Page 1

1

Operation Manual

Maruyama Boom Sprayer

Be sure to read before use.

BSA-950LM

Page 2

2

Introduction

Thank you for purchasing a Maruyama product. This Operation Manual explains the correct handling of the

product and how you can easily inspect and care for it, so that you can carry out your work safely and comfortably

using the machine.

Before using the product, read this manual carefully and understand the contents fully so that the product will

continue to demonstrate excellent performance.

After reading this manual, keep it in a safe place and reference it every time you have a question. Please note

that information contained in this manual may not exactly match the product you purchased due to specification

changes of the product, etc.

If you have any feedback on this product, please contact the Maruyama dealer or sales office near you.

◼ Scope of Use

⚫ This product is designed primarily for spraying chemicals over paddy fields and crop fields. Maruyama shall

assume no responsibility for any accident caused by using the product outside the foregoing scope of use or

accident arising from an unauthorized modification or disassembly.

◼ Precautions

⚫ The precautions contained in this manual and warning labels bearing you see on the machine provide

important items that may cause injury if neglected. Read these precautions and labels carefully and be sure to

follow the instructions.

In this Operation Manual, particularly important handling precautions are denoted as follows:

Danger --- Failure to follow this instruction will lead to death or serious injury.

Warning --- Failure to follow this instruction may lead to death or serious injury.

Caution --- Failure to follow this instruction may lead to injury.

Caution --- Failure to follow this instruction may lead to machine damage.

◼ Lending the Machine to a Third Party

⚫ Pass this Operation Manual/Safety Manual together with the machine and instruct the user to carefully read

these manuals to understand the contents and get the hang of handling the machine, so that your friendly

gesture will not turn into a tragedy. Same thing goes with your family. In particular, spend time explaining the

prohibited items.

Page 3

3

◼ International Units

⚫ This Operation Manual uses the units based on the new measuring system. Carefully read the table below to

understand the conversion values before use.

Conversion Table

Item

Unit indication

under new measuring system

Conversion

Conventional

unit indication

Remarks

Area

[m2] (square meters)

[a] (are)

[ha] (hectare)

10000 [m2]

= 1 [ha] = 100 [a]

= 10 tanbu = 3,000 tsubo

[a] (are)

[ha] (hectare)

Tsubo, chobu, hanpo

*[1]

Rotational

speed

[rpm] (revolutions per minute)

[min-1] (per minute)

1 [min-1] = 1 [rpm]

[rpm]

*[2]

Force

[N] (Newton)

9.8 [N] = 1 [kgf]

[kgf] (weight kilogram)

Moment of

force

[Nm] (Newton meter)

9.8 [Nm] = 1 [kgfm]

[kgfm]

Pressure

[Pa] (Pascal)

0.98 [MPa]

= 10 [kgf/cm2]

9.8 [Pa] = 1 [mmH2O]

[kgf/cm2]

[mmH2O]

Work ratio/

drive power

[W] (watt)

735.5 [W] = 1 [PS]

9.8 [W] = 1 [kgfm/s]

[PS]

[kgfm/s]

* Notes

[1] [a] and [ha] may be used to indicate land areas.

[2] The number of revolutions per unit time is indicated as “rotational speed” not as “revolutions.”

Specifications

In this Operation Manual, products of different specifications are indicted as follows. Confirm the specification of

the product you purchased to make sure you are referring to the correct product.

Table of Contents

1.

For Safe Work ..................................................................................................................................... 4

2.

Name of Each Part ..................................................................................................................................... 6

3.

Main Specifications .................................................................................................................................... 8

4.

Handling of Warning Labels ............................................................................................................... 9

5.

Name and Function of Each Device.........................................................................................................11

6.

How to Travel/Transport ...........................................................................................................................19

7.

Pest Control Work ....................................................................................................................................22

8.

Maintenance .............................................................................................................................................29

9.

Piping Diagram .........................................................................................................................................40

10.

Causes of Failures and Remedial Actions ...............................................................................................41

Page 4

4

1

For Safe Work

The precautions you must observe to ensure safe work are explained below.

Other precautions are found in the main text, accompanied by

Danger

,

Warning

,

Caution

and Caution

.

Use this machine at an inclination angle of within 5 except when entering a field or installing the machine

on a truck.

(1) Overview

Carefully read the “Operation Manual (and

operation manual of each option installed),”

“Safety Manual” and instruction of the

agrichemical used, to carry out work correctly and

safely.

Caution

If the machine is to be parked or stored, do

not place anything underneath the booms.

The booms may drop down and damage the

item underneath them

[1] When carrying out work, be sure to wear protective

gears appropriate for each work (helmet, mask and

gloves) and proper clothes.

[2] Before inspecting/servicing or repairing the

machine, stop the engine on flat ground, apply the

parking brake and remove the ignition key. Failure

to do so may cause the machine to suddenly move,

resulting in an accident.

[3] Keep non-operators (especially children) away

from the area where pest control work is

performed. Failure to do so may lead to an

accident.

[4] Exercise due caution not to pollute water supply

systems, rivers, ponds, lakes, etc.

[5] Never refuel near a fire source as it may cause fire.

Refueling while smoking is strictly prohibited.

(2) Items to Note before Operation

[1] Carefully read the Operation Manual and become

familiar with the machine operation.

[2] Apply the parking brake on flat ground and be sure

to perform startup inspection to prevent problems

during pest control work.

Maintenance, P. **

[3] Wipe clean all spilled fuel or oil. If not, fire may

occur.

[4] Dust, fuel or mud attached or deposited on the

wires, muffler and engine area may cause fire, so

inspect and clean these areas before starting the

day’s work.

(3) Starting the Engine

[1] If the machine is operated indoors, exhaust gas will

pollute the air and may cause gas poisoning. Open

the windows and doors and provide sufficient

exhaust ventilation.

[2] Before starting the engine, look around carefully

and give a cue to others indicating that the machine

“will start moving.”

Page 5

5

(4) Traveling

[1] This machine cannot travel on local road and must

be carried on a truck, etc., to the field.

[2] This machine can carry only one person. No one

except for the driver can ride the machine. Any

consequence of the machine carrying a person or

persons other than the driver will be the

responsibility of the user.

[3] Do not drive at high speed, take off suddenly,

accelerate rapidly, apply emergency braking or

make a sharp turn unless necessary.

[4] Do not carry a load exceeding the maximum

payload (reagent tank filled with water and

attachments installed). Excessive loading will not

only lead to machine damage, but it may also

cause an accident.

(5) Entering/Exiting a Field (Refer to P.**.)

[1] Enter the field at low speed by orienting the

machine vertically to the furrows.

[2] If there are large height gaps or the approach path

is soft, be sure to use footboards as you enter/exit

the field. Failure to do so may cause the machine to

tip over, creating a very dangerous situation.

[3] Maintain the approach path so that the inclination

angle of approach to the field is kept within 15

degrees.

(6) Loading/Unloading to/from a Truck

(Refer to P. **.)

[1] When loading the machine to a truck, empty the

reagent tank and drive the machine head in. When

unloading the machine, drive the machine slowly in

reverse.

[2] Use a truck whose payload is 2,000 kg or more.

[3] Move the machine slowly using anti-slip footboards

of sufficient strength, length and width (30 cm or

more).

[4] Securely hook the footboards by leaving no height

gap or misalignment on the load-carrying platform.

[5] If the engine of the machine stalls during loading or

unloading, immediately step on the brake pedal

and then gradually release the brake to lower the

machine onto the road.

[6] Choose flat ground and load/unload the machine in

the presence of/with guidance from the assistant.

(7) Chocking the Tires

Prepare concrete blocks, wooden blocks or other

objects that can be used to chock the tires so that the

machine can be parked safely.

Agricultural

15 degrees

Approach path

Field

Concrete block

Wooden block

10 cm or more

15 cm or more

10 cm or

more

Page 6

6

2

Name of Each Part

(1) External View

(2) Driving Devices

Work lamp

(optional)

Right boom

Steering wheel

Seat

Reagent tank lid

Reagent tank

Hood

Boom receiver

Fuel tank

Steps

Left boom

Floor

Auxiliary shift lever

2-4WS selector switch

4WS indication lamp

HST lever

2WS indication lamp

Work lamp switch

(optional)

Fuse box

Fuel level gauge

Page 7

7

Standard accessories

Name

Part number

Quantity

Remarks

Operation Manual

K38546

1

BSA-950LM

Hook

869758 2

Left boom cross lever switch

Throttle lever

Charge lamp

Parking brake lamp

Combination switch

Brake pedal

Differential lock pedal

Pressure adjustment dial

Water temperature

warning lamp

Oil pressure lamp

Main spray cock

Pump button

Spray cock

Glow lamp

Right boom cross

lever switch

Boom high/low switch

Right boom extension/

retraction switch

Key switch

Hour meter

Left boom extension/retraction switch

Parking brake lever

Accelerator pedal

Page 8

8

3

Main Specifications

Name

BSA-950

Category

LM

Machine dimensions *1

Overall length

(mm)

3940

Overall width

(mm)

2150

Overall height

(mm)

2400

Wheelbase

(mm)

1500

Tread

(mm)

1500

Effective ground

clearance

(mm)

800 (axle hosing)

Minimum ground

clearance

(mm)

710 (fuel tank)

Mass

(kg)

1195

Engine

Name

D1105

Type

Water-cooled 4-cycle, 3-cylinder standing diesel engine

Total displacement

(cm3)

1123

Rated output

(kW(PS)/(min-1)

15.4(20.9)/2600

Fuel tank capacity

(L)

20

Starting method

Cell starter

Traveling gears

Type 4WD・4WS (with 2-4WS selector)

Steering system Full hydraulic power steering

Shift gears

HST (variable shift), 2 auxiliary shift gears

Traveling speed

(km/h)

Moving: 0 to 11 / Spraying: 0 to 4.0

Clutch

Dry-type single plate type (interlocked with the brake pedal)

Brake (also used as

parking brake)

Wet, multi-disk, mechanical type

Tires (front/rear)

120/90-26 6PR (Air pressure: 300 kPa)

Battery

55B24R

Reagent tank capacity

(L)

850 (900 max.)

Agitation method Propeller (mechanical type)

Spray pump

Name

MS1000F

Type

Lateral quintuple piston type

Rotational speed

(rpm)

1250

Water absorption

(L/min)

100

Pressure (max.)

(MPa)

1.0 to 2.5

Pest control devices

Boom device type

Slide (powered) or open/close and up/down/high/low movements

(hydraulic power)

Horizontal control unit Trapezoid link hoist type

Nozzle type

Ceramic cone nozzle 1.6

Kirinashi nozzle N-KA-8R

Number of nozzles

(pcs)

53 (2 WAY NOZZLE)

Number of divisions

3 Spray width

(m)

15.9

Ground clearance of

nozzle

(mm)

465 to1305

*1. The dimensions assume that the booms are stored on the boom receivers.

*2. 1.6 ceramic cone Kirinashi nozzle (N-KA-8R)

Page 9

9

4

Handling of Warning Labels

* Warning labels are attached on this machine. Carefully read these labels and understand the contents before

commencing work. Peruse the following information provided on the labels.

Warning

⚫ Constantly remove soiling and mud over the

labels so that the information provided on

them remains clearly visible.

⚫ Replace damaged warning labels with new

ones.

⚫ If a part on which a warning label is attached

has been replaced, be sure to attach a new

label on the new part at the same location.

