Page 1

Royal Elm Designer Table U-7200C

Assembly Instructions

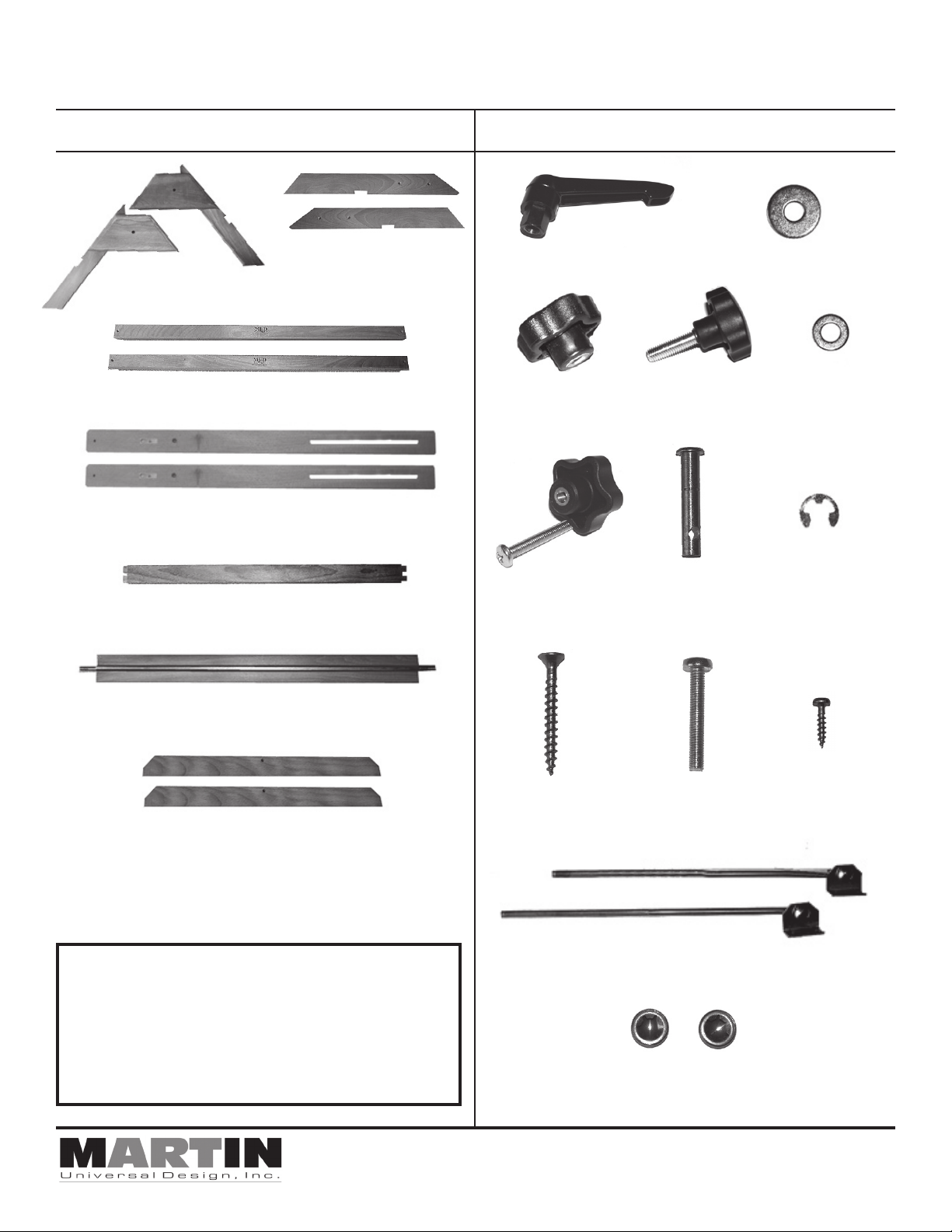

Contents of Carton: Contents of Parts Bag:

[2] A-Base Ends [A]

[2] A-Base Cross Supports [C]

