Page 1

Stage Cyclo

User manual

Page 2

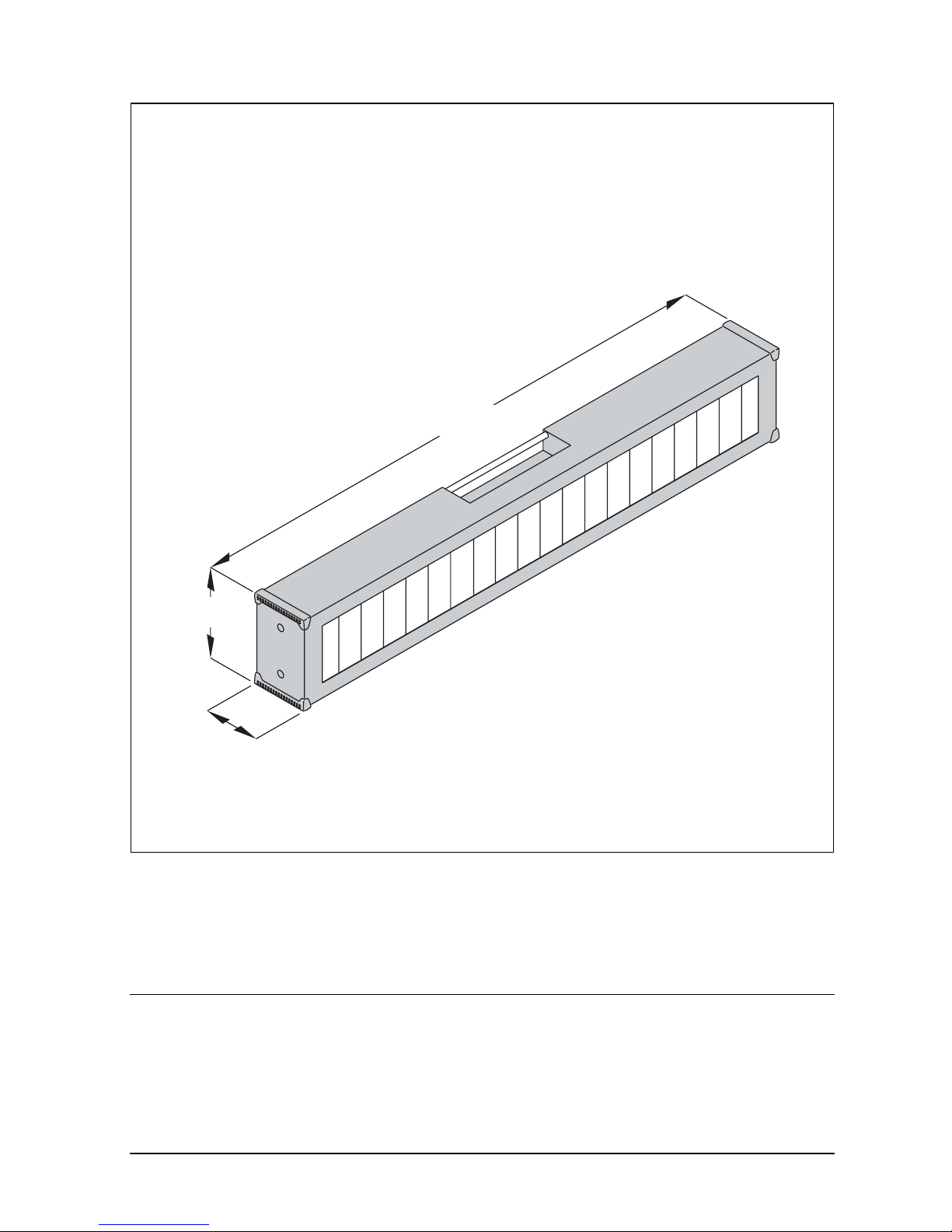

Dimensions

Measurements are in millimeters

1272

209

135

© 2005 Martin Professional A/S, Denmark.

All rights reserved. No part of this manual may be reproduced, in any form or by any means,

without permission in writing from Martin Professional A/S, Denmark.

Printed in Denmark.

P/N 35000167, Rev. B

Page 3

Contents

Product overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Connecting to a data link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Burning in fluorescent tubes . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Ambient temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Stand-alone operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

DIP-switch settings in stand-alone mode . . . . . . . . . . . . . . . . 15

Stand-alone operation settings . . . . . . . . . . . . . . . . . . . . . . . . 15

Single stand-alone operation. . . . . . . . . . . . . . . . . . . . . . . . . . 17

Master/slave stand-alone operation . . . . . . . . . . . . . . . . . . . . 17

DMX-controlled operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Setting a DMX control address . . . . . . . . . . . . . . . . . . . . . . . . 21

Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Fluorescent tubes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Main fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DMX protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Stage Cyclo Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Page 4

