Page 1

F80P & F130P FLEX-SELECT® Series

Adaptable Broadcast Spreader

Assembly and Operating Instructions

PLEASE CONTACT US: IF YOU ARE MISSING ANY PARTS, HAVE ANY DIFFICULTY IN ASSEMBLY, OR HAVE ANY

QUESTIONS REGARDING THE SAFE OPERATION OF THIS SPREADER. THIS MODEL INCLUDES LIFETIME

TECHNICAL SUPPORT. SUPPORT HOT LINE: 800-294-0671

HELPFUL HINTS:

; If your spreader does not spread evenly, be sure the FRONT on the gear box points to the front of the spreader. The

impeller must turn clockwise. Reversing the gearbox will cause the impeller to turn counter clockwise. Clean the impeller

after each use as some fertilizer may become stuck on the impeller blades and will cause uneven spreading.

; Your spreader is designed to be pushed at three miles per hour, which is a brisk walking speed. Slower or faster speeds

will change the spread patterns. Wet fertilizer will also change the spread pattern and ow rate.

; Clean and dry your spreader thoroughly after each use, wash between the shut-off plate and bottom of the hopper

regularly. To prevent rust, coat all metal parts (inside and out) including the frame tubes with a light oil, silicon spray, or

Fluid Film®.

; Gears are permanently lubricated at the factory. Do not open the gearbox or dirt may enter.

; When using Rock Salt to prevent damage to the gearbox remove salt from the hopper daily. Rock Salt will reconstitute

back into a solid block if left in the hopper overnight and will damage your gearbox if pushed with the salt in place.

WARNING

Do not use air tools to assemble.

To prevent seizing coat all bolts

with a wax or grease prior to

installation.

Remove all parts, hardware, and assemblies from carton

and lay them out on the oor to help in assembly.

Below are tools needed for assembly - 7/16”

wrench, ratchet and 7/16” socket, and pliers.

The following photos are for assembly

purposes, and please follow them from left to

right, top to bottom.

4-2015 Pt# F52153 PAGE 1

Page 2

ASSEMBLY

1

2

3

4

PAGE 2

Page 3

ASSEMBLY - continued

5

6

7

8

PAGE 3

Page 4

ASSEMBLY - continued

9

10

CONFIRM THE CALIBRATION:

Lever at #30 and the drop holes fully open

TO COMPLETE ASSEMBLY:

Install Agitator, bend the Agitator up slightly to prevent contact

with the STANDARD-OUTPUT tray, and install debris screen.

Press over 1/4 turn fasteners to secure.

This only applies to the RED 3-hole drop

STANDARD-OUTPUT Trays.

The HIGH-OUTPUT (Blue) and LOW-OUTPUT (Black)Trays

do not use the Agitator or Debris Screen shown below.

11

PAGE 4

Page 5

TRAY INSTALLATION

HIGH-OUTPUT AND LOW-OUTPUT:

require the use of the Part #F12117

No Agitator or Debris

screen are included

HIGH-OUTPUT AND LOW-OUTPUT:

require the use of the Part #F12117

No Agitator or Debris

screen are included

PAGE 5

Page 6

Flex-Select®

0

30

GAUGE &

LEVER

Setup and Calibration Techniques

How to Install a Tray

First ensure the hopper is clean and there is no debris trapped around the tray

mounting area. Secondly install the Pivot Rod Clip into the Shut-off of the

selected Tray. Next, insert the Pivot Rod into the Clip. TIP: The Clip

may have a burr in the hole, use a Phillips screwdriver to remove the burr.

See to make installing the Pivot Rod easier. Pliers may be required to help

squeeze the Pivot Rodinto the Clip. When the Rod is secure inside the

Clip push the free end of the Clip over the Pivot Rod to rmly secure the

rod to the clip. Next, install the Tray from the top downwards into the hopper

(see gure) positioning the center hole of the tray over the Pinion Shaft from

the gear box with the Pivot Rod through the bottom of the hopper and facing

toward the spreader’s handlebar. For ease of locating into position the shut-off

of the chosen tray is best in the open position, with the exception of the red

STANDARD-OUTPUT Tray where the two adjustable throwing ports are best

in the closed position.

NOTE: The gearbox can be moved along the axle to ease aligning of the tray

hole and the pinion shaft. Once the tray is in place check that the tray is sealed

and ush against the hopper sides. To check if the tray is properly located, push

the tray edges downwards. Install the two quarter turn fasteners (see gure)

through the two exposed tray holes and push down and twist a quarter turn to

secure.

