Marvel MP15CLP2LP, MP15CPS2LS, MP15CLS2RS, MP15CPS2RS, MP15CLS2LS User Guide

...

EN Installation, Operation and Maintenance Instructions

FR Instructions d’installation, d’utilisation et d’entretien

ES Instrucciones de instalación, operación y mantenimiento

Built in Clear Ice Machine

Machine à glacons

transparente intégrées

Máquina de hielo claro

empotradas

MP15CL

MP15CP

CONTENTS

Contents:

Welcome ..............................................................................2

Warranty registration ..........................................................2

Safety information ...............................................................3

Unpacking your appliance ..................................................3

Installing your appliance ......................................................4

Cabinet clearances .........................................................4

Leveling the appliance ....................................................4

Electrical connection ......................................................5

Installing the drain plumbing ...............................................6

Gravity drain ...................................................................6

Drain pump .....................................................................7

Installing the water supply ...................................................8

Filler panel kit ......................................................................9

Ice-maker operation ..........................................................10

Product dimensions ..........................................................12

Using your Electronic control ............................................14

Starting your appliance ..................................................14

Turning your appliance "ON" or "OFF" ..........................14

Control lock ...................................................................15

Door ajar alarm.............................................................15

Error codes ...................................................................15

Delay start / Vacation mode .........................................15

Clean reminder ............................................................15

Options menu ...............................................................16

Normal and eco mode .............................................16

Cleaning your ice machine ..............................................16

Clean mode ...............................................................16

Overlay door panel installation ........................................18

Care and cleaning .............................................................22

Energy saving tips ............................................................22

Obtaining service .............................................................23

Troubleshooting the ice machine .....................................24

Preparing the ice machine for storage ...........................26

Drain pump removal .........................................................29

Warranty ...........................................................................31

Welcome

Congratulations on your purchase of the

industry's quietest clear ice machine with

the best ice clarity and purity. Your new investment is protected by a limited warranty

for the rst year, and hermetically sealed

refrigeration system parts are covered for

an additional 4 years.

Here's your guide to the operation and maintenance of your

Marvel Clear Ice Machine to ensure years of enjoyment. If

you have any questions, please contact Marvel Customer

Service or Tech Support at:

Phone: (800) 223-3900

Email:

• Customer Service: orderdesk@agamarvel.com

• Tech Support: techsupport@agamarvel.com

Warranty Registration:

We encourage all new ice machine owners to take a moment to register their product for a more tailored experience

should you need support from us in the future. It's recommended to send in your warranty registration card immediately after taking delivery of your appliance.

To Register:

• Mail in your warranty registration card or register online

at marvelrefrigeration.com

• The following elds are required:

• Service Number

• Serial Number

• Date of Purchase

• Dealer Name and Address

• The service number and serial number can be found on

the serial plate located on the inside of the cabinet on

the left side (See Figure 1).

XXXXXXXXXXXX

XXXXXXXXXXXX

Figure 1

About your Marvel clear ice machine:

Performance

• The quietest ice machine you can buy.

• New energy-saving options to conserve water and

energy.

• Engineered to consistently produce pure, clear ice with

unrivaled clarity and slower melt.

• Produces up to 39 pounds of clear ice daily.

• Soft close integrated hinge prevents energy loss by

automatically drawing door to a gentle close.

Storage Capabilities

• Stores 35 pounds of clear ice in thermo-insulated ice

bin.

• Sleek scoop design is positioned for easy reach.

• Easy-to-clean, hygienic interior surface.

Touchscreen Controls

• Multifunction Marvel Intuit™ Integrated Controls

• Eco Ice™, Delayed Start and Vacation mode adapts ice

production to usage.

• Audible alerts and programmed cleaning reminders.

Aesthetics

• New IlluminICE™ feature projects LED lighting through

clear ice for a dazzling illumination effect.

• Sturdy stainless steel handle and black interior.

• Easy-to-install panel-ready option with soft-close integrated hinge.

• 4" stainless steel adjustable toe kick.

• Height adjustment up to 1" with leveling legs.

2

UNPACKING YOUR APPLIANCE

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situations that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for occupational health and safety from Lloyd’s Register Quality

Assurance.

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

!

CAUTION

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause cancer.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding internal components in place. The owners manual is shipped

inside the product in a plastic bag along with the warranty

registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly.

!

CAUTION

Dispose of the plastic bags which can be a suffocation

hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

!

WARNING

State of California Proposition 65 Warning:

This product contains one or more chemicals known

to the State of California to cause birth defects or

other reproductive harm..

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

3

INSTALLING YOUR APPLIANCE

!

CAUTION

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the appliance to sit upright for a period of at least 24 hours before

plugging in. This will assure oil returns to the compressor.

Plugging the appliance in immediately may cause damage

to internal parts.

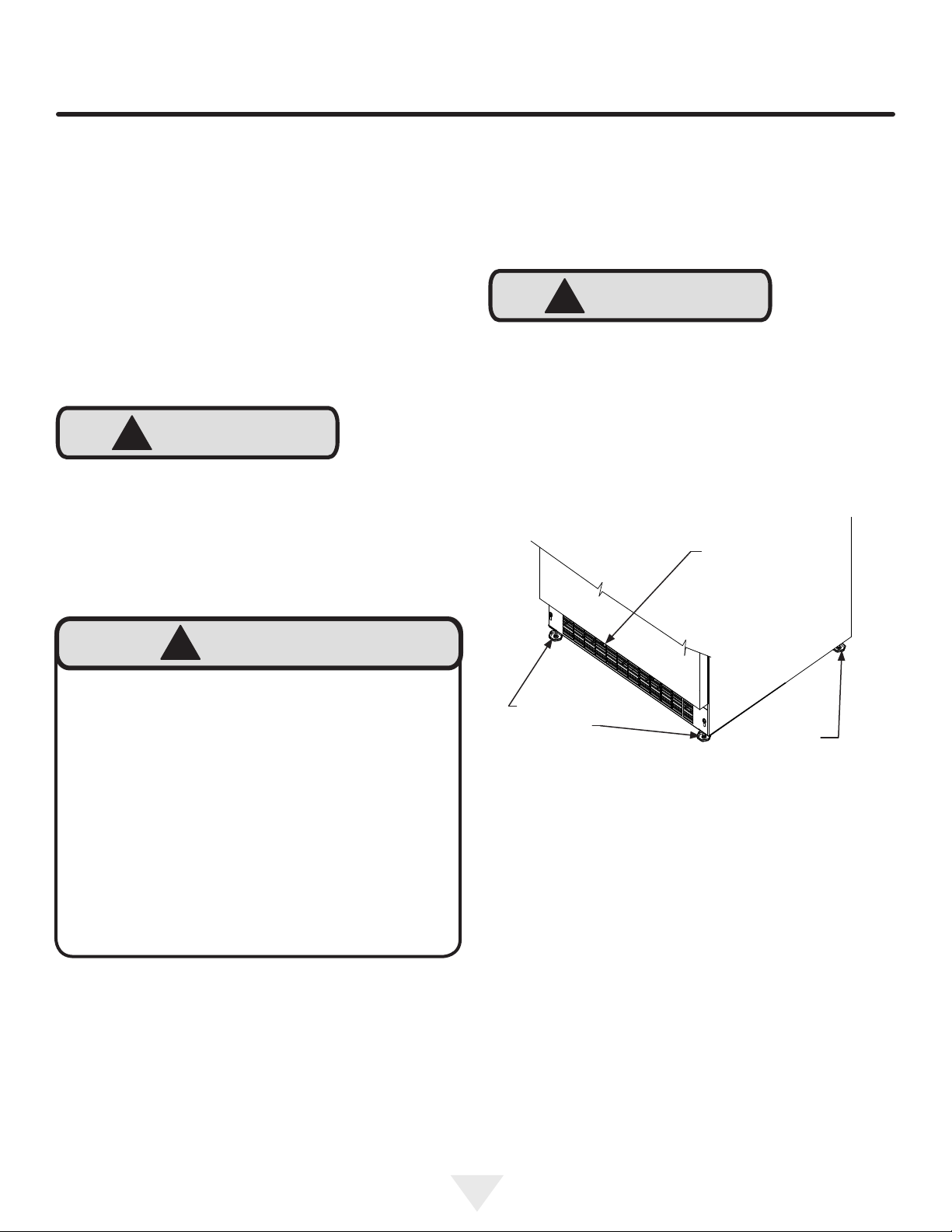

Cabinet Clearance

Ventilation is required from the bottom front of the appliance. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the appliance as long as the front grille remains unobstructed.

!

CAUTION

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat exchanger. Restrictions to this air ow will result in increased

energy usage, loss of cooling capacity and low ice production. For this reason it is important this area not be obstructed and the grille openings kept clean. AGA MARVEL does

not recommend the use of a custom made grille as air ow

may be restricted. (See Figure 2).

Front Grille,

keep this area

open.

!

WARNING

WARNING - Help Prevent Tragedies

Child entrapment and suffocation are not problems of

the past. Junked or abandoned refrigerators are still

dangerous - even if they sit out for "just a few hours".

If you are getting rid of your old refrigerator, please

follow the instructions below to help prevent accidents.

Before you throw away your old refrigerator or

freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not

easily climb inside.

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the ice machine will be out of direct sunlight and away from heat

sources. To ensure your product performs to specications,

the recommended installation location temperature range

is from 55 to 90°F (13 to 32°C) for built in ice machines.

Ice machines will not perform correctly in ambient temperatures less than 55°F (13°C).

Front Leveling

Legs

Figure 2

Rear

Leveling

Legs

Leveling Legs

Adjustable legs at the front and rear corners of the appli-

ance should be set so the unit is rmly positioned on the

oor and level from side to side and front to back. The

overall height of your Marvel appliance may be adjusted

between the minimum, 34" (86.4 cm), by turning the leveling leg in and the maximum, 35" (88.9 cm) by turning the

leveling leg out.

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the appliance forward using caution. On a level surface check the

appliance for levelness and adjust accordingly.

The front grille screws may be loosened to raise or lower

the grille to the desired height. When adjustment is complete tighten the two front grille screws. (See Figure 5).

4

Figure 3

INSTALLING YOUR APPLIANCE

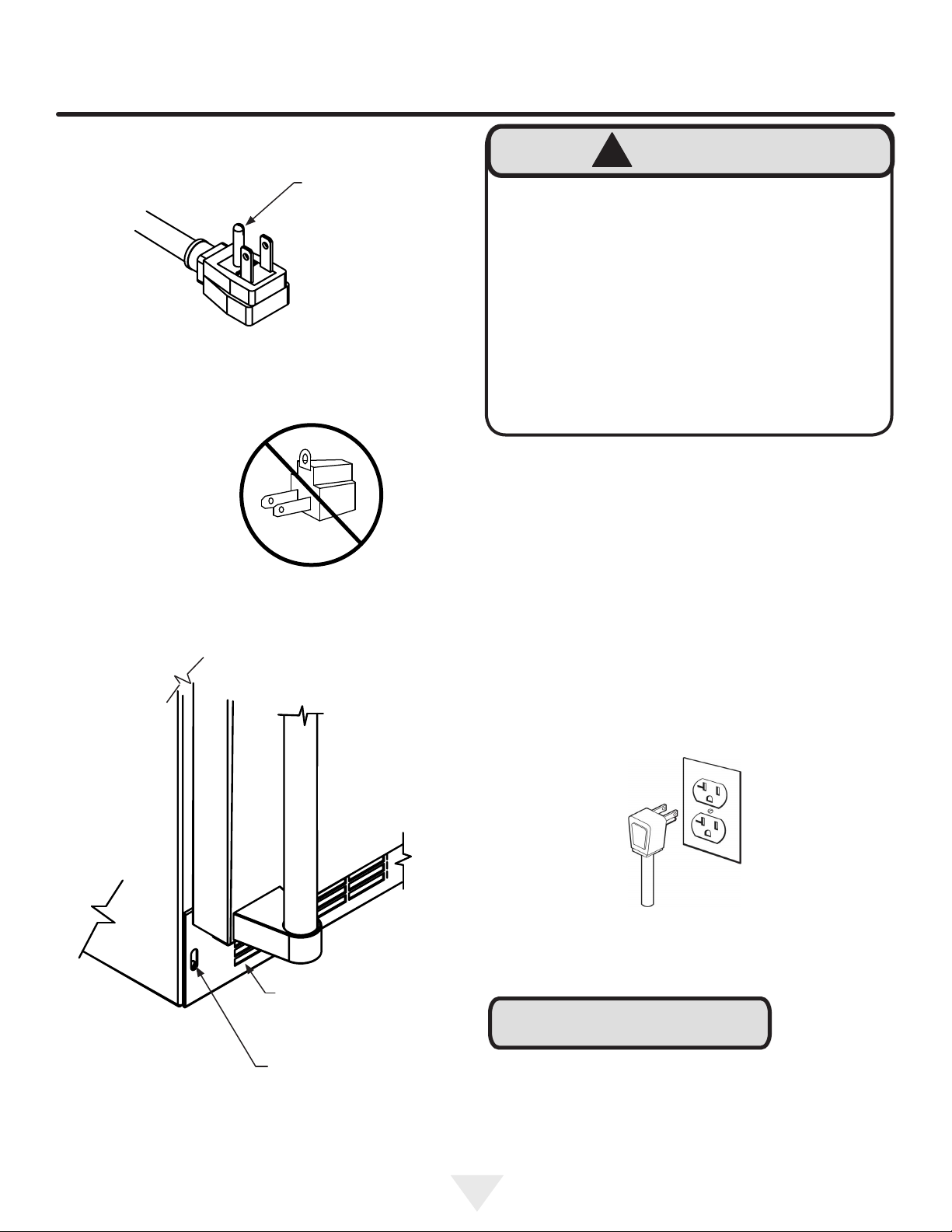

!

Do not remove

ground prong

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any circumstances, be installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the power

cord. (See Figure 3).

• Do not use an adapter. (See Figure 4).

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

Electrical Shock Hazard

WARNING

Figure 4

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable local codes and ordinances (see Figure 6). If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third ground prong should not, under any circumstances, be cut or removed.

Figure 6

Figure 5

Front grille

Front grille screw

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to nuisance tripping which will cause the appliance to shut down.

GFCI’s are generally not used on circuits with power equipment that must run unattended for long periods of time, unless required to meet local building codes and ordinances.

5

!

CAUTION

INSTALLING THE DRAIN PLUMBING

!

CAUTION

Failure to use an adequate drainage system, will result in

surrounding water damage and/or poor ice production.

!

WARNING

Electrical Shock Hazard

Reasonable care and safe methods should be practiced. Do NOT work with energized electrical equipment in a wet area. Read and follow the installation

instructions listed in this manual.

