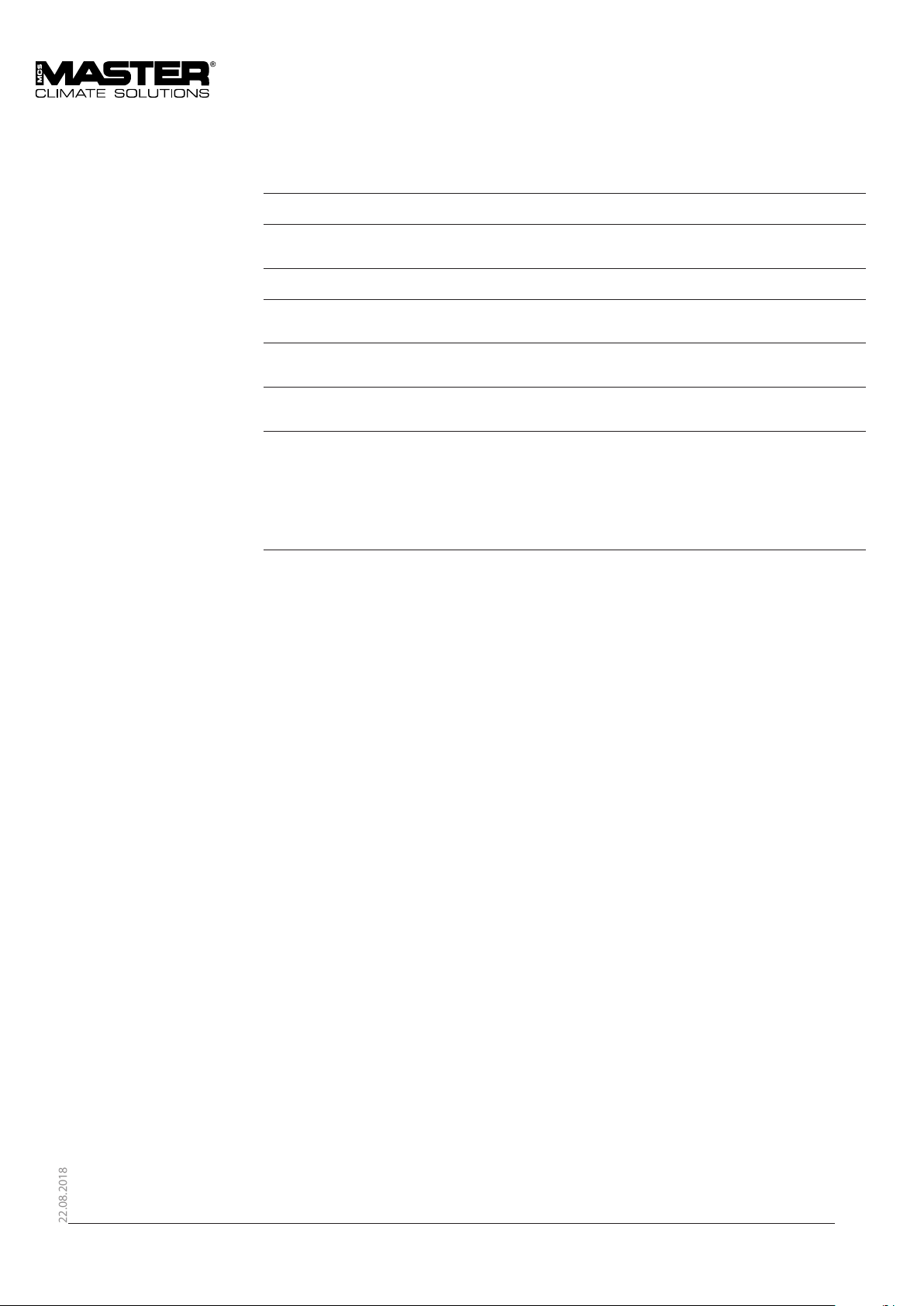

Table of contents

Table of content

Product description See page

General description 8

Transport of the unit 8

Description of parts 8

Syntax 9

Description of the cooling system 10

Description of the control board 15

Description of room thermostat 17

Description of the high and low pressure switch function 18

Functional Description 19

User´s guide

Preparations 21

Setup 22

Recommended camp conguration 23

Transport of the unit 26

Starting up and shutting down the air conditioner 27

Reset of thermo relay and control circuit fuse 28

Service guide

Preventive maintenance 30

Spare parts 33

Fault nding guide 41

Service agreement 43

Technical information

Technical data 45

Dimensions 46

Wiring diagram, AC 24 47

Wiring diagram reference 49

5

Page 6

22.08.2018

Product description

Introduction This section will give you a description of the AC 24 and its functionality.

Content The section covers the following topics:

Topic See page

General description 8

Transport of the unit 8

Description of parts 8

Syntax 9

Description of the cooling system 10

Description of the control board 15

Description of room thermostat 17

Description of the high and low pressure switch function 18

Functional Description 19

6

Page 7

22.08.2018

General description

Introduction

General

Typical applications

Functionality

WARNING

This section describes the unit as a whole.

The following sections describe the dierent parts of the unit..

The AC 24 is a portable air conditioner that is made of high quality materials and the production process is

subject to constant quality checking. The instructions in this service manual have been prepared to ensure

that, when followed, this air condi-tioner will provide long and ecient service.

The AC 24 is designed primarily to supply cooled air to tents and other types of temporary portable

shelters.

The function of the unit is based on a cooling circuit and two powerful centrifugal fans. The lower section

contains the evaporator and the evaporator fan which draws warm ambient or recirculated air through the

cold evaporator coil and blows out the cooled air through the discharge.

The upper section of the unit houses the condenser fan and the condenser coil which returns the heat

taken from the cooled air to the surrounding atmosphere.

Do not cover, block or obstruct the air openings. This may cause malfunction!

Do not operate the product outside the specied temperature range.

See section “Technical data”.

