Page 1

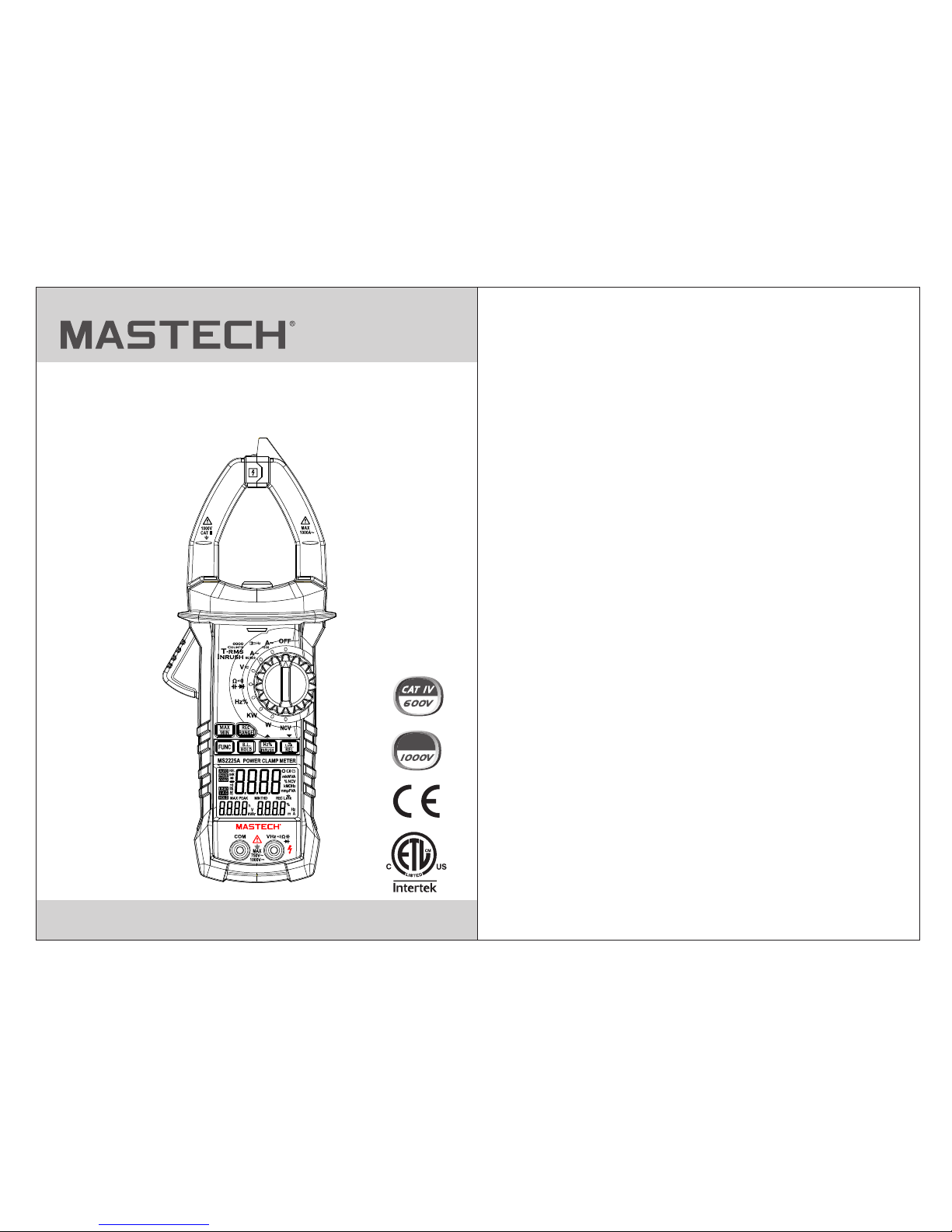

Digital Clamp Power Meter

Operation Manual

MS2225A

CAT III

Page 2

CONTENTS CONTENTS

1. Safety information ..............................................01

1.1 Preparation ...............................................01

1.2 Use ...........................................................02

1.3 Mark ..........................................................03

1.4 Maintenance .............................................04

2. Description .........................................................04

2.1 Name of parts ...........................................06

2.2 Descriptions of switch, button and input jack

..................................................................07

2.3 LCD display ..............................................09

3. Specification .......................................................11

3.1 General .....................................................11

3.2 Technical specifications ............................12

3.2.1 Alternating current .........................12

3.2.2 Inrush current ................................12

3.2.3 DC voltage ....................................13

3.2.4 AC voltage .....................................13

3.2.5 Frequency .....................................14

3.2.6 Duty ratio .......................................15

3.2.7. Resistance ...................................16

3.2.8 Circuit continuity test .....................16

3.2.9. Capacitance .................................16

3.2.10 Diode test ....................................17

3.2.11 Single-phase active power ..........17

3.2.12 Single-phase apparent power .....18

3.2.13 Single-phase reactive power .......18

3.2.14 Power factor ................................19

3.2.15 Harmonics measurement ............19

4 Operation Guide .................................................19

4.1 Reading holding ........................................19

4.2 Manual range ............................................20

4.3 Switchover of frequency and duty ratio .....20

4.4 Selection of maximum/minimum value

measurement ...........................................21

4.5 Function switching ....................................21

4.6 Measurement of relative value .................22

4.7 LINK measurement ...................................22

4.8 REC function ............................................23

4.9 ▼function ..................................................23

4.10 ▲function ................................................24

4.11 INRUSH measurement ...........................24

4.12 Back-light and clamp lighting .................24

4.13 Automatic shutdown ...............................25

Page 3

01

4.14. Measurement preparation ......................25

4.15 AC current measurement ........................26

4.16. Voltage measurement ............................28

4.17 Measuring frequency and duty ratio ........30

4.18 Resistance measurement .......................34

4.19 Diode test ................................................36

4.20 Circuit continuity test ...............................38

4.21 Capacitance measurement .....................40

4.22 Measurement of inrush current ...............42

4.23 NCV measurement ................................. 44

4.24 Active power measurement .....................46

4.25 Apparent power measurement ................48

4.26 Power factor measurement .....................50

4.27 Phase angle measurement .....................52

4.28 Harmonics measurement (voltage signal)

..............................................................53

4.29 Harmonics measurement (current signal)

...............................................................56

5 Maintenance .......................................................58

5.1 Battery replacement ..................................58

5.2 Replacing Test Leads.............................. 58

6 Attachments ........................................................59

CONTENTS

1. Safety information

Please pay special attention when using this meter,

improper use may result in electric shock or damage to the

meter. Please follow the common safety rules, and fully

comply with the safety precautions specified in the user

manual.

To make full use of the meter, and ensure safe operation,

please read carefully and follow the application methods in

this specification.

WARNING

This meter conforms to IEC 61010 Safety Requirements of

Electronic Measuring Instrument. It causes secondary pollution,

and the over-voltage standard is CAT IV 600 V and

CAT III 1000V. Please abide by the safe operation guidance to

ensure the safety use of the meter. Appropriate use and

protection of the meter will bring you satisfactory service

1.1 Preparation

1.1.1 The users must comply with the following safety

regulations when using the meter:

- General electric shock protection

- Prevent the misuse of the meter

1.1.2 After receiving the meter, check whether it is damaged in

the transportation.

1.1.3 Check and verify whether the meter is damaged after

being stored and shipped in poor condition.

1.1.4 The probe must be in good condition. Check whether the

insulation of the probe is broken and the metal wire of the

conductor is exposed before using.

Page 4

1.1.5 The probe provided with the meter can ensure the safe

use, and it must be replaced with the same probe or the

probe of the same grade, if necessary.

1.2 Use

1.2.1 You must use the meter according to requirements of

correct functions and measuring range.

1.2.2 Do not exceed the indicated value of protection scope of

each measuring range during the measurement.

1.2.3 Do not touch the top of the probe when the meter is

connected for measuring the circuit.

1.2.4 During the measurement, if the measured voltage is

higher than 60V DC or 30 V AC (effective value), you

should keep your fingers behind the probe protector all

the time.

1.2.5 Do not measure the voltage when the AC voltage

between the measuring terminal and the ground is

greater than 750 V.

1.2.6 Select the highest range of the manual range if you don't

know the measured value in advance.

1.2.7 Remove the probe from the measured circuit before

rotating the change-over switch to change the measuring

function.

1.2.8 Do not perform the live line measurement for the

resistance, capacitance, diodes and circuit continuity.

1.2.9 Do not connect the meter to the voltage source during

the current, resistance, capacitance, diodes and circuit

continuity test.

1.2.10 Do not measure the capacitance before the capacitor is

fully discharged.

1.2.11 Do not use this meter near the explosive gas, steam or

dust.

1.2.12 In case of any abnormality or fault, please stop using

the meter.

1.2.13 Do not use this meter, unless the bottom case and the

battery cover are fully fastened in situ.