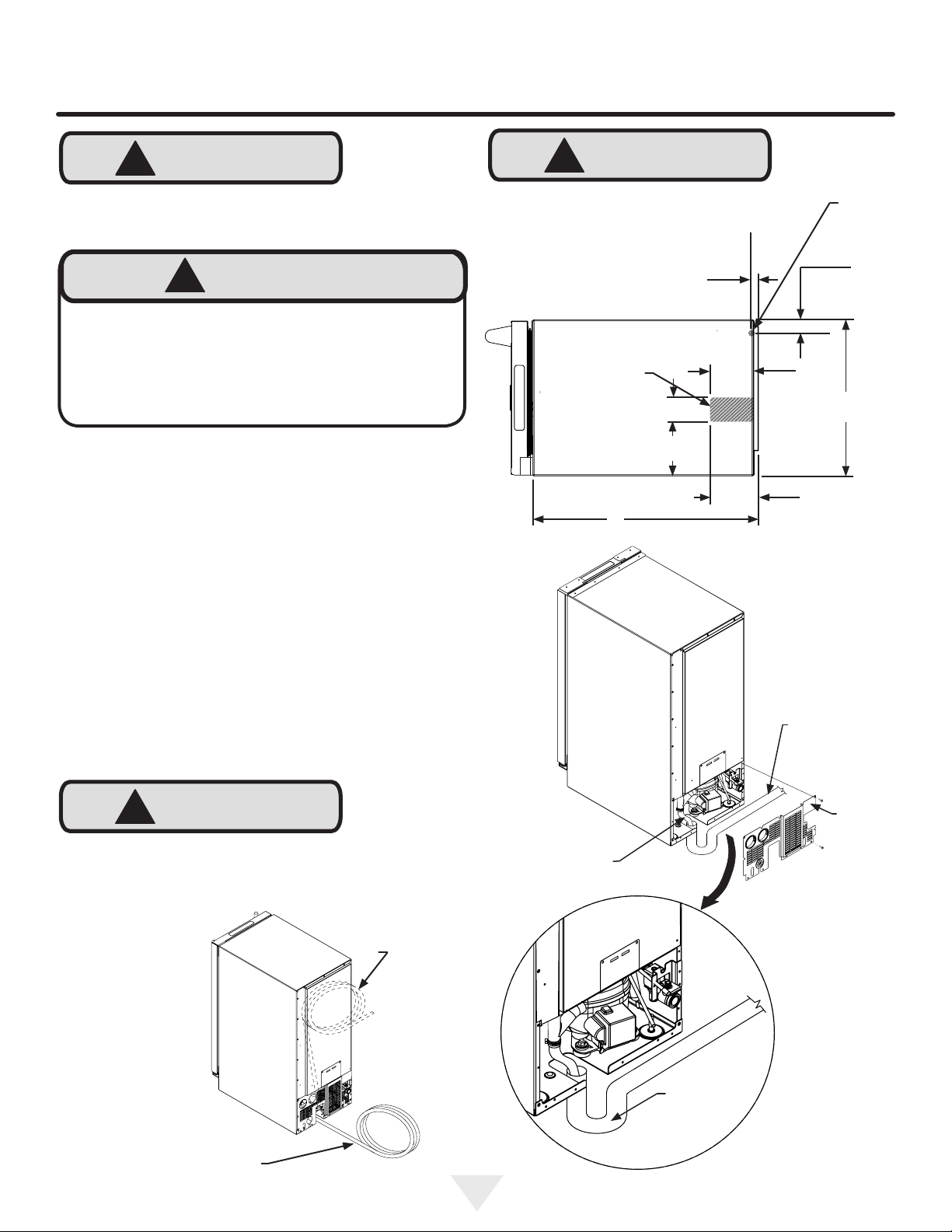

Drain Plumbing

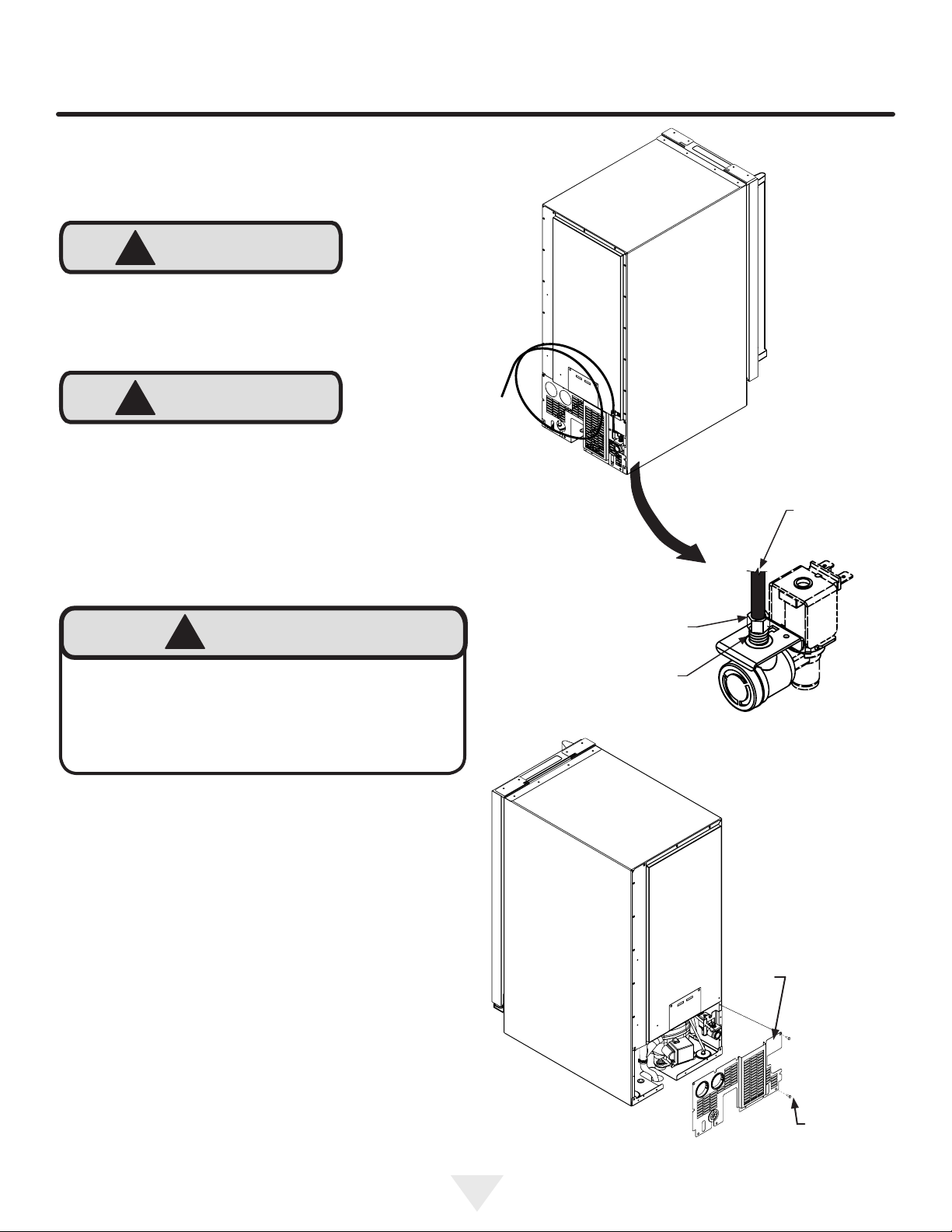

Your ice machine requires drain plumbing. There are 2

variations of ice machines in regards to the installation of

the drain plumbing, without a drain pump (gravity drain),

and with a drain pump.

Gravity Drain (no drain pump):

The ice machine is shipped with the drain line installed,

coiled and secured to the back of the cabinet as shown

in Figure 7. It can be uncoiled, routed to an appropriate

drain and cut to length as required. Additionally there is the

provision of drain routing through the cut-out in the bottom

of the unit, (see the gray area in Figure 8). A drain can be

installed in this gray area with the drain line cut to a short

length and positioned into the drain as shown in Figure 9,

or if the ice machine is to be built-in, the drain tube could be

routed through a hole in the oor in this gray area to a drain

below.

Observe and follow all local building

codes when installing this ice machine

and drain lines.

11

⁄16"

(17mm)

Drain access in

bottom of unit

Figure 8

21⁄4"(5.7 cm)

51⁄8" (13 cm)

211⁄2"

(54.6 cm)

C

L

43⁄32"

(10.4 cm)

417⁄32"

(11.5 cm)

Drain pipe, (not

provided)

11⁄4"

(3.2 cm)

C

L

147⁄8"

(37.8 cm)

Water

supply

inlet

!

CAUTION

The gravity drain line must be routed no higher than 6"

(15.2 cm) off the oor to assure proper drainage.

Drain line coiled

and secured to

the back of the

unit

Figure 7

Uncoil the drain line, route

to an appropriate drain and

cut to the required length

Drain tubing, cut

to length and in-

stall in the drain

6

Access

panel

Figure 9

Sanitary

trap

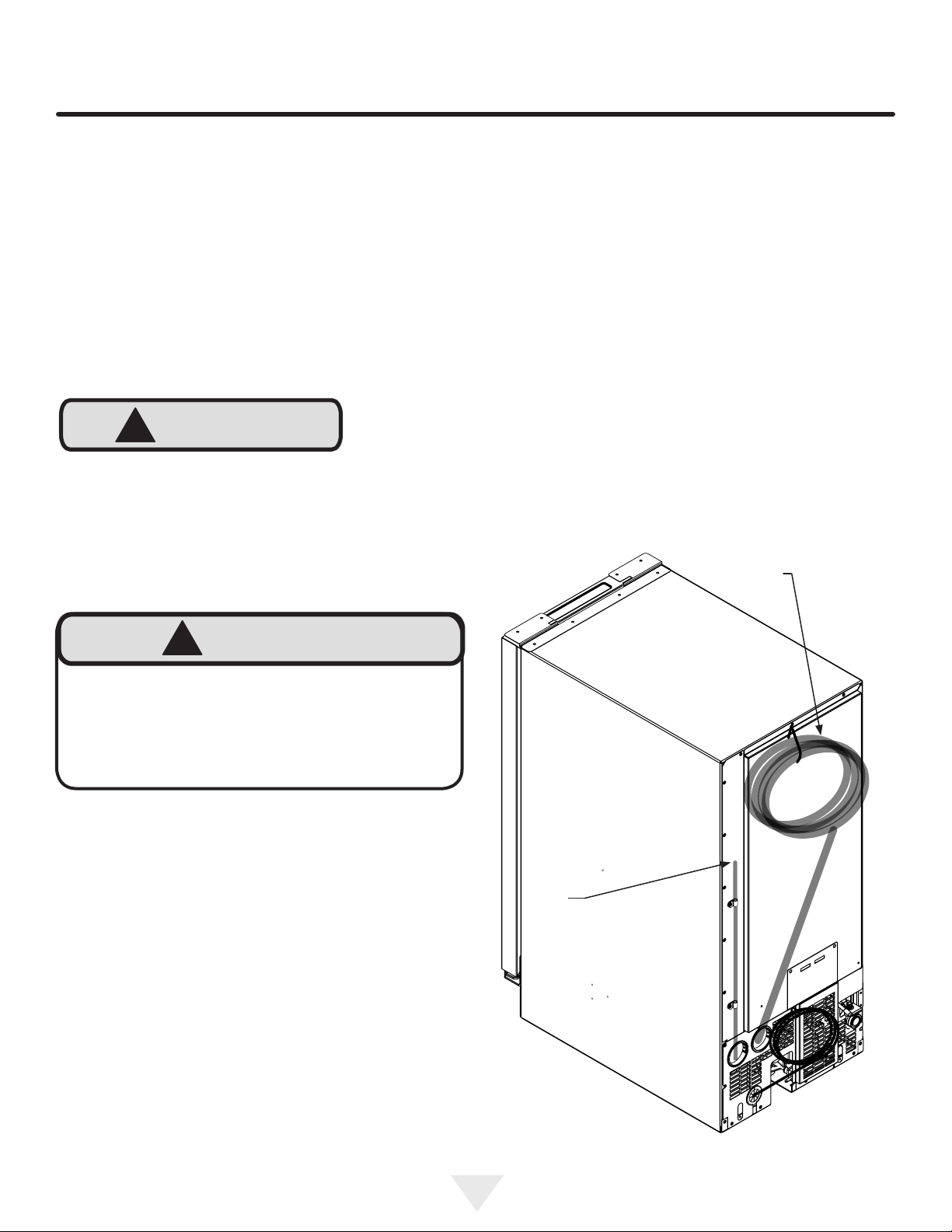

INSTALLING THE DRAIN PLUMBING

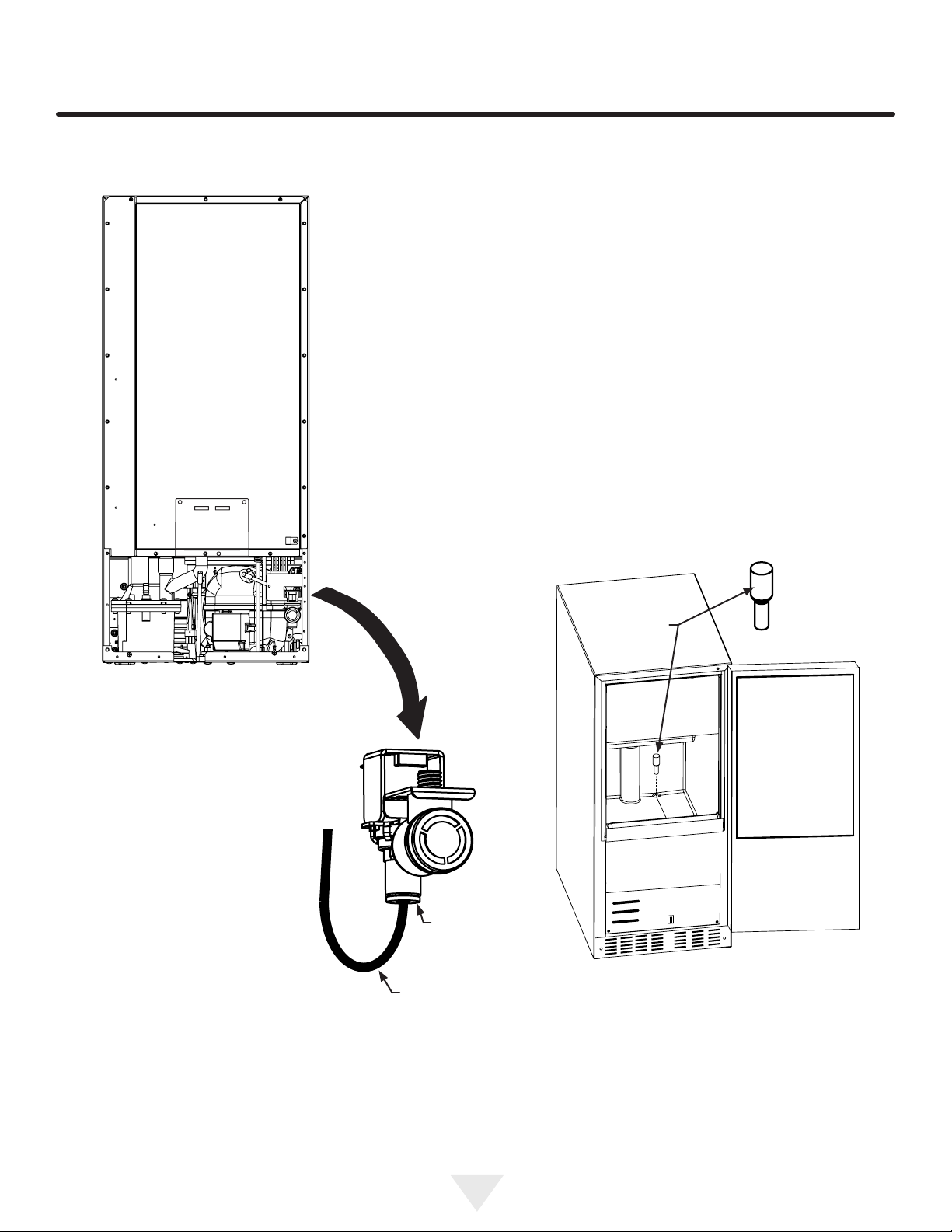

With a factory installed drain pump:

The Marvel Drain Pump is designed to remove drain water

from ice machines installed in areas without direct drainage

access. The sealed reservoir pump collects the melted ice

water and pumps it to a maximum lift of eight (8) feet (2.44

meters) using no more than the 20 feet of 3⁄8” I.D. vinyl tub-

ing.

If the ice machine has a factory installed drain pump. Discharge tubing is coiled up and attached to the back of the

ice machine. The 3⁄8 inch I.D. tubing needs to be plumbed

and connected to a sanitary sewer. Refer to Figure 10.

!

CAUTION

This drain pump is designed to be installed in Marvel ice

machines only and is approved for use with water only.

Optional Drain Pump.

