Page 1

THRILL Mini Profile

Safety and Installation Guide

WARNING!

Read the safety precautions in this guide before

installing or using this product.

Introduction

The THRILL Mini Profile is a compact moving-head lighting

fixture with an 18 watt long-life LED light source. It provides

8 pattern gobos, 8 glass color filters, full-range dimming, strobe

effects, and manually adjustable focus. The rugged, lightweight

construction makes it ideal for mobile DJs and small venues.

It is supplied with this guide, a user guide, power cables, and

bracket for attachment of a suitable, user-supplied rigging clamp.

Before installing and using the fixture:

1. Read the safety information.

2. Unpack the fixture and ensure that there is no

transportation damage. Do not attempt to operate

a damaged fixture.

3. Ensure that your AC voltage and frequency match

the power requirements of the fixture.

4. Check the Martin Professional website at www.martin.com

for the most recent product documentation and technical

information. Martin document revisions are identified by

the revision letter below the legal notices.

Safety information

The following symbols identify important safety information:

Warning!

Safety hazard.

Risk of severe

injury or death.

Warning!

Powerful light

emission. Risk

of eye injury.

Warning!

See user

manual for

important

safety

information.

Warning!

Hazardous

voltage. Risk of

lethal electric

shock.

Warning!

Hot surfaces.

Warning!

Fire hazard.

Warning! Risk Group 2 product according to

EN 62471. Possibly hazardous radiation emitted

from this product. May be harmful to the eyes.

Do not stare at operating lamp and do not view

the light output with optical instruments or any device that may

concentrate the beam.

This lighting fixture presents risks of severe injury or death due

to fire hazards, electric shock and falls. It produces a powerful,

concentrated beam of light that can create a fire hazard or a risk

of eye injury if the safety precautions are not followed.

Install, operate and service this product only as directed,

or you may create a safety hazard or cause damage that is

not covered by product warranties.

Follow the safety precautions below and observe

all warnings on the product. Follow the instructions

and observe all warnings in the product’s user

guide. Keep this information for future reference.

For the latest user documentation and other information about

this and all Martin products, visit the Martin website at

http://www.martin.com.

Respect all locally applicable laws, codes and regulations

when installing, operating or servicing the product.

Protection from electric shock

Do not expose the product to water or moisture.

Disconnect the product from AC power before

carrying out installation or maintenance and

when the product is not in use.

Ensure that the product is electrically connected to ground

(earth).

Use only a source of AC power that complies with local building

and electrical codes and has both overload and ground-fault

(earth-fault) protection.

Socket outlets or external power switches used to supply the

product with power must be located near the product and easily

accessible so that it can easily be disconnected from power.

Replace blown fuses with ones of the specified type and rating.

Isolate the product from power immediately if the power plug

or any seal, cover, cable, or other component is damaged,

defective, deformed, wet or showing signs of overheating.

Do not reapply power until the problem is corrected.

Before connecting the product to power, check that all power

distribution equipment and cables are undamaged and rated

for the electrical requirements of all connected products.

Protection from burns and fire

Do not operate the fixture if the ambient

temperature (Ta) exceeds 40° C (104° F).

The surface of the product casing can reach up

to 45° C (113° F) after 5 minutes of operation and

during a steady on state. Avoid contact by persons

and materials. Allow the fixture to cool for at least

10 minutes before handling.

Keep flammable materials well away from the

fixture. Keep all combustible materials (e.g. fabric, wood, paper)

at least 100 mm (4 in.) away from the fixture head.

Ensure that there is free and unobstructed airflow around the

fixture. Provide a minimum clearance of 100 mm (4 in.) around

fans and air vents.

Do not illuminate surfaces within 200 mm (8 in.) of the fixture.

Do not attempt to bypass thermostatic switches or fuses.

Do not stick filters, masks or other materials onto any optical

component.

The fixture’s lenses can focus the sun’s rays ins ide the fixture,

creating a risk of fire and damage. Do not expose the front of

the fixture to sunlight or any other bright light source.