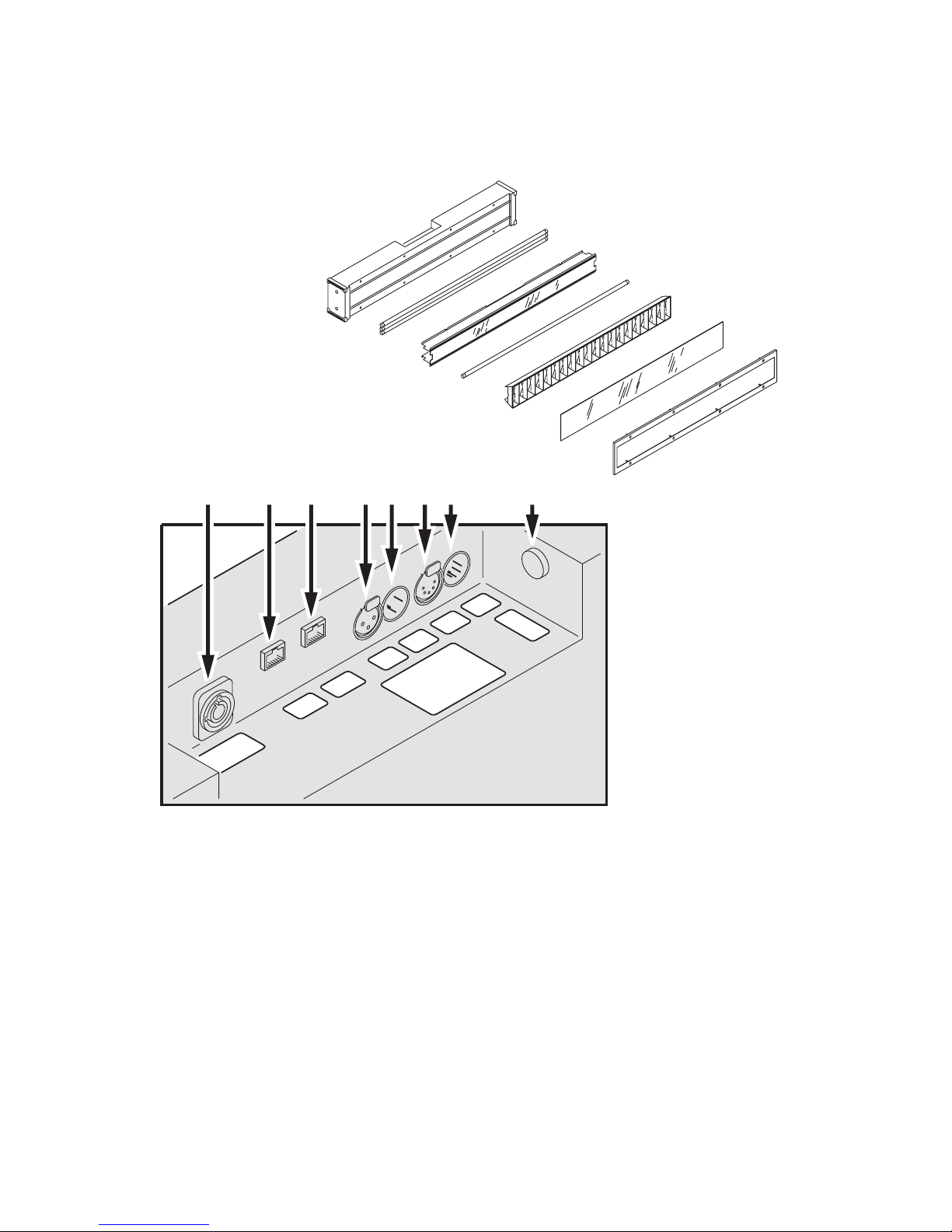

Product overview

DMX

IN

DMX

OUT

RJ45

DMX

OUT

DMX

IN

DMX

IN

DMX

OUT

MAINS

INPUT

RJ45

H I J K L M N O

A

B

C

D

E

F

G

MAINS INPUT

Main assembly

A Housing

B Colored tubes

C Diffuser

D White tube

E Reflector

F Clear plastic cover

GFront frame

X

M

D

IN

X

M

D

O

X

M

D

IN

X

M

D

T

U

O

T

J45

U

R

O

X

M

D

J45

IN

R

X

M

D

FUSE

T

U

Connections panel

H AC power input

I DMX in (RJ-45)

J DMX out (RJ-45)

K DMX out (3-pin XLR)

L DMX in (3-pin XLR)

M DMX out (5-pin XLR)

N DMX in (5-pin XLR)

O Main fuseholder

4 Stage Cyclo user manual

Page 5

Introduction

Thank you for selecting the Martin Stage Cyclo. The Stage Cyclo is

designed for wash illumination of sets, features, and artists. A patented

optical system ensures effective color mixing, allowing the fixture to be

positioned close to illuminated surfaces without color hot-spots.

The Stage Cyclo can be controlled via DMX or programmed with a standalone light show (which it can run alone or in a synchronized group). It has a

wide range of mounting options, including stacking to form dynamic colorchanging light walls. Four dimmable T5 high-output fluorescent tubes

combine high efficiency, bright color and long lamp life.

The Stage Cyclo features:

• Full 0-100% intensity control of red, green, blue and white tubes to give

RGB color mixing and fine-tuned color temperature

• High output, long life T5 fluorescent tubes

• Tough steel case with rubber corner protectors and carrying handle

• XLR 3-pin, XLR 5-pin and RJ-45 DMX connectors.

• One-tenth peak angle 107° x 121°

• Optional accessories include an adjustable bracket that allows flexible

rigging options.

Important! Read this manual before attempting to install this product.

Updated user manuals for this and all other Martin products are available

from the Support area of the Martin website at http://www.martin.com.

Safety information

Warning! This product is for professional use only. It is not for household

use.

This product presents risks of lethal or severe injury due to fire and heat,

electric shock and falls. Read this manual before powering or installing this

fixture, follow the safety precautions listed below, and observe all warnings

in this manual and on the fixture. If you have any questions about how to

operate this fixture safely, contact your Martin dealer or call the Martin 24hour service hotline at +45 70 200 201.

Introduction 5

Page 6

Protection from electric shock

• Disconnect the fixture from AC power before removing or installing a tube

or any component, and when not in use.

• Always ground (earth) the fixture electrically.

• Do not operate the fixture if any cover or component is damaged,

deformed or defective.

• Use only a source of AC power that complies with local building and

electrical codes and has both overload and ground fault (earth fault)

protection.

• Use only a power cable approved for extra hard usage. Do not operate

the fixture if the power cable or power connections are damaged,

deformed or defective.

• Do not expose the fixture to rain or moisture.

• Refer all service not described in this manual to a Martin service

technician.

Protection from burns and fire

• Provide a minimum clearance of 25 mm (1 inch) around the fixture.

• Never place filters or other materials over the clear polycarbonate cover.

• The exterior of the fixture can become hot to the touch. Allow the fixture to

cool for at least 5 minutes before handling.

• Do not modify the fixture or install other than genuine Martin parts.

• Do not operate the fixture if the ambient temperature (T

(104°F).

) exceeds 40°C

a

Protection from injury due to falls

• Ensure that all fasteners and components are secure and use an

approved means of secondary attachment such as a safety cable.

• Ensure that all supporting structures, surfaces and fasteners can bear ten

times the weight of all fixtures installed.

• Block access below the work area whenever installing, servicing or

removing the fixture.

• Secure stacked fixtures with safety attachments so that they cannot fall or

be pushed over.

6 Stage Cyclo user manual

Page 7

Installation

This section describes in general terms how to install the fixture, connect it

to AC power and connect to a DMX controller. These procedures must be

performed by qualified professionals.

Mounting

The Stage Cyclo features a range of

mounting and stacking options when

used in combination with Martin

Omega clamps.

Warning! Check that all fasteners,

structures and surfaces used to

mount the Stage Cyclo can bear

at least ten times the total

weight of all devices installed.