An optional drain pump is available if you have purchased

an ice machine without one and do not have access to a

gravity drain. Installation instructions are provided with the

optional drain pump. Contact AGA Marvel customer service

at 800-223-3900 or your dealer for ordering.

Drain line coiled and

secured to the back of the

cabinet. Uncoil, route to

an appropriate drain and

cut to length.

!

WARNING

Electrical Shock Hazard

Risk of electrical shock or personal injury could occur

due to moving components, if the machine compartment access cover is removed before unplugging the

ice machine power cord.

Drain pump

vent tube.

Keep this

open to

assure air

ows freely

as water

enters the

pump reservoir.

Figure 10

7

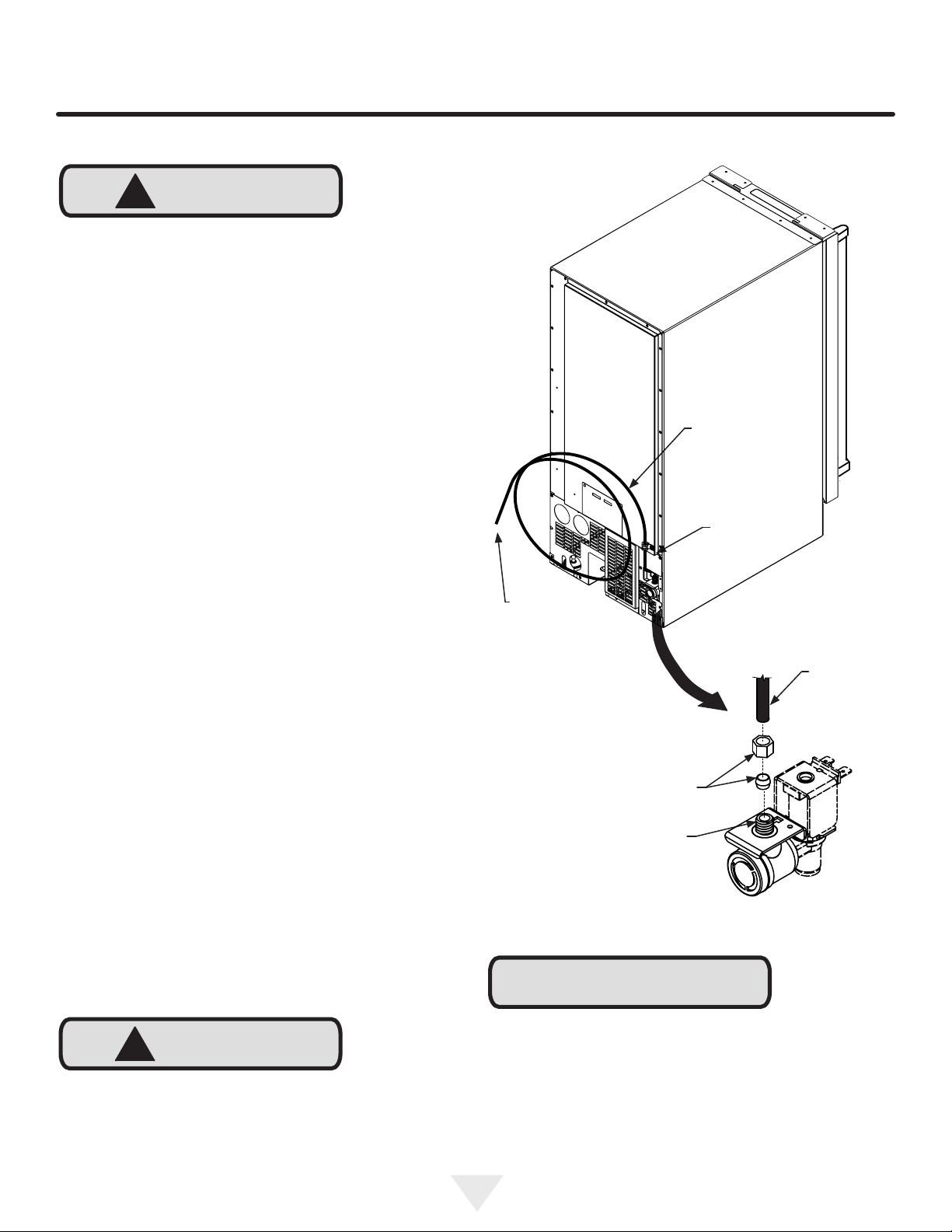

INSTALLING THE WATER SUPPLY

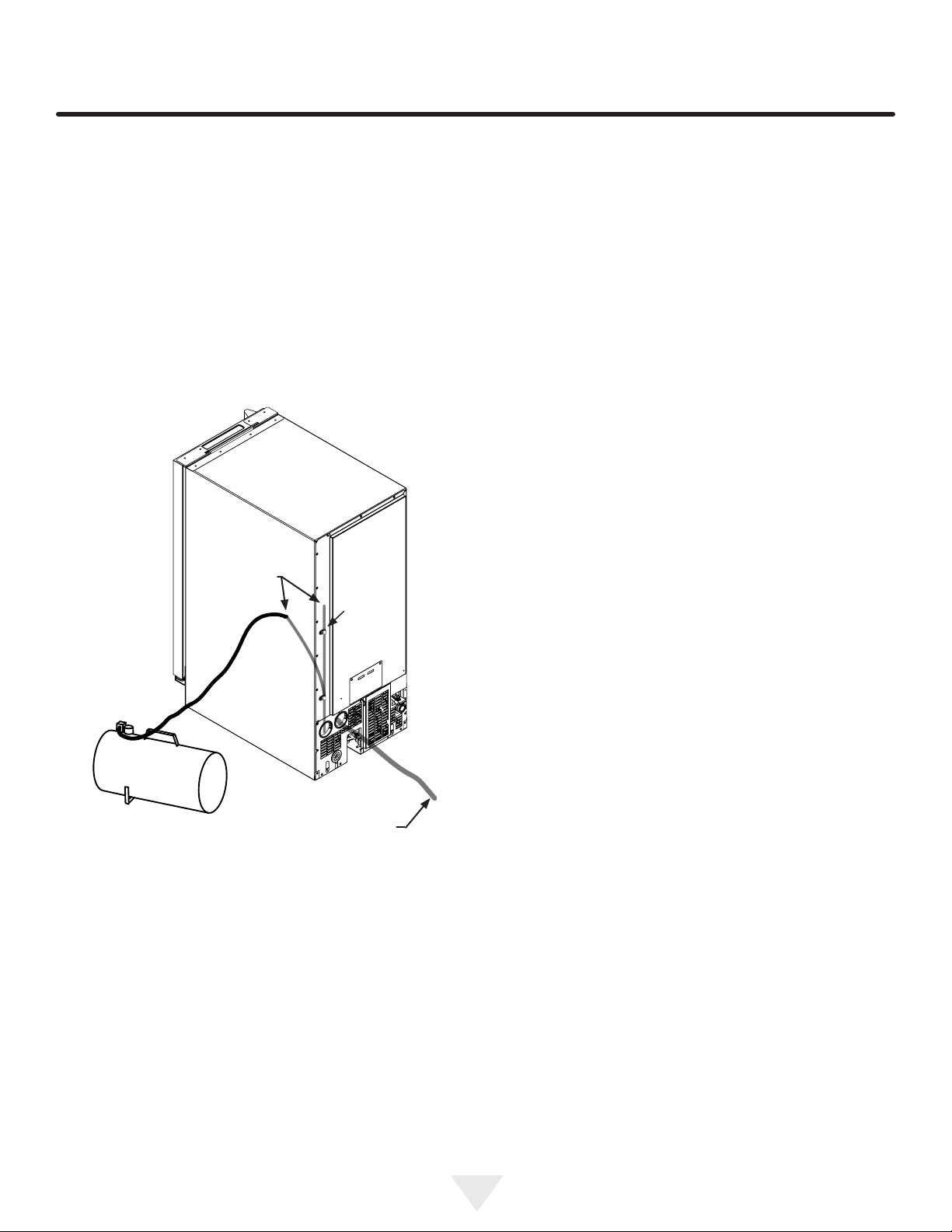

Water Supply

!

CAUTION

Observe and follow all local building codes when installing

this appliance.

This ice machine must be connected to a potable cold water supply line. delivering water pressure between a minimum of 20 psi and a maximum of 120 psi.

Use 1⁄4" copper tubing for your water supply which is avail-

able at any local hardware or plumbing supply store. Route

the 1⁄4" copper tubing to suit your installation being sure not

to kink the tubing. Purchase enough copper tubing length to

allow a coil to be formed behind the unit for a "service loop"

which will allow the appliance to be pulled out from the

installation for servicing or cleaning. (See Figure 11). Connect the copper tubing to the "top side" of a cold water pipe

to prevent the ice-maker from plugging with sediment.

A shutoff valve is recommended on the water supply line to

ease servicing the appliance. NOTE: A SELF-PIERCING

TYPE VALVE IS NOT RECOMMENDED as they are prone

to clogging with sediment which will create pressure drop

reducing the water supply to the unit.

Connect the copper tubing water supply to the water valve

inlet with the compression nut tting provided.

IMPORTANT: Secure the water supply line to the back of

the cabinet with the screw and strain relief clamp provided

in the corner of the back panel. (See Figure 11).

Water supply

service loop

to shut off

valve)

Figure 11

Back view of

ice machine

Water

Supply

Line

Clamp and

Screw

Water

supply

line

Make certain all connections are watertight after installation. Form the tubing so that it will not vibrate against the

cabinet body or kink when your appliance is moved in and

out of position.

This ice machine is designed to make clear ice from the

majority of water sources on a daily basis. If your results

are unsatisfactory, your water may need to be ltered or

treated. A water specialist can recommend proper water

treatment.

!

CAUTION

To prevent water leaks:

• The water line tting is to be used with copper tubing

only. Do not use with plastic tubing.

• Do not use any thread sealers on this water line tting.

Compression

tting

Water valve

inlet

NOTE

Reverse osmosis, (RO), water, softened water, and deionized water are not recommended as they can adversely

affect the quality and quantity of the ice.

8

FILLER PANEL KIT (OPTIONAL)

Filler Panel Kit

This Filler Panel Kit will add 3 inches to the width of the ice

machine for installation into an 18 inch wide opening. Order

one of the following part numbers for the color you require:

P/N 42242831 White Filler Panel Kit

P/N 42242832 Black Filler Panel Kit

P/N 42242833 Stainless Steel Filler Panel Kit

To order: Call AGA Marvel customer service at

800-223-3900.

Optional Filler Panel kit includes the following:

quantity 2 Cabinet Extensions

quantity 2 Kick plate Extensions

quantity 6 #10 x .50” sheet metal screws

177⁄8"

(45.4 cm)

Figure 12

9

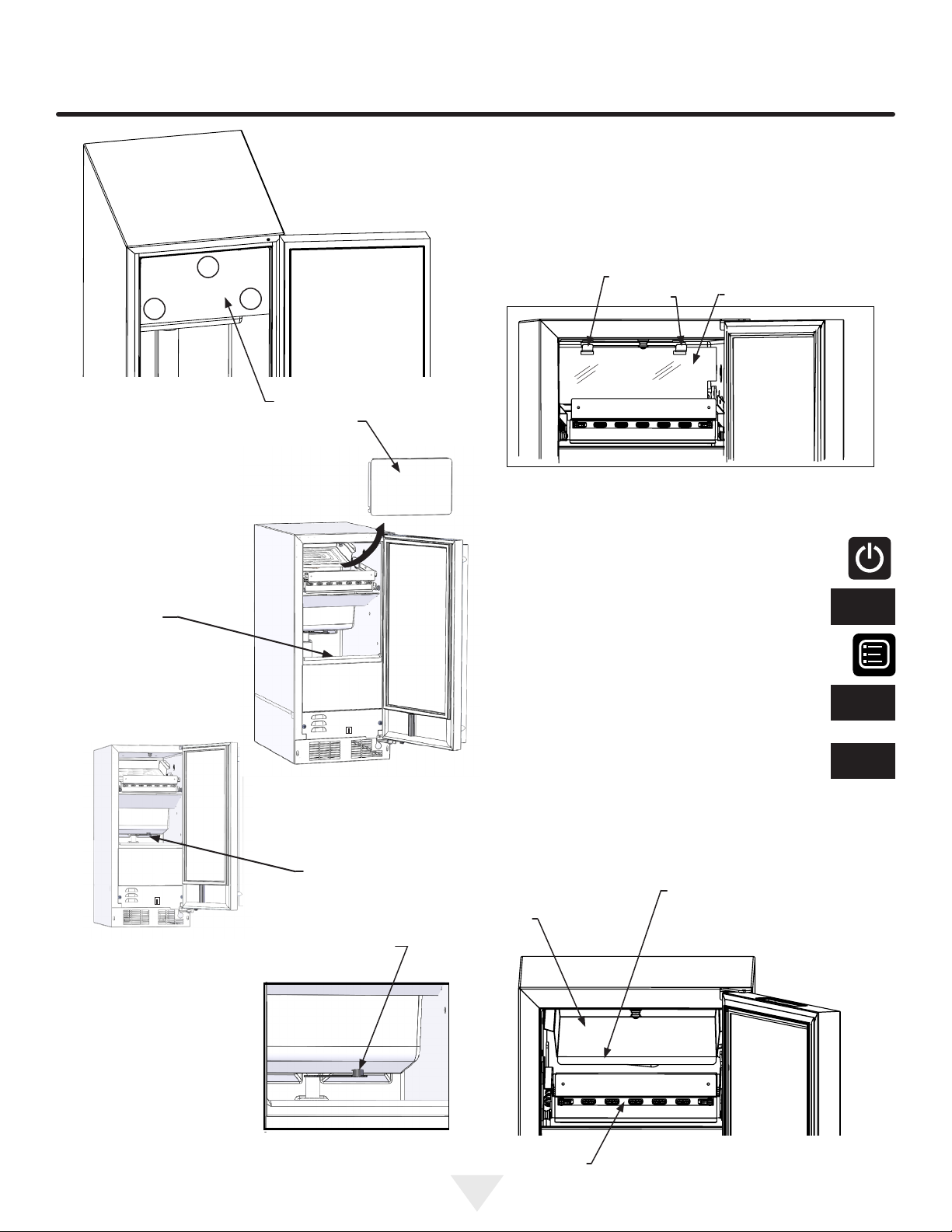

OPERATION OF THE ICE MACHINE

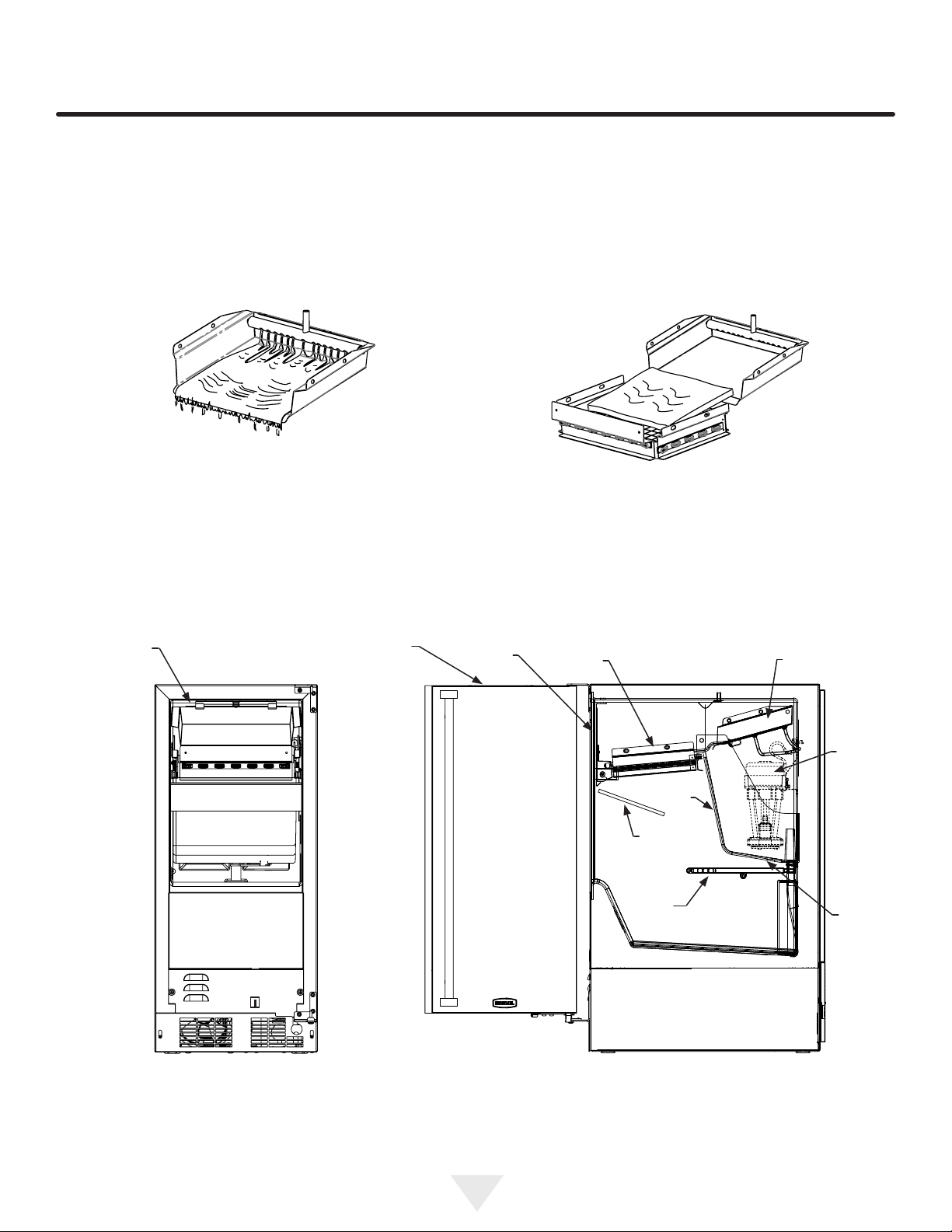

The Ice Making Process

Your ice machine is unique in how it forms ice with fractional freezing to form a slab of ice that is clear and has less

