Marvel ML15BC, ML24BC, MA24BC, ML24BR, MA24BR INSTALLATION INSTRUCTIONS AND OPERATION MANUAL

...

EN Installation, Operation and Maintenance Instructions

FR Instructions d’installation, d’utilisation et d’entretien

ES Instrucciones de instalación, operación y mantenimiento

Refrigerators

Réfrigérateurs

Refrigeradores

ML15BC

ML24BC

MA24BC

ML24BR

MA24BR

ML15RA

ML24RA

MA24RA

CONTENTS

Contents:

Safety information ...............................................................2

Unpacking your appliance ..................................................3

Warranty registration .....................................................3

Installing your appliance ......................................................4

Cabinet clearances .........................................................4

Leveling the appliance ....................................................4

Electrical connection ......................................................5

Installing the anti-tip device .................................................6

Product Dimensions ...........................................................8

Using your Electronic control ............................................10

Starting your appliance ..................................................10

Sleep mode ...................................................................10

Turning your appliance "ON" or "OFF" ..........................10

Adjusting the temperature .............................................11

Interior display lighting ...................................................11

Temperature mode ........................................................11

Control lock ....................................................................11

Alarms ............................................................................12

Door ajar ...................................................................12

Power failure .............................................................12

Temperature alarm ....................................................12

Vacation mode .............................................................13

Overlay door panel installation .........................................14

Shelving congurations .....................................................21

Care and cleaning .............................................................24

Energy saving tips ............................................................24

Door alignment .................................................................25

Obtaining service .............................................................25

Troubleshooting ................................................................26

Warranty ...........................................................................27

Important Safety Instructions

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situations that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operating this appliance.

Recognize Safety Symbols,

Words, and Labels.

!

WARNING

WARNING-Hazards or unsafe practices with high

probability of personal injury or property / product

damage.

!

CAUTION

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE

NOTE-Important information to help assure a problem

free installation and operation.

is committed to building a quality product

in an environmentally friendly manner. Our processes are

tightly controlled and closely monitored. We have achieved

certications in ISO 9001 for quality assurance, ISO 14001

for environmental management, and OHSAS 18001 for occupational health and safety from Lloyd’s Register Quality

Assurance.

2

UNPACKING YOUR APPLIANCE

!

WARNING

EXCESSIVE WEIGHT HAZARD

Use two or more people to move product.

Failure to do so can result in personal injury.

Remove Interior Packaging

Your appliance has been packed for shipment with all parts

that could be damaged by movement securely fastened.

Remove internal packing materials and any tape holding internal components in place. The owners manual is shipped

inside the product in a plastic bag along with the warranty

registration card, and other accessory items.

Important

Keep your carton and packaging until your appliance has

been thoroughly inspected and found to be in good condition. If there is damage, the packaging will be needed as

proof of damage in transit. Afterwards please dispose of all

items responsibly.

Warranty Registration

It is important you send in your warranty registration card

immediately after taking delivery of your appliance or you

can register online at www.agamarvel.com.

The following information will

be required when registering

your appliance.

Service Number

Serial Number

Date of Purchase

Dealer’s name and address

The service number and serial number can be found on the

serial plate which is located inside the cabinet on the left

side near the top. (See gure 1).

Online registration

available at

www.agamarvel.com

!

CAUTION

Dispose of the plastic bags which can be a suffocation

hazard.

Note to Customer

This merchandise was carefully packed and thoroughly

inspected before leaving our plant. Responsibility for its

safe delivery was assumed by the retailer upon acceptance

of the shipment. Claims for loss or damage sustained in

transit must be made to the retailer.

NOTE

DO NOT RETURN DAMAGED MERCHANDISE TO THE

MANUFACTURER - FILE THE CLAIM WITH THE

RETAILER.

!

CAUTION

If the appliance was shipped, handled, or stored in other

than an upright position for any period of time, allow the appliance to sit upright for a period of at least 24 hours before

plugging in. This will assure oil returns to the compressor.

Plugging the appliance in immediately may cause damage

to internal parts.

XXXXXXXXXXXX

XXXXXXXXXXXX

Figure 1

!

CAUTION

Help Prevent Tragedies

Child entrapment and suffocation are not problems of the

past. Junked or abandoned refrigerators are still dangerous

- even if they sit out for "just a few days".

If you are getting rid of your old refrigerator, please follow

the instructions below to help prevent accidents.

Before you throw away your old refrigerator or freezer:

• Take off the doors or remove the drawers.

• Leave the shelves in place so children may not easily

climb inside.

3

INSTALLING YOUR APPLIANCE

Select Location

The proper location will ensure peak performance of your

appliance. We recommend a location where the unit will

be out of direct sunlight and away from heat sources. To

ensure your product performs to specications, the recommended installation location temperature range is from 55

to 100°F (13 to 38°C).

Cabinet Clearance

Ventilation is required from the bottom front of the appliance. Keep this area open and clear of any obstructions.

Adjacent cabinets and counter top can be installed around

the appliance as long as the front grille remains unobstructed. Overlay door models with articulated hinges are

intended for built-in applications only.

!

WARNING

An optional stacking kit, shown in Table "A", is required

to stack products. Failure to use a stacking kit could

result in personal injury. Contact your dealer or Aga

Marvel customer service at 800-223-3900 to order.

Front Grille,

keep this area

open.

Front Leveling

Legs

Figure 2

Rear

Leveling

Legs

Leveling Legs

Adjustable legs at the front and rear corners of the appli-

ance should be set so the unit is rmly positioned on the

oor and level from side to side and front to back. The

overall height of your Marvel appliance may be adjusted

between the minimum (by turning the leveling leg in) and

the maximum (by turning the leveling leg out) dimensions

as shown in Table "B".

Color Door Swing Kit Part Number

Stainless Steel Left Hand 42249095

Stainless Steel Right Hand 42249096

Black Left Hand 42249097

Black Right Hand 42249098

White Left Hand 42249099

White Right Hand 42249100

Table A

!

CAUTION

Front Grille

Do not obstruct the front grille. The openings within the

front grille allow air to ow through the condenser heat exchanger. Restrictions to this air ow will result in increased

energy usage and loss of cooling capacity. For this reason

it is important this area not be obstructed and the grille

openings kept clean. AGA MARVEL does not recommend

the use of a custom made grille as air ow may be restricted because of inadequate openings. (See Figure 2).