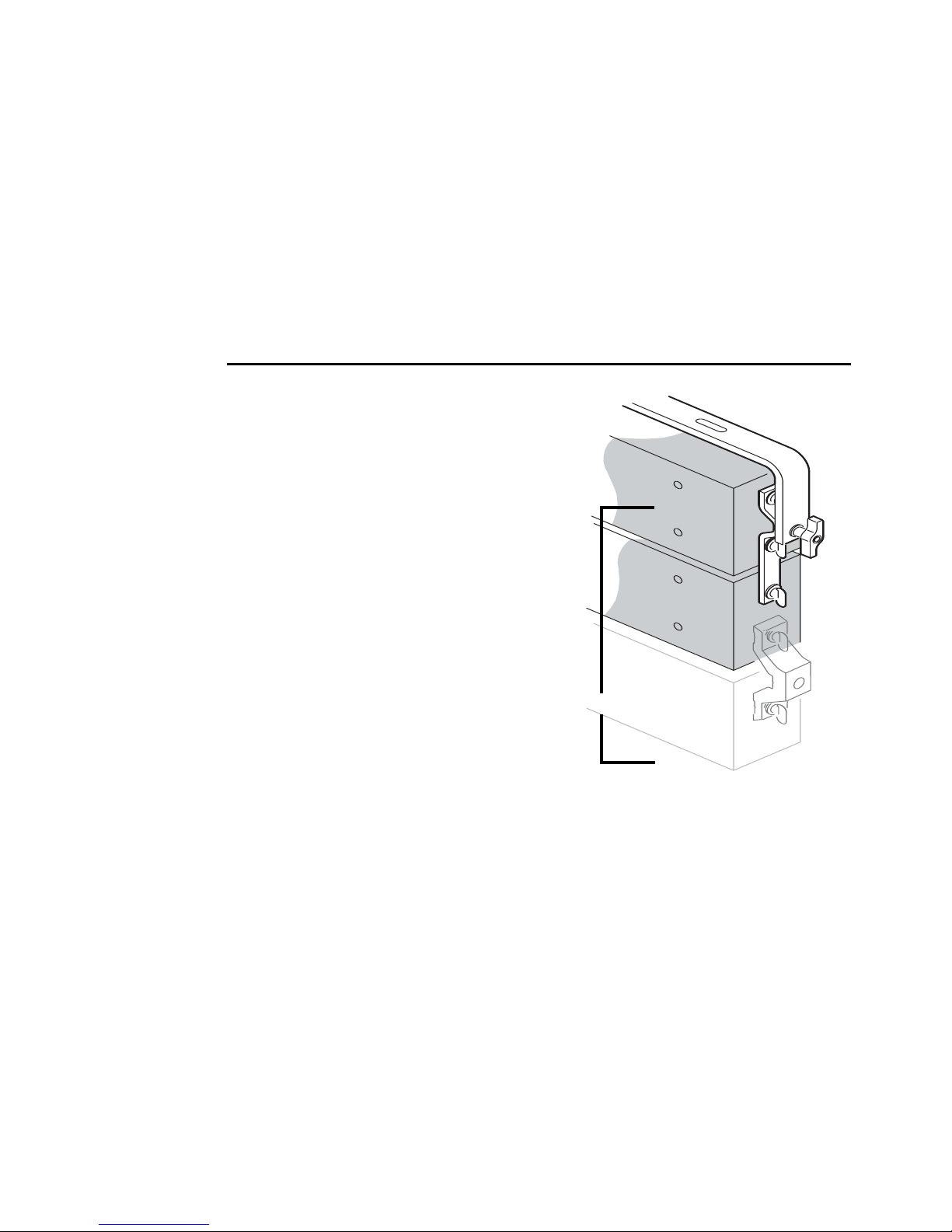

A maximum of 8 Stage Cyclos

may be hung vertically using

the Stage Cyclo mounting

bracket and Martin omega

clam p s.

Max. 8 fixtures

Work from a stable platform and

block access below the work

area when installing or

servicing fixtures above headheight.

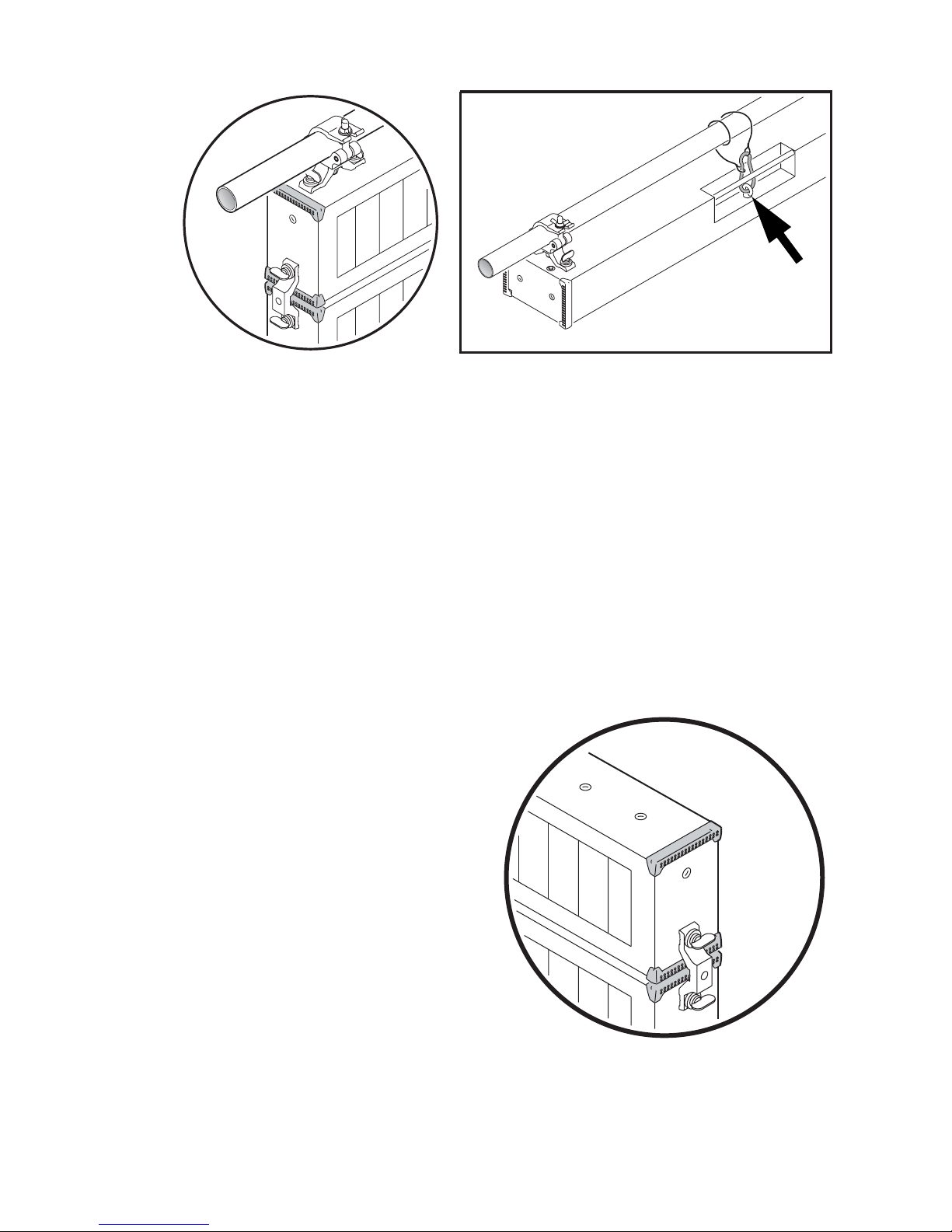

Rigging options

The clamp attachment points on the top, ends and back of the fixture

provide a range of rigging options.

An adjustable mounting bracket is available as an optional accessory (P/N

91611206).

Figure 1: Mounting bracket

Installation 7

Page 8

Figure 2: Rigging with a

Figure 2: Safety wire attachment

Martin half-coupler

Ensure that mounting hardware can bear at least ten times the total weight

of the fixtures installed. Using the mounting bracket or Martin half-coupler

(P/N 90602005) and Martin omega clamps (P/N 91602001), a maximum of

eight fixtures may be flown in one connected stack.

Anchor fixtures securely to the supporting structure with safety cables that

can bear at least 10 times the weight of all suspended fixtures. Attach safety

cables to every fixture using the eyebolts on the fixtures’ connections panels

(see Figure 2). Do not use mounting brackets or clamps as attachment

points, as this will leave fixtures unsecured.

Stacking

The quarter-turn clamping

points allow multiple Stage

Cyclos to be clamped together

with omega clamps to form

light walls.

Ensure that stacked fixtures

are secured with a safety

attachment so that they cannot

fall over.