dissolved solids than the water it is produced from. This is

accomplished by running water over the cold evaporator

plate (see Figure 13) which gradually freezes the water to

produce the ice slab. Pure water freezes rst, leaving the

dissolved solids in the residual reservoir water to provide

clear ice.

Figure 13

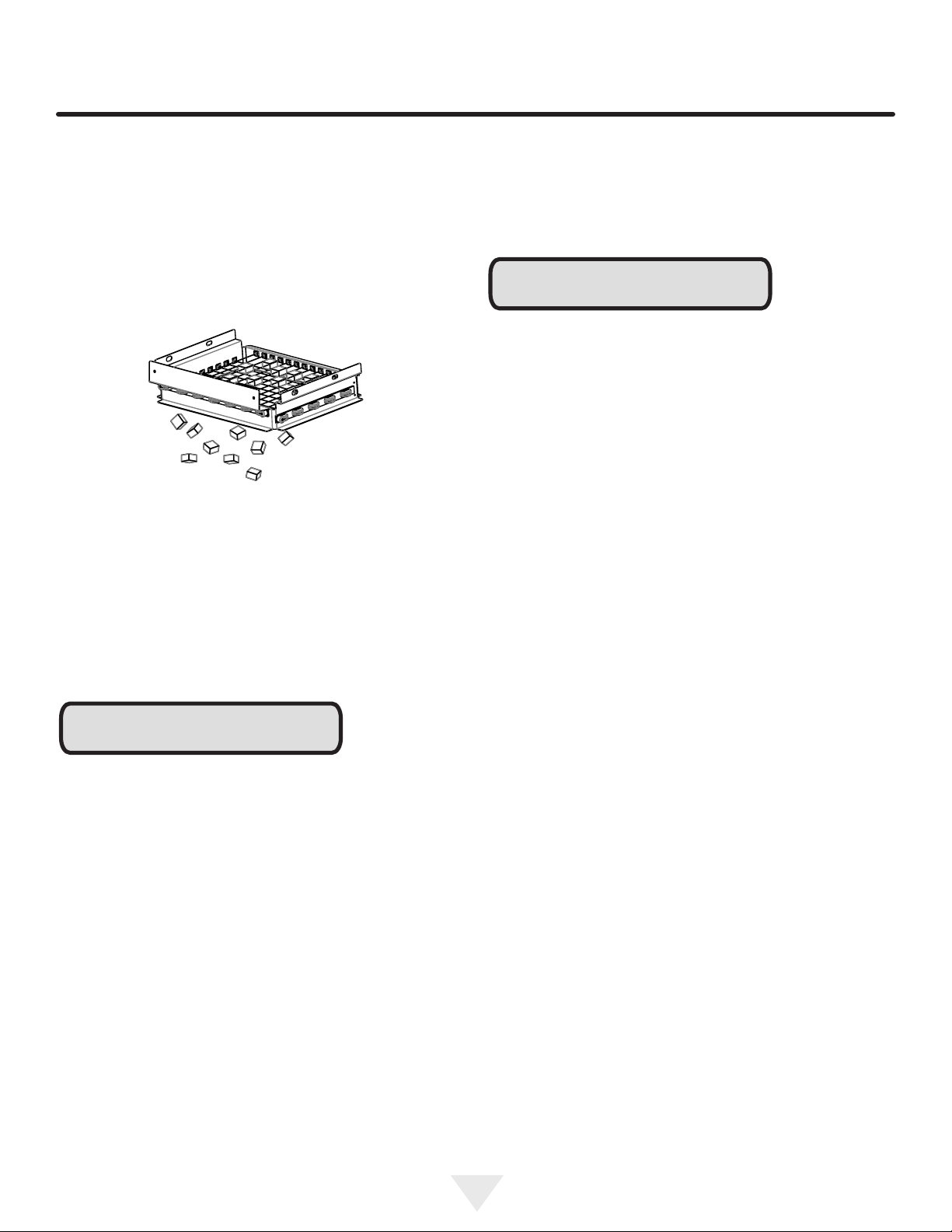

When the ice slab reaches the correct thickness, the ice

sheet is released and slides onto the grid cutter (see Figure

15). Here, the ice slab is cut into squares by the grid cutter’s heated wires (see Figure 16). The water containing

the dissolved minerals is drained after each freezing cycle.

Fresh water enters the machine for the next ice making

cycle.

Figure 15

Water distributor

Ice machine

electronic

control in top

of door

Front

panel

Grid Cutter

Water

reservoir

Ice Deector

Bin Level

Sensor

Evaporator

Circulation

Pump

Reservoir

drain plug

Figure 14

10

OPERATION OF ICE MACHINE

The ice machine will keep producing ice until the ice

machine’s bin is full and will restart automatically when ice

needs to be replenished in the bin. The ice bin is not refrigerated, and some melting will occur by design to preserve

the ice quality and clarity. Allow your ice machine to run for

24-48 hours to accumulate ice in the ice machine’s bin.

Figure 16

Ice Production

In normal mode the ice machine will produce up to 39

pounds (17.7 kg) of clear ice in a 24-hour period when

installed in a 72°F ambient with a 55°F water supply. In

"ECO" mode (see page 16) the ice machine will produce up

to 29 pounds (13.2 kg) of clear ice in the 24 hour period.

NOTE

“Initial” ice production and ice accumulated in the storage

bin will vary signicantly. This is normal. During the rst

24-hours of operation the unit will produce up to 39 lbs of

ice at the above ambient and water temperature conditions,

but when starting with an empty ice storage bin, the storage

bin may only accumulate up to 18 lbs of ice. By design,

the ice storage bin is maintained at a temperature slightly

above freezing to allow the stored ice to slowly melt, to

preserve the ice quality and clarity and assure a constant

supply of fresh ice. As ice is accumulated in the bin, the ice

production rate will overcome the ice melt and the storage

bin will ll to capacity.

The bin level sensor is located in the ice bin, it senses

when the ice supply is low or full and starts or stops the ice

making process accordingly.

NOTE

If the water supply is turned off to the ice machine be sure

to set the electronic control to the “OFF” position or remove

power to the unit.

New Sounds

The ice machine will make sounds that are different than

your household refrigerator. Because these sounds are

new to you they may be of a concern but are most likely

normal. The ice production process will make noises that

are not typical in a refrigeration product, ice falling onto

hard surfaces, water cascading across the evaporator, and

valves opening and closing. Following are some of the

sounds that you may hear:

A buzzing sound will be heard when the water valve

opens to ll the water reservoir.

A rattling noise which could be water owing through the

water line.

A splashing sound when water is owing over the evaporator plate and into the water reservoir.

A "thud" when the ice slab is released from the evaporator plate and slides onto the grid cutter.

"Clicks" when the cubes fall into the ice storage bin.

A gurgling sound which is refrigerant owing in the ice

machine.

An air noise from the condenser fan.

11

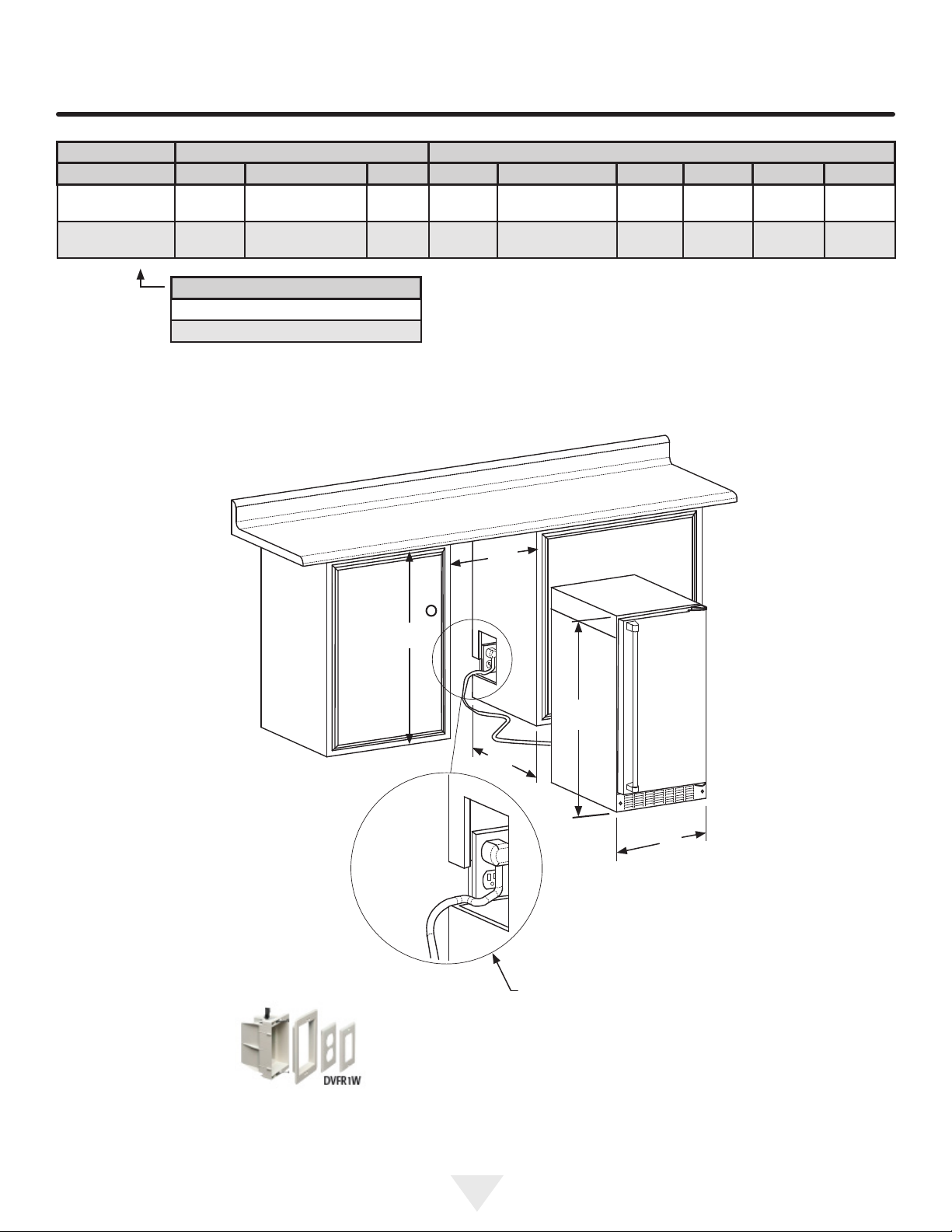

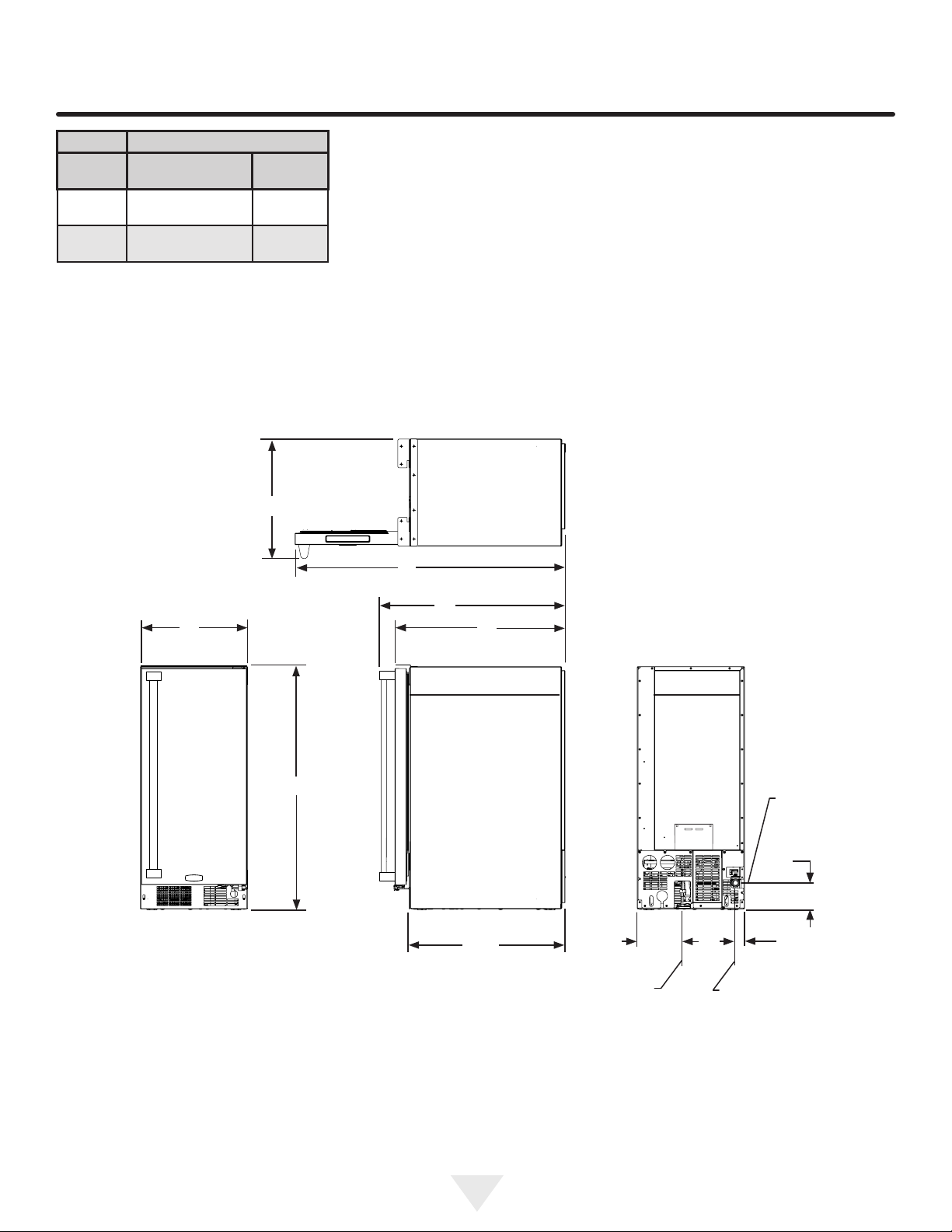

PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "J"

MP15C*S

`MP15C*P

15"

(38.1 cm)

15"

(38.1 cm)

DOOR STYLE

(S) Solid Door

(P) Solid Overlay Door (no handle)

** 341⁄4" to 351⁄4"

(87 to 89.5 cm)

** 341⁄4" to 351⁄4"

(87 to 89.5 cm)

24"

(61 cm)

*24"

(61 cm)

147⁄8"

(37.8 cm)

147⁄8"

(37.8 cm)

34" to 35"

(86.4 to 88.9 cm)

34" to 35"

(86.4 to 88.9 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

267⁄32"

(66.6 cm)

-

385⁄8"

(98.1 cm)

385⁄8"

(98.1 cm)

(44.3 cm)

(35.9 cm)

177⁄16"

141⁄8"

Figure 17a

Figure 18

"B"

"A"

"E"

Figure 17

"C"

"D"

If necessary to gain clearance inside the rough-in

opening a hole can be cut through the adjacent cabinet and the power cord routed through this hole to a

power outlet. Another way to increase the available

opening depth is to recess the power outlet into the

rear wall to gain the thickness of the power cord plug.