Lastly, connect the free end of the Pivot Rod into the Pivot linkage at the

bottom of the Control Rod. Position the Clip into the free hole and push the

Pivot Rod into the clip. TIP: The Clip may have a burr in

the hole, use a Phillips screwdriver to remove the burr (see

gure) When the Pivot Rod is positioned inside the Clip

push the free end of the Clip over the Pivot Rod to rmly

secure the rod and the clip together.

HIGH-OUTPUT

F13130HKIT

Blue Tray

install Pivot Rod

from the bottom

4

Deburr

Rod Clip

STANDARD-OUTPUT

PRO F13130DKIT

to the top

2

Shut-Off End

LOW-OUTPUT

F13130LKIT

Black Tray

install Pivot Rod

from the top

to the bottom

2

1

Red Tray

install Pivot Rod

from the bottom

to the top

1

2

Shut-Off End

1

Shut-Off End

3

3

3

How to ensure your spreader is

properly calibrated

HIGH-OUTPUT and LOW-OUTPUT Trays: Make sure the

drop holes in the bottom of the hopper are FULLY CLOSED

when the Rate Control Lever is resting on the Stop #0. If the

shut-off is not set correctly, please adjust Control Rod at the

Pivot to position the shut-off for FULLY CLOSED at position at the Stop #0

on the Rate Control Lever. As a side note, the HIGH-OUTPUT and LOW-

OUTPUT Trays do not include or use a horizontal agitator.

Calibration Adjustment

Review the Control Lever position to conrm that it is set so that the forward

edge of the Lever is resting at #0 (the stop) and the drop holes are closed.

Move the spreader back & forth to ensure that the cam is positioned to allow

the Oscillating Shut-off to close fully. If the shut-off is not properly positioned,

you will need to adjust the Control Rod at the Pivot Bracket shown below.

TIP: If your shut-off is not able to CLOSE fully, loosen the top nut a few turns, then tighten the lower nut so that it allows you

to push the shut-off fully closed. Next, tighten each nut so that they contact the pivot bracket without moving it, and then

carefully tighten each nut fully so they do not loosen during use. Recheck adjustment as outlined above.

Quarter Turn

Tray Fastener

6

CALIBRATION

POINT

continued

Page 7

How to ensure your spreader is properly calibrated - continued

STANDARD-OUTPUT Tray: Make sure the drop holes in the bottom of the hopper are

FULLY OPEN when the Rate Control handle is on #30. If the shut-off is not set correctly,

please adjust Control Rod at the Pivot to position the shut-off for FULLY OPEN hopper position

at #30 on the Rate Control Lever. Install the horizontal agitator through the pinion shaft in the

hopper bottom. Finally, install the debris screen onto the Quarter-turn fasteners and push down

to snap and secure.

Calibration Adjustment

Review the Control Lever position to conrm that it is set so that the rear edge of the Lever is

resting at #30 (the stop) and the drop holes are open. If the shut-off is not properly positioned,

you will need to adjust the Control Rod at the Pivot Bracket shown below. TIP: If your shut-off

is not able to OPEN fully, loosen the bottom nut a few turns, then tighten the upper nut so that

it allows you to push the shut-off fully open. Next, tighten each nut so that they contact

the pivot bracket without

moving it, and then

carefully tighten each nut

fully so they do not loosen

during use. Recheck

adjustment as outlined

above.

#30

#0

30

0

GAUGE &

LEVER

CALIBRATION

Control Lever Drag adjustment

If the Control Lever does not stay in position causing the setting rate to change without

your intervention, you can adjust the drag on the Lever by tightening or loosening the nut

shown to the right until the drag is appropriate.

POINT

Lever

Drag

Adjustment

If you have any questions regarding the assembly or safe operation your spreader, please contact us at 800-294-0671 or

574-848-7491 Monday - Friday 9:00am - 4:00pm Eastern.

Page 8

Using the EV-N-SPRED® Dual Port PRO

S

p

r

e

a

d

P

a

t

t

e

r

n

Adjustable Throwing Ports

with 8 repeatable settings

to balance the left or right

spread pattern to

the center.

Adjustable Shut-Off System

The EV-N-SPRED® Dual Port PRO Adjustable Shut-Off System is included on all professional models and

allows the operator to balance the spread pattern evenly across the full 180o spread width, regardless of the

weight or size of granular material. By closing either the right and or left

side throwing ports you can balance the spread pattern to exacting

precision without compromising spread width or application

rate.

