Page 1

The complete range of versatile, high performance tractors

HP

86-145

MF

54005400

VISION INNOVATION LEADERSHIP QUALITY RELIABILITY SUPPORT PRIDE COMMITMENT

Page 2

The MF 5400 Series

04 Pure quality inside and out

06 A wide range of choice

Engines

08 Powerful delivery

10 PowerBoost

12 Dyna-4 Transmission & Power control

PTO & Hydraulics

16 Total operating flexibility

18 The perfect linkage system

A better working environment

20 Cab suspension

22 Cab interior

26 The essential tractor & loader combination

Straightforward, intuitive technology

28 TopCon technology

The ultimate platform

30 MF 5400 Series Platform tractors

32 Fast, easy routine maintenance

Ensuring a cost effective future for your business

34 Manager Service and Extended Warranty Plan

36 AGCO Aftersales Support

38 Customer testimonials

40 Specifications

44 MF 5400 Series highlights

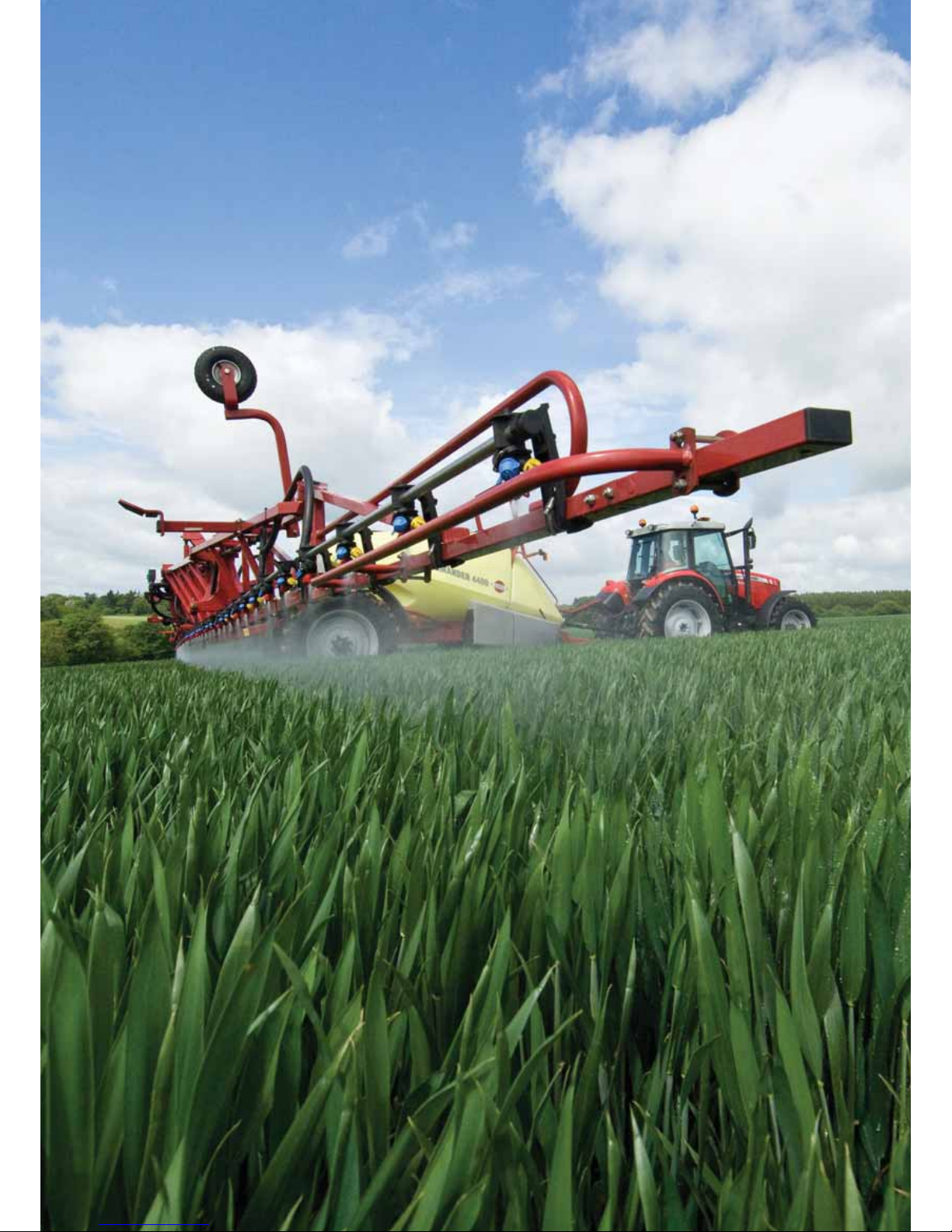

If you haven’t yet discovered what makes the MF 5400 Series so

popular, then do your business justice and take a look

at the versatile line-up of mid-horsepower tractors from

Massey Ferguson. Powerful, fuel efficient engines and comfortable

cabs come as standard, whilst full factory-fitted, front-end loaders

can also be specified. For unsurpassed levels of performance and

versatility, look no further than the MF 5400 Series.

Discover the perfect partnership.

The MF 5400 Series from

Massey Ferguson.

Contents

02

Page 3

03

Page 4

Pure quality, inside

and out

Simply the perfect all-round

workhorse. From small stock to

large mixed farms, arable and

contracting businesses as well as

the municipal sector. Wherever

there are demanding operations

to tackle, the MF 5400 Series will

deal with them - effortlessly.

Rugged power is delivered from

86-145 hp through reliable, workhungry yet fuel efficient engines.

Now you can get even more power

from 6 km/h, in 3rd or 4th range,

with Massey Ferguson’s new,

torque-filled, PowerBoost feature.

All nine models have the superior

Dyna-4, semi-powershift

transmission with

Massey Ferguson’s industryleading Power Control Lever.

The MF 5400 is straightforward to

operate, while the ease of access

makes light work of jumping in

and out of the tractor all day, as a

multitude of tasks are completed.

It’s your tractor – you specify

Whatever your business requires,

whatever the job, the MF 5400

range can handle the toughest

tasks you can throw at it. Whether

mounted with the MF 900

Series front loader, operating a

high-capacity mower, pulling a

cultivator or hauling trailers, you’re

guaranteed maximum productivity.

The MF 5400 Series carries a

range of choices in bonnet design,

cab height and visibility to enable

purchasers to tailor their new

machine to precisely match the

tasks required of it.

The Visio roof option can be

specified, together with factoryinstalled sub-frame and hydraulics

for an MF 900 Series front loader,

all perfect for both dairy and arable

businesses.

The MF 5400 Series.

Get the job done!

04

Page 5

05

Page 6

A wide range of choice

At Massey Ferguson,

we understand the needs of

every individual. Whether you are

running a large-scale dairy unit

or family farm, each feature

and optional extra in the

MF 5400 Series has been

designed specifically to suit

your needs.

Key features throughout the

range include:

Industry-leading loader options

Get the complete package to

ensure optimum productivity

with our industry-leading

MF 900 Series loaders.

Styling, with clean, modern lines

The pivoting bonnet allows

improved access for regular

maintenance of the air filter

and radiators.

Pivoting cooling package

on the MF 5465/75

For easier access

and maintenance.

Latest generation Tier III engines

Emissions compliant, fuel-

efficient power units providing

improved power and torque

characteristics and less

fuel consumption.

Every Massey Ferguson tractor has outstanding attributes that

makes it the most popular and enduring choice within the

mid-horsepower sector.

Engine PowerBoost

Increasing power from 6 km/h

and when it’s needed most Better pulling capacity, improved

performance, transporting

heavier loads faster and reducing

journey times.

The superb Dyna-4

transmission as standard

Simple to use, four speeds

‘under load and on the go’ equals

less power loss.

New (optional) Integrated Front

Linkage System (IFLS) with

heavy duty front axle support

on the MF 5465/75

For greater strength and

manoeuvrability.

Power Take-off

Four PTO options plus

groundspeed PTO are available

allowing you to meet the demands

of your farm precisely.

Cab options

MF 5400 Series cabs can be

uniquely specified to give you the

best performance and productivity.

Choose from high-spec cab or

platform with ROPS and suncanopy with either a pivoting or

‘steep-nose’ bonnet.

A lower profile cab is available

for working in restricted height

buildings, whilst the Visio roof

option provides excellent visibility

when using a loader at height.

Optional Cab suspension

Get more productivity and

enjoyment from your working day,

and operate effortlessly in comfort.

This new cab suspension allows

you to graft for longer in a variety

of applications.