[2] Chanelled Side Supports [D]

[1] Upper Cross ESupport [E]

[2] Left & Right Legs

for A-Base [B]

[1] Threaded Lever [AA] [1] Large Washer for Lever

[BB]

[1] Female Knob

[CC]

[2] Female Knobs

with bolt & washer

included [FF]

[2] Male Knob [DD] [1] Washer for

[2] Large Pin with

hole [EE]

Female Knob

[EE]

[2] “C” Washers for

Large Pins

[FF]

[1] Chanelled Cross Member with Threaded Rod [F]

[2] Drawing Top Braces [G]

IMPORTANT

If you have difficulty assembling your U-7200C Royal Elm

or need customer service assistance.

Please call: Martin Universal Design, Inc.

Customer Service Hot Line at

1-313-895-0700. If you need additional parts, it is not nec-

essary to contact your dealer, our Customer Service Rep.

will forward them to you immediately.

4444 Lawton Avenue, Detroit, MI 48208 USA • Tel:(313)895-0700/Fax:(313)895-0709

Email: Custservmud@aol.com • visit us at www.MartinUniversalDesign.com

[12] Long Wood

Screws [GG]

[2] Metal Tilt Adjustment Rods [JJ]

[2] Metal Pin End Caps for Tilt Rods [KK]

[2] 1-3/4” Bolts

[HH]

[4] Small Wood

Screws [II]

Created July 06 - RPI

Page 2

Assembly Instructions:

