Page 1

IMPORTANT NOTICE

YOU WILL FEEL A SLIGHT

“BOUNCE-BACK” WHEN YOU SIT DOWN.

THIS IS NORMAL: NOT A DEFECT.

THE PNEUMATIC CYLINDER FOR THE

SEAT HEIGHT ADJUSTMENT REACTS TO

YOUR WEIGHT BY GIVING A LITTLE

Parts

a.

b.

A. [1] Base Plate

Mechanism

B. [1] Cylinder

[a] 91-1006 model

[b] 91-1009 model

D. [1] Plastic Ring insert

Model 91-1006 only

(This part can be found in

the foot ring Part F)

C. [5] Castors

STANFORD Model’s

91-1006 & 91-1009

Assembled 91-1006

Assembled 91-1009

F. [1] Foot Ring with Knob

Model 91-1006 only.

E. [1] 5-Star Base

I. [10] 1-1/2” Hex Head Screws

& [10] Washers

IMPORTANT

If you have difficulty assembling your chair or need customer service assis

tance. Please call: Martin Universal Design, Inc. Customer Service Hot Line at

1-800-366-7337. If you need additional parts, it is not necessary to contact your

dealer, our Customer Service Rep. will forward them to you immediately.

G. [1] Backrest with Support bar

J. [1] Black Cylinder

Model 91-1009 only

-

H. [1] Seat

Bellows

K. [2] Loop Armrests

4444 Lawton Avenue, Detroit MI 48208 USA

Tel:(313)895-0700 • Fax:(313)895-0709

E-mail: Custservmud@aol.com

Visit us at:

www.MartinUniversalDesign.com

Revised 05/06 RPI

Page 2

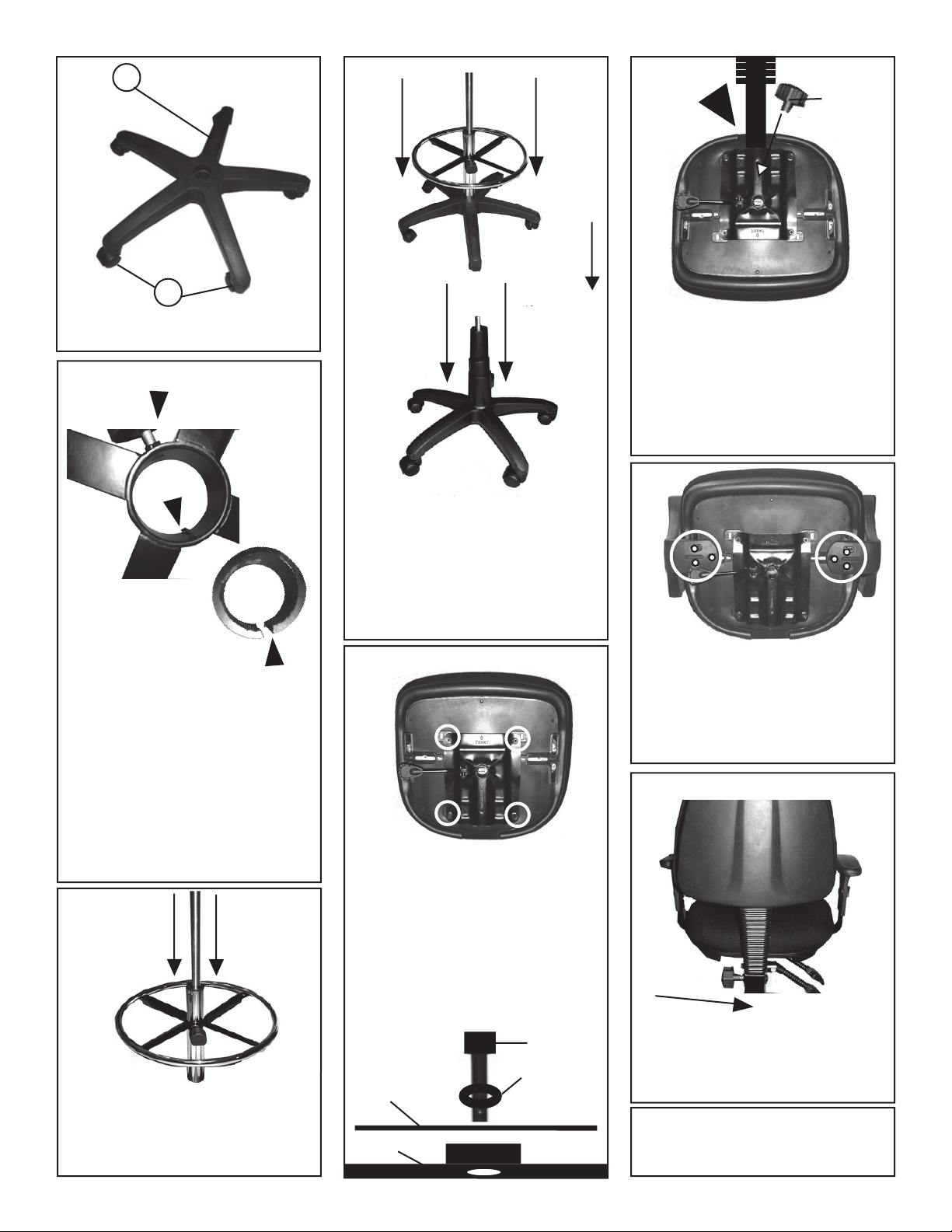

1.

E

4.

Model #

91-1006

6.

Knob

C

Place 5-star base (E) face down and

push [5] castors (C) into each position.

knob on foot ring

2.

weld

Cut ends of plastic

insert must run parallel

with the weld.

THIS STEP IS ONLY FOR

MODEL 91-1006 ONLY.

Before attaching foot ring (F) to cylinder

(B). Begin by loosening the knob on the

foot ring and position the plastic ring

insert properly, by making sure the cut

ends of the insert run parallel with the

weld on the inside of the foot ring hole.

The insert should be already in the foot

ring. NOTE: THIS MUST BE

POSITIONED PROPERLY TO ALLOW

THE CYLINDER TO SLIDE THROUGH

THE INSERT EASILY.

3.

Model #

91-1009

PLEASE NOTE: If you have model

number 91-1009, your assembly

will be the same but instead of foot

ring you will need to place black

bellows (J) over top of cylinder after

inserting cylinder into base.

Insert wider end of cylinder into hole in

base, as shown above.

5.

Attach mechanism (A) to seat (H)

using [4] 1.5” hex head screws (J) and

[4] Washers . See picture above for

specified locations that are circled.

Tighten with hex wrench

Attach as shown in th order pictured

below::

Attach back rest (G) to seat mechanism,

by inserting backrest support bar into

raised area of mechanism. Attach knob

making sure it is positioned through

mechanism and into hole in back support bar. Tighten knob to secure. NOTE:

This knob is also used for horizontal

adjustment of backrest.

7.

Attach armrests (K) to bottom side

of seat using [3] 1-1/2” screws and 3

washers (I) per armrest (K). Please see

circled areas in the above picture for

locations of screw holes.

Tighten with hex wrench

8.

Slide cylinder down through foot

ring and tighten knob . After chair is

assembled completely, you may adjust

foot ring to desired height.

Mechanism

Seat Bottom

Screw

Metal

washer

Attach seat/backrest/armrest assembly

to cylinder by inserting top of cylinder

into hole on bottom of seat mechanism.

Weight of sitting on seat will secure seat

assembly to cylinder.

NOTE: 2 Paddles below seat

are for seat height adjustment

and Backrest tilt adjustments.

Revised 05/06 RPI

Loading...

Loading...