Each EV-N-SPRED

System drop hole has a corresponding 1/3rd coverage

area on the spread width of the spreader leaving

a feathered-edge for overlapping the spread path.

The illustration to the right shows each port and the

corresponding 1/3rd coverage area of the spread path.

These ports can be adjusted to effectively balance the spread

pattern, giving equal amounts of material across the full 180o

spread pattern.

EV-N-SPRED®Dual Port PRO System Setup

Test all material prior to beginning your spreading job. You will need

a 50’ measuring tape, a small scale to weigh the material, bucket or

container to hold the material for re-weighing, chalk or a line marking

device, and (7) low baking tins. Using the EarthWay® Bag Calibrator

#77016 can greatly reduce the time needed for determining the Setting

Rates on any material but is not mandatory to

establish a setting rate.

Dual Port PRO Adjustable Shut-Off

®

FINE

MEDIUM LARGE

Gauge & Lever

15

1. Evaluate the material being spread by comparing

it to the following standard as a reference.

Large/Heavy is the size of a BB (⅛ in / 3mm), spread width is 28 - 36 feet (8.5 11 meters)

Medium/Mixed (½ the size of a BB), spread width is 20 - 24 feet (6.1 - 7.3 meters)

Small/Fine (the size of sand), spread width is 16 - 18 feet (4.8 - 5.5 meters)

2. Add a small amount of the material into the spreader, enough to cover

the bottom (2-3 in / 5 - 7 cm) and begin to test for spread width.

Set the stop on the gauge to #15 and push the spreader several feet /

meters at normal walking speed on a at hard surface (where the material

will be visible), and OPEN the lever to the STOP while continuing to

walk for 3-4 paces, and CLOSE the shut-off and STOP (don’t move the

spreader from that position). Measure the spread width and evaluate

the spread pattern for even distribution on either side of the spread width

center line. TIP: Typical spread width references are listed above. The

spread width that you measure is used to calculate the actual Setting

Rate for the material.

SPREAD WIDTH

P

d

a

e

r

p

S

a

t

t

e

r

n

Page 9

ADJUSTING THE EV-N-SPRED® DUAL PORT SHUT-OFF SYSTEM

Next, using the (7) low baking tins position, them in a straight line on 2-foot

centers across the spread width as shown at the right.

Adjust the left or right variable throwing ports to EVEN THE SPREAD pattern.

TIP: For large/heavy materials, close the LEFT SIDE (LINES) port slightly

before you start your EV-N-SPRED® test. For small/light materials, open the

LEFT SIDE (LINES) port fully and close the RIGHT SIDE (CIRCLES) port slightly before you

start your EV-N-SPRED® test. With BOTH ports closed, the spread is only from the center

port, and will give you a 3-4ft spread width in the center of the spreader - great for medians.

Begin pushing the spreader several feet before the line of tins and at normal walking speed.

Walk along the Center Line, and OPEN the Lever to the STOP 3-4

paces before the line of tins and continue walking past the tins 1 or 2

paces and CLOSE the Lever and STOP.

Visually evaluate the material in the baking tins to determine if your

spread pattern is balanced - having the same amount of material in each

baking tin.

Empty each tin back into the spreader, adjust the ports and RETEST

until you are satised that the coverage is balanced.

Spread width

in feet

7 142’ 10” 17 58’ 10” 27 37'

8 125’ 18 55’ 7” 28 35' 9"

9 111’ 1” 19 52’ 7” 29 34' 6"

10 100’ 20 50’ 30 33' 4"

11 90’ 11” 21 47' 7" 31 32' 3'

12 83’ 4” 22 45' 5" 32 31' 3"

13 76’ 11” 23 43' 6" 33 30' 4"

14 71’ 5” 24 41' 8" 34 29' 5"

15 66’ 8” 25 40' 35 28' 7"

16 62’ 6” 26 38' 6" 36 27’ 9”

Length needed

for 1,000 Sq Ft

Spread width

in feet

Length needed

for 1,000 Sq Ft

Spread width

in feet

Length needed

for 1,000 Sq Ft

p

S

2’ 2’ 2’2’2’2’

d

a

e

r

P

a

t

t

e

r

n

ESTABLISH THE SETTING RATE

Remove the material from the hopper, and mark the distance that you

need to travel with the spreader to attain the designated coverage area

- i.e. 1,000 square feet using the spread width you determined earlier.

Above is a chart to help determine the distance needed for 1,000 square

foot calculation.