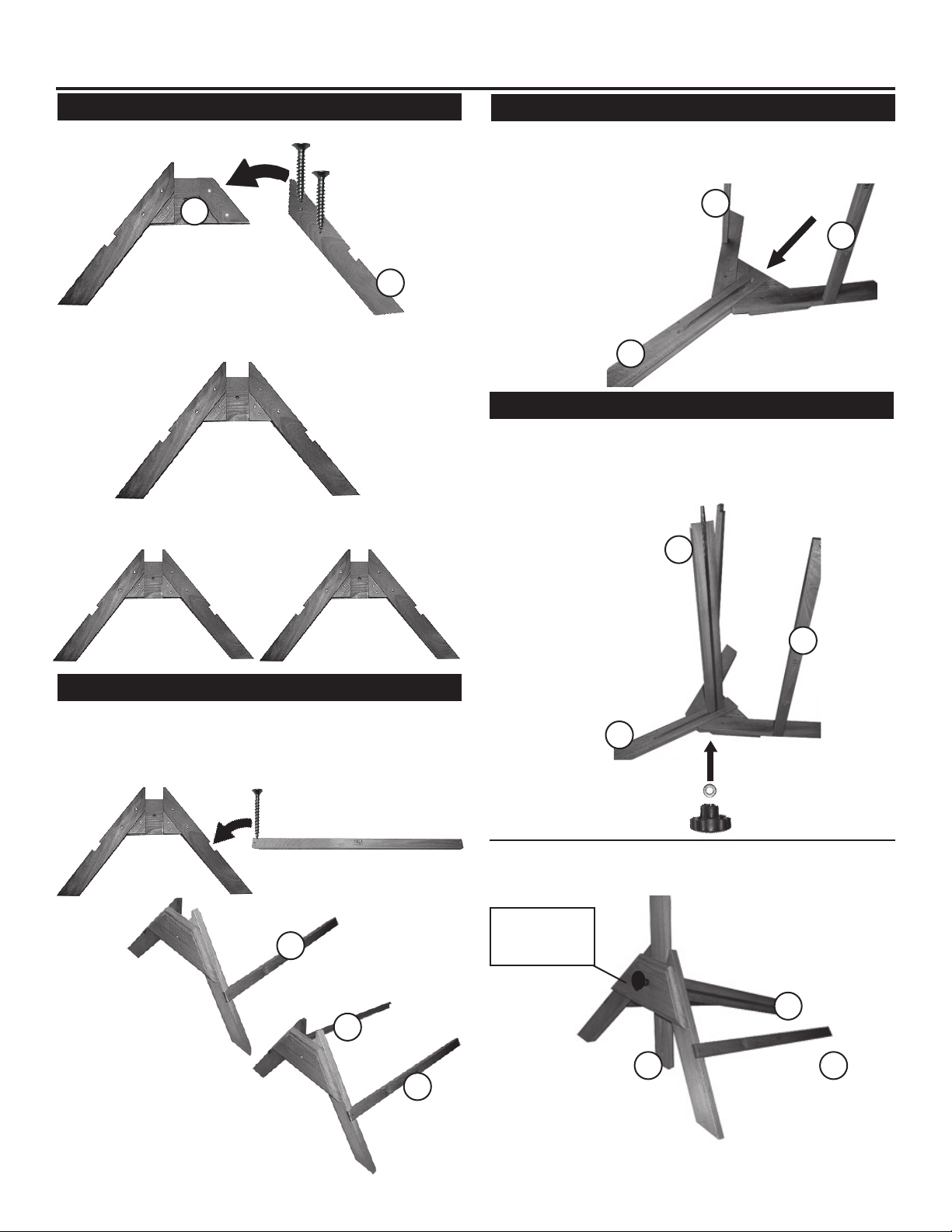

STEP 1] Assembling A-Base(s)

Take the A-Base end [A] as shown below and the Left Leg

[B] for the A-Base.

A

A-Base end [A]

Position the Left Leg [B] onto the A-Base, lining up holes.

Secure with [2] Long Wood Screws. Tighten. See below for

proper assembly.

Repeat with other side.

Now, you should have [2] complete A-Base Assemblies.

Long Wood

Screws [GG]

Left Leg [B]

B

STEP 3] Attaching Channelled Side

Take A-Base end that has the two supports attached and

place on flat surface. Position Channelled Side Support [D]

into middle section of A-Base. Making sure channel is on

bottom end. As shown below.

C

C

D

STEP 4] Adding Lower Support & Rod

With above assembly still laying flat on surface, insert one

end of Channeled Cross Member with Threaded Rod [F]

into Channelled Side Support [D] making sure rod end goes

through other end of A-base assembly. Secure with Washer

[EE] and Female Knob [CC]

F

STEP 2] Attaching A-Base Supports

Take one assembled A-Base end and attach [1] support

bar (with Logo reading up in correct position) and place into

notch and secure with [1] long wood screw [GG]. See below

for proper assembly.

A-Base Cross Supports [C]

A-Base Assembly

C

Proper assembly of

A-Base & support.

C

C

C

D

After securing with washer [EE] and Female Knob [CC],

turn assembly up onto base as shown below.

Washer [EE]

and Female

Knob [CC]

F

D

C

Pg. 2

Repeat with other support.

Attach as shown to right.

Created July 06 - RPI

Page 3

Assembly Instructions continued:

STEP 5] Securing Lower Support & Rod

Repeat with other A-Base assembly on other side.

First by sliding Channelled Side Support [D] down into A-Base

assembly, then continue by inserting Lower Support & Rod

[F] into Channel in Side Support [D] making sure threaded

rod goes all the way through A-Base assembly, this time

securing with large washer [BB] and Lever [AA].

See photos below.

D

F

C

Close-up photo of

Lever and large

Washer.

STEP 6] Attaching Upper Cross Support

Take Upper Cross Support [E] and insert one end into small

slot in upper portion of the Channelled Side Support [D].

Secure with 1-3/4” Bolt [HH]. Tighten with Phillips

Screwdriver. Insert other end into other side of Channelled

Side Support [D]. Secure with other 1-3/4” Bolt [HH]. PLEASE

NOTE: You may have to loosen Lever to allow Side Support

to pull away enough to allow end of Upper Cross Support

[E] to be inserted into slot. Retighten Lever once completing

Step 6.

