Page 1

92-2100 • MURANO Professional Studio Easel

ASSEMBLY INSTRUCTIONS

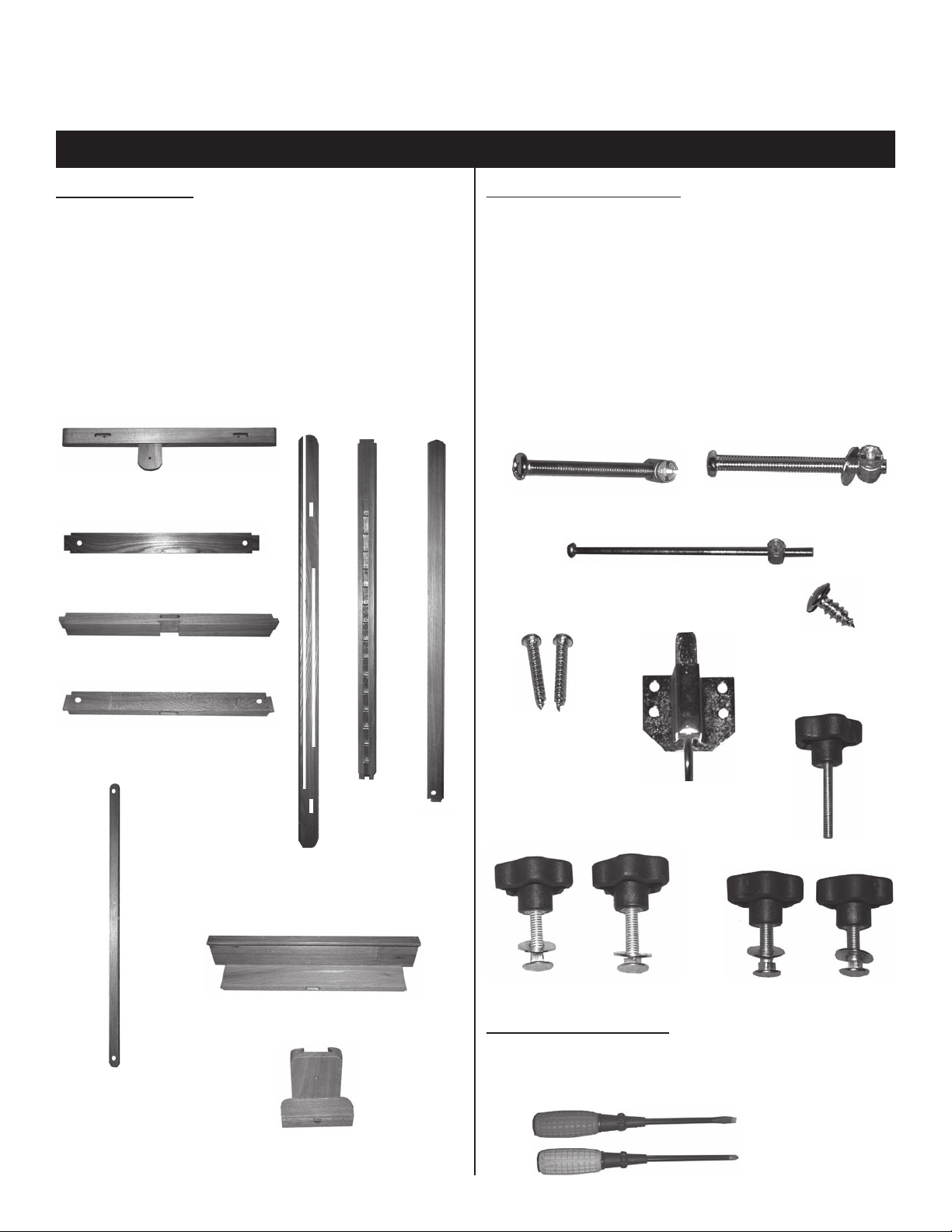

MAKE SURE CARTON CONTAINS THE FOLLOWING PARTS

WOOD PARTS

Quantity ........ Description ID#

2 ea. ........ Base Foot [1]

2 ea. ........ Base Foot Connectors [2]

2 ea. ........ Side Arms (1 Left & 1 Right) [3]

1 ea. ........ Upper Side Arm Connector [4]

