Martin Logan Logos Owners manual

User's Manual

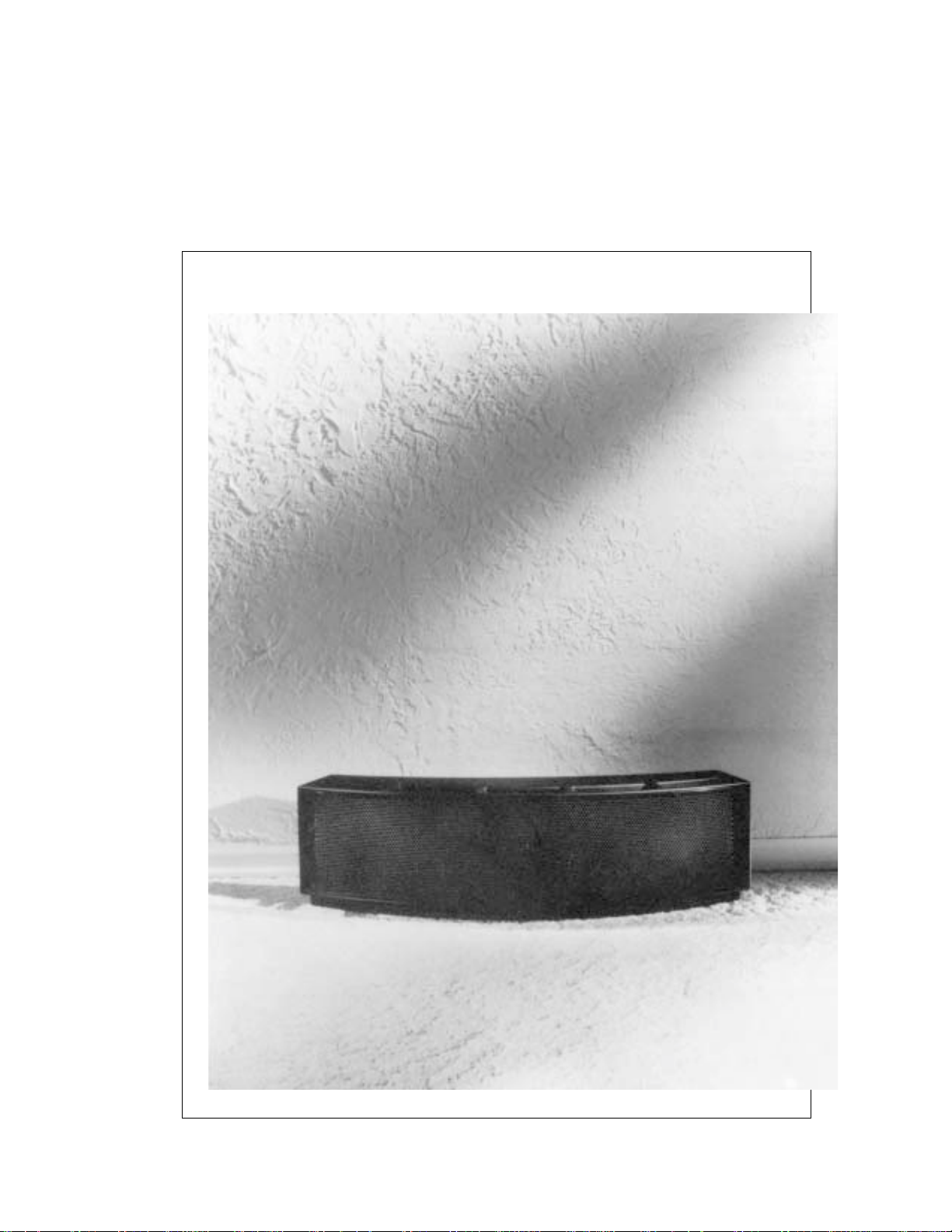

The Logos Center Channel

Important

Contents

Your Logos

Limited 90 Day Warranty coverage.

You have the option, at no additional charge, to receive

Limited 3 Year Warranty coverage. To obtain Limited 3

Year Warranty coverage you need only complete and

return the Certificate of Registration that was included

with your speaker along with a copy of your invoice to

Martin-Logan, within 30 days of purchase.