[1] Part No. 880263

[2] Part No. 880271

[3] Part No. 880258

[4] Part No. 880260

[5] Part No. 880259

[5]

[1] [2] [3] [4]

Page 10

10

[6] Part No. 880264

[7] Part No. 880268

[6] Part No. 866073

[9] Part No. 880270

[10] Part No. 880261

[11] Part No. 880269

[12] Part No. 880265

[13] Part No. 869745

[10] [11] [13] [12]

[6] [7] [8] [9]

Page 11

11

5

Name and Function of Each Device

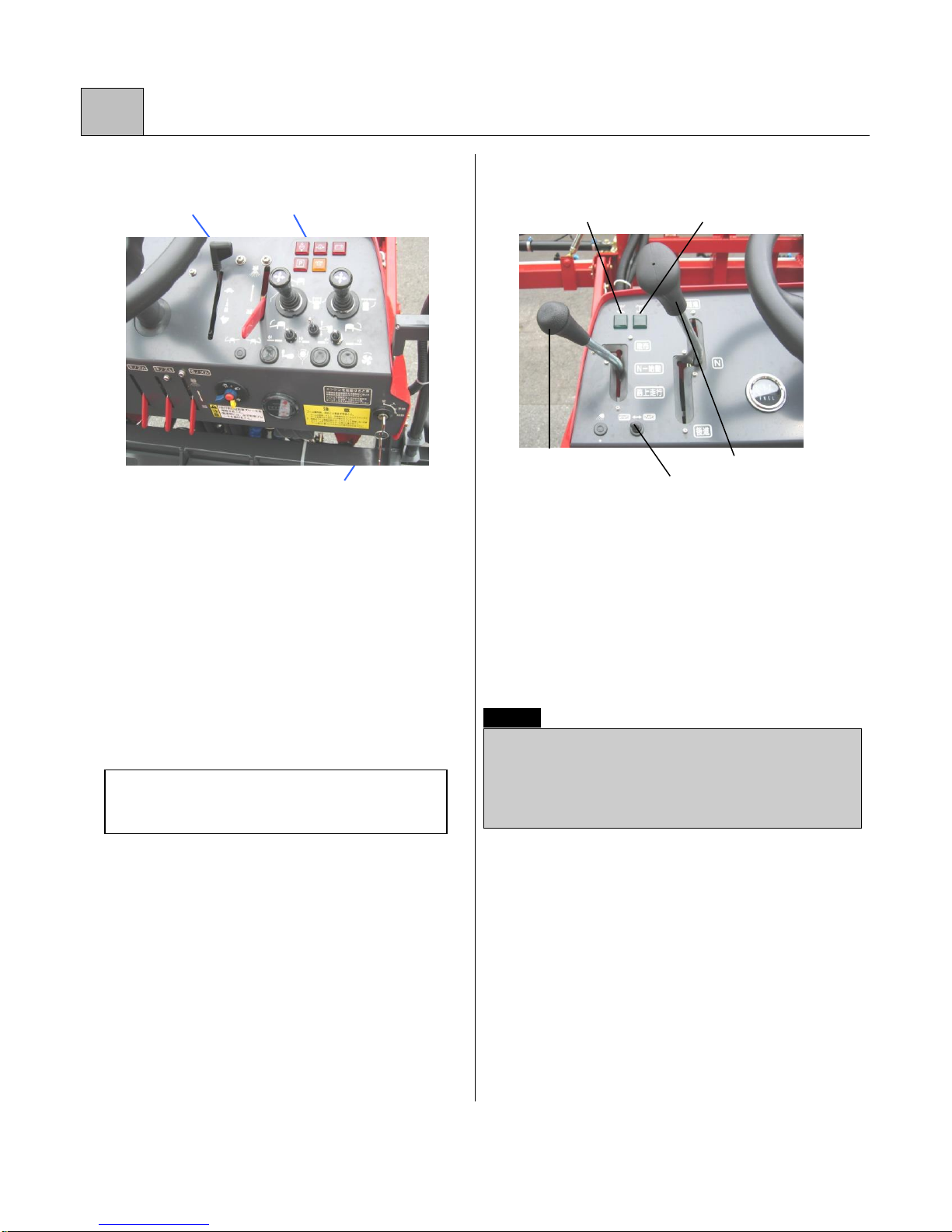

◼ Relating to Engine Operation

(1) Key Switch

“OFF” --- The engine is stopped.

Current does not flow. The ignition key is

inserted and removed in this position.

“ON” --- The engine is turning.

Current flows to each electrical component.

“GL” --- The glow lamp turns on. When the hand is

released in this position, the switch will

automatically return to the “ON” position.

“ST” --- The cell motor turns to start the engine.

When the engine has started, immediately

release the hand. When the hand is

released, the switch will automatically return

to the “ON” position.

(2) Throttle Lever

Pull the throttle lever toward you to turn the engine at

high speed, or tilt it forward for low speed operation.

When traveling on the machine, use the accelerator

pedal to adjust the engine speed.

◼ Relating to Traveling Operation

(1) HST Lever

Tilt the lever forward from the “N” position to move

forward, or tilt it rearward to move in reverse. The more

you tilt the lever, the higher the machine speed

becomes.

(2) Auxiliary Shift Lever

There are two shift gears: one for high speed and the

other for low speed. To start the engine, put the

auxiliary shift lever in the “N – Start” position.

Caution

⚫ To perform auxiliary shift operation, put the

HST lever in the “N” position and be sure to

stop the machine. If the auxiliary shift lever is

operated before the machine stops completely,

the auxiliary transmission may be damaged.

Glow lamp

Throttle lever

Key switch

⚫ Because of the starting safety device, the

engine will not start unless the auxiliary

shift lever is put in the “N – Start” position.

4WS indication lamp

Auxiliary shift lever

2WS indication lamp

HST lever

2-4WS selector switch

Page 12

12

(3) 2-4 WS Selector Switch

While the lamp is on, the selected steering state is

indicated. Move the selector switch to the opposite side

to switch the steering state. While the selector is being

switched, the lamp will blink and the buzzer will sound.

Caution

Strictly adhere to the instructions below when

operating the 4WS selector switch in order to

prevent collision, fall or tip-over.

1. When operating the switch, be sure to park the

machine on a flat ground first. Operating the

switch while traveling may distract the driver,

causing a collision or tip-over.

2. Set the steering wheel in the straight forward

position before operating the switch.

3. If the switch is operated with the tires not set

in the straight forward position, the lamp will

blink and the buzzer will sound while the 2WS

and 4WS switches are being toggled. When

the switch is being toggled, do not travel, but

set the tires in the straight forward position,

and confirm that the lamp turns on and the

buzzer stops.

4. Use 2WS while traveling.

5. If you operate the steering wheel as if the 2WS

switch is selected after it is switched to 4WS,

it is dangerous as a greater than anticipated

change in the posture may occur. Before

starting to move or travel, confirm the steering

state selected.

2WS: The machine can travel in a stable condition at

high speed, etc. This makes it easier to pull the vehicle

over to the side.

4WS: This steers the rear wheels, making it possible to

make tight turns.

(4) Differential Lock Pedal

The differential lock device allows the front and rear

tires on the left and right to be driven at the same

speed. This is useful in preventing slips. The differential

lock is actuated when the differential lock pedal is

depressed, and cancelled when the pedal is released.

Use this function in the following situations:

[1] The wheels on one side slip when going up/down

an agricultural road or going over a furrow and the

machine cannot move straight.

[2] The machine gets into an area of soft ground in the

field and encounters difficulty traveling due to

slipping wheels.

Caution

⚫ Before actuating the differential lock, be sure

to adjust the steering wheel to the

straight-moving position. Also remember not

to turn while the differential lock is actuated.

The machine may not turn in the intended

direction.

Caution

⚫ Be sure to cancel the differential lock before

turning. If the machine is turned forcibly with

the differential lock on, the drivetrain may be

damaged.

Differential lock pedal

Page 13

13

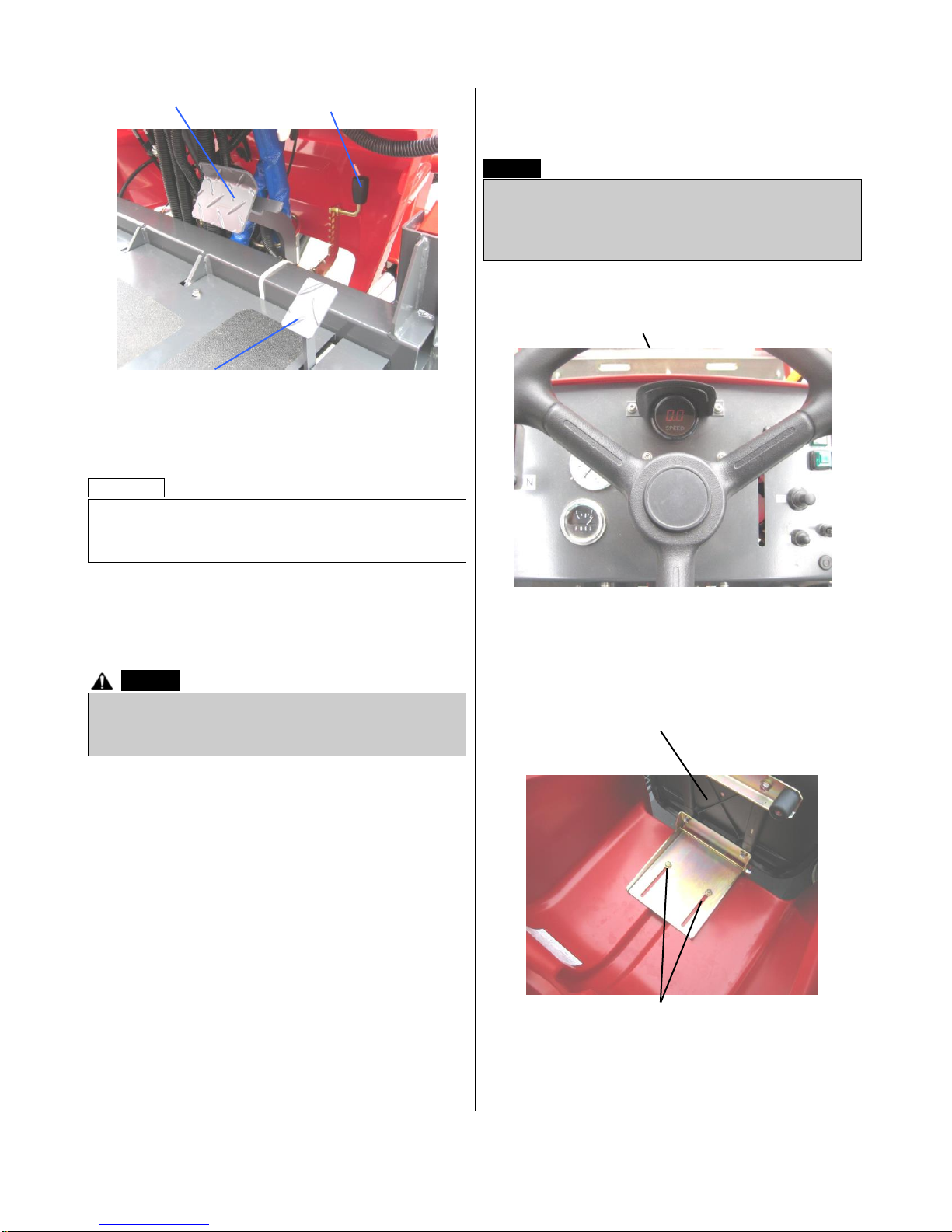

(5) Brake Pedal

Stepping on this brake applies brake to the machine.

Reference

⚫ Stepping on the brake pedal disengages the

clutch and applies the brake. To apply brake,

step on the brake pedal all the way down.

(6) Parking Brake

Depress the brake pedal fully and hook the parking

brake lever to the brake pedal. To release the brake,

depress the brake pedal fully once again.

Caution

⚫ Before leaving the machine, stop the engine

and be sure to apply the parking brake, remove

the ignition key, and chock the tires.

(7) Accelerator Pedal

While traveling, use the accelerator pedal to adjust the

engine speed. Step on the accelerator pedal to raise

the engine speed, or release it to run the engine idle.

It is interlocked with the throttle lever, and when the

throttle lever is pulled, the pedal will be automatically

set to the position where it is stepped on.

(8) Power Steering Wheel

This hydraulic steering wheel is used to turn the

machine or change its course.