To adjust the leveling legs, place the appliance on a solid

surface and protect the oor beneath the legs to avoid

scratching the oor. With the assistance of another person,

lean the appliance back to access the front leveling legs.

Raise or lower the legs to the required dimension by turning

the legs. Repeat this process for the rear by tilting the appliance forward using caution. On a level surface check the

appliance for levelness and adjust accordingly.

The front grille screws may be loosened and the grille adjusted to the desired height. When adjustment is complete

tighten the two front grille screws. (See Figure 3).

Model Door Style

ML(15)(24)* (S) or (G)

ML(15)(24)* (P or (F)

MA24* (S) or (G)

MA24* (P or (F)

Table B

Minimum

Height

33 3⁄4"

(85.7 cm)

34"

(86.4 cm)

1/

31

8"

(79.1 cm)

313⁄8"

(79.7 cm)

Maximum

Height

34 3⁄4"

(88.3 cm)

35"

(88.9 cm)

32 1⁄8"

(81.6 cm)

323⁄8"

(82.2 cm)

4

INSTALLING YOUR APPLIANCE

!

Electrical Shock Hazard

• Do not use an extension cord with this appliance.

They can be hazardous and can degrade product

performance.

• This appliance should not, under any circumstances, be installed to an un-grounded electrical supply.

• Do not remove the grounding prong from the power

cord.

• Do not use an adapter.

• Do not splash or spray water from a hose on the

appliance. Doing so may cause an electrical shock,

which may result in severe injury or death.

Electrical Connection

A grounded 115 volt, 15 amp dedicated circuit is required.

WARNING

Figure 3

Front grille

Front grille screw

This product is factory equipped with a power supply

cord that has a three-pronged, grounded plug. It must be

plugged into a mating grounding type receptacle in accordance with the National Electrical Code and applicable lo-

cal codes and ordinances (see Figure 4). If the circuit does

not have a grounding type receptacle, it is the responsibility

and obligation of the customer to provide the proper power

supply. The third ground prong should not, under any circumstances, be cut or removed.

Figure 4

NOTE

Ground Fault Circuit Interrupters (GFCI) are prone to nuisance tripping which will cause the appliance to shut down.

GFCI’s are generally not used on circuits with power equipment that must run unattended for long periods of time, unless required to meet local building codes and ordinances.

5

INSTALLING THE ANTI TIP DEVICE

Anti-Tip

Bracket

Leveling Leg

Figure 5

Anti-Tip Device

!

CAUTION

If your refrigerator is not located under a counter top (free

standing), you must use an anti-tip device installed as

per these instructions. If the refrigerator is removed from

its location for any reason, make sure that the device is

properly engaged when you push the refrigerator back into

the original location. If the device is not properly engaged,

there is a risk of the refrigerator tipping over, causing property or personal injury if you or a child stand, sit, or lean on

an open shelf.

211⁄2"

(54.6 cm)

Bottom View of

Refrigerator

Front of cabinet

Figure 6

Step by step instructions for locating the

position of the bracket:

1) Decide where you want to place the refrigerator. Slide it

into place, being careful not to damage the oor, leaving 1"

(2.5 cm) of clearance from the rear wall to allow room for

the anti-tip bracket.

2) Raise the rear leveling legs approximately 1⁄4" (6 mm) to

allow engagement with the anti-tip bracket. Level the unit

by adjusting all the leveling legs as required. Turning the

leveling leg counterclockwise will raise the unit and clockwise will lower the unit.

NOTE

If installing on a concrete oor, concrete fasteners are

required, (not included with the anti-tip kit).

!

CAUTION

Any nished ooring should be protected with appropriate

material to avoid damage when moving the unit.

Floor Mount Installation

The anti-tip bracket is to be located on the oor in the left or

right rear corner of the refrigerator as shown in Figure 6.

3) Make sure the refrigerator is in the desired location, then

mark on the oor the rear and side corner of the cabinet

where the anti-tip bracket will be installed. If the installation

does not allow marking the rear corner of the cabinet, then

make temporary lines on the oor marking the front corner

of the cabinet, excluding the door. Slide the refrigerator out

of the way. From the temporary line extend the sidewall line

back 211⁄2" (54.6 cm) as shown in Figure 7.

4) Align the anti-tip bracket to the marks on the oor so

the side of the bracket lines up with the side of the cabinet

mark, and the "V" notches on the anti-tip bracket line up

with the end of the 211⁄2" (54.6 cm) line (Rear of cabinet

line).

5) Fasten the anti-tip bracket to the oor using the supplied

screw. (See Figure 7).

6) Slide the cabinet back into position, making sure the rear

cabinet leveling leg slides under the anti-tip bracket engaging the slot.

6

INSTALLING THE ANTI TIP DEVICE

!

WARNING

TIP OVER HAZARD: One of the rear cabinet

leveling legs must be engaged under an anti-tip

bracket.

NOTE

When the oor mounted anti-tip bracket is used the minimum adjusted height of the cabinet is increased by

3

⁄8" (9 mm).

Front of cabinet line

Side of cabinet line

211⁄2"

(54.6 cm)

Figure 7

Rear Leveling leg

Rear of cabinet line

Screw

"V" notches

in bracket

Figure 7a

"V" notches

in bracket

7

PRODUCT DIMENSIONS

ROUGH-IN OPENING DIMENSIONS CABINET DIMENSIONS

MODEL "A" "B" "C" "D" "E" "F" "G" "H" "J"

ML15**(G) or (S)

ML15**(P) or (F)

ML24**(G) or (S)

ML24**(P) or (F)

MA24**(G) or (S)

MA24**(P) or (F)

15"

(38.1 cm)

15"

(38.1 cm)

24"

(61 cm)

24"

(61 cm)

24"

(61 cm)

24"

(61 cm)

DOOR STYLE

(G) Glass Frame Door

(S) Solid Door

(P) Solid Overlay Door (no handle)

(F) Frame Glass Overlay Door (no handle)

**34" to 35"

(86.4 to 88.9 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

**34" to 35"

(86.4 to 88.9 cm)