1.2.14 Do not store or use this meter in direct sunlight, high

temperature, or high humidity.

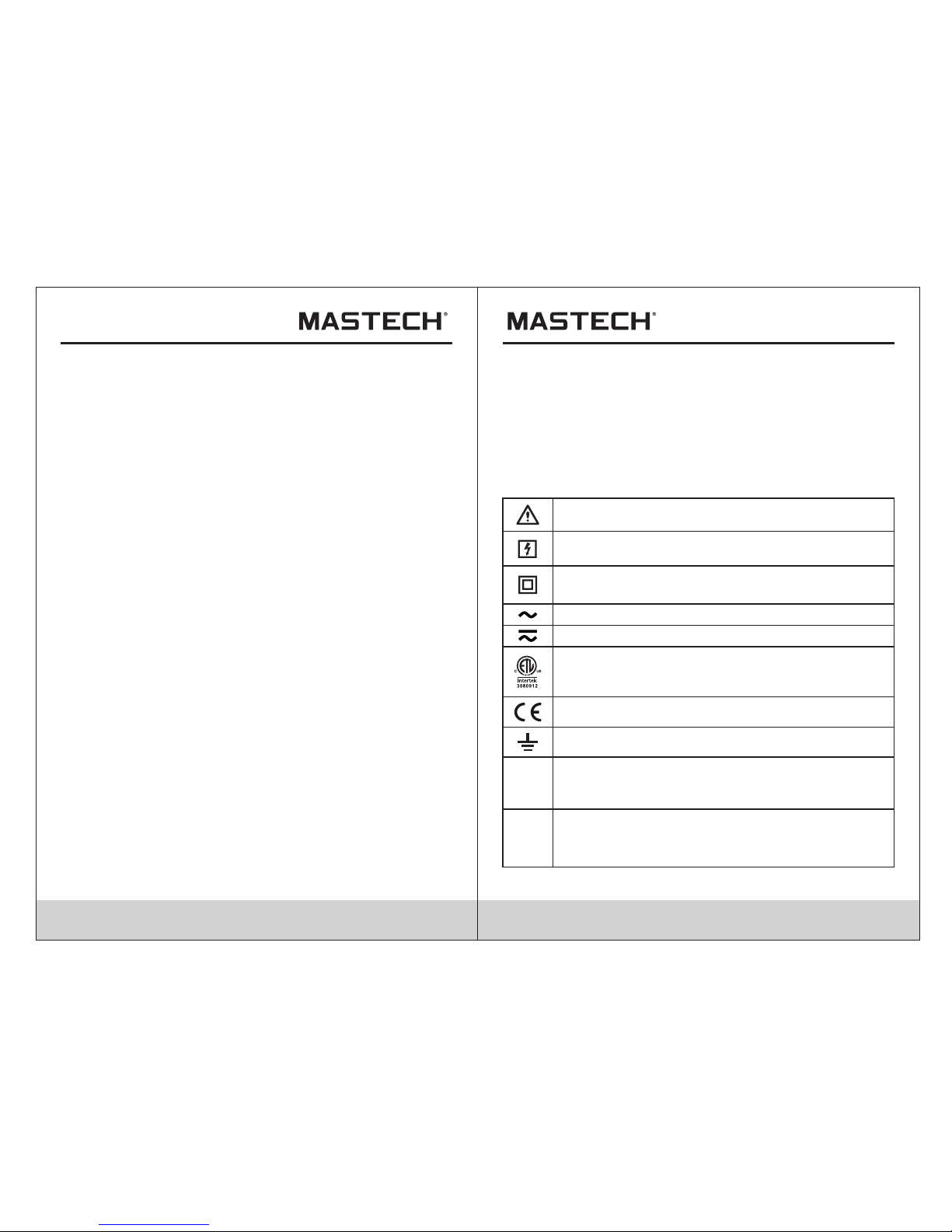

1.3 Mark

Note-Important safety information, refer to the

instruction manual.

Application around and removal from UNINSULATED

HAZARDOUS LIVE conductors is permitted.

Complies with European (EU) safety standards

Conforms to UL STD. 61010-1, 61010-2-032,

61010-2-033; Certified to CSA STD C22.2 NO.

61010-1, 61010-2-032,61010-2-033

Earth (ground) TERM INAL

CAT III

It i s applica ble to test a nd measur ing circuits

co nnected to the distributi on part of the

bu ilding's low-v oltage MA INS insta llation .

Equipment protected throughout by double

insulation or reinforced insulation.

Alternating current

Both direct a nd al terna ting cu rrent

MEASUREMENT CATEGORY IV is applicable to

test and measuring circuits connected at the source

of the building’s low-voltage MAINS installation.

CAT IV

02 03

Page 5

04 05

1.4 Maintenance

1.4.1 Do not try to open the bottom case of the meter for

adjustment or repair. These operations can only be

performed by the technicians who understand the meter

and the shock hazard adequately.

1.4.2 Please remove the probe from the measured circuit

before opening the bottom case or the battery cover of

the meter.

1.4.3 In order to avoid the electric shock caused by the

incorrect reading, when the meter displays ""

replace the battery immediately.

1.4.4 Use wet cloth and mild detergent to clean the meter, and

do not use the abrasive or solvent.

1.4.5 Turn off the power of meter when you don't use it, rotate

the range switch to the OFF gear.

1.4.6 Take off the battery to prevent the damage to the meter,

if you do not use it for a long time.

2. Description

-MS2225A single-phase clamp-type harmonic power meter is

hand-type intelligent power measuring meter, which combines

the digital multimeter and power measurement with Bluetooth

function. The range switch with one-handed performance is

convenient for the measurement, and this meter can perform

the functions of overload protection and low battery indicator.

- The meter can be used for the measurement of the

alternating current, alternating voltage, direct voltage,

frequency, duty ratio, resistance and capacitance and circuit

continuity, diode test, non-contact voltage detection, as well as

the measurement of the active power, reactive power,

apparent power, power factor, harmonics measurement and

phase angle measurement.

- The meter supports the auto range and manual range.

- The meter supports reading holding.

- The meter supports maximum measurement.

- The meter supports minimum measurement.

- The meter supports relative measurement.

- The meter supports Bluetooth.

- The meter supports data storage.

- The meter supports back-light and clamp lamp.

- The meter supports automatic shutdown.

- The meter supports low voltage indicator.

Page 6

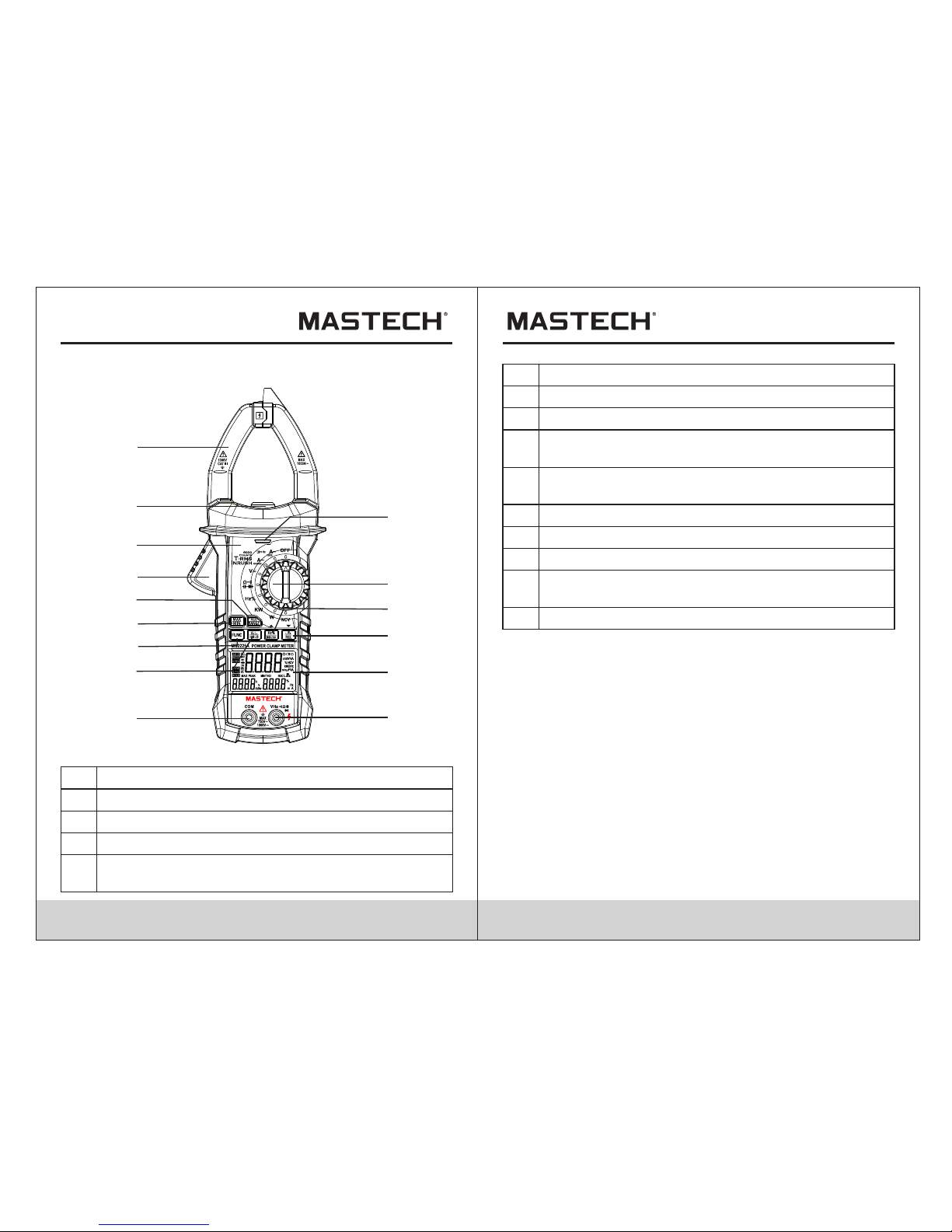

2.1 Name of parts

(1)

Current clamp: for current measurement.