Mark the START and END POINTS on the surface required for the test.

Weigh a small amount (10-20lbs/4-9kg) of the material, and add that into

to the spreader. Using the Setting Matrix included with the spreader,

estimate a setting rate based on material manufacturers recommendations

and adjust the STOP on the Gauge to that position.

Now to test, start walking 1-2 paces before the START LI NE and OPEN

the Lever to the stop and then CLOSE when you cross the END POINT

LINE.

Pour the remaining material from the spreader and weigh to calculate the

amount applied over the area. Adjust the Setting Rate to a higher number

if you need to increase the application rate, or to a lower number if you

applied too much in the test.

You may need to repeat this process to acquire the exact rate.

The EV-N-SPRED® Dual Port PRO Adjustable Shut-Off System ensures that EarthWay® Professional spreaders

evenly spread all types of fertilizers, seed, ice melt, or other granular products, and is only available from

EarthWay®.

COVERAGE AREA

i.e. 1,000 SQ FT

END

START

Page 10

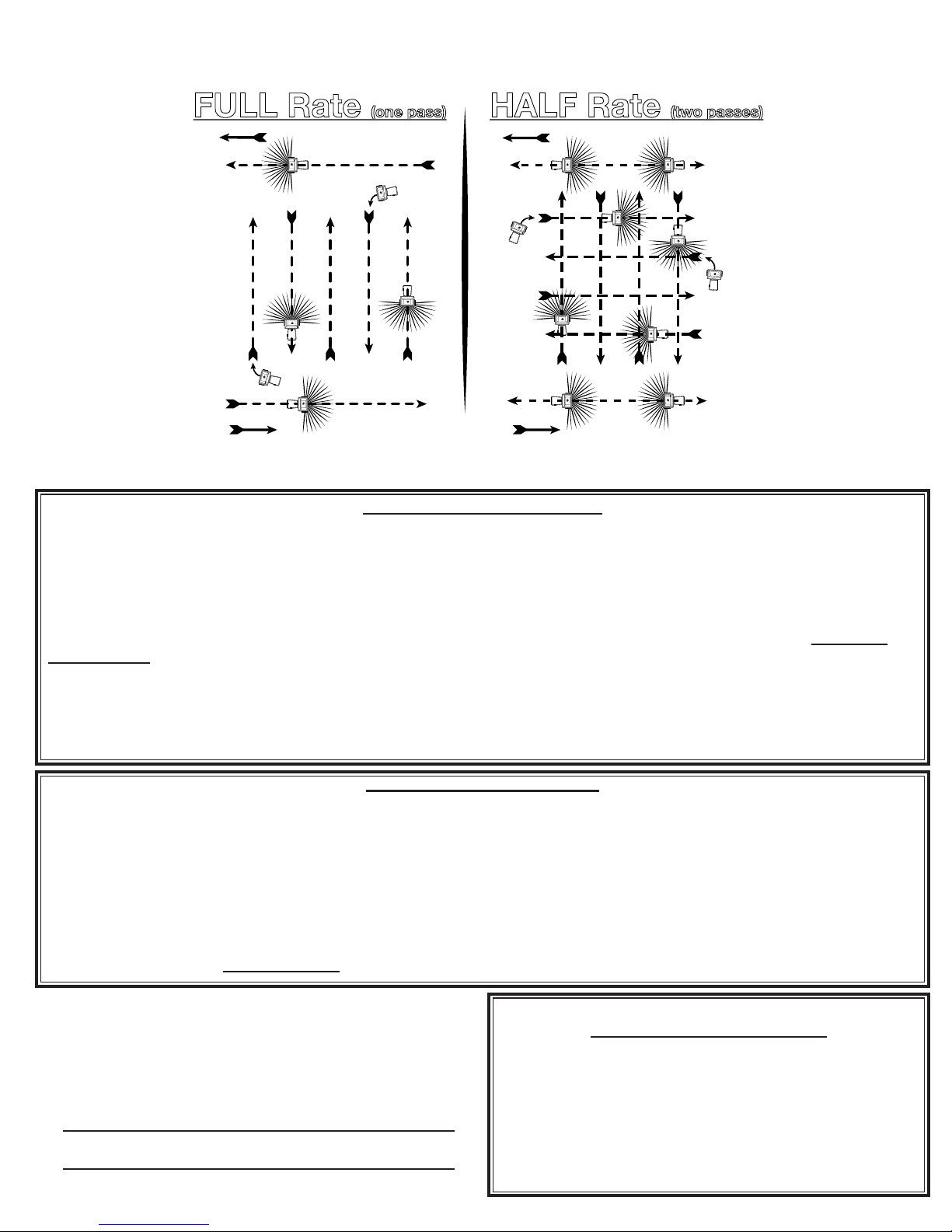

SPREAD PATH

FULL Rate (one pass)