Caution

⚫ Avoid static steering (turning the steering

wheel when the machine is not traveling),

because it will cause the tires, rims, etc., to

wear quickly.

(9) Speedometer

The traveling speed (km/h) is indicated.

* If the tires are slipping in a field, etc., the actual

traveling speed may differ from what is indicated by

the speedometer.

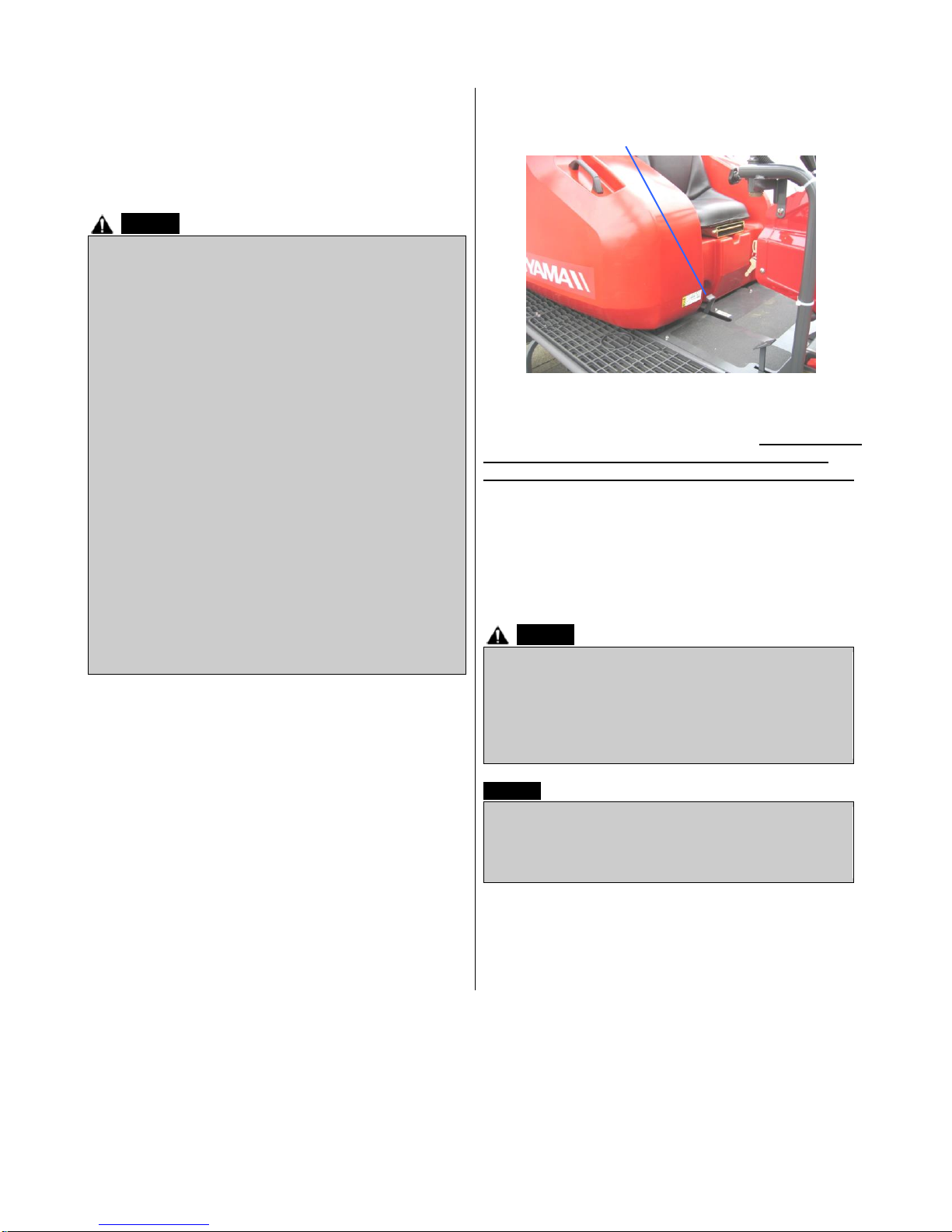

(10) Seat

You can loosen the hexagonal bolts to slide the seat

forward and backward. Once the seat position has

been adjusted, securely tighten the hexagonal bolts.

Brake pedal

Parking brake lever

Accelerator pedal

Speedometer

Seat

Hexagonal bolts

Page 14

14

(11) Combination Switch

With the key switch in the “ON” position, the light can

be turned on, the blinker can be operated, and the horn

can be sounded.

Caution

⚫ If the light is turned on for a long period of time

with the engine stopped, the battery level may

decrease and the engine may not start.

(12) Work Lamp Switch (Optional)

With the key switch in the “ON” position, move the

switch upward to turn the work lamp on, and move it

downward to turn the lamp off.

(13) Warning Lamp

⚫ Charge lamp (charge warning lamp)

This lamp turns on to warn

when a charge system error is

detected while the engine is

turning.

Caution

⚫ If this lamp turns on, stop the engine and

inspect the fan belt. If the belt is normal, have

the machine inspected by the Maruyama dealer

near you.

⚫ Oil pressure lamp (oil pressure warning lamp)

This lamp turns on to warn

when the pressure of oil

lubricating the engine interior

drops while the engine is

turning.

Caution

⚫ If this lamp turns on while the engine is turning,

immediately stop the machine in a safe place

and stop the engine, and contact the Maruyama

dealer near you.

⚫ Continuing to travel on the machine despite the

lamp remaining on may damage the engine.

⚫ The oil pressure warning lamp does not

indicate insufficiency of oil. Check the oil

amount using the oil level gauge.

Checking/adding engine oil: P. **

⚫ Water Temperature Warning Lamp

This lamp turns on to warn

when the engine is

overheated.

Caution

⚫ Never remove the radiator cap immediately

after the engine has stopped or while the

engine is turning, because it will cause burns.

Wait for the water temperature to drop, and then

put a piece of cloth, etc., over the radiator cap

and remove the cap slowly.

Caution

⚫ If this lamp turns on, move the machine to a

well-ventilated place and keep the engine idle.

When the water temperature warning lamp

turns off, stop the engine and check if the

engine oil or cooling water level is low, check

the fan belt tension, and also check the radiator

core and air cleaner for clogging. If the lamp

turns on frequently, have the machine

inspected by the Maruyama dealer near you.

Work lamp switch

Light

Blinker

Horn

Page 15

15

(14) Monitor Lamp

(operation status check indicator lamp)

⚫ Glow lamp (preheating indication)

This lamp turns on if the key

switch is in the “GL” position

when starting the engine.

It turns off once preheating is

complete.

⚫ Parking brake lamp

This is a warning lamp to

prevent the parking brake lever

from not being reset. It turns on

when the parking brake lever is

still engaged with the brake

pedal when the key switch is in

the “ON” position.

◼ Relating to Pest Control

(1) Pressure Adjustment Dial

Adjust the discharge pressure of the spray pump.

While monitoring the pressure gauge, turn the pressure

adjustment dial to a desired pressure.

(2) Pressure Gauge

The pressure adjusted with the pressure adjustment

dial is indicated.

(3) Main Spray Cock

Raising the lever causes the reagent to be sprayed

from the boom nozzle. Spraying can be stopped at

once from the left, center and right boom nozzles.

(4) Spray Cocks

Raising the lever causes reagent to be sprayed from the

boom nozzle. A desired spray location can be selected

from among the left, center and right bottom nozzles.

(5) Spray Pump Switch

Pressing the pump button turns the spray pump and

the agitator.

Spray pump switch

P

Pressure adjustment dial

Pressure gauge

Spray cocks

Main spray cock

Page 16

16

(6) Boom High/Low Switch

Turn this switch up/down to adjust the height of the

entire boom.

(7) Cross Lever Switch

Operating the lever up and down tilts the boom.

Moving the lever to the left and right opens/closes

the boom. The left and right levers can be operated

independently to perform these operations.

(8) Boom Extension/Retraction Switch

Operating the switch to the left and right

extends/retracts the boom. The left and right levers

can be operated independently to perform these

operations.

Caution

⚫ If the steering wheel is turned with the booms

stored at the lowest position, the tires will

come in contact with the booms and damage

them. Raise and store the booms at the

position where the tires do not come in

contact with the booms when the machine

travels.

⚫ Do not operate the booms while they are

secured on the boom receivers with ropes,

etc. because doing so may damage the

booms.

⚫ The switch can be operated with a small

force. Do not apply an excessive force on the

switch.

(9) Horizontal Control Unit

This maintains the booms in parallel to the field on an

uneven field, while keeping the boom shaking to the

minimum. While traveling on an incline or if the left and

right boom lengths are different, tilt the booms to keep the

booms in parallel to the field.

Reference

⚫ The control unit may not be able to sufficiently

control the machine on an extremely uneven field.

⚫ The unit cannot control the machine sufficiently if

the incline of the path exceeds 3 suddenly.

⚫ The unit does not perform the control function if

the boom on one side or both booms are closed.

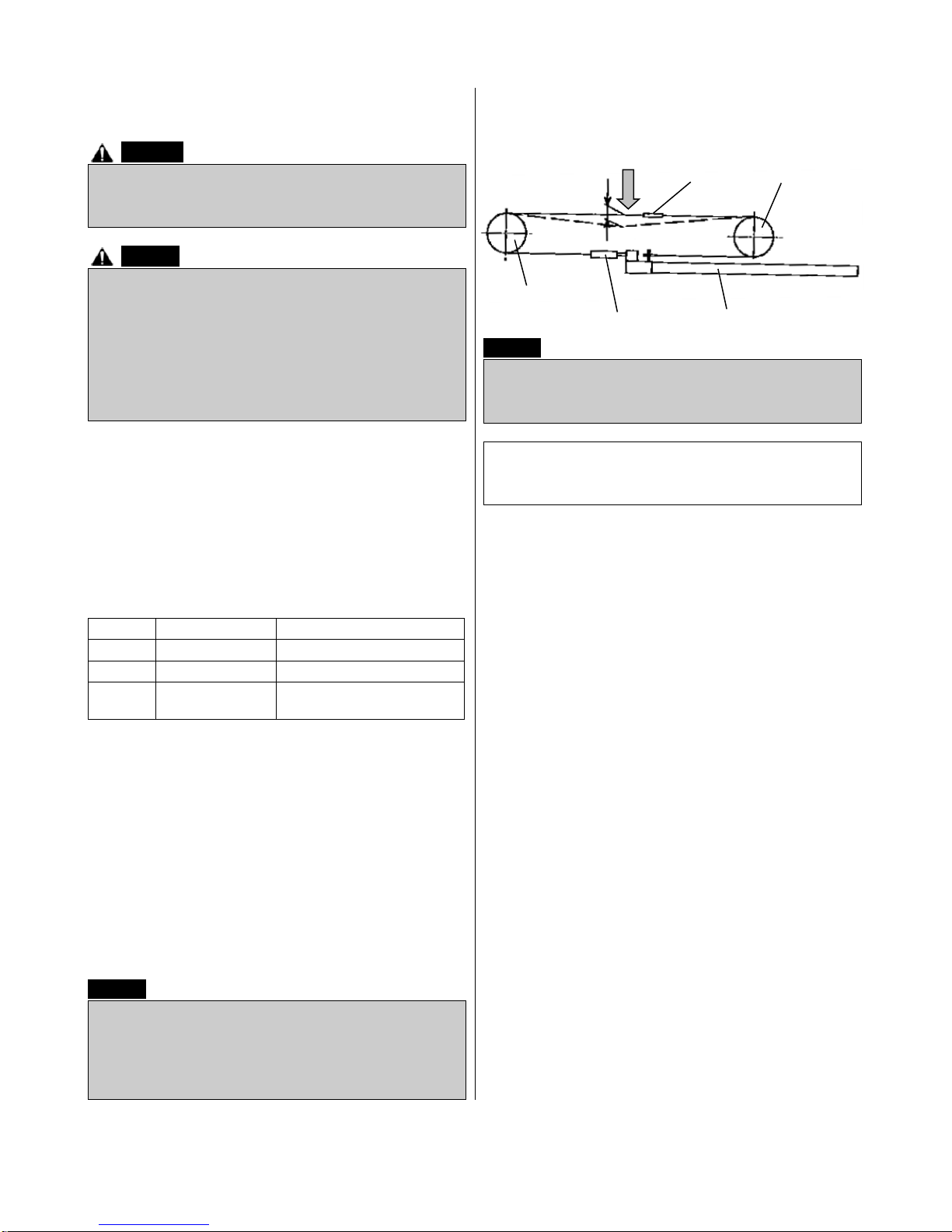

⚫ Horizontal control unit lock mechanism

To store the booms securely, lock the horizontal control

unit while traveling. With the booms open, match the

left and right boom lengths. Next, while pulling the lock

lever, turn it in the direction so that it faces down

towards the opposite side, slowly release one hand

from the lever to lock the unit. To unlock the unit,

perform the same operation in reverse order. If a boom

on one side is retracted or the left and right boom

lengths are not the same, the booms will tilt toward the

side on which the boom is longer.