8 Stage Cyclo user manual

Figure 3: Stacking with omega clamps

Page 9

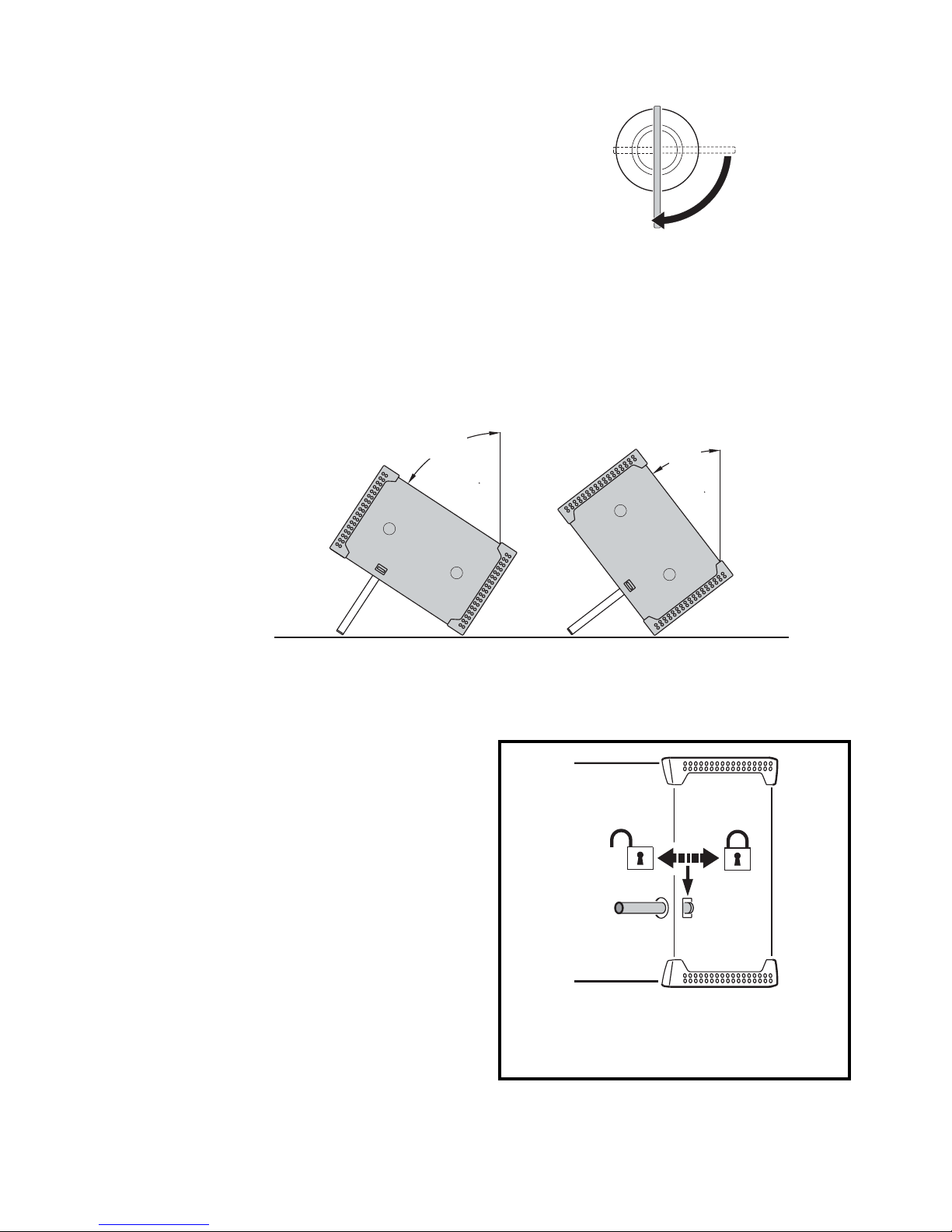

Important! Make sure that all

quarter-turn fasteners are

turned fully clockwise

until they lock.

Placing on a surface

The Stage Cyclo can be placed flat or at an angle on a level surface and

used as an uplight. The adjustable support rods allow the fixture to be

placed at various angles.

Figure 4: Quarter-turn fasteners

57°

Figure 5: Placing on a level surface

Release the support rods by

pushing the clips on the ends

of the housing.

38°

Figure 6: Support rod release

Installation 9

Page 10

AC power

It is the installer’s responsibility to ensure that all local regulations and legal

requirements are observed when installing and powering the Stage Cyclo.

The Stage Cyclo is available in two models, one for 100-130 V, 60 Hz AC

power only, and one for 208-250 V, 50/60 Hz AC power only. Full power

compatibility and consumption data are given in the Specifications section

on page 29.

Many fixed installations use common neutral conductors in branch circuit

distribution boxes. To avoid unintentional tripping of the RCD (ground fault

circuit breaker), ensure that the Stage Cyclo’s neutral conductor is

connected to AC power via the same RCD as the live conductor.

Important! Stage Cyclos contain electronic ballasts that “leak” a total

current of between 0.8mA and 4mA to ground (earth). Make sure

that fixtures are correctly connected to ground (earthed) so that

this “leakage” current can be absorbed.

Because of the “leakage” current, we recommend connecting a

maximum of seven Stage Cyclo fixtures per circuit where each

circuit is protected by a 30mA RCD. This should avoid

unintentional tripping of RCDs. Bear in mind that some RCDs

rated at 30mA may trip when leakage to ground is as low as

20mA.

Depending on the type of installation, electrical regulations in

some countries may permit the use of RCDs with a trip current

rating higher than 30mA. When considering this option, the

installer must ensure that all lo cal saf ety, building and electrical

regulations are respected.

10 Stage Cyclo user manual

Page 11

Connecting to mains power

Warning! Check that your local AC power voltage matches the voltage

specified on the serial number label before applying power.

®

The Stage Cyclo is supplied with a Neutrik PowerCon

cable connector that must be installed on a power cable approved for extra

hard usage. The cable connector accepts power cable from 5 mm (0.20 in.)

to 11 mm (0.43 in.) diameter when fitted with a white chuck, or from 9.5 mm

(0.38 in.) to 15 mm (0.59 in.) diameter when fitted with a black chuck.

Some common color-coding systems for AC power wiring are given below:

Wire (EU) Wire (US) Pin Marking

brown black live L

blue white neutral N

yellow/green green ground

Table 1: Wiring codes

NAC3FCA power

To install the connector:

1. Assemble the bushing and chuck on your power cable as shown in

Figure 7.

ChuckInsertHousing

Figure 7: Cable connector assembly

Installation 11

Bushing

Page 12

2. Prepare the power cable and use a screwdriver to clamp the wires in the

appropriate terminals in the insert as shown in Figure 8.

20 mm

8 mm

[0.315”]

[0.787”]

N

L

Figure 8: Cable connector wiring

3. Slide the insert and chuck into the housing, making sure that the raised

tabs engage in the keyways inside the housing..

4. Use an open-ended wrench (spanner) to fasten the bushing onto the

housing (max. torque: 2.5 Nm /1.8 ft-lbs).

To plug the power cable in, line up the raised tab on the cable connector

with the keyway in the chassis connector, push the cable connector in and

twist clockwise to lock.

