Page 1

RoboScan Pro 918

user manual

Page 2

©1998 - 1999 Martin Professional A/S, Denmark.

All rights reserved. No part of this manual may be

reproduced, in any form or by any means, without

permission in writing from Martin Professional A/S,

Denmark.

Printed in Denmark.

P/N 35000053, Rev. C

Page 3

3

RoboScan Pro 918

section 1

Introduction

Safety precautions....................................................................................................................................................4

section 2

Setup

Unpacking .......................................................................................... ...... ..... ...... ...... ..... ...... .... . ...... ...... ..... ...... ..... ...5

Installing or changing the lamp.................................................................................................................................5

Powering the fixture.......................................... ...... ...... ..... .......................................................................................6

Installation ...............................................................................................................................................................6

Connecting the serial link.........................................................................................................................................7

section 3

Control Panel

Personality settings................................................................................................................................................10

Protocol and address selection ..............................................................................................................................11

Readouts................................................................................................................................................................11

Manual control........................................................................................................................................................12

Stand-alone sequences..........................................................................................................................................12

Utilities....................................................................................................................................................................12

section 4

Operation

Martin RS-485 control ...................................... ...... ........................................................ ...... ..... ...... ...... ..... ...... ......14

DMX-512 control ....................................................................................................................................................14

Stand-alone control................................................................................................................................................14

Controllable effects.................................................................................................................................................1 5

section 5

Basic Service and Maintenance

Accessing parts......................................................................................................................................................17

Changing voltage and frequency settings ..............................................................................................................18

Replacing fuses......................................................................................................................................................19

Changing the XLR pin-out......................................................................................................................................19

Updating software ..................................................................................................................................................19

Custom gobos........................................................................................................................................................20

Changing rotating gobos........................................................................................................................................20

Changing color filters..............................................................................................................................................21

Lamp replacement..................................................................................................................................................21

Optimizing lamp alignment.....................................................................................................................................21

Cleaning.................................................................................................................................................................22

Lubrication.............................................................................................................................................................. 2 2

section 6

Appendices

DMX Protocol ........................................................................................................................................................23

Error Messages......................................................................................................................................................28

Troubleshooting ..................................................................................................................................................... 29

Circuit Board Layout................................................................ ...... ..... ...... ..... ...... ...................................................30

Specifications......................................................... ...... ..... ...... ...... .........................................................................31

Page 4

4

Introduction

section 1

INTRODUCTION

Thank you for selecting the Martin RoboScan Pro 918. This scanner, with its highly efficient optical and thermal

design, provides quiet operation and crisp, bright output in a compact, easy-to-handle package.

This manual covers all models of the RoboScan Pro 918 and describes the features found in CPU software version 1.4.

The latest Pro 918 information and software is available from the Martin Professional web site at http://

www.martin.dk.

S

AFETY PRECAUTIONS

The RoboScan Pro 918 is for professional use only. It presents potential risks due to electrical shock, heat and ultraviolet radiation burns, lamp explosion, falls, high-in tensity light , and fire. A thorough understandin g of the dangers,

genuine concern for safety, and attention to detail are required to prevent accidents. Read this manual before power-

ing or installing the fixture, follow the safety precautions listed below and observe the warnings in this manual

and printed on the fixture, and always double check the safety conditions. If you have questions a bout how to

operate the Pro 918, please contact your Martin dealer for assistance.

• $OZD\VýGisconnect the fixture from AC power before:

- Changing the transform er or ballast settings

- Installing or removing the lamp

- Checking or replacing fuses

- Removing any cover or part

• Replace the lamp before usage exceeds the maximum rated service life or if the lamp becomes defective or worn out.

Allow the fixture to cool for 15 minutes before replacing the lamp.

• Keep all combustible materials (for example fabric, wood, paper) at least 0.5 meters (20 inches) away from the fixture.

Keep flammable materials well away from the fixture.