Unlocked

Left cross lever switch

Right cross lever switch

Boom high/low switch

Left boom extension/

retraction switch

Right boom extension/

retraction switch

Lock lever

Page 17

17

Caution

⚫ The horizontal control unit should be locked

only when the machine travels.

⚫ Spraying with the horizontal control unit still

locked may damage the frames or booms. Be

sure to unlock the horizontal control unit when

spraying.

(10) Water Absorption Strainer/Discharge

Strainer/Water Filter Net

Caution

⚫ The water absorption strainer, the discharge

strainer, and the water filter net all filter dust,

etc., so be sure to clean them after work.

[1] Keep the three-way cock in the “Spray” position

during spraying or while the jet pump (optional) is

used.

[2] When cleaning the water absorption strainer, keep

the three-way cock in the “Water feed” position if

the reagent tank contains reagent.

[3] To discharge the remaining liquid from the reagent

tank, first put the three-way cock in the “Drain”

position. After draining the liquid, put it in the

“Spray” position, remove the cap on the water

absorption strainer, and discharge the remaining

liquid from the strainer.

[4] Open the cock located at the bottom of the

discharge strainer to discharge the soiled liquid

from inside the strainer. If the strainer is very dirty,

remove the discharge strainer and clean the net

inside.

(11) Boom Receiver

Keep the left and right booms on the boom receivers

while traveling or during transport.

Caution

⚫ Do not operate the booms while the booms are

secured on the boom receivers with ropes, etc.,

because doing so may damage the booms.

Boom receiver

Water absorption strainer

Three-way cock

Water feeding hose

connecting joint

(also used for the drain)

Spray

Drain

Water feed

Water filter net

Page 18

18

◼ Other

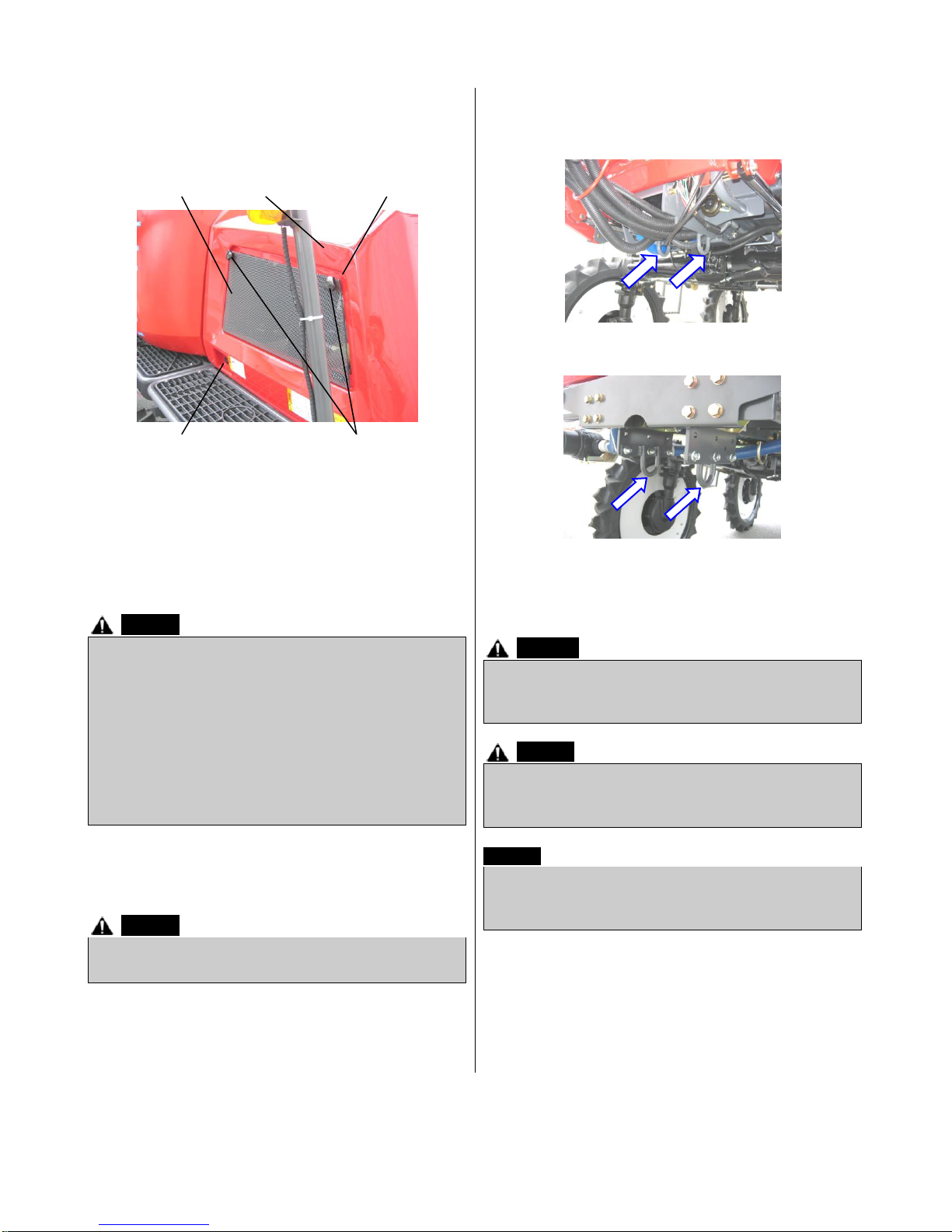

(1) How to Install/Remove the Side Cover and the

Hood

[1] To remove the hood, remove the two knob bolts A

on the left and right, and hold it at the left and right

latch positions to pull it out.

[2] To remove the side cover, loosen the four knob

bolts B on the left and right, and pull it toward you.

[3] Perform the same steps in the reverse order to

install the cover or hood.

Caution

⚫ Never open the hood or the side cover while the

engine is turning. Since the rotating parts are

exposed, injury accidents may occur.

⚫ Do not touch the muffler while hot. It may cause

burns.

⚫ After installing the side cover, be sure to

tighten the knob bolts strongly. If the knob

bolts are not tightened sufficiently, they may

detach and fall during transport, causing

accidents.

(2) Tires

The wheelbase can be adjusted by reversing the tires

or adding spacers (optional).

Caution

⚫ Never use spacers other than those provided as

options.

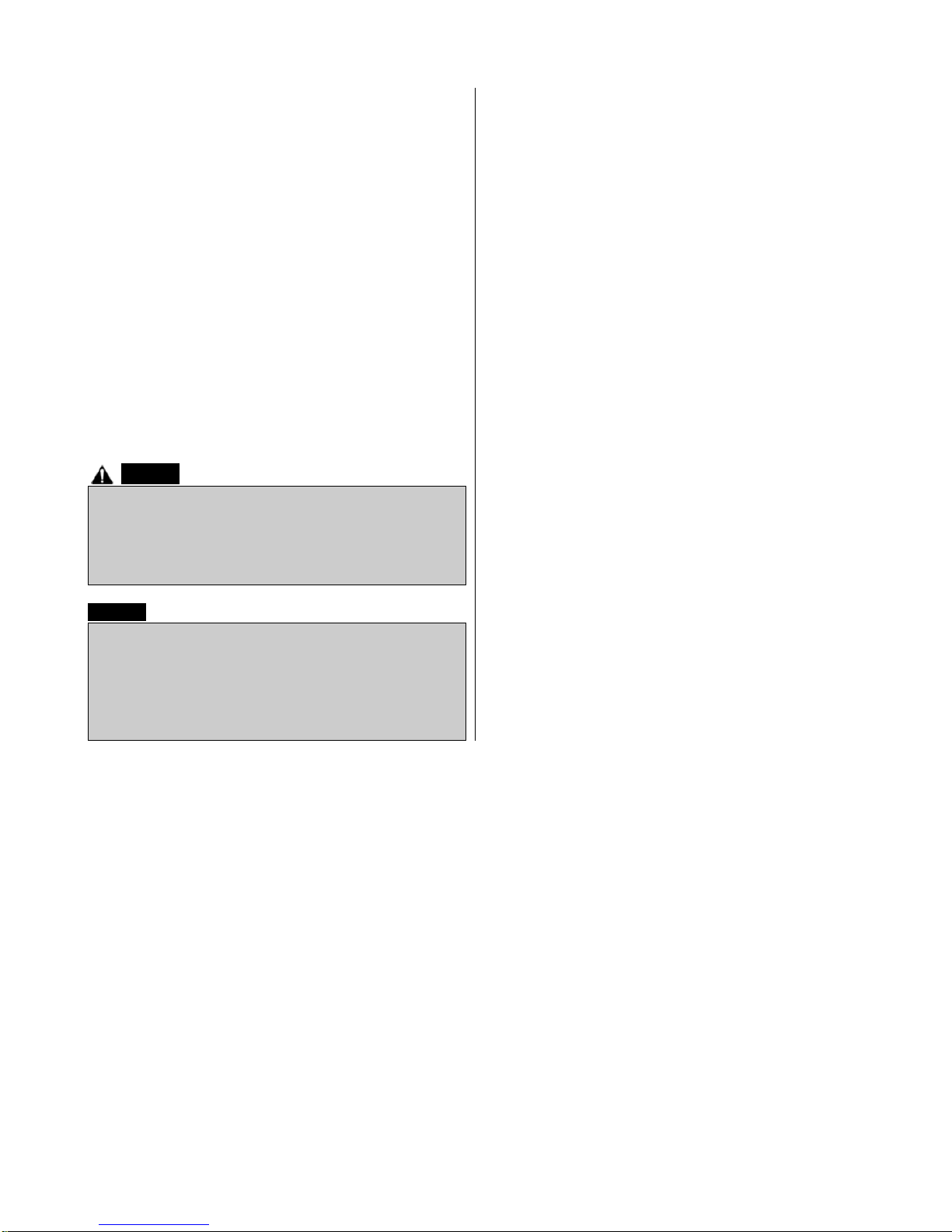

(3) Towing Hooks

[Front of Frame]

[Rear of Frame]

If the machine gets stack in a field, use these hooks to

pull the machine forward/backward. When doing this,

keep the booms at the top positions.

Warning

⚫ Do not use the towing hooks to tow other

machine, etc. It may cause the machine to tip

over.

Caution

⚫ Never pull the towing hooks sideways. The

hooks may detach easily and also cause the

machine to tip over.

Caution

⚫ Never pass ropes, etc., over the boom devices

and pull the ropes. The machine will be

damaged.

Side cover

Hood

Latch position

Knob bolt A

Knob bolt B

Page 19

19

6

How to Travel/Transport

◼ How to Start/Stop the Engine

(1) How to Start

Warning

⚫ To ensure safety, apply the parking brake, put

the auxiliary shift lever in the “N – Start”

position and put the HST lever in the “N”

position before starting the engine.

⚫ Provide sufficient ventilation when starting the

engine indoors. Failure to do so may cause

exhaust gas poisoning.