To remove the cable connector, pull back the latch to release the lock, twist

the connector counterclockwise and pull out.

Additional connectors can be obtained from Martin dealers (P/N 05342804)

and Neutrik

®

stockists

Connecting to a data link

Important! Never connect more than 1 data input and 1 data output.

Fixtures on a serial data link must be daisy-chained in one single line,

maximum 500 meters (1640 ft.) long, with maximum 32 fixtures. To exceed

32 fixtures or 500 meters, or to add branches, use an optically isolated

splitter-amplifier such as the Martin RS-485 Opto-Splitter (P/N 90758060).

A reliable data connection requires suitable cable. Standard microphone

cable is unsuitable. For touring applications, use DMX cable designed for

RS-485 devices. For fixed installations, Category 5 network cable is an

acceptable alternative. Recommended minimum wire sizes are 24 AWG

(0.25mm

2

) for runs up to 300 meters (1000 ft) and 22 AWG (0.32 mm2) for

Content in the line drawings on this and the previous page is copyright ©2003 Neutrik® AG and

used by permission. These illustrations may not be reproduced in any form without the written

permission of Neutrik

12 Stage Cyclo user manual

®

AG.

Page 13

longer cable runs. Your Martin Architectural dealer can advise and supply

suitable cable.

The Stage Cyclo has RJ-45 as well as 3-pin and 5-pin XLR sockets for DMX

input and output. To avoid damage to the fixture, use only one input and one

output at the same time.

• XLR connectors are wired pin 1 to shield, pin 2 to cold (-), and pin 3 to hot

(+). There is no connection to pins 4 and 5 on 5-pin XLR connectors.

• RJ-45 connectors are wired pins 7 & 8 to shield, pin 2 to signal - (cold)

and pin 1 to signal + (hot).

Some older fixtures have reversed polarity XLR sockets (pin 2 hot and pin 3

cold). Socket polarity is normally labelled on products and specified in user

manuals. Use a phase-reversing cable between the Stage Cyclo and any

device with reversed XLR connector polarity.

To connect the data link:

1. Connect the DMX data output from the controller to one of the DMX input

sockets of the nearest fixture.

2. Connect one DMX output of this fixture to the DMX input of the next

fixture, and continue connecting output to input.

3. Terminate the link by inserting a male XLR DMX termination plug (P/N

91613017) or RJ-45 DMX termination plug (P/N 91613028) in the data

output of the last fixture.

Burning in fluorescent tubes

For optimum tube life and performance, burn in new fluorescent tubes for

100 hours at full power.

Ambient temperature

Do not operate the Stage Cyclo if ambient temperature (Ta) exceeds 40°C

(104°F).

The Stage Cyclo can be started at full intensity from -20°C (-4°F), but needs

to be at operating temperature for best dimming characteristics. When

operating at extremely low ambient temperatures, start the fixture at full

power and allow it to warm up for approximately 10 minutes before

dimming. If dimming characteristics are impaired when running tubes at low

intensity in extreme cold conditions, the fixture may need to be warmed up

by periodically running tubes at higher intensity.

Installation 13

Page 14

Stand-alone operation

In stand-alone operation, the Stage Cyclo can be used without a DMX

controller. Static single colors or two-color mixes can be displayed, or

fixtures can be programmed to change colors in cycles. Changes can be

programmed at 1, 5, 10 or 30 second intervals.

Two stand-alone operation modes are available:

•In single stand-alone operation, fixtures run independently of each

other. No data link is required.

•In master/slave stand-alone operation, fixtures must be linked.

Synchronized action in all fixtures is triggered by one “master” fixture.

Programming single and

master/slave stand-alone

operation involves setting the

pins on the fixture’s DIP

switch. The DIP switch is

protected behind a sliding

cover on the back of the

fixture’s housing. To access

the switch, pull the knob in

the connections panel recess

(see illustration) and slide

open the cover.

Figure 9: Dip switch access

An overview of the DIP switch settings is provided on the next page. A quick

reference table covering DIP switch functions is also provided on the back

cover of this manual.

14 Stage Cyclo user manual

Page 15

DIP-switch settings in stand-alone mode

Pin Function

1 White active

2 Red active

3 Green active

4 Blue active

5 & 6 Program speed

Pin 6 Pin 5 Speed

OFF OFF 1 sec. steps (fastest setting)

OFF ON 5 sec. steps

ON OFF 10 sec. steps

ON ON 30 sec. steps (slowest setting)

7 OFF = Blackout fading, ON = Crossfading

8 OFF = Run program, ON = Pause program

9 OFF = Master, ON = Slave (Note: do not set more than one fixture as master)

10 ON = Stand-alone mode.

Stand-alone operation settings

Activating colors

DIP switch pins 1 to 4 each activate a color in the stand-alone program.

Setting program speed

Combinations of DIP switch pins 5 and 6 allow one of four different speeds

to be set.

Fading between colors

If DIP switch 7 is set to OFF (blackout fading), colors fade to almost

blackout before the next color fades in.

If DIP switch 7 is set to ON (crossfading), color fading overlaps. If two or

more colors are active, one color fades in while another is fading out, giving

a color mixing effect. For example, if red and blue are activated and

crossfading is selected, colors will crossfade from red through purple to

Stand-alone operation 15

Page 16

blue, then back through purple to red in a continuous cycle (see example in

100% Blue

0% Red

50% Blue

50% Red

0% Blue

100% Red

Figure 10).

100%

50%

0%

Red

Blue

100% Blue

0% Red

Blue

50% Red

50% Blue

Purple

100% Red

0% Blue

Time

Red

Figure 10: Crossfading between red and blue

Setting a static color display

In stand-alone operation, a static (non-changing) color display can be set by

pausing the program at the point where it is showing the desired color.

Either one color or a mix of two colors can be “frozen” in this way.

To set a static color display:

1. Activate the color you wish to display (if you wish to display a two-color

mix, activate these two colors) on DIP switch pins 1 to 4.

2. Set the fixture as master by setting DIP switch pin 9 to OFF.

3. Set DIP switch pins 5 and 6 to ON to activate the slowest program speed.

4. Set DIP switch pin 7 to OFF to activate crossfading and DIP switch pin 8

to OFF to activate the program.

5. When the desired color or color mix appears, pause the program by

moving DIP switch 8 to ON. This color will remain “frozen” until DIP

switch 8 is moved to OFF.

Note that the paused color is lost when the fixture is powered off. When

powering the fixture on again, DIP switch pin 8 must be moved to OFF

before the program will start.

16 Stage Cyclo user manual

Page 17

Single stand-alone operation

In single stand-alone operation, a fixture runs its own program

independently of all other fixtures. To do this, the fixture must be set as a

master.

Activating single stand-alone operation

To activate single stand-alone operation:

1. Set DIP switch pin 10 to ON (activates stand-alone mode).

2. Set DIP switch pin 9 to OFF (activates master mode).

3. Apply power and program the fixture using DIP switch pins 1 - 8 (see

“DIP-switch settings in stand-alone mode” on page 15).

Master/slave stand-alone operation

Important! Do not set more than one fixture on a data link as master, and

do not set a fixture as master on a data link with a DMX

controller. Doing so may cause damage to the electronics that is

not covered by the product warranty.