(2)

Clamp lamp

(3)

Faceplate

(4)

Trigger

(5)

Button for data storage and switch of auto and

manual range

(6)

Button for maximum/minimum selection

(7)

Button for function switch

(8) Button for reading holding/back-light

(9)

Button for frequency and duty ratio measurement,

inrush current and up

(10)

Button for Bluetooth function, relative

measurement and down

(11) Change-over switch

(12) NC V indic ator li ght

(13)

LCD display

(14)

Input jack of resistance, capacitance, voltage,

frequency, di ode and c ontin uity.

(15)

Jack of common terminal

12

11

1

2

3

4

5

6

7

8

14

9

10

13

15

2.2 Descriptions of switch, button and

input jack

FUNC button: for switching the measurement function.

B.L/HOLD button: the readings will be held by the short press,

and the back-light will be turned on by long press. The backlight and clamp lamp will be turned on at the same time by

pressing the B.L/HOLD button in the current gear and in the

power gear on the current interface.

REC/RANGE button: short press for switching between auto

and manual range mode, and long press for data storage.

LINK/REL/▼ button

1) Long press for validating Bluetooth in all gears.

2) Short-press in the harmonic measurement interface at KW

and W gears to scroll down, and to switch between the 1st

06 07

Page 7

08 09

harmonic and 20th harmonic. At the KW and W gears, shortpress the function key in the maximum/minimum value

measurement interface to scroll down, and switch and display

the maximum/minimum value.

3) Short press on alternating current, AC/DC voltage and

capacitance for relative value measurement mode.

Hz%/INRUSH/▲button

1) Short press on alternating current, alternating voltage and

HZ% gear for the switch among alternating current or

alternating voltage, frequency and duty ratio.

2) Short-press on the harmonic measurement interface at KW

and W gears to scroll up, and switch between the 1st harmonic

and 20th harmonic. At the KW and W gears, short-press the

function key in the maximum/minimum value measurement

interface to scroll up, and switch and display the

maximum/minimum value.

3) Long press on the alternating current gear for switching to

the measurement mode of inrush current.

MAX/MIN button: for the switch between the

maximum/minimum measurement.

OFF gear: for power off.

INPUT jack: input terminal of voltage, resistance, frequency,

duty ratio, capacitance, diode and circuit continuity.

COM jack: common terminal of voltage, resistance, frequency,

duty ratio, capacitance, diode and circuit continuity.

Change-over switch: for selection of functions and ranges.

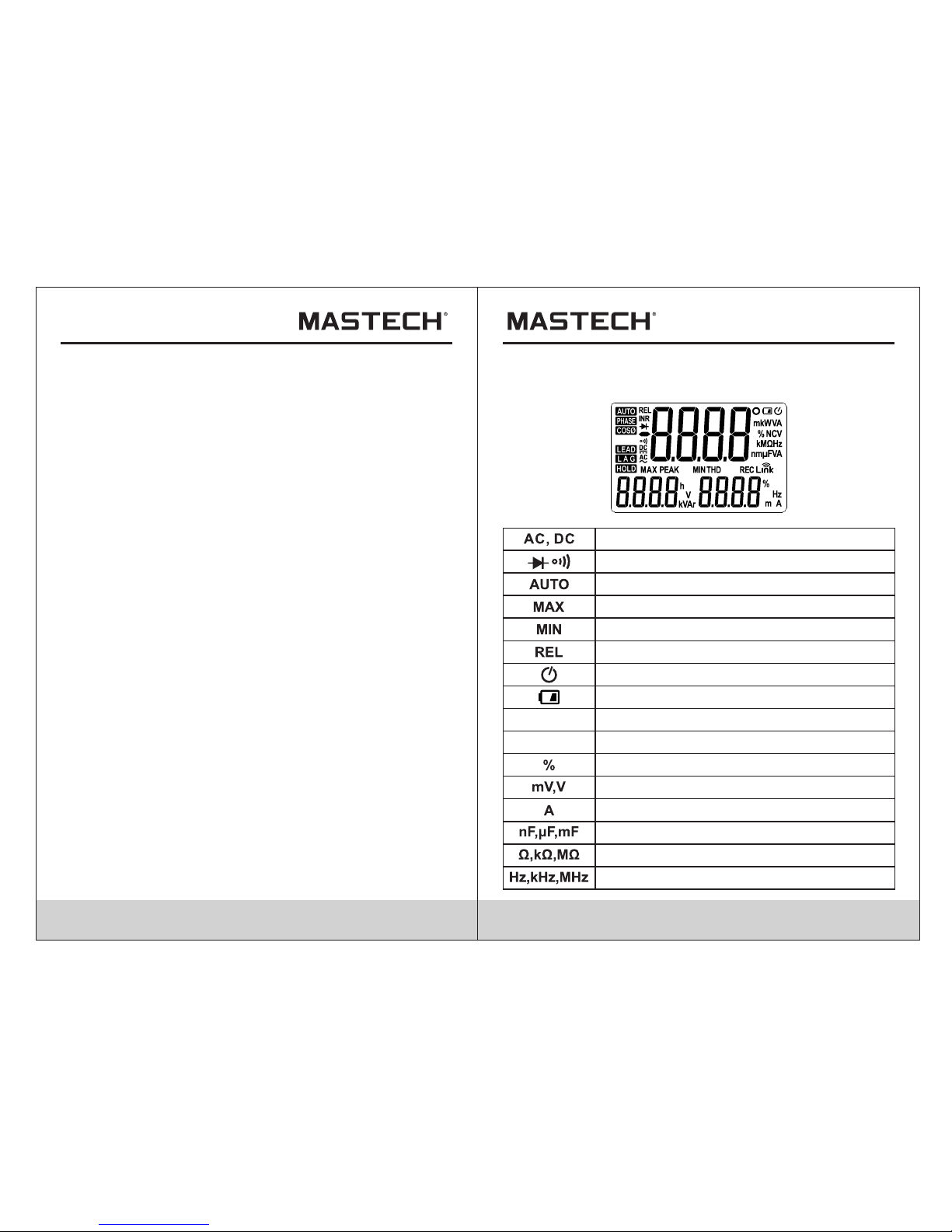

2.3 LCD display

Alternating current/Direct current

Diode and continuity

Auto range mode

Status of maximum measurement

Status of minimum measurement

Status of relative measurement

Status of automatic shutdown

LOW BATT ERY

Status of reading holding

HOLD

HZ

Frequency measurement

Percentage (duty ratio)

Millivolt, volt (voltage)

Ampere (electric current)

Nano farad, microfarad and millifarad

Ohm, kilo-ohm and megohm (resistance)

Hertz, kilohertz and megahertz (frequency)

Page 8

Non-contact voltage detection

Watt and kilowatt (active power)

Unit of apparent power

Reactive power

Phase angle

Peak value measurement

Total harmonic distortion

Total harmonic distortion F (relative to

fundamental wave)

Total harmonic distortion r (relative to

actual effec tive va lue)

Power factor

Phase

Status of inrush current measurement

Data recorder

Bluetooth function

Leading phase angle

Lagging phase angle

Hour (time unit)

Negative sign

W,KW

VA, KVA

Var, KVAr

O

PEAK

THD

H01F

H01r

COSФ

Phase

INR

REC

LEAD

LAG

h

3. Specification

Recalibrate the meter under the conditions of 18°C~28°C

and the relative humidity less than 75%, with the

calibration cycle of 1 year.

3.1 General

Auto range and manual range.

Full-scale overload protection.

Maximum allowable voltage between measured end

and the ground: 1000 V DC or 750 V AC .

Worki ng heig ht: les s than 2, 000 m.

Displayer: LCD.

Maximum displayed value: 5999 dgt.

Polar indication: self-indicating, "-" means negativ e

polarity.

