Marvel Refrigeration MS24RFSG Owner’s Manual

OPERATION AND MAINTENANCE

OF

MECHANICAL FIELD WARD

REFRIGERATOR

NSN4110-01-629-6841

MARVEL MODEL

#4570105-MODIFIED-230/115 VOLT, 60/50 Hz.

CONTRACT #

41012491 revision C

Marvel Refrigeraon

1260 E. VanDeinse St.

Greenville MI 48838

800.223.3900

CONTENTS

CHAPTER/PARAGRAPH

1. Introducon ...............................................................................................................................................

1-1 Introducon ...............................................................................................................................

1-2 Warning .....................................................................................................................................

1-4 Organizaon of the manual .......................................................................................................

1-5 Purpose of the Refrigerator .......................................................................................................

1-6 Descripon .................................................................................................................................

1-8 Specicaons .............................................................................................................................

1-9 Required Tools ...........................................................................................................................

1-10 Safety ........................................................................................................................................

2. Operaon ..................................................................................................................................................

2-1 Introducon ...............................................................................................................................

2-3 Shelf life, storage requirements, unpacking procedures, packaging, and preservaon

and storage inspecon ..............................................................................................................

2-4 Installaon .................................................................................................................................

2-5 Operaon and Theory of Operaon ..........................................................................................

3. Maintenance .............................................................................................................................................

3-1 Introducon ..............................................................................................................................

3-3 Safety ........................................................................................................................................

3-4 Prevenve Maintenance ...........................................................................................................

3-5 Troubleshoong ........................................................................................................................

3-6 Correcve Maintenance Procedures .........................................................................................

3-7 Fan Assembly Replacement .......................................................................................................

3-8 Transformer / 230 Volt Power Cord Replacement .....................................................................

3-9 115 Volt power Cord Replacement ............................................................................................

3-10 Door Gasket Replacement ........................................................................................................

3-11 Thermostat Replacement .........................................................................................................

3-12 Front Glide Replacement ..........................................................................................................

3-13 Rear Glide Replacement ...........................................................................................................

3-14 Freezer Door Replacement .......................................................................................................

3-15 Depot-Level Repair or Replacement Assemblies ......................................................................

3-16 Defrosng .................................................................................................................................

PAGE

4

4

4

4

4

4

7

7

8

9

9

9

11

12

15

15

15

15

16

17

18

20

20

21

22

23

24

25

25

25

4. Replacement Parts List ...............................................................................................................................

4-1 Introducon ...............................................................................................................................

5. Diagrams ....................................................................................................................................................

5-1 Introducon ...............................................................................................................................

2

27

27

31

31

LIST OF ILLUSTRATIONS

FIGURE

NUMBER DESCRIPTION

1-1 Refrigerator, Front View ...................................................................................................................

1-2 Refrigerator, Rear View ....................................................................................................................

2-1 Door Handle Installaon .................................................................................................................

2-2 Refrigerator Funconal Block Diagram ............................................................................................

.

3-1 Mechanical Assembly .......................................................................................................................

4-1 Refrigerator, front View ....................................................................................................................

4-2 Refrigerator, Rear View ....................................................................................................................

4-3 Mechanical Assembly ......................................................................................................................

5-1 Refrigerator Wiring Diagram ............................................................................................................

LIST OF TABLES

TABLE

NUMBER DESCRIPTION

1-1 Specicaons ...................................................................................................................................

1-2 Required Tools ..................................................................................................................................

2-1 Shelf Life ..........................................................................................................................................

2-2 Storage Requirements .....................................................................................................................

PAGE

5

6

12

14

19

26

29

29

31

PAGE

7

7

9

9

3

CHAPTER 1

INTRODUCTION

1-1 Introducon

1-2 This operaon and maintenance manual provides you with the necessary informaon for using and

maintaining the Mechanical and Biological Refrigerator, NSN 4110-01-629-6841. The manual includes informaon for operaon, prevenve maintenance, and correcve maintenance.