**341⁄4" to 351⁄4"

(87 to 89.5 cm)

** 313⁄8" to 323⁄8"

(79.7 to 82.2 cm)

** 315⁄8" to 325⁄8"

(80.3 to 82.9)

*

*

*

*

*

*

147⁄8"

(37.8 cm)

147⁄8"

(37.8 cm)

237⁄8"

(60.7 cm)

237⁄8"

(60.7 cm)

237⁄8"

(60.7 cm)

237⁄8"

(60.7 cm)

333⁄4" to 343⁄4"

(85.7 to 88.3 cm)

34" to 35"

(86.4 to 88.9 cm)

333⁄4" to 343⁄4"

(85.7 to 88.3 cm)

34" to 35"

(86.4 to 88.9 cm)

311⁄8" to 321⁄8"

(79.1 to 81.6 cm)

313⁄8" to 323⁄8"

(79.7 to 82.2 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

2323⁄32"

(60.2 cm)

227⁄8"

(58.1 cm)

2521⁄32"

(65.2 cm)

-

2521⁄32"

(65.2 cm)

-

2521⁄32"

(65.2 cm)

-

3713⁄32"

(95 cm)

371⁄2"

(95.2 cm)

4613⁄32"

(117.9 cm)

461⁄2"

(118.1 cm)

4613⁄32"

(117.9 cm)

461⁄2"

(118.1 cm)

1611⁄16"

(42.4 cm)

141⁄8"

35.9 cm)

2511⁄16"

(65.2 cm)

231⁄8"

(58.7 cm)

2511⁄16"

(65.2 cm)

231⁄8"

(58.7 cm)

"C"

"A"

"B"

Figure 8

"E"

"D"

Figure 8a

If necessary to gain clearance inside

the rough-in opening a hole can be cut

through the adjacent cabinet and the

power cord routed through this hole to a

power outlet. Another way to increase the

available opening depth is to recess the

power outlet into the rear wall 1" (2.5 cm)

to gain the thickness of the power cord

plug.

8

PRODUCT DATA

MODEL

ML15**(G) or (S) 115V/60Hz/15A

ML15**(P) or (F) 115V/60Hz/15A

ML24**(G) or (S) 115V/60Hz/15A

ML24**(P) or (F) 115V/60Hz/15A

MA24**(G) or (S) 115V/60Hz/15A

MA24**(P) or (F) 115V/60Hz/15A

ELECTRICAL

REQUIREMENTS #

PRODUCT DIMENSIONS

PRODUCT

WEIGHT

105 lbs

(47.7 kg)

105 lbs

(47.7 kg)

140 lbs

(63.6 kg)

140 lbs

(63.6 kg)

140 lbs

(63.6 kg)

140 lbs

((63.6 kg)

"D"

"J"

"H"

"G"

* Depth dimension of rough-in opening may vary depending on each individual installation. To recess entire door "F"

dimension plus 1" (2.5 cm) for thickness of power cord plug

is required.

** Minimum rough-in opening required is to be larger than

the adjusted height of the cabinet.

# A grounded 15 amp dedicated circuit is required. Follow

all local building codes when installing electrical and appliance.

"E"

Figure 9

211⁄2"

(54.6 cm)

"F"

APPLIES TO THE FOLLOWING MARVEL MODELS

ML15BC MA24BC

ML15RA MA24BR

MA24RA

ML24BC

ML24BR

ML24RA

!

WARNING

Floor mount Anti-tip Bracket must be installed for freestanding applications. Not required for built in applications.

9

USING YOUR ELECTRONIC CONTROL

Temp

On/Off

Minus

keypad Display Area

keypad

Temp

Plus

keypad

Figure 10

Electronic single zone control

Power Failure

ALARM RESET

Starting your appliance:

Plug the appliance power cord into a 115 volt wall outlet.

Your appliance is shipped from the factory in the "On" position and will begin start-up of cooling as soon as power is

supplied. If the appliance does not start, conrm that the

wall outlet has power, and that the control is in the "On"

position, (See "Turning your appliance On and Off" below).

Lights keypad

(glass door

only)

Lock

keypad

System Status

indicators

To wake the display press any keypad. A conrm tone will

sound, and the current storage compartment temperature

will be displayed.

The control display is covered with a clear plastic lm. This

lm may be removed by carefully lifting the lm at a corner.

On initial power up, the control display will indicate a

"Power Failure" alarm. This is a normal condition as the appliance was powered-up at the factory for quality inspection

and then removed from power. A momentary press of the

"On/Off" keypad will reset this alarm condition. (See Alarms

section on page 12).

Sleep mode:

If no keypads are pressed for 60 seconds, the display will

enter sleep mode to conserve power. The control panel will

go dark with the exception of the system status "OK" indicator which will remain enabled. Alarm conditions will wake

the display, (see alarms on page 12).

The sleep mode can be disabled if you prefer to have the

display on continuously. Press and hold the "Lock" keypad until the display goes past "Loc" and reads "nSL". To

enable the sleep mode, repeat the instruction, again going

past "Loc" until the display reads "SLP".

Turning your appliance ON and OFF:

If the appliance is "On", (and out of sleep mode) the temperature will be shown in the display area of the control.

To turn the appliance "Off", press and hold the "On/Off"

keypad for 4-seconds. "OFF" will now be displayed on the

control.

To make the following changes to the control settings

(turning the appliance ON/OFF, adjusting the temperature, changing the interior lights, and activating vacation mode), the control must be awake.

To turn the appliance "On", press and hold the "On/Off"

keypad for 4-seconds.

10

USING YOUR ELECTRONIC CONTROL

Adjusting the temperature:

To set or check the set-point temperature (with the control

out of sleep mode), press the "-" or "+" keypads. "SET" will

be indicated on the user interface panel and the current

set-point temperature will display and ash. Subsequent

presses of the "-" or "+" keypads will adjust the temperature

colder or warmer respectively. When you have reached

your desired set-point temperature, press the "On/Off" keypad to accept, or do nothing and the "Set" mode will timeout in 10-seconds accepting the displayed temperature as

the new set-point.

The available set-point temperature range for your ap-

pliance is 34°F (1.2°C) to 42°F (5.7°C). If you attempt to

adjust the temperature outside of this range you will receive

an audible notication.