Martin-Logan may not honor warranty serviceMartin-Logan may not honor warranty service

Martin-Logan may not honor warranty service

Martin-Logan may not honor warranty serviceMartin-Logan may not honor warranty service

claims unless we have a completed Warrantyclaims unless we have a completed Warranty

claims unless we have a completed Warranty

claims unless we have a completed Warrantyclaims unless we have a completed Warranty

Registration card on file!Registration card on file!

Registration card on file!

Registration card on file!Registration card on file!

Should you be using your Martin-Logan product in a

country other than the one in which it was originally

purchased, we ask that you note the following:

1) The appointed Martin-Logan distributor for any given

country is responsible for warranty servicing only on

units distributed by or through it in that country in

accordance with its applicable warranty.

2) Should a Martin-Logan product require servicing in a

country other than the one in which it was originally

purchased, the end user may seek to have repairs

performed by the nearest Martin-Logan distributor,

subject to that distributor's local servicing policies,

but all cost of repairs (parts, labor, transportation)

must be born by the owner of the Martin-Logan

product.

3) If you relocate to another country, other than where

you purchased your Martin-Logan product, after

owning your speakers for 6 months your warranty

may be transferable. Contact Martin-Logan for

details.

If you did not receive a Certificate of Registration with

your Logos

received a new unit. If this is the case, please contact

your Authorized Martin-Logan dealer.

speaker is provided with an automatic

speaker you cannot be assured of having

Introduction 3

History 4

The Electrostatic Concept 6

Martin-Logan Exclusives 7

Installation Options 8

Operation 9

Logos Bracket Assembly/Setup 1 0

Room Acoustics 1 2

Dispersion Characteristics 1 4

Home Theatre 1 5

Questions 1 6

Troubleshooting 1 7

Glossary 1 8

Page 2

Logos Specifications 2 0

Logos User's Manual

Introduction

Congratulations, you have invested in the world's first

electrostatic hybrid home theatre speaker!

The advantages of Martin-Logan hybrid technology will

present themselves to you from moment the movie

begins. The box effect (a phenomenon similar to cupping

your hands around your mouth when speaking) produced

by dynamic midrange drivers is absent and the natural

openness of the human voice comes through. Never

before in home theatre has the midrange been so clear.

Sounds float around the screen clearly defining the area

from where they were created, not the area of the

speaker that created them. This superior performance is

made possible through the use of our proprietary curved

electrostatic transducer. This is the same design technology that is used in the state-of-the-art Martin-Logan

Loudspeaker Systems.

All materials in your new Logos speaker are of the

highest quality to provide years of enduring enjoyment

and deepening respect. The cabinetry is constructed from

a special high-density hardwood powderboard for

structural integrity and is finished with a durable and

attractive matte surface finish.

Through rigorous testing, the curvilinear electrostatic

panel has proven itself to be one of the most durable and

reliable transducers available today. Fabricated from a

specially tooled, high-grade steel, the panel is then

coated with a special high dielectric compound that is

applied via a proprietary electrostatic deposition process.

This panel assembly houses a membrane 0.0005 of an

inch thick! Ruggedly constructed and insulated, as much

as 200 watts of continuous power has driven the Logos

energized diaphragm into massive excursions with no

deleterious effects.

Please read and follow these instructions as you initially

install the Logos

important and will prevent you from experiencing any

delay, frustration, or system damage which might occur in

a trial-and-error procedure.

The other sections of your

detail the operation of your Logos

philosophy applied to its design. A clear understanding of

your speaker will insure that you obtain maximum

performance and pleasure from this most exacting

transducer.

Happy Listening!

into your system. These instructions are

User’s Manual User’s Manual

User’s Manual will explain in

User’s Manual User’s Manual

speaker and the

Logos User's Manual

Page 3

History

In the late 1800’s, any loudspeaker was considered

exotic. Today, most of us take the wonders of sound

reproduction for granted.

It was 1880 before Thomas Edison had invented the first

phonograph. This was a horn-loaded diaphragm that was

excited by a playback stylus. In 1898, Sir Oliver Lodge

invented a cone loudspeaker, which he referred to as a

“bellowing telephone”, that was very similar to the

conventional cone loudspeaker drivers that we know

today. However, Lodge had no intention for his device to

reproduce music, because in 1898 there was no way to

amplify an electrical signal! As a result, his speaker had

nothing to offer over the acoustical gramophones of the

period. It was not until 1906 that Dr. Lee DeForrest

invented the triode vacuum tube. Before this, an electrical

signal could not be amplified. The loudspeaker, as we

know it today, should have ensued then, but it did not.