1 ea. ........ Lower Side Arm Connector [5]

1 ea. ....... Center Ratchet Column [6]

1 ea. ........ Center Column [7]

1 ea. ........ Lower Canvas Tray [8]

2 ea. ........ Side Leg Angle Supports [9]

1 ea. ........ Upper Canvas Support [10]

Base Foot [ID# 1]

Base Foot Connectors

[ID# 2]

HARDWARE PARTS

Quantity Description ID#

4 ea. ........ 6 x 60mm Carriage Bolts and T-nuts [A]

4 ea. ........ 6 x 50mm Carriage Bolts/Wash & T-nut [B]

1 ea. ........ 6 x 120mm Carriage Bolt and T-nut [C]

2 ea. ........ 6 x 45mm Wood Screws [D]

1 ea. ........ Loop-Pull Mechanism [E]

4 ea. ........ Small Wood Screws (with Loop-pull) [F]

1 ea. ........ 2.25” Knob - male [G]

2 ea. ........ Bolt 6x45mm, Knob & Washer [H]

2 ea. ........ Bolt 6x35mm, Knob & Washer [ I ]

Carriage Bolt with T-Nut

6 x 60mm [ID# B]

Carriage Bolt with T-Nut

6 x 120mm [ID# C]

Carriage Bolt with Washer & T-Nut

6 x 50mm [ID# A]

Upper Side Arm Connector

[ID# 4]

Lower Side Arm Connector

[ID# 5]

Side Leg Angle

Supports

[ID# 9]

Created June 06 RPI

Center

Ratchet

Column

[ID# 6]

Side Arms

[ID# 3]

Lower Canvas Tray

[ID# 8]

Upper Canvas

Support

[ID# 10]

Center

Column

[ID# 7]

Small Wood

Screws

[ID# F]

6 x 45mm Wood

Screws

[ID# D]

Loop-pull Mechanism

[ID# E]

2.25” Knob [ID# G]

Bolt 6 x 45mm, Knob & Washer

[ID# H]

Bolt 6 x 35mm, Knob & Washer

[ID# I]

TOOLS INCLUDED

Quantity ........ Description ID#

1 ea. ........ Flat Screwdriver [X]

1 ea. ........ Phillips Screwdriver [Y]

[X]

[Y]

