Page 1

92-3010 • MONSTER AMALFI STUDIO EASEL

ASSEMBLY/SET-UP INSTRUCTIONS

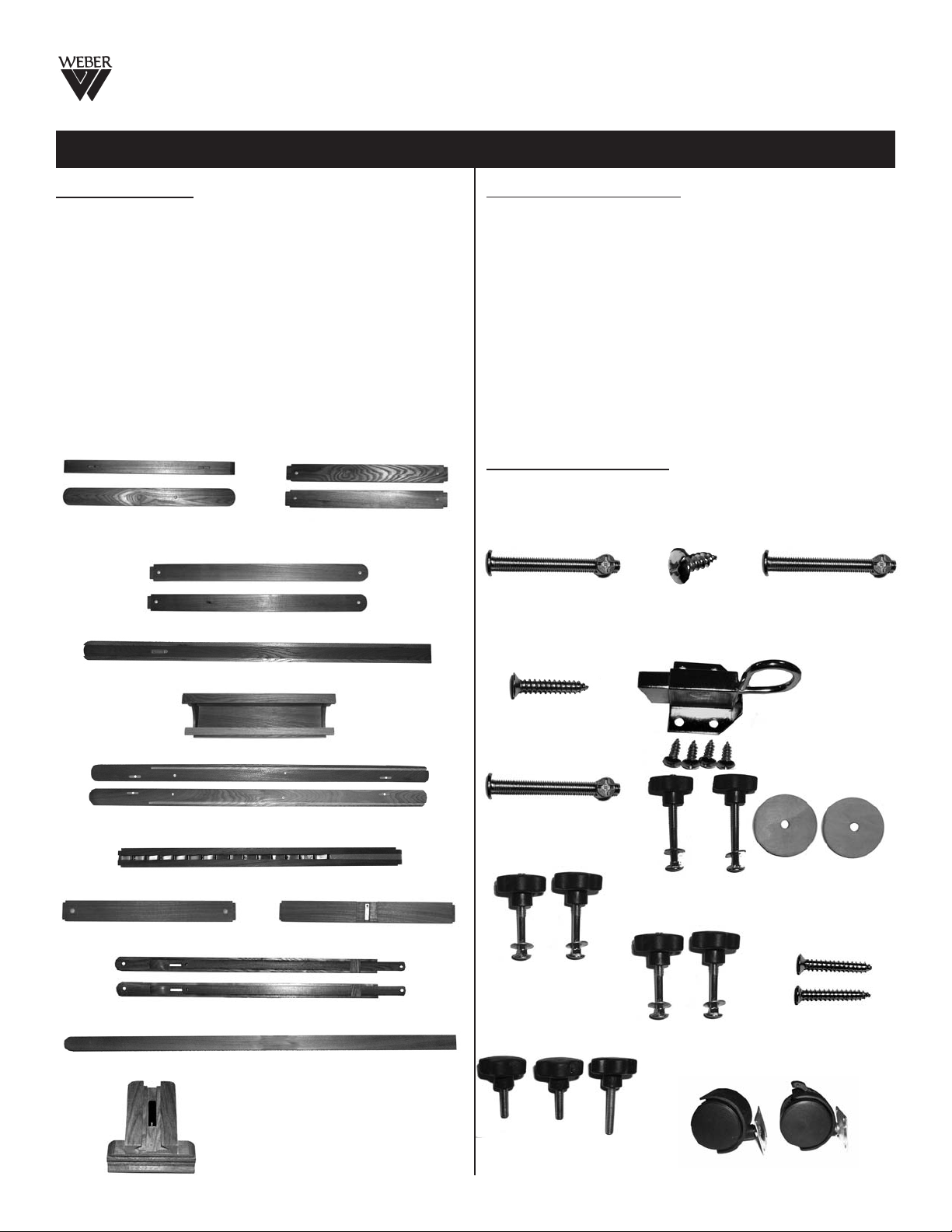

MAKE SURE CARTON CONTAINS THE FOLLOWING PARTS

WOOD PARTS

Quantity ........ Description ID#

2 ea. ........ Base Feet

2 ea. ........ Base Cross Members

2 ea. ........ Uprights

1 ea. ........