WARNING

WHEN THE REFRIGERANT LINE HAS BEEN OPENED, OR FOR ANY OPERATION REQUIRING OPENING THE REFRIGERANT LINE, ONLY QUALIFIED MAINTENANCE PERSONNEL, USING PROCEDURES AND EQUIPMENT SPECIFIED

BY THE MANUFACTURER OR BY DEPOT-LEVEL AUTHORITIES, SHOULD WORK ON THE REFRIGERATION SYSTEM.

ANY MOISTURE THAT IS ALLOWED INTO THE REFRIGERATION LINES WILL COMBINE WITH THE FLUORINE REFRIGERANT TO PRODUCE HYDROFLUORIC ACID, AN EXTREMELY POWERFUL AND CORROSIVE ACID.

1-3 All procedures in this manual refer to the electrical and mechanical elements of operaon and maintenance.

1-4 Organizaon of the manual. As shown in the Table of Contents, this manual is organized as follows:

Chapter 1: INTRODUCTION. Provides informaon on organizaon of the manual, purpose of the

refrigerator, descripon and specicaons for the refrigerator, list of required equipment, and

safety informaon.

Chapter 2: OPERATION. Tells you shelf life, storage requirements, how to unpack, install, and oper

ate the refrigerator, with a brief theory of operaon.

Chapter 3: MAINTENANCE. Details the procedures for preventave and correcve maintenance of

the refrigerator.

Chapter 4: PARTS LIST. Lists, by assemblies, the replacement parts for the refrigerator, with part

numbers and illustraons.

Chapter 5: DIAGRAMS. Contains all illustraons cited in the text, but not otherwise included.

1-5 Purpose of the refrigerator. The refrigerator is to be used as a refrigerator-freezer at ward level in eld

hospitals as designated by the Department of Defense.