Interior display lighting: (Glass door models only)

Your appliance is equipped with a dual light level display

lighting feature. With the control out of sleep mode press

the "Light" keypad once to activate the interior lighting

display feature at full illumination. A conrmation tone will

sound, and the light bulb "Icon" will illuminate. Pressing

the "Light" keypad a 2nd time will dim the lighting to 50%.

A 3rd press will deactivate the display lighting feature. The

display lighting will automatically deactivate after 4-hours.

When initially loading your product with warm contents, it

may take up to 48-hours for the storage compartment temperature to stabilize.

When making temperature set-point changes, it may take

up to 24-hours for the stored contents to stabilize at your

new set-point temperature.

Factors that affect the storage compartment stabilized

temperature:

• Changes to temperature setting.

• Room temperature changes.

• Temperature of stored contents.

- Loading warm contents.

- Cold content load will delay the change to a warmer

set-point temperature.

- Warm content load will delay the change to a colder

set-point temperature.

• Usage, (number and duration of the door openings).

• Use of the storage compartment display lighting, (glass

door product only).

• Installation of the appliance in direct sunlight or next to

a heat source.

Temperature mode:

The temperature mode is preset from the factory in Fahren-

heit (°F) but you have the option to change it to Centigrade

(°C). To change the mode, press and hold the "-" keypad,

while pressing the "+" keypad, then release the "-" keypad.

The temperature will now be displayed in Centigrade (°C).

Repeat the procedure to change the temperature mode

back to Fahrenheit (°F).

Control lock:

The control panel can be locked to avoid unintentional

changes. To lock the control, press and hold the "Lock" key-

pad until the display reads "Loc" then release your nger

from the keypad. The lock icon will ash 3-times and then

continuously illuminate. When the control panel is locked,

only the Lock keypad, System Status OK indicator, and

the Alarm indicator are active. To un-lock the control panel,

repeat this instruction until the display reads "nLc".

11

USING YOUR ELECTRONIC CONTROL

Alarms:

The control will alert you to conditions that could adversely

affect the performance of the appliance.

Temp

ALARM RESET

Door Ajar

ALARM RESET

• Door ajar - If the door is open, or not closed prop-

erly, for more than 5-minutes the System Status OK

indicator will turn-off, the "Door Ajar" indicator will ash,

and a tone will sound every 60 seconds. Additionally,

an "ALARM RESET" indicator will be displayed below

the "On/Off" keypad. This alarm condition can be reset

by closing the door or momentarily pressing the "On/

Off" keypad, (i.e.-if you are cleaning the storage com-

partment, etc.). The alarm will recur in 5-minutes if the

alarm condition persists.

Power Failure

ALARM RESET

• Power failure - If power to the appliance is inter-

rupted the System Status indicator will turn-off and

the "Power Failure" indicator will ash. Additionally, an

"ALARM RESET" indicator will be displayed below the

"On/Off" keypad. No audible tone will sound. This alarm

condition can be reset by momentarily pressing the

"On/Off" keypad. If this alarm occurs, it is recommended that you check the condition of any perishables,

even if the appliance is operating normally and the temperature has recovered, as prolonged power outages

could result in excessive temperature excursions which

may spoil perishables.

• Temperature alarm - If the storage compartment

temperature exceeds 10°F from set-point for more than

a 1-hour duration, the System Status indicator will turn

off, the "Temp" indicator will ash, and an audible tone

will sound every 60-seconds. Additionally, an "ALARM

RESET" indicator will be displayed below the "On/Off"

keypad. This alarm condition can be reset by momentarily pressing the "On/Off" keypad. If this alarm occurs

it is recommended that you check the condition of your

stored contents, even though the appliance is operating

normally and the temperature has recovered, as prolonged temperature excursions could spoil perishables.

Door Ajar

NOTE

Multiple alarms are possible, i.e.- "Door Ajar" for a prolonged period may trigger a "Temp" alarm, in which case

both "Door Ajar" and "Temp" indicators will activate.

Temp

12

USING YOUR ELECTRONIC CONTROL

Vacation mode:

This operating mode can be used to save energy during

high cost energy periods, or when you won't be using your

appliance for an extended period of time by disabling the

lights, alarm tones, and keypad entry tones. Vacation mode

also serves as a Sabbath mode, disabling functions and

its controls in accordance with the weekly Sabbath and

religious holidays observed within the Orthodox Jewish

community. When used as Sabbath mode, you may open

or close the door at any time to access contents without

concern of directly turning on or off any lights, digital readouts, solenoids, fans, valves, compressor, icons, tones, or

alarms.

When activated, the display, alarm indicators and tones,

keypad touch tones, interior lights, and all options are disabled. All keypad functions are disabled, with the exception

of the "On/Off" keypad which is required to exit Vacationmode. Storage compartment temperatures are monitored

and controlled at the settings prior to entering Vacation

mode.

To enter Vacation Mode (with the control out of sleep

mode), press and hold the "On/Off" keypad until the display

goes past "OFF" and reads "VAC". The display will ash

"VAC" 3-times to acknowledge your request, then will

display "VAC" continuously until Vacation mode is exited.

A power outage will not exit Vacation mode, exiting can

only be accomplished manually. To exit Vacation mode and

return to normal operation, press and hold the "On/Off"

keypad until the control displays the temperature.

13

OVERLAY DOOR PANEL INSTALLATION

If you purchased an overlay panel model, your unit is

equipped with articulated hinges to allow fully integrated

built-in installations. Custom panel thicknesses of 5⁄8" (15

mm) and 3⁄4" (18 mm) are accommodated.

!

CAUTION

It is important to use the factory provided grille that came

with the product to assure proper air ow is maintained

through the condenser. The use of a custom grille is not

recommended and will void the warranty.

!

WARNING

!

WARNING

Use extreme caution with the articulated hinges. The

hinge is self closing and many pinch points exist prior

to built-in installation. Do not remove the cabinet "Z"

bracket from the top of the cabinet.

Overlay panel models are designed for use with builtin installations only. Use in freestanding installations

could result in personal injury.

Step 1: Removing the Door

With a phillips screwdriver remove the screw and "P" clamp

from the bottom of the door near the hinge. See Figure 11b.