Protection from eye injury

Lighting fixtures emit possibly hazardous radiation.

Do not look at an operating lamp. Eye injury

may result.

To minimize the risk of eye injury or irritation,

disconnect lighting fixtures from power at all times when not in

use, and provide well-lit conditions to reduce the pupil diameter

of anyone working on or near them.

Do not look at output from lighting fixtures with magnifiers,

telescopes, binoculars or similar optical instruments that may

concentrate the light.

Ensure that persons are not looking directly into a lighting fixture

when it lights up suddenly. This can happen when power is

applied, when the fixture receives a remote control signal,

or when certain control menu items are selected.

Protection from injury

Do not attempt to repair a defective product or

modify the product in any way. LEDs are not userreplaceable. Refer all service to your Martin dealer

or contact Martin directly for technical support

through www.martin.com/contact-support.

Fasten the fixture securely to a fixed surface or structure when

in use. The fixture is not portable when installed.

Ensure that any supporting structure and/or hardware used can

hold at least 10 times the weight of all the devices they support

and complies with locally applicable regulations.

If suspending from a rigging structure, fasten the fixture to a

rigging clamp. Do not use safety cables as the primary means

of support.

If the product is installed in a location where it may cause injury

or damage if it falls, install as directed a secondary attachment

such as a safety cable that will hold the machine if a primary

attachment fails. The secondary attachment must be approved

by an official body such as TÜV as a safety attachment for the

weight that it secures, must comply with EN 60598-2-17 Section

17.6.6 or BGV C1 / DGUV 17, and must be capable of bearing a

static suspended load at least six times the weight of the fixture

(or more if required by locally applicable regulations).

Allow enough clearance around the head to ensure that it

cannot collide with an object or another fixture when it moves.

Check that all external covers and rigging hardware are

securely fastened.

Block access below the work area and work from a stable

platform whenever installing, servicing or moving the fixture.

Do not operate the fixture with missing or damaged covers,

shields or any optical component.

Do not lift or carry the fixture by its head. Support the fixture

by its base only.

In the event of an operating problem, stop using the fixture

immediately and disconnect it from power. Do not attempt

to use a fixture that is obviously damaged.

Do not modify the fixture in any way not described in this

manual or install other than genuine Martin parts.

Refer any service operation not described in this manual

to a qualified technician.

Flashing light can trigger epileptic seizures in flicker-sensitive

persons. Provide notice when strobe lighting is in use at the

entrance(s) to the venue. Mount flashing lights as high above

head height as practicable and avoid extended periods of

continuous flashing, particularly at 10 to 20 flashes per second.

Stop lights from flashing immediately if a person has an epileptic

seizure.

Note that whenever power is applied to the fixture, it will reset

moving parts to their home (neutral) positions. Be prepared for

the head to move. A reset usually takes around 20 seconds.

Physical installation

The THRILL Mini Profile is designed for indoor

use only and must be used in a dry location with

adequate ventilation. Ensure that none of the

fixture’s ventilation slots are blocked and all

minimum distances are observed.

The fixture must be oriented vertically, either upright on the floor

or other horizontal surface, or suspended upside-down from

a suitable structure.

Fasten the THRILL Mini Profile to a secure structure or surface.

Do not stand it on a surface or leave it where it can be moved

or fall over. If you install the fixture in a location where it may

cause injury or damage if it falls, secure it as directed using a

securely anchored safety cable that will hold the fixture if the

primary fastening method fails.