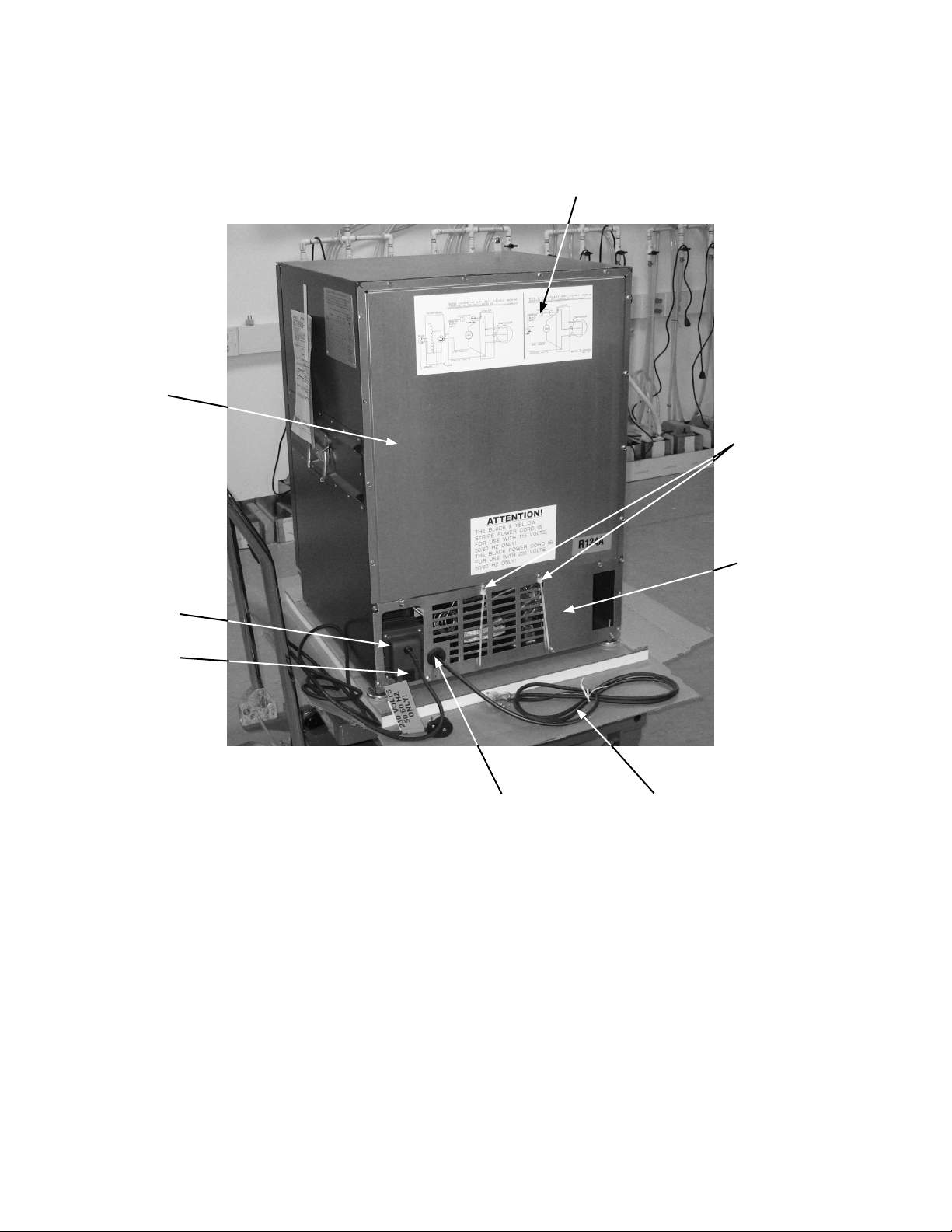

1-6 Descripon. Refer to Figures 1-1 and 1-2. The refrigerator is light weight and portable, designed for

eld operaons. Providing 6.1 cubic feet of refrigeraon and freezing space, the refrigerator incorporates three

shelves, drip pan, 0.7 cubic foot freezer compartment, adjustable thermostat, carrying handles, glide feet, and

corrosion resisng steel shield for mounng over rear mechanical openings. The refrigerator compartment operates over a temperature range of 34 to 42 degrees Fahrenheit, and the freezer compartment operates over

a range of 12 to 20 degrees Fahrenheit. The operaon of this unit may vary from unloaded performance when

loaded with commodies in various amounts and temperatures.

The refrigerator has a 230/115 VAC step-down transformer; it can operate from either 230 or 115 VAC, 60/50

Hz source. Figure 1-2, No. 2, 3, 7.

4

Figure 1-1. Refrigerator, Front View

9

1

2

3

4

5

6

10 11

7

12

8

1. Restraining strap 7. Thermostat, behind grill

2. Freezer door 8. Glides (4)

3. Drip tray 9. Hinge pin, top

4. Wire shelves (2) 10. Door gasket

5. Cabinet 11. Door

6. Crisper shelf and tray 12. Grill

5

Figure 1-2. Refrigerator, Rear View

4

1

5

6

2

3

78

1. Cabinet back cover 5. Power cord holding strap (2)

2. Transformer/230 Volt Power Cord 6. Stainless steel back shield

3. Transformer/ 115 Volt outlet 7. 115 Volt power cord

4. Wiring diagram 8. Grommet

6

1-7 The outer shell of the refrigerator and the door cover are 1/32nd inch carbon steel with olive drab

nish. The inner shell and door liner are plasc. The door has a magnec latch. There is a door security snap

fastener located at the upper le corner for use during transport.