HALF Rate (two passes)

5-YEAR LIMITED WARRANTY

EPI warrants this product free of defects in original workmanship and materials for a period of 5-Years to the end user with

the original purchase receipt. If a manufacturing non-conformance is found, EPI at its discretion will repair or replace the

part(s) or product at no charge provided the failure is not the result of incorrect installation, mishandling, misuse, tampering,

or normal wear and tear as determined by EPI. EPI at its discretion may require that the part(s) or product be returned along

with the original purchase receipt at owners’ expense for examination and compliance with the terms of this warranty. Do not

return any product without rst receiving authorization from EPI. To seek remedy under this warranty, contact EPI at 574-8487491, or write to EPI P.O. Box 547 Bristol, Indiana 46507 and describe the nature of the manufacturing defect. SPECIFIC

LIMITATIONS: This warranty covers only the part(s) or product; any labor charges associated with repair or replacement of

non-conformances are specically excluded. Due to the corrosive nature of most fertilizers and ice melt products, EPI makes

no warranty against and specically excludes part(s) or product degradation or failure due to corrosion or its effects. Clean

and dry your spreader thoroughly after each use, as a preventative measure, coat all metal parts with a light oil or silicon

spray.

OPERATING INSTRUCTIONS

Before lling hopper, become familiar with the operation of this spreader.

5 Obtain proper setting for material to be used from the enclosed SETTING MATRIX included with this spreader, or from our

web site under the MANUALS SECTION.

5 Move stop bolt on rate gauge assembly to the proper setting.

5 While pushing spreader forward, pull control lever back to stop bolt.

5 To stop, push lever forward to close ow holes before you stop moving.

5 When nished, empty any remaining material from hopper.

5 Thoroughly wash spreader and allow to dry before storing. Apply coating of light oil to help prevent corrosion.

5 If you use Rock Salt, remove agitator when using Rock Salt to prevent damage to the gearbox.

EPI

1009 Maple Street, PO Box 547

Bristol, IN 46507

For Your Records

Date Purchased

Place of Purchase

HOW TO ORDER SPARE PARTS

All spare parts listed may be ordered direct from

EPI

Be sure to give the following information when ordering.

Model Number

Part Number

Part Description

Call (574) 848-7491

Page 11

33

3

23

15

32

13

12

10

23

14

17

2

28

25

21

29

27

10

13

32

32

9

32

16

23

32

16

12

26

11

37

18

23

30

32

39

36

40

8

22

1

24

38

34

35

F77080 or F77130

OPTIONAL

Heavy-Duty

Rain Cover

1”

Bolt Identifier

1-1/2”

31

32

15

9

12

26

7

19

60435KIT

OPTIONAL

Left Side Deflector Kit

13

12

4

5

60166R

OPTIONAL

3-Side Deflector Kit

2”

2-1/4”

2-3/4”

20

4

6

F80P & F130P Series Professional Broadcast Spreader

Key # Part # Description Key # Part # Description

1 12110 IMPELLER 9" ROUND DISHED

2 12147 SPACER (PIVOT LINK) 24 F60333 GEAR BOX ASSEMBLY FLEX -SELECT

3 12209 HOPPER BUSHING 25 37100 1/4-20 X 1" CARRIAGE BOLT ZINC

4 12352 BEARING (COMMERCIAL) EACH 26 42237 FRAME BRACE

5 19117 13" DIA PNEU TIRE DRIVE 27 42256 CONTROL ROD

6 24500 AXLE, COINED 28 60027 WING NUT ASSEMBLY BLACK

7 24704 CROSS BRACE (11.125") 29 60298 GAUGE & LEVER ASSEMBLY

8 25108 FRAME 30 F12135 1/4 TURN FASTENER FLEX SELECT

9 25202 LOWER HANDLE COMPLETE 31 FLEX-SELECT 80# HOPPER (F13105) 130# HOPPER (F13106)

10 25301 HANDLE SHAFT 32 36404 1/4 CUPPED WASHER S.S.