Caution

⚫ Before starting the engine, check the

surrounding areas to ensure safety and also

confirm that the cover is closed.

Caution

⚫ Once the engine is started, do not apply load but

simply warm up the engine for approx. 5 minutes

so as to spread oil to each metal area fully. Take

note that, if load is applied immediately after the

engine is started, breakdown may occur due to

seizure, damage, etc.

Start the engine from the driver seat after giving a cue

to people around the machine and also checking the

surroundings to ensure safety.

[1] Apply the parking brake.

[2] Put the HST lever in the “N” position and auxiliary

shift lever in the “N – Start” position.

[3] Insert the ignition key in the key switch.

[4] Tilt the throttle lever forward for “low speed”

operation.

[5] Turn the key switch to the “GL” position and keep it

in this position until the glow lamp turns off.

[6] Turn the key switch key to the “ST” position. Once

the engine has started, release the switch. The key

switch will automatically return to the “ON” position.

[7] Check each warning lamp to confirm that the engine

is normal. If any warning lamp is on, immediately

stop the engine and take an appropriate measure. If

you hear abnormal noise different from what you

hear every day, stop the engine and investigate the

cause. If the cause cannot be identified, contact

your Maruyama dealer.

[8] Return the throttle lever to the “low speed” side, and

warm up the engine for 5 minutes before

commencing work.

Warning

⚫ Warm up the engine outdoors to prevent

exhaust gas poisoning.

Caution

⚫ Be sure to apply the parking brake and keep

your eyes on the machine while the engine is

warming up.

⚫ If the engine does not start with the first try on a

cold day, etc., repeat preheating and try starting

the engine. Do not turn the cell motor for more

than 10 to 15 seconds. Before restarting the

engine, wait for 30 seconds to restore the

battery voltage.

⚫ Do not turn the key switch to the “ST” position

while the engine is turning.

⚫ The engine is still cold immediately after the

start, so do not rev up the engine or raise the

engine speed unnecessarily. It may cause

breakdown.

⚫ Check the exhaust condition for abnormality

and if any abnormality is found, immediately

stop the engine and change fuel or oil, or

contact your Maruyama dealer.

(2) How to Stop

[1] Push the throttle lever forward to lower the engine

speed.

[2] Let the engine operate at the low speed for approx.

5 minutes to cool down.

[3] Turn the key switch to the “OFF” position.

(3) Break-In Operation

Caution

⚫ How the machine is handled when new (during

initial 50 hours) affects the life and performance

of the machine. In particular, pay attention to

the items specified below during this period.

[1] Fully warm up the engine before commencing work.

[2] Change oils according the Oil Change Table after

initial 50 hours of operation. (Refer to P. **.)

Page 20

20

◼ How to Travel

Warning

⚫ This machine cannot travel on local road and

must be carried on a truck, etc., to a field.

Caution

⚫ When taking off, check the surroundings to

ensure safety.

⚫ Before leaving the machine, be sure to apply

the parking brake, stop the engine and remove

the ignition key. Otherwise, an unexpected

person may touch the machine when no one is

around and cause an accident.

⚫ The brake pedal is also used for the traveling

clutch. If the auxiliary shift lever is in a position

other then “N” and the HST lever is set to the

forward or rearward position, it is dangerous to

release the pedal suddenly as the machine may

take off suddenly. Be sure to slowly release the

pedal.

(1) Taking Off

[1] Put the HST lever in the “N” position and auxiliary

shift lever in the required position.

[2] Release the parking brake.

[3] Gradually tilt the HST lever in the required position

to take off.

Caution

⚫ When moving rearward, thorough check not

only the rear, but also the left and right and be

careful not to let the booms contact people or

obstacles.

⚫ Operate the HST lever slowly. Quick operation

may cause the machine to take off or stop

suddenly, creating a dangerous situation.

⚫ While traveling, do not keep your foot on the

brake pedal. Doing so may shorten the service

life of the clutch.

(2) How to Travel

Caution

⚫ Do not carry anyone other than the driver, or

objects.

⚫ Wear a helmet to ensure safety.

⚫ Exercise due caution and lower the speed when

going through a narrow agricultural land or on a

road with shoulders, Trim weeds to expose the

road shoulders.

⚫ Adjust the traveling speed using the HST lever,

the throttle lever, and the accelerator pedal.

⚫ Drive according to the traffic rules even on

private roads or on agricultural land.

Caution

⚫ When traveling, be sure to store the booms on

the boom receivers. If the booms are floating on

the boom receivers, the booms will be damaged

as a result of traveling.

(3) How to Stop

[1] Slowly return the HST lever to the “N” position to

stop the machine.

[2] Tilt the throttle lever forward to lower the engine

speed.

Caution

⚫ Before leaving the machine, remove the ignition

key to ensure safety.

⚫ If you step on the brake pedal to stop the

machine while traveling at high speed, be sure

to return the HST lever to the “N” position.

Releasing the brake pedal without returning the

HST lever to “N” may cause the machine to

jump out suddenly.

(4) Auxiliary Shift Operation

[1] Stop the machine fully.

[2] Shift the auxiliary shift lever to the required position.

Caution

⚫ Do not perform shift operation while traveling.

It may cause breakdown.

(5) How to Park

[1] Apply the parking brake.

[2] Stop the engine.

[3] Set the fuel cock to “Close.”

[4] Chock the wheels.

Caution

⚫ When parking, stop the engine, apply both the

parking brake and chocks, and be sure to

remove the ignition key.

Page 21

21

◼ How to Load/Unload to/from a Truck

Loading/unloading the machine to/from a truck involves

great danger. Observe the following instructions and

exercise due caution to safety when loading/unloading

the machine to/from a truck.

Warning

⚫ To load/unload the machine, select flat ground

where the footboards will not tilt due to the

weight of the machine in the presence of/with

guidance from the assistant. Also, keep people

away from the machine.

⚫ The guiding person must not stand immediately

in front of or at the back of the machine.

⚫ Load/unload the machine when the reagent tank

is empty.

⚫ Use anti-slip, hook-type footboards of sufficient

strength, length and width.

⚫ Securely hook the footboards by leaving no

height gap or misalignment on the load-carrying

platform.

⚫ Suddenly turning the steering wheel or

operating the HST lever while traveling over

footboards may derail the wheels and cause the

machine to fall from the footboards. To change

the direction, first return to the ground or onto

the load-carrying platform, change the

direction, and then resume going up/down the

footboards.

⚫ To load/unload, be sure to set the machine to

2WS. Operating the machine in 4WS may cause

the machine to fall and is very dangerous.

Length

At least four times the load-carrying

platform of the machine

Width

30 cm or more

Quantity

2 pcs

Strength

Each board should be able to withstand

at least 750 kg of mass.

[1] Use a truck whose maximum payload is 2,000 kg or

more.

[2] Put the shift lever on the truck in the “1st” or “R”

position, pull the parking brake, and apply chocks.

[3] Stop right before the footboards, and make sure

that the front and rear tires on both left and right are

in parallel with the footboards, aligning the center of

each to the center of the footboards. Then,

load/unload the machine at a right angle to the

slope.

[4] Empty the reagent tank, and drive forward to load

the machine and drive rearward to unload. While on

the footboards, check the positions of the wheels

and the footboards, and move at a very low speed

by tilting the HST lever forward slightly with the

auxiliary shift lever in the spray position.

[5] If the engine of the machine stalls during loading or

unloading, immediately step on the brake pedal and

then gradually release the brake to lower the

machine onto the road.

[6] Once the machine has been loaded onto the truck,

apply the parking brake.

[7] During transport, secure the booms to the boom

receivers with ropes, etc., to prevent the booms

from opening.

[8] Pass ropes at the front and rear towing hooks to

secure the machine.

[9] Be sure to close the gate of the truck.

Caution

⚫ If ropes are passed at positions other than the

towing hooks, the machine may be damaged.

⚫ When securing the machine to the truck, do not

tighten the wire ropes with an excessive load

exceeding 4900 N (500 kg)..

⚫ Do not operate the booms while they are

secured to the boom receivers with ropes, etc.,

because the booms may be damaged.

15 degrees

Guiding personal

Flat ground

Chocks

Footboard

Page 22

22

7

Pest Control Work

◼ How to Enter/Exit a Field

Pay due attention when entering a field from road.

Warning

⚫ Enter/exit a field at a very slow speed by tilting

the HST lever forward slightly, with the auxiliary

shift lever in the spray position. When entering,

also orient the machine perpendicular to the

furrows. If the machine is diagonal, it may tilt

sideways and tip over, causing an accident.

⚫ Maintain the approach path so that the

inclination angle of approach to the field is kept

within 15 degrees.

⚫ If the approach path to the field is soft, or the

inclination angle is 15 degrees or more, be sure

to use footboards to keep the inclination angle

within 15 degrees.

* If the length of the approach path is at least four

times the height of the road from the field, the

inclination angle is within 15 degrees.

⚫ When going over a furrow, be sure to approach

by orienting the machine perpendicular to the

furrow and use footboards whenever possible.

Move slowly with the auxiliary shift lever in the

spray position.

Agricultural

road

Approach

path

Furrow

Furrow

15 degrees

At least four

times the height

Height

Furrow pan

Agricultural

Footboard

Page 23

23

◼ How to Feed Water

Warning

⚫ Never feed water directly from a drinking water

source or any lake or pond used for aquatic

farming.

(1) Move the three-way cock in the “Spray” position

and add the required amount of water in the

reagent tank.

* If no water supply facility is available, a spray pump

water feeding hose or a jet pump (optional) would be

useful.

(2) How to Operate the Spray Pump Water Feeding

Hose

[1] Connect the spray pump water feeding hose.

Spray pump water feeding hose

[2] Open the lid of the reagent tank.

[3] Throw the strainer end of the spray pump water

feeding hose into the water source.

[4] Press the spray pump switch and confirm that the

water inside the reagent tank is circulating. At this

point, set the throttle lever in the idling position.

[5] Set the three-way cock in the “Water feed” position.

[6] Once the water feeding begins, pull the throttle

lever fully to set the engine to a normal speed.

[7] Using the reagent tank water gauge as the

guideline, when the tank is filled with the required

amount of water for spraying, return the throttle

lever to the idling position, set the three-way cock

to the “Spray” position, and then press the spray

pump button to stop the water feeding.

[8] Disconnect the spray pump water feeding hose.

Caution

⚫ Be sure to add priming water when feeding

water. If the idling lasts too long while feeding

water, the spray pump may be damaged.

Supplement

⚫ Use all of the reagent in the tank first before

adding water. When feeding water when the

reagent tank still has residual liquid, use a jet

pump (optional) or another water feeding

device.

⚫ Exercise caution as a small amount of residual

water will come out from the pipe when

disconnecting the spray pump water feeding

hose.

(3) How to Operate the Jet Pump

[1] Prime around 20 L of water into the reagent tank.

[2] Connect the pipe from the jet pump and open the

cock.

[3] Throw the strainer end of the jet pump into the

water source and insert the opposite end to the

water inlet of the reagent tank.

[4] Close the spray cock fully.

[5] Put the throttle lever in the idling position and press

the spray pump switch.

[6] Pull the throttle lever and set the engine to the

medium speed.

[7] Confirm that all spray cocks are closed, and raise

the main spray cock lever to increase the pressure.

[8] Operate the pressure adjustment dial to set the

spray pressure to 2 to 2.5 MPa.

[9] Once the required amount for spraying has been

added, close the jet pump cock.

[10] Lower the main spray cock lever, return the throttle

lever to the idling position, press the spray pump

switch to stop the pump, and disconnect the jet

pump.

Three-way cock

Water feeding hose

connecting joint

(also used for the drain)

Spray

Drain

Water feed

Page 24

24

◼ Reagent Preparation and Handling

(1) Reagent Preparation

[1] Before preparing the reagent, check the spray

condition with water.

(Refer to P.**.)

[2] Prepare only the required amount using a dedicated

container.