Amazingly, it was almost twenty years before this would

occur.

In 1921, the electrically cut phonograph record became a

reality. This method of recording was far superior to the

mechanically cut record and possessed almost 30 dB of

dynamic range. The acoustical gramophone couldn't

begin to reproduce all of the information on this new disc.

As a result, further developments in loudspeakers were

needed to cope with this amazing new recording medium.

By 1923, Bell Telephone Laboratories made the decision

to develop a complete musical playback system consisting of an electronic phonograph and loudspeaker to take

advantage of the new recording medium. Bell Labs

assigned the project to two young engineers, C.W. Rice

and E.W. Kellogg.

Rice and Kellogg had a well equipped laboratory at their

disposal. This lab possessed a vacuum tube amplifier

with an unheard of 200 watts, a large selection of the new

electrically cut phonograph records and a variety of

loudspeaker prototypes that Bell Labs had been collecting over the past decade. Among these were Lodge’s

cone, a speaker that used compressed air, a corona

discharge (plasma) speaker, and an electrostatic

speaker.

After a short time, Rice and Kellogg had narrowed the

field of "contestants" down to the cone and the electrostat.

The outcome would dictate the way that future generations would refer to loudspeakers as being either

"conventional", or "exotic".

Bell Laboratory’s electrostat was something to behold.

This enormous bipolar speaker was as big as a door. The

diaphragm, which was beginning to rot, was made of the

membrane of a pigs intestine that was covered with fine

gold leaf to conduct the audio signal.

When Rice and Kellogg began playing the new electrically cut records through the electrostat, they were

shocked and impressed. The electrostat performed

splendidly. They had never heard instrumental timbres

reproduced with such realism. This system sounded like

real music rather than the honking, squawking rendition

of the acoustic gramophone. Immediately, they knew they

were on to something big. The acoustic gramophone was

destined to become obsolete.

Due to Rice and Kellogg's enthusiasm, they devoted a

considerable amount of time researching the electrostatic

design. However, they soon encountered the same

difficulties that even present designers face; planar

speakers require a very large surface area to reproduce

the lower frequencies of the audio spectrum. Because the

management at Bell Labs considered large speakers

unacceptable, Rice and Kellogg's work on electrostatics

would never be put to use for a commercial product.

Reluctantly, they advised the Bell management to go with

the cone. For the next thirty years the electrostatic design

lay dormant.

During the Great Depression of the 1930's, consumer

audio almost died. The new electrically amplified

loudspeaker never gained acceptance, as most people

continued to use their old Victrola-style acoustic gramophones. Prior to the end of World War II, consumer audio

saw little, if any, progress. However, during the late

1940's, audio experienced a great rebirth. Suddenly there

was tremendous interest in audio products and with that,

a great demand for improved audio components. No

sooner had the cone become established than it was

challenged by products developed during this new

rebirth.

Page 4

Logos User's Manual

In 1947, Arthur Janszen, a young Naval engineer, took

part in a research project for the Navy. The Navy was

interested in developing a better instrument for testing

microphone arrays. The test instrument needed an

extremely accurate speaker, but Janszen found that the

cone speakers of the period were too nonlinear in phase

and amplitude response to meet his criteria. Janszen

believed that electrostats were inherently more linear

than cones, so he built a model using a thin plastic

diaphragm treated with a conductive coating. This model

confirmed Janszen's beliefs, for it exhibited remarkable

phase and amplitude linearity.

Janszen was so excited with the results that he continued

research on the electrostatic speaker on his own time. He

soon thought of insulating the stators to prevent the

destructive effects of arcing. By 1952 he had an electrostatic tweeter element ready for commercial production.

This new tweeter soon created a sensation among

American audio hobbyists. Since Janszen's tweeter

element was limited to high frequency reproduction, it

often found itself used in conjunction with woofers, most

notably, woofers from Acoustic Research. These systems

were highly regarded by all audio enthusiasts.

presented a difficult load that some amplifiers did not like,

its dispersion was very directional, and its power handling was limited to around 70 watts. As a result, many

people continued to use box speakers with cones.

In the early 1960's Arthur Janszen joined forces with the

KLH loudspeaker company and together they introduced

the KLH 9. Due to the large size of the KLH 9, it did not

have as many limitations as the Quad. The KLH 9 could

play markedly louder and lower in frequency than the

Quad ESL. Thus a rivalry was born.