Not all recessed outlet boxes will work for this application as they are too narrow, but a recessed outlet box

equivalent to Arlington #DVFR1W is recommended for

this application, (see Figure 18).

12

PRODUCT DIMENSIONS

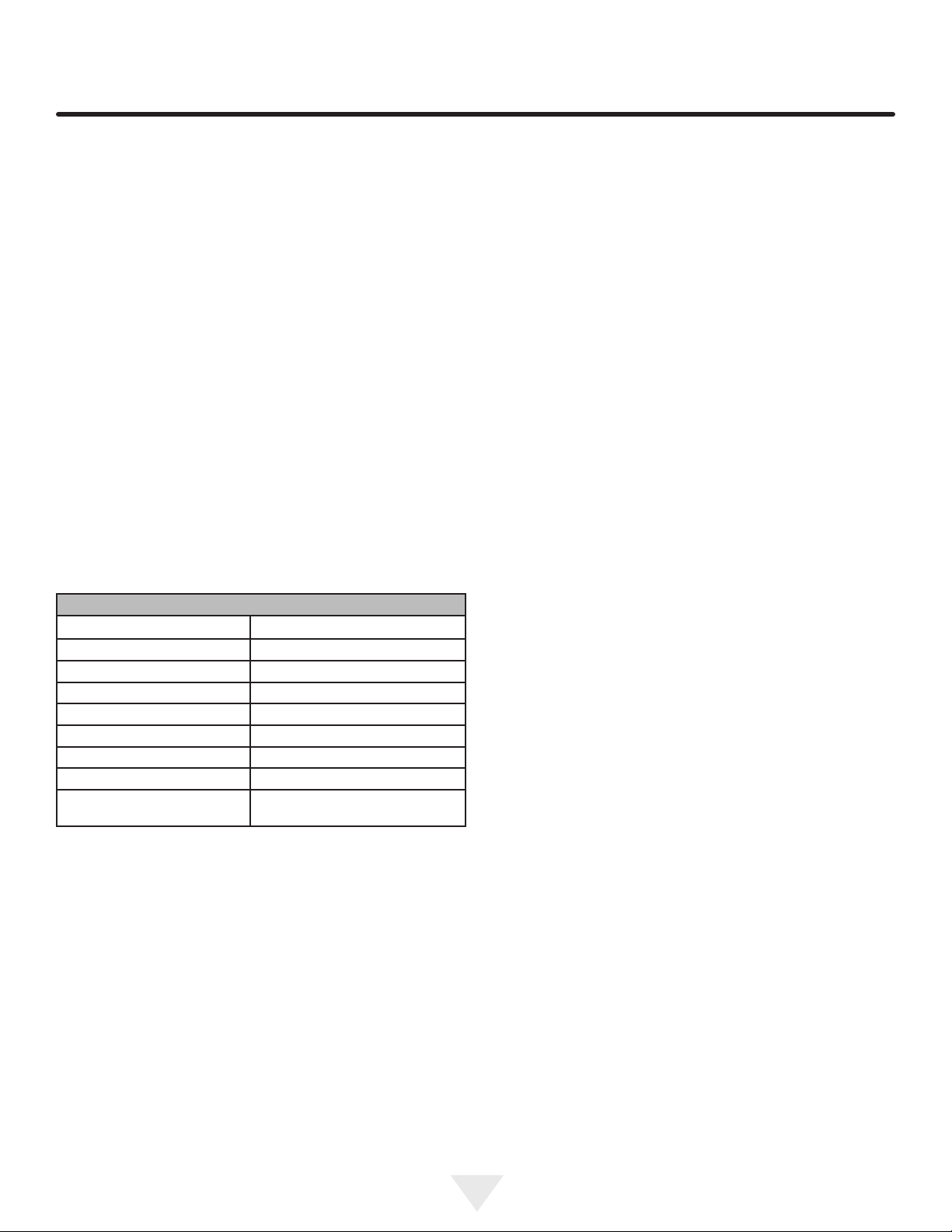

PRODUCT DATA

MODEL

MP15C*S 115V/60Hz/15A

MP15C*P 115V/60Hz/15A

ELECTRICAL

REQUIREMENTS #

PRODUCT

WEIGHT

105 lbs

(47.7 kg)

105 lbs

(47.7 kg)

"J"

* To install MP15C*P models with the door face ush with

the adjacent cabinet doors, custom decorative panel thickness cannot exceed 3⁄4" (19 mm).

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

# A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and appliance.

"H"

"D"

"E"

Figure 19

(S) Solid

door shown

"G"

"F"

211⁄2"

(54.6cm)

615⁄16"

(17.6 cm)

CL Gravity

drain

CL

Water

inlet

47⁄8"

(12.4 cm)

11⁄4"

(3.2 cm)

CL

Water

inlet

13

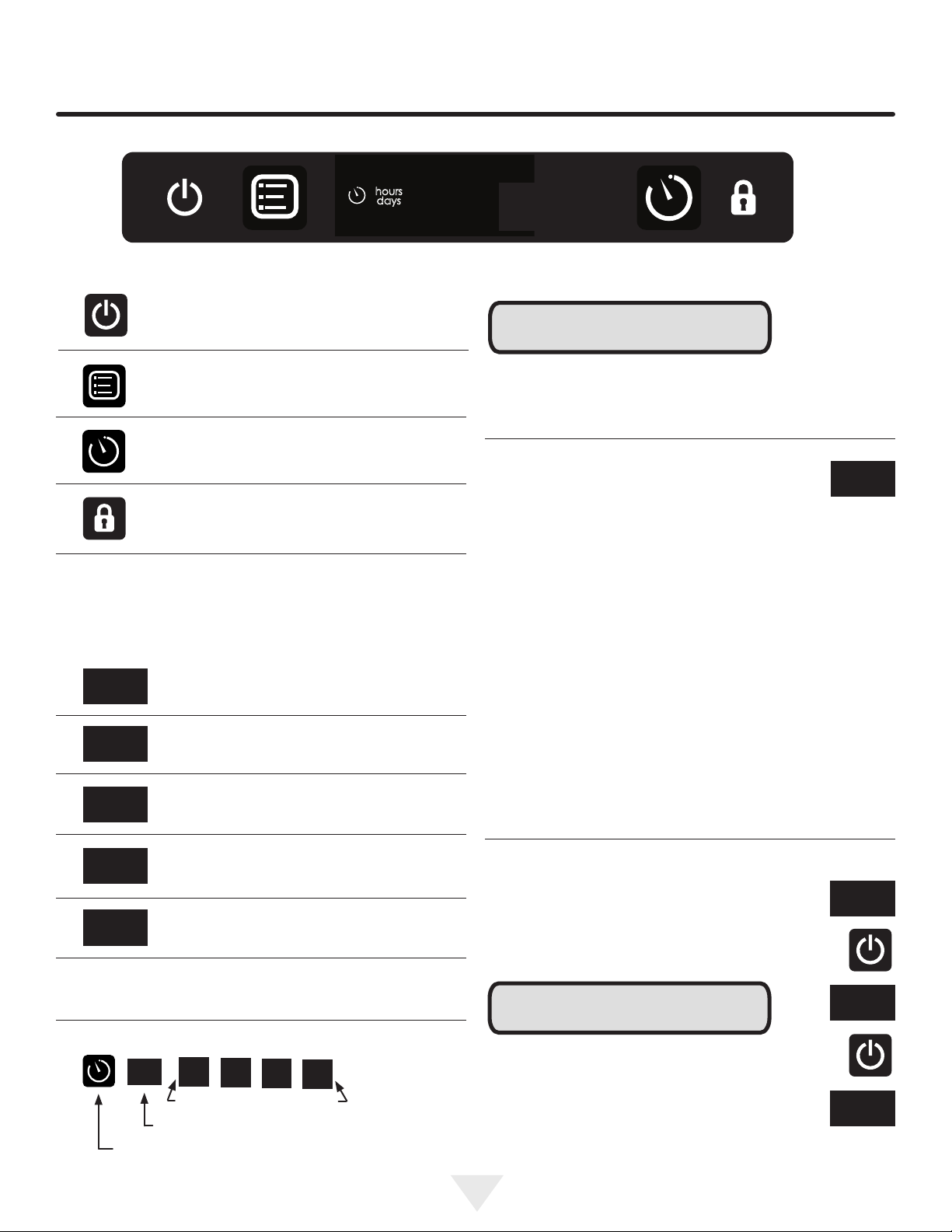

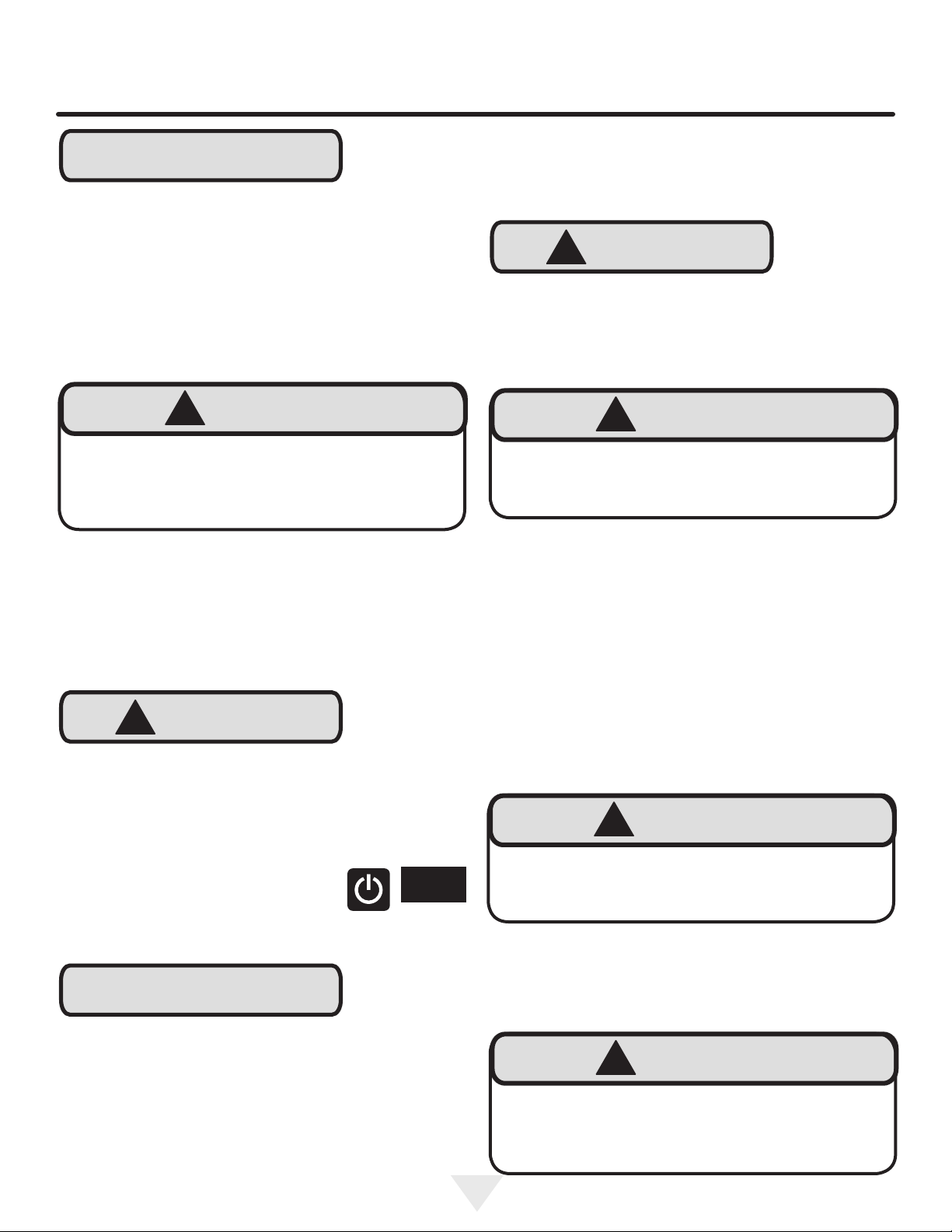

USING YOUR ELECTRONIC CONTROL

ICE

DOOR

On/off Menu Display area Delay timer Lock

ECO

hours

1 4 6 8

days

OFF CLEAN

Display icons:

"ON/OFF" icon : used for turning the appliance on and off.

"MENU" icon : used to access optional functions in the user interface.

"Clock" icon : used to enter the Delay start/

vacation mode.

"LOCK" icon : used to lock out functions in

the user interface.

Display area text:

ICE

ECO

OFF

Signies the appliance is on and producing

ice.

Signies the appliance is in economical ice

production mode.

Signies the appliance is off

Figure 20

User interface display

The control display is covered with a clear plastic protec-

tive lm. This lm may be removed by carefully lifting at a

corner.

Starting your clear ice machine:

Plug the ice machine into a 115 volt wall outlet,

(see page 5 for electrical information). Your appliance is shipped from the factory in the "ICE" mode and will

begin start-up of ice production after the start-up routine.

Upon applying power to the unit, or after a power interruption, the Ice machine will perform a self-test, followed by a

harvest cycle to clear any in-process ice production. This

start-up routine, (“after power is applied to the unit”), takes

approximately 13 minutes to complete before an ice production cycle starts.

If the appliance does not start, conrm the wall outlet has

power, and the control is in the "ICE" mode, (see Options

section below). Do not start the ice machine in "ECO"

mode. "ECO" mode should only be used after there is a full

bin of ice.

NOTE

ICE

DOOR

CLEAN

Delay start/Vacation mode:

hours

days

Hours or days will be lit

When lit, this signies the delay start/vacation mode is operational.

Signies a door ajar alarm condition.

Cleaning is recommended or the appliance

is in the clean mode.

1

4

6

8

Hours or days timer is set for

Turning your ice machine On and Off:

If your appliance is on, "ICE" will be displayed.

To turn the appliance off, push and hold the "ON/

OFF" icon for 3-seconds. The display will show

"OFF" .

NOTE

When turned off, the ice machine will complete its

current ice production cycle then shut off.

The drain pump (if equipped) and the interior light

will still be functioning during the OFF mode. To

turn the appliance back on, press and hold the "ON/OFF"

icon for 3-seconds, the display will show "ICE".