7

Page 8

22.08.2018

General description, continued

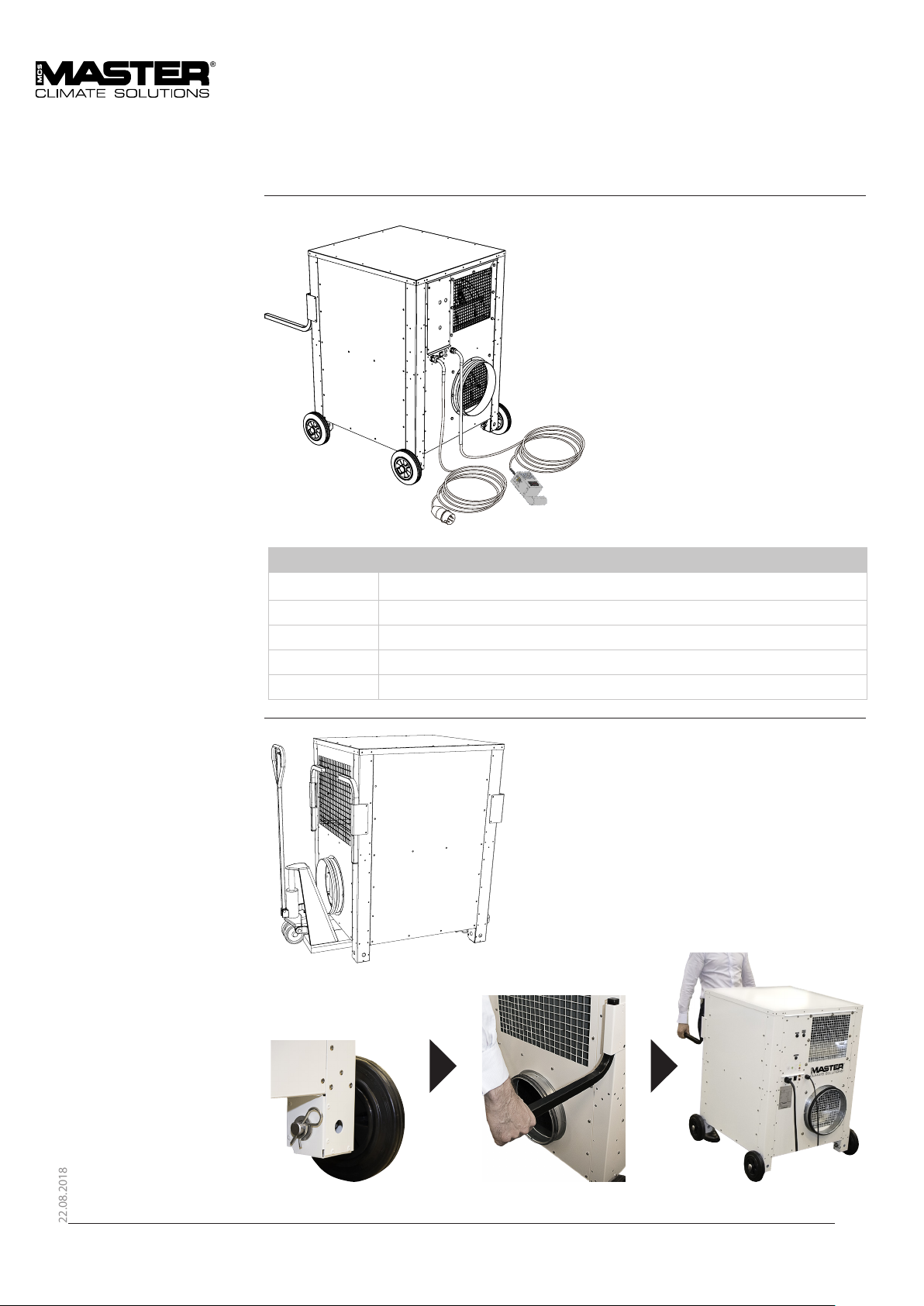

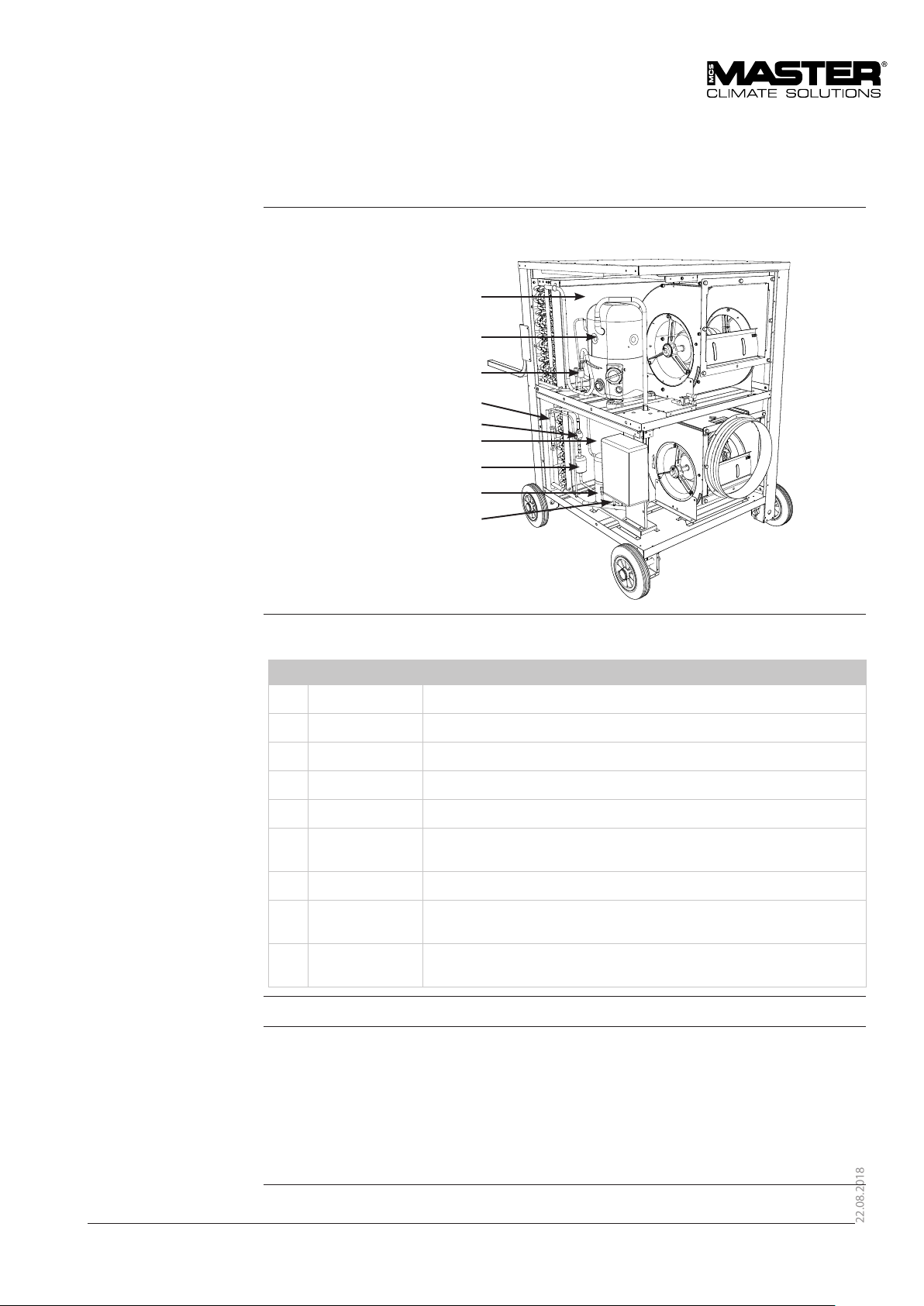

Illustration This illustration gives an overview of the unit.

Parts

Transport of the unit.