Janszen continued to develop electrostatic designs. He

was instrumental in the design of the Koss Model One,

the Acoustech, and the Dennesen speakers. Roger West,

the chief designer of the JansZen Corporation became

the president of Sound Lab. When JansZen Corporation

was sold, the RTR loudspeaker company bought half of

the production tooling. This tooling was used to make the

electrostatic panels for the Servostatic, a hybrid electrostatic system that was Infinity's first speaker product. Other

companies soon followed; each with their own unique

applications of the technology. These include Acoustat,

Audiostatic, Beverage, Dayton Wright, Sound Lab, and

Stax to name a few.

As good as these systems were, they would soon be

surpassed by another electrostatic speaker.

In 1955, Peter Walker published three articles on

electrostatic loudspeaker design in

Wireless World

, a

British electronics magazine. In these articles Walker

demonstrated the benefits of the electrostatic loudspeaker. He explained that electrostatics permit the use

of diaphragms that are low in mass, large in area, and

uniformly driven over their surfaces by electrostatic

forces. Due to these characteristics, electrostats have the

inherent ability to produce a wide bandwidth, flat frequency response with distortion products being no

greater than the electronics driving them.

By 1956 Walker backed up his articles by introducing a

consumer product, the now famous Quad ESL. This

speaker immediately set a standard of performance for

the audio industry due to its incredible accuracy. However, in actual use the Quad had a few problems. It could

not play very loud, it had poor bass performance, it

Logos User's Manual

Electrostatic speakers have progressed and prospered

because they actually do what Peter Walker claimed they

would. The limitations and problems experienced in the

past were not inherent to the electrostatic concept. They

were related to the applications of these concepts.

Today, these limitations have been addressed. Advancements in materials due to the U.S. space program give

designers the ability to harness the superiority of the

electrostatic principle. Today's electrostats use advanced

insulation techniques or provide protection circuitry. The

poor dispersion properties of early models have been

addressed by using delay lines, acoustical lenses,

multiple panel arrays or, as in our own products, by

curving the diaphragm. Power handling and sensitivity

have been increased.

These developments allow the consumer the opportunity

to own the highest performance loudspeaker products

ever built. It's too bad Rice and Kellogg were never able

to see just how far the technology would be taken.

Page 5

The Electrostatic Concept

How can sound be reproduced by something that you are

able to see through? Electrostatic energy makes this

possible.

Where the world of traditional loudspeaker technology

deals with cones, domes, diaphragms and ribbons that

are moved with magnetism, the world of electrostatic

loudspeakers deals with charged electrons attracting and

repelling each other.

To fully understand the electrostatic concept, some

background information will be helpful. Remember when

you learned, in a science or physics class, that like

charges repel each other and

opposite charges attract each

other? Well, this principle is the

An Electrostatic TransducerAn Electrostatic Transducer

An Electrostatic Transducer

An Electrostatic TransducerAn Electrostatic Transducer

foundation of the electrostatic

concept.