Disconnect the door wire harness by pressing and holding

down the locking tab on the wire connector and pulling the

connector apart. See Figure 12.

Open the door and loosen the screws holding the hinges to

the cabinet (2 at the top and 2 at the bottom hinge). Do not

remove the screws but loosen them enough so the hinges

can be slipped off of the screws when sliding the door to

the side.

!

WARNING

The articulated hinges have many pinch points. Carefully close / collapse the hinges as soon as the door is

removed from the cabinet.

Loosen (do not remove ) these

2 phillips head screws on the

top and bottom hinges

Figure 11a

Cabinet

"Z" Bracket

Figure 11

"P" clamp

and screw

With a helper, and being careful not to scratch the cabinet

or the door, slide the door to the side about 1⁄2 inch and

remove the hinges and door from the unit.

14

Figure 11b

Bottom of

door

Wire connector

see Figure 12

OVERLAY DOOR PANEL INSTALLATION

Step 2: Remove the door gasket

With the door laying on a at surface and starting at a

corner of the door remove the magnetic door gasket from

the interior side of the door, see Figure 13. Set the gasket

aside on a at surface.

There are 10 holes in the gasket retainer extrusions, (3 on

each side and 2 at the top and bottom which are used to

fasten the panel to the front of the door. The screws are

provided in the literature pack along with the door lock,

which is provided on certain models.

Press and hold down this

tab on the wire connector and pull the connector

apart.

Overlay panel

ush with top

of door.

Overlay panel

to overhang 3⁄16"

(5 mm) on each

side of door

Holes in

gasket

retainer.

Figure 13a

Figure 12

Magnetic Gasket

remove starting at a

corner, grasp and pull

away from the door.

Figure 13

Step 3: Cut and drill the overlay panel

Depending on your model cut the overlay door panel to the

dimensions shown in Figures 14 to 21. Also see Table "D"

for the height dimension and door styles. The window cut

out is for glass door models only. If your appliance has a

lock also drill the lock hole in the panel, see Figure 23.

15

Clearance for

screw head,

6 places

Figure 14

Left Hand Hinged Door

15" (38.1 cm) wide appliance

OVERLAY DOOR PANEL INSTALLATION

Top of door

Hinge side of door

Hinge side of door

Clearance for

screw head,

6 places

Figure 16

Right Hand Hinged Door

15" (38.1 cm) wide appliance

1" (25.4 mm) diameter

counter bore 1⁄4" (6 mm)

deep 6 places.

13⁄8"

(3.5 cm)

327⁄32"

(9.8 cm)

17⁄32"

(3.1 cm)

typical

31⁄8"

(7.9 cm)

Minimum

Clearance

for hinge

2 places

147⁄8"

(37.8 cm)

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

415⁄16"

(12.5 cm)

1

⁄4" (6 mm)

31⁄8"

(7.9 cm)

(See Table D)

31⁄8"

(7.9 cm)

Minimum

Deep

13⁄4"

(4.4 cm)

"A"

1

⁄4" (6 mm)

Deep

13⁄4"

(4.4 cm)

"A"

(See Table D)

(7.9 cm)

Minimum

31⁄8"

(7.9 cm)

31⁄8"

415⁄16"

(12.5 cm)

Clearance

for hinge

2 places

147⁄8"

(37.8 cm)

5"

(12.7 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

1" (25.4 mm) diameter

counter bore 1⁄4" (6 mm)

deep 6 places.

13⁄8"

(3.5 cm)

327⁄32"

(9.8 cm)

17⁄32"

(3.1 cm)

typical

31⁄8"

(7.9 cm)

Minimum

41⁄8"

(10.5 cm)

Minimum

This side

to door

11⁄2"

111⁄16"

(4.3 cm)

(3.8 cm)

typical

Figure 15

Left Hand Hinged Door

15" (38.1 cm) Wide Appliance

311⁄16"

(9.4 cm)

2"

(5.1 cm)

16

2"

(5.1 cm)

This side

to door

311⁄16"

(9.4 cm)

11⁄2"

(3.8 cm)

typical

111⁄16"

(4.3 cm)

Figure 17

Right Hand Hinged Door

15" (38.1 cm) wide appliance

41⁄8"

(10.5 cm)

Minimum

OVERLAY DOOR PANEL INSTALLATION

Clearance for

screw head,

6 places

Top of door

Weight of overlay door panel must not

exceed 15 pounds (6.8 kg) for a solid

door model or 10 pounds (4.5 kg) for a

glass door model.

Hinge side of door

Figure 18

Left Hand Hinged Door

24" (61 cm) wide appliance

Clearance for hinge

at top and bottom

237⁄8"

(60.7 cm)

1

⁄4"

(6 mm)

Deep

!

CAUTION

24" (61 cm) wide appliance

Figure 20

Right Hand Hinged Door

Clearance for hinge

at top and bottom

237⁄8"

1

⁄4"

(6 mm)

Deep

(60.7 cm)

Clearance for

screw head,

6 places

Top of door

Hinge side of door

13⁄8"

(3.5 cm)

17⁄32"

(3.1 cm)

typical

31⁄8"

(7.9 cm)

111⁄16"

(4.3 cm)

11⁄2"

(3.8 cm)

typical

415⁄16"

(12.5 cm)

14"

(35.6 cm)

13⁄16"

(3 cm)

327⁄32"

(9.8 cm)

1

⁄4" (6 mm)

radius is

permissible

This side

to door

41⁄8"

(10.5 cm)

1" (2.5 cm) diameter

x 1⁄4" (6 mm) deep

6 places

Left Hand Hinged Door

24" (61 cm) wide appliance

31⁄8"

(7.9 cm)

(9.4 cm)

Figure 19

(4.4 cm)

31⁄8"

(7.9 cm)

311⁄16"

13⁄4"

(5.1 cm)

"A"

(See Table D)

2"

"A"

(See Table D)

(5.1 cm)

17

13⁄4"

(4.4 cm)

31⁄8"

(7.9 cm)

(35.6 cm)

13⁄16"

(3 cm)

1

⁄4" (6 mm)

radius is

permissible

31⁄8"

(7.9 cm)

This side

to door

2"

311⁄16"