Over-range display: '0L' or '-0L'.

Sampling time: around 3 times/s.

Unit display: display the functions and the unit of

electric quantity.

Time of automatic shutdown: 30 minutes.

Power supply: DC power supply 9 V.

Type of battery: NEDA 1604 or 6F22.

Under-voltage indication of battery: LCD display

symbol.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Temperature coeffic ient: l ess tha n 0.1×d egree o f

accuracy/°C.

10 11

Page 9

16

Worki ng temp eratu re: 18° C~28° C.

Storage temperature: -10°C~50°C.

17

1819Dimension: 238×92×50 mm.

Weigh t: arou nd 420 g (i nclud ing bat tery) .

3.2 Technical specifications

Environmental temperature: 23±5°C relative

humidity: ≤ 75%

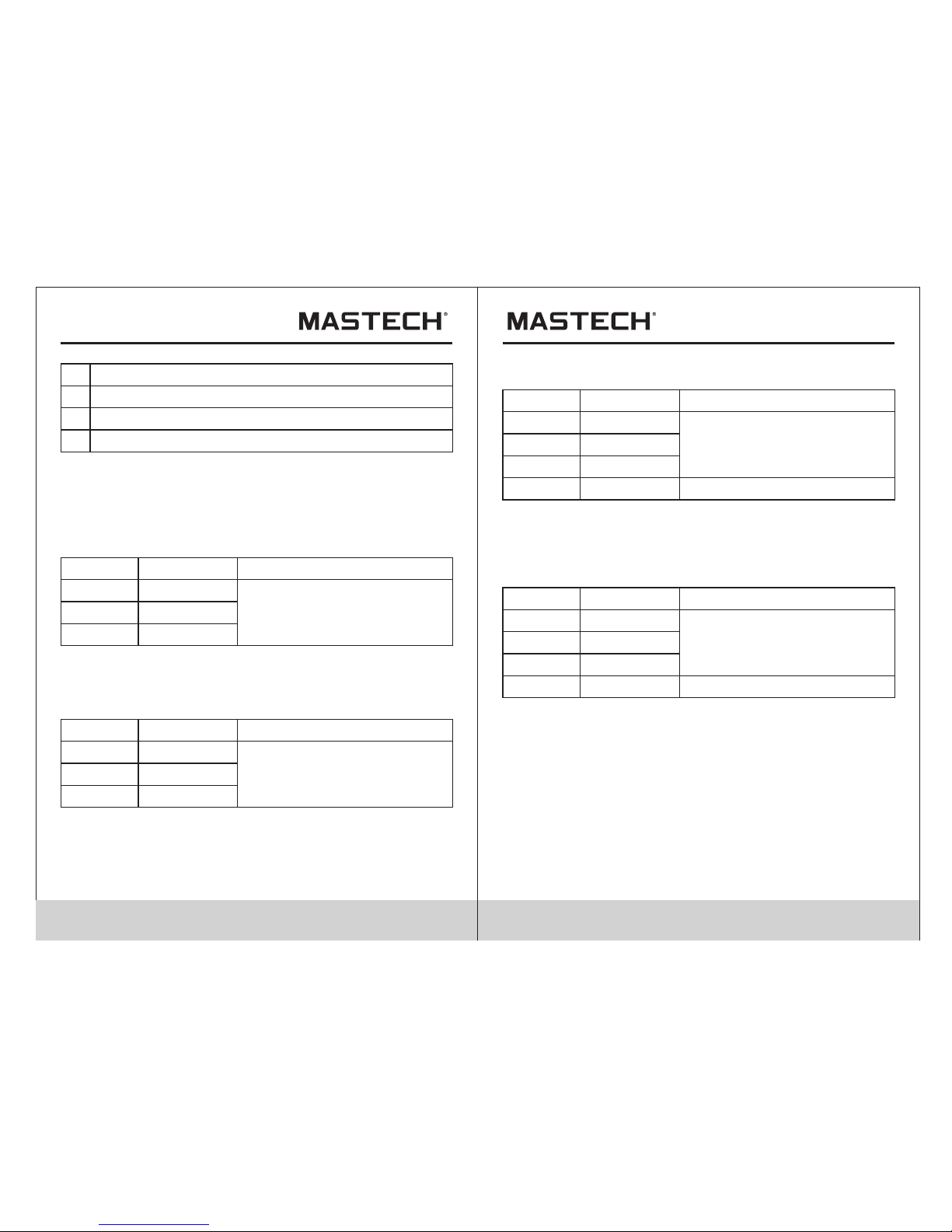

3.2.1 Alternating current

Range

Resolution

Accuracy

±(2.0% rdg+ 8 dgt)

60A 0.01A

600A 0.1A

1000A

1A

- Maximum input current: 1000A AC

- Frequency range: 40~400 Hz

3.2.2 Inrush cu rrent

Range

Resolution

Accuracy

<60 A (fo r refer ence on ly)

±(5% rdg+ 60 dgt)

60A 0.01A

600A 0.1A

1000A

1A

Integral time: 100 ms; measurement range: 20~1000 A;

frequency range: 40~400 Hz

3.2.3 DC voltag e

Range

Resolution

Accuracy

±(0.5% rdg+ 5 dgt)

-Input impedance: 10M

-Maximum input voltage: 750 V AC (effecti ve valu e) or

1000 V DC.

6V

60V

600V

1000V

0.001V

0.01V

0.1V

1V

±(0.8% rdg+ 4 dgt)

3.2.4 AC voltage

Range

Resolution

Accuracy

±(0.6% rdg+ 4 dgt)

- Input impedance: 10M

- Maximum input voltage: 750 V AC (effecti ve valu e) or

1000 V DC.

- Frequency range: 40~400 Hz.

±(0.8% rdg+ 4 dgt)

6V

60V

600V

750V

0.001V

0.01V

0.1V

1V

Note:

Under the small voltage range, there might be reading o n

the meter before the probe is connected to the measured

circuit.

The above phenomenon is normal because the meter has

high sensitivity and it has no influence on the actual

measurement result.

12 13

Page 10

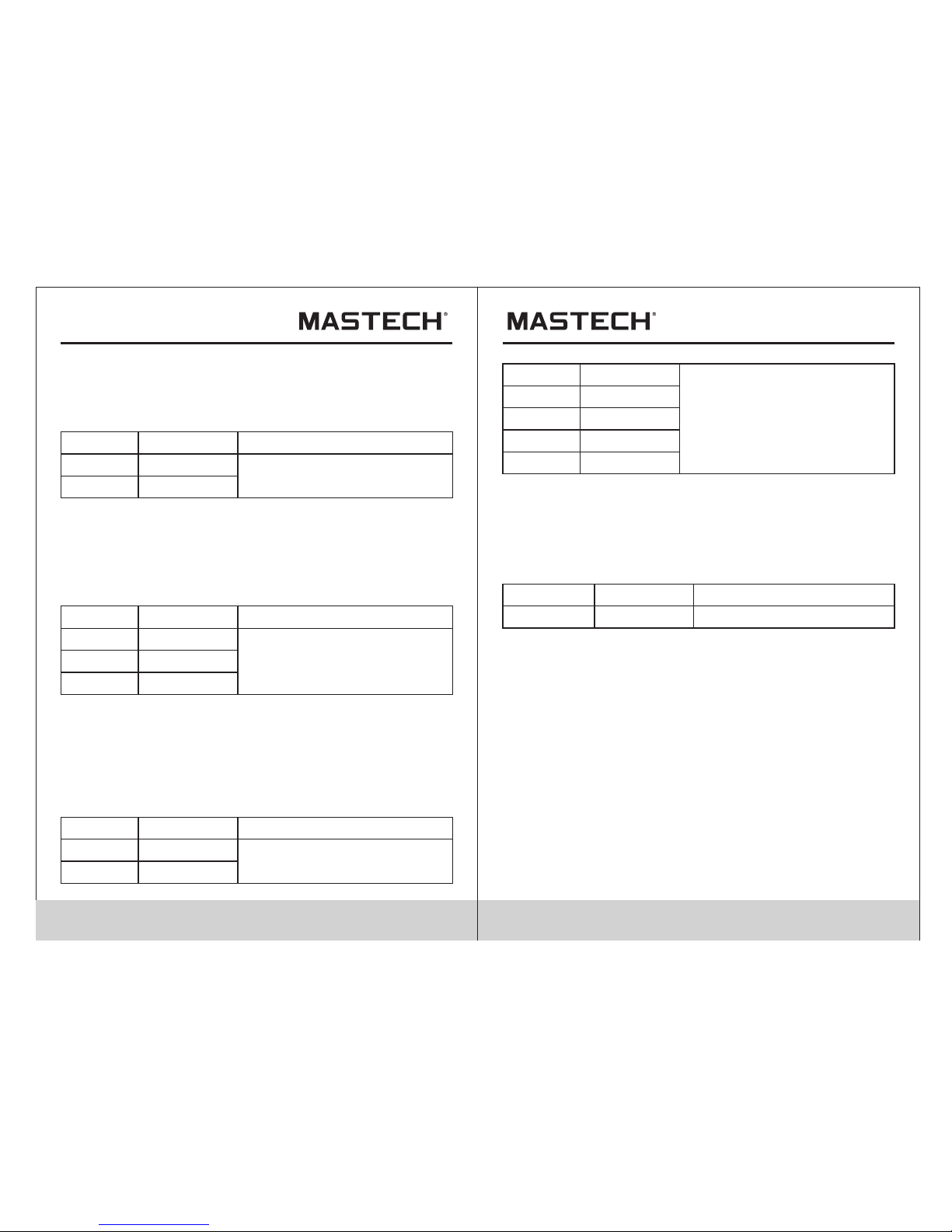

3.2.5 Frequency

3.2.5.1 Frequ ency measurement with clam p

(at A g ear):