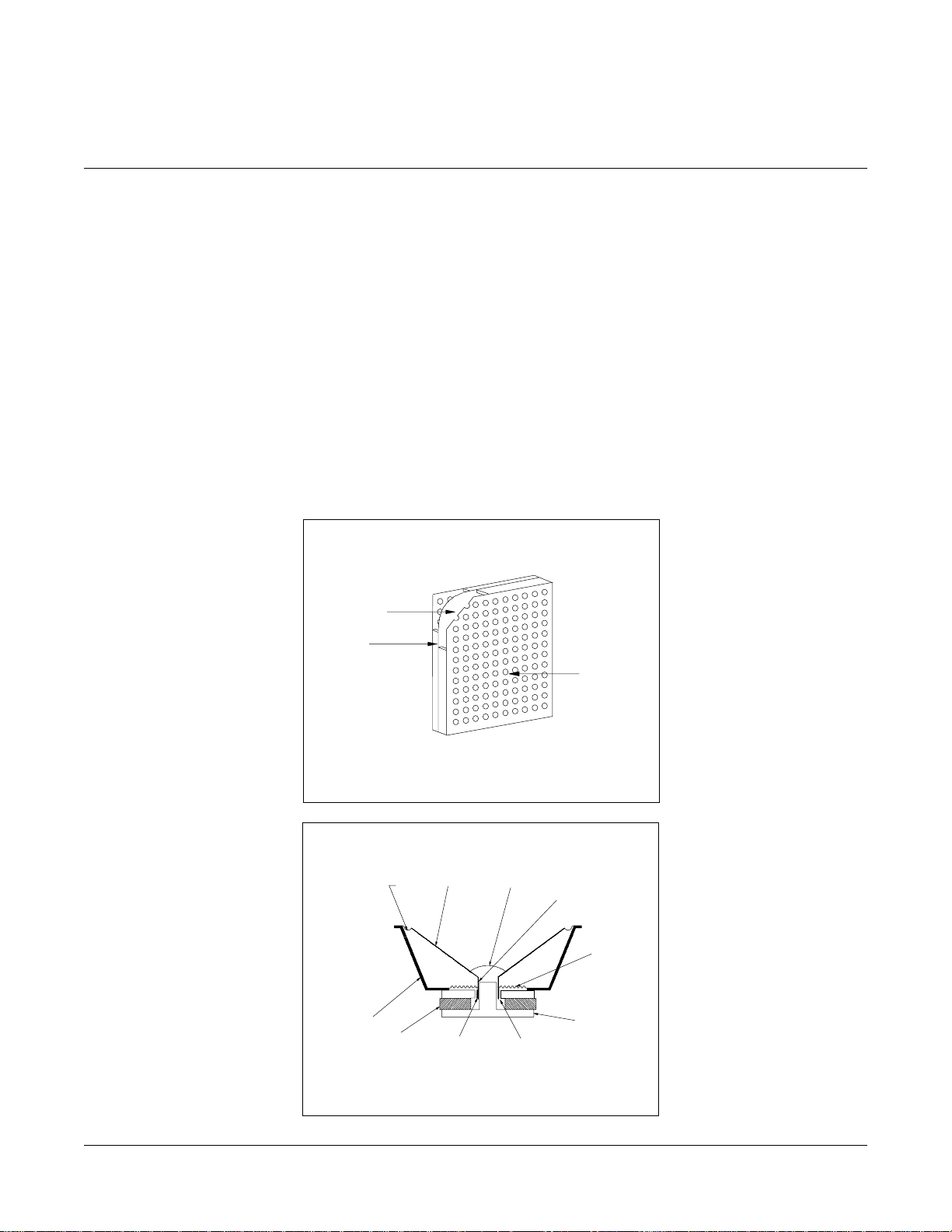

An electrostatic transducer

consists of three pieces: the

stators, the diaphragm and the

spacers.

See Figure 1

. The

Diaphragm

Spacer

diaphragm is what actually

moves to excite the air and

create music. The stator's job is

to remain stationary, hence the

word stator, to provide a

reference point for the moving

diaphragm. The spacers

provide the diaphragm with a

Figure 1Figure 1

Figure 1. Cut away view of an electrostatic transducer.

Figure 1Figure 1

Notice the simplicity due to minimal parts usage.

fixed distance in which to move

between the stators.

An Electromagnetic TransducerAn Electromagnetic Transducer

An Electromagnetic Transducer

An Electromagnetic TransducerAn Electromagnetic Transducer

As your amplifier sends music

signals to an electrostatic

Surround

speaker, these signals are

changed into two high-voltage

signals that are equal in

strength but opposite in polarity.

These high voltage signals are

then applied to the stators. The

resulting electrostatic field,

created by the opposing high

voltage on the stators, works

Basket Assembly

Magnet

simultaneously with and against

the diaphragm, consequently

moving it back and forth,

producing music. This tech-

Figure 2.Figure 2.

Figure 2. Cut away view of a typical moving coil driver.

Figure 2.Figure 2.

Notice the complexity due to the high number of parts.

Cone

nique is known as push-pull operation and is a major

contributor to the sonic purity of the electrostatic concept

due to its exceptional linearity and low distortion.

Since the diaphragm of an electrostatic speaker is

uniformly driven over its entire area, it can be extremely

light and flexible. This allows it to be very responsive to

transients, thus perfectly tracing the music signal. As a

result, great delicacy, nuance and clarity is possible.

When you look at the problems of traditional electromagnetic drivers, you can easily see why this is so beneficial.

The cones and domes which are used in traditional

electromagnetic drivers cannot be driven uniformly

because of their design.