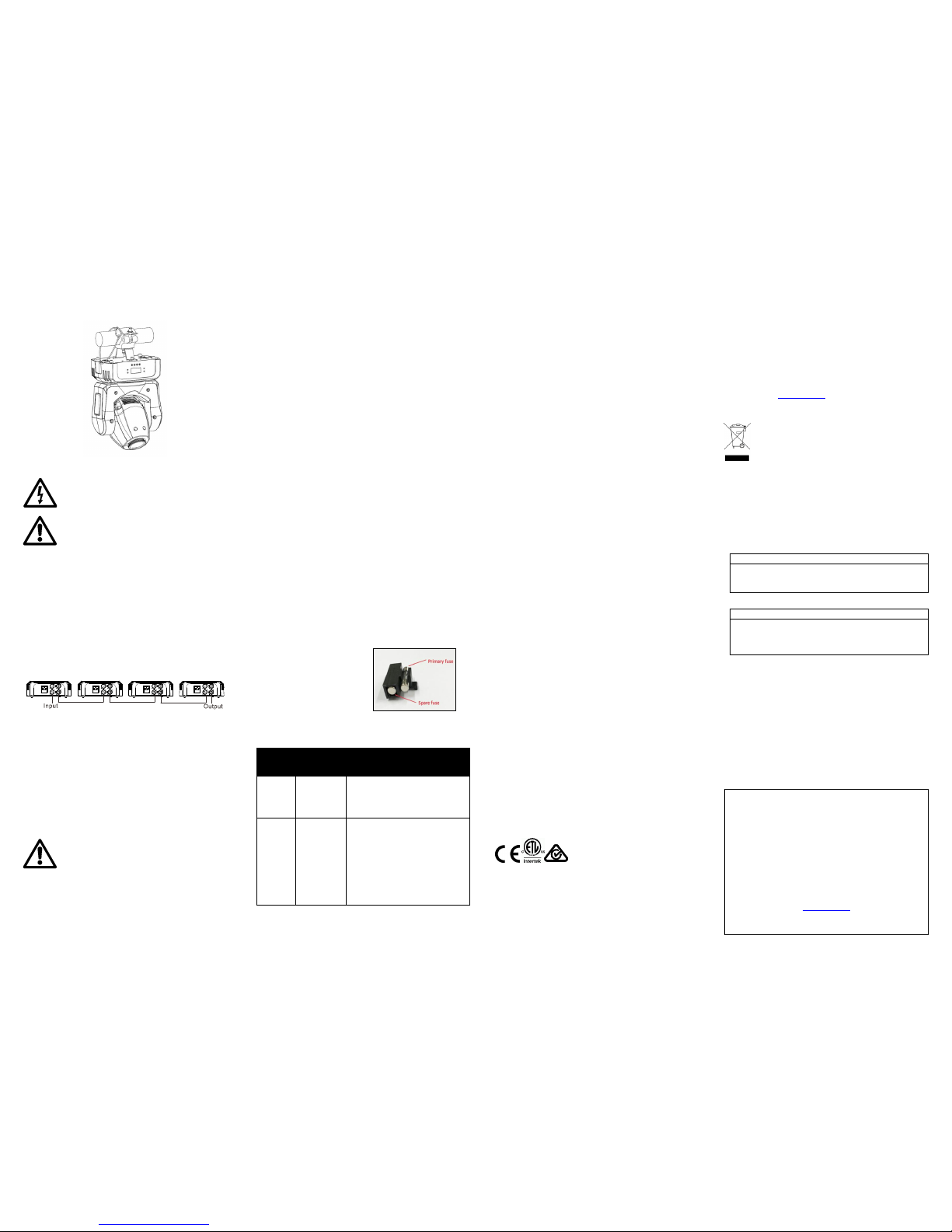

Fastening the fixture to a flat surface

The fixture can be fastened to a hard, fixed, flat surface. Ensure

that the surface and all fasteners used can support at least 10

times the weight of all fixtures and equipment they support and

comply with locally applicable regulations.

Fasten the fixture securely. Do not stand it on a surface or leave

it where it can be moved or fall over. If you install the THRILL

Mini Profile in a location where it may cause injury or damage

if it falls, secure it as directed with a securely anchored safety

cable that will hold the fixture if the primary fastening method

fails and complies with locally applicable regulations.

Mounting the fixture on a truss

The fixture can be clamped to a truss or similar

rigging structure. It must be suspended vertically,

hanging downwards only. Use a suitable rigging

clamp such as a half-coupler clamp (shown to right)

fastened to the included clamp attachment bracket.