06

Page 7

07

Page 8

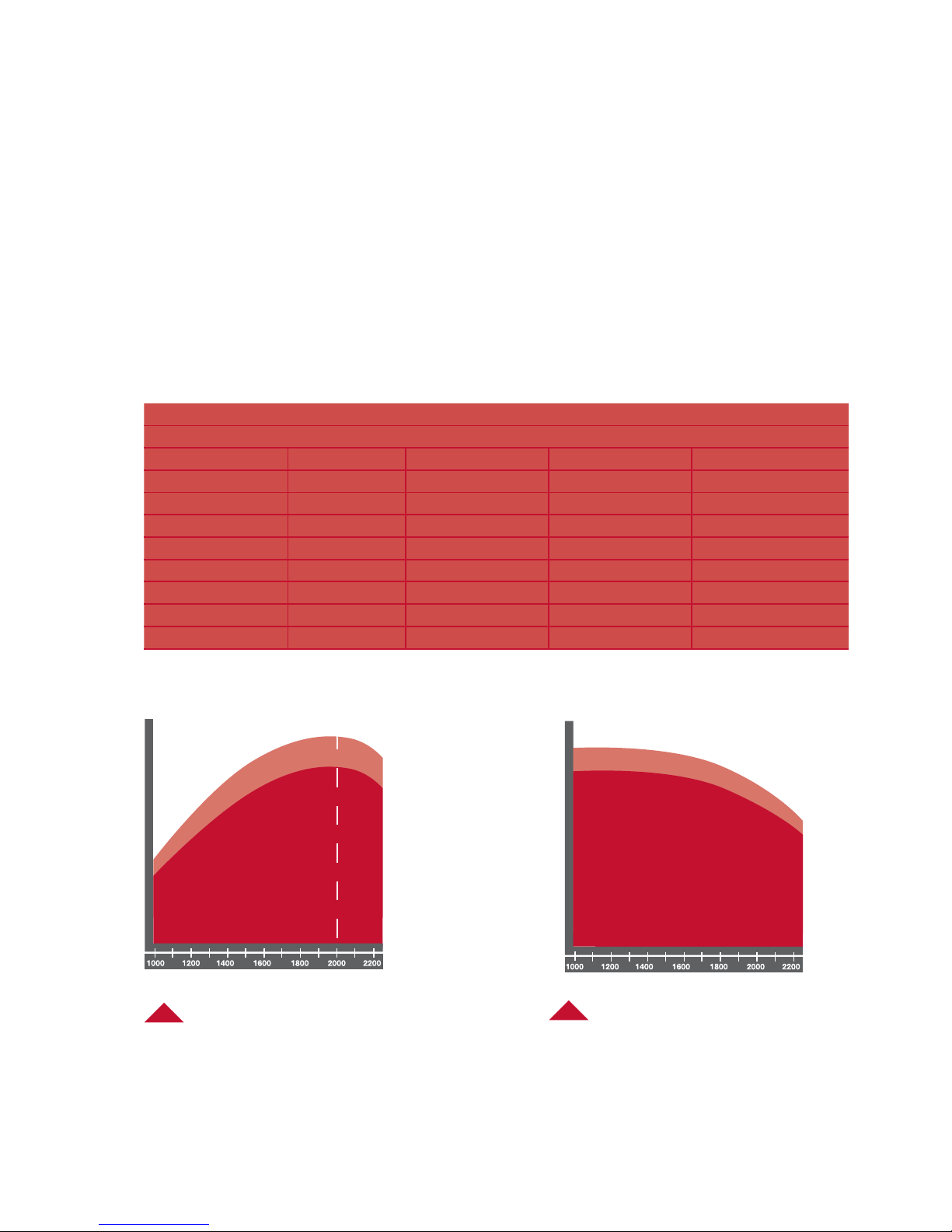

Torque reserve

B

A

The torque curve shows how ‘pulling

power’ is maintained as engine speed

falls and how it is increased with

PowerBoost right down to idle

A: Normal torque curve

B: Boosted Performance: extra torque,

available when 3rd or 4th range

is selected.

Torque (Nm)

Engine speed - rev/min

Powerful delivery

B

A

Power increase

Power (PS)

Engine speed - rev/min

High power, with power increase as

engine speed falls between 2200 and

2000 rev/min

A: Normal power curve

B: Boosted Performance: extra power,

available when 3rd or 4th range

is selected.

08

Technologically advanced, high powered and economical;

benchmarks in engine design that others can only aspire to.

Outstanding power comes from the latest Tier III common rail and

four-valve engines. Within its class, every MF 5400 Series tractor

benefits from the highest levels of performance and power.

Model range

Model Cylinder Engine capacity Max Power. hp PowerBoost hp

1

MF 5425 4 4.4 86 MF 5435 4 4.4 96 MF 5445 4 4.4 100 110

MF 5455 4 4.4 112 125

MF 5460 4 4.4 125 135

MF 5465 6 6.6 132 144

MF 5470 4 4.4 135 145

MF 5475 6 6.6 144 156

MF 5480 4 4.9 145 155

1

hp figures - ISO TR14396.

Page 9

09

MF 5400 Series tractors have highly responsive engines that offer uncompromised performance and strength.

The excellent build quality and latest engine technology guarantees optimum fuel efficiency, maximum power, reliability

and longevity.

MF 5425/MF 5435 with

PowerMax! – turbocharged

to provide 86 and 96 hp, with

intercooled mechanical fuel

injection. Tried and trusted

engines within this range

guarantee exceptional power

and torque whilst maintaining

low emissions.

Power and torque

Maximum power is achieved

at 2000 rev/min, resulting in

significant fuel savings and lower

noise levels. In fact, these tractors

have excellent power delivery

capabilities across an impressively

wide speed range, with a constant

power range exceeding

400 rev/min.

Reassuring torque back-up means

you can reduce engine speed

when pulling away under load, or

on headland turn manoeuvres,

with ease and in safety.

MF 5445/55/60/65/70/75/80 with

PowerBoost!

A new generation of

4 & 6-cylinder engines

Incorporating the same advanced

engine technology as our higher

horsepower models, electronic

common rail fuel injection and

16 valves combine to deliver

95 hp - 135 hp.

Featuring impressive torque

capabilities and PowerBoost,

all models have significantly

more power at 2000 rev/min

than previously produced at

2200 rev/min.

PowerBoost

Perfect for use in transport mode

and when hauling heavy loads over

long distances. PowerBoost gives

additional engine power across the

full engine speed range from idle to

2200 rev/mins.

With PowerBoost as standard on

all models (excluding MF 5425 &

MF 5435) jobs such as

transportation, top work, spraying

and spreading on larger arable

farms are simple, economical and

efficient. There are no buttons or

switches, just let the engine do the

thinking.

When the operator selects either

3rd or 4th range, the engine will

automatically create ‘boost’,

providing more power and torque

all the way from 6 Km/h up to

40 Km/h.

As well as providing higher

maximum power, PowerBoost

also provides additional power at

lower engine speed for improved

productivity and greater

fuel savings.