Cones are driven only at the

apex. Domes are driven at

their perimeter. As a result,

the rest of the cone or dome

is just "along for the ride".

The very concept of these

drivers require that the cone

or dome be perfectly rigid,

Stator

damped and massless.

Unfortunately these conditions are not available in our

world today.

To make these cones and

domes move, all electromagnetic drivers must use voice

coils wound on formers,

spider assemblies, and

surrounds to keep the cone

See

Dust Cap

Voice Coil Former

or dome in position.

Figure 2.

These pieces, when

combined with the high mass

of the cone or dome materials used, make it an extremely complex unit with

Spider

many weaknesses and

potential for failure. These

faults contribute to the high

distortion products found in

Magnet Assembly

Magnetic GapVoice Coil

these drivers and is a

tremendous disadvantage

when you are trying to

change motion as quickly and

as accurately as a loudspeaker must (40,000 times

per second!).

Page 6

Logos User's Manual

Martin-Logan Exclusives

Vapor Deposited FilmVapor Deposited Film

Vapor Deposited Film

Vapor Deposited FilmVapor Deposited Film

The diaphragm material used in all Martin-Logan

speakers employs an extremely sophisticated vapor

deposited conductive polymer membrane. A

proprietary conductive compound is vaporized then

electrostatically driven into the surface of the

polymer film in a vacuum chamber. This process

allows an optically transparent membrane, adds no

mass to the diaphragm and is extremely uniform in its

surface resistivity characteristics. This uniform surface

resistivity controls the electrostatic charge on the

diaphragm surface and regulates its migration. As a

result, no discharging or “arcing” can occur.

Transducer IntegrityTransducer Integrity

Transducer Integrity

Transducer IntegrityTransducer Integrity

All Martin-Logan transducers begin with two pieces

of high grade, cold rolled steel. These steel pieces

are then custom perforated and insulated with an

exotic composite coating. This proprietary coating

insulates the stator to 3 times its actual needed

working voltage and gives the Logos a wide margin

of safe operation. In addition to the electrical

insulation properties, this coating also provides the

Logos with a durable, attractive finish that dampens

the steel to prevent ringing. The finished metal plates

are curved into a 30 degree arc. Placed between

them is our exclusive vapor deposited diaphragm

and spacers. This assembly is then bonded together

with aerospace adhesives whose strength is so great

that it is commonly used as an alternative to welding.

The result of these advanced technologies is a

transducer that is attractive, durable, highly rigid, well

dampened, and neutral.

Mechanical/AcousticalMechanical/Acoustical

Mechanical/Acoustical

Mechanical/AcousticalMechanical/Acoustical Tone ShapingTone Shaping

Tone Shaping

Tone ShapingTone Shaping

The clear Lexan® panels on the back of the Logos stator

are the key elements of an innovative pressure compen-

sation technology. Martin-Logan is able to tone-shape the

diaphragm + or - 6dB without the use of an insertion loss

crossover. The advantage of this system is a high

efficiency driver with wide bandwidth capabilities of

dimensions which are easily integrated into a domestic

environment.

Curvilinear Line SourceCurvilinear Line Source

Curvilinear Line Source

Curvilinear Line SourceCurvilinear Line Source

Since the beginning of audio, achieving smooth full

range dispersion has long been a problem for all

loudspeaker designers. Large panel transducers

present even more of a challenge because the

larger the panel, the more directional the dispersion

pattern becomes.

Full range electrostatics have always been one of

the most complex transducers because they attain

their full range capabilities via a large surface area. It

looked as if they were in direct conflict to smooth

dispersion and almost every attempt to correct this

resulted in either poor dispersion or a serious compromise in sound quality.

After extensive research, Martin-Logan engineers

discovered an elegantly simple solution to achieve a

smooth pattern of dispersion without degrading

sound quality. By curving the horizontal plane of the

electrostatic transducer, a controlled horizontal

dispersion pattern could be achieved, yet the purity

of the almost massless electrostatic diaphragm

remained uncompromised. After creating this technology, we developed the production capability to

bring this technology out of the laboratory and into

the market place.

You will find this proprietary Martin-Logan technology

used in all of our products. It is one of the many

reasons behind our reputation for high quality sound

with practical usability. This is also why you see the

unique "see through" cylindrical shape of all MartinLogan products.

Logos User's Manual

Page 7

Loading...

Loading...