[3] Dissolve the water-dispersible powder well with a

small amount of water and then add the diluted

powder.

[4] Confirm that the main spray cock and spray cock

are in the “Closed” position and the liquid feed valve

is “Open,” and then press the spray pump switch.

The spray pump will actuate and agitation will start

in the reagent tank at the same time.

[5] Put the reagent in the reagent tank by making sure

it does not spill out of the tank, and agitate the

reagent fully.

Caution

⚫ The spray pump and jet agitation are

interlocked. Once the spray pump stops, jet

agitation also stops. Do not stop the spray

pump while reagent remains in the tank,

because chemical damage may occur.

Caution

⚫ Carefully read the operation manual of the

applicable reagent and use the reagent

correctly.

⚫ Be sure to use the water filter net and when the

spraying is over, clean the net together with the

water absorption strainer/discharge strainer.

Page 25

25

◼ Spray Inspection

(1) Opening the Spray Cock and Checking the

Spray Condition

[1] Inspect the nozzle for clogging due to dust, etc.

[2] Check the open/close condition of the main spray

cock and each spray cock (left nozzle, center

nozzle and right nozzle).

⚫ Long hours of use causes the nozzle plate to wear

and discharge flow rate to increase. When this

happens, replace the nozzle plate.

⚫ Types and quantities of standard factory-set nozzles

[Other than J or L type]

Left boom

Ceramic cone

nozzle

(1.6)

Kirinashi

nozzle

N-KA-8R

23 pcs

Center boom

7 pcs

Right boom

23 pcs

Total

53 pcs

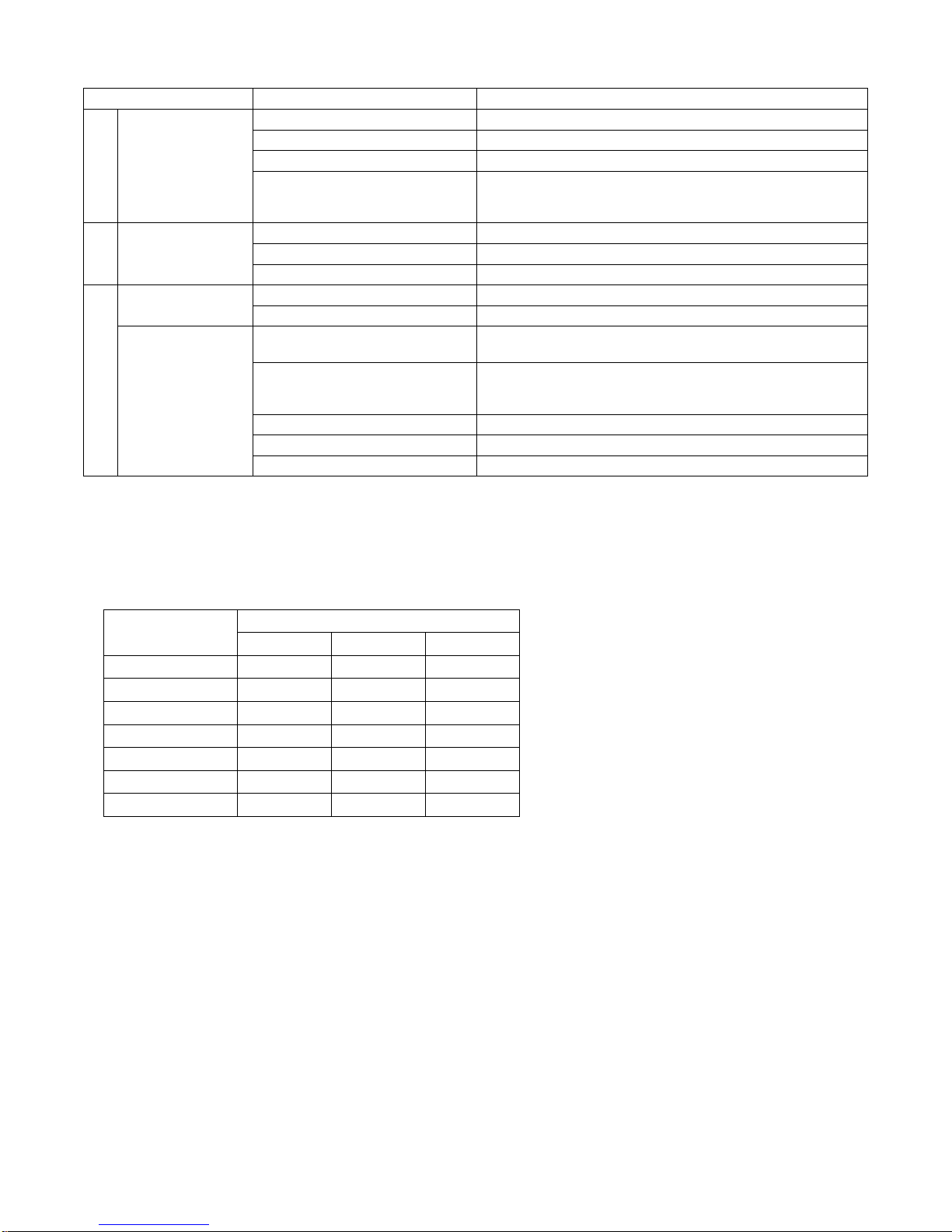

⚫ Table of nozzle discharge flow rates (per nozzle)

Ceramic cone nozzle (L/min)

1.0 MPa

1.5 MPa

2.0 MPa

1.0

0.53

0.66

0.77

1.1

0.60

0.73

0.85

1.2

0.66

0.82

0.96

1.3

0.73

0.89

1.05

1.4

0.78

0.98

1.12

1.5

0.86

1.09

1.28

1.6

0.96

1.20

1.39

Caution

⚫ Be sure to use water when inspecting the spray

condition.

Caution

⚫ Do not switch between the two-way and

three-way switch nozzles while spraying. Doing

so may damage the switch nozzle.

⚫ Turn the two- or three-way switch nozzle to the

right to toggle.

The figure above illustrates an optional three-way

switch nozzle type.

Assemble with the

discharge mark

facing downward.

Rice shower nozzle

Strainer (80 mesh)

Triple-cut gasket

Cap

Nozzle board

Gasket

Tang washer

Gasket

Gasket

Triple-cut gasket

Gasket

O-ring

Double-nozzle type

Page 26

26

◼ Spray Plan

Warning

⚫ Make the spray planning so that there won’t be

any chemical left.

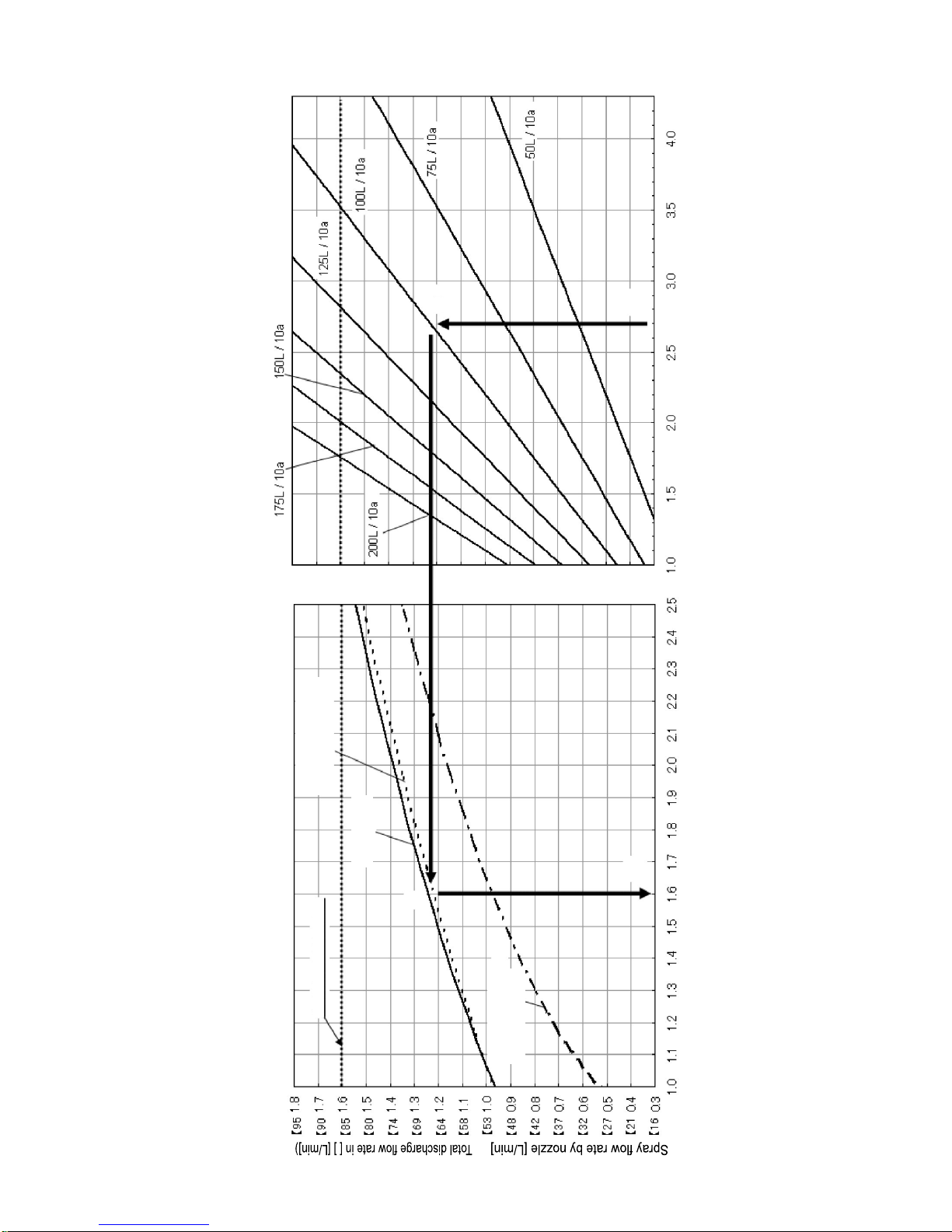

(1) Spray Planning

In spray planning, determine the spray amount per unit

area (spray amount per 10 a) first, and then select the

spray speed and obtain the nozzle pressure. The

nozzle pressure can be obtained using quick

calculation diagrams.

(2) How to Use the Quick Calculation Diagrams

You can use the quick calculation diagrams to obtain

the nozzle pressure with ease.

“Example”

[1] Spray speed: 2.7 km/h

[2] Spray amount: 100 L per 10 a

[3] Use a standard cone (ceramic) 1.6 nozzle.

[4] From the quick calculation diagrams, the nozzle

pressure is obtained as 1.6 (MPa).

Supplement

The quick calculation diagram assumes a tire

slip factor of 10% for the boom sprayer, taking

the nozzle loss rate, etc. into account.

Depending on the conditions of the field,

however, the tire slip factor of the boom sprayer

may change. In this case, the slip factor must be

corrected.

Depending on the state of the field, the tire slip factor

may vary and the spray speed may deviate, in which

case the nozzle spray amount must be set according to

these different slip factor/spray speed.

For more accurate spraying measure the actual slip

factor in the field.

⚫ Rough guide for slip factor

5% --- General crop field where the depth to the

furrow pan is approx. 10 cm

10% --- Field where the depth to the furrow pan is

approx. 15 to 20 cm (where a ride-on rice

planting machine can be used without

problems)

15% --- Field where the depth to the furrow pan is

approx. 20 to 25 cm

* Take note that the machine may not be able to travel

in a field where the depth to the furrow pan is 25 cm

or more. Also remember that the machine can travel

more smoothly when the field is filled with water.

Caution

⚫ When spraying in a field of a higher slip factor

(greater depth to the furrow pan), reduce the

amount of water added to the tank.

⚫ Adjust the nozzle pressure within a range of 1.0

to 2.5 MPa.