Channelled Center Column [4]

1 ea. ....... Material Tray

2 ea. ........ Channelled Side Columns

1 ea. ........ Ratchet Column

1 ea. ........ Lower Cross Member

1 ea. ........ Upper Cross Member

2 ea. ........ Extendable Rear Legs [10 & 11]

1 ea. ........ Adjustable Center Column

1 ea. ........ Upper Canvas Support [13]

Side View

Top View

Base Feet [1]

Uprights [3]

Base Cross Members

[1]

[2]

[3]

[5]

[6]

[7]

[8]

[9]

[12]

[2]

HARDWARE PARTS

Quantity ........ Description ID#

4 ea. .. Bolts & Cams: 6 X 60mm [A]

16 ea. . Screws: 4 X 16mm [B]

2 ea. .. Bolts & Cams: 6 X 60mm [C]

4 ea. . Screws: 4 X 25mm [D]

1 ea. .. Loop Mechanism & [4] Screws [E]

4 ea. .. Bolts & Cams: 6 X 60mm [F]

2 ea. .. 6 X 70mm Bolt/Knob/Washer&Wood Washer [G]

2 ea. .. 6 X 45mm Bolt/Knob & Washers [H3]

2 ea. .. 6 X 40mm Bolt/Knob & Washers [H4]

2 ea. .. 5 X 35mm Screws [H5]

3 ea. .. Knobs: 2 same size one longer

4 ea. .. Castors: 2 locking, 2 not locking

TOOLS INCLUDED

Quantity ........ Description

1 ea. ........ Flathead Screwdriver - Red Handle

1 ea. ........ Phillips Head Screwdriver - Orange Handle

6 X 60mm

Bolt & Cams

(4 each)

[A]

4 X 16mm

Srews for Castors

(16 each)

[B]

6 X 60mm

Bolt & Cams

(2 each)

[C]

Channelled Center Column [4]

Material Tray [5]

Channelled Sides [6]

Ratchet Column [7]

Lower Cross Member [8] Upper Cross Member [9]

Extendable Rear Legs [10 & 11]

Adjustable Center Column [12]

Upper Canvas Support [13]

Page 1

4 X 25mm

Screws (4 each)

[D]

6 X 60mm

Bolt & Cams

(4 each)

[F]

6 X 45mm

Bolts, Knobs & Washers

(2 each)

[H3]

3 Knobs

2 same size one longer

[unmarked]

Screws * Loop Mechanism

6 X 70mm Bolts, Knobs, Washers

& Wood Washers (2 of each)

6 X 40mm

Bolts, Knobs & Washers

(2 each)

[H4]

[4] Floor Castors (2 Locking)

3 X 12mm

[E]

[G]

5 X 35mm

Screws (2 each)

[H5]

Page 2

IMPORTANT - READ ALL INSTRUCTIONS BEFORE ASSEMBLING EASEL and USE 2 PEOPLE WHEN ASSEMBLING!