Page 1

Page 2

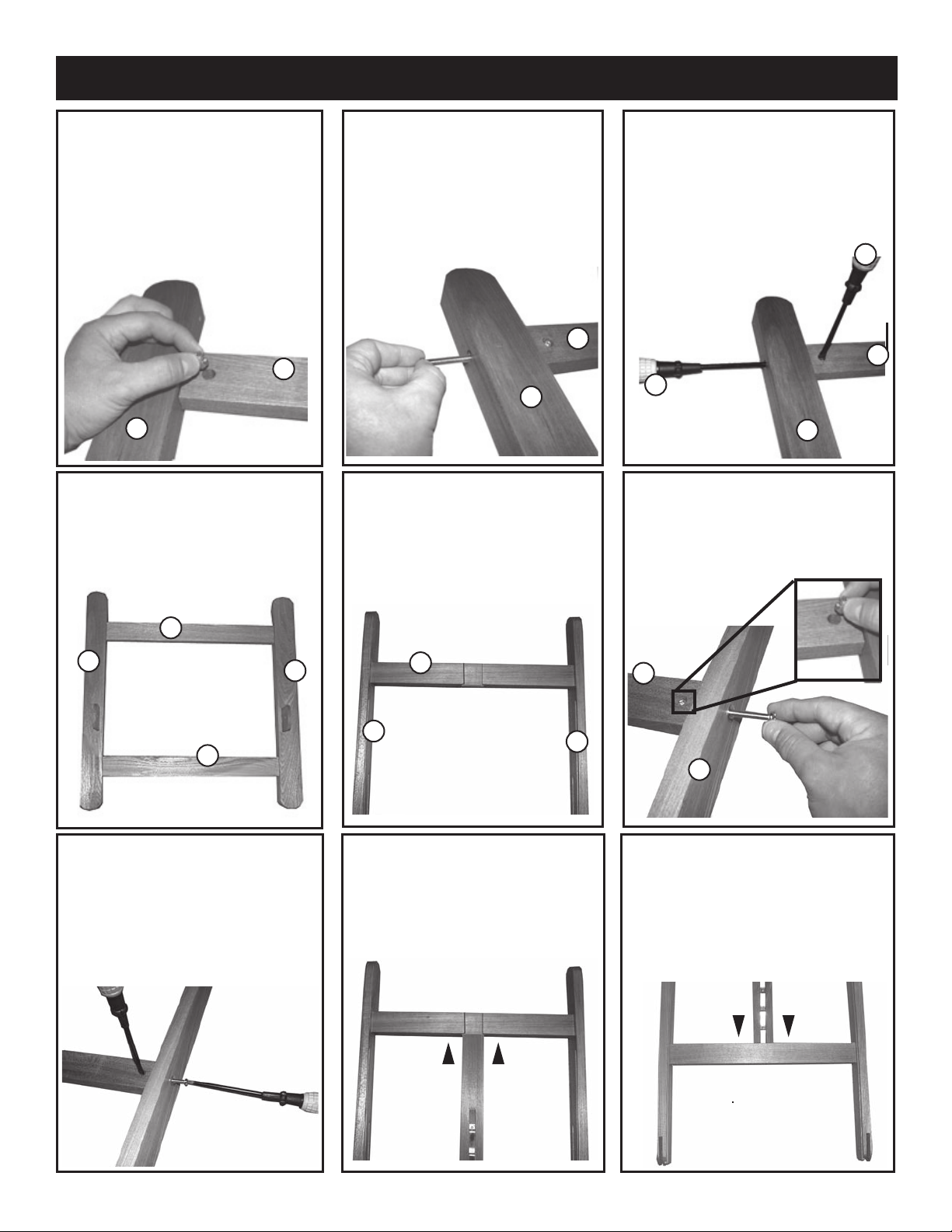

For recommended assembly lay all wood parts on flat surface with all holes facing up.

STEP 1. Assembling Base.

Take each Base Foot [ID#1] (make

sure wood hinges are on top.) along

with each Base Foot Connectors

- Make sure holes are on bottom

of base. [ID#2]. Insert T-Nut from

Carriage Bolt [ID# A] into hole in

Base Foot Connector. See FIG 1.

Repeat on all 4 sides.

FIG 1

2

1

STEP 4. Assembled Base.

The Base assembly should look like

FIG 4. NOTE: Holes where T-Nuts

should be located on bottom of

assembled base, if properly

assembled.

STEP 2. Assembling Base.

After inserting T-Nuts, continue by

inserting Carriage Bolt (6x60mm)

into the sides of the Base Foot

[ID#1] making sure bolt screws into

T-nut by aligning T-nut opening with

bolt. Repeat for each of the

remaining 3 sides. See FIG 2.

FIG 2

2

1

STEP 5. Assembling Side Arms.

Start by taking the two side arms

[ID#3] and the upper side arm connector [ID#4]. Position as shown in

FIG 5. Please note: The ends of the

side arms that have slots are the

bottom ends.

STEP 3. Assembling Base.

Secure each Carriage bolt by

attaching bolt with Philips

Screwdriver [ID#Y]. Use the Flat

Screwdriver [X] to hold the T-Nut in

place. See FIG 3.

X

FIG 3

2

Y

1

STEP 6. Assembling Side Arms.

Insert T-nut into upper arm

connector. Continue by inserting

carriage bolt 6x50mm into hole on

side of Side arm and into T-nut.

See Fig 6.

FIG 6

2

1

FIG 4

2

STEP 7. Assembling Side Arms.

Secure Carriage bolt by attaching

bolt with Philips Screwdriver [ID#Y].

Use the Flat Screwdriver [X] to hold

the T-Nut in place. Repeat with

other side. See FIG 7 & FIG 5 for

final result of this step.

1

FIG 7

4

3

FIG 5

STEP 8. Ratchet Center Column

Insert Ratchet Center Column up

into slotted section of upper side arm

connector. Make sure ratchet center

column is positioned as shown in

FIG 8.

FIG 8

3

4

3

STEP 9. Lower Side Arm Connector

Insert Ratchet Center Column down

into the oval hole on the end of the

lower side arm connector. Make sure

ratchet center column is positioned as

shown in FIG 9. T-nut Holes in

connector should be on backside.