Range

Resolution

Accuracy

±(1.5% rdg+ 5 dgt)

99.99Hz

999.9Hz

0.01Hz

0.1Hz

- Measurement range: 10 Hz~1 kHz

- Range of input signal: ≥ 20A AC (t he inpu t curre nt is

increased with the measured frequency)

- Maximal input current: AC 1 000 A (e ffective value)

3.2.5.2 At V gear:

Range

Resolution

Accuracy

±(1.5% rdg+ 5 dgt)

99.99Hz

999.9Hz

9.999kHz

0.01Hz

0.1Hz

0.001kHz

- Measurement range: 10 Hz~10kHz

- Range of input voltage: ≥ 1 V AC (eff ectiv e value ) (the

input voltage is increased with the measured frequency)

- Input impedance: 10MΩ

- Maximum input voltage: 750 V AC (effecti ve valu e)

3.2.5.3 At HZ/DUTY gear:

Range

Resolution

Accuracy

±(0.3% rdg+ 5 dgt)

9.999Hz

99.99Hz

999.9Hz

9.999kHz

99.99KHZ

999.9KHZ

9.999MHZ

±(0.3% rdg+ 5 dgt)

0.001Hz

0.01Hz

0.1Hz

0.001kHz

0.01kHZ

0.1KHZ

0.001MHZ

- Overload protection: 1000 V DC or 750 V AC (effecti ve

value)

- Range of input voltage: ≥ 2 V (the input voltage is

increased with the increase of the measured frequency)

3.2.6 Duty ratio

Range

Resolution

Accuracy

±(3.0% + 3 )

0.1 - 99.9%

0.1%

- Frequency response: 10 ~ 1 kHz.

- Range of input current: ≥ 20 A A C (effective value)

-Maximal input current: AC 1000 A

3.2.6.1 At A gear (from the clamp):

3.2.6.2 At V gear:

- Frequency response: 10 ~ 10kHz.

- Range of input voltage: 1 V AC.

- Input impedance: 10MΩ

- Maximum input voltage: 750 V AC (effecti ve valu e)

- Frequency response: 10 ~ 10MHz.

- Range of input voltage: ≥ 2V AC ( effective value) (the

input voltage is increased with the measured frequency)

- Maximum input voltage: 250V AC (effe ctive v alue)

3.2.6.3 At HZ/DUTY gear:

14 15

Page 11

16 17

3.2.7. Resistance

Range

Resolution

Accuracy

±(0.8% rdg+ 3 dgt)

600Ω

6kΩ

60kΩ

600kΩ

6MΩ

60MΩ

0.1Ω

0.001kΩ

0.01kΩ

0.1kΩ

0.001MΩ

0.1MΩ

±(2% rdg+ 5 dgt)

- Open-circuit voltage: around 0.78 V

- Overload protection: 1000 V DC or AC ( effective value)

3.2.8 Circuit continuity test

Range

Resolution

Function

600Ω 0.1Ω

If the resistance of measured

circuit is less than 50Ω, the

buzzer inside the meter will

send a sound.

- Open-circuit voltage: around 1.48V

- Overload protection: 1000 V DC or 750 V AC (effecti ve

value)

3.2.9. Capacitance

Range

Resolution

Accuracy

±(3.0% rdg+ 5 dgt)

9.999nF

99.99nF

999.9nF

9.999µF

99.99µF

0.001nF

0.01nF

0.1nF

0.001µF

0.01µF

±(3.0% rdg+ 5 dgt)

999.9µF

9.999mF

99.99mF

0.1µF

0.001mF

0.01mF

- Overload protection: 1000 V DC or 750 V AC (effecti ve

value)

3.2.10 Diode test

Range

Resolution

Function

3V 0.001V

Display the approximate

value of diode forward

voltage

- DC forward current is around 1 mA

- DC reverse voltage is around 3.2 V

- Overload protection: 1000 V DC or 750 V AC (effecti ve

value)

3.2.11 Single-phase active power

Range

Resolution

Accuracy

±(3.0% rdg+ 5 dgt)

3W

100W

4000W

10kW

100kW

750kW

0.01W

0.1W

1W

0.01kW

0.1kW

1kW

Page 12

18 19

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3.2.12 Single-phase apparent power

Range

Resolution

Accuracy

±(3.0% rdg+ 5 dgt)

0.01VA

0.1VA

1VA

0.01kVA

0.1kVA

1kVA

3VA

100VA

4000VA

10kVA

100kVA

750kVA

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3.2.13 Single-phase reactive power

Range

Resolution

Accuracy

±(3.0% rdg+ 5 dgt)

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3W

100W

4000W

10kW

100kW

750kW

0.01W

0.1W

1W

0.01kW

0.1kW

1kW

3.2.14 Power factor

Range

Resolution

Accuracy

0.3 ~ 1 capacitive

0.3 ~ 1 inductive

0.001

0.001

±(3.0% rdg+ 5 dgt)

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

3.2.15 Harmonics measurement

Range

1

2-6

7-8

9-10

11-15

16-20

±(3.0% rdg+ 10 dgt)

±(3.5% rdg+ +10 dgt)

±(4.5% rdg+ 10 dgt)

±(5.0% rdg+ 10 dgt)

±(7.0% rdg+ 10 dgt)

±(10.0% rdg+ 10 dgt)

Accuracy of harmonic electrical level

Minimum input current: 1 mA, and minimum input

voltage: 1 V.

4. Operation Guide

4.1 Reading holding

1) During the measurement, if the reading shall be held ,

short-press the "HOLD/B.L" key to lock the display

value of the display, an d short -pres s the "HO LD/B. L"

key to unlock the kept reading.

Page 13

4.2 Manual range

The RANGE key is used for setting the auto/manual range,

and this key can be activated through triggering. Its

startup default state is auto range. Press the key once to

switch to the manual range. In the manual range mode,

move the meter to the next higher gear after pressing the

key once, and after moving to the highest gear, press the

key continuously to move the meter to the lowest gear.

Perform the cyclic operations in sequence. If press the

key for more than 2 s, the meter will be switched to the

state of auto range.

Note:

During the measurement of diode, continuity test,

capacitance, and frequency KW, W and NCV gear, the

manual range is unavailable.

4.3 Switchover of frequency and duty ratio

1) When the meter is at AC c urren t gear, sh ort-p ress th e

"Hz/%/INRUSH/▲" key, the me ter can b e in Hz

measurement state to measure the frequency of

measured AC v oltag e and cur rent si gnals . Then,

short-press the "Hz/%/INRUSH/▲" key again, the meter

will be in DUTY me asure ment st ate to me asure t he duty

ratio of measured voltage and current signals. If the

meter is in HZ/% gear, short-press "Hz/%/INRUSH/▲"

key to switch the meter to the HZ and DUTY st ates

circularly.

2) If the meter is in AC current and AC/DC voltage gear,

short-press the "Hz/%/INRUSH/▲" key, th e meter w ill

be in the voltage and current measurement state.

4.4 Selection of maximum/minimum value

measurement

1) Press the "MAX/MIN" key in the kW and W gear, the

interface will simultaneously display the maximum and

minimum values obtained after the test for a period of

time, and then press the ▲or ▼key on this interface to

enter the interface displaying the time of record. After

that, the specific time period of these maximum and

minimum values will be displayed.

2) When the meter is at AC c urren t gear, AC/ DC volt age

gear and resistance gear, press the "MAX/MIN" to enter

the MAX mode and measure the maximum value all the

time; press "MAX/MIN" key once again to enter the state

for measuring the minimum value; and then press the

"MAX/MIN" key for the third time to exit the

measurement mode of maximum and minimum value.

Note:

1) The me ter is in m anual r ange mo de unde r the

measurement states of max/min value.

4.5 Function switching

1) Long-press the FUNC key in the power measurement

interface to enter the power, voltage and current

measurement interface.

2) Short-press the FUNC key in the power measurement

interface to enter the active power, apparent power,

reactive power, power factor and phase angle

measurement interface.