In master/slave stand-alone operation, one master fixture transmits a

synchronizing signal to slave fixtures over the data link each time it starts a

new action. Slave fixtures start their next programmed action when they

receive this signal from the master fixture. Programs can be identical on all

fixtures, or fixtures can – subject to certain practical constraints – run

programs that are synchronized but not identical.

Note that:

• Colors are always displayed in the order: white, red, green then blue. This

means for example that if red is activated, it will always be first in the

program. If red is not activated but green is activated, green will be first in

the program.

• Each fixture follows the program set on its own DIP switch as described in

“DIP-switch settings in stand-alone mode” on page 15.

More sophisticated light shows can be programmed using a DMX controller

(see “DMX-controlled operation” on page 21).

The synchronization signal used by Stage Cyclo fixtures is identical to that

used in other DMX-controllable Cyclo fixtures with the same number of

tubes, allowing these products to be combined in master/slave operation on

one data link.

Stand-alone operation 17

Page 18

Identical light shows

Master and slave fixtures can be set to behave identically. In this mode, the

master sends synchronizing signals to the slaves, and all fixtures run the

same light show. Each slave fixture follows the program set on its own DIP

switch, so for identical operation, all fixtures’ DIP switch settings must be the

same apart from pin 9, which is set to ON for slaves and OFF for the master.

Synchronized non-identical light shows

It is also possible to synchronize changes but program slave fixtures to

behave differently from the master. To use this feature effectively, you need

to plan your light show using scenes as building blocks and set the fixtures’

DIP switches accordingly.

A scene is a change from one output to another. When a fixture is in slave

mode, it starts a scene when it receives a synchronization signal from the

master. The time taken by the scene is determined by the speed setting of

the DIP switch. A slave will not respond to new synchronization signals until

its scene is complete.

When crossfading is selected, each color takes up one scene (fade in only).

When blackout fading is selected, each color takes up two scenes (fade in

and fade out). This means that a maximum of 8 scenes can be programmed

with all 4 tubes activated and blackout fading selected.

Each time the master fixture starts at scene 1, it sends a signal to all the

slave fixtures to start at scene 1. This means that if a slave fixture has:

1. Fewer scenes than the master fixture, it will run these in a cycle until the

master fixture signals that the program should start from the beginning

again.

2. More scenes than the master, the additional scenes will never run,

because the program will reset to the first scene when the master starts

its program from the beginning.

Here is an example of what will happen if a slave fixture has fewer scenes

than the master fixture:

Fixture setting Scene pattern

Master with 6 scenes 123456 123456 123456 ...

Slave with 4 scenes 123412 123412 123412 ...

Program examples

The following examples show how an individual fixture’s program is made

up of scenes.

18 Stage Cyclo user manual

Page 19

The following symbols are used in program diagrams:

Tube turned fully off

Fade in

Fade out

Fade to 50% and back to 100% in one scene

(applies when only one color is active and

crossfading is selected)

Example 1

DIP switch 7 is set to ON (crossfading) and only red is activated:

Red

Scene

1 1 11 111 1 111 1

Example 2

DIP switch 7 is set to OFF (blackout fading) and only red is activated:

Red

Scene

21 21 21 21 21 21

Example 3

DIP switch 7 is set to ON (crossfading) and red and blue are activated:

Red

Blue

Scene

1 2 21 211 2 21 21

Example 4

DIP switch 7 is set to OFF (blackout fading) and red and blue are activated:

Red

Blue

Scene

21 43 421 3 421 3

Stand-alone operation 19

Page 20

Example 5

To achieve a rainbow effect, activate red, green and blue and set DIP switch

pin 7 to ON (crossfading).

Red

Green

Blue

Scene

1 2 3 1 2 3 1 2 3 1 2 3

Activating master/slave stand-alone operation

To activate master/slave stand-alone operation:

1. Power all fixtures off.

2. Set all fixtures as slaves and put them into stand-alone mode by setting

DIP switch pins 9 and 10 to ON.

3. Decide which fixture to use as master and set this fixture’s DIP switch pin

9 to OFF. Note that any fixture can be set as master, but you will obtain

the most reliable data signal by either setting the first fixture on the link as

master or using RJ-45 DMX termination plugs at both ends of the data

link.

4. When power is applied, slave fixtures will go to the next scene in their

program each time the master goes to its next scene. Slave fixtures will

also start scene 1 of their programs each time the master starts scene 1

of its program.

20 Stage Cyclo user manual

Page 21

DMX-controlled operation

The Stage Cyclo may be operated with any USITT DMX (1990) lighting

control device. The fluorescent tubes can be dimmed from maximum output

right down to zero using four channels on a DMX controller. This allows a

wide range of color shades with almost infinitely variable intensity to be

obtained using additive color mixing. The color temperature of white light

can be fine-tuned by running the white tube at high power and adding blue

or red at low power. Replacement white tubes with various color

temperatures are available (see “Accessories” on page 31).

The four DMX channels are used to control the tubes as follows:

• First channel: white

• Second channel: red

• Third channel: green

• Fourth channel: blue

Setting a DMX control address

The DMX address, also known as the start channel, is the first of the four

DMX control channels used. It must be set on the fixture’s DIP switch before

the controller can send commands to the fixture. The Stage Cyclo responds

to commands sent to the DMX address and the next three channels. For

example, if the DMX address is set to 100, the Stage Cyclo uses channels

100, 101, 102 and 103.

Allow enough channels when setting the DMX address. If control channels

for two fixtures overlap, one of the fixtures will receive the wrong

commands.

If two or more Stage Cyclos

share the same DMX address,

they will receive the same

commands and respond

identically. Individual control

will be impossible.

To access the fixture’s DIP

switch, slide the hatch open

by pulling on the pin in the

connections panel recess (see

Figure 11)

Figure 11: DIP switch access

DMX-controlled operation 21

Page 22

The default factory-set control address is ‘1’. To reset the Stage Cyclo’s

DMX address:

1. Decide on a DMX address for the fixture. If you are calculating the DMX

addresses for multiple fixtures, save time by using the online Martin

Address Calculator at

http://www.martin.dk/service/utilities/AddrCalc/index.asp (see illustration

below).

2. You can also look up DIP-switch settings using the Martin DIP Switch

Calculator, available for use and downloadable free at

http://www.martin.dk/service/dipswitchpopup.htm

If you do not have Internet access, refer to "Table 2: DMX address DIP-

switch settings" on page 23.

3. Set DIP switch pins 1 through 9 to ON (1) or OFF (0) to set the address.

22 Stage Cyclo user manual

Page 23

To use this table, first find the DMX address in the main block in the table.

Then read the settings for pins 1 - 5 to the left and read the settings for pins

6 - 9 above the address. “0” means OFF and “1” means ON.

For example, to set the DMX address to 101, you need to set DIP-switch

pins 1, 3, 6 and 7 to ON, as highlighted in the table.