14

ICE

OFF

ICE

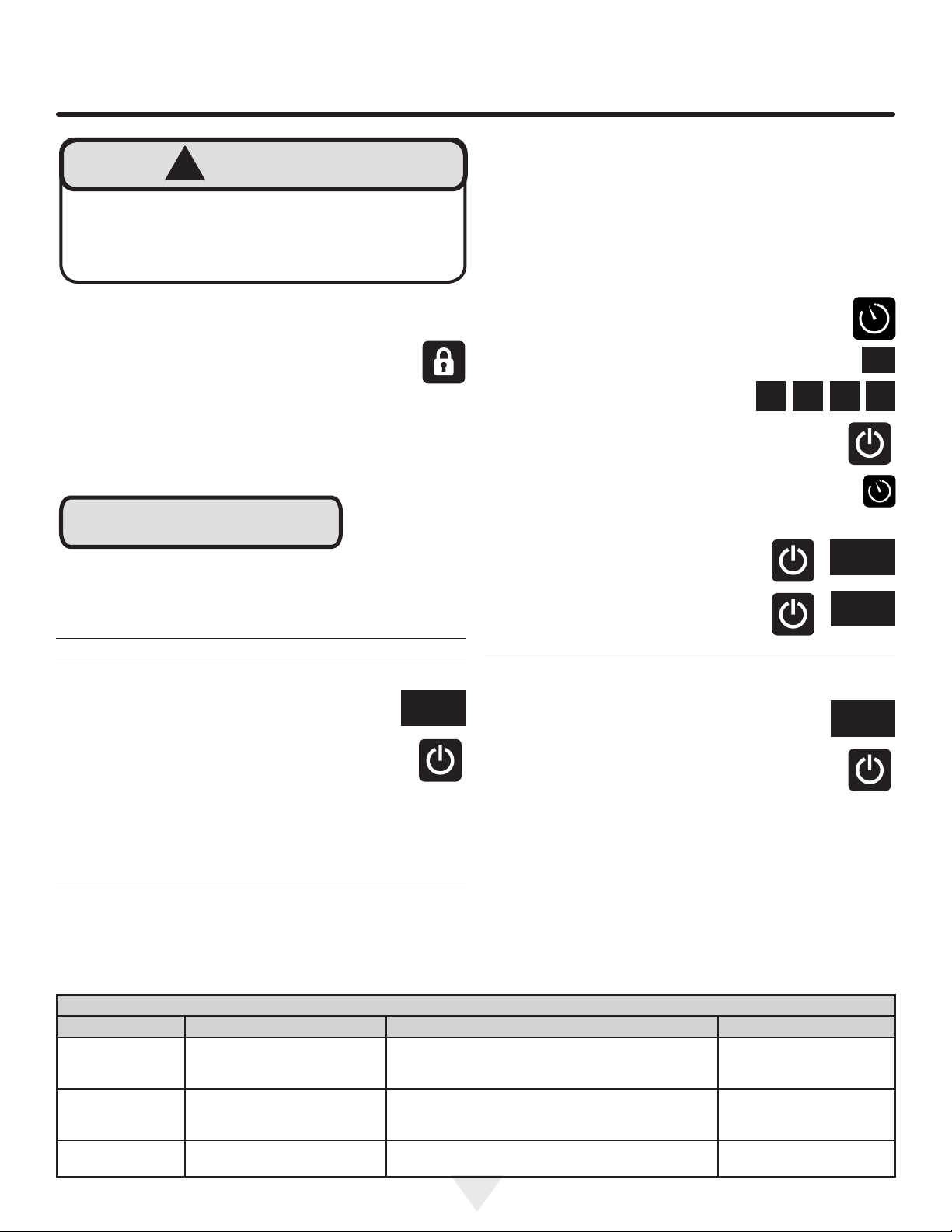

USING YOUR ELECTRONIC CONTROL

!

WARNING

Turning the ice machine "OFF" will only terminate the

ice production, it does not remove power from the appliance. Always unplug the power cord from the wall

outlet before servicing the unit.

Control Lock:

The user interface can be locked to avoid unintentional changes from things like cleaning. To lock

the appliance, push and hold the "LOCK" icon for

5-seconds. The "LOCK" icon will ash 3 times, then change

to steady back-lit. To unlock the user interface, press and

hold the "LOCK" icon for 5-seconds, and the back-light will

turn off.

NOTE

The "LOCK" icon is the only active key in this mode. If other

icons are pressed while in the lock mode the "LOCK" icon

will ash 3 times, and an audible tone will sound, to remind

the user the appliance is in the lock mode.

Delay start/Vacation mode:

Your ice machine is equipped with a delay start function.

This feature can be used to temporarily shut the appliance

off for 1, 4, 6, or 8 hours or days. Upon completion of the

selected delay period, the appliance will resume operation.

This is ideal for temporarily stopping ice machine noises or

to save water and electricity if you are away from home but

want fresh ice upon your return.

To enter the delay start mode, press the "CLOCK"

icon while the appliance is in "ICE" mode. This will

delay the next harvest by the time displayed. Each

additional press of the "CLOCK" icon will add time,

from 1, 4, 6, or 8 hours, to 1, 4, 6, or 8

days. The next press after 8 days will

1 4 6 8

leave delay set mode. After the desired

time has been selected, press the "ON/OFF" icon

for 2 seconds to accept, your unit will shut off and a

clock icon and your selected time will be displayed.

When the selected time has elapsed, normal ice production will resume.

To cancel the delayed start, press and

hold the "ON/OFF" icon until the appliance enters OFF, then press and hold

the "ON/OFF" icon again until the appliance enters "ICE" mode.

hours

OFF

ICE

days

Door ajar alarm:

If the door is open, or not closed properly for 5

minutes the "DOOR" indicator will illuminate and

ash and an audible tone will sound. This alarm

condition can be reset by closing the door or momentarily pressing the "ON/OFF" icon, (i.e.-if you

are cleaning the storage compartment, etc.). The

alarm will recur in 5 minutes if the alarm condition persists.

If the door is intentionally left open for long periods, the

alarm can be disabled by turning the unit off.

DOOR

Error codes:

The ice machine is monitored continuously. Any OPEN or

SHORTED circuit condition with a temperature sensor or

miscommunications between the control and user interface

will initiate an ERROR CODE as listed below:

Error Codes

Error Displayed Code Error Description Action to Take

Bin Sensor error

System Sensor error

Communication error

"OFF" will ash continuously in 1

second intervals in the display. No

audible alarm will sound.

"ICE" will ash continuously in

the display. No audible alarm will

sound.

Continual ashing of all indicators

on the display.

Failed temperature sensor. Machine operation will imme-

Failed condenser temperature sensor. Machine opera-

tion will continue but ice production cycle will not adapt to

varying ambient conditions, so ice quality may vary.

Loss of communication between the main board and the

Clean reminder:

A "CLEAN" reminder will occur every 6 months

to remind you that it may be time to clean your

appliance. Over time mineral build up on the cold

evaporator plate can occur which can adversely

affect the quality of your ice. This build-up is dependent on your water source and usage. Normal ice

production will continue while the "CLEAN" reminder is displayed. You may clear the "CLEAN" reminder at any time

by momentarily pressing the "ON/OFF" icon. When reset,

the "CLEAN" reminder will reset and not occur for another

6 months. If you choose to clean the appliance at this time,

see the options menu section below.

diately enter an OFF state.

user interface.

Call service to have the

temperature sensor replaced.

Call service to have the

temperature sensor replaced.

Call service to have a

diagnostic check.

CLEAN

15

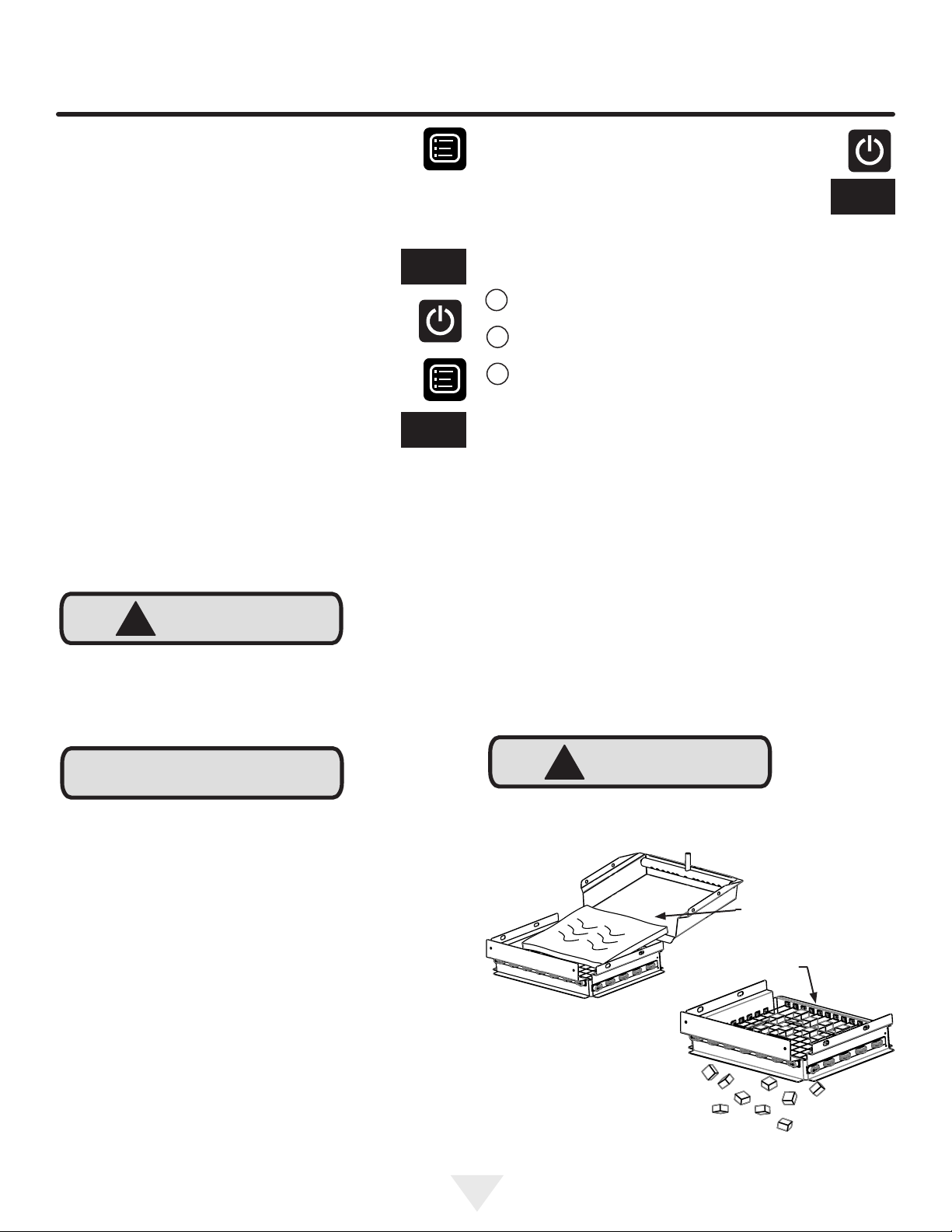

CLEANING YOUR ICE MACHINE

Options menu:

Normal and ECO mode:

Your ice machine comes with an optional "ECO" mode.

While in this mode ice production will slow and the appliance will use less water and electricity. "ECO" mode should

only be initiated after there is a full bin of ice.To

enter "ECO" mode do the following:

• Press the "MENU" icon twice and the green

"ECO" will ash.

• Press and hold the "ON/OFF" icon until the

green "ECO" stops ashing and remains illuminated.

• To return to the standard operating rate press

the "MENU" icon twice, the ECO will turn off and

the "ICE" will be ashing. Press and hold the

"ON/OFF" icon until the "ICE" stops ashing

and remains illuminated.

ECO

ICE

Clean mode:

To ensure maximum performance and ice quality, it is

recommended to clean your ice machine once every six

months.

!

CAUTION

Use only approved ice machine cleaners and be sure to

follow all label warnings and directions. Incorrect chemical usage, and any damage or injury that may result, is not

covered by warranty.

Once you have your cleaner:

Turn the ice machine off by pressing and holding the

"ON/OFF" icon for 3 seconds. "OFF" will be displayed on the control.

Follow the following three step procedure for

removing the grid cutter cover from the ice machine, Refer

to Figures 23 and 24:

1

-pull out on this corner rst to remove the cover corner

from the mounting peg.

2

-pull out on this corner next to remove it from the

mounting peg.

3

-reach behind cover and push cover towards you to

remove cover from the center mounting peg.

Remove all ice from the ice bin, (see Figure 24).

Drain the water from the water reservoir, by removing the

black plug from the bottom of the fresh water reservoir.

(See Figure 25). After the water is drained replace the plug

in the bottom of the reservoir.

Allow all of the ice to fall from the evaporator plate and

remove any ice from the grid cutter. If there is ice embedded in the grid cutter wires, wait for it to melt and fall out.

Do not try to remove ice that is embedded in the grid

cutter wires as that may break the wires. (See Figures

21 and 22).

OFF

NOTE

For reference see our "Care and Cleaning video" at the

website: www.marvelrefrigeration.com.

To clean your ice machine you will need to purchase a

"nickel safe" ice maker cleaner. Cleaner can be obtained by

contacting AGA Marvel customer service at 800-223-3900

or are available at most appliance retailers or through the

cleaners website. Several recommended cleaners are

listed below:

• Kirby's Certied ice machine cleaner. 100% nickel safe.

• Nu-Calgon nickel safe ice machine cleaner.

• Franklin Machine Products Nickel safe ice machine

cleaner.

!

CAUTION

Forcing ice through the grid cutter will break the grid cutter

wires.

Remove all ice

from the evaporator

plate and grid cutter area

Figure 21

Figure 22

16

CLEANING YOUR ICE MACHINE

Refer to your cleaning solution instructions to determine

the proper amount of cleaning solution to add based on 2

quarts (1.9 liters) of water. Remove the plastic splash shield

to improve access. (See Figure 26). Pour the cleaning solu-

tion slowly on the evaporator plate so it ows down into the

fresh water reservoir. (See Figure 27).

2

Figura 23

Remove all of

the ice from

the ice bin

3

1

Remove the grid

cutter cover

Replace the splash shield if removed.

Turn the ice machine back on by pressing and

holding the "ON/OFF" icon for 3 seconds. The

display will indicate "ICE" mode. Press and hold the

"MENU" icon until a ashing "CLEAN" is displayed. Press the "ON/OFF" icon until "CLEAN"

stops ashing. Your ice machine will now enter

the clean cycle.

The clean and rinse cycle will take about 49 minutes.

Splash shield

brackets

Figure 26

Splash shield

ICE

CLEAN

Figura 25

Figura 24

Remove the

black reservoir

drain plug from

the bottom of

the reservoir.

Figura 25b

After the clean cycle is complete the ice machine

will return to the "OFF" position.

After the cleaning cycle is completed, verify that all build-up

has been removed. If not repeat the clean cycle procedure.

Evaporator

plate

Grid cutter

Pour cleaning solution slowly

onto front edge of evaporator

plate behind the grid cutter.

Figure 27

OFF

17

OVERLAY DOOR PANEL INSTALLATION

NOTE

Canceling clean mode:

To exit clean mode press and hold the "ON/OFF" icon

until "OFF" is displayed. Wait 3 minutes for clean mode to

complete it's cancel routine before turning unit back on by

pressing and holding the "ON/OFF" icon. If you turn the unit

back on before the 3 minutes has elapsed, the display will

show "CLEAN" and the unit will shut itself off upon completion of the 3 minute clean cancel routine.

!

WARNING

If you purchased an overlay panel model, your unit is

equipped with articulated hinges to allow fully integrated

built-in installations. Custom panel thicknesses of 5⁄8" (15

mm) and 3⁄4" (18 mm) are accommodated.

!