Page 10

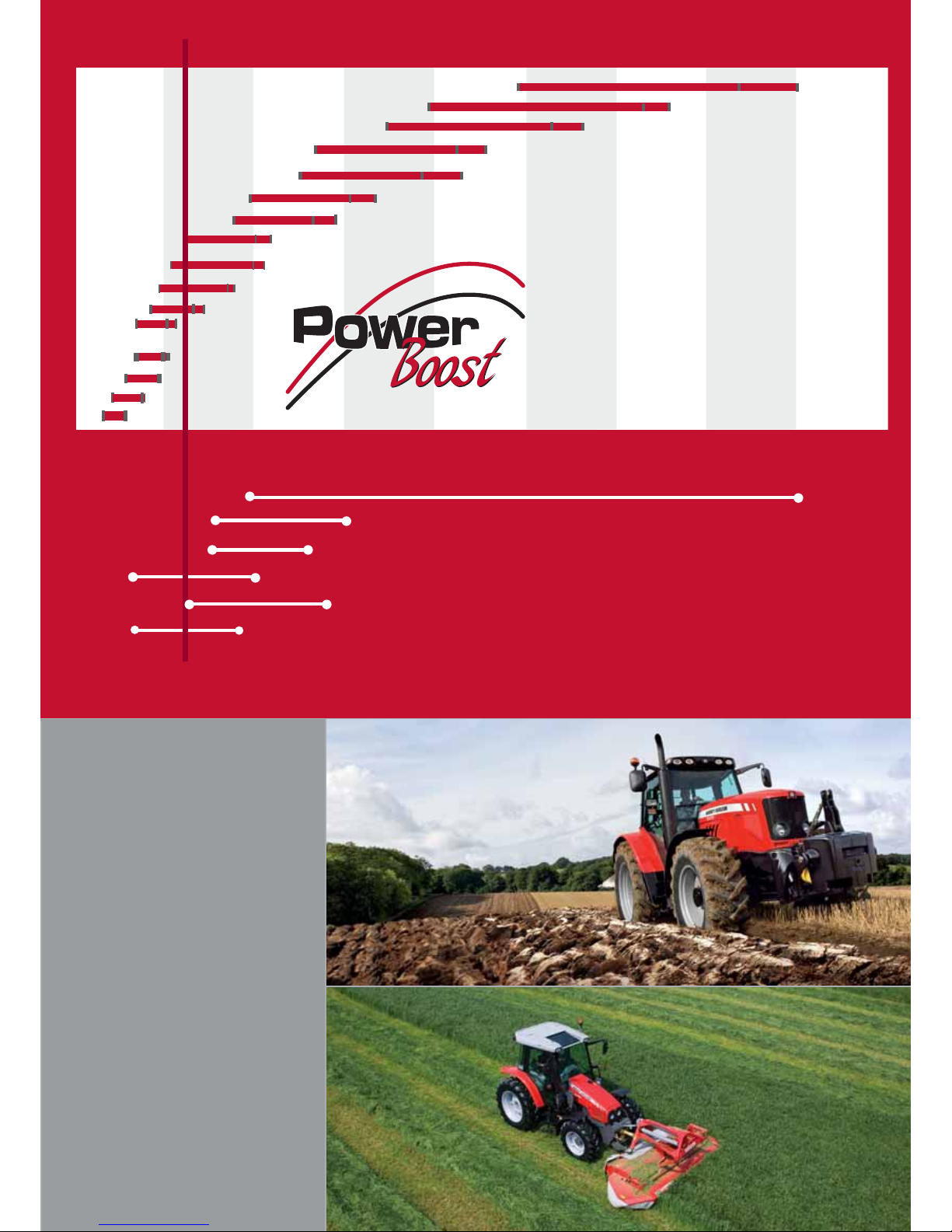

Enhanced performance

and flexibility with

PowerBoost

10

Whether in the field or on the road, the latest engine technology

allows engine performance to be enhanced to maximise

productivity in a wide range of applications.

Getting more power, with

less effort

PowerBoost provides more power

and ultimately more productivity

with effortless performance,

whenever 3rd or 4th range is

selected. This functionality is

available on models from

MF 5445 up to the MF 5480.

The fuel injection system in each

engine is electronically managed,

allowing the characteristics of

engine performance to change and

accommodate the toughest tasks.

Electronic Engine Management

(EEM) monitors and increases

the amount of fuel being supplied

to the engine, so depending on

the application, additional power

and torque can be available

automatically through an

automated system.

Power + Performance

Extra power equals extra

performance and essentially

more productivity, particularly in

transport and haulage applications.

However, as 3rd range provides

forward speeds as low as 6 km/h

@ 1400 rev/min, the extra power

and torque is readily available

for many field applications such

as mowing, fertiliser spreading,

cultivation and baling.

For additional power in feeder/

mixer wagon and slurry pump

applications, PowerBoost is also

provided when the PTO is engaged

and the tractor is stationary.

Page 11

0.0

5.0 10.0

15.0

20.0

25.0

30.0

35.0

40.0

4

3

2

1

8

7

6

5

12

11

10

9

16

15

14

13

Manure/slurry spreading

Round baling

Ploughing/cultivating

Fertiliser spreading/spraying

Mowing

Transport

11

6 km/h

Boosted power from 3A

Km/h

Reasons why

PowerBoost pays!

PowerBoost perfectly •

optimises engine

power

PowerBoost provides •

extra power when it’s

needed most!

PowerBoost •

maximises fuel

efficiency

Extra power from •

idling to maximum

engine revs!

Efficient engine •

operation thanks to

4-valves per cylinder

Page 12

Left-hand control

The left-hand Power Control lever

provides convenient forward/

reverse shuttle, powershift and

range changes and fingertip

de-clutching, leaving the right

hand free to operate the loader

or rear implements.

Right-hand control

Simply move the T-shaped

transmission control lever forwards

or backwards to change up or

down through the four Dynashift

ratios. To change range, simply

press the range selection button as

you move the lever.

When changing range,

Speedmatching automatically

selects the correct Dyna-4 ratio to

match the tractor’s forward speed.

Comfort control

Smooth or fast shuttling – the

choice is yours – adjust the

Comfort Control knob and you

have the perfect tractor for

loader work.

Creep and Supercreep options

Close control in specialist lowspeed tasks is assured with an

additional 8 (creep) or

16 (supercreep) gears, enabling

forward speeds as low as 500m/hr

and 160m/hr respectively to

be achieved.

How you will benefit:

Optimum field performance, •

four mechanical range

changes provide 16 forward

and 16 reverse speeds, all

available without having to

use the clutch pedal!

12

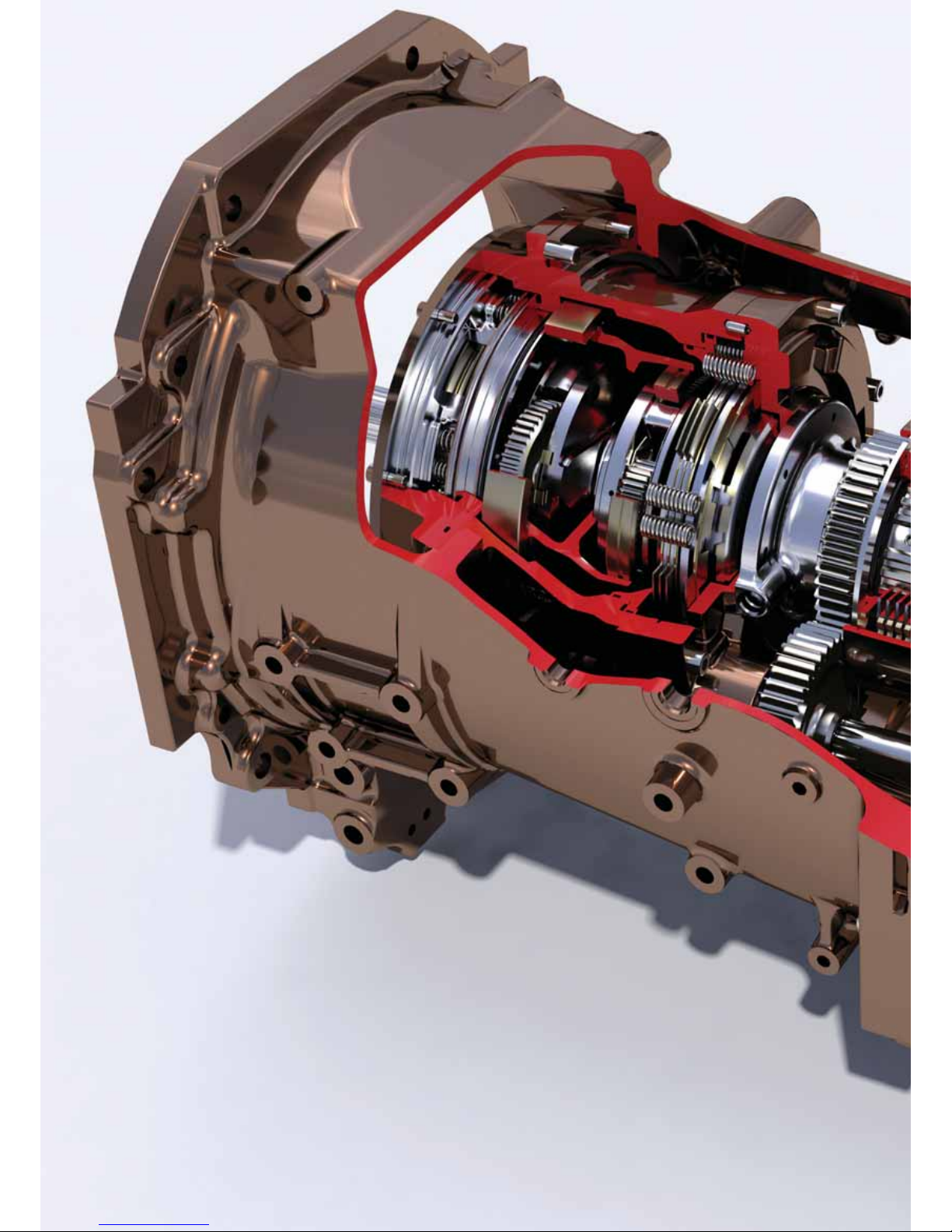

Unbeaten design:

and Power

Control

The straightforward & efficient design behind the Dyna-4

transmission continues to impress with incredibly smooth 4-speed,

powershift change in each of the four gears, giving you first-rate

productivity, everytime.

