Marvel Industries 30WCM User Manual

MARVEL CUSTOM WOOD FRAME OVERLAY FOR GLASS DOORS

Custom Wood Frame Overlay for

Glass Doors

Installation Instructions

Wine Cellars

3SWC

3SWCE

30WC

30WCM

Beverage Centers

3SBAR

3SBARE

3BAR

3BARM

CUSTOM WOOD FRAME INSTALLATION INSTRUCTIONS

STEP 1: WOOD SCREWS REQUIRED

A #8 pan head wood screw should be used to properly 1.

secure the wood frame. A total of 10 screws will be

needed for a 3 1/2 inch toe kick or 8 screws for a 4

inch toe kick.

Use only pan head screws.2.

DO NOT select a screw that is longer than the wood 3.

thickness at the screw locations.

Use recommended pilot holes for the frame material 4.

(see Table A below).

Table A: Pilot Hole Drill Sizes For Wood Screw

Work Material

Wood Screw Size

8

Hardwood 3/32

Softwood 5/64

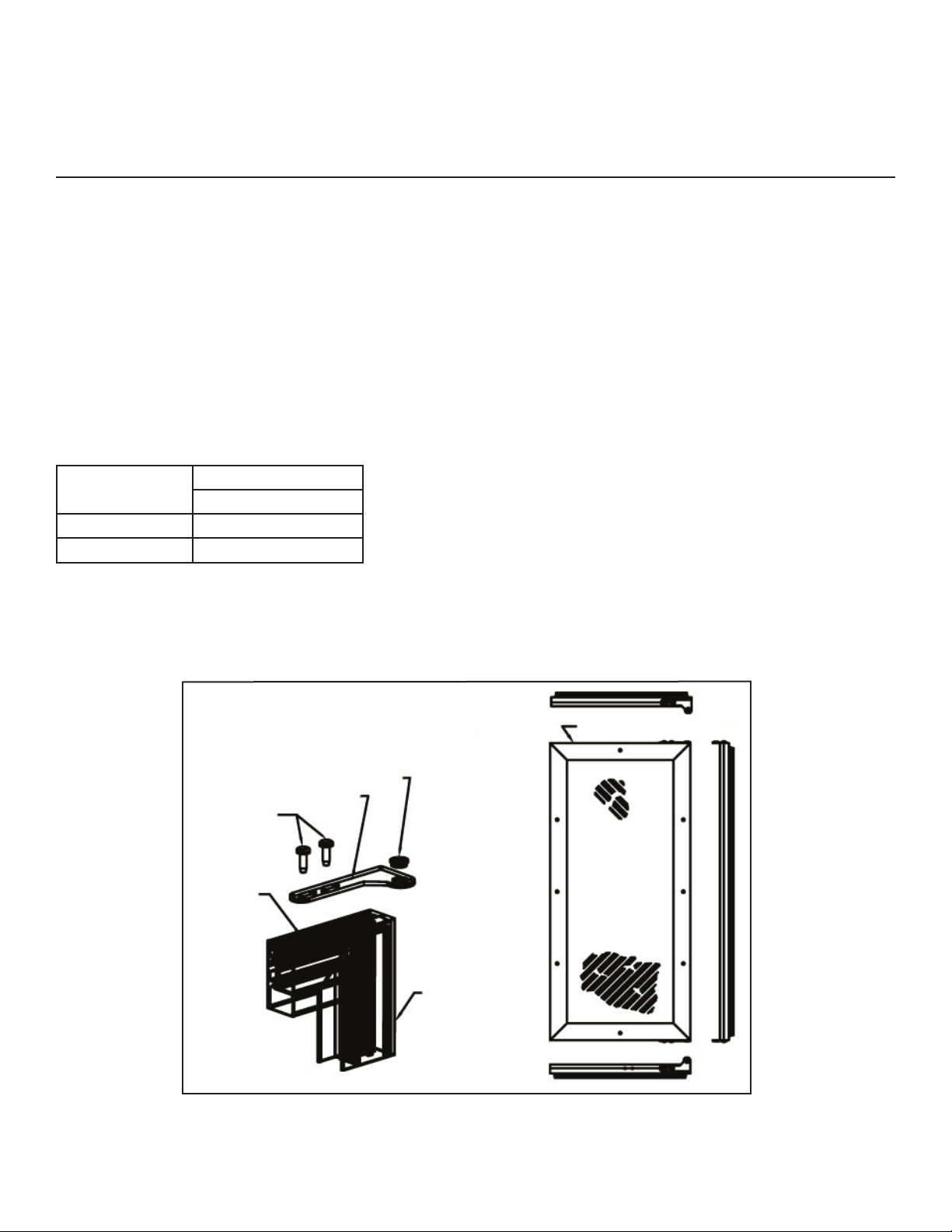

STEP 2: ASSEMBLING DOOR HINGE BRACKETS

Disregard if hinges are already attached.

Attach the top and bottom door hinge bushing brack-1.

ets to the door with the 1/4-20 machine screws and a

5/32 inch Allen head driver as shown in Figure 1.

Press in the shoulder bushings to the top and bottom 2.

door hinges. Make certain that the shoulder is to the

outside of the door as shown in Figure 1.

Test fit the door to the unit to make certain door will 3.

hang correctly. The door is hung correctly when the

top of the door is parallel to the top of the unit. Adjustments can be made by loosening the door hinge machine screws and moving the door hinge on the door.

Tighten all 4 machine screws after adjustments have 4.

been made.

Remove the door from the unit by removing the unit’s 5.

top hinge set screw and angling the door off of the

bottom hinge pin.

1/4-20 Machine

Screws

Door Hinge

Screw Holes

This surface parallel to the unit

(right hand swing door shown).