Item Description

1 Handlebars for transport ( Accessories)

2 Wheels for easy eld mobility of the unit (Accessories)

3 Control panel with function switch and lamps

4 Mains cable

5 Room thermostat

8

Page 9

22.08.2018

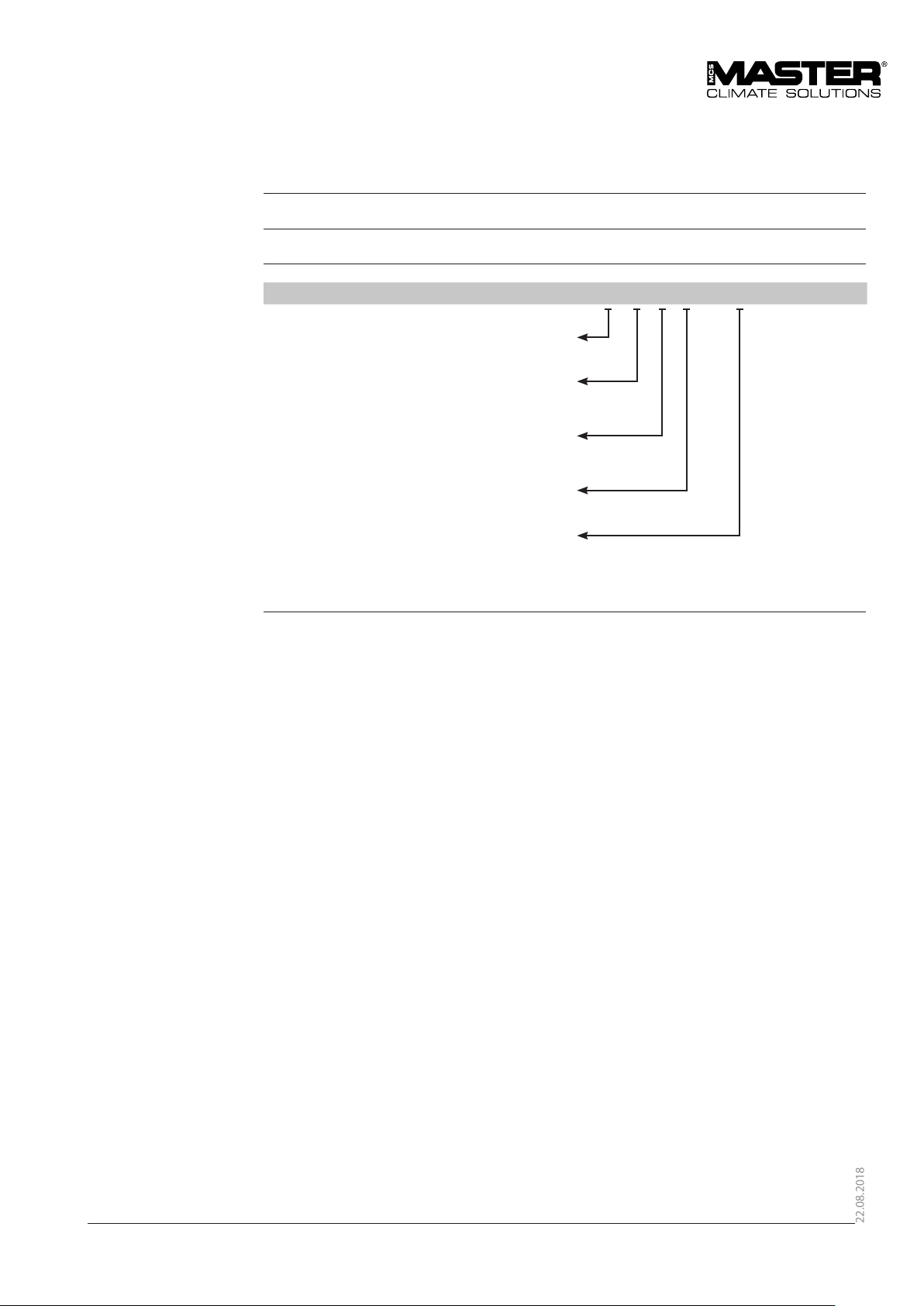

Syntax

Introduction

Example

All products are named according to a syntax giving information about the specic unit conguration.

This example is not necessarily related to the specic unit this manual describes:

AC_24_B_305_R9010

AC Air conditioner

24 Nominal performance 24.000BTU/h

B 1ph; 230VAC; 50Hz

C 1ph; 230VAC; 60Hz

305 Duct connection size - mm

R RAL Color code

9

Page 10

22.08.2018

Description of parts

Introduction This section gives a description of the following parts of the AC 24:

• Cabinet • Fans

• Air lters • Mains cable

• Heating coil • Air openings

The following sections in this chapter give separate detailed descriptions of the cooling circuit,

the control board and operation.

For illustration of the single components – please see section “General description”

Cabinet The unit is made of strong construction in sheet metal plates which are galvanized to protect

against corrosion.

The outside paint nish is standard white, RAL 9010.

In the middle plate there is a drain outlet for condensate.

On each side of the unit a plate can be removed to make inspection and service possible.

Inside the unit there is a horizontal partition dividing it into an upper and a lower section.

Fans In both upper and lower sections there is a centrifugal fan with a direct-coupled motor.

Condenser fan

Evaporator fan

Air lters The internal airow enters through a standard washable, easily removable air lter, PPI 15.

The lter is situated behind the return air inlet

The rods keeping the lter

in place are accessible

through the fan opening

without having to remove

the cover.

The airow will be inuenced by the resistance in lters, hoses and coils, which must be kept

clean to minimize the pressure drop.

10

Page 11

22.08.2018

Description of parts, continued

Mains cable The unit requires an external electric power source.

The mains cable is 10 m long and normally has a 16 A CEE connector at its end.

Air openings

Varm air outlet

Cold air intake

Cold air out

Hot Air intake

11

Page 12

22.08.2018

Description of parts, continued

Air openings, continued

WARNING Do not cover or obstruct air openings!

inlets/outlets Purpose

Supply air outlet,

1 × 315 mm

Return air inlet,

1 × 315 mm

Ambient air inlet Ambient air is ducted in through the

Exhaust air outlet Condenser exhaust air leaves the air

Air is supplied to the tent/shelter through

these openings.