11 25723 FRAME Foot (Flex-Select Painted) 33 33117 AGITATOR

12 31100 1/4-20 X 1 1/2 HHMS ZINC 34 F13130D STANDARD OUTPUT DUAL PORT PRO FLEX-SELECT TRAY KIT

13 31106 1/4-20 X 2 1/4" HHCS ZINC 35 F40003 SQUARE SCREEN FLEX-SELECT

14 31127 ROD CLIP (Flex-Select) 36 36300 1/4-20 NYLON INSERT LOCKNUT S.S.

15 3111 4 1/4-20 X 1 3/4" HHCS ZINC 37 F44251 PIVOT ROD STD OUTPUT FLEX-SELECT

16 36305 1/4-20 HEX NUT STAINLESS STEEL 38 F12219D DUAL PORT PRO FLEX-SELECT SHUTOFF ASSEMBLY

17 60069 UPPER HANDLE ASSEMBLY W/GRIPS 39 31138 #8 X 3/8" PMT #8 HD COARSE BLACK

18 60299 PIVOT & BRACKET ASSEMBLY 40 43020 BACKPLATE WASHER

19 36103 3/16 X 2" COTTER PIN S.S. Optional 60435KIT SIDE DEFLECTOR

20 36104 3/16 X 1" COTTER PIN S.S. Optional HEAVY DUTY RAIN COVER (F77080 for F80 / F77130 FOR F130)

21 31107 1/4-20 X 2 3/4" HHCS ZINC Optional 12195 GAUGE OVERLAY- LESCO SETTINGS

22 36214 1/4-20 X 1 1/2" PHPMS S.S. Standard 12196RT GAUGE OVERLAY- RT

23 32103 1/4-20 NYLON INS LOCKNUT ZINC

Page 12

32

3

23

15

13

12

23

10

9

17

29

10

25

27

12

16

13

23

14

35

2

28

21

16

26

11

31

23

30

24

23

22

38

36

37

8

7

1

12

26

31

19

15

33

34

Left Side Deflector Kit

9

13

12

4

5

F77080 or F77130

60435KIT

OPTIONAL

OPTIONAL

Heavy-Duty

Rain Cover

60166R

OPTIONAL

3-Side Deflector Kit

20

4

6

F80PS & F130PS Series Professional Broadcast Spreader

Key # Part # Description Key # Part # Description

1 12110 IMPELLER 9" ROUND DISHED

2 12147 SPACER (PIVOT LINK) 23 36300 1/4-20 NYLON INSERT LOCKNUT S.S.

3 12209 HOPPER BUSHING 24 F60333 GEAR BOX ASSEMBLY FLEX -SELECT

4 12352 BEARING (COMMERCIAL) EACH 25 37100 1/4-20 X 1" CARRIAGE BOLT ZINC

5 19117 13" DIA PNEU TIRE DRIVE 26 42237 FRAME BRACE

6 24500 AXLE, COINED 27 42256 CONTROL ROD

7 24704 CROSS BRACE (11.125") 28 60027 WING NUT ASSEMBLY BLACK

8 24111 FRAME 29 60298 GAUGE & LEVER ASSEMBLY

9 24202 LOWER HANDLE COMPLETE 30 F12135 1/4 TURN FASTENER FLEX SELECT

10 24300 HANDLE SHAFT 31 FLEX-SELECT 80# HOPPER (F13105) 130# HOPPER (F13106)

11 25723-SS FRAME FOOT SS 32 33117 AGITATOR

12 36200 1/4-20 X 1 1/2" HHCS S.S. 33 F13130D STANDARD OUTPUT DUAL PORT PRO FLEX-SELECT TRAY KIT

13 36205 1/4-20 X 2 1/4" HHCS S.S. 34 F40003 SQUARE SCREEN FLEX-SELECT

14 31127 ROD CLIP (Flex-Select) 35 F44251 PIVOT ROD STD OUTPUT FLEX-SELECT

15 36209 1/4-20 X 1 3/4" HHCS S.S. 36 F12219D DUAL PORT PRO FLEX-SELECT SHUTOFF ASSEMBLY

16 36305 1/4-20 HEX NUT STAINLESS STEEL 37 31138 #8 X 3/8" PMT #8 HD COARSE BLACK

17 60070 UPPER HANDLE ASSEMBLY W/GRIPS 38 43020 BACKPLATE WASHER

18 60299 PIVOT & BRACKET ASSEMBLY

19 36103 3/16 X 2" COTTER PIN S.S. Optional 60435KIT SIDE DEFLECTOR

20 36104 3/16 X 1" COTTER PIN S.S. Optional HEAVY DUTY RAIN COVER (F77080 for F80 / F77130 FOR F130)

21 36207 1/4-20 X 2 3/4" HHCS S.S. Optional 12195 GAUGE OVERLAY- LESCO SETTINGS

22 36214 1/4-20 X 1 1/2" PHPMS S.S. Standard 12196RT GAUGE OVERLAY- RT

22 36214 1/4-20 X 1 1/2" PHPMS S.S.