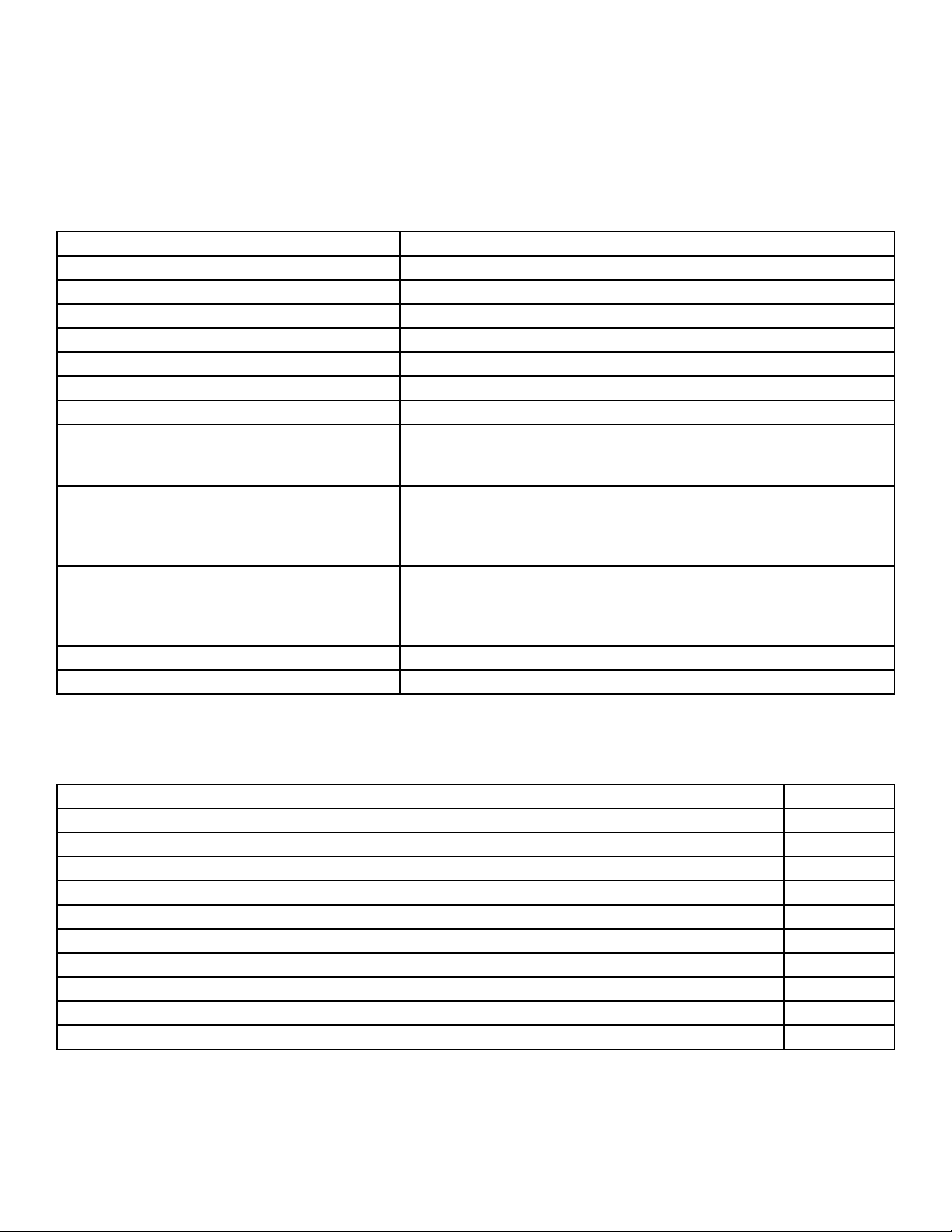

1-8 Specicaons. Table 1-1 lists the complete specicaons and parameters for the refrigerator,

NSN 4110-01-629-6841.

Table 1-1

Parameter Specicaon

Acceptable input voltages 115/230 VAC. Step-down transformer provided for use with 230 VAC source.

Acceptable input frequencies 50/60 Hz.

Power consumpon 380 was nominal; 2100 was maximum surge

Line current, maximum 18 amps inrush at 115 V; 9 amps inrush at 230 V.