DIP switch pins setting

0 = OFF

1 = ON

#1 #2 #3 #4 #5

0 0 0 0 0 32 64 96 128 160 192 224 256 288 320 352 384 416 448 480

1 0 0 0 0 1 33 65 97 129 161 193 225 257 289 321 353 385 417 449 481

0 1 0 0 0 2 34 66 98 130 162 194 226 258 290 322 354 386 418 450 482

1 1 0 0 0 3 35 67 99 131 163 195 227 259 291 323 355 387 419 451 483

0 0 1 0 0 4 36 68 100 132 164 196 228 260 292 324 356 388 420 452 484

1 0 1 0 0 5 37 69 101 133 165 197 229 261 293 325 357 389 421 453 485

0 1 1 0 0 6 38 70 102 134 166 198 230 262 294 326 358 390 422 454 486

1 1 1 0 0 7 39 71 103 135 167 199 231 263 295 327 359 391 423 455 487

0 0 0 1 0 8 40 72 104 136 168 200 232 264 296 328 360 392 424 456 488

1 0 0 1 0 9 41 73 105 137 169 201 233 265 297 329 361 393 425 457 489

0 1 0 1 0 10 42 74 106 138 170 202 234 266 298 330 362 394 426 458 490

1 1 0 1 0 11 43 75 107 139 171 203 235 267 299 331 363 395 427 459 491

0 0 1 1 0 12 44 76 108 140 172 204 236 268 300 332 364 396 428 460 492

1 0 1 1 0 13 45 77 109 141 173 205 237 269 301 333 365 397 429 461 493

0 1 1 1 0 14 46 78 110 142 174 206 238 270 302 334 366 398 430 462 494

1 1 1 1 0 15 47 79 111 143 175 207 239 271 303 335 367 399 431 463 495

0 0 0 0 1 16 48 80 112 144 176 208 240 272 304 336 368 400 432 464 496

1 0 0 0 1 17 49 81 113 145 177 209 241 273 305 337 369 401 433 465 497

0 1 0 0 1 18 50 82 114 146 178 210 242 274 306 338 370 402 434 466 498

1 1 0 0 1 19 51 83 115 147 179 211 243 275 307 339 371 403 435 467 499

0 0 1 0 1 20 52 84 116 148 180 212 244 276 308 340 372 404 436 468 500

1 0 1 0 1 21 53 85 117 149 181 213 245 277 309 341 373 405 437 469 501

0 1 1 0 1 22 54 86 118 150 182 214 246 278 310 342 374 406 438 470 502

1 1 1 0 1 23 55 87 119 151 183 215 247 279 311 343 375 407 439 471 503

0 0 0 1 1 24 56 88 120 152 184 216 248 280 312 344 376 408 440 472 504

1 0 0 1 1 25 57 89 121 153 185 217 249 281 313 345 377 409 441 473 505

0 1 0 1 1 26 58 90 122 154 186 218 250 282 314 346 378 410 442 474 506

1 1 0 1 1 27 59 91 123 155 187 219 251 283 315 347 379 411 443 475 507

0 0 1 1 1 28 60 92 124 156 188 220 252 284 316 348 380 412 444 476 508

1 0 1 1 1 29 61 93 125 157 189 221 253 285 317 349 381 413 445 477 509

0 1 1 1 1 30 62 94 126 158 190 222 254 286 318 350 382 414 446 478 510

1 1 1 1 1 31 63 95 127 159 191 223 255 287 319 351 383 415 447 479 511

#90000 000011111111

#80000 111100001111

#70011 001100110011

#60101 010101010101

Table 2: DMX address DIP-switch settings

DMX-controlled operation 23

Page 24

Service

With long-life fluorescent tubes and virtually no moving parts, the Stage

Cyclo is almost service-free.

Fluorescent tubes

The Osram high output T5 tubes fitted as standard meet color specifications

for at least 10 000 hours, after which color intensity may gradually fall.

Average tube life is 20 000 hours, but note that tube life will vary depending

on operating conditions.

Tube positions

Tube positions in the Stage Cyclo are identified as shown below:

Marking in

fixture

R

G

B

No marking. Tube

located above

diffuser.

The burning positions of fluorescent tubes affect their warm-up times,

operating temperature, light output and tube life. For best results:

• Install tubes so that the manufacturer’s markings are all at the same end

of the fixture.

• If the fixture is mounted in a vertical position or at an angle from the

horizontal, place the ends of the tubes that carry the manufacturer’s

markings at the lower end of the fixture (in a cold environment, i.e. where

temperatures are generally around or below freezing point, locate the

markings at the upper end of the fixture).

Marking on

tube Reference illustration

OSRAM FQ

54W/60 RED

OSRAM FQ

54W/66 GREEN

OSRAM FQ

54W/67 BLUE

OSRAM FQ

54W/860 Daylight

R

G

B

24 Stage Cyclo user manual

Page 25

Changing a tube

3

To change a tube:

1. Disconnect the fixture from AC power and allow to cool for 5 minutes.

2. For access to the white tube, use a 3mm Allen key to remove the 8

retaining screws and remove the front frame (G) and clear plastic cover

(F). Be ready to catch the reflector, as this is a loose fit in the housing, but

note that a ground (earth) lead connects the reflector to the housing.

Disconnect this lead and remove the reflector.

mm

F

G

Figure 12: Access to white tube

3. To remove a tube, press on

the metal caps at both ends of

the tube and rotate the tube

1/4 turn in whichever direction

is easiest. Then slide the

tube’s terminal pins out of their

sockets. Support the tube at

both ends as it is released.

Figure 13: Tube removal

Service 25

Page 26

4. For access to the colored tubes, remove the eight Pozidriv PZ2 screws

and remove the diffuser.

Figure 14: Access to colored tubes

5. When installing new tubes, line them up so that the manufacturer’s

markings on all tubes are at the same end of the fixture. Slide the tube’s

terminal pins fully into their sockets and rotate the tube 1/4 turn to

engage the pins. Check that the tube is held securely in the sockets.

6. Replace all components – remembering to attach the earth strap to the

reflector – before reapplying power.

Main fuse

The main fuseholder is located in the connections panel recess (see

“Product overview” on page 4´). Using a flat-head screwdriver, turn the

fuseholder cover approximately 1/8 turn to release the cover and main fuse.

Isolate the fixture from power and make sure power cannot be reapplied

accidentally before changing the fuse.

Never replace a fuse with one of a different type or rating. See “Power” on

page 30 for main fuse details.

Cleaning

Turn off power to the fixture before cleaning, and use a damp cloth to wipe

clean.

26 Stage Cyclo user manual

Page 27

Troubleshooting

Problem Probable cause(s) Remedy

No response from fixture when

power is applied.

Fixture does not respond

correctly to DMX control.

Fixtures do not behave

correctly in master/slave mode

No power to fixture. Check power connections.

Ground fault protection circuit

breaker (RCD) has tripped.

Controller not connected. Check DMX data link. Inspect

Incorrect DMX addressing. Check address setting on

Data link not terminated. Insert DMX ter mination plug in

Fixture on link set as master. Check that all fixtures are set

Defective fixture. Bypass fixtures one at a time

Two fixtures operating as

masters.

Reset RCD. If problem

persists, have an electrician

replace the RCD or reduce the

number of fixtures powered

via one RCD.

connections and test cables.

Repair or replace as

necessary.

fixture and controller.

unused socket of last fixture

on data link.

as slaves (DIP switch pin 9

ON).

until normal operation is

regained.

Check that only one fixture is

set as master.

Poor quality light output and/or

color rendering.