CAUTION

It is important to use the factory provided grille that came

with the product to assure proper air ow is maintained

through the condenser. The use of a custom grille is not

recommended and will void the warranty.

!

WARNING

If you cancel clean mode after adding ice maker

cleaner, you must re-start cleaning and allow clean

cycle to complete to remove the cleaning solution

before resuming ice production.

Optional: After the cleaning cycle has been completed ,

you may wash the interior with a mild detergent / dish soap

or a solution of two tablespoons of baking soda and one

quart of water. Rinse with clean water.

Replace the grid cutter cover.

!

CAUTION

Do not use bleach based cleaners or any abrasive cleaning

products. Chlorine based cleaners will attack the stainless

steel, making it susceptible to corrosion.

Your ice machine is now ready to

restart. Press and hold the "ON/OFF"

icon for 3 seconds until "ICE is displayed.

ICE

Overlay panel models are designed for use with builtin installations only. Use in freestanding installations

could result in personal injury.

Step 1: Removing the Door

With a phillips screwdriver remove the screw and "P" clamp

from the bottom of the door near the hinge. See Figure 28b.

Disconnect the door wire harness by pressing and holding

down the locking tab on the wire connector and pulling the

connector apart. See Figure 29.

Open the door and loosen the screws holding the hinges to

the cabinet (2 at the top and 2 at the bottom hinge). Do not

remove the screws but loosen them enough so the hinges

can be slipped off of the screws when sliding the door to

the side.

!

WARNING

The articulated hinges have many pinch points. Carefully close / collapse the hinges as soon as the door is

removed from the cabinet.

NOTE

After cleaning it is recommended you discard the ice produced after 3 hours of ice production.

With a helper, and being careful not to scratch the cabinet

or the door, slide the door to the side about 1⁄2 inch and

remove the hinges and door from the unit.

!

WARNING

Use extreme caution with the articulated hinges. The

hinge is self closing and many pinch points exist prior

to built-in installation. Do not remove the cabinet "Z"

bracket from the top of the cabinet.

18

OVERLAY DOOR PANEL INSTALLATION

Cabinet

"Z" Bracket

Loosen (do not remove ) these

2 phillips head screws on the

top and bottom hinges

Figure 28a

Holes in

gasket

retainer.

Figure 30a

Overlay panel

ush with top

of door.

Overlay panel to

be centered on

width of door.

Figure 28

"P" clamp

and screw

Bottom of

door

Figure 28b

Press and hold down this

tab on the wire connector

and pull the connector apart.

Figure 29

Wire connector

see Figure 29

Step 2: Remove the door gasket

With the door laying on a at surface and starting at a corner of the door remove the magnetic door gasket from it's

retainer by pulling it away from the interior side of the door,

see Figure 30. Set the gasket aside on a at surface.

Magnetic Gasket

remove starting at a

corner, grasp and pull

away from the door.

Figure 30

!

CAUTION

Weight of overlay door panel must not exceed 15

pounds (6.8 kg).

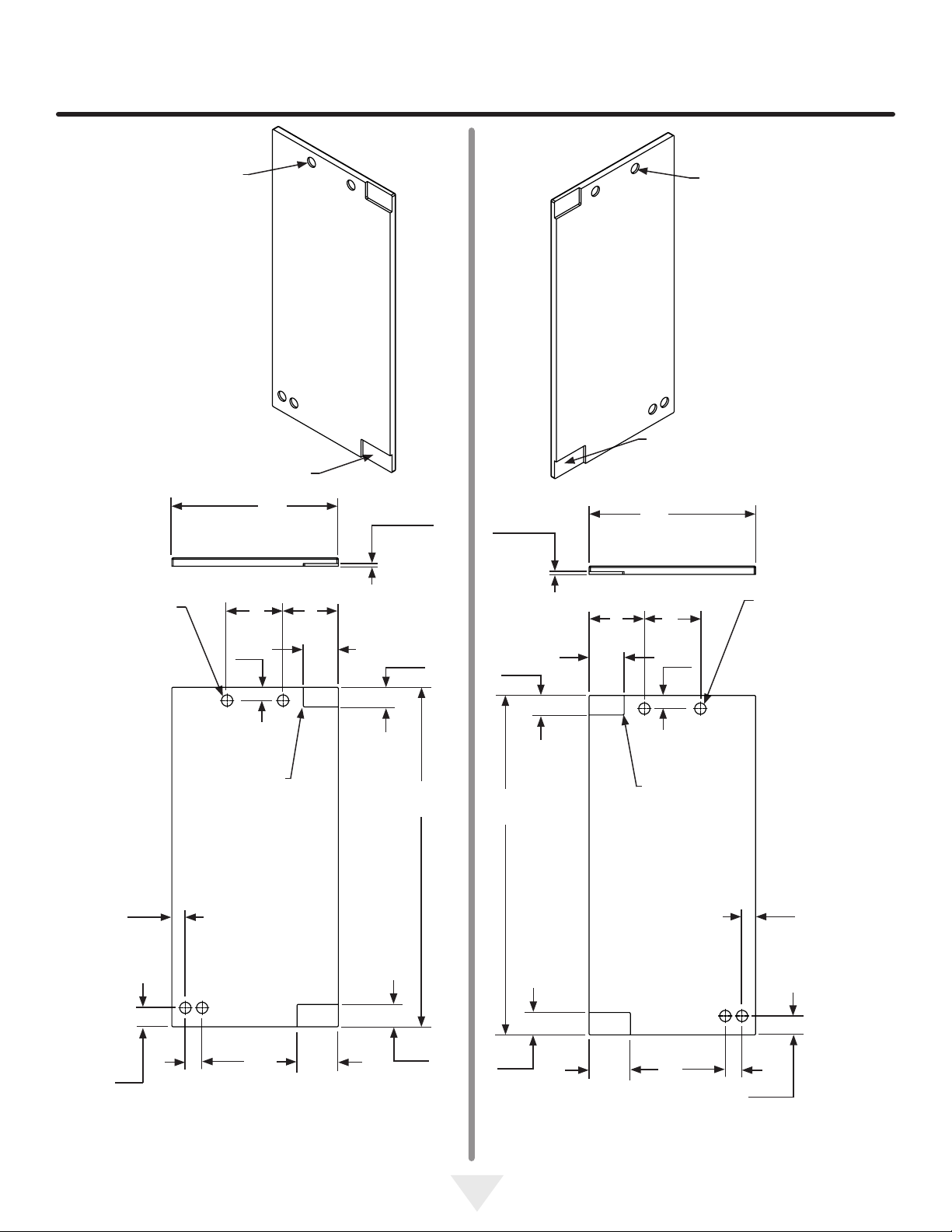

Step 3: Cut and drill the overlay panel

Depending on your model cut the overlay door panel to the

dimensions shown in Figures 31 to 34.

There are 10 holes in the gasket retainer extrusions, (3 on

each side and 2 at the top and bottom which are used to

fasten the panel to the front of the door. The screws are

provided in the literature pack.

19

Clearance for

screw head,

4 places

Figure 31

Left Hand Hinged Door

15" (38.1 cm) wide appliance

OVERLAY DOOR PANEL INSTALLATION

Top of door

Hinge side of door

Hinge side of door

Clearance for

screw head,

4 places

Figure 33

Right Hand Hinged Door

15" (38.1 cm) wide appliance

1" (25.4 mm) diameter

counter bore 1⁄4" (6 mm)

deep 4 places.

Clearance

for hinge

2 places

143⁄4"

(37.5 cm)

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

47⁄8"

(12.4 cm)

31⁄8"

(7.9 cm)

1

⁄4" (6 mm)

Deep

13⁄4"

(4.4 cm)

3011⁄32"

(77.1 cm)

1

⁄4" (6 mm)

Deep

13⁄4"

(4.4 cm)

3011⁄32"

(77.1 cm)

31⁄8"

(7.9 cm)

47⁄8"

(12.4 cm)

Clearance

for hinge

2 places

143⁄4"

(37.5 cm)

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

1" (25.4 mm) diameter

counter bore 1⁄4" (6 mm)

deep 4 places.

15⁄32"

(2.9 cm)

This side

facing interior

11⁄2"

111⁄16"

(4.3 cm)

(3.8 cm)

typical

Figure 32

Left Hand Hinged Door

15" (38.1 cm) Wide Appliance

311⁄16"

(9.4 cm)

2"

(5.1 cm)

20

2"

(5.1 cm)

15⁄32"

(2.9 cm)

This side

facing interior

311⁄16"

(9.4 cm)

11⁄2"

(3.8 cm)

typical

111⁄16"

(4.3 cm)

Figure 34

Right Hand Hinged Door

15" (38.1 cm) wide appliance

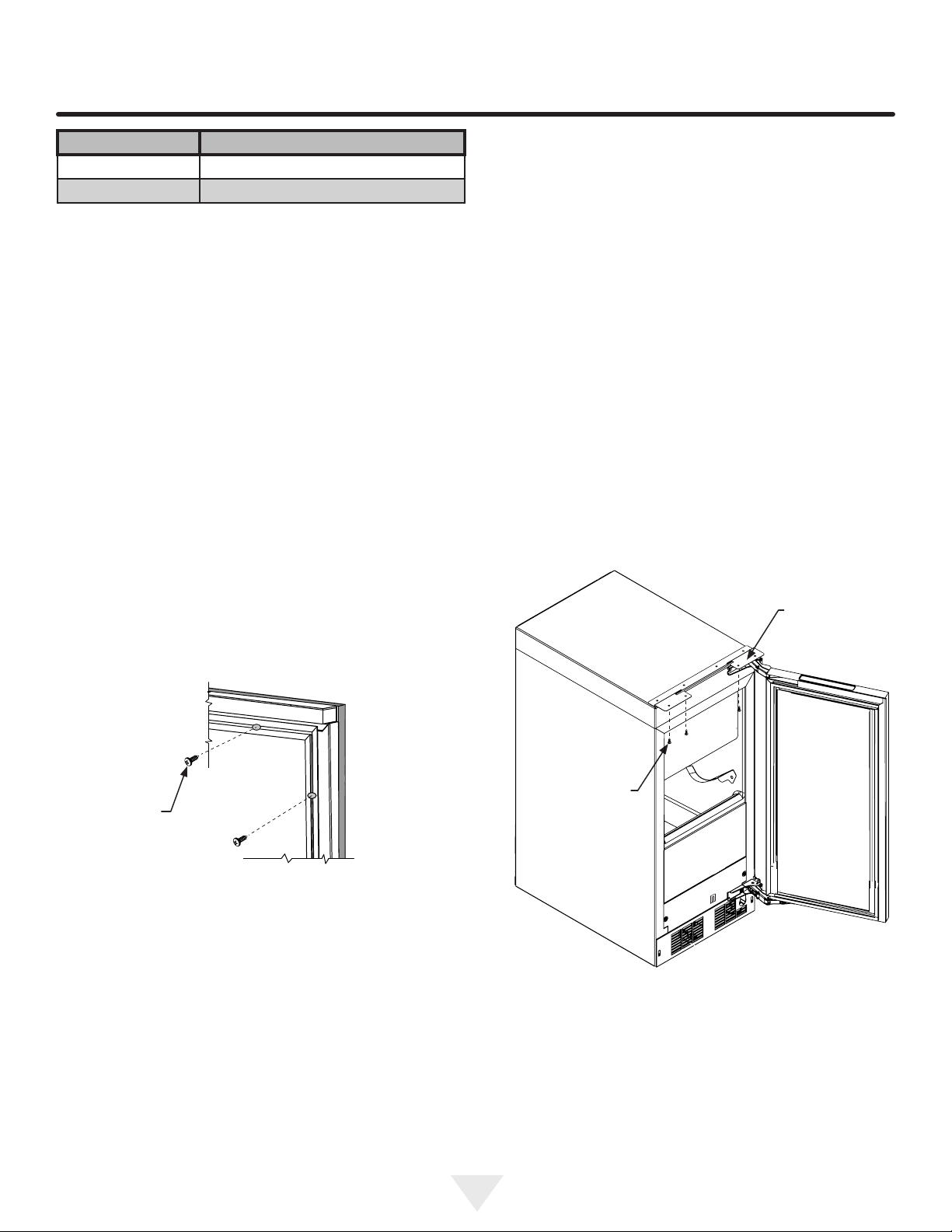

OVERLAY DOOR PANEL INSTALLATION

Material Type #10 Wood Screw

Hardwood

Softwood

1

⁄8" (3.2 mm) Diameter Pilot Hole

7

⁄64 (2.8 mm) Diameter Pilot Hole

Table A

Step 4: Assemble the panel to the door

The preferred method of attaching the panel to the door

is to clamp the panel to the door so it cannot move while

drilling the screw pilot holes. Use bar clamps or "C" clamps

with pads on the clamping surfaces that will not mar the

panel or the door. The custom overlay panel should be

ush with the top of the door and centered along the width

of the door. See Figure 30a. Drill holes through the gasket

extrusion using the 10 holes as pilot holes. Use the drill

size from the chart in Table "A", being careful not to drill

through the front surface of the panel. If the overlay panel is

thinner than 5⁄8" (16 mm) thick shorter screws will have to be

obtained. Fasten the panel to the door with the 10 screws

provided in the literature pack. (See Figure 35). Remove

the clamps and replace the gasket in the gasket extrusion

channels of the door. Some force may be required to seat

the gasket into the channels. Be sure the gasket corners

are seated properly.

Step 5: Install the door

Carefully open the top and bottom hinges on the door being

careful as there are many pinch points. Place the hinges

over the 4 screws in the cabinet, 2 at the top and 2 at the

bottom and slide the door into position. Tighten the 4 hinge

screws with a phillips screwdriver. (See Figures 28 and

28a). Place wire harness from the grille and mount to the

bottom of the door with the screw and "P" clamp removed

in step 1. (See Figure 28b). Reconnect the wire harness,

(See Figure 29).

Step 6: Secure the cabinet

Use the #8 x 3⁄4" black screws from the literature pack to

secure the counter top to the cabinet top through the holes

in the cabinet "Z" bracket.

#10 x 1⁄2"

screw

Cabinet

"Z" bracket

#8 x 3⁄4" black

screws

(3 places)

Figure 35

Figure 36

21

CARE AND CLEANING AND ENERGY SAVING TIPS

Front Grille

Be sure that nothing obstructs the required air ow openings in front of the cabinet. At least once or twice a year,

brush or vacuum lint and dirt from the front grille area (see

page 4).

!

CAUTION

SHOCK HAZARD: Disconnect electrical power from the

appliance before cleaning with soap and water.

Cabinet

The painted cabinet can be washed with either a mild soap

and water and thoroughly rinsed with clear water. NEVER

use abrasive scouring cleaners.

Interior

Wash interior compartment with mild soap and water. Do

NOT use an abrasive cleaner, solvent, polish cleaner, undiluted detergent or chlorine based cleaners.

Care of Appliance

1. Avoid leaning on the door, you may bend the door

hinges or tip the appliance.

2. Exercise caution when sweeping, vacuuming or mopping near the front of the appliance. Damage to the

grille can occur.

3. Periodically clean the interior of the appliance as

needed.

4. Periodically check and/or clean the front grille as

needed.

Energy Saving Tips

The following suggestions will minimize the

cost of operating your ice machine appliance.

1. Do not install your appliance next to a hot appliance,

(stove, dishwasher, etc.). heating air duct, or other heat

sources.

2. Install product out of direct sunlight.

3. Assure the front grille vents at front of the ice machine

beneath the door are not obstructed and kept clean to

allow ventilation for the refrigeration system to expel

heat.

4. Plug your appliance into a dedicated power circuit. (Not

shared with other appliances).

5. Minimize door openings and duration of door openings.

6. Set the control to the “off” position if accessing the

interior to spot clean or remove large quantities of ice

requires the door to be open for an extended period of

time.

7. Use ECO mode if maximum ice production quantities

are not required.