(9.4 cm)

1" (2.5 cm) diameter

Figure 21

Right Hand Hinged Door

24" (61 cm) wide appliance

14"

327⁄32"

(9.8 cm)

41⁄8"

(10.5 cm)

x 1⁄4" (6 mm) deep

6 places

415⁄16"

(12.5 cm)

13⁄8"

(3.5 cm)

17⁄32"

(3.1 cm)

typical

31⁄8"

(7.9 cm)

111⁄16"

(4.3 cm)

11⁄2"

(3.8 cm)

typical

OVERLAY DOOR PANEL INSTALLATION

Step 4: Assemble the panel to the door

The preferred method of attaching the panel to the door

is to clamp the panel to the door so it cannot move while

drilling the screw pilot holes. Use bar clamps or "C" clamps

with pads on the clamping surfaces that will not mar the

panel or the door. The custom overlay panel should be

ush with the top of the door and overhang the sides of the

door 3⁄16" (5 mm) on each side. See Figure 13a. Drill holes

through the gasket extrusion using the 10 holes as pilot

holes. Use the drill size from the chart in Table "C", being

careful not to drill through the front surface of the panel, drill

no deeper than 1⁄2" (12.7 mm) deep. If the overlay panel is

thinner than 5⁄8" (16 mm) thick shorter screws will have to be

obtained. Fasten the panel to the door with the 10 screws

provided in the literature pack. (See Figure 23a). Remove

the clamps and replace the gasket in the gasket extrusion

channels of the door. Some force may be required to seat

the gasket into the channels. Be sure the gasket corners

are seated properly.

Material Type #10 Wood Screw

Hardwood

Softwood

1

⁄8" (3.2 mm) Diameter. Pilot Hole

7

⁄64 (2.8 mm) Diameter. Pilot Hole

DOOR

MODEL

DESCRIPTION DIM "A"

ML15RAP*RP Solid, Right Hand

ML15RAP*LP Solid, Left Hand

ML15BCF*RP Glass, Right Hand

ML15BCF*LP Glass, Left Hand

ML15BCP*RP Solid, Right Hand

ML15BCP*LP Solid, Left Hand

ML24RAP*RP Solid, Right Hand

ML24RAP*LP Solid, Left Hand

ML24BRF*RP Glass, Right Hand

ML24BRF*LP Glass, Left Hand

ML24BRP*RP Solid, Right Hand

ML24BRP*LP Solid, Left Hand

MA24BRF*RP

MA24BRF*LP

MA24RAP*RP

MA24RAP*LP

Glass, Right Hand

with Lock

Glass, Left Hand

with Lock

Solid, Right Hand

with Lock

Solid, Left Hand

with Lock

3011⁄32" (77.1 cm)

2723⁄32" (70.4 cm)

Table C

Table D

18

OVERLAY DOOR PANEL INSTALLATION

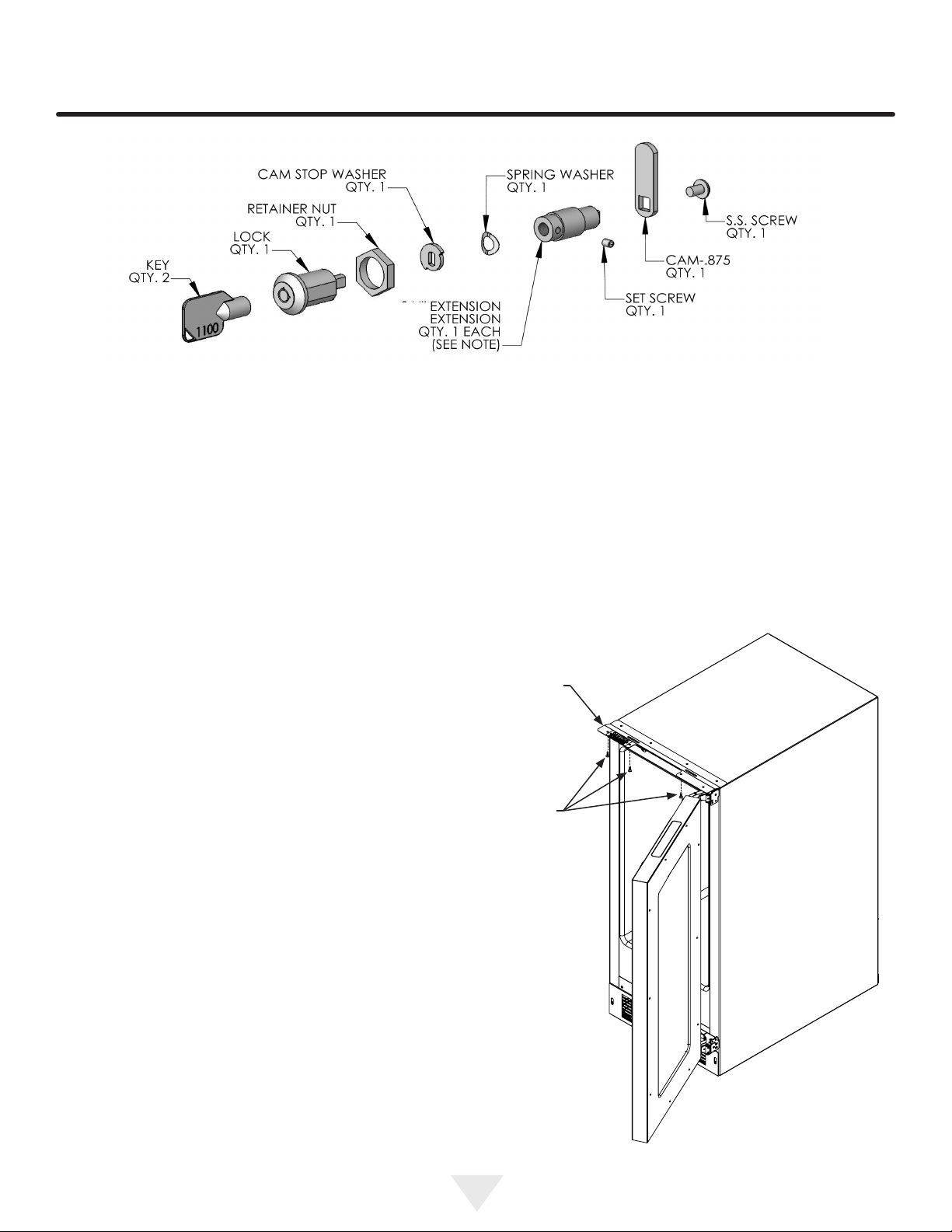

Step 5: Assemble lock parts

Two (2) lock extensions are provided with the lock. Use

the longer extension for 3⁄4" thick overlay panels and the

shorter one for 5⁄8" thick overlay panels. Assemble the lock

extension, cam stop washer, spring washer, and set screw

to the lock as shown in Figure 22 and 24.