Page 27

27

Nozzle pressure [MPa]

Quick Calculation Diagrams

[3]

[4]

1.6 L/min must not be exceeded.

Eco Shower B08

Kirinashi N

-KA-8R

Double

-nozzle

type 1.6

Cone 1.6

[1]

[2]

Spray speed [km/h]

Page 28

28

◼ Spray Method

Warning

⚫ Wear clothes that properly fit your body.

Prepare protective clothes, pest control mask,

protective glasses, rubber gloves, work shoes,

etc., and dress safely during work.

[1] Spray safely using a method appropriate for the

terrain and field condition.

[2] The person performing spraying should wear

protective gears for agrichemical spraying (such as

a pest control mask, protective glasses, boots,

rubber gloves, work uniform and helmet) to prevent

the reagent from coming in direct contact with the

body.

[3] Whenever possible, spray early in the morning or in

the event when there is no wind.

[4] Do not enter the areas where agrichemical has

already been sprayed.

[5] Keep only the required amount of spray agent in

the reagent tank to prevent leftovers.

[6] Check the applicable spray amount, spray pressure

and traveling speed beforehand.

[7] Remove obstacles from the traveling path

beforehand and make preparations to ensure safe

traveling, and provide wide enough turning areas

so that the machine can turn without problems.

◼ Spraying

[1] Press the spray pump switch to operate the spray

pump. The agitator will turn at the same time.

[2] Pull the throttle lever fully to set the engine to a

normal speed.

[3] Check if the reagent has been agitated fully.

[4] Adjust the pressure using the pressure adjustment

dial. Since the pressure when the spray cock fully

closed is different from the pressure during

spraying, adjust the pressure once again to a

desired level during spraying.

[5] Open the booms. Extend/retract the booms and

align the spraying width with the ground.

[6] Put the auxiliary shift lever in the spray position.

[7] Open the spray cock and slowly tilt the HST lever in

the moving direction until a desired speed is

achieved. Thereafter, open/close the spray cock to

switch between spraying and stopped modes.

[8] When the spraying is over, lower the engine speed

and press the spray pump button to stop the spray

pump.

◼ After Spraying

[1] Remove the cap on the water absorption strainer

and collect the remaining liquid.

[2] Open the reagent tank lid and remove the water

filter net, and wash the net together with the water

absorption strainer.

[3] Install the water absorption strainer/water filter net

once again, add around 100 L of freshwater in the

reagent tank, close the reagent tank lid, and

operate the spray pump.

[4] Spray freshwater from the nozzle to perform

cleaning of pipe interior.

[5] When the reagent tank becomes empty, run the

spray pump idle for approx. 30 seconds with the

engine running at low speed, to drain water from the

tank.

[6] Stop the main spray cock, idle the spray pump for

30 seconds with the engine running at a low speed

to discharge the water from inside.

[7] Remove the water absorption strainer and collect

the remaining liquid.

Caution

⚫ Do not perform cleaning while the tank lid is

open. The reagent may splash and scatter.

Page 29

29

8

Maintenance

◼ Maintenance and Inspection (Inspection and Servicing Methods)

So that this machine can be used safely, perform the necessary periodic servicing based on the methods

explained here.

The inspection and servicing methods are divided into “Startup inspection” and “Period inspection.” Applicable

methods are explained under each grouping.

Caution

⚫ Before performing inspection and servicing, be sure to stop the engine, apply the parking brake,

remove the ignition key, and disconnect the negative terminal end of the battery cable from the battery.

⚫ If any inspection or servicing item requires the engine to remain running, do not perform such item on

your own, but always contact the service personnel at your Maruyama dealer instead.

⚫ Dispose of the battery, oils, coolant, etc., properly after consulting your Maruyama dealer, etc.

Disposing of such items on land or in river may be punishable by law.

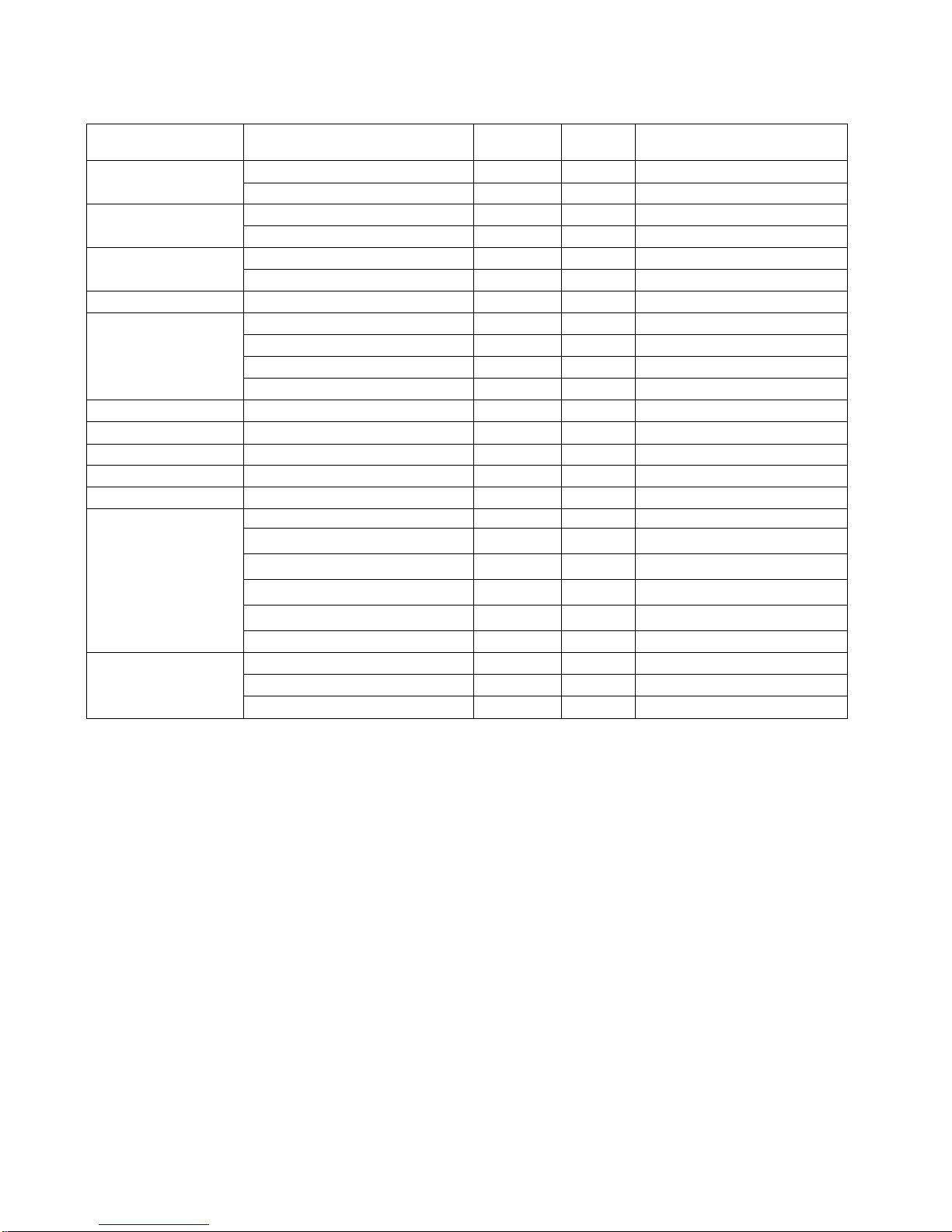

Periodic Inspection Standards

1. The applicable inspection timing is indicated by .

2. The timing of initial inspection is indicated by *.

Inspection item

Inspection timing

Judgment

criterion

Start of

work

Every

6 months

Every

12 months

Hours

Steering operation

Steering wheel handle

Play, looseness, rattling

*50

Operating feel

*50

Rods and arms

Looseness, rattling, damage

*50

Knuckle

Rattling of joint

Steering device

Wheel, alignment

Toe-in:

0 mm

Steering wheel

Looseness, rattling, damage

*50

Power steering

Clogging of oil filter

Hose damage, amount of oil

Brake

Brake pedal

(also used as clutch)

Catching by parking brake lever

Brake effect

*50

Activation of clutch

Rods and cables

Looseness/rattling and damage

Running gears

Wheel

Tire pressure

*50

300 kPa

Tire cracks and damage

Abnormal wear of tire

Metal pieces, stones and other

foreign matters on tire

Cracks, rattling

Looseness of bolt

*50

Wheel bolt

tightening

torque:

100 Nm

Rim damage

Rattling of wheel bearing

Page 30

30

Periodic Inspection Standards

1. The applicable inspection timing is indicated by .

2. The timing of initial inspection is indicated by *.

Inspection item

Inspection timing

Judgment criterion

Start of

work

Every

6 months

Every

12 months

Hours

Drivetrain

HST

Leakage of oil

Auxiliary transmission

Rattling of operating mechanism

Leakage of oil

Propeller shaft

Looseness of link

*50 Rattling of spline

*50 Rattling of bearing

*50

Run-out of propeller shaft

*50

Differential

Leakage of oil

V belt and ribbed belt

Looseness and damage of belt

*50

Hydraulics

Oil tank

Amount and leakage of oil

Oil cooler

Clogging of cooling fan

Leakage of oil

Hydraulic valve Note 1

Leakage of oil

Hydraulic cylinder Note 1

Leakage of oil

Filter

Clogging

Piping

Looseness of joint and leakage of oil

Motor

Starting device

Degree of pinion meshing

Charge device

Charge action

Battery

Fluid level

*50

Fully charged:

1.260 (20C)

Fully discharged:

1.060 (20C)

Specific gravity of fluid

Electrical wirings

Loose and damaged connection parts

Main body

Ease of starting and abnormality

Condition at low speed and during

acceleration

Exhaust condition

Condition of air cleaner element

Replace every year.

Compressive pressure

Valve gap

0.1 mm to 0.2 mm

Lubrication device

Leakage of oil

Dirtiness and amount of oil

*35

Replace every 100

hours.

Clogging of oil filter

*35

Replace every 150

hours.

Fuel device

Leakage of fuel

Fuel strainer

*25

Replace every 400

hours.

Fuel line cracks/damage

Cooling device

Leakage of water

Amount of water

Function of radiator cap

Open/close pressure:

90 kPa

Looseness and damage of fan belt

100

Deflection when the

center of the belt is

pushed with a force of

100 N: 7 mm

Page 31

31

Periodic Inspection Standards

1. The applicable inspection timing is indicated by .

2. The timing of initial inspection is indicated by *.

Inspection item

Inspection timing

Judgment criterion

Start of

work

Every

6 months

Every

12 months

Hours

Agitator

Confirm that it rotates smoothly.

Damage of the flexible shaft

Lighting device/warning

device/measuring

instrument

Operation

Soiling and damage

Exhaust pipe and muffler

Looseness and damage of mount

Muffler function

Machine frame and body

Looseness and damage

Location where abnormality

was found during operation

the day before

Confirm that the applicable location is

free from abnormality.

Other

Lubrication condition at each part of

chassis

Other items

Fuel tank

Water absorption

strainer

Note1

Clean.

Line strainer

Note1

Clean.

Tank water filter net

Note1

Clean.

Nozzle

Inspect for clogging

and wear, and replace.

Boom

Operating condition

Floor

Cracks, fissures

Each fastening part

Tighten securely.

Note 1. Clean after every operation.

Page 32

32

◼ Oil Change Table

No.

Item

Applicable oil

Volume

Initial change

(hours)

Periodic change

and adding

(after every

specified hours)

1

Fuel

Diesel oil

20 L - -

2

Engine oil

SAE10W-30

API CF grade or better

3.0 L

50

Every 100 hours

or every year

3

Oil tank

Hydraulic oil (wear resistance)

VG46 (ISO)

18 L

200

4

Auxiliary transmission oil

Gear oil SAE 90

0.8 L

600

5

Front/rear differential oil

1.0 L

6

Spray pump,

crank case

SAE10W-30

API SJ grade or better

0.6 L

100

7

Spray pump,

cylinder base metal

3 to 5 drips

-

Every 100 hours

or every year

8

Boom shaft receiver

2 to 3 drips

At start of work

At start of work

9

Each wire

10

Boom lift &

open/close shaft

(Refer to the following.)