Flexible air hose(s) will be connected here

Air is drawn into the unit through this/these

opening(s). With connected air hose(s) the

unit is supplied with recirculated return air

from the tent/shelter

Flexible air hose(s) will be connected here

condenser after entering the external

removable lter

conditioner

through these openings

12

Page 13

22.08.2018

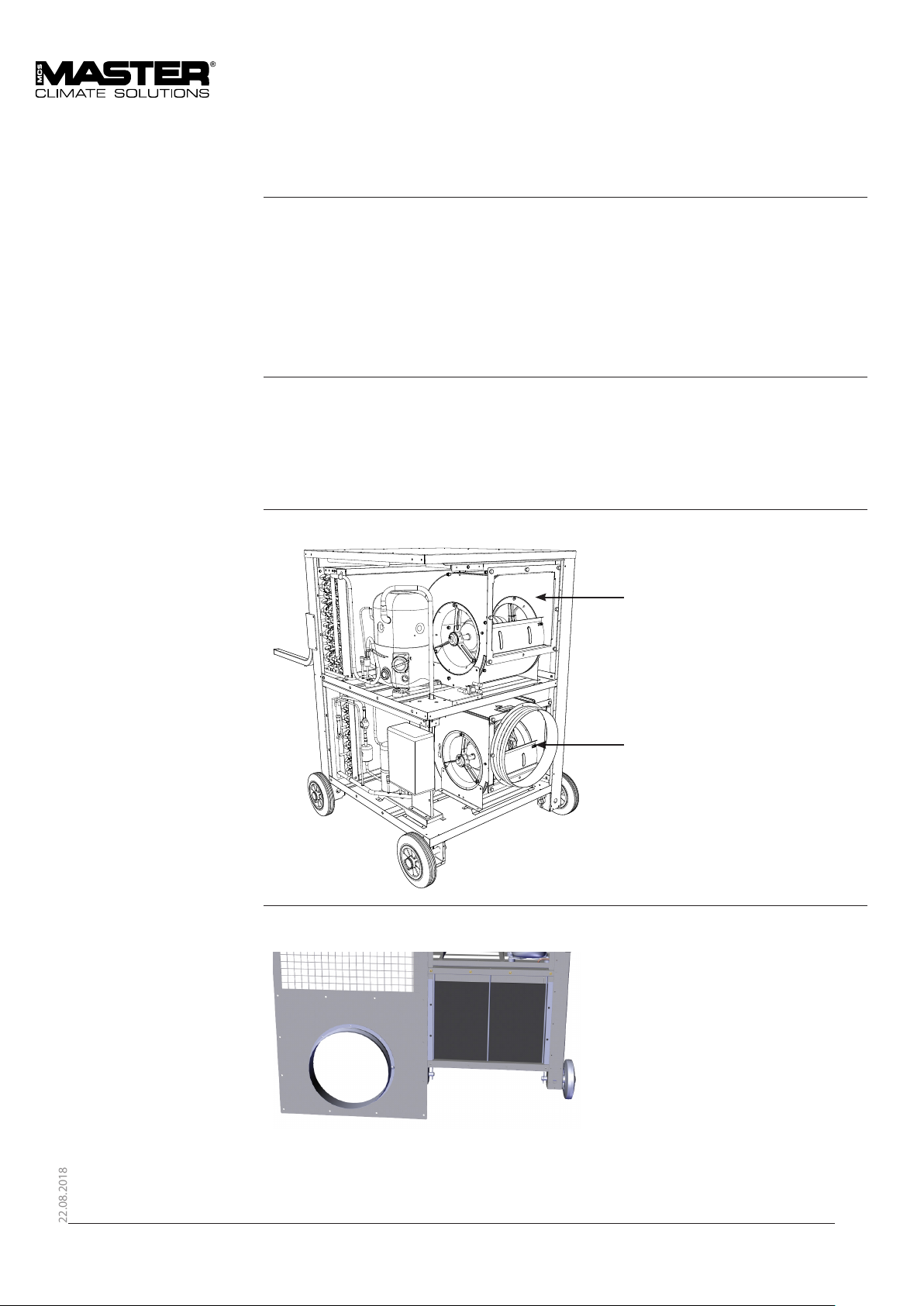

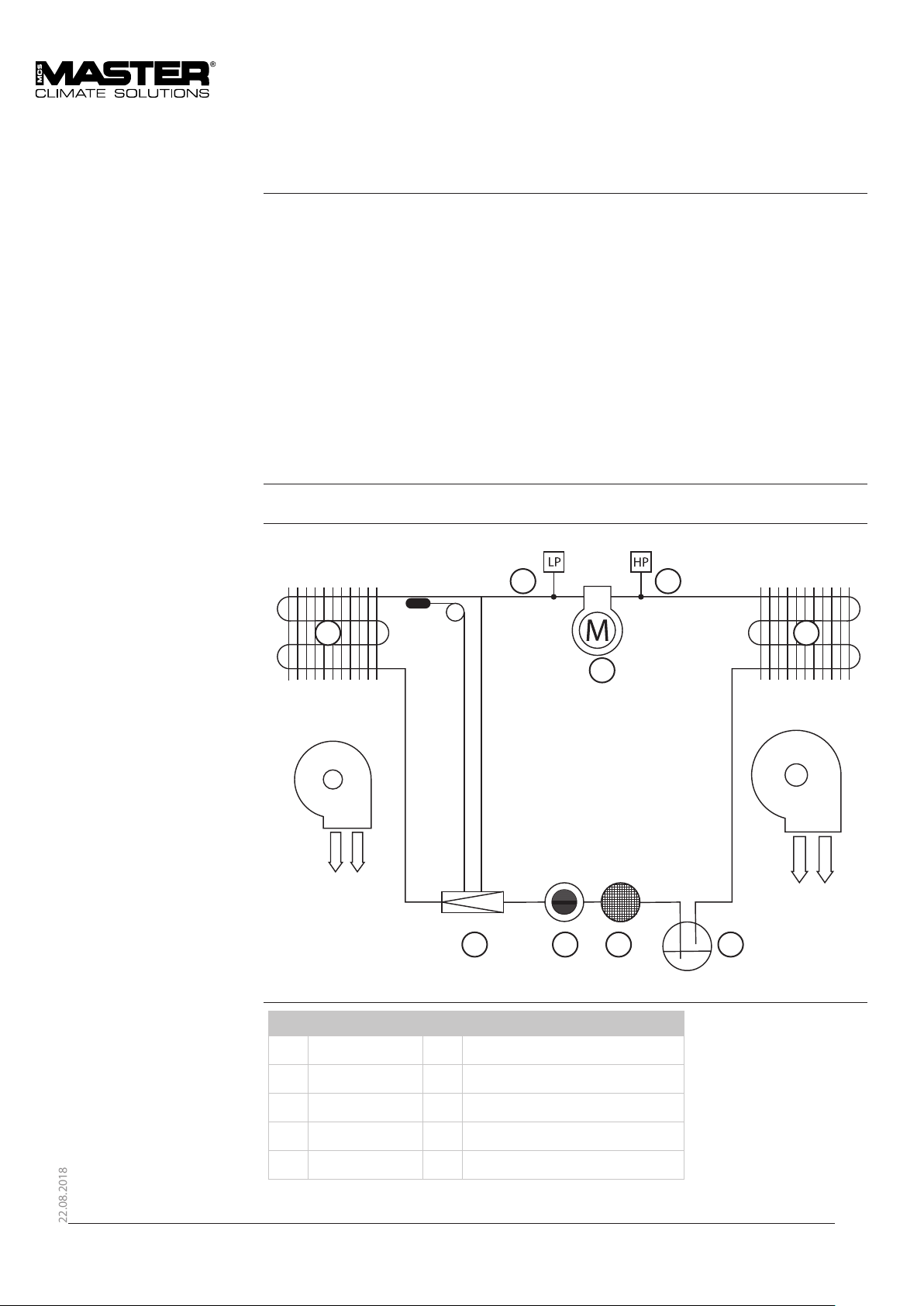

Description of the cooling system

Illustration This drawing illustrates the dierent parts

of the cooling circuit and where

they are situated in the AC 24 unit:

Parts and their function This table gives an overview and short description of each part shown above and on

the next page:

Compressor Circulates the uid in the cooling system

Condenser Emits the heat generated in the tent/room to the outside air

Receiver Accumulates surplus coolant in connection with the cooling process

Dry lter Absorbs moisture and impurities in the cooling circuit

Sight glass Enables a visual check of the coolant

Expansion valve Supplies the correct quantity of coolant into the evaporator. It also

Evaporator Absorbs heat from the shelter by cooling down the circulated air

HP pressure

switch

LP Pressure

switch

Refrigerant The cooling circuit is hermetically sealed and lled with refrigerant (R134a).

Liquid ow

From the receiver liquid refrigerant will ow under high pressure through the liquid line

dryer and the sight glass to the thermostatic expansion valve which releases the pressure. Here

the refrigerant is led into the evaporator where it evaporates under low pressure and low

temperatures.

The evaporated refrigerant is drawn back to the hermetic compressor and compressed. From

the compressor the refrigerant vapour goes to the condenser, where it is cooled to below the

dew point and condensed to liquid refrigerant.

reduces the pressure

Ensures that the compressor does not operate at too high pressure

Ensures that the compressor does not operate at too low pressure

13

Page 14

22.08.2018

Description of the cooling system, continued

Description Both evaporator and condenser are heat exchangers with copper tubes and aluminium coated

ns. By the cooling of the evaporator air stream heat is adapted to the cooling circuit and

released in the condenser together with the electric energy consumption of the compressor.

At room temperatures below 20 °C, where cooling is not normally required, the humidity in

the airow will form ice on the evaporator. To prevent this, the LP pressure switch cuts out

at low pressure in the circuit. If the room temperature is too low, the LP activation will cause

the compressor to start and stop frequently. This may damage the compressor and must be

avoided at any time by not operating the product outside the specied temperature range. See

section “Technical data”, page 54. At high ambient temperatures (above 55 °C) the cooling of the

condenser airow will be too poor, and the high pressure results in cut out of the HP pressure

switch.

The yellow lamp on the front panel will illuminate if the HP/LP pressure switch cuts out. The HP/

LP pressure switch automatically resets after a few minutes and the lamp will switch o again. If

the lamp continues to illuminate, please refer to the “Fault nding guide”, page 50.

Schematic view This schematic drawing illustrates the dierent parts of the cooling circuit.