Install this lock assembly into the lock hole in the overlay

panel and secure with the retaining nut on the back side

with a 15 mm socket and ratchet. Make sure the key slot in

the front of the lock is vertical.

#10 x 1/2"

screw

Counter bore

lock hole

on back side.

Figure 23a

BRASS EXTENSION

SPRING WASHER

NUT

LOCK

1/2 HOLE

13/16 COUNTER

BORE 7/16 DEEP

3/4 INCH

WOOD PANEL

SECTION A-A

SCALE 1 : 1

Figure 22

CAM

PHILLIPS SCREW

INNER

DOOR

17

⁄32"

(13.7 mm)

39⁄16"

(90 mm)

1

⁄2" (13 mm) diameter drill

through door panel, from

other side (see detail

above) 13⁄16" (20.5 mm)

counter bore, 7⁄16" (11 mm)

deep.

Step 6: Install lock cam

Attach the lock cam to the back of the lock assembly with

the phillips head screw provided. Orient the lock cam vertically when installing on the lock.

Hinge side of door

Figure 23

19

OVERLAY DOOR PANEL INSTALLATION

1.234" (31.3 mm)

.991" (25.2 mm)

Figure 24

Step 7: Install the door

Carefully open the top and bottom hinges on the door being

careful as there are many pinch points. Place the hinges

over the 4 screws in the cabinet, 2 at the top and 2 at the

bottom and slide the door into position. Tighten the 4 hinge

screws with a phillips screwdriver. (See Figures 11 and

11a). Place wire harness from the grille and mount to the

bottom of the door with the screw and "P" clamp removed

in step 1. (See Figure 11b). Reconnect the wire harness,

(See Figure 12).

Step 8: Secure the cabinet

Use the #8 x 3⁄4" black screws from the literature pack to

secure the counter top to the cabinet top through the holes

in the cabinet "Z" bracket.

Cabinet

"Z" bracket

#8 x 3⁄4" black

screws

(3 places)

20

Figure 25

SHELVING CONFIGURATIONS

Loading Tips and Suggestions

Your appliance is equipped with a cantilever shelf system

which provides maximum adjust ability and customizing of

the shelving arrangements listed below.

Beverage Center:

15" (38.1 cm) Wide Models:

Shown with a glass door. Figure 26.

(2) frame and at glass cantilever shelves. (See Figure 34).

Beverage Refrigerator:

24" (61 cm) Wide Models:

Shown with a glass door. Figure 28.

(1) half width at glass cantilever shelf. (See Figure 33).

(1) wine cutout and at glass

cantilever shelf. (See Figure 35).

(1) frame and at glass crisper

cover.

(1) roll-out crisper pan

Figure 28

Refrigerator:

15" (38.1 cm) Wide Models:

Shown with a solid door. Figure 29.

Beverage Center:

24" (61 cm) Wide Models:

Shown with a glass door. Figure 27.

(2) wine cutout and at

glass cantilever shelf.

(See Figure 35).

(1) half depth roll-out

4 bottle wine shelf.

Figure 26

(2) frame and at glass cantilever shelves. (See Figure 34).

Figure 29

Refrigerator:

24" (61 cm) Wide Models:

Shown with a solid door. Figure 30.

(2) perforated metal

cantilever shelves.

(See Figure 32).

Figure 27

21

Figure 30

SHELVING CONFIGURATIONS

Refrigerator:

24" (61 cm) Wide Models:

Shown with a solid door with door racks. Figure 31.

(1) half width at glass

cantilever shelf. (See

Figure 34).

(1) frame and

slumped glass

cantilever shelf.

(1) frame and at

glass crisper cover.

(1) roll-out crisper pan.

(1) full width door

storage rack.

(1) half width door

storage rack.

Figure 31

Wine shelf

underneath glass

Figure 35

Wine cutout and at glass shelf with

vibration dampening mat,

all or part of the glass can be

removed to increase or decrease

wine storage and beverage areas.

Figure 32

Perforated metal shelf

Frame and at glass shelf

Figure 33

Half width shelf shown

Tall bottle

storage area

Door storage racks

Figure 36

To remove the crisper :

Pull out until it stops. Lift up on the

front of the pan, and remove it from

the frame.

Figure 34

Frame and at glass shelf

Half width shelf shown

22

SHELVING CONFIGURATIONS

!

CAUTION

Make sure your cantilever shelf is secure on the shelf supports by pressing down on the shelf before loading.

Shelf support

slot

Installed shelf

tang

Rear tang

(hook) on

shelf

To Add or Remove a Shelf

Remove stored product from the shelf. Do not try to remove

a loaded shelf from the appliance. Grasp the shelf front with

both hands, rotate the front upward and lift out. (See Figure

37b). To install a shelf insert the shelf in the appliance and

insert the hooks into the shelf support slots and drop the

shelf down so the hooks drop over the bottom of the slots.

Figure 37a

Tall bottle

storage

area

Figure 37

Grasp the shelf by the front with

Figure 37b

both hands and rotate the front

of the shelf up, then lift the shelf

up and remove the shelf from the

shelf ladders.

!

CAUTION

Never try to move a loaded shelf, remove everything from

the shelf before moving. Use both hands when moving the

shelf.

23

CARE AND CLEANING AND ENERGY SAVING TIPS

Front Grille

Be sure that nothing obstructs the required air ow openings in front of the cabinet. At least once or twice a year,

brush or vacuum lint and dirt from the front grille area (see

page 4).

!

CAUTION

SHOCK HAZARD: Disconnect electrical power from the

appliance before cleaning with soap and water.