3) When the meter is at power gear, short-press the FUNC

key in the voltage measurement interface to enter the

voltage effe ctive v alue, h armon ic, har monic d istor tion

rate TH D-R and h armon ic dist ortio n rate THD-F

measurement interface.

20 21

Page 14

22 23

4) When the meter is at power gear, short-press the FUNC

key in the current measurement interface to enter the

current effe ctive v alue, h armon ic, har monic d istor tion

rate TH D-R and h armon ic dist ortio n rate THD-F

measurement interface.

5) When the meter is at DC/AC gear, short-press the FUNC

key to switch between the DC voltage measurement and

AC voltage measurement interface.

6) When the meter is at resistance/diode/buzzer/

capacitance gear, short-press the FUNC key to switch

among resistance, diode, buzzer and capacitance

measurement.

4.6 Measurement of relative value

1) Short-press the LINK/REL/▼ key at AC current, AC /DC

voltage and capacitance gears to enter the relative

value measurement mode and store the current

displaying value in memory as the reference value. For

the sequent measurement, the displayed value is the

diffe rence v alue be tween t he inpu t value a nd refe rence

value, i.e. REL▲ (current reading) = input value reference value.

2) This function of relative value measurement only can b e

available in the manual measurement mode.

4.7 LINK measurement

At any gear (excluding OFF gear), long-press LINK/REL/▼

to turn on the Bluetooth of meter. Then op en the

corresponding AP P (iOS or Android) of the meter through

mobile phone or other equipment and search the signal t o

link them. Af ter the l inkin g, the APP will display the

content displayed on meter in real time. Long-press the

LINK/REL/▼ key once again, the Bluetooth of meter will

be turned off an d the met er will b e disco nnect ed from t he

APP.

4.8 REC function

The meter performs the functions of data recording and

Bluetooth data reading.

1) Data recording: the meter can save 1000 pieces of

data records. Long-press REC/RANG key to enable

the meter to record data. The RE C indic ator on L CD

will be on, and the meter will store the current

measurement data at the rate of 3 times/s. Long-press

REC key again to exit the data recording function. Th e

meter also can exit the data recording function when

the 1000 pieces of data are recorded or a key operation

or gear switching operation is performed.

2) Data reading: the meter cannot support the direct

reading of stored data, and it only support the reading of

the stored data with the Bluetooth function through a

specific AP P on the mobile phone.

4.9 ▼function

Short-press LINK/REL/▼ in the harmonic measurement

interface at KW and W gears to scroll down, and to switch

between the 1st harmonic and 20th harmonic. At the KW

and W gears, short-press the function key in the

maximum/minimum value measurement interface to

scroll down, and switch and display the

maximum/minimum value.

Page 15

4.10 ▲function

Short-press in the harmonic measurement interface at

KW and W gears to scroll up, and to switch between the

1st harmonic and 20th harmonic. At t he KW and W g ears,

short-press the function key in the maximum/minimum

value measurement interface to scroll up, and switch and

display the maximum/minimum value.

4.11 INRUSH measurement

Long-press "Hz/%/INRUSH/▲" for more than 2 s at AC

current gear to enterthe inrush measurement state.

4.12 Back-light and clamp lighting

1) During measurement, if the ambient light is too dim to

read, press the "B.L/HOLD" for more than 2 s to turn on

the back-light, and the back-light will be off 20 s lat er.

2) In this period, press the "B.L/HOLD" key for 2 s to turn

off the b ack-l ight.

3) Turn on the back-light of the meter at the current gear,

and the clamp lamp will be on at the same time.

The lum inous o bject o f the bac k-lig ht is LED w ith hig h

working current.

Although this meter is set with timing circuit (with time

of 30 s), the service life of battery will be shortened

with frequent use of back-light.

There fore, y ou shal l minim ize the u se of bac k-lig ht as

far as possible under the unnecessary conditions.

Note:

When the battery voltage ≤ 7.2 V, the display will displa y

the symbol of " "(under-voltage). However,

if the back-light is used, when the battery voltage ≥ 7.2 V,

the battery voltage is reduced due to high working current,

the display may display the symbol " "(when the

symbol of " " is displayed, the measurement accuracy

cannot be guaranteed). Under such circumstance, the

battery will not be replaced until the symbol " " is

displayed without back-light.

4.13 Automatic shutdown

1) After startup, in case of no operation within 30 minutes,

the meter will enter the dormant state and shut down

automatically for saving electric energy. There will be

voice prompt (a prolonged blast) from the buzzer 1

minute before shutdown, and then the meter will shut

down automatically.

2) After shutdown, press FUNC key and the meter will

resume operation.

3) If the "B.L/HOLD" key is pressed during startup, the

function of automatic shutdown will cancel automatical ly.

4.14. Measurement preparation

1) Turn the change-over switch to power on the meter. If

the battery is in under-voltage state (the voltage ≤ 7.2 V),

the display will display the symbol " ", and then the

battery shall be replaced.

2) " " means that the input voltage or current shall not

be greater than the indicated value in order to prevent

the internal circuit from damage.

3) Turn the change-over switch to the required

measurement function and range.

4) For wiring, connect the public testing line at first and

then connect the energized testing line. For

disconnecting,remove the energized testing line at firs t.

24 25

Page 16

26 27

4.15 AC current measurement

WARNING

Electric shock.

Remove the probe from the meter before measuring

with the current clamp.

1) Turn the change-over switch to AC current gear. At this

time, the meter is in AC c urren t measu remen t state , and

then the suitable range shall be selected.

2) Hold the trigger, and open the clamp to clamp one

conductor of measured circuits.

3) Read the current value from LCD display.

Note:

1) If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

2) In order to acquire the accurate reading, the measured

conductor shall be in the center of clamp as far as

possible.

3) " " means that the maximum AC input current is

1000 A.

4) When the reading is greater than 600.1 A at 60 A/600 A ,

there will be the alarm sound "beep" from the meter.

When the reading is greater than 620 A rm s, the ACA wi ll

display overload.

5) When the reading is greater than 1001 A a t 1,000 A,

there will be the alarm sound "beep" from the meter.

When the reading is greater than 1,100 A rms, the AC A

will display overload.

Figur e 1 Sch ema tic Diagram for Curr ent M eas urement at AC Gear

Page 17

this case, the meter is in the DC voltage measurement

state. If the AC voltage shall be measured, press the

FUNC key and the meter will enter the AC v oltag e

measurement state.

3) Connect the probe to both ends of voltage source or

load to conduct measurement.

4) Read the voltage value from LCD.

Note:

1) The au to rang e will be u navai lable u nder th e relat ive

measurement mode.

2) " " means that the maximum input voltage is 750 V

AC or 1000 V DC.

3) Ther e will be t he alar m sound " beep" f rom the m eter,

when the measured reading of the meter is greater than

600 V rms ACV.

When the reading is greater than 750 V rms ACV, the

meter will display overload.

4) Ther e will be t he alar m sound " beep" f rom the m eter,

when the measured reading of the meter is greater than

1000 V rms DCV.

When the reading is greater than 1100V r ms, the D CV

will display overload.

4.16. Voltage measurement

WARNING

Electric shock.

Pay special attention to high voltage measurement to

avoid electric shock.

Do not input the voltage with the effec tive va lue

greater than AC 750.

1) Plug the black probe into COM jack, plug the red probe

into INPUT jac k, and se lect th e suita bleran ge.

2) Turn the change-over switch to AC/DC voltage gear. In

Figur e 2: Sc hem atic Diagram for AC Vo lta ge Me asurement at

AC/DC Volta ge Ge ar

28 29

Page 18

30 31

4.17 Measuring frequency and duty ratio

1) Frequency me asurement with clamp (at

current gear) :

WARNING

Electric shock.

Remove the probe from the meter before measuring

with the current clamp.

(1) Turn the change-over switch to AC c urren t gear.

(2) Hold the trigger, and open the clamp to clamp one

conductor of measured circuits.

(3) Press the "Hz/%INRUSH/▲"button shortly to switch

into the status of frequency measurement.

(4) Read the frequency value from LCD display.

(5) Press "Hz/%INRUSH/▲"again to enter the status of

duty ratio measurement.

Note:

(1) If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

(2)The measurement range of frequency is 10 Hz ~ 1 kHz.

If the measured frequency is less than 10 Hz, the

frequency greater than 10 kHz might be measured, but

the accuracy of measurement cannot be guaranteed.

(3) The m easur ement r ange of d uty rat io is 10 ~ 95 %.

(4) The m aximu m input c urren t of " " is 100 0A AC

(effe ctive v alue) .

2) At voltage gear:

WARNING

Electric shock.

Pay special attention to high voltage measurement to

avoid electric shock.

Do not input the voltage with effecti ve valu e great er

than AC 750.

(1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

(2) Turn the change-over switch to AC /DC vol tage ge ar,

press FUNC to enter the status of AC voltage

measurement.