Weight 106 lbs.

Volume, internal 6.1 cubic feet

Outer dimensions 34-3/4” H x 25-3/8” W x 24-1/16” D

Internal volume

Freezer

Refrigerator

Pull down mes at ambient temperature of:

120 degrees F

100 degrees F

77 degrees F

Nominal weight and volume in shipping container

Weight

Volume

Dimensions

Type of refrigerant R-134a

Weight of full charge of refrigerant 4.4 oz. (0.27 lb. or 0.12 kg.)

0.7 cubic feet, minimum

4.5 cubic feet, minimum

5.0 hours, max.

2.0 hours, max.

1-1/4 hours, max.

135 lbs.

16.8 cubic feet

38-1/2” H x 28” W x 27” D

1-9 Required tools. Table 1-2 lists all of the tools required for normal use and maintenance of the refrigerato r.

Table 1-2

Descripon No. Req.

Hex Key Wrenches, 1/8” and 5/32” 1 of each

Phillips head screwdriver (8” long) 1

Flat blade screwdriver, (small approximately 1/8” wide blade) 1

Hand roller 1

36” x 36” cardboard sheet 1

36” x 36” table or bench 1

Channel lock adjustable pliers 1

Combinaon open end / box end wrenches 1

any standard mul-meter for checking voltages and connuity of circuits 1

Nut Driver, 5/16” and 3/8” 1 of each

Marvel Refrigeraon

For tools and associated equipment used in maintenance

procedures NOT described in this manual, refer to Depot-level

1260 E. VanDeinse St.

Greenville MI 48838

maintenance organizaon or contact the manufacturer:

800.223.3900

7

1-10 Safety. ALWAYS observe the warning noce shown aer paragraph 1-2 above. Always disconnect power

before servicing. Failure to do so could result in property damage, physical injury, or death. For connecon to a

230 VAC source, be sure to use the step down transformer, as detailed in par. 2.4h, below.

1-11 When the refrigerator is in operaon, the condenser (radiator), the compressor, and the refrigerant

lines can get hot enough to burn the skin.

1-12 NEVER use an ungrounded cord or power outlet with this refrigerator. Such a pracce can produce electrical shocks and possibly damage operang elements of the system.

8

CHAPTER 2

OPERATION

2-1 INTRODUCTION

2-2 This chapter details shelf life, storage requirements, unpacking, installaon, and operaon of the refrigerator, with a brief explanaon of the theory of operaon.

2-3 SHELF LIFE STORAGE REQUIREMENTS, UNPACKING PROCEDURES, PACKAGING, AND PRESERVATION

AND STORAGE INSPECTION.