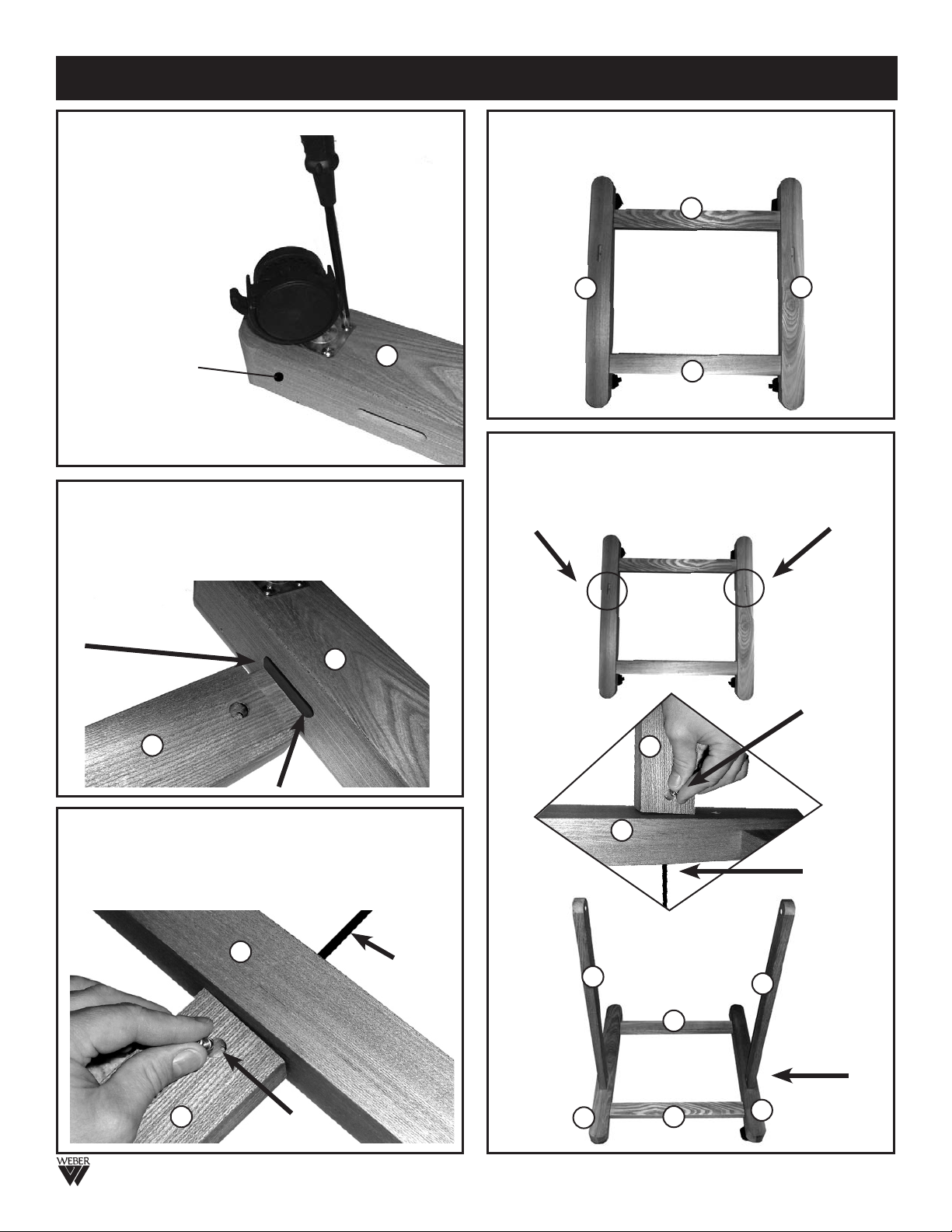

STEP 1. Attach the [4] castors to

the two base feet (1) making sure

the 2 locking castors are

positioned in the rear. NOTE:

the rear of the base has the hole

nearest that castor position.

Secure with four screws (B)

per castor.

See FIG 1.

Rear of the base

with hole.

STEP 2. Attach the two Base Cross members

base feet (1) By inserting the oval male end of the Base

Cross member into the oval female cut-out of the base

foot. See Fig 2. NOTE: The hole in the cross member

should be up, since the base is upside down.

Repeat with

second cross

member.

1

FIG 2

2

FIG 1

1

(2) to the

STEP 4. Turn your base assmebly over onto the

castors and you should now have a base that is

assembled like FIG 4.

2

1

2

STEP 5. This next step involves attaching the uprights

(3) to the base assembly. You will find two oval holes on

the top side of the assembled base, these oval holes

are for the oval male ends of the uprights (3) to go into.

Secure with two 6 x 60mm bolts and cams (C).