9 8

7

Compressor

Condenser

Receiver

Dry lter

Sight glass

Expansion valve

Evaporator

HP pressure switch

LP pressure switch

2

1

3456

14

Page 15

22.08.2018

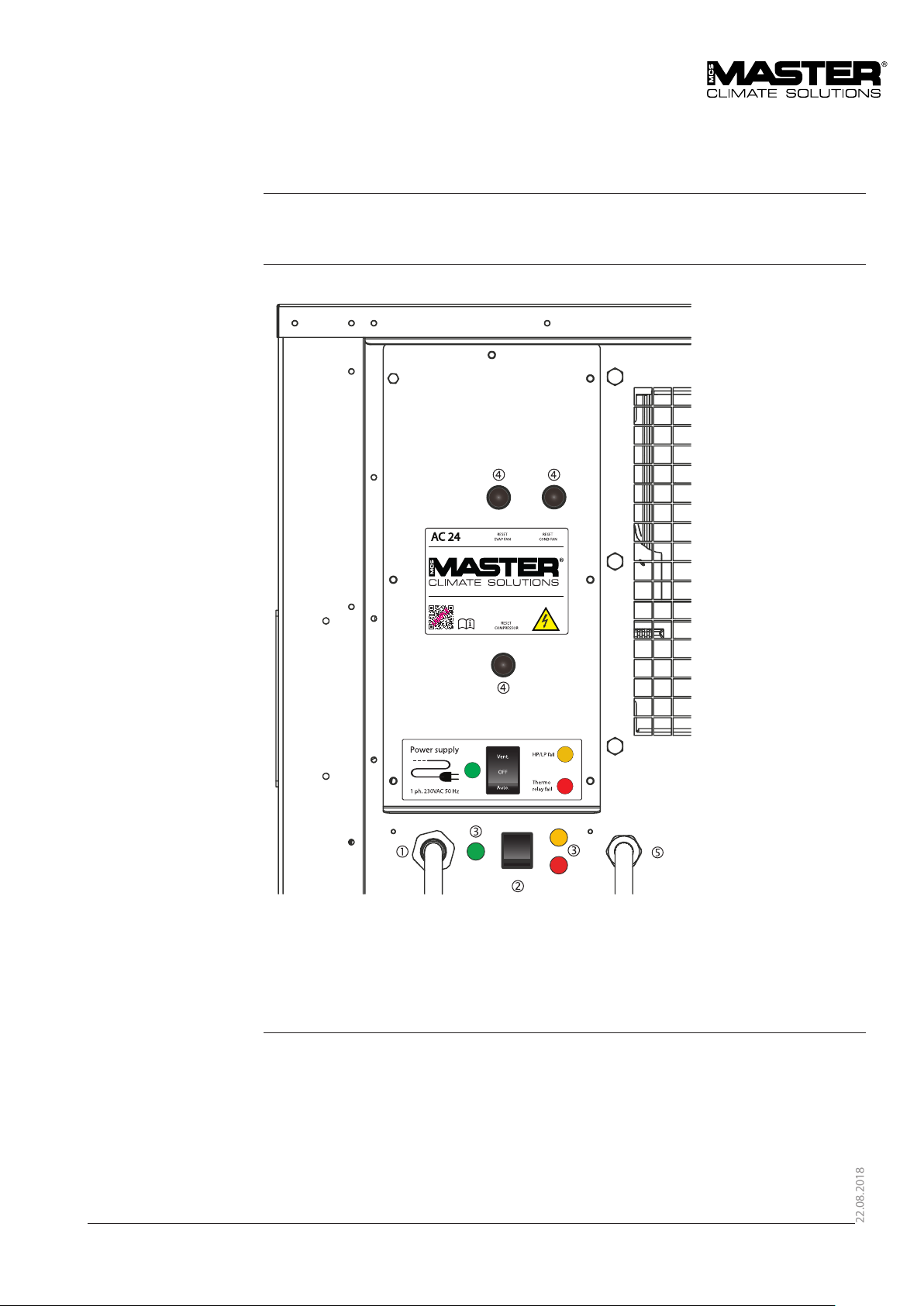

Description of the control board

Introduction This section gives a description of the control board.

A description of how to start up, for example, is found in the relevant sections.

The control panel on the front contains the controls required for normal operation.

Illustration This drawing illustrates the control board of the AC 24:

15

Page 16

22.08.2018

Description of the control board, continued

Part/function This table gives an overview of each part of the control panel in g. 6:

No

Part Function

Electric

connection

Function

switch

Indicator

lamps

Mains cable with a 16 A CEE connector at the end

The function switch selects the operating mode and has three positions:

VENT, OFF and AUTO

On the operator panel there are three control lamps, indicating the

following:

Color Unit Description

Green Power Shows that power has been connected to the unit

Red Thermo

relay fail

Illuminates if the compressor, evaporator fan or

condenser fan thermo relay has cut o because of a

too high running current.

Please also refer to the “Fault nding guide”

Yellow HP/LP Illuminates when the built-in HP/LP pressure switch

cuts out and stops the com-pressor because of too

high pressure (HP) or low pressure (LP) in the cooling

circuit. The HP/LP pressure switch automatically

resets after a few minutes. Do not let the product

operate with HP/LP switching ON and OFF.

If the lamp continues to illuminate, please refer to

the “Fault nding guide”

Reset

button

•Compressor

•Evaporator fan

•Condenser fan

Thermostat

connection

If the failure indicator (Thermo relay ) illuminates, the thermo relay will

have to be reset on one of the reset buttons.

If it is not clear which one of the thermo relays has disconnected, push the

reset buttons one by one.

See also “Fault nding guide”

Cable for the remote thermostat

16

Page 17

22.08.2018

Description of room thermostat

Introduction This section gives a detailed description of the room thermostat.

Illustration This drawing illustrates the dierent

parts of the room thermostat:

Sensor

Parts and their function

Location The thermostat must be placed inside the tent.

No Part Function

Knob Setting of the temperature

Scale Shows the temperature setting

Scale Shows the dierential temperature setting

14 m cable -

See more about the placement in section “Set-up”

17

Page 18

22.08.2018

Description of the high and low pressure switch function

Introduction This topic describes the HP/LP function.

System protection The cooling system is protected by pressure switches. If the pressure falls outside of the

normal operating range, the air conditioner compressor is automatically switched o. This is to

prevent component damage. If the pressure is too high or too low, the unit is switched o. The

malfunction must normally be identied by a trained technician and corrected.

Reset The HP/LP pressure switch automatically resets after a few minutes.

If the lamp continues to illuminate, please refer to the “Fault nding guide”.

LP (low pressure) The cooling system is protected by a low-pressure switch (LP switch). The switch is set at 1 bar

and will automatically reset at 2.5 bar. The safety function cuts o the com-pressor.

The LP function will be activated if:

• The cooling system loses refrigerant

• The internal temperature is so low that the low pressure gets below set point (1 bar).

Do not operate the product with frequent operating LP function.

• The evaporator is blocked or does get not sucient air ow

HP (high pressure) The cooling system is protected by a high-pressure switch (HP switch). The switch is set at 25 bar

and will automatically reset at 18 bar. The safety function cuts o the compressor.

The HP function will be activated if:

• The outdoor temperature is too high

• The condenser is blocked or does not have sucient airow

18

Page 19

22.08.2018

Functional description

VENT

Ventilation-only operation

AUT. or AUTO

Room thermostat operation,

cooling/heating (if installed)

OFF or 0 OFF

With the function switch in this position the evaporator fan will operate continuously and the

cooling unit, heating coil (if installed) and condenser fan will be turned o.

This mode can be used to bring in fresh outdoor air or to recirculate the indoor air - even when

cooling or heating (if installed) is not needed.

With the function switch in this position, the unit will operate according to the room thermostat

settings.

On the AC 24 with heating coils the room thermostat has a ip switch with the following

positions:

• Cool

With the ip switch in the cool position, the unit will cool as long as the thermostat senses a

temperature higher than the set point. When the temperature reaches the set point it cuts o

the compressor and fans.

With the function switch in this position all functions will stop immediately and only the

illuminated green lamp will indicate that the power is still on if the main switch is on.

19

Page 20

22.08.2018

User’s guide

Introduction This section describes how to utilise the dierent functions.

WARNING Do not try to restart the compressor several times within a short period.

This will make the compressor overheat and may damage it. The internal compressor

thermostatic protection may also cut out.

Operating the product outside the temperature range specied in the technical data will

cause the cooling system to start frequently.

Do not operate the product at temperatures outside the specications.

Warning If forklift (MHE) is to be used it is imperative that the tine is fully engaged, thereby supporting

the entire unit. Rough and incorrect handling can cause damage and loss of function.

Contents This User`s guide contains the following topics:

Topic See page

Preparations 21

Setup 22

Recommended camp conguration 23

Transport of the unit 26

Starting up and shutting down the air conditioner 27

Reset of thermo relay and control circuit fuse 28

20

Page 21

22.08.2018

Preparations

Location Follow these conditions when siting the air conditioner:

Conditions

Place in the shade as close as possible to the tent/shelter that needs to be ventilated

Place the air supply ducts in both ends of the tent/shelter

Allow sucient space around the air conditioner for operating and servicing access

Avoid sharp bends or kinking when locating air supply ducts in order to avoid disrup-tion of

the airow (see “Recommended camp conguration”, page 23)

Keep any source of engine exhaust fumes (vehicles/generators etc.) away from air in-takes

Air distributing channels It is imperative that the cooled air is distributed equally inside the tent/shelter. For that purpose

the use of air distributing hoses are recommended (accessory).

Power The air conditioner requires 1 x 230 V AC/50 Hz.

The mains cable is 10 m long and has a 16 A CEE connector at the end.

Note The maximum combined length of exible air hoses should not exceed 9-10 m.

21

Page 22

22.08.2018

Setup

Procedure

Step Action

1 Find a suitable location for the air conditioner as described on previous page.

2 Supply ducts.

Connect the exible insulated air hoses to the evaporator discharge openings and

insert the opposite end of the hose to the tent. If there are any internal distribution

hoses in the tent, these can be connected too

3 Return ducts.

A return air hose may be connected from the shelter to the evaporator air inlet. As

long as the return air is colder than the ambient air this will save cooling capacity

4 Place the room thermostat inside the tent/shelter at the optimal location

• Avoid sunlight

• Avoid direct cold air from the air conditioner ducts

• 1.5 m above the oor

• Near the return air end of the tent/room

5

• Set the desired temperature

in the shelter by pressing the

buttons on the thermostat.

In cooling mode – do not

require less than 20ºC which

would make the unit operate

outside its´ specied limits.