02

Neutral

De-clutch

Forward drive

Reverse drive

Change up ratio

Change down ratio

N

01

01

Operation is simple and less •

repetitive with ergonomically

placed controls, reducing

operator fatigue and stress

The left-hand Power Control •

lever enables convenient and

straightforward operation

For rapid and precise loader •

work, Comfort Control

maintains stability during

smooth or fast shuttling

Speedmatching minimises •

operator effort and maximises

productivity

Straightforward design and •

proven, reliable components

provide exceptionally smooth

operation with strength and

longevity

Page 13

40

3020151050

4

1

2

3

1400 2200

A

B

C

D

Main Range

Field working

range

Dynashift Range

Engine Speed

Forward/Reverse Speed

(MF 5455 16.9R38)

km/h

04

03

01 Simple, multi-function,

left-hand Power Control lever

02 The Dyna-4 ratios

03 Dyna-4 controls include

left- or right-hand gear selection

plus variable, operator-controlled

forward/reverse shuttle take-up

04 The Dyna-4 transmission offers

four Dynashift changes in each

range, excellent ground speed

‘overlap’ and 40 km/h maximum

speed for efficient haulage

operations

13

Page 14

Precision and performance from Massey Ferg

u

14

Page 15

son

15

Page 16

Total operating flexibility

The MF 5400 Series has

excellent lift capacity and loader

capability with endless hydraulic

potential and PTO specifications

to give you total operating

flexibility.

Simple, effective hydraulic

system

57 litre/min of oil available for •

linkage and external hydraulic

functions

Plenty of flow and pressure •

to cater for lifting heavy

equipment or powering

ancillary accessories

100 litre ‘Twin’ flow

Optional across the range: 100 •

litre/min oil flow is achieved

at the flick of a switch, the

three-point linkage is ‘locked

out’ and the higher flow is

made available to give extra

speed and power for loader

operation

110 litre Closed Centre Load

Sensing (CCLS)*

For applications that require

extra hydraulic power, the CCLS

hydraulic system can be specified.

CCLS will react responsively in the

field, meeting the demands

of oil-hungry implements to

boost productivity

The high pressure pump •

allows a varying flow of

between 0 and 110 litres/min

An ‘intelligent’ load sensing •

valve recognises the amount

of oil and automatically

adjusts the pump to meet

demand

When there’s no demand, the •

pump will idle, reducing power

and enhancing fuel economy

The 110 litres/min max flow •

will provide speedy operation

of hydraulic applications and

rapid cycle times in loader

operations

The key to reliable, hard-working machinery is to choose a tractor

that meets the requirements of today’s modern implements and

utilises them to their full potential within a wide range of agricultural

applications.

Fade-free braking

The rear axle houses large •

disc brakes with constant

pressure lubrication

Differential locks

At the touch of a button, •

simultaneous actuation of

front and rear differential locks

ensures maximum traction at

all times, under all conditions

The ‘Hydralock’ differential •

lock ensures fast,

100% engagement and

disengagement with no

slippage or loss of power

Gives true 4-wheel drive when •

engaged

4-wheel drive axle

All 4-wheel drive models •

feature a centre-mounted

drive shaft design for excellent

ground clearance

A tight steering angle for •

manoeuvrability and tight

headland turns is guaranteed

QuadLink front axle**

Massey Ferguson’s renowned

QuadLink suspended front axle is

available as an option, significantly

enhancing ride comfort and

control.

A compact, simple design, •

QuadLink automatically

maintains a constant

suspension height, regardless

of the load on the axle, to give

increased stability with greater

comfort, productivity and

safety – in field and on road.

Automated control

‘Transmission Controller’ •

simplifies operation by

partially automating a number

of frequently used functions

Including: Differential lock •

control, PTO control and

gearbox range selection

Versatile PTO

Four PTO options are available •

plus Groundspeed PTO

Independent 540/1000 rev/min •

as standard

540/1000 rev/min ‘economy’ •

offers standard PTO speeds at

1550 engine revs to save fuel

and cut production costs

In-cab or external shiftable •

options available

Ground speed is also available•

All options perfectly match •

any farm’s requirements

PTO STOP button on the rear •

fender allows the operator to

use attached machinery safely

and securely from the exterior

of the tractor cab

Optional front PTO available•

Auxiliary spool valves

Allowing the operator to get the

most output from the hydraulic

system, a range of auxiliary valve

options are available.

Between two and four •

mechanically controlled

valves can be specified, to

ideally meet customer and

application requirements

Optional integrated joystick •

control for two valves is

available which will operate

additonal electro-hydraulic

services for loader or front

linkage applications for even

more versatility

Spool valve couplers are •

conveniently placed to allow

quick and easy attachment

and detachment of implement

hoses

16

* CCLS available on models MF 5465-80 ** Quadlink available on models MF 5460-80

Page 17

01

03

05

04

02

01

17

01 Combined flow ensures loaders

operate with power and efficiency

02 PTO and combined oil flow

switches

03 Simple PTO control and selection

04 Optional fender-mounted PTO

STOP switch

05 Operate attached machinery

securely and safely

Page 18

08

16

Highly specified three-point

linkage

A tough 5,000 or 6,000 kg

(optional) lift capacity means

that heavy-mounted equipment

can be lifted with ease

A variety of hitches are •

available, with twin telescopic

stabilisers and two spool

valves fitted as standard

Fender-mounted switches •

provide convenient linkage

height adjustment for fast,

easy implement attachment

Linkage height can be •

adjusted using switches

conveniently mounted on the

fender, so implements are

attached quickly and easily.

Industry-leading Electronic

Linkage Control (ELC)

ELC provides precise and

responsive control of the linkage

functions, ensuring accurate

control of the depth of work

for soil engaging implements

plus working height for non-soil

engaging implements.

The ELC ‘mouse’ is placed

specifically to the right of the

operator to provide quick and

easy access, allowing precise

control of implement depth and

lifting and lowering of linkage.

The Electronic Lift Control panel

allows straightforward adjustment

of other rear linkage functions for

enhanced productivity.

The perfect linkage

system

All Massey Ferguson 5400 Series tractors are built with heavy-duty,

category 2 & 3 rear linkage. There’s a choice of options too, that

suit all applications. Our specifications ensure that your tractor has

the perfect linkage system to suit your exact requirements.

18

Functions include:

Position/Intermix/Draft control •

- For precise operation with all

types of implement

Rate of linkage lowering •

control - For optimum

performance and safety,

including lock

Maximum lift height control • Adjust the lift height accurately

and protect PTO drive shafts,

safeguard both tractor and

implement and reduce cycle

times during headland turns

Lift/Lower/Height/Depth •

control - Allows for precise

adjustment and ensures

accurate control

Active Transport Control (ATC) •

- Provides shock dampening

for the rear linkage and

protects the tractor during

transport of heavy implements,

resulting in approved driver

comfort

Front linkage and PTO (optional)

Take full advantage of productivity

gains when using both front/rear

implement combinations.

Benefit from real time savings •

- up to 30% when drilling

2.5 tonne lift capacity and •

the option of an accumulator,

hydraulic couplers and PTO

Integrated Front Linkage System

(IFLS)

For six-cylinder tractors, an

integrated front linkage system is

available. The front axle support

casting enables factory-installation

of the Massey Ferguson IFLS: a

neat, fully integrated front linkage

and PTO system.

The integrated front linkage •

design also has tremendous

strength to cater for heavy,

high-productivity frontmounted equipment.

Attached to an exceptionally •

strong structural engine sump

means that no additional

side rails are necessary when

specifying the front linkage.

Engine access is further •

improved

A tighter steering lock is •

achieved, for faster headland

turns and manoeuvring.

The new front linkage also •

incorporates a towing clevis,

electrical connector and up to

two spool valve couplers.

01 & 02 Optional front linkage

and PTO available

03 Electronic linkage control

(ELC) ‘mouse’

04 Electronic Lift Control panel for

straightforward adjustment of rear

linkage functions

05 Fender-mounted lift/lower

switches

06 Lower link - Hook-end

07 Lower link - Ball-end

Page 19

19

06

01

07

03 04

05

02

Page 20

20

A better working

environment

High-productivity depends on

many factors within the agricultural

industry. Reliable, good quality

machinery and a safe and healthy

working environment are two of

those factors.

It is estimated that around five

million working days are lost

each year due to driving-related

activities*, leading to loss of

productivity and in some cases

long-term health problems.

Looking after people and

machinery in the workplace is

essential. Depending on the

application, you could spend up

to 18 hours a day in your tractor;

so comfort, practicality and

ergonomics are essential attributes

to a profitable and effective

business.

Our priority is your comfort

The cab of the MF 5400 Series

has been ergonomically designed

to reduce stress on the operator.

Well-positioned controls, an

adjustable driver’s seat plus

easy accessibility to the cab all

contribute towards better working

conditions.

Enhanced driver comfort is something that we pay particular

attention to. Understandably you’ll be spending plenty of time in

your tractor, so we now offer an optional cab suspension system

for higher levels of comfort and safety. This new feature brings

Massey Ferguson to the forefront of agricultural innovation with

excellent levels of operator comfort down to 86 horsepower.

This flexible new feature for

Massey Ferguson’s range of

machinery means that the entire

MF 5400 Series can be specified

with cab suspension as an optional

feature on all standard, flat floor

cab versions.

The MF 5400’s tough yet simple

cab suspension will help to reduce

driver fatigue and discomfort.

Whichever application you’re

working in, you can be assured

that this simple system requires

no operator input and works

independently and to its full

potential.