3

1

FIG 4

Insert Cam

here and

tighten bolt from

bottom of Base

with phillips

screwdriver

STEP 3. Secure Base Cross Members to base using

the four 6 X 60mm Bolts and Cams (A). Insert Cam into

hole found in Base Cross Member and insert bolt into

base foot. Tighten by holding Cam in position while

tightening down bolt with phillips screwdriver. See FIG 3.

FIG 3

2

1

Cam

Phillips

Screwdriver

FIG 5

1

6 X 600 mm

bolt here

3

2

1

2

3

After proper

assembly, base

with uprights

should look like

this.

1

Page 2

Page 3

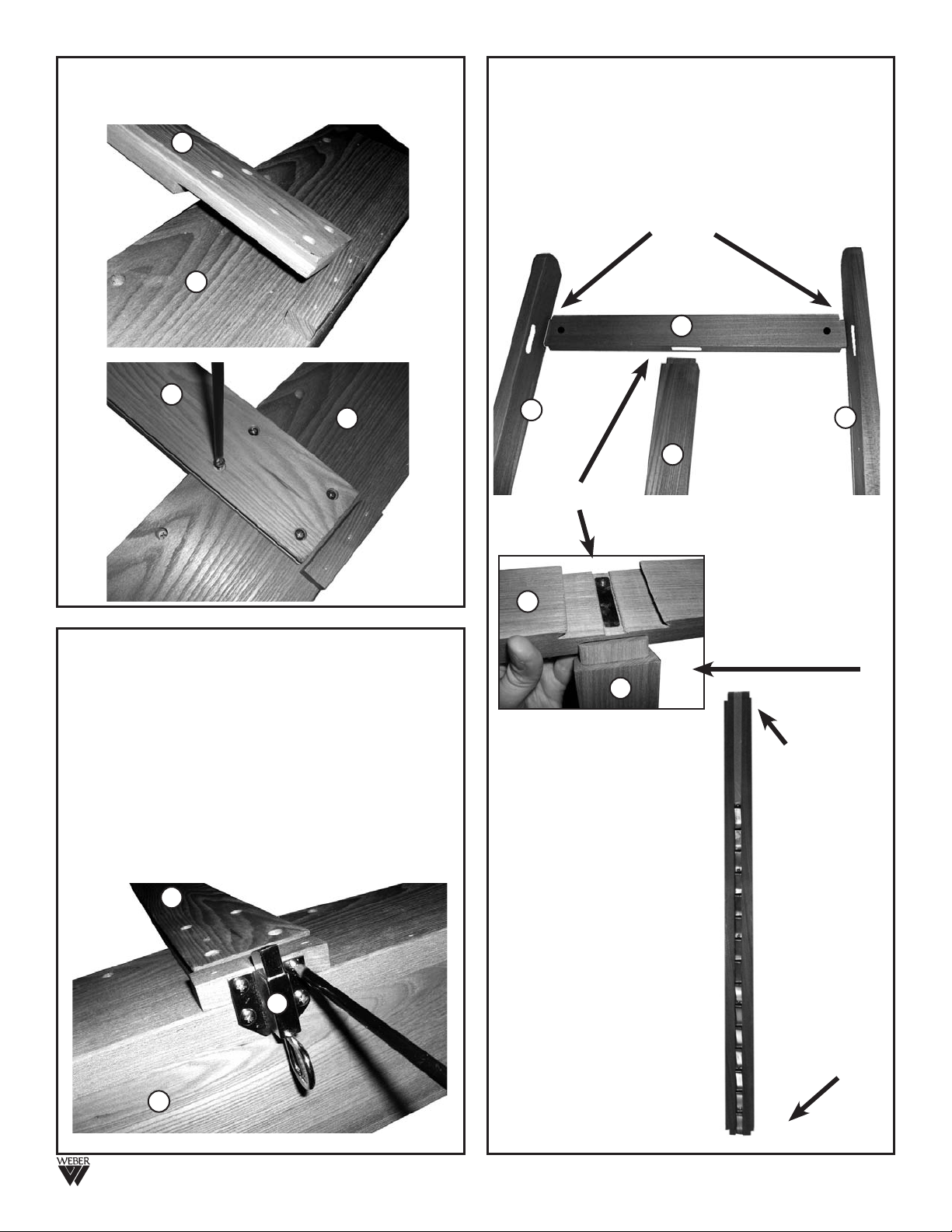

STEP 6. Attach Material Tray

Column (4) using four 4 X 25mm Screws (D).