Page 13

12209 HOPPER BUSHING

33117 AGITATOR

F13130DKIT

STANDARD-OUTPUT PRO

12209 HOPPER BUSHING

F12135 1/4 TURN

FASTENER

31127 ROD CLIP

F12219D DUAL-PORT PRO

SHUT-OFF ASSY

F44251 PIVOT ROD

STANDARD-OUTPUT

31138 #8 X 3/8

PMT #8HD (BLACK)

F13130HKIT

HIGH-OUTPUT

31127 ROD CLIP

F12135 1/4 TURN

FASTENER

HIGH-OUTPUT

F44251H PIVOT ROD

31135 #8 X 1/2 PHPS (BLACK)

F14102 SHUT OFF

PLATE RETAINER RING

SHUTOFF ASSY

F12219H HIGH-OUTPUT

36208 #6 X 3/8" TYPE

25 PHPS S.S.

F12117 CAM

36107 1/8 X 1 FLAT HD

18-8 SS RIVET

These parts are wear items and designed to be

consumed with normal operation and have a 90 day warranty

F12111 AGITATOR

PIN RETAINER

F40003 DEBRIS SCREEN

Included with both

STANDARD-OUTPUT

Trays only

F13130KIT

STANDARD-OUTPUT

12209 HOPPER BUSHING

33117 AGITATOR

F12135 1/4 TURN

FASTENER

31127 ROD CLIP

F12219 STANDARD-OUTPUT

F44251 PIVOT ROD

STANDARD-OUTPUT

SHUT-OFF ASSY

31138 #8 X 3/8

PMT #8HD (BLACK)

F13130LKIT

LOW-OUTPUT

12209 HOPPER BUSHING

F12135 1/4 TURN

FASTENER

31127 ROD CLIP

LOW-OUTPUT

F44251L PIVOT ROD

31135 #8 X 1/2 PHPS (BLACK)

SHUTOFF ASSY

F12219L LOW-OUTPUT

F14102 SHUT OFF

PLATE RETAINER RING

F12117 CAM

36107 1/8 X 1 FLAT HD

18-8 SS RIVET

F12111 AGITATOR

36208 #6 X 3/8" TYPE

25 PHPS S.S.

PIN RETAINER

These parts are wear items and designed to be

consumed with normal operation and have a 90 day warranty

Page 14

GRANULAR MATERIAL

PARTICLE SIZES:

Fine/Small

Medium

Large

EXTRA LARGE

(SAND) (HALF BB) (BB) ROCK SALT

SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SETTING WIDTH FT METERS SETTING WIDTH FT METERS SETTING W IDTH FT METERS SETTING W IDTH FT METERS

10 10 18 5.5 13 24 7.3 18 36 11.0 22 37 11.3

15 13 18 5.5 16 24 7.3 23 36 11.0 24 37 11.3

20 14 18 5.5 20 24 7.3 27 36 11.0 26 37 11.3

24 16 18 5.5 22 24 7.3 30 36 11.0 28 37 11.3

29 18 18 5.5 25 24 7.3 23 x 2 pass 36 11.0 29 37 11.3

34 20 18 5.5 27 24 7.3 25 x 2 pass 36 11.0 30 37 11.3

39 22 18 5.5 28 24 7.3 27 x 2 pass 36 11.0 26 x 2 pass 37 11.3

44 24 18 5.5 30 24 7.3 28 x 2 pass 36 11.0 27 x 2 pass 37 11.3

49 26 18 5.5 22 x 2 pass 24 7.3 30 x 2 pass 36 11.0 28 x 2 pass 37 11.3

SETTING WIDTH FT METERS SETTING WIDTH FT METERS

15 16 8 2.4 25 14 4.3

20 18 8 2.4 28 14 4.3

PARTICLE SIZES:

Fine/Small

Medium

Large

EXTRA LARGE

(SAND) (HALF BB) (BB) ROCK SALT

SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SPREAD

SPREAD

SETTING WIDTH FT METERS SETTING WIDTH FT METERS SETTING W IDTH FT METERS SETTING W IDTH FT METERS

10 10 16 4.9 13 20 6.1 18 30 9.1 20 24 7.3

15 12 16 4.9 18 20 6.1 23 30 9.1 25 24 7.3

20 13 16 4.9 20 20 6.1 28 30 9.1 27 24 7.3

24 16 16 4.9 22 20 6.1 30 30 9.1 30 24 7.3

29 18 16 4.9 25 20 6.1 23 x 2 pass 30 9.1 25 x 2 pass 24 7.3

39 21 16 4.9 29 20 6.1 28 x 2 pass 30 9.1 27 x 2 pass 24 7.3

44 23 16 4.9 30 20 6.1 29 x 2 pass 30 9.1 29 x 2 pass 24 7.3

49 24 16 4.9 22 x 2 pass 20 6.1 30 x 2 pass 30 9.1 30 x 2 pass 24 7.3

15 18 9 2.7 24 15 4.6

25 24 9 2.7 30 15 4.6

PARTICLE SIZES:

Fine/Small Medium Large EXTRA LARGE

(SAND) (HALF BB) (BB) ROCK SALT

SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD SPREAD

SETTING WIDTH FT METERS SETTING WIDTH FT METERS SETTING W IDTH FT METERS SETTING W IDTH FT METERS

10 5 16 4.9 6 22 6.7 10 28 8.5 11 26 7.9

15 6 16 4.9 8 22 6.7 12 28 8.5 13 26 7.9

20 7 16 4.9 9 22 6.7 14 28 8.5 14 26 7.9

24 8 16 4.9 11 22 6.7 15 28 8.5 15 26 7.9

29 10 16 4.9 13 22 6.7 17 28 8.5 16 26 7.9

34 11 16 4.9 15 22 6.7 20 28 8.5 17 26 7.9

39 12 16 4.9 16 22 6.7 21 28 8.5 18 26 7.9

44 13 16 4.9 17 22 6.7 23 28 8.5 19 26 7.9

49 14 16 4.9 18 22 6.7 24 28 8.5 21 26 7.9

SETTING WIDTH FT METERS SETTING WIDTH FT METERS

15 9 10 3.0 14 15 4.6

20 11 10 3.0 16 15 4.6

25 13 10 3.0 18 15 4.6

Meter

FLEX-SELECT®

BROADCAST SPREADER SETTING MATRIX

Meter

Standard-Output Red Tray

Grams PER Square

5 7 18 5.5 9 24 7.3 14 36 11.0 17 37 11.3

GRASS SEED

Grams PER Square

Meter

10 14 8 2.4 22 14 4.3

25 20 8 2.4 30 14 4.3

FINE SPREAD SPREAD COARSE SPREAD SPREAD

GRANULAR MATERIAL

ow-Output Black Tray

L

Grams PER Square

5 8 16 4.9 10 20 6.1 15 30 9.1 18 24 7.3

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the

Standard-Output Tray

are fully open when the Rate Control handle is on #30. If not,

please adjust control rod at the pivot to allow for a full open

hopper holes with the handle at position at #30.

34 20 16 4.9 27 20 6.1 25 x 2 pass 30 9.1 26 x 2 pass 24 7.3

GRASS SEED

Grams PER Square

Meter

10 15 9 2.7 21 15 4.6

20 21 9 2.7 27 15 4.6

FINE SPREAD SPREAD COARSE SPREAD SPREAD

SETTING WIDTH FT METERS SETTING WIDTH FT METERS

GRANULAR MATERIAL

H

igh-Output Blue Tray

Grams PER Square

Meter

5 3 16 4.9 5 22 6.7 7 28 8.5 8 26 7.9

GRASS SEED

Grams PER Square

Meter

10 7 10 3.0 11 15 4.6

FINE SPREAD SPREAD COARSE SPREAD SPREAD

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the LOW-OUTPUT TRAY

are fully closed when the Rate Control Handle is resting on the

stop #0. If not, please adjust control rod at the pivot to ensure

the shut-off is fully closed with the handle at position at #0.

Move the spreader slightly to confirm the calibration because of

the cam.

Calibration: Start by ensuring that your spreader calibration is

correct. Make sure the drop holes in the

HIGH-OUTPUT TRAY

are fully closed when the Rate Control Handle is resting on the

stop #0. If not, please adjust control rod at the pivot to ensure

the shut-off is fully closed with the handle at position at #0.

Move the spreader slightly to confirm the calibration because of

Loading...

Loading...