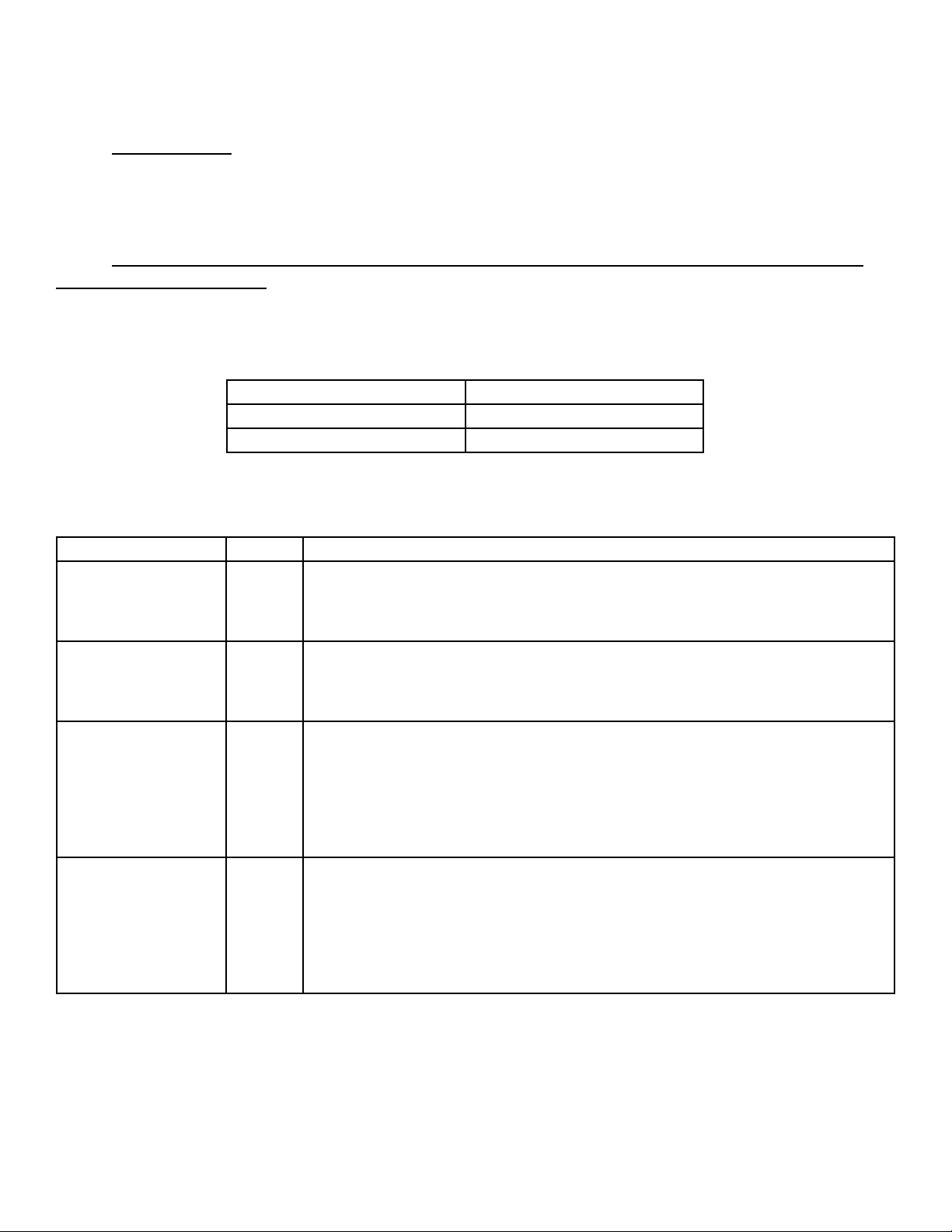

a. Shelf life. Table 2-1 lists the shelf life for the refrigerator.

Table 2-1

Locaon Shelf Life

Indoors 2 years (see Table 2-2 for details)

Outdoors 6 months (see Table 2-2 for details)

b. Storage Requirements. Table 2-2 lists the storage requirements for the refrigerator.

Table 2-2

State of Product Locaon Condions Required

Cartoned refrigerator Indoors Dry building, concrete or wooden oor, temperature maintained between -10° to

+120°F.,humidity up to 100% with units not stacked over three high. An earthen oor is

acceptable, if a metal, plasc, or wooden material/structure is used that prevents groundwater or rain from coming in contact with the cartons.

Cartoned refrigerator Outdoors Cartons covered with weatherproof material and kept o the ground by metal, plasc, or

wooden material/structure that prevents groundwater or rain from coming in contact with

the cartons. Temperatures to be between -10° to +120°F., humidity up to 100% and units

not stacked over two high.

Uncartoned refrigerator Indoors Dry building, concrete or wooden oor, temperature maintained between -10° to

+120°F.,humidity up to 100% with units not stacked over two high. A heavy wall 24” x 24”

piece of cardboard is to be placed on the top of the boom unit, if the refrigerators are

stacked two high, to protect the paint on the boom unit. An earthen oor is acceptable,

if a metal, plasc, or wooden material/structure is used that prevents groundwater or rain

from coming in contact with the refrigerators. See par. 2.3.d. for required packaging and

preservaon procedures.