Pg. 2

FIG 9

Created June 06 RPI

Page 3

STEP 10. Center column to Lower

Canvas Tray

Insert Center Column [ID#7] into

oval slot on top edge of Lower Canvas Tray [ID#8]. Insert T-nut from

part [ID#C]. See FIG 10.

FIG 10

7

STEP 11. Center column to Lower

Canvas Tray continued

Insert Carriage bolt [ID#C] into hole

in bottom end of Lower Canvas

Tray [ID#8]. Using phillips screw

driver [ID# Y] tighten and secure

bolt into T-nut. See FIG 11.

7

FIG 11

STEP 12. Attaching Loop-pull to

Lower Canvas Tray

Attach Loop-pull mechanism [ID#E]

to bottom end of Lower Canvas Tray

using [4] small wood screws [ID#F].

See FIG 12.

7

8

STEP 13. Attaching Center Column

to Side Arm Frame Assembly.

With Side Arm Frame Assembly

laying face up on carpeted surface,

slide Center column’s angled edge

up through Upper side arm connector

[ID#4]. See FIG 13.

3

7

6

4

FIG 13

8

STEP 14. Attaching Center

Column to Side Arm Frame

Assembly, continued...

When attaching Center column to

Side Arm Frame Assembly line up

grooves in Lower Canvas tray to

channels in Side Arms. See FIG 14.

8

3

FIG 14

8

E

FIG 12

STEP 15. Loop-pull Adjustment

To allow Center column to move

freely, you must pull up on loop-pull

mechanism [ID#E]. See FIG 15.

7

E

6

FIG 15

5

STEP 16. Upper Canvas Support

Attach Upper Canvas Support, by

sliding it down over the Center

Column. Secure with Knob [ID#G].

NOTE: Loosen Knob to move Upper

Canvas Support to desired position

once Easel is assembled.

See FIG 16.

G

10

7

FIG 16

Created June 06 RPI

STEP 17. Side Leg Angle Supports

Attach Side Leg Angle Supports

[ID#9] to Side Arms using the [2]

Knobs [ID#H], washer and bolt.

NOTE: make sure angle support is

attached to inside of Side Arm.

See FIG 17.

9

3

FIG 17

STEP 18. Side Leg Angle Supports.

Continued...

See FIG 18 for the correct order of

attachment.

Side Arm

Washer

Angle Support

Knob

6x45mm

Bolt

3

9

FIG 18

Pg. 3

Page 4

STEP 19.

Side Arm Frame Assembly to Base Attachment

STEP 20.

Side Leg Angle Support to base assembly

With Base laying face-up on

carpeted floor, line up notched grooves on bottom ends of

the Side Arm Frame Assembly with wooden supports on

base. Secure with Knob, washer and 6x35mm bolt [ID#I].

Insert bolt through inside side of side arm through base

foot, then back through other side of side arm. Attach

washer and then secure with knob.

Repeat with other side.

See FIG 19.

NOTE: This knob can be loosened when angle of

easel needs to be adjusted. Re-tighten when desired

angle is achieved.

3

1

Attach side leg angle support [ID#9] to base using one

6x45mm wood screw [ID#D]. Repeat with other side.

Tighten with phillips screwdriver [ID#Y].

See FIG 20.

9

1

D

Y

FIG 19

Angle Adjustment:

Loosen knobs on side leg angle supports and tighten at

desired angle.

Height Adjustment of Center Column:

Unlock loop-pull on lower canvas support, adjust to desired height and release loop-pull.

Enjoy your Easel!

If you have any problems with assembling this

easel, please call (313)895-0700 or e-mail us at

Custservmud@aol.com.

Thank You.

FIG 20

Easel should

like photo to

right after

correct

assembly.

Martin/F. Weber Co. • 4444 Lawton Avenue, Detroit, MI 48208 USA

Tel:(313)895-0700 • Fax:(313)895-0709 • E-mail:Custservmud@aol.com

www.MartinUniversalDesign.com • www.weberart.com

Made in China

Created June 06 RPI

92-2100

Murano

Professional

Studio Easel

Pg. 4

Loading...

Loading...