Chassis grease

Appropriate

amount

20

20

11

Radiator

LLC

4.9 L - 600

⚫ Greasing locations

Boom opening/closing/tilting shafts

(four locations on left and right)

Boom lift shafts

(eight locations on left and right)

Page 33

33

◼ Inspection Procedures

(1) Engine Oil

[Check] With the machine horizontal, pull out the

oil gauge, wipe the tip with a clean cloth

and put back the gauge, and pull it out

again to check the oil level. If oil is at the

LOWER level or below, add oil to the

specified level.

(Check the oil level before the engine is

started or at least 5 minute after the engine

has stopped.)

[Change] Remove the drain plug, drain oil, and fill

new engine oil.

[Engine oil] SAE10W-30 API CF grade

for diesel engine

[Amount of oil] 3.0 L

[When to change] Initial change: 50 hours

Periodic change: Every 100 hours

Used oil can be drained easily when the engine is hot.

Caution

⚫ When draining oil, exercise caution not to get

burned. Do not touch any of the parts directly

with your hand.

⚫ Oil filter cartridge

Replace every 150 hours (or after 50 hours

initially).

⚫ The oil filter is of cartridge type, so remove the entire

case with a filter wrench and replace it with a new

one.

⚫ After the new oil filter has been assembled, operate

the engine to check for leakage of oil.

⚫ After the oil change, stop the engine after (5 minutes

of) idling, wait for 10 to 20 minutes and then check

the oil level. If there is not enough oil, add oil.

(2) Air Cleaner

Caution

⚫ Be sure to remove and clean the air cleaner

element before operating the machine.

⚫ To clean the element, spray air (0.7 MPa or less)

onto the inner side of the element or shake the

element gently to remove dust.

⚫ Replace the element once a year.

⚫ When installing the cup, be sure to assemble with

the “top” side facing up.

Oil gauge

Drain plug

TOP

Page 34

34

(3) Inspecting the Fuel System

◼ Fuel Tank

Check if the tank contains enough diesel oil.

If not, add diesel oil.

(Tank capacity: Approx. 20 L)

Drain water from the tank from the fuel filler port

or fuel filter every 100 hours.

Add fuel before the fuel tank becomes empty and

should the fuel tank become empty, immediately add

fuel and bleed air.

◼ Bleeding Air

[1] Fill the fuel tank with diesel oil.

[2] Loosen fuel filter screw A and bleed air trapped

between the fuel tank and fuel filter.

[3] When only fuel starts to come out from the screw,

tighten screw A.

[4] Next, loosen screw B and bleed air trapped

between the fuel filter and the solenoid pump in the

same manner, and then tighten screw B.

[5] Turn the key switch to “ON.” Operate the solenoid

pump for approx. 10 seconds in this condition to

bleed air trapped between the solenoid pump and

engine.

Caution

⚫ When bleeding air, put clothes underneath and

wipe off any spilled fuel.

⚫ Stop the engine during refueling.

◼ Fuel Filter

Clean the fuel filter every 100 hours or so of

operation, and replace the element every 400

hours.

The cleaning method is as follows:

[1] Close the fuel filter cock.

[2] Remove the ring screw and take out the filter cup.

[3] Rinse the element in diesel oil. Also clean the inside

of the filter cup with diesel oil.

[4] After the cleaning, assemble the filter cup correctly

as before by paying attention not to let dust or dirt

attach to the element.

[5] Open the cock.

[6] Bleed air.

A

B

Close the cock.

O-ring

O-ring

Element

Spring

Filter cup

Ring screw

Page 35

35

(4) Inspecting the Cooling System

Caution

⚫ If the radiator cap is removed while the engine

is hot, hot water gushes out. Wait for the engine

to cool and remove the radiator carefully by

putting a cloth over it.

[1] Cooling water level

Check the cooling water level based on the amount

in the reserve tank. The level is normal if between

“FULL” and “LOW”. If cooling water is low, add to

the “FULL” level. After cooling water has been

added, press the top lid and make sure the lid is

securely latched.

* Do not open the radiator cap except when checking

and changing cooling water.

* Long-life coolant that does not freeze until -20C has

been charged at the factory prior to shipment. Adjust

the concentration of coolant according to the outside

air temperature.

-10C or above 30%

-10 to -25C 40%

[2] Cleaning the inside of the radiator

Open the drain plug and drain cooling water fully.

Thereafter, clean the inside with tap water until the

flushed water no longer contains rust.

(5) Changing the Transmission Oil

Remove the plug on the oil check port and drain plug at

the bottom of the transmission, and drain oil. At this

time, open the oil filler port also.

Open the oil check port to bleed air from inside the

transmission when adding oil.

[Type of oil] Gear oil SAE 90

When changing the oil for the first time, first drain

the oil, and then remove the speed detection

sensor, and thoroughly clean the tip of the sensor

to remove the iron powder adhered on it.

[Amount of oil] Approx. 0.8 L

[When to change] Initial change: 50 hours

Periodic change: Every 600 hours

Caution

⚫ After oil has been added, confirm that the drain

plug and oil check port plug are securely

tightened, and firmly tighten the oil filler cap to

prevent loosening.

Reserve tank

Oil filler port

Oil check port

Drain plug

Radiator drain

Cooling water drain

on the engine side

Speed

detection

sensor

Page 36

36

(6) Changing the Front/Rear Differential Oil

Remove the drain plug and plug on the oil check port to

drain oil.

Add oil from the oil filler port until oil overflows from the

oil check port.

[Type of oil] Gear oil SAE 90

[Amount of oil] Approx. 1.0 L

[When to change] Initial change: 50 hours

Periodic change: Every 600 hours

(7) Checking the Oil Level in the Hydraulic Oil Tank

Check the oil level using the gauge provided on the

side face of the oil tank. The oil surface changes based

on the boom position. Check the level when the booms

are at the lowest position. Add more oil if the level is

low.

When changing oil, replace the filter also.

[Type of oil] Hydraulic oil (wear resistant)

VG46

[Amount of oil] Approx. 18 L

[When to change] Initial change: 50 hours

Periodic change: Every 200 hours

(8) Inspecting the Spray Pump

Oil in the crank case

Check if the oil level reaches the top of the level gauge.

If not, add more oil.

[Type of oil] SAE 10W-30SJ grade or above

[Amount of oil] Approx. 0.6 L

[When to change] Initial change: 50 hours

Periodic change: Every 100 hours

(9) Greasing

Refer to the Oil Change Table (P. **).

(10) Adjusting the Belt Tension

Adjust the belt tension based on the table below.

Press the center of the belt with the amount of force

indicated in the table, and adjust to the deflection

indicated.

Drive part

Belt type

Amount of

force to press

the center of

belt (N)

Deflection

(mm)

Engine

Electromagnetic

clutch (counter)

PK975

30

5

Counter

Spray pump

LA43

16

5

Counter

Agitator

PCLA20

10

2.5

(11) Inspecting the Tires and Wheels

⚫ Inspect each tire for wear, cracks, low air pressure

or any other abnormality.

⚫ If the air pressure is excessively low, adjust it to the

appropriate level. If there is a significant enough

crack or wear, replace the part with a new one.

Standard air pressure for front/rear wheels: 300 kPa

Caution

⚫ If the tire air pressure is too high, the tires tend

to wear out more easily. On the other hand, if

the air pressure is too low, a flat tire may occur

more easily and the fuel efficiency may decline.

⚫ Inspect each wheel for cracks or looseness.

Oil filler port

Gage

Drain plug

Oil filler port

Oil check port

Filter

Page 37

37

(12) Inspecting the Battery

Warning

⚫ Do not use or charge the battery when the

battery fluid level is low, because the battery

may rupture (explode) or ignite.

Caution

⚫ When inspecting the battery terminals, do not

let the terminals get short-circuited.

⚫ When disconnecting the battery cable, be sure

to disconnect the negative terminal end first.

⚫ Battery fluid is very corrosive, so do not spill

the fluid. If battery fluid attached to your hand,

clothes or any metal part, rinse the affected

area thoroughly with water.

◆ Maintenance-free battery

The battery without top cap is a maintenance-free

battery.

[1] Look at the charge indicator vertically.

[2] If the charge indicator is clear or yellow, gently tap

the battery to remove air bubbles and then check

again.

[3] Take an appropriate action according to the table

below based on the indicator color.

Color

Charge state

Action

Green

Normal

The battery can be used.

Black

Insufficient

Auxiliary charge is required.

Clear

Not enough fluid

Replace the battery if the

engine does not start.

* There is no need to inspect the battery at the start of

work.

◆ Conventional battery

[1] Check if the battery fluid level is between “UPPER”

and “LOWER”. If the level is low, add distilled

water to the “UPPER” level.

[2] After distilled water has been added, securely

tighten the cap.

[3] Inspect the battery terminals and if loose, securely

tighten the terminals. If white powder is attached to

the terminals, clean with hot water and tighten the

terminals, and then apply a small amount of

grease on the terminals.

Caution

⚫ Do not continue using the machine once the

electrolyte level in the battery has dropped to or

below the lower limit (LOWER level) indicated

on the side face of the battery. Deterioration of

each part of the battery cell will be promoted.

(13) Adjusting the Chain Wire for Boom

Extension/Retraction and Adding Oil

Caution

⚫ Apply grease to the entire surface of the boom

extension/retraction chain wire once every year

to prevent rust.

⚫ When adjusting the boom extension/retraction

chain wire or adding oil, please contact the

Maruyama dealer near you.

If the boom extension/retraction wire is stretched out,

adjust the chain tension.

With the boom fully extended, rotate the turn buckle to

adjust. (If used with the boom not fully extended, the

wire may be disengaged.) {The target condition is to

have the boom body not touch the chain when it is

extended until it touches the stopper.}

10N

30 m 3 mm

Joint

Wire roller

Sprocket

Turn buckle

Two-level boom

Page 38

38

(14) Inspecting the Agitator

[1] Press the spray pump switch to actuate the spray

pump and the agitator, and inspect if the agitator

blades are rotating smoothly.

[2] Remove the screw mounting the flexible shaft to

remove the shaft.

[3] Pull out the inner wire from the flexible shaft and

inspect for any damage. If it is damaged, replace it

with a new one.

[4] Apply grease to the entire surface of the inner wire

and assemble it back to the original position.

(15) Inspecting the Rear Axle Stopper Bolts

If the machine body tilts significantly when the driver

gets on board or gets off, request to have the rear axle

stopper bolts adjusted at the sales dealer where the

machine was purchased.

(16) Inspecting the Floor

Inspect the floor for cracks, fissures or any other

abnormality. If any abnormality is found, submit a

request for replacement to the sales dealer where the

machine was purchased.

Mounting

screw-on

Flexible shaft

Inner wire

Stopper bolts

Floor

Page 39

39

◼ Method for Long-term Storage

If the machine is not used for a long period of time,

follow the care procedure below:

(1) Run through all maintenance and inspection

items.

(2) Service problem locations, if any.

(3) Inspect the bolt and nut in each part and tighten

them if loose.

(4) Rotate the spray pump at a low speed using clean

water to clean the inside of the tank, pipe and the

nozzle, and circulate the water for three to four

minutes. To prevent damage from freezing, drain

the liquid from inside the spray pump and the pipe

by idling the pump and by removing the water

drains (two positions).

(5) Remove the nozzle cap and drain water remaining

inside the nozzle.

(6) Clean the exterior of the machine.

(7) Change engine oil with new oil and operate the

engine for around 5 minutes to spread oil to each

part.

(8) Be sure to keep the throttle lever in the “Low

speed” position.

(9) Fill up the fuel tank with fuel (diesel oil).

(10) Use sandpaper, etc., to remove rust from areas

where paint has peeled, and apply a fresh coat of

paint.