See FIG 6a & FIG 6b.

4

(5) to Channelled Center

STEP 8a. Assembling the H-Frame. This step involves

assembling parts (6, 7, 8 & 9) to form the H-Frame

portion of the easel. Begin by taking the channelled

sides (6) & the upper cross member (9) and inserting

the oval male ends of the upper cross member into the

oval holes of the channelled sides. See FIG 8a.

Secure this step using two 6 X 60mm bolts and Cams

as previously described in earlier steps. (as in Step 3)

5

FIG 6a

4

5

FIG 6b

STEP 7. Attach Loop Mechanism

(5) using the four 3 X 12mm screws. Secure with

Phillips Screwdriver (provided) See FIG 7.

NOTE: Make sure the Loop Mechanism is in the

proper position as shown in FIG 7. This will allow

for proper adjustments when moving the material

tray up or down the Ratchet Column.

4

FIG 7

(E) to Material Tray

E

FIG 8a

9

NOTE: This image

is the rear side of

6

FIG 8b

9

7

Make sure the Ratchet column

is positioned so that the metal

part that is closest to one end

of the column is the bottom

end. See FIG 8c.

NOTE: This column is secure

once the bottom portion of

the H-Frame is assembled.

the H-Frame. The

metal portion of

the ratchet

7

column is on the

reverse side. Not

visable in this

photo.

6

STEP 8b. Continue by

inserting the ratchet

column (7) up into the

oval hole of the upper

cross member (9).

Top Portion of

Ratchet

Column

connects with

upper cross

member (9)

Bottom End

of Ratchet

Column

connects with

lower cross

member (8)

5

FIG 8c

Page 3

Page 4

STEP 10. Finish assembling the H-Frame by attaching

the lower cross member (8) to the ratchet column (7) by

inserting the ratchet column down into the oval hole of

the lower cross member. Secure by fitting the lower cross

member into the oval holes of the channelled sides (6).

See FIG 10. Secure this step, using two 6 X 60mm bolts

and Cams as previously described in earlier steps.

(as in Step 3)

7

8

6

FIG 10

6

STEP 12. Attach assembled H-Frame to easel uprights

found on assembled base. Make sure the metal ratchet

front is facing out towards the front of the easel.

This step involves securing the H-Frame assembly to the

uprights of the easel base as shown in FIG 12.

FIG 12

7

6

3

STEP 11. Your assembled H-Frame should look like

FIG 11.

NOTE: This is the front view of the assembled

H-Frame

9

7

6

6

8

STEP 13. To secure the H-Frame to the uprights, have

one person hold the H-frame while the other inserts one

part (G) 6 X 70mm Bolt through the inside edge of the

channelled sides and though the other side, then attach

one wood washer to the bolt

end. See FIG 13a.

Continue through the

upright and secure with

metal washer and black knob.

See FIG 13b.

REPEAT with other side

of H-Frame to

complete this Step.

FIG 13a

The completed

assembly should look

like FIG 13b.

3

6

3

8

FIG 11

FIG 13b

6

Page 4

Page 5

STEP 14. Attach Extendable Rear Legs (10&11) to base

(1) and upper portion of Channelled Sides (6).

Attach the wider end of the adjustable Rear legs (10) to

the base by securing with one 5 X 25mm Screw.

See FIG 14 for proper location. Secure with Phillips

screwdriver. Repeat with other Extendable Leg.

FIG 14

STEP 15. Attach upper portion of Extendable Rear Legs

(11) to upper portion of Channelled Sides (6).