(3) Press the "Hz/%INRUSH/▲"button to switch into the

frequency measurement state.

(4) Connect the probe to both ends of signal source or

load to conduct measurement.

(5) Read on the LCD.

(6) Press "Hz/%INRUSH/▲"again to enter the status of

duty ratio measurement.

Note:

(1) The m easur ement r ange of f reque ncy is 10 H z ~ 10kHz .

If the measured frequency is less than 10 Hz, the LCD

will display "00.0", the frequency less than 10 kHz

might be measured, but the accuracy of measurement

cannot be guaranteed.

(2) The m easur ement r ange of d uty rat io is 10 ~ 95 %.

(3) The m aximu m input v oltag e of " " is 750 V AC

(effe ctive v alue) .

Page 19

32 3 3

3) At HZ/DUTY gear :

WARNING

Electric shock.

Pay special attention to high voltage measurement to

avoid electric shock.

Do not input the voltage with effecti ve valu e great er

than AC 750 V.

(1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

(2) Turn the change-over switch to HZ% gear.

(3) Connect the probe to both ends of signal source or load

to conduct measurement.

(4) Read on the LCD.

(5) Press "Hz/%INRUSH/▲"again to enter the status of

duty ratio measurement.

Note:

The measurement range of frequency is 10 Hz ~ 9.999

MHz, if the measured frequency less than 10 Hz, the LCD

will display "00.0"; the frequency greater than 9.999 MHz

might be measured, but the accuracy of measurement

cannot be guaranteed.

Figur e 3: Sc hem atic Diagram for Fre que ncy M easurement at

HZ% Gear

Page 20

34 35

4.18 Resistance measurement

WARNING

Electric shock.

When measuring the impedance on the circuit, the

circuit power should be disconnected, and the

capacitor in the circuit should be completely

discharged.

1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

2) Place the change-over switch on the gear, and set

the meter in the status of resistance measurement.

3) Connect the probes to both ends of the measured

resistor or the circuit for measurement.

4) Read on the LCD.

Note:

1) When the input is open-circuited, the LCD will display

"0L" for over range.

2) If the resistance of measured resistor is greater than

1 MΩ, the reading of the meter might be stable after a

few seconds, and it is common for the high resistance

readings.

Figur e 4 Sch ema tic Diagram for Resi sta nce M easurement at

Gear

Page 21

36 37

4.19 Diode test

1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

2) Turn the change-over switch to the gear.

3) Press "FUNC" to switch into the status of

measurement.

4) Connect the red probe to the positive pole of the diode,

and connect the black probe to the negative pole for

measurement.

5) Read on the LCD.

Note:

1) The ap proxi mate va lue of th e forwa rd volt age dro p of

diode will be displayed on the meter.

2) If the probe is connected inversely or the probe is

open-circuited, the LCD will display "0L".

Figur e 5 Sch ema tic Diagram for Diod e Te sting at Gear

Page 22

38 39

4.20 Circuit continuity test

WARNING

Electric shock.

For the circuit continuity test, the circuit power should

be disconnected, and the capacitor in the circuit

should be completely discharged.

1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

2) Turn the change-over switch to the gear.

3) Press "FUNC" button to switch to the status of

circuit continuity testing.

4) Connect the probes to both ends of the circuit for

measurement.

5) If the resistance of measured circuit is less than 50Ω ,

the buzzer inside the meter will make a sound.

6) Read the resistance value of the circuit from LCD.

Note:

If the probe is open-circuited or the resistance of the

measured circuit is greater than 600Ω , the "0L" will be

displayed.

Figur e 6 Sch ema tic Diagram for Circ uit C ont inuity Test at

Gear

Page 23

40 41

4.21 Capacitance measurement

WARNING

Electric shock.

To avoid electric shock, the capacitor should be

completely discharged before the capacitance

measurement.

1) Insert the black probe into COM jack, and insert the red

probe into INPUT jack .

2) Turn the change-over switch to the gear.

3) Connect the probe to the both ends of the measured

capacitor for measurement after the capacitor is

completely discharged.

4) Read the capacitance value from LCD.

Note:

To improve the accuracy of the measured value less than

10 nF,t he dist ribut ed capa citan ce of the m eter an d

conductors should be subtracted.

Figur e 7 Sch ema tic Diagram for Capa cit ance Measurement a t

Gear

Page 24

42 4 3

4.22 Measurement of inrush current

WARNING

Electric shock.

Remove the probe from the meter before measuring

with the current clamp.

4.22.1 Turn the change-over switch to 60/600 A o r 1000 A

AC current gear.

4.22.2 Hold the trigger, and open the clamp to clamp one

conductor of measured circuits.

4.22.3 Long press the "HZ%/INRUSH/▲" button more

than 2 seconds to enter the mode of inrush current

measurement. Then t he LCD wi ll disp lay "IN R", and

the meter will display and hold the inrush current

value until the motor start-up is detected.

4.10.4 Read the inrush current value from LCD display.

Note:

1) If two or more circuits of the measured circuits are

clamped, the measurement result will be not correct.

2) In order to acquire the accurate reading, the measured

conductor shall be in the center of clamp as far as

possible.

3) The LC D only di splay s "OL" in t he manu al rang e mode

indicating the over range, and the higher range should

be selected.

4) Under the manual range mode, if the measured value is

not known in advance, the highest level should be set

for the range.

5) " " means that the maximum input current is 1000A

AC (effe ctive v alue) .

Figur e 8 Sch ema tic Diagram for Inru sh Cu rre nt Measurement at

AC Curre nt Ge ar

Page 25

44 45

4.23 NCV measurement

1) Turn the change-over switch of the meter to the NCV

gear.

2) The to p of the me ter sho uld be ar range d near th e

conductor. When the detected voltage is great than 110

Vac (RMS ), the vo ltage s ensin g indic ator ma y be on,

and the buzzer may make the alarm sound "beep".

Note:

1: The vo ltage m ay stil l exist e ven wit hout in struc tions .

Do not determine whether there is voltage in the

conductor only by using the non-contact voltage

detectors. The detecting operation might be affected by

the socket design, insulation thickness, type and other

factors.

2: When there is input voltage to the input terminal of the

meter, the voltage sensing indicator may also be on.

3: Intrusive sources (such flashlight, motor, etc.) in the

external environment may cause a wrong trigger of

non-contact voltage detection.

Figur e 9 Sch ema tic Diagram for Volta ge De tection at NCV Gear

Page 26

46 47

4.24 Active power measurement

WARNING

Electric shock.

Pay special attention to high voltage and high current

measurement to avoid electric shock.

Do not input the voltage with the effec tive va lue

greater than AC 750 and the current with the effect ive

value greater than 1000 A.

1) Turn the change-over switch to kW or W gear.

2) Clamp the measured conductor of the power supply or

load with the clamp. Input the measured voltage from

the V end and COM end. After the measuring circuits

are connected correctly, th e activ e power s hall be r ead

from the LCD and the LCD displays the eff ectiv e value s

of measured voltage and current simultaneously.

3) Determine whether the switch shall be turned to the KW

gear or W gear according to the measured current. At

the W gear, the measurement range of current is 1 mA 4,000 mA and at the KW gear, the measurement range

of current is 1 A - 10 00 A. The measurement range of

voltage at both the KW gear and W gear is 1 V -750 V.

4) Press MAX/MIN key in the active power measurement

interface to enter the maximum/minimum value

measurement mode, and the LCD will display the

measured value of active power and the maximum and

minimum values of active power within a certain period

simultaneously. Pr ess the H z/%IN RUSH/ ▲ key or

LINK/REL/▼ key again in this interface, the LCD will

display the recording time and real-time measurement

value of active power.

Note:

1) The ma ximum m easur ement r ange of a ctive p ower is

750 kW, and the LCD will display OL for over range.

2) The ma ximum m easur ed curr ent is 40 00 mA a t W gear.

Please do not operate by mistake.

3) The mi nimum m easur ed volt age is 1 V an d the

minimum measured current is 1 mA.

4) The ma ximum m easur ed volt age is 75 0 V and the

maximum measured current is 1000 A.

Figur e10 S che matic Diagram for Act ive P ower Measurement at

KW Gear

Page 27

48 49

4.25 Apparent power measurement

WARNING

Electric shock.

Pay special attention to high voltage and high current

measurement to avoid electric shock.

Do not input the voltage with the effec tive va lue

greater than AC 750 and the current with the effect ive

value greater than 1000 A.

1) Turn the change-over switch to the kW or W gear, press

FUNC key to enter the apparent power measurement

interface.

2) Clamp the measured conductor of the power supply or

load with the clamp. Input the measured voltage from

the V end and COM end. After the measuring circuits

are connected correctly, re ad the ap paren t power f rom

the LCD and the LCD displays the effect ive val ues of

measured voltage and current simultaneously.