Shoulder Bushing

Door Hinge

Door Front

Surface

Figure 1: Typical Top and Bottom Door Hinge Assembly

1

CUSTOM WOOD FRAME INSTALLATION INSTRUCTIONS

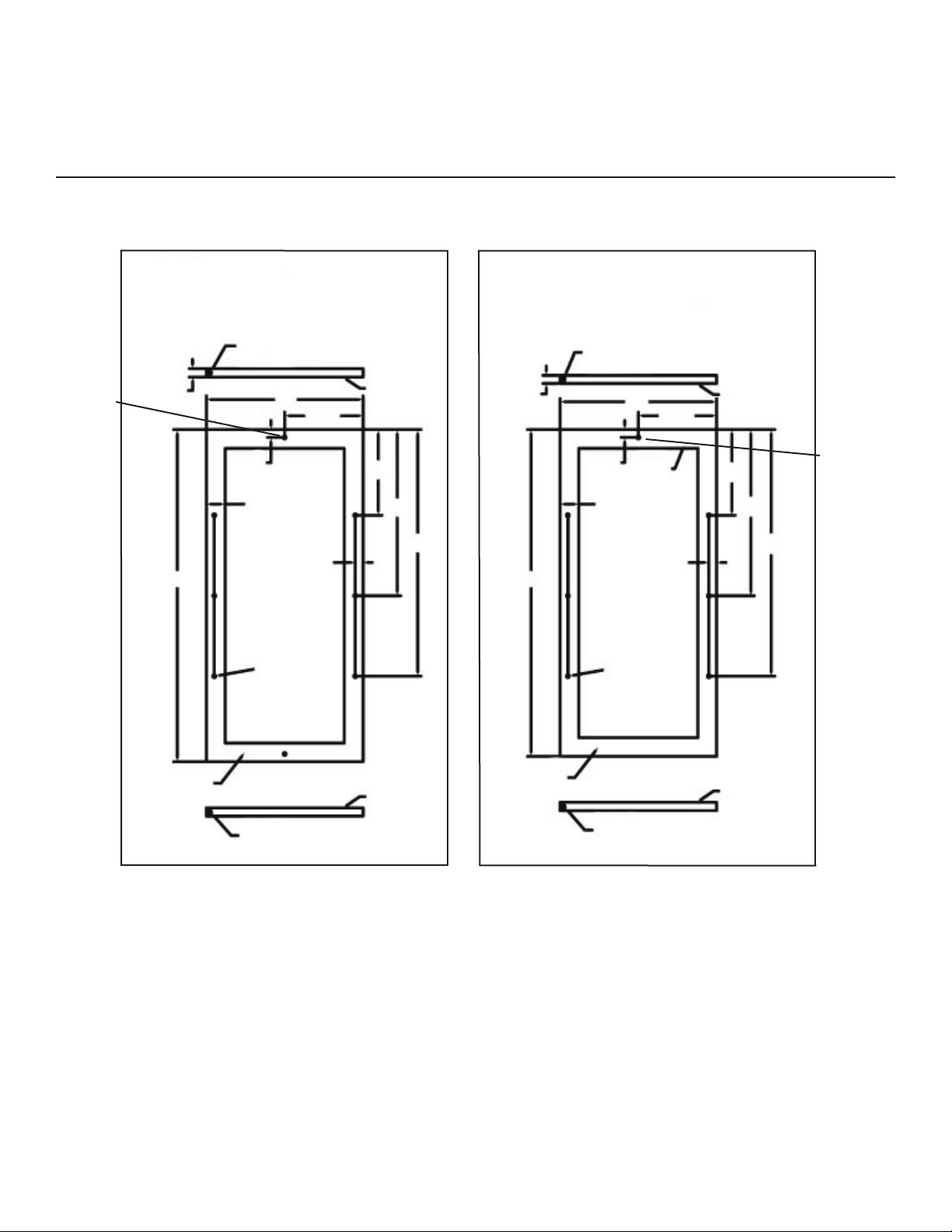

STEP 3: SELECTING AND PREPARING THE WOOD FRAME

0.81 dia

Counter Bore,

0.44 deep

For a 3.5 inch Toe Kick

(Covers the Entire Door Extrusion)

0.63 Min

0.75 Max

0.25 x 0.375 Deep Hinge Screw Clearance Hole.

Locate and drill using door hinge hole after the

door has been aligned to the unit and when the

wood is positioned on door.

14.31

7.16

0.72

1.72 Minimum

Width to Cover

Door Extrusion

Pre-Drilled

Pilot Holes

8 Places

Mounting

Surface

(Non-Face) Side

7.81

15.16

22.50

0.63 Min

0.75 Max

29.8130.31

Optional for a 4 inch Toe Kick

(To Match Existing Cabinetry

Toe Kick Height)

0.25 x 0.375 Deep Hinge Screw Clearance Hole.

Locate and drill using door hinge hole after the door

has been aligned to the unit and when the wood is

positioned on door.

Mounting Surface

14.31

0.72

Top Surface

1.72 Minimum

Width to Cover

Door Extrusion

Pre-Drilled

Pilot Holes

8 Places

7.16

0.720.72

(Non-Face) Side

7.81

15.16

22.50

0.81 dia

Counter Bore,

0.44 deep

Mounting

Surface

(Non-Face) Side

Mounting

Surface

(Non-Face) Side

0.25 x 0.375 Deep Hinge Screw Clearance Hole.

Locate and drill using door hinge hole after the

door has been aligned to the unit and when the

wood is positioned on door.

Figure 2

Mounting

Surface

(Non-Face) Side

Mounting Surface

(Non-Face) Side

0.25 x 0.375 Deep Hinge Screw Clearance Hole.

Locate and drill using door hinge hole after the door

has been aligned to the unit and when the wood is

positioned on door.

Figure 3

OPTIONAL LOCK AND KEY

The optional lock and key helps protect your contents from tampering or misuse. The lock and key kit contains a lock cylinder, catch bracket, keys, and an installation nut. Some assembly is required as the lock and key is installed on the front of

the wood frame. See Figures 2 and 3 above for lock and key installation dimensions.

2

Loading...

Loading...