STEP 7] Inserting Pin into Side Support

Take the [2] Large Pins with Hole [EE] and insert each one

into the hole which is below cross support bolt. Insert pin

through inside of base and through other side as shown be

low. Secure pin [EE] with “C” Washer by sliding “C” washer

over and onto Pin slot which is located right where Pin and

Side Support meet. PLEASE NOTE: This is difficult to

accomplish. You must use a flat screwdriver to push “C”

washer into slot.

STEP 8] Attaching Tilt Adjustment Rods

Take [1] of the Metal Tilt Adjustment Rods [JJ] and insert it

into the hole in the Pin [EE]. Secure with Metal Pin End Cap

[KK]. Repeat with other side.

KK

JJ

-

Close-up photo of

1-3/4” Bolt attachment.

After Steps 1 - 6.

Base should look like

photo to right.

Pg. 3

D

D

EE

E

STEP 9] Securing Tilt Adjustment Rods

Take [1] Male Knob [DD] and attach to Pin end. Screw in to

tighten. Repeat with other Adjustment Rod.

F

E

C

D

F

DD

C

Created July 06 - RPI

Page 4

Assembly Instructions continued:

STEP 10] Attaching Top Braces

When attaching the [2] Drawing Top Braces [G], position the

drawing board brace in the position shown here:

Attach to the inside of the Side Support [D] using the [2]

remaining knobs, washers and bolts [F]. Insert bolt through

hole on inside of Drawing top Brace, making sure bolt goes

through side support [D]. Finish by attaching washer and

then female knob.

F

G

D

PLEASE NOTE:

Correct attachment of Drawing Top Braces will have

large holes on Drawing Top Brace facing downward.

Before securing base of table to Drawing Board top, you must center

the base to the top.

Rear Edge of Top

Front Edge of Top

Center base by measuring 7” in [Measurement Y] from outside

edges of Drawing Board to outside edge of Base Braces and

5-1/8” in from front edge of drawing board to front edge of Base

Brace and 5-1/8” in from rear edge of drawing board to rear edge

of base Brace. See illustration below. Secure using [4] Long

Wood Screws [GG] per Base brace.

Y = 7”

Y = 7”

Attach

Bracket on

Tilt

Adjustment

Rods into

Top

STEP 11] Turning Base over

PLEASE NOTE: BEFORE TURNING BASE OVER

ONTO DRAWING BOARD: MAKE SURE DRAWING

BOARD BRACES ARE IN A HORIZONTAL

POSITION AND KNOBS ARE TIGHTENED.

Use two people with this next step. Lay top on carpeted flat surface.

Carefully turn completed base assembly up and over and place on

top of bottom side of drawing board.

PLEASE NOTE: Both sides of Drawing board can be the bottom

side. Choose best looking for Top Side.

STEP 12] Attaching Base to Drawing Top

Base should look and be positioned to Drawing Board as pictured

below.

X = 5-1/8”

X = 5-1/8”

STEP 13] Attaching Tilt Adjustment Rods

to Drawing Board

Attach metal tilting brackets to top using [2] each small wood

screws [II] per bracket as shown above. PLEASE NOTE: Break

Table Top Surface by making a small hole in top surface where

screw will go in with hammer and a nail.

STEP 14] Table Top Tilt Adjustments

To make your table top tilt: Loosen the [2] black knobs

(with tilt rods through them), proceed by holding onto

the front edge of the top. Tilt top until desired position is

reached. Tighten [2] black plastic knobs.

STEP 15] Table Height Adjustment

To adjust the height of your table, loosen the lever slightly.

PLEASE NOTE: When loosening the lever, the table

will want to lower because of the weight of the top.

Carefully, loosen lever and support table top with

hands and lower or raise until desired height. Retighten Lever to secure. This adjustment is safest with

another adult helping.

Pg. 4

4444 Lawton Avenue, Detroit, MI 48208 USA • Tel:(313)895-0700/Fax:(313)895-0709

Email: Custservmud@aol.com • visit us at www.MartinUniversalDesign.com

Created July 06 - RPI

Loading...

Loading...