Where transporting, mowing and

cultivating can be amongst the

most arduous and repetitive of

tasks, the MF 5400 Series’ new

cab suspension will cushion the

impact of heavy-duty applications

that may involve the operator

being continuously jolted.

This straightforward cab

suspension system consists of

silent bloc bushes at the front

of the cab and a pair of spring

assisted shock absorbers mounted

at the rear.

MF 5400 Series tractors: further

improving driver comfort by

giving a smoother ride and

faster, safer transport of

mounted equipment.

The opposite page shows

the range and applications in

which the MF 5400 Series cab

suspension will work at maximum

productivity whilst ensuring your

health, safety and comfort at

all times.

* Based on UK findings from the Health and Safety Executive.

** Average working speed may vary depending on conditions and attached implements.

01 Left-hand front silent bloc

02 Left-hand rear suspension

Page 21

01

21

02

Ideal in: Transportation - Perfectly in control and

sitting comfortably when faced with less than perfect

roads!

At: 10-40 km/h**

Ideal when: Spraying/fertiliser spreading - Work within

a safe, productive and stable environment even at higher

working speeds.

At: 5-15 km/h**

Ideal when: Mowing/tedding/raking and baling - An

application that requires a large amount of repetitive driving

on uneven ground will benefit greatly from the

MF 5400 Series cab suspension.

At: 5 - 15 km/h**

Ideal in: Bale handling - Driving on rough, uneven

ground such as tramlines is made easier and more

comfortable.

At: 5 - 20 km/h**

Page 22

05

22

Get something back for the long

hours you put in - low noise levels,

a spacious cab and great visibility

make the MF 5400 Series an

enjoyable place to work.

The cab retains its popular and

practical layout, with controls

positioned exactly where you

would expect to find them.

Two wide-opening, rear-hinged

doors make access easy. There

is a choice of mechanical or

air suspension seats, both

with a comprehensive range of

adjustments including 30o of swivel

and long, adjustable armrests.

Visio-roof models offer sidemounted radio (optional) and

ventilation controls.

With the optional air suspension

seat, at the touch of a lever,

accurate adjustment to

compensate for driver weight or

the terrain is quickly achieved. For

further driver comfort an optional

lever allows adjustment of the

steering column height and tilt.

A handy folding auxiliary

seat is also available which can

be raised and locked into position

when required.

Active Transport Control

Active Transport Control (ATC) is

a shock-absorbing system that

reduces implement ‘bounce’,

which can occur when driving

across the headland or transporting

heavy-mounted equipment.

ATC is fitted as standard on all

MF 5400 Series tractors.

Everything about the

MF 5400 Series has

been designed to

make your time at work

comfortable, relaxing

and productive.

Page 23

23

Page 24

Page 25

Page 26

For further information on

MF 900 Series loaders and

implements, contact your local

Massey Ferguson dealer and ask for

a brochure.

High performance construction

from the world’s leading loader

manufacturer ensures that these

loaders deliver first class versatility

and outstanding reliability.

Low running costs, operator

comfort and an effortless working

environment make the MF 5400

Series the right choice for any

dairy, livestock or arable business.

Add to this a factory-fitted,

optimum usage loader and you

can achieve maximum productivity,

whatever the application.

Choose from an extensive range

Full integration of tractor and

loader is achieved easily with the

MF 900 Series, to suit 50 - 300 hp

Massey Ferguson tractors. You

can choose from either ‘standard’

or ‘parallel’ linkage, available

throughout an extensive range of

12 models, along with numerous

options to enhance performance

and convenience.

Lock & Go - smarter, better

Work smarter with ‘Lock & Go’.

A ground-breaking, semiautomatic connection and

disconnection system which saves

you valuable time when hookingup loaders. By utilising the

combination of a unique sub-frame

design, lift cylinders and locking

pin, you can attach/detach loaders

efficiently and reliably.

Together with the multifunction

joystick control levers you can be

assured of operational ease and

safety with all functions.

An full range of loader implements

are available as well as rear ballast

configurations to ensure optimum

handling, greater performance and

safe operation.

Here’s why both the MF 5400

Series and MF 900 Series meet

the operational challenges of

modern farming:

MF 5400: the perfect loader

tractor...

Steep nose bonnet available •

on MF 5425 through to

MF 5455 - For maximum

clearance, manoeuvrability

and visibility

Visio roof - Allows the operator •

to view the task at hand

57 litres/min standard flow•

100 litres/min combined flow•

110 litres/min CCLS hydraulic •

system

Dyna-4 transmission with •

Power Control lever and

shuttle control

Adjustable shuttle •

progressivity

Heavy-duty 4WD front axle •

with hydralock

55˚ max turning angle•

...MF 900: the perfect loader

Robust and efficient •

construction - ensures

maximum output

Loader sub-frames are •

designed to allow drive-in

attachment - for quick and

easy connection

The semi-automatic ‘Lock & •

Go’ system holds the loader

rigidly and securely in position

All hydraulic hoses are safely •

concealed for protection

and greater visibility for the

operator

‘SoftDrive’ system (optional) •

- Innovative shock absorption

system is available on all

models and ensures stability

and comfort on rough terrain

and in transport

An extensive range of optional •

extras are available. Ask your

Massey Ferguson dealer for

more information.

01 & 02 ‘Lock & Go’. Save time

when attaching and detaching

loaders

03 Visio roof for excellent visibility

26

The essential tractor &

loader combination

MF 5400 Series tractors have been designed to work specifically

with the MF 900 Series loader. Both are fully integrated at factory

source to give you optimum performance and ultimately, the

perfect all-purpose tractor.

Page 27

27

01

02

03

Page 28

28

System 110 lightbar guidance

simplifies key operations

for added productivity and

efficiency on your farm.

Topcon SYSTEM 110

System 110 delivers maximum

operating simplicity in a light bar

guidance product. With features

such as a detachable light bar for

optimum ‘field of view’ placement

and a 5” high-visibility colour

display that operates in separate

‘day’ and ‘night’ modes, System

110 will quickly become the field

tool of choice.

Key points

Simple on-screen set-up•

Sub-meter guidance, •

upgradeable to automatic

steering*

Quick action keys for simple •

operation

On-screen status indicators: •

Row Number, Speed, and

Area Applied

Interchangeable field •

views including Overhead,

Perspective and North up

Multiple contour pattern•

Features and benefits

GX-45 Console

Rugged housing, built for the •

field

Colour, 5 inch diagonal screen•

Quick action keys for simple •

operation

Visual indicators include: area •

applied, speed, row number

and satellite information

Convenient USB port for data •

transfer

Detachable LED light bar for •

optimum placement in field of

view

Guidance Patterns

AB lines•

Adaptive Curves•

Centre Pivot •

Viewing Perspective

Overhead View•

Perspective View •

North Up View •

Additional features

Create and save field •

boundaries

Automatic coverage maps•

Topcon’s light bar guidance systems are tried and trusted tools

within the agricultural sector, improving efficiency and operating

speeds while reducing overlap and extending hours of operation.

End of row alarms•

Radar speed output for •

external controllers

GPS signal output•

Export PDF coverage report•

Import and export boundary •

and coverage files

Auto Section Control and •

application rate control

Easy to Install and Operate

You can be operating in minutes.

Lightweight, rugged and portable,

System 110 is easy to install with

minimal training or instruction.

System 110 allows you to set up

configurations such as attached

front and rear implements or single

and double-trailed hitch points.

Plus, the System 110 is simple to

move from machine to machine.

Straightforward,

intuitive technology

*Additional/optional components required

Page 29

29

Useful on-screen indicators show

Area Applied, Speed, and Row

Number, all while building a colour

coverage map. The convenient

USB port allows you to easily

export reports and shape files.

Automatic Coverage Maps

Coverage mapping can be used

to track the area covered by

your machine. Avoid missed

areas or areas of overlap. With

remote master hookup, automatic

coverage maps can be generated

more accurately without additional

work.

Boundary Mapping

Boundary mapping lets you create

field outlines that you can use over

and over for any application jobs

performed on that field. Knowing

the field’s size and shape helps

you plan application quantities and

coverage routes.

Automatic Section Control

Option

With optional Automatic Section

Control (ASC-10), System 110

automatically switches up to ten

sprayer sections on or off as you

cross previously applied areas,

reducing inputs while protecting

your crops.

No Limits

Topcon’s intuitive software allows

you to quickly create and follow

the most efficient or practical

guidance. Instead of limited, fixed

patterns which may not be exactly

right for your field, System 110

provides three basic ‘modes’

that can be used in a variety of

combinations, allowing you to

work easily with virtually any

field shape.