To clamp the fixture to a truss:

1. Check that the rigging structure can support at least 10

times the weight of all fixtures and equipment to be installed

on it and complies with locally applicable regulations.

2. Block access under the work area.

3. Fasten a rigging clamp securely to the supplied clamp

attachment bracket. The bolt used must be M12, grade 8.8

steel minimum, and fastened with a self-locking nut or

wing-nut/self-locking washer combination. Comply with

instructions provided from the manufacturer of the clamp

being used.

4. Fasten the hanging bracket to the fixture by screwing the

two hex type socket cap screws provided fully into holes A

in the base (see above) using the lock washers provided.

5. Working from a stable platform, hang the fixture vertically

on the truss and fasten the rigging clamp onto the truss.

6. Secure the fixture with a safety cable as directed.

7. Check that the head will not collide with other objects.

Note – Use only the socket cap screws provided to fasten the

bracket to the fixture. Using a screw longer than 12 mm (0.5 in.)

may damage the fixture. If screws are missing or damaged,

contact Martin® service and support for assistance.

Securing with a safety cable

Secure the THRILL Mini Profile with a safety cable or other

secondary attachment that is approved for the weight of the

fixture so that the safety cable will prevent it from falling if the

primary attachment fails. Loop the safety cable through one of

the two attachment points B in the base (see illustration above)

and around a secure anchoring point.

A

B

B

Page 2

Information subject to change without notice. HARMAN

Professional Denmark ApS disclaims liability for any injury,

damage, direct or indirect loss, consequential or economic

loss or any other loss occasioned by the use of, inability to

use or reliance on the information contained in this document.

©2017 HARMAN Professional Denmark ApS. All rights reserved.

Martin® is a trademark of HARMAN Professional Denmark ApS

registered in the United States and/or other countries. Features,

specifications and appearance are subject to change without

notice.

HARMAN Professional Denmark ApS

Olof Palmes Allé 18 • 8200 Aarhus N • Denmark

www.martin.com

Document revision: A

If a safety cable attachment point becomes damaged

or deformed, do not suspend the fixture.

AC power

For protection from electric shock, the fixture must

be grounded (earthed). The power distribution

circuit must be equipped with a fuse or circuit

breaker and ground-fault (earth-fault) protection.

Socket outlets or external power switches used to

supply power must be located near the fixture and

easily accessible so that it can easily be

disconnected from power.

Do not use an external dimming system to supply power to the

THRILL Mini Profile, as this may cause damage to the fixture

that is not covered by the product warranty.

The fixture has an auto-ranging power supply that accepts AC

mains power at 100-240 V at 50/60 Hz. Do not apply AC mains

power at any other voltage or frequency.

Control data link

If using a DMX controller for fixture control, connect them to the

controller’s output. The THRILL Mini Profile ha s 3-pin and 5-pin

XLR connectors for DMX-standard data input and output. The

pin-out on all connectors is pin 1 = shield, pin 2 = cold (-), and

pin 3 = hot (+). Pins 4 and 5 are not used by the fixture but allow

for throughput to devices that may use them.

Up to 32 DMX devices can be linked together on a single daisy

chain. The total number of devices connected to a 512 channel

controller output is limited by the number of DMX channels

required by the devices. Use shielded twisted-pair cable

designed for RS-485 devices: standard microphone cable cannot

transmit control data reliably over long runs. 24 AWG cable is

suitable for runs up to 300 meters (1000 ft.). Heavier gauge cable

and/or an amplifier is recommended for longer runs.

Terminate the data link by installing a termination plug in the

output of the last fixture. The termination plug “soaks u p” the

control signal so it does not reflect and cause interference.

If a splitter is used, terminate each branch of the link.

Maintenance

The user may carry out the maintenance

operations described in this manual. Do not open

the housing, there are no user serviceable parts

inside the fixture, and do not try to repair a

defective fixture.

Disconnect the fixture from mains power before performing

maintenance.

Service fixtures in an area where there is no risk of injury

from falling parts, tools or other materials.

Cleaning

Excessive dust, effects fluid, and particle buildup degrades

performance, causes overheating and will damage the fixture.