8. Use the delay start function if the ice machine will not

be used for long periods of time.

In the Event of a Power Failure

If a power failure occurs, try to correct it as soon as possible. Minimize the number of door openings while the

power is off so as not to adversely affect the appliance's

temperature.

Light assembly replacement

All models use LED lamps to illuminate the interior of the

appliance. This component is very reliable, but should one

fail, contact a qualied service technician for replacement

of the LED.

22

OBTAINING SERVICE

If Service is Required:

• If the product is within the rst year warranty period

please contact your dealer or call AGA MARVEL Customer Service at 800.223.3900 for directions on how to

obtain warranty coverage in your area.

• If the product is outside the rst year warranty period,

AGA MARVEL Customer Service can provide recommendations of service centers in your area. A listing

of authorized service centers is also available at www.

agamarvel.com under the service and support section.

• In all correspondence regarding service, be sure to

give the service number, serial number, and proof of

purchase.

• Try to have information or description of nature of the

problem, how long the appliance has been running, the

room temperature, and any additional information that

may be helpful in quickly solving the problem.

• Table "B" is provided for recording pertinent information

regarding your product for future reference.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State

Dealer’s Zip Code

Appliance Serial Number

Appliance Service Number

Date Warranty Card Sent (Must

be within 10 days of purchase).

Table B

23

TROUBLESHOOTING THE ICE MACHINE

Before You Call for Service

If the appliance appears to be malfunctioning, read through

this manual rst. If the problem persists, check the troubleshooting guide below. Locate the problem in the guide and

refer to the cause and its remedy before calling for service.

The problem may be something very simple that can be

solved without a service call. However, it may be required

to contact your dealer or a qualied service technician.

Troubleshooting guide:

!

WARNING

Electrocution Hazard

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the unit's wiring.

• Replace all parts and panels before operating.

Ice Machine Operation

Ice machine does not operate

Is the ice machine’s power cord plugged in? Plug the

power cord into a grounded 3 prong outlet.

Is the electronic control showing the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is a fuse blown or a circuit breaker been tripped? Replace a blown fuse or reset a tripped circuit breaker.

Is the temperature of the room cooler than it normally

is? The minimum room temperature is 55°F (13°C). The

bin thermistor may be sensing the room temperature and

shut off before the bin is full of ice. If the room temperature

remains low the ice machine may not restart.

Is there a drain pump in the ice machine? The drain

pump is designed to temporarily shut the unit off when

large quantities of water create a high-limit condition. Wait

a few minutes as the drain pump will continue to operate

to dispose of the excess water. If there is still water in the

ice bin check the drain pump vent line and drain line for

obstructions or kinking.

Ice Production

Little or no ice production from the ice machine

Is the electronic control set to the "ICE" position?

Check the control to be sure it is in the "ICE" position.

Is water getting to the ice machine? Make sure nothing

is restricting the water supply such as a closed water valve

or a blown fuse or tripped circuit breaker, or a kinked supply line, or low water pressure.

Has the ice machine just been started? A typical ice

production cycle can take up to 11⁄2 hours. Initial start up

cycles can take longer. Check the ice machine after 24

hours for ice accumulation in the bin.

Is the reservoir drain plug in place? Check that the

reservoir drain plug is properly seated.

Is the water distributor tube restricted? Run a cleaning

cycle to clean the ice machine. Also check any lters to

make sure they are not restricted.

Is the condenser fan air ow restricted? Make sure the

grille in the front of the ice machine is open for proper air

circulation.

The ice machine is noisy

Many sounds of an ice machine are different than your

household refrigerator. This subject is discussed on page

11, but check the following:

Do you hear water being circulated in the ice machine? This is a normal sound as water is added once

every ice making cycle.

Is there a “whoosing” sound? Make sure water is getting to the ice machine. Also check to make sure the drain

plug is fully seated in the water reservoir.

Is there an ice slab caught between the evaporator

plate and the grid cutter? First check to see if the ice

machine is level. If the ice machine is level run a cleaning

cycle.

Is the room and/or water temperature to warm? Move

the ice machine to an area where the ambient temperature is below 90°F (32°C). The ice machine should not be

placed next to a heat source such as an oven. Check the

cold water connection.

Is there scale build up in the ice machine? If there is

scale build up on the evaporator, the ice machine needs to

be cleaned. See “Cleaning the Ice machine”.

24

TROUBLESHOOTING THE ICE MACHINE

Ice Quality

Odor, grey color, or off taste in the ice

Is there mineral scale build up on the evaporator

plate? The ice machine needs cleaning. See “Cleaning

the Ice Machine”.

Is there a high mineral content in the water? The water

may need to be ltered.

Are food items being stored in the ice bin? Remove

food from the ice bin.

Unpleasant Odors may require the use of a charcoal lter

on the water supply line.

Clumps of ice

Are there clumps of ice in the bin? If the ice isn’t used

on a regular basis it will melt and form into clumps. Break

up the ice clumps with the ice scoop.

Ice cubes are too big, too small

Is there low ice consumption? Ice is slowly melting in

the ice bin which will affect the size of the cubes. This is

normal. When the ice bin needs to be replenished, cubes

will return to the regular size.

Is the ice slab releasing? Clean the evaporator. See

“Cleaning the Ice Machine”.

Is the distributor tube restricted? Check the water line

to the ice machine to make sure there are no restrictions

or kinks in the line. Check all lters to make sure they are

not restricted. Check that the water ows evenly out of the

distributor tube, if not, clean the ice machine. See “Cleaning the Ice Machine”.

Troubleshooting the Drain Pump

NOTE

If the drain pump reservoir (not the ice machine bin)

reaches overll condition, the power to the ice machine will

be shut off.

If the ice machine is not working, check the following:

• Make sure there is power at the receptacle.

• Make sure the ice machine is turned on.

• Make sure the ice bin is not full.

Then check the drain pump:

The pump does not run:

• Make sure the pump is plugged in and there is power

to the receptacle.

• Check the inlet to the drain pump for debris and clean

as needed. Remove clamps and inlet tube from drain

pump to check for and remove debris.

• Make certain the vent line is free of kinks/sharp bends

or restrictions.

• Make certain there is enough water to activate the

drain pump. It will take at least one (1) quart (.95 liters)

of water to activate the drain pump.

The pump runs, but no water is pumped out:

• Check that the vent is clear and free of restrictions.

• Check the discharge line to make certain there are no

restrictions.

• Make sure that the discharge tubing has not exceeded

the maximum lift of eight (8) feet (2.44 meters) and the

horizontal run is not greater than twenty (20) feet (6.1

meters).

Plumbing Problems

Is the drain hose aligned over the drain? Move the ice

machine to align the drain.

Is the ice machine draining properly? Check that there

are no kinks or restrictions in the drain lines; this can

cause water to back up in the ice bin. Check that foreign

material is not blocking the ice bin drain located at the

right rear corner of the ice bin. Check the drain pump

discharge and vent line or any restrictions or kinks. Check

that the drain pump is level.

NOTE

If there are plumbing issues outside of the ice machine,

they cannot be repaired by the service technician. A quali-

ed plumber will have to be called.

The pump runs and then quickly turns off repeatedly:

• Check to make certain the drain pump is level.

• Check that the vent is clear and free of restrictions.

The ice machine is running but not producing ice:

• Check to make sure water is not backing up in the ice

bin.

25

PREPARING THE ICE MACHINE FOR STORAGE

If the ice machine is moved, not used for an extended

period of time, or will be in an area that will be near freezing temperatures, it is necessary to remove any remaining

water in the ice-making system.

!

CAUTION

This ice machine must have all water drained and removed

to prevent ice machine damage as well as possible water

damage to the surrounding area in freezing conditions.

These damages are not covered under warranty.

!

CAUTION

Do not use any type of anti-freeze or other solution as a

substitution for properly draining the ice machine.

Clean the Ice Machine

Cleaning the ice machine will help prevent mold and mildew growth as well as sanitize the ice machine for storage

or when it is put back into service. See page 16 for instructions for cleaning the ice machine.

!

WARNING

Electrocution Hazard

Risk of electrical shock or personal injury could occur

due to moving components, if machine compartment

access cover is removed before unplugging the ice

machine.

Draining and Removing Water from the IceMaking System with a Gravity Drain.

1. Turn off the water supply to the ice machine.

2. Disconnect the water supply tting at the inlet of the

water valve. (See Figure 37a).

3. Change the electronic control to the "CLEAN" position

for approximately one (1) minute. This will energize and

open the water valve and remove most of the water

from the water valve and the water valve’s outlet water

line to the reservoir.

4. Change the electronic control to the "OFF" position.

This will energize and open the drain valve to drain the

reservoir and the ice machine drain system.

5. Unplug the ice machine from the electrical outlet.

6. Remove the access cover from the rear of the ice machine. (See Figure 38).

Figure 37

Back view of

ice machine

Water

supply

line

Water supply

tting

Water valve

inlet

Figure 37a

Access

cover

Screw

Figure 38

26

PREPARING THE ICE MACHINE FOR STORAGE

7. Disconnect the water valve’s outlet water line to the

reservoir and drain the remaining water left in the water

line trap area. (See Figure 39 and 39a).

8. Reconnect the water valve outlet water line.

(See Figure 39 and 39a).

9. Reinstall the ice machine’s access cover.

10. Clean and dry the ice machine’s storage bin.

11. Prop the door open for air circulation to prevent mold

and mildew.

12. Leave the water supply line disconnected or reconnect

the supply line and leave it shut off. Do NOT turn the

water on and allow water to enter back into the water

valve.

Draining Water for Factory Installed Drain

Pump Applications

Follow steps 1 through 12 for the gravity drain then do the

following:

13. Install the winterization plug in the water drain hole

inside the ice bin. (See Figure 40).

Figure 39

To disconnect the water outlet

line: Push up on the white collar

and pull the plastic water line

from the bottom of the water

valve.

To reconnect the water outlet

line: Simply insert the plastic

tubing into the white collar and

push until it stops (about 1⁄2", 12

mm, of water line will enter the

valve).

Figure 39a

White

collar

Plastic outlet

water line

Winterization

plug

Figure 40

27

PREPARING THE ICE MACHINE FOR STORAGE

14. Remove the top clamp from the vent tube, for easier

access for the air hose.

15. Apply air pressure (approximately 10 psi) to the end of

the vent tube which will purge the remainder of the

water from the drain pump and the drain line. (See

Figure 41).

16. Reinstall the vent tube and clamp to the back of the ice

machine and remove the winterization plug from the ice

bin and save it for future use.

Vent

tube

To Restart the Ice Machine

1. Reconnect or turn on the water supply line.

2. Reconnect drain tubing if removed.

3. Plug in the power cord to a wall outlet and turn the ice

machine on, (refer to page 14 for turning the ice machine on and off).

4. Check the water inlet, drain lines, and ttings for any

water leaks.

5. Check drain pump (if equipped) operation by pouring

approximately two (2) quarts of water into the ice storage bin. The drain pump should activate and discharge

water. Check for water leaks at all hose connections.

Figure 41

Remove

clamp

screw

Drain

line

28

DRAIN PUMP REMOVAL INSTRUCTIONS

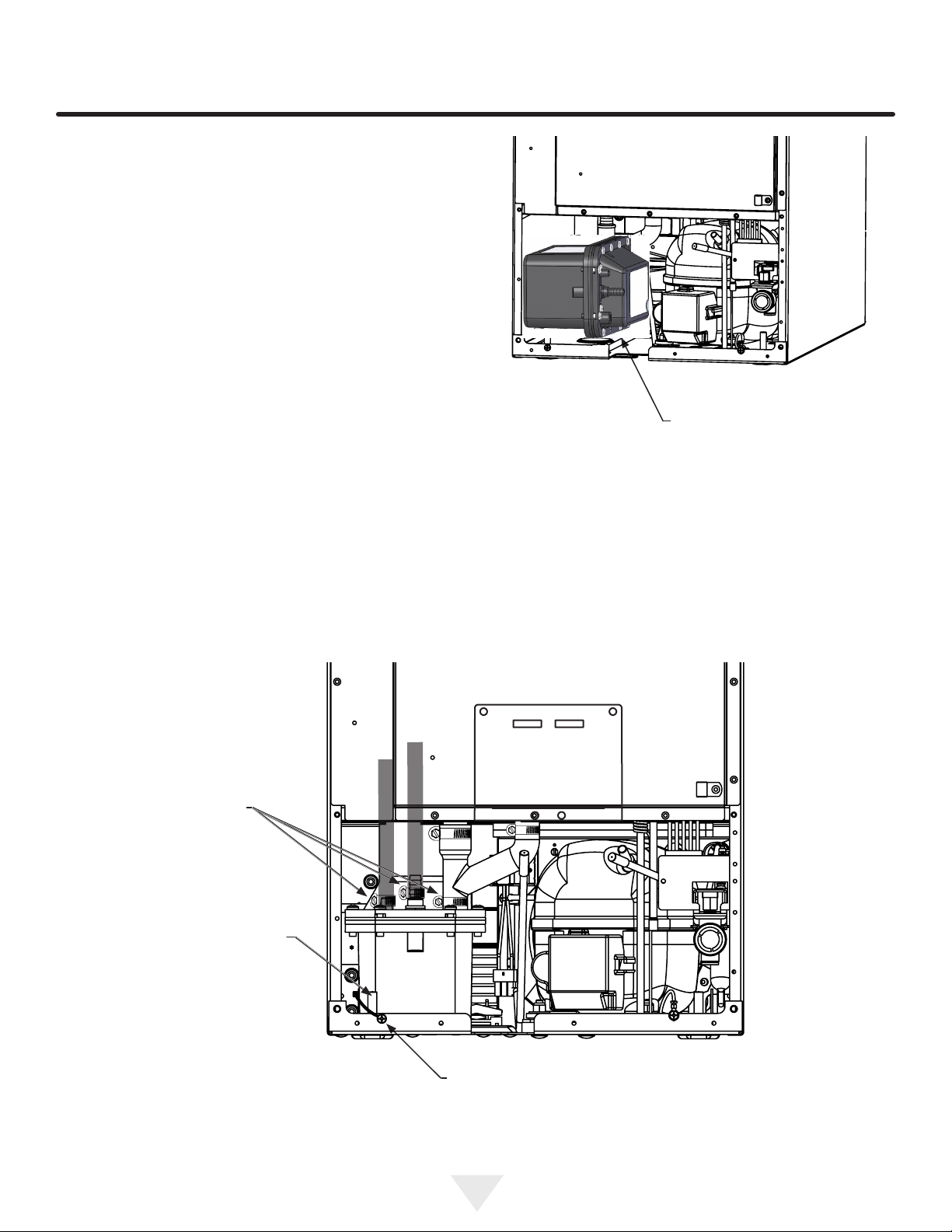

Drain Pump Removal Instructions:

1. Unplug the ice machine from the electrical supply and

remove the rear access cover from the ice machine.

(See page 26 for instructions).

2. Unscrew the leveling leg in the back corner until the

end of the threaded portion is ush with the threaded

nut insert in the base. (see Figure 43).

3. Unscrew the 3 hose clamps and remove the 3 hoses

from the front of the drain pump. (See Figure 43).

4. Rotate the drain pump and remove from the ice machine, (See Figure 42). It may be necessary to discon-

nect the ground wire connection in the back ange of

the cabinet. (See Figure 43).

5. Disconnect the ice machine power cord from the drain

pump (See Figure 44).

6. Drain the water in the drain pump’s reservoir by turning the pump upside down and allowing water to drain

through the pump’s inlet and vent tube ttings.

7. Installation of drain pump is reverse of this procedure.

Figure 42

Rotate drain pump and

remove from back of

ice machine.

Remove these 3 hose

clamps, then remove

the 3 tubes from the

drain pump

Unscrew the leveling leg so

the end of the threads is ush

with the top of the nut insert.

Figure 43

Drain pump ground

wire connection

29

Loading...

Loading...