6 Check that the function switch is set at “0” or „OFF“

7 Check that the power switch is OFF

8 Connect the CEE plug to the external power source and switch on

22

Page 23

22.08.2018

Recommended camp conguration

Introduction The conguration is an important factor for gaining the highest performance and reliability from

the air conditioner including lowest power consumption. A camp can be set up in various ways

and still work, but a few important hints will be given in this section.

This section describes the following:

• Ducting

• Solar heat

• Air distribution

• Sand storms

• Air re-circulating

Ducting The ducts will introduce a pressure loss every

time they are bent. Slight bends are not as

critical as tight bends > 45°.

The shorter the ducts the higher performance

frmo the air conditioner.

In some cases the tent does not allow for

ducting as per the air conditioner design. Be

aware that blocking one or two of the duct

holes on the air conditioner will reduce the

cooling performance signicantly.

Use as few ducts as possible. As a rule of

thumb expect that each 3 m insulated duct

changes the temperature inside the duct by

3-5 °C (6-10 °F).

Solar heat Solar heat gain to shelter surfaces and to duct-/air conditioner reduces the eciency of the

unit. If possible use a sun shield to cover the shelter, the air conditioner, and the associated air

ducting. Additional eciency is gained by using insulated panels/liners in the shelter.

• Doors and openings

• Heat sources

• Surroundings

• Drains

23

Page 24

22.08.2018

Recommended camp conguration, continued

Air distribution In cases where air distribution plenums are used for distributing the internal cooled air, it can be

an advantage if the plenum is located under the roof.

The cold air will slowly fall to ground and be sucked back into the air conditioner.

Sand storm In case of sand storms it is important that the air conditioner is shielded against the sand.

Do not shield to the extent where the air ow will become obstructed.

Air re-circulating In order to cool down the air most eciently, the air being introduced to the air conditioner

must be as cold as possible. If the room temperature is lower than the am-bient temperature

outside, it is most ecient to re-circulate the air from the room. To do so, connect insulated

ducts between the tent and the air conditioner internal air in-take.

If the tent temperature is higher than the ambient temperature, it can be an advantage to

operate without return ducts. Also be aware of the dust risk and generation of over pressure in

the tent.

24

Page 25

22.08.2018

Recommended camp conguration, continued

Doors and openings In order to achieve best performance it is imperative that doors and openings are kept closed.

Heat sources Heat producing sources will degrade the eciency of the air conditioner and thus non-

essential heat sources should be turned o whenever possible.

Surroundings Do not cover, block or obstruct the air path. Make sure that the air conditioner is clear of

obstruction on all sides allowing air to be drawn in and exhausted out freely.

25

Page 26

22.08.2018

Recommended camp conguration, continued

Drain Water draining from the evaporator will saturate the area around the drain outlet. Pay attention

to this potential problem and route away condensate if necessary. If possible raise the air

conditioner above ground level by use of a pallet or other suitable means.

WARNING

Do not park vehicles where exhaust gases can be drawn into the air intake of the AC-24

26

Page 27

22.08.2018

Starting up and shutting down the air conditioner

Start up After preparation and set-up the air conditioner is ready for operation.

Turn the function switch to the desired mode (see “Description of the control board”, page 14)

and the unit will operate according to the “Functional description”,

Fault If the unit does not operate it might have been switched o by a safety device:

• HP pressostat: High ambient temperature stopped condenser fan or reduced airow

over the condenser

• LP pressostat: Low return air temperature stopped evaporator fan or reduced airow

over the evaporator

• Evaporator or condenser thermo relay: Running current for fan motor too high

• Compressor thermo relay: running current for compressor too high

• ETA relay: running current for control current too high

Refer to the “Fault nding guide”, for possible solutions.

WARNING Do not attempt to repeatedly restart the compressor.

This will cause the compressor to overheat and may damage it.

The internal compressor thermostatic protection may also cut out.

Shutting down Follow this procedure to shut down the air conditioner from any mode of operation:

1. Turn the function switch to OFF/0

Result: All operations will stop immediately

2. Disconnect the connector from the power source if any servicing has to be performed.

If the air conditioner is not to be re-used for a long period, continue shutting down as

follows:

3. Disconnect the air ducts and stow them in their compression sacks.

27

Page 28

22.08.2018

Reset of thermo relay and control circuit fuse

Introduction The procedures below describe how to reset the thermo and replace the control circuit fuse.

Thermo relay If the running current for the compressor, condenser fan or evaporator fan exceeds the set value,

the thermo relay will switch o the compressor or fan and will have to be reset.

Reset Thermo relay Push the buttons one by one in no particular order to reset the thermo relay.

See buttons marked with arrows below.

Control circuit fuse If the running current for the control circuit is too high, the fuse will blow, and will have to be

replaced. See location below.

28

Page 29

22.08.2018

Service guide

Contents

Topic See page

Preventive maintenance 30

Spare parts 32

Fault nding guide 40

Service agreement 42

29

Page 30

22.08.2018

Preventive maintenance

Introduction In order to achieve the best possible operation and long lifetime of the air conditioner it has to

be maintained properly within dened guide lines.

This section contains the description of daily, monthly and annual maintenance.

Tools For service and maintenance no special tools are required.

A 10 mm spanner and a at headed screwdriver are sucient for most maintenance tasks.

CAUTION Before doing any maintenance, be sure that the air conditioner has been shut down and that

the power cable is disconnected from the unit.

See section “Starting up and shutting down the air conditioner”

Daily preventive

maintenance

Daily preventive

maintenance

Preventive maintenance to be carried out daily or every 8 hours of operation:

After shutdown each day or after every eight hours of operation perform the following

preventive maintenance procedures:

Preventive maintenance to be carried out daily or every 8 hours of operation:

After shutdown each day or after every eight hours of operation perform the following

preventive maintenance procedures:

Step Action

1 Inspect electrical cables for damage or loose connections

2 Inspect the air lter and remove any debris or foreign objects that may have

accumulated on lters.

3 Inspect air hoses for damage or sharp bends

30

Page 31

22.08.2018

Preventive maintenance, continued

Monthly preventive

maintenance

Step Action

1 Perform daily maintenance as described on previous page.

2 Remove the air lter which have to be vacuum cleaned or washed in lukewarm soapy

water.

The evaporator lter is easily removed. In order to remove the lter material, Remove

the three exible plastic rods holding the lter in place . Access the rods through

the duct hole. Make sure that the lter is dry before it is returned to service and are

subjected to dust.

Annual preventive

maintenance

3 Remove the two side cover plates and inspect the evaporator and condenser coils.

If they are dirty vacuum clean or wash with warm soapy water and a brush

4 Check that the condensate drain is not blocked

5 Inspect and clean the radial wheels in the two fans if necessary

Step Action

1 Perform daily and monthly maintenance as described

2 Have a refrigerant mechanic check the cooling circuit and all electrical functions

This control must follow the national rules for control of cooling equipment.

31

Page 32

22.08.2018

32

Page 33

22.08.2018

Spare parts

Introduction This section contains the general information needed when ordering spare parts.

For units in military services spares will normally be ordered through the military logistic

system.

When ordering When ordering, kindly inform us about:

• Dantherm S.p.A. spare parts number/text

• NATO stock number of parts

• Dantherm S.p.A. eld unit type

• Dantherm S.p.A. production and serial number from the data plate of the eld unit

(or approximate date of delivery).

Information If it is part of a group naturally forming a whole or part of a purchased, complete component,

ome items may not be available for individual delivery.

Dantherm S.p.A reserve the right to make this assessment.

Reservations Dantherm S.p.A. reserve the right to make any necessary changes of construc-tion and choices

of components without notice - but will, as far as possible, maintain a stock of the changed

parts.