Damage caused by inadequate cleaning or maintenance is not

covered by the product warranty.

The cleaning of external optical lenses must be carried out

periodically to optimize light output. Cleaning schedules for

lighting fixtures vary greatly depending on the operating

environment. It is therefore impossible to specify precise

cleaning intervals for the fixture. Environmental factors that may

result in a need for frequent cleaning include:

Use of effect machines.

High airflow rates (near air conditioning vents, for example).

Presence of cigarette smoke.

Airborne dust.

If one or more of these factors is present, inspect fixtures within

their first 100 hours of operation to see whether cleaning is

necessary. Check again at frequent intervals. This procedure

will allow you to assess cleaning requirements in your particular

situation.

Use gentle pressure only when cleaning, and work in a clean,

well-lit area. Do not use any fixture that contains solvents or

abrasives, as these can cause surface damage.

To clean the fixture:

1. Disconnect the fixture from power and allow it to cool for at

least 10 minutes.

2. Vacuum or gently blow away dust and loose particles from

the outside of the fixture and the air vents at the back and

sides of the head and in the base with low-pressure

compressed air.

3. Clean surfaces by wiping gently with a soft, clean lint-free

cloth moistened with a weak detergent solution. Do not rub

glass surfaces hard: lift particles off with a soft repeated

press. Dry with a soft, clean, lint-free cloth or low-pressure

compressed air. Remove stuck particles with an unscented

tissue or cotton swab moistened with glass cleaner or

distilled water.

Replacing the primary fuse

If the fixture is completely dead,

the primary fuse may have blown

and it may be necessary to install

a new fuse. Replace with a fuse

of the same size and specified

rating only. A spare fuse is

located in the fuse holder.

Troubleshooting

This section describes some typical problems and how to solve

them.

Symptom

Potential

Causes

Remedies

No light

from fixture,

or fans not

working.

Power supply

issue such as

blown fuse,

faulty connector

or damaged

cable.

Ensure that the mains supply is connected

and supplying power to the fixture.

Check all power connections and cables.

Check and if necessary replace the fuse.

Fixture

does not

respond to

DMX

control.

Fault in the

DMX network

due to

connector or

cable damage,

incorrect DMX

addressing, or

potential

interference

from proximity to

a high voltage

installation.

Ensure that fixture’s DMX address matches

address set on DMX control device.

Check that DMX LED is on, and if not, check

all DMX cables and connections.

Ensure that DMX link is terminated.

Check that all components on DMX link use

standard DMX polarity.

Attempt to control the fixture with another

DMX control device.

Move or shield link if it is close to an

unshielded high-voltage installation.

Specifications

Physical

Dimensions (L x W x H) ........ 237 x 155 x 338 mm (9.3 x 6.1 x 13.3 in.)

Weight ............................................................................ 4.3 kg (9.5 lbs.)

Dynamic Effects

Color wheel................ 8 colors plus open, variable and random rotation

Static gobo wheel ...... 8 gobos plus open, variable and random rotation

Strobe ...................Variable 3 - 20 Hz, pulse effects and random strobe

Electronic dimming ......................0 - 100%, four dimming curve options

Pan ...................................................................................................540°

Tilt .....................................................................................................230°

Control and Programming

Control options ...................... DMX, 4 stand-alone shows, master/slave

DMX channels ..................................................................................... 10

Stand-alone trigger ............................................ Sound-trigger, auto-run

User Interface ............................. Control panel with backlit LCD display

DMX compliance ........................................................ USITT DMX512-A

Optics

Light source ....................................................... 18 W white LED engine

Minimum LED lifetime ...........50 000 hours (to >70% luminous output)*

Beam angle ........................................................................................ 14°

Focus ........................................................................................... Manual

*Figure obtained under manufacturer´s test conditions

Construction

Color ............................................................................................... Black

Housing ... High-impact flame-retardant thermoplastic on metal chassis

IP rating ........................................................................................... IP 20

Installation

Orientation .............................................................. Standing or hanging

Mounting points ................. Bracket for single rigging clamp, M12 or ½”

Location ........................................................................ Dry location only

Minimum distance to Iilluminated surfaces ......................200 mm (8 in.)