Upgradeable to SYSTEM 150

automatic steering system

A SYSTEM 110 can be upgraded

to a full featured automatic steering

system.*

For further information on Topcon’s

guidance systems, contact your

local Massey Ferguson dealer or

go online at

www.agcotechnologies.com

Page 30

Outstanding ‘Platform’

performance

Ranging from 86 to 112 •

ISO hp (125 max boosted),

outstanding performance and

high levels of comfort and

safety are assured

MF 5400 Series platform •

models meet the most

stringent noise and safety

legislation

Now available in most •

European markets as well as

countries more traditionally

associated with non-cab

tractors

‘Pivot’ or ‘steep nose’ bonnet •

styles available

Downswept-or side-mounted •

exhaust

2- or 4-wheel drive •

All models feature a modern, •

safe, flat-floor platform area

with up-to-the-minute styling,

excellent visibility and simple

instruments and controls

Gearbox options

Platform models are available •

with the Dyna-4 gearbox (see

pages 12 & 13) with ‘creep’

and ‘supercreep’ available,

maximising productivity

in specialist low speed

applications

Simple ELC

Massey Ferguson ELC •

Electronic Linkage Control

System is simple, reliable and

easy to use, giving exceptional

accuracy and control

Muscular lift capabilities and •

high capacity hydraulics mean

that even large implements

can be handled with ease

Automatic 4-wheel braking

Automated control of 4-wheel •

drive, differential lock and PTO

give optimum efficiency whilst

minimising driver input

The electro-hydraulic •

system provides automatic

engagement of 4-wheel drive

when the brakes or parking

brake are applied

Giving 4-wheel braking, for •

added braking efficiency,

stability and safety

Hydralock differential lock

Hydralock is standard on •

all 4-wheel drive models

and provides simultaneous

actuation of both front and

rear differential locks

The result is true 4-wheel drive •

with both front wheels locked

together and turning at a

speed proportional to the rear

wheels

Sharing many of the advanced design features of the cab models,

the four MF 5400 Series ‘platform’ tractors are durable workhorses

built for the toughest conditions.

Unlike ‘limited slip’ systems, •

when disengaged, Hydralock

operates as a normal

differential, so tyre scrub and

soil damage are reduced and

tyre life is extended

Choice of PTO options

Wide choice of PTO options •

including 540 and 1000

rev/min, economy and

ground speed PTO so all

implement and power takeoff requirements can be met

efficiently.

The Ultimate Platform

30

Page 31

31

Page 32

01 Easy access to dual element

dry air cleaner

02 Excellent accessibility to the

engine and cooling pack

03 Externally accessible cab

air filter

04 Ground-level fuel filler means

quick, spillage-free refuelling

From the initial high build quality to

the world-leading AGCO Parts and

Service back-up and ultimately

high residual values, everything

is in place to reduce overall

‘life-time’ costs.

Extended service periods

Simple servicing and minimised

routine checks are other key

areas in reducing down-time. The

MF 5400 Series has a number of

significant design features; some

large, some small, to help make

life more simple:

• Large diameter, oil-cooled, multi plate clutch, for a long service

life, with no adjustment required

• Self-adjusting brakes

• Maintenance-free battery

• There are no more than ten,

readily accessible, grease points

• Engine oil dipstick, filler, filters

and lift pump are all grouped on

the left side of the engine

• Transmission oil and filters only

need to be changed every 1200

hours, with an engine oil change

only needed every 400 hours

Obviously, costs

are increasingly

important in today’s

competitive farming

environment so

when buying a new

tractor you have to

look at more than

just the initial outlay.

This is where the

MF 5400 Series

makes the

difference.

32

Fast, easy routine

maintenance

Page 33

02

04

03

01

33

Page 34

With a manager plan and through

this ‘preventative’ servicing, your

machine will maintain excellent

productivity throughout its long

working life. The most important

aspect of this package is that you

will never incur any unexpected

additional costs.

It is possible to cut the cost of

maintaining your machine through

‘preventative’ servicing and

maintenance, thereby reducing

long-term ownership costs and

securing a productive future for

your business.

Tailored specifically for you

manager has been designed to

cater for your individual needs.

Cover is available for up to 5 years

or 6,000 hours, depending on

your requirements. Available at

initial point of sale or, for added

flexibility, you can choose to take

on a manager plan any time

up to six months after machine

registration.

manager Service and Extended

Warranty Plan* is a complete

package aimed at providing total

care for your tractor including

routine maintenance, repair cover

and full AGCO backed warranty.

This fully-backed plan will cover

critical components such as:

Engine and transmission•

Hydraulics•

PTO•

Steering•

Electronics•

Cab and controls•

Axles•

Assurance for the life of the

machine

You can be assured of ‘preventative’

servicing using the latest technology

and professionally trained

technicians. With years of experience

they are on hand to ensure that

your machine runs at optimum

performance.

All of this will be carried out

according to a strict maintenance

schedule supplied by

Massey Ferguson.

Your dealer will prepare the

servicing plan and can tailor

it to last up to a maximum of

10,000 hours.

By choosing a manager Service

and Extended Warranty Plan, not

only are you assured of complete

peace-of-mind for you and your

business but also a higher residual

value for your machinery, full

dealer history and genuine AGCO

Parts, inside and out.

For more information on the

manager Service and Extended

Warranty Plan, speak to your

Massey Ferguson dealer.

It makes good business sense to plan for the unexpected and

where machinery is concerned, there’s no price on complete

peace-of-mind. Secure your assets with a manager Service and

Extended Warranty Plan.

Ensure a cost effective

future for your business

*manager Service and Extended Warranty

Plan

may not be available or may be

market dependant. Please contact your

Massey Ferguson dealer to check

availability in your area. Terms and

conditions apply.

34

Page 35

35

Page 36

Massey Ferguson is a true global

brand with machines operating all

over the world, from revolutionary

“little grey fergie” tractors to

the latest high-tech tractors

and combines. Have you ever

wondered how we continue to

provide industry-leading parts

and service support to such

a vast array of machines and

technologies across the globe?

Behind every Massey Ferguson

machine is the powerful aftersales

support of AGCO’s Customer

Support organisation.

Our main aim is to ensure that

every machine - old or new - is

fully supported locally, offering

every Massey Ferguson owner:

• The best service in the industry

• Low cost of ownership

• A reliable and durable machine

• Minimum machine downtime

• A high resale value

State-of the art warehousing and

logistics from AGCO Parts

Of course, every Massey Ferguson

dealer is fully backed-up by

the AGCO Customer Support

organisation which provides

industry-leading parts supply

through AGCO Parts’ state-ofthe-art warehousing and logistics.

With outstanding service levels,

overnight delivery and inventory

covering all Massey Ferguson

machines - even those over 10

years old - we only ever supply

genuine parts, and we guarantee

the right fit, first time.

AGCO Customer

Support…

providing local

service to the

global brand

The right aftersales solution

whatever the age of machine

Whatever the age of your

Massey Ferguson machine,

AGCO Customer Support has

the right aftersales solution to

save time & money, providing

appropriate, affordable and

reliable servicing and maintenance

solutions in every situation.

Practical local support

where you need it

AGCO places great emphasis on

providing the best service to our

Massey Ferguson dealers and this

extends beyond the exceptional

servicing and maintenance

solutions and parts supply:

• Expert training and

specialist equipment

• Advanced diagnostic techniques

• Information retrieval technology

to communicate the very latest

parts and service information

• Highly skilled technical

support groups

With aftersales support from

AGCO Customer Support, it’s

not just about supplying a filter

or doing an oil change. It’s about

providing the best solution to our

customers’ needs, wrapped up

with industry-leading parts and

service support.

01 Ensuring the best service

support

02-03 Industry-leading parts

supply from AGCO Parts

04 Practical, local support,

wherever you are

05 Lifetime support for all

Massey Ferguson machines

36

Total support, no matter

where or when!

Page 37

01

02

04

03

03

05

37

Page 38

The multi-task tractor

Lionel Carret, Gaec de Pomeyrieux Farm, France

“We are located in a hilly area so we really appreciate

the smoothness of the Dyna-4 transmission and the

ease of the gear changes.”

Features that Lionel particularly likes about his MF 5455

include the hydraulics and the styling of the machine.

“The Steepnose allows me to have good visibility which

is beneficial during loader work especially from a safety

point of view as you can see the front of the tractor and

the material the loader is carrying, easily.”

“As we use this tractor more often for transport in steep

areas, I really do save time thanks to the extra power

available with the PowerBoost.”

“Using a tractor in our region can be quite dangerous

so stability and safety were our main buying criteria

and the MF 5400 Series made me feel really safe in all

situations.”

“This is our first Massey Ferguson machine and we

have been very impressed by its level of performance

combined with its compact size, manoeuvrability and

visibility.”

Built with passion...

Total versatility

Marco Tosi, Tosi Claudio e Marco Societa’

Agricola, Cella (RE), Italy

Marco Tosi is a dedicated livestock producer

which provides milk for ‘Consorzio’ of

Parmigiano Reggiano (Parmesan cheese).

They work 85 hectares of land comprising of

grass, forage and corn.