Uncartoned refrigerator Outdoors Refrigerators covered with waterproof material and kept o the ground with a metal, plas-

c, or wooden material/structure that prevents groundwater or rain from coming in contact

with the refrigerators. Temperatures to be maintained between -10° to +120°F.,humidity

up to 100% with units not stacked over two high. A heavy wall 24” x 24” piece of cardboard

is to be placed on the top of the boom unit, if the refrigerators are stacked two high, to

protect the paint on the boom unit. See par. 2.3.d. for required packaging and preservaon procedures.

c. Unpacking Procedures Unpacking is easy. The refrigerator is shipped in a heavy duty card

board carton, with slip-o top and boom covers held on by plasc straps. To unpack:

1. Stand the carton upright.

2. With n snips cut the lower plasc band.

3. Pull all four sides of the boom cover away and down from the sides of the carton.

4. Liing from the top, pull the carton up and o the refrigerator.

5. Dispose of the carton, wipe o the refrigerator, and its ready for installaon.

9

d. Packaging and Preservaon Refrigerators that have been uncartoned and used in service re quire that the following procedures be done to them before they are made inacve and placed in

storage.

1. Turn the thermostat knob to the “OFF” posion to deacvate the refrigerator and before

removing the electrical plug(s) from the electrical supply outlet(s). The “OFF” posion on the

thermostat knob is achieved when the “OFF” marking on the knob is at the twelve o’clock

posion.

2. Remove the refrigerator electrical plug(s) from the electrical supply outlet(s). Roll up each

power-cord in an approximate one foot diameter coil. Secure each power cord to the back of

the refrigerator with the use of the plasc holding straps on the back of the refrigerator. Snap

the strap over its plasc prong unl it clips in place.

3. Open the refrigerator door, remove all commodies from the refrigerator, freezer, and door

shelves. Empty and dry any ice trays in the freezer compartment.

4. Allow the freezer compartment and its cold plate to completely defrost. You may leave the

cabinet and freezer door open to facilitate defrosng. Also, a heat source such as a pan of hot

water or a hair dryer may be used to speed up defrosng. NEVER use an ice pick or sharp instru ment to chip or break the ice away from the cold plate. Doing so may rupture the aluminum

tubes in the cold plate, allowing the refrigerant to escape and causing the system to fail. Escap ing refrigerant may cause injury to skin, due to frostbite or blindness to eyes due to contact with

the supercold refrigerant liquid/gas.

5. Aer all ice and frost have been removed from the refrigerator and freezer, thoroughly dry all

interior surfaces and parts. Place dried out ice trays in drip tray of refrigerator and the Opera on and Maintenance Manual in a 9” x 12” plasc bag. Place bag and manual on the cabinet

shelf.

6. Close the cabinet door and snap the plasc door latch onto the buon of the top le side of

the cabinet door.

7. Remove any dust or dirt that may be on the condenser coils and ns. The condenser is locat ed on the back of the cabinet on the lower right side as you look at the back, just inside the rect angular 5-1/4” x 2-1/4” opening on the stainless steel motor guard. A small vacuum cleaner

brush aachment works well in removing any dust or dirt that may exist.

8. Examine the cabinet and door outer painted surfaces. If any nicks or scratches exist in the

painted surface, use matching appliance touch up paint to cover and seal any nicks or

scratches.

9. The refrigerator is ready for uncartoned storage. See par. 2.3.b. for details.

10. If the refrigerator is to be re-cartoned and placed in storage, obtain a carton service assem bly kit from Marvel. Re-carton the unit as specied in the instrucons included with the kit.

The refrigerator, once re-cartoned, is ready for cartoned storage. See par.2.3.b. for details.

10

Loading...

Loading...