Cabinet

The painted cabinet can be washed with either a mild soap

and water and thoroughly rinsed with clear water. NEVER

use abrasive scouring cleaners.

Interior

Wash interior compartment with mild soap and water. Do

NOT use an abrasive cleaner, solvent, polish cleaner or

undiluted detergent.

Care of Appliance

1. Avoid leaning on the door, you may bend the door

hinges or tip the appliance.

2. Exercise caution when sweeping, vacuuming or mopping near the front of the appliance. Damage to the

grille can occur.

3. Periodically clean the interior of the appliance as

needed.

4. Periodically check and/or clean the front grille as

needed.

In the Event of a Power Failure

If a power failure occurs, try to correct it as soon as possible. Minimize the number of door openings while the

power is off so as not to adversely affect the appliance's

temperature.

The following suggestions will minimize the

cost of operating your refrigeration appliance.

1. Do not install your appliance next to a hot appliance

(cooker, dishwasher, etc.), heating air duct, or other

heat sources.

2. Install product out of direct sunlight.

3. Ensure the front grille vents at front of appliance beneath door are not obstructed and kept clean to allow

ventilation for the refrigeration system to expel heat.

4. Plug your appliance into a dedicated power circuit. (Not

shared with other appliances).

5. When initially loading your new product, or whenever

large quantities of warm contents are placed within

refrigerated storage compartment, minimize door

openings for the next 12 hours to allow contents to pull

down to compartment set temperature.

6. Maintaining a relatively full storage compartment will

require less appliance run time than an empty compartment.

7. Ensure door closing is not obstructed by contents

stored in your appliance.

8. Allow hot items to reach room temperature before placing in product.

9. Minimize door openings and duration of door openings.

10. Use the warmest temperature control set temperature

that meets your personal preference and provides the

proper storage for your stored contents.

11. When on vacation or away from home for extended pe-

riods, set the appliance to warmest acceptable tem perature for the stored contents.

12. Set the control to the “off” position if cleaning the

appliance requires the door to be open for an extended

period of time.

13. For wine storage products:

When serving temperatures are not required,

return the compartment(s) set temperature to the

ideal red and white wine long term storage tem perature of 13°C / 55°F.

Light assembly replacement

All models use LED lamps to illuminate the interior of the

appliance. This component is very reliable, but should one

fail, contact a qualied service technician for replacement

of the LED.

24

DOOR ALIGNMENT AND OBTAINING SERVICE

Door alignment for solid and glass door

models:

The door should be parallel to the sides and top of the appliance. If alignment is necessary the door may be adjusted

by loosening the 2 screws which secure the door adjust-

ment bracket on the bottom of the door (see Figure 38a)

and adjusting the door side to side. Use a 5⁄32” allen wrench

for this procedure. (See Figure 38 below). When nished

aligning the door, tighten the screws securely.

If Service is Required:

• If the product is within the rst year warranty period

please contact your dealer or call AGA MARVEL Cus-

tomer Service at 800.223.3900 for directions on how to

obtain warranty coverage in your area.

• If the product is outside the rst year warranty period,

AGA MARVEL Customer Service can provide recommendations of service centers in your area. A listing

of authorized service centers is also available at www.

agamarvel.com under the service and support section.

• In all correspondence regarding service, be sure to

give the service number, serial number, and proof of

purchase.

• Try to have information or description of nature of the

problem, how long the appliance has been running, the

room temperature, and any additional information that

may be helpful in quickly solving the problem.

• Table "E" is provided for recording pertinent information

regarding your product for future reference.

For Your Records

Date of Purchase

Dealer’s name

Dealer’s Address

Dealer’s City

Dealer’s State

Dealer’s Zip Code

Appliance Serial Number

Appliance Service Number

Date Warranty Card Sent (Must

be within 10 days of purchase).

Figure 38

Table E

Door should be

parallel to top

and sides of the

appliance.

Door

adjustment

bracket

Bottom

of door

Figure 38a

Loosen (don't remove)

these two screws.

25

TROUBLESHOOTING

Before You Call for Service

If the appliance appears to be malfunctioning, read through

this manual rst. If the problem persists, check the troubleshooting guide below. Locate the problem in the guide and

refer to the cause and its remedy before calling for service.

The problem may be something very simple that can be

solved without a service call. However, it may be required

to contact your dealer or a qualied service technician.

Problem Possible Cause Remedy

Appliance not cold enough

(See “Adjusting the temperature" on

page 11)

Appliance too cold

(See “Adjusting the Temperature” on

page 11)

No interior light. • Failed LED light assembly or light

Light will not go out when door is

closed

Noise or Vibration • Appliance not level

Appliance will not run. • Appliance turned off

• Control set too warm

• Content temperature not stabilized.

• Excessive usage or prolonged

door openings.

• Airow to front grille blocked.

• Door gasket not sealing properly.

• Control set too cold

• Door gasket not sealing properly.

switch.

• Display light is turned on. (Glass

door models only.

• Door not activating light switch.

• Failed light switch

• Fan hitting tube obstruction.

• Power cord not plugged in.

• No power at outlet.

• Never attempt to repair or perform maintenance on

the appliance until the main electrical power has been

disconnected. Turning the appliance control "OFF"

does not remove electrical power from the unit's wiring.

• Replace all parts and panels before operating.

!

WARNING

Electrocution Hazard

• Adjust temperature colder. Allow 24 hours for temperature to

stabilize.

• Allow temperature to stabilize for

at least 24 hours.

• Airow must not be obstructed to

front grille. See “clearances” on

page 4.

• Check door alignment and/or

replace door gasket.

• Adjust temperature warmer.

Allow 24 hours for temperature to

stabilize.

• Check door alignment and/or

replace door gasket.

• Contact a qualied service technician.

• Turn off display light, shut door.

• Appliance not level, level appli-

ance, (See page 4, “leveling legs”)

• Verify the door is aligned properly,

refer to page 25 for instructions.

• Contact a qualied service technician.

• Level appliance, see “Leveling

Legs” on page 4.

• Contact a qualied service technician.

• Turn appliance on. See “Starting

your appliance” on page 10.

• Plug in power cord.

• Check house circuit.

26

Loading...

Loading...