3) Determine whether the switch shall be turned to the KW

gear or W gear according to the measured current. At

the W gear, the measurement range of current is 1 mA 4000 mA and at the KW gear, the measurement range

of current is 1 A - 10 00 A. The measurement range of

voltage at both the KW gear and W gear is 1 V -750 V.

4) Press MAX/MIN key in the apparent power

measurement interface to enter the maximum/minimum

value measurement mode, and the LCD will display the

measured value of apparent power and the maximum

and minimum values of apparent power within a certain

period simultaneously. Pr ess the H z/%IN RUSH/ ▲ key

or LINK/REL/▼ key once again in this interface. The

LCD will display the recording time and real-time

measurement value of apparent power.

Note:

1) The ma ximum m easur ement r ange of a ppare nt powe r

is 750 kW, and the LCD will display OL for over range.

2) The ma ximum m easur ed curr ent is 40 00 mA a t W gear.

Please do not operate by mistake.

3) The mi nimum m easur ed volt age is 1 V an d the

minimum measured current is 1 mA.

4) The ma ximum m easur ed volt age is 75 0 V and the

maximum measured current is 1000 A.

Figur e11 Schem ati c Dia gram for A ppa rent Power Measure men t

at KW Gear

Page 28

50 5 1

4.26 Power factor measurement

WARNING

Electric shock.

Pay special attention to high voltage and high current

measurement to avoid electric shock.

Do not input the voltage with the effec tive va lue

greater than AC 750 and the current with the effect ive

value greater than 1000 A.

1) Turn the change-over switch to the kW or W gear, press

FUNC key to enter the power factor measurement

interface.

2) Clamp the measured conductor of the power supply or

load with the clamp. Input the measured voltage from

the V end and COM end. After the measuring circuits

are connected correctly, th e power f actor f rom the L CD

shall be read and the LCD displays the value of reactive

power simultaneously.

3) Determine whether the switch shall be turned to the KW

gear or W gear according to the measured current. At

the W gear, the measurement range of current is 1 mA 4,000 mA and at the KW gear, the measurement range

of current is 1 A - 10 00 A. The measurement range of

voltage at both the KW gear and W gear is 1 V -750 V.

4) Ther e is a phas e difference between the voltage value

and current value of the inductive load and capacitive

load. Generally. the p ower fa ctor is i ndica ted by th e

cosine COSø of phase angle ø. When t he powe r facto r

is negative, it means that the measured load is

capacitive load.

5) The re activ e power i s a indir ectly m easur ed valu e. The

computational formula of kVAr is: , an d

ﻮ22

k kWkVAVAr -=

the value is calculated out with the measured voltage,

current and active power value.

Note:

1) The ma ximum m easur ed curr ent is 40 00 mA a t W gear.

Please do not operate by mistake.

2) The mi nimum m easur ed volt age is 1 V an d the min imum

measured current is 1 mA.

3) The ma ximum m easur ed volt age is 75 0 V and the

maximum measured current is 1000 A.

Figur e12 S che matic Diagram for Po wer F act or Measurement at

KW Gear

Page 29

52 53

4.27 Phase angle measurement

WARNING

Electric shock!

Pay special attention to high voltage and high curren t

measurement to avoid electric shock.

1) Turn the change-over switch to the kW or W gear, press

FUNC key to enter the phase angle measurement

interface.

2) Clamp the measured conductor of the power supply or

load with the clamp. Input the measured voltage from

the V end and COM end. After the measuring circuits

are connected correctly, th e phase a ngle sh all be re ad

from the LCD and the LCD displays the eff ectiv e value s

of measured voltage and current simultaneously.

3) Determine whether the switch shall be turned to the KW

gear or W gear according to the measured current. At

the W gear, the measurement range of current is 1 mA 4,000 mA and at the KW gear, the measurement range

of current is 1 A - 10 00 A. The measurement range of

voltage at both the KW gear and W gear is 1 V -750 V.

4) Ther e is a phas e difference between the voltage vale

and current value of the inductive load and capacitive

load. Generally, the p hase di fference is indicated by the

phase angle ø.

Note:

1) The ma ximum m easur ed curr ent is 40 00 mA a t W gear.

Please do not operate by mistake.

2) The mi nimum m easur ed volt age is 1 V an d the min imum

measured current is 1 mA.

3) The ma ximum m easur ed volt age is 75 0 V and the

maximum measured current is 1000 A.

Figur e 13 Sc hem atic Diagram for Pha se Ang le Measurement at

KW Gear

4.28 Harmonics measurement (voltage

signal)

WARNING

Electric shock.

Pay special attention to high voltage measurement to

avoid electric shock.

Do not input the voltage with the effec tive va lue gre ater

than AC 750.

Page 30

54 5 5

1) Turn the change-over switch to the kW or W gear, first

long-press the FUNC key to enter the voltage

measurement interface, and then short-press the

FUNC key to enter the harmonics measurement

interface, and switch from 1st - 20th harmonic through

pressing the Hz/%INRUSH/▲ key or LINK/REL/▼ key.

2) Input the measured voltage signal from the V end and

COM end.

3) After the measuring circuits are connected correctly,

the eff ectiv e value o f the nth h armon ic comp onent s hall

be read.

4) Short-press the FUNC key in the harmonic

measurement interface once again to enter into TH D-R

(relative to the actual effe ctive v alue) o r THD-F (relative

to the fundamental wave) measurement mode. The

main interface displays the effec tive va lue of th e nth

harmonic component and the minor interface displays

the total harmonic distortion.

5) Press MAX/MIN key in the voltage measurement

interface to enter the maximum/minimum value

measurement mode. In this case, the main interface

displays the measured effe ctive v alue of v oltag e and

the minor interface displays the maximum and minimum

values within a certain period. Press the

Hz/%INRUSH/▲ key or LINK/REL/▼ key again in this

interface to enter into the time recording interface. In

this case, the main interface displays the limited voltage

measurements, and the minor interface displays the

time of maximum and minimum values.

Note:

1) The mi nimum m easur ed volt age is 1 V an d the

maximum measured voltage is 750 V. Th is inte rface w ill

display OL for over 750 V.

WARNING

Electric shock.

Pay special attention to high current measurement to

avoid electric shock.

Do not input the current with the effec tive va lue gre ater

than AC 1000 A.

Figur e 14 Sc hem atic Diagram for Har mon ics Measurement of

Voltag e Sig nal a t KW Gear

Page 31

56 57

4.29 Harmonics measurement (current

signal)

1) Turn the change-over switch to the kW or W gear, first

long-press the FUNC key to enter the current

measurement interface, and then short-press the FUNC

key to enter into the harmonics measurement interface,

and switch from 1st - 20th harmonic through pressing

the Hz/%INRUSH/▲ key or LINK/REL/▼ key.

2) Clamp the measured conductor of the power supply or

load with the clamp.

3) After the measuring circuits are connected correctly,

the eff ectiv e value o f the nth h armon ic comp onent s hall

be read.

4) Short-press the FUNC key in the harmonic

measurement interface once again to enter into TH D-R

(relative to the actual effe ctive v alue) o r THD-F (relative

to the fundamental wave) measurement mode. The

main interface displays the effec tive va lue of th e nth

harmonic component and the minor interface displays

the total harmonic distortion.

5) Press MAX/MIN key in the current measurement

interface to enter the maximum/minimum value

measurement mode. In this case, the main interface

displays the measured effe ctive v alue of c urren t and

the minor interface displays the maximum and minimum

values within a certain period. Press the

Hz/%INRUSH/▲ key or LINK/REL/▼ key again in this

interface to enter into the time recording interface. In

this case, the main interface displays the limited voltage

measurements, and the minor interface displays the

time of maximum and minimum values.

Note:

1) The mi nimum m easur ed curr ent is 1 mA an d the

maximum measured current is 1000A. This in terfa ce

will display OL for over 1000A.

Figur e 15 Sc hem atic Diagram for Har mon ics Measurement of

Curre nt Si gna l at KW Gear

Page 32

58

5 Maintenance

5.1 Battery replacement

WARNING

Before opening the battery cover of meter, take the

probe away from the measuring circuits to avoid

electric shock.

1) If the meter displays the symbol " ", the battery

shall be replaced.

2) Unscrew the fastening screw of the meter battery cover

and remove it.

3) Replace the old battery.

4) Install the battery cover in the original position.

Note:

Do not install the battery in the incorrect direction.

5.2 Replacing Test Leads

6 Attachments

1)

Probe

Grade: 1000V 10A

A pair

2)

Operation instruction

1 copy

3)

Battery

6F22 9VOLTS

R-00-05-2313

Replace test leads if leads become damaged or worn.

Use meet EN 61010-031 standard, rated CAT III 1000V,

MAX 10A or better test leads.

WARNING

To avoid electric shock,make sure the probes are

disconnected from the measured circuit before

removingthe rear cover.Make sure the rear cover is

tightly screwed before using the instrument.

Warning

Loading...

Loading...