Minimum distance to combustible materials ....................100 mm (4 in.)

Minimum clearance around fans and vents .....................100 mm (4 in.)

Connections

AC power input ......................................................... IEC male inlet, C14

DMX data in/out .............................................. 3-pin & 5-pin locking XLR

Electrical

AC power .................................................. 100-240 V nominal, 50/60 Hz

Fuse .................................................................................. T 2.0 A, 250 V

Typical power and current

120 V, 60 Hz ......................................................................... 52 W, 0.9 A

230 V, 50 Hz ......................................................................... 50 W, 0.4 A

Typical half-cycle RMS inrush current ............................................ 6.4 A

Measurements made at nominal voltage with all LEDs at full intensity.

Allow for a deviation of +/- 10%.

Thermal

Cooling ........................... Forced air (temperature-regulated, low noise)

Maximum ambient temperature (Ta max.) ...................... 40° C (104° F)

Minimum ambient temperature (Ta min) ............................... 0°C (32° F)

Total heat dissipation* ......................................................... 180 BTU/hr.

*Calculated, +/- 10%, at full intensity, full white

Approvals

EU safety ........... EN 60598-2-17, EN 61000-3-3, EN 62471, EN 62493

EU EMC ...................................................................................................

.............. EN 55015, EN 55032, EN 55103-2, EN 61000-3-2, EN 61547

US safety ................................................................................... UL 1573

US EMC .................................................. CFR Title 47, Part 15, Class A

Canadian safety ...................................................... CSA C22.2 No. 166

Canadian EMC ........................................................... ICES-003 Class A

Australia/NZ (pending) .................................................................... RCM

Included Items

Power Cable, EU, IEC C13 female, molded Schuko, 1.9 m (6.3 ft.)

Power Cable, US, IEC C13 female, molded NEMA 5-15, 1.9 m (6.3 ft.)

Bracket and hardware for rigging clamp attachment

Accessories

Super-llightweight half-coupler clamp, black ................... PN: 91602018

Safety Cable, SWL 60 kg (132 lb.),

BGV C1/DGUV 17, black ................................................ PN: 91604006

Related Items

RUSH® Software Uploader ............................................. PN: 91611399

Martin® M-Touch ............................................................. PN: 90737040

Martin® M-Play ................................................................ PN: 90737030

Ordering Information

THRILL Mini Profile ......................................................... PN: 90240090

Specifications subject to change without notice. For latest product

specifications, see www.martin.com

Disposing of this product

THRILL by Martin® products are supplied in

compliance with Directive 2012/19/EC of the

European Parliament and of the Council of the

European Union on WEEE (Waste Electrical and

Electronic Equipment), where applicable. Help

preserve the environment! Ensure that this product is recycled

at the end of its life. Your supplier can give details of local

arrangements for the disposal of THRILL by Martin® products

Photo Biological Safety Warning

The warning shown below is displayed on this fixture. If it

becomes difficult or impossible to read, it must be replaced

using the illustration below to reproduce a new label sized 45 x

18 mm, in black on a yellow background.

RISK GROUP 2

CAUTION. Possibly hazardous optical radiation emitted from this

fixture.

Do not stare at operating lamp. May be harm ful to the eyes.

GROUPE DE RISQUE 2

PRUDENCE. Produit à émission de radiations visibles potentiellement

dangereuses.

Ne pas fixer le faisceau en fonctionnement. Risque de lésions

oculaires.

FCC Compliance

This device complies with Part 15, Class B, of the FCC Rules. Operation is subject

to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference

that may cause undesired operation.

Canadian Interference-Causing Equipment Régulations - Règlement sur le

Matériel Brouilleur du Canada

This Class B digital apparatus meets all requir ements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe B respecte toutes les exigences du

Règlement sur le Matériel Brouilleur du Canada.

Loading...

Loading...