Pull-out the narrower end of the extendable leg (11) and

attach it to the inside edge of the channelled sides by

inserting one 6 X 45mm bolt (H3) through the outside side

of the channelled side continuing through the extendable

leg (11) and then placing the metal washer over the bolt

and tightening with the knob to secure. See FIG 15.

See FIG 15b for proper view of assembly step 15.

FIG 15

STEP 16. Attach 6 X 40mm Bolts, knobs & washers (H4)

to Extendable legs (10 & 11). These adjustment knobs

are used along with the others to lower the easel into a

horizontal position. Insert the bolt through the inside edge

of the extendable

leg (11), continue

going though to the

other side and

complete with metal

washer and knob.

Tighten to secure.

See FIG 16.

FIG 16

STEP 17. Loosen all knobs to lower the easel into the

horizontal position. Once in flat position, tighten all knobs

to secure. See FIG 17. This step involves inserting and

sliding the Channelled Center Column (4) and Material

tray (5) assembly through the upper cross member (indicated by the circle) and guiding the material tray corners

into the channelled Sides (indicated by the squares). See

FIG 17. See inset photos below for detail.

FIG 17

H3

6

H3

11

FIG 15b

9

6

7

11

6

11

Page 5

Page 6

STEP 18. Once Channelled Center Column is in its

proper location in the upper Cross Support, secure with

the longest of the three remaining knobs by threading the

threads of the knob in the hole in the rear of the cross

support. Tighten to secure. See FIG 18.

4

9

STEP 20. Final step involved in the assembly of your

New 92-3010 Easel.

Attach the Upper Canvas Support (13) to the Adjustable

Center Column (12) by sliding the grooves of the canvas

support down into the channels of the Adjustable Center

Column. Do this from the top end of the Adjustable

Center Column. Secure with remain knob. tighten to

secure at desired position. See FIG 20

12

7

FIG 18

STEP 19. This step involves adding the Adjustable

Center Column (12) down into the Channelled Center

Column (4). See FIG 19. To secure into place, thread one

of the remaining two shorter knobs into the hole found on

the rear of the Channelled Center Column. See FIG 19b.

12

FIG 19

4

Rear view of

Channelled Center

Column where knob

4

FIG 19b

is to be threaded.

13

FIG 20

ADJ 1. Adjusting Height Material Tray.

Insert finger in locking loop pin below Material Tray and

pull outward. This will cause the material tray support to

release from the metal ratchet column allowing you to

raise or lower the material tray and center column.

PLEASE NOTE: Be careful when raising the

material tray, that you are aware that the top of the

column will not interfere with ceiling or any other

object in rooms that have low ceilings.

IMPORTANT

If you have difficulty assembling your 92-3010 Weber Monster

Amalfi Studio Easel or need customer service assistance.

Please call: Martin Universal Design, Inc. Customer Service Hot

Line at 1-313-895-0700. If you need additional parts,

it is not necessary to contact your dealer, our Customer Service

Rep. will forward them to you immediately.

Martin/F. Weber Co. • 4444 Lawton Avenue, Detroit, MI 48208 USA

Tel:(313)895-0700 • Fax:(313)895-0709 • E-mail:Custservmud@aol.com

www.MartinUniversalDesign.com • www.weberart.com • Made in China

Created NOV07RPI

Page 6

Page 7

92-3010

Extendable Rear legs (11)

Extendable Rear legs (10)

Base Foot (1)

Base Cross Support (2)

Locking Castor

Weber Monster Amalfi Studio Easel

Upper Canvas Support (13)

Adjustable Center Column (12)

Upper Cross Member (9)

Adjustable Material Tray

Height Adjustable Center Column/Material Tray

by pulling loop out from ratchet system

Ratchet Cloumn (7)

Lower Cross Member (8)

Uprights (3)

Martin/F. Weber Co.

4444 Lawton Avenue, Detroit, MI 48208 USA

Tel:(313)895-0700 • Fax:(313)895-0709

E-mail:Custservmud@aol.com

www.MartinUniversalDesign.com • www.weberart.com • Made in China

Created NOV07 RPI

(5)

Page 7

Loading...

Loading...