• For protection against dangerous electric shock, always ground (earth) the fixture electrically. Use only a source of AC

power that complies with local building and electrical codes. Do not expose the fixture to rain or moisture.

• Ensure that the air flow through fans and vents is free and unob structed.

• When suspending the fixture above ground level, verify that the structure can hold at least 10 times the weight of all

installed devices and secure the fixture with an approved safety cable. Block access below the work area whenever

installing or removing the fixture.

• Refer any service operation not described in this manual to a qualified technician.

• The covers get very hot under normal operation: to avoid burns, locate the fixture where it cannot be accidentally

touched or bumped, and allow the fixture to cool before servicing.

• Do not illuminate surfaces within 1 meter of the fixture.

• Never place filters or other materials over the lens or mirror.

• Do not operate the fixture if the ambien t temperature (Ta) exceeds 40° C (104° F).

• Do not look directly into the light from a close distance.

• Never op e rat e the fixture without all lenses and co vers installed: an unshielded lamp can e xp lod e with ou t warn in g a nd

emits dangerous UV radiation tha t can cause burns and eye damage.

• Do not modify the fixture or install other than genuine Martin accessories and upgrade kits.

Page 5

5

RoboScan Pro 918

section 2

SETUP

This section describes the steps required to prepare the RoboScan Pro 918 for operation.

U

NPACKING

The RoboScan Pro 91 8 package includes:

• 1 5-meter, 3-pin shielded XLR control cable

• 1 3-meter, 3-wire IEC power cable (EU version only)

• 1 user manual

• 9 extra rotating gobos

• 1 spare rotating-gobo spring

The packing materials are c arefully designed to protect t he fixture during shipment - always use them or a custom

flight case to transport the fixture.

I

NSTALLING OR CHANGING THE LAMP

The RoboScan Pro 918 is designed to work with the Philips MSR-575/2, Philips MSD-575, or the Osram HSR-575/2

discharge lamp. Installing any other lamp may damage the fixture. The lamp holder is pre-adjusted at the factory; pre-

cise alignment may be necessary due t o sl ight variations between lamps. The procedure is described on page 21.

WARNING!

Disconnect the fixture from AC power before proceeding. Always wear safety

goggles to protect your eyes and allow a hot lamp to cool for at least

15 minutes before removing it from the fixture.

1.

The RoboScan Pro 918 must be cool and isolated from AC power. Remove the 2 screws (A) securing the

lamp assembly to the back plate. Gently pull out the assembly.

2.

If changing the lamp, remove the old lamp from the socket.

3.

Holding the new lamp by its ceramic base (do not touch the glass), insert it firmly and squarely into the lamp

socket. Cle an the gla ss b ulb with the cloth su pplied with the lam p , particularly if y our fingers touc h the glas s .

A clean, lint-free cloth wetted with alcohol may also be used.

4.

Reinsert the lamp assembly and replace the screws.

5.

Before turning the lamp on, reset the

RLAH

and

RLST

counters. See “Readouts” on page 11.

Page 6

6

Setup

P

OWERING THE FIXTURE

WARNING!

For protection from dangerous electric shock, the fixture must be grounded

(earthed). The AC mains supply shall be fitted with a fuse or circuit breaker and

ground-fault protection.

1.

Verify that the voltage and frequency settings match the local AC supply. These settings are printed on the

serial number label next to the control panel. If the settings do not match the supply, then the ballast and

transformer must be rewired as described under “Changing voltage and frequency settings” on page 18.

2.

You may need to install a cord cap that fits your supply on the power cable. Following the manufacturer’s

instructions, connect the wires as shown below. Note: The table shows some possible pin identification

schemes; if the pins are not clearly identified, or if you have any doubts about proper installation, consult a

qualified electrician.

3.

Verify that the supply cable is undamaged and rated for the current requirements of all connected devices.

Do not connect the Pro 918 to a dimmer system: doing so will damage the fixture.