Contents

Topic Page

Spare parts for cabinet 34

Spare parts for cooling system 36

Spare parts for controller 38

Accessories 40

33

Page 34

22.08.2018

Spare parts for cabinet

Illustration Available spare parts

1.6

1.9

1.7

1.3

1.8

1.5

1.4

1.1

1.2

1.3

34

Page 35

22.08.2018

Spare parts for cabinet

Cabinet

Cabinet Art.No. Name NSN

1.1 098820 Sideplate right/left 4130-22-632-1603

1.2 098822 Rear plate with hose connection 4130-22-632-1606

1.3 098823 Hose connection 5999-22-632-1609

1.4 098824 Filter mounting 5340-22-632-1612

1.5 081579 Filter 4130-22-632-1614

1.6 093803 Roomthermostat complete. 5930-22-632-1619

1.7 081582 Condenser fan 4140-22-632-1622

1.8 075499 Evaporator fan 4130-22-632-1626

1.9 098830 Front for controller 4130-22-632-1664

35

Page 36

22.08.2018

Spare parts for Cooling system

Illustration Available spare parts for cooling system

2.1

2.32.2 2.4

36

2.5

2.6 2.7 2.8 2.9

2.10

2.2 2.11

Page 37

22.08.2018

Spare parts for Cooling system

Cabinet

Cabinet Art.No. Name NSN

2.1 081580 Condenser coil 4130-22-632-1665

2.2 063125 Service valve 4820-22-632-1667

2.3 298976 Low Pressure switch (LP) 5930-22-632-1668

2.4 098840 Compressor cpl. 4130-22-632-1670

2.5 091283 Evaporator coil 4130-22-632-1672

2.6 081631 Thermostatic valve 4820-22-632-1677

2.7 063123 Sight glass 6680-22-632-1679

2.8 298974 Filter drier 4130-22-616-3541

2.9 063128 Reciver 4130-22-632-1682

2.10 098868 Capacitor for Compressor 5910-22-632-1683

2.11 086414 High Pressure switch (HP) 5930-22-632-1684

Note: All spare parts for cooling system includes lter drier.

37

Page 38

22.08.2018

Spare parts for Controller

Illustration Available spare parts for controller

3.1

3.2 3.3

3.5

3.4

3.10

3.6

3.7

3.8

3.9

3.12

3.11

38

Page 39

22.08.2018

Spare parts for Controller

Cabinet

Cabinet Art.No. Name NSN

3.1 081686 Transformer 6120-22-632-1689

3.2 098858 K1 - Contactor Cpl. 6110-22-632-1709

3.3 098859 K2 - Contactor Cpl. 6110-22-632-1710

3.4 098860 K3 - Contactor Cpl. 5945-22-632-1712

3.5 098861 Fuse Block 5920-22-632-1713

3.6 098862 Fuse 10 pcs. 5925-22-632-1714

3.7 098863 Terminal block cpl. 5940-22-632-1726

3.8 098864 Controller front 1670-22-632-1727

3.9 064274 Cable gland set 5975-22-620-1668

3.10 091287 Controller for Roomthermostat 4130-22-632-1696

3.11 091288 Sensor for Roomthermostat 6685-22-632-1698

3.12 098865 Power supply cable 6150-22-632-1699

39

Page 40

22.08.2018

Accessories

Accessories

Art. No. Description Illustration

096673 Wheel set and handles

097754 Hose Ø320mm L. 3000mm

097756 Air distribution hose

Ø320mm L. 5000mm

098108 Hose ties

3x

Nato Stock Number

4520-22-631-7709

2x

4x

4720-22-631-7710

4720-22-631-7163

5340-22-631-7711

093894 Handles

5340-22-631-7708

2x

40

Page 41

22.08.2018

Fault nding guide

Fault nding Malfunctions that might occur in the operation of the air conditioner are listed in the table

below. Reference to actions required to restore the air conditioner to normal op-erating

condition are also indicated.

If the air conditioner should malfunction, nd the problem in column 1. Columns 2 and 3

describe the possible causes and corrective actions. The list of problems, causes, and remedies

will only give an indication of where a possible problem can be and what actions are needed to

correct the problem.

Problem Cause Action

Air conditioner does not

operate

Green indicator lamp on

control panel is not ON

No power input Check that the power cable is

correctly connected to power

source and unit. Check that

power source is turned on and

providing 1 x 230 V AC

Controller fuse is blown. Replace fuse.

Location shown on page 27

Air conditioner (compressor)

does not operate.

Green and yellow HP/LP

indicator lamps are on, but

they switch o again after a

few minutes

Air conditioner (compressor)

does not operate.

Green and yellow HP/LP

indicator lamps are on, and

they do not switch o after a

few minutes

Compressor does not operate

Green and red THERMO RELAY

indicator lamps are on

High ambient temperature

resulting in HP pressure switch

cut-out

Reduced condenser airow

perhaps combined with

ambient temperature just

below 55 °C

Reduced evaporator airow

perhaps combined with low

ambient temperature resulting

in LP pressure switch cut-out

Faulty thermostatic valve A refrigeration engineer has to

Refrigerant leak on the cooling

circuit

Compressor thermo relay has

cut o

The HP pressure switch will

automatically reset when

the ambient temp. has fallen

below 55 °C.

Hereafter the unit will restart

Clean evaporator coil and

airow lter Check that the

grill at the air outlet are not

blocked

replace the valve.

A refrigerant engineer has to

check on the problem

Press the reset button for

compressor on the control

panel (see section “Reset of

thermo relay”, page 27)

41

Page 42

22.08.2018

Fault nding guide, continued

Fault nding, continued

Condenser or evaporator fan

does not operate.

Green and red thermo relay

indicator lamp are on

WARNING Do not try to restart the compressor several times within a short period. This will overheat

and may damage the compressor. The internal compressor thermostatic protection may also

cut out.

High ambient temperature If the surrounding temperature is higher than the max working temperature: 55 °C, the

condenser will not be cooled enough, resulting in too high pressure in the cooling circuit and

thereby operating the pressure switch (HP). Allow some time for cooling of the system.

Low ambient temperature If the air conditioner is operating below 20 °C the humidity in the airow can form ice in the

evaporator coil. As the ice is insulating, the pressure in the cooling circuit will decrease until the

pressure switch (LP) operates. In this case the mode selector should be turned to ventilationonly so that the evaporator coil can be defrosted by the airow.

Reduced airow A reduced airow can be caused by dirty lters or sharp kinks in the air hoses etc.

This can result in activation of the pressure switch (LP). Check the unit.

Problem Cause Action

Fan thermo relay has cut o Press the reset button for

the evaporator or condenser

fan on the control panel (see

section “Reset of thermo",

page 28)

42

Page 43

22.08.2018

Service agreement

Introduction The unit includes mechanical and electrical parts and the unit is often placed in a rough

environment where the components are exposed to dierent climate conditions. Therefore

the unit will need preventative maintenance on a regular basis.

The After Sales Support Department of Dantherm S.p.A. is ready to help you

in case of a problem.

To be able to oer quick and ecient help, please have the following information ready

when contacting Dantherm S.p.A. :

• Name • Phone no. • Site/location (unit)

• Company • Email • Serial no/order no.

• Country • Type (unit) • Description of the problem

Contact Dantherm S.p.A. and ask for the After Sales Support department and help

will be provided as soon as possible:

Phone: +45 96 14 37 00

Fax: +45 96 14 38 00

Email: service@dantherm.com

Preventive maintenance Dantherm S.p.A. oers to do the preventive maintenance on the units so that they at all times

will operate according to factory standards.

Corrective and

emergency repair

Setup Dantherm S.p.A. has established a network of service partners to do the preventative

Further information For further information about a service agreement in your country or region, please contact:

In case of malfunctions of the product Dantherm S.p.A. oers to do emergency repair on the

climate units. Agreements will be made with the customer on response time and price.

maintenance. The partner is trained and certied on the actual climate units. The partner will

also carry an adequate number of spare parts – so that any repairs can be made during the

same visit.

The agreement will be made with Dantherm S.p.A. – and the overall responsibility for the

agreement belongs to Dantherm S.p.A.

Claus Havboe Rasmussen

After Sales Manager

Dantherm S.p.A.