Defective fixture. Bypass fixtures one at a time

until normal operation is

regained.

Tube or tubes not burnt in. Run fixture for at least 100

hours to burn in tubes.

Tube defective. Disconnect fixture and replace

tube.

Troubleshooting 27

Page 28

DMX protocol

Channel Value Percent Function

1

2

3

4

0-2

3-252

253-255

0-2

3-252

253-255

0-2

3-252

253-255

0-2

3-252

253-255

0

1 - 99

100

0

1 - 99

100

0

1 - 99

100

0

1 - 99

100

White intensity

Tube off

Intensity 1

Intensity 100%

Red intensity

Tube off

Intensity 1

Intensity 100%

Green intensity

Tube off

Intensity 1

Intensity 100%

Blue intensity

Tube off

Intensity 1

Intensity 100%

→100%

→100%

→100%

→100%

Start code = 0

Page 29

Stage Cyclo Specifications

PHYSICAL

L x W x H. . . . . . . . . . . . . . . . .1272 x 209 x 135 mm (50 x 8.2 x 5.3 in.)

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.5 kg (23.1 lbs)

Shipping weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.5 kg (25.3 lbs)

Shipping dimensions . . . . . . . . 1300 x 350 x 210 mm (52 x 14 x 8,4 in.)

Fixture color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Gunmetal

SOURCE

Light source. . . . . . . . . . . . . . . . . . . . . . T5 fluorescent tubes (4 x 54W)

Approved lamp type. . . . . . . . . . . . . . . . . . OSRAM T5 high output 54W

Color authenticity . . . . . . . . . . . . . . . . . . . Guaranteed to 10 000 hours

Average tube life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 000 hours

PHOTOMETRICS

Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28%

Total Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3976 lumens

Half peak angle C0 (horizontal). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95°

Half peak angle C90 (vertical) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83°

One-tenth peak angle C0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107°

One-tenth peak angle C90 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121°

Illuminance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2066/distance

Measurement conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . 230V, 50Hz

Measurement source. . . . . . . . . . . Osram T5 FQ54W/840+/60+/66+/67

2

[lux]

DYNAMIC EFFECTS

0-100% dimmable tubes . . . . . . . . . . . . . . . Red, green, blue and white

CONTROL AND PROGRAMMING

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . USITT DMX512 (1990)

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .RS-485

DMX addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DIP switch

Data input/ output . . . . . . . . . . . . . . . . . . . . 3-pin and 5-pin XLR, RJ-45

Number of DMX channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

INSTALLATION

Floor or surface mounting with adjustable legs

Stacking/side-by-side/end-to-end: lockable with Martin omega brackets

Rigging with optional adjustable mounting bracket and omega brackets

Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Any

Minimum free space around fixture . . . . . . . . . . . . . . . . 25 mm (1 inch)

Page 30

POWER

AC power, 230 V model. . . . . . . . . . . . . . . . . . . . 198 - 250 V, 50/60 Hz

AC power, 110 V model. . . . . . . . . . . . . . . . . . . . . . . 100 - 120 V, 60 Hz

®

AC input. . . . . . . . . . . .Neutrik PowerCon

(A-type) lockable connector

Main fuse, 230 V model. . . . . . . . . . . . . . . . . . . . . 2 AT (P/N 05020009)

Main fuse, 110 V model . . . . . . . . . . . . . . . . . . . 2.5 AT (P/N 05020010)

Maximum current and power

@ 100 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 A, 218 W, PF 0.998

@ 120 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 A, 235 W, PF 0.999

@ 208 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 1.2 A, 235 W, PF 0.993

@ 230 V, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 1.1 A, 234 W, PF 0.988

@ 240 V, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 A, 233 W, PF 0.986

@ 250 V, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 A, 231 W, PF 0.983

PF = power factor

THERMAL

Maximum ambient temperature (T

) . . . . . . . . . . . . . . . . . 40°C (104°F)

a

Minimum ambient temperature (started at full power) . . . . . -20°C (-4°F)

Maximum total heat dissipation (calculated) . . . . . . . . . . . . 737 BTU/hr.

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Convection

CONSTRUCTION

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Mild steel

Optics . . . . . . . . . . . . . . . . . . . . . . . . . . High specular 99.9% aluminum

Protection factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP20

APPROVALS

European safety: EN 60598-1

EN 60598-2-17 + Corr + A2-1997

CSA C22.2, NO 166 pending

ANSI/UL 1573 pending

INCLUDED ITEMS

Red T5 high output tube . . . . . . . . . . . . . . . . . . OSRAM T5 FQ 54W/60

Green T5 high output tube. . . . . . . . . . . . . . . . . OSRAM T5 FQ 54W/66

Blue T5 high output tube . . . . . . . . . . . . . . . . . . OSRAM T5 FQ 54W/67

Cool white (4000 K) T5 high output tube . . . . OSRAM T5 FQ 54W/840

2 x omega brackets incl. 1/4 turn fasteners. . . . . . . . 2 x P/N 91602001

®

Neutrik PowerCon

NAC3FCA power cable connector . P/N 05342804

User manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P/N 35000167

Page 31

ACCESSORIES

Stage Cyclo mounting bracket. . . . . . . . . . . . . . . . . . . . . P/N 91611206

Omega bracket with 1/4 turn fasteners . . . . . . . . . . . . . . P/N 91602001

Warm white tube (2700 K, Osram T5 FQ 54W/827) . . . . P/N 97020009

Daylight white tube (6000 K, Osram T5 FQ 54W/860) . . P/N 97020011

DMX link termination plug RJ-45 . . . . . . . . . . . . . . . . . . P/N 91613028

DMX link termination plug male XLR 3-pin . . . . . . . . . . . P/N 91613017

RJ-45 patch cable (250 mm/ 9.8 in.) . . . . . . . . . . . . . . . P/N 11840088

XLR male to RJ-45 converter . . . . . . . . . . . . . . . . . . . . . P/N 11840087

XLR female to RJ-45 connector . . . . . . . . . . . . . . . . . . . P/N 11840086

50 x CAT5 network cables - 2 m (6.5 ft) . . . . . . . . . . . . . P/N 91611044

30 x CAT5 network cables - 5 m (16.4 ft) . . . . . . . . . . . . P/N 91611045

15 x CAT5 network cables - 10 m (32.8 ft) . . . . . . . . . . . P/N 91611046

ORDERING INFORMATION

Stage Cyclo, 208-250 V, 50/60 Hz. . . . . . . . . . . . . . . . . . P/N 90350000

Stage Cyclo, 100-130 V, 60 Hz . . . . . . . . . . . . . . . . . . . . P/N 90350100

Page 32

Page 33

Page 34

Page 35

Page 36

3. Green

8. ON = Pause

OFF = Play

9. ON = Slave or DMX

OFF = Master

2. Red

1. White

4. Blue

5/6. Program speed

10. ON = Stand-alone

1 2 3 4 5 6 7 8 9 10

ON

7. ON = Crossfading

OFF = Blackout fading

Quick reference

Stage Cyclo DIP switch settings

OFF = DMX

Martin Professional A/S - Olof Palmes Allé 18 - DK-8200 Aarhus N - Denmark

Phone: +45 87 40 00 00 Internet: www.martin.com

Loading...

Loading...