“We are very happy with our MF 5480 due to its

versatility, we use it for many farming activities

and it is the main tractor on the farm - clocking

up 800 hours per year” Marco tells us.

“It works faultlessly when ploughing, seeding,

grass cutting and baling. We specified front

linkage and PTO which has saved us a lot

of time and money, giving us maximum

productivity.”

“We use the MF 5480 a lot more now to

transport produce. The suspension copes well

with road conditions and haulage applications.”

38

...owned with pride! Read why people choose Massey Ferguson’s

award-winning, industry-leading machinery!

Page 39

Compact all-round workhorse

Clive Jones of Lower Pendre Farm, Llangorse, Brecon, Wales, UK

“Our MF 5435 is a real little all-rounder, and was purchased for mowing and tedding as well as for hauling

silage and straw and is fitted with a front loader.

“We have found a lot more jobs than we expected for the MF 5435 since it arrived in June. It has hauled

1000 bales of silage and 500 of straw this year, and we also use it for all of our spraying and fertiliser

application.”

Dyna-4 transmission

Jeremy Platt, Dairy Farmer, Northwich, Cheshire, UK.

“This is an ideal tractor for a dairy farm – easy to use, comfortable and with enough technology without

being overcomplicated,” he explains.

He picks out the Dyna-4 transmission with its unique left-hand shuttle as its strongest feature. “On the

feeder wagon, there’s no need to use the clutch when feeding out and moving around the buildings – it’s

really useful. I wasn’t aware of just how good this transmission was until I used it.”

Professional service, quality products

Pawel Zienczyk, Zienczyk Farm, Jarzabkowo, Niechanowo, Poland

The latest addition to Pawel’s long-line of Massey Ferguson machinery is an MF 5435 with a front loader.

Purchased for its multi-application capabilities on the livestock and arable farm, the MF 5435 now

completes a range that secures the smooth running of Pawel’s business.

“We love the MF machinery on our farm, owning MF tractors means we can work quickly and without

faults whilst maintaining best operator comfort.” Pawel tells us.

“We receive a good quality service from our local dealership, they are professional, helpful and always

friendly. This means a lot to us, especially at busy times of the year when we need all the support we

can get.”

39

Powerful hydraulics

Mark Channell, Agricultural Contractor,

Cambridge, UK

“An important role for our MF 5480 is powering

a hydraulically-driven waste baler. We specified

Closed Centre Load Sensing hydraulics with

110l/min flow, which has improved cycle times

considerably – we have gone from 35 minutes

per bale to as little as 20 minutes” comments

Mark.

“The generous hydraulic capacity has also

speeded cycle times with our MF 955 loader,

which is used for tasks such as moving topsoil

as well as in the waste recycling operation, and

when working around the confines of the yard,

the tractor is also highly manoeuvrable.”

“This tractor ticks all the boxes – it is exactly

what my business needs.”

and on fuel economy...

“The 145hp MF 5480 is very economical on fuel,

at least as good as my previous tractor which

was just 90hp. “There is ample power for the

job which means the tractor is not working as

hard and uses less fuel.”

We’d like to hear from you! If you want to tell us about your Massey Ferguson machinery, please go to

www.masseyferguson.com/contactus and submit a testimonial.

Page 40

Engine Performance

MF 5425

▲

MF 5435

▲

MF 5445

▲

MF 5455

▲

Max. hp @ 2000 rpm

✪

ISO hp (kW)

86 (63.3) 96 (70.7) 100 (73.6) 112 (82.4)

Rated hp @ 2200 rpm

✪

ISO hp (kW)

82 (60.4) 92 (67.7) 95 (69.9) 105 (77.3)

Max. hp in boost

✪

ISO hp (kW)

- - 110 (81) 125 (92)

Max. torque @ 1400 rpm

✪ Nm

379 405 420 463

Max. torque with PowerBoost @

1400 rpm

✪ Nm

- - 463 525

Specific fuel consumption

†

g/kWh 210 210 209 209

Engine

Diesel, direct injection type 1104D-44TA 1104D-44TA 1104D-E44TA 1104D-E44TA

Aspiration Turbo/

Intercooled

Turbo/

Intercooled

Turbo/

Intercooled

Turbo/

Intercooled

Capacity/ no. of cylinders litre/no. 4.4/4 4.4/4 4.4/4 4.4/4

Exhaust, side-mounted cab

●●●●

Exhaust, Downswept/side-mounted platform

●/❍●/❍●/❍●/❍

Transmission

16F/16R ‘Dyna-4’ Semi-powershift

gearbox with left-hand Power Control. Speedmatching. 40 km/h max

speed

†

●●●●

Additional 8F/8R ‘Creeper’ speeds

❍❍❍❍

Additional 16F/16R ‘Supercreep’

speeds

❍❍❍❍

Power Take-Off (Rear)

Operation and control

Independent, electro-hydraulic with automated control.

Speed change, exchangeable shaft (●) or shiftable (❍)

PTO speed @ engine rev/min

540 rpm (6 spline shaft) rpm 1980 1980 1980 1980

1000 rpm (21 spline shaft) rpm 2000 2000 2000 2000

Ground speed PTO

❍❍❍❍

Economy PTO

❍❍❍❍

540 or 1000 rpm rpm 1550 1550 1550 1550

Front Linkage and Power Take-Off

Linkage lift capacity kg 2500 2500 2500 2500

PTO operation and control Independent, electro-hydraulic. 6 or 21 spline, 35 mm (13/8in)

diameter PTO shaft.

Linkage and Hydraulics

Linkage control Electronic control of draft, position and Intermix,

plus Active Transport Control (ATC)

Max. oil flow - Stage 1 43 litre/min, supplying gearbox range changes, diff.lock,

PTO, 4WD, steering, brakes, clutch and lubrication

Max. oil flow - Stage 2 57 litre/min, supplying 3-point linkage,

auxiliary hydraulics, trailer brakes

Twin flow (Option)

- Control

Stage 1 pump plus Combined Flow giving 100 litre/min

to spool valves

Switch on right-hand console, engages flow and

‘locks out’ linkage

Lower links, hook end

●●●●

Maximum lift capacity, at link ends,

kg ●

5000 5000 5000 5000

kg ❍

– – 6000 6000

Page 41

21

Auxiliary hydraulics

MF 5425

▲

MF 5435

▲

MF 5445

▲

MF 5455

▲

Control

●

2 single/double acting spool valves

❍

Up to 4 single/double acting spool valves with flow divider, kickout

and zero leak facility

Steering

Hydrostatic: fixed/adjustable

steering column

● /❍● /❍● /❍● /❍

Brakes

Type Oil-cooled, single plate discs with hydraulic actuation

Parking brake Independent disc on transmission, hand lever operated

Trailer brakes, hydraulic cab/platform

● /❍● /❍● /❍● /❍

4WD Front axle

‘Hydralock’ differential lock

●●●●

Wheels and Tyres

Front 2/4WD 10.00-16 /

13.6R24

10.00-16 /

13.6R24

10.00-16 /

13.6R24

11.00-16 /

13.6R24

Rear 16.9R34 16.9R34 16.9R34 16.9R34

Operator Area

Cab models

‘Standard’/‘Steep nose’ bonnet

● /❍● /❍● /❍● /❍

Standard equipment includes:

De-luxe ‘flat floor’ cab, side exhaust, tinted glass, opening side and

rear windows, four-speed fan with heater unit, mechanical swivelling

seat, electronic linkage control, 2 spool valves, 2 front and

2 rear work lights, flashing beacon

Variable equipment includes: Full air conditioning, pneumatic swivelling seat, passenger seat,

rear windscreen wash/wipe, additional work lamps, 1 or 2 additional

spool valves, hitch viewing mirror, ‘Visio’ roof, opening front screen,

roof hatch, radio/CD player, High visibility hitch.

Platform models

‘Standard’/‘Steep nose’ bonnet

design

● /❍● /❍● /❍● /❍

Standard equipment includes: Rubber-mounted ‘flat floor’ platform, low exhaust, weather-proof

spring suspension seat, electronic linkage control (ELC), 2 spool

valves, 2-post folding ROPS, flashing beacon

Variable equipment includes: 1 or 2 additional spool valves, 2 rear work lights, rear view mirrors

(Note: Please ask your dealer for details of the MF 5400 Series’ high-value ‘Option packs’)

Weights and Dimensions (approximate, less fuel)

Weight - Cab, 2/4WD kg 3550/3865 3550/3865 3605/3900 3605/3900

Weight - Platform, 2/4WD kg 3320/3635 3320/3635 3375/3670 3375/3670

Length, links horizontal m 4.21 4.21 4.21 4.21

Height

Over cab - Standard/Low Profile m *2.75/**2.54 *2.75/**2.54 *2.75/**2.54 *2.75/**2.54

Platform - over steering wheel m 2.16 2.16 2.16 2.16

- over ROPS, folded/unfolded m 2.15/2.70 2.15/2.70 2.15/2.70 2.15/2.70

Wheelbase - steep nose

- pivoting bonnet

m

m

2.46

2.55

2.46

2.55

2.46

2.55

2.46

2.55

Turning circle - dia. less brakes,

2/4WD

m 7.4/8.4 7.4/8.4 7.4/8.4 7.4/8.4

Fuel tank capacity

litre ●

130 130 130 130

litre ❍

200 200 200 200

Specifications

Every effort has been made to ensure that the information contained in this publication is as accurate and current as possible.