Phone: +45 9614 3725

Mobile: +45 6168 1233

Email: Claus.Rasmussen@dantherm.com

43

Page 44

22.08.2018

Technical information

Overview This section provides technical information about the AS 24 and covers the following topics:

Contents

Topic See page

Technical data 45

Dimensions 46

Wiring diagram, AC 24 47

Wiring diagram reference 49

44

Page 45

22.08.2018

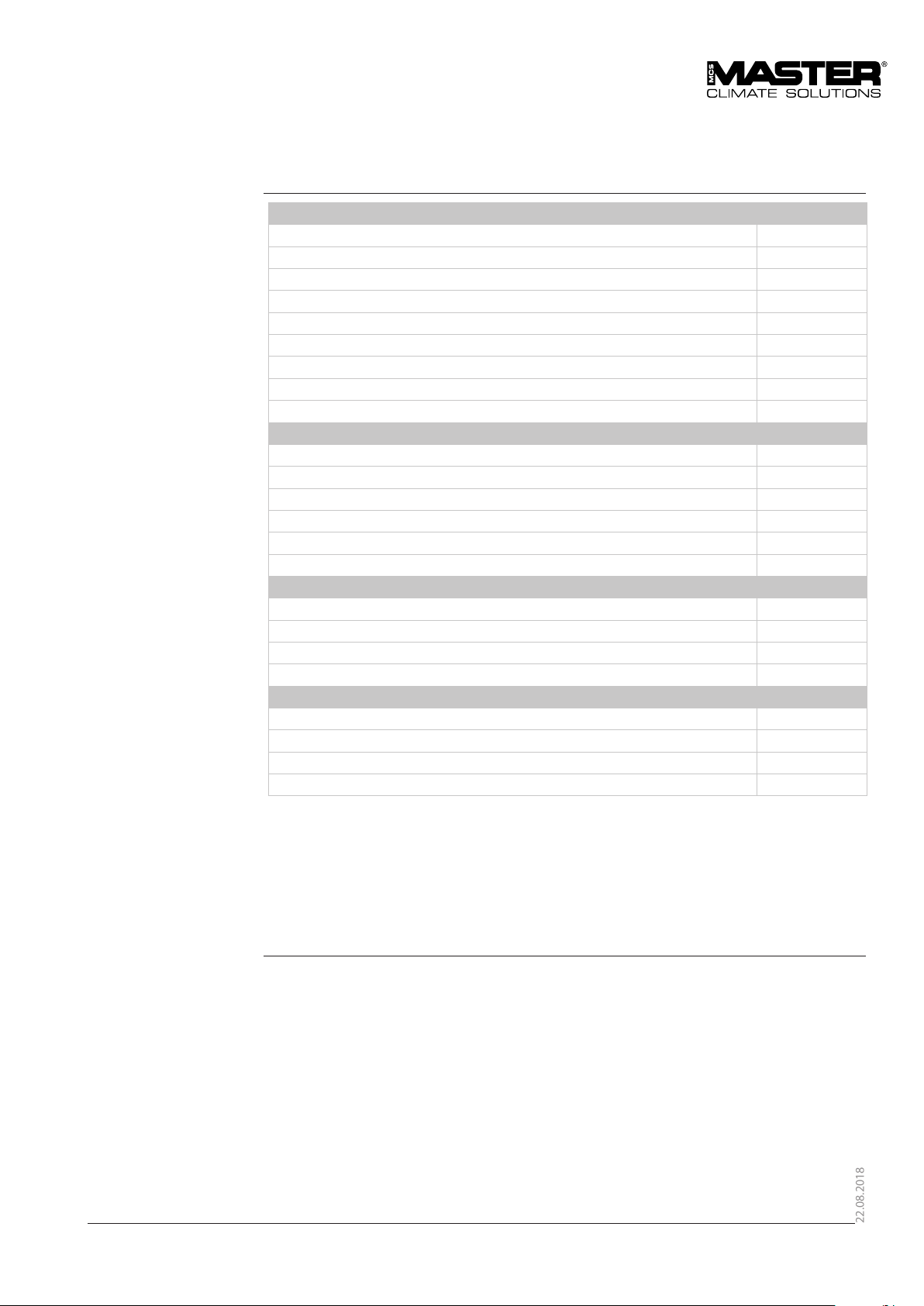

Technical data

Introduction Technical data for the AC 24 units.

*Note: All data regarding heating is only relevant for models with heating coil installed.

Performance

characteristics

The air conditioner has a maximum cooling capacity of 6.0 kW.

When the relative humidity of the air inlet is high, the air can be cooled below its dew point and

thus condense some of the water vapour to free water. This requires a certain amount of latent

cooling but provides a dehumidication process, which is an important factor in comfortable air

supply conditions.

The operating range is between 20 and 55 °C approximately and is controlled by the HP/

LP-pressure switch. In relatively dry locations the air temperature drop will depend on inlet

conditions.

Data Data and dimensions on the cabinet are shown in the following table:

Specication Designation Value 6,0 kW

Dimensions Height × width × depth

- mm

Weight kg 162

Cabinet material 0.9 mm galvanized sheet

Packaging - Wooden pallet and

Voltage supply V/PH/Hz 230/1/50

Max current Amp 16A

Airow, evaporator,

Standard setup2)

Cooling capacity, max W 6.000

m/h 2,800

1110 x 754 x 920 mm

metal plates

cardboard

Refrigerant/Load Type/kg R134a/2,3

Max. refrigerant pressure Bar 25

Operation temp. range C° 20-55

Minimum room

temperature setting

GWP

(Global Warming potential)

IP 55

Locked rotor amperange

(LRA)

C° 20

1430

A 46

45

Page 46

22.08.2018

Dimensions

Dimensions

46

Page 47

22.08.2018

Wiring diagram

Wiring diagram

47

Page 48

22.08.2018

Wiring diagram, Continued

Wiring diagram, continued

48

Page 49

22.08.2018

References

References The following references refer to the wiring diagrams on the previous pages:

Reference Description Reference Description

A El. Heating coil K1 Contactor evaporator fan

B3 HP pressure switch K2 Contactor condenser fan

B4 LP pressure switch K3 Contactor compressor

B2 OT thermostat el. heating coil K4 Contactor heating coil

B1 Limit thermostat el. heating coil K5 Timer (After run) el. heating coil

C1 Evaporator fan motor condenser M1 Evaporator fan motor

C2 Condenser fan motor condenser M2 Condenser fan motor

F1 Evaporator fan motor thermo

relay

F2 Condenser fan motor thermo

relay

F3 Compressor thermo relay S1 Function switch

H1 Green lamp “M ains” T1 Transformer

H2 Red lamp “Thermo relay” XRT Thermostat plug

H3 Yellow lamp “HP/LP” XT Control current breaker

M3 Compressor

RT Room thermostat

Master can accept no responsibility for possible errors and changes.

49

Page 50

22.08.2018

50

Page 51

22.08.2018

51

Page 52

Dantherm S.p.A.

Via Gardesana 11

37010

Pastrengo, Italy

t. +39 045 6770533

info@mcsitaly.it

Dantherm Sp. z o.o.

ul. Magazynowa 5a

62-023 Gądki Poland

t. +48 61 65 44 000

office@mcs-ce.pl

Dantherm LLC

Transportnaya 22/2

142800, Stupino

Moscow, Russia

t. +7 (495) 642 444 8

info@mcsrus.ru

Dantherm SP S.A.

C/Calabozos,

6 (Poligono Industrial)

28108 Alcobendas

Madrid Spain

t. +34 91 661 45 00

euritecsa@euritecsa.es

MCS China

Unit 2B, No. 512 Yunchuan Road Baoshang,

Shanghai,

201906 China

t. +8621 61486668

office@mcs-china.cn

Dantherm Group S.p.A

Marienlystvej 65

7800 Skive

Denmark

t. +45 99 14 90 00

Dantherm AB

Fridhemsvagen 3

602 13 Norrkoping

Sweden

t. +46 (0)11 19 30 40

Lars Skou Nielsen

Dantherm S.p.A

Marienlystvej 65

7800 Skive

Denmark

t. +45 96 14 37 00

Dantherm GmbH

Oststrase 148

22844 Norderstedt

Germany

t. +49 40 526 8790

Dantherm Ltd.

Unit 2, Galliford Road

Maldon CM9 4XD

United Kingdom

Dantherm AG

Im Vorderasp 4

8154 Oberglatt ZH

Switzerland

t. +41 44 851 51 51

Dantherm AS

Lokkeasveien 26

3138 Skallestad

Norway

t. +47 33 35 16 00

Dantherm Dubai

Suite #1009

Prism Tower,

Business Bay Dubai

United Arab Emirates

t. +971 56 831 7466

Data, descriptions and pictures are for indication only and absolutely not binding.

e Company reserves the right to modify or improve them without prior notice.

Master is a part of

Loading...

Loading...