However, inaccuracies, errors or omissions may occur and details of the specifications may be changed at any time without notice.

Therefore, all specifications should be confirmed with your Massey Ferguson Dealer or Distributor prior to any purchase.

● = Standard

❍ = Optional

– = Not applicable/available

▲ = Also available as a ‘Platform’ model

✪ = ISO TR14396

† = On 34 and 38 inch tyres (also depending on market legislation)

* = With ‘standard’ roof. For Visio roof add 20 mm.

** = With ‘slimline’ roof. For Visio roof add 110 mm.

Page 42

Engine Performance MF 5460 MF 5465 MF 5470 MF 5475 MF 5480

Max. hp @ 2000 rpm

✪

ISO hp (kW)

125 (92) 132 (98) 135 (99) 144 (106) 145 (106)

Rated hp @ 2200 rpm

✪

ISO hp (kW)

115 (85) 120 (88) 125 (92) 132 (98) 135 (99)

Max. hp in PowerBoost

✪

ISO hp (kW)

135 (99) 144 (106) 145 (106) 156 (115) 155 (114)

Max. torque @ 1400 rpm

✪ Nm

525 543 585 600 625

Max. torque with PowerBoost

@ 1400 rpm

✪ Nm

545 600 625 650 652

Specific fuel consumption

†

g/kWh 208 210 205 208 205

Engine

Water cooled, direct

injection diesel

type 1104D-E44TA 66CTA 44CTA 66CTA 49CTA

Aspiration Turbo/

Intercooled

Turbo/

Intercooled

Turbo/

Intercooled

Turbo/

Intercooled

Turbo/

Intercooled

Capacity/ no. of cylinders litre/no. 4.4/4 6.6/6 4.4/4 6.6/6 4.9/4

Exhaust, side-mounted cab

●●●●●

Transmission

16F/16R ‘Dyna-4’ Semipowershift gearbox with

left-hand Power Control

Speedmatching. 40 km/h

max speed

†

●●●● ●

Additional 8F/8R ‘Creeper’

speeds

❍❍❍❍❍

Additional 16F/16R ‘Supercreep’ speeds

❍❍❍❍❍

Power Take-Off (Rear)

Operation and control

Independent, electro-hydraulic with automated control.

Speed change, exchangeable shaft (●) or shiftable (❍)

PTO speed @ engine rev/min

540 rpm (6 spline shaft) rpm 1980 1980 1980 1980 1980

1000 rpm (21 spline shaft) rpm 2000 2000 2000 2000 2000

Ground speed PTO

❍❍❍❍❍

Economy PTO

❍❍❍❍❍

540 or 1000 rpm rpm 1550 1550 1550 1550 1550

Front Linkage and Power Take-Off

Linkage lift capacity kg 2500 2800 2500 2800 2500

PTO operation and control Independent, electro-hydraulic. 6 or 21 spline, 35 mm (1

3

/8in) diameter

PTO shaft. 1000 rpm @ 2040 engine rpm

Linkage and Hydraulics

Linkage control Electronic control of draft, position and Intermix,

plus Active Transport Control (ATC)

Max. oil flow - Stage 1 42 litre/min, supplying gearbox range changes, diff.lock, PTO, 4WD,

steering, brakes, clutch and lubrication

Max. oil flow - Stage 2 57 litre/min, supplying 3-point linkage,

auxiliary hydraulics, trailer brakes

Twin flow (Option)

- Control

Stage 1 pump plus Twin Flow system giving

100 litre/min to spool valves

Switch on right-hand console, engages flow

and ‘locks out’ linkage

–

–

–

–

Lower links, hook end

●●●●●

Category (I/II/III) II/III II/III II/III III III

Maximum lift capacity, at link

ends,

kg ●

5000 5000 5000 6000 6000

kg ❍

6000 6000 6000 - -

Closed Centre (load sensing) Litres/min /bar

❍❍❍❍❍

❍❍❍

110/200 110/200

Page 43

Auxiliary hydraulics MF 5460 MF 5465 MF 5470 MF 5475 MF 5480

Control

●

2 single/double acting spool valves

❍

Up to 4 single/double acting spool valves with flow divider, kickout

and zero leak facility

Steering

Hydrostatic: fixed/adjustable

steering column

● /❍● /❍● /❍● /❍● /❍

Brakes

Type Oil-cooled, single plate discs with hydraulic actuation

Parking brake Independent disc on transmission, hand lever operated

Trailer brakes, hydraulic cab

● ● ● ● ●

air –

❍

–

❍

–

4WD Front axle

‘Hydralock’ differential lock

●●●●●

QuadLink suspended axle

❍❍❍❍❍

Wheels and Tyres

Front 2 / 4WD 10.00-16 /

13.6R28

10.00-16 /

14.9R28

10.00-16 /

14.9R28

10.00-16 /

14.9R28

10.00-16 /

14.9R28

Rear 16.9R38 18.4R38 18.4R38 18.4R38 18.4R38

Operator Area

Standard equipment includes:

Deluxe ‘flat floor’ cab, vertical side exhaust, tinted glass, opening

side and rear windows, four-speed fan with heater unit, mechanical

swivelling seat, radio/CD player, electronic linkage control, 2 spool

valves, 2 front and 2 rear work lights, flashing beacon.

Variable equipment includes: Full air conditioning, pneumatic swivelling seat, passenger seat,

rear windscreen wash/wipe, additional work lamps, 1 or 2 additional

spool valves, hitch viewing mirror, Visio roof, opening front screen,

roof hatch.

(Note: Please ask your dealer for details of the MF 5400 Series’ high-value ‘Option packs’)

Weights and Dimensions (approximate, less fuel)

Weight - Cab, 4WD kg 4320 5400 4510 5400 4610

Length, links horizontal m 4.30 4.82 4.37 4.82 4.37

Height

Over cab - Standard m 2.74 2.80 2.77 2.80 2.77

Wheelbase m 2.55 2.83 2.67 2.83 2.67

Turning circle - dia. less brakes,

4WD

m 8.40 9.60 8.90 9.60 8.90

Fuel tank capacity

litre ●

145 150 145 150 145

litre ❍

200 215 200 215 200

Specifications

Every effort has been made to ensure that the information contained in this publication is as accurate and current as possible.

However, inaccuracies, errors or omissions may occur and details of the specifications may be changed at any time without notice.

Therefore, all specifications should be confirmed with your Massey Ferguson Dealer or Distributor prior to any purchase.

● = Standard

❍ = Optional

– = Not applicable/available

✪ = ISO TR14396

† = Optimum specific fuel consumption (Manufacturer’s test)

Page 44

QuadLink provides exceptional ride comfort

without compromising the turning angle

or ground clearance.

Straightforward operation enables an easy

progression from minimum speed to maximum

speed with the minimum of driver effort.

Creep and Supercreep provides slow

and very slow speeds.

Exceptional power and torque characteristics

allied to the efficiency of the Dyna-4

transmission provide superb work outputs

with very low fuel consumption.

New high power and torque ratings increase

productivity and reduce journey times.

New optional cab suspension system improves

operator comfort and provides safer transportation

of mounted implements.

Visio roof and steep-nose bonnet available for

enhanced visibility.

Seven 4-cylinder models up to 145 hp and two

6-cylinder models up to 144 hp provide an

excellent choice of horsepower on livestock and

arable farms and in many municipal sectors.

Modern, large capacity 4-cylinder and 6-cylinder

engines provide excellent power and torque in a

wide variety of applications.

High performance common rail and 4-valve

engines provide an unrivalled combination of

power and economy.

Additional power through ‘PowerBoost’ when

either 3rd or 4th range is selected, increasing

output during PTO and transport work.

Pivoting bonnet provides better access for regular

maintenance of the air filter and radiators.

Dyna-4 makes the MF 5400 Series the perfect

loader tractor. 16 forward and 16 reverse speeds

ensure the correct gear for every job. Four Dyna-4

ratios provide a wide choice of speeds available

under full load.

The unique Power Control Lever keeps you firmly

in control by allowing convenient operation of

forward/reverse shuttle, powershift, range changes

as well as fingertip de-clutching.

01

08

02

09

03

10

04

11

05

12

06

07

13

14

is a worldwide brand of AGCO.

© AGCO Limited. 2010 | A-English/14885/0610/20m

Here’s a quick reminder of some of the advanced features of the

MF 5400 Series tractor that makes it the superior choice.

MF 5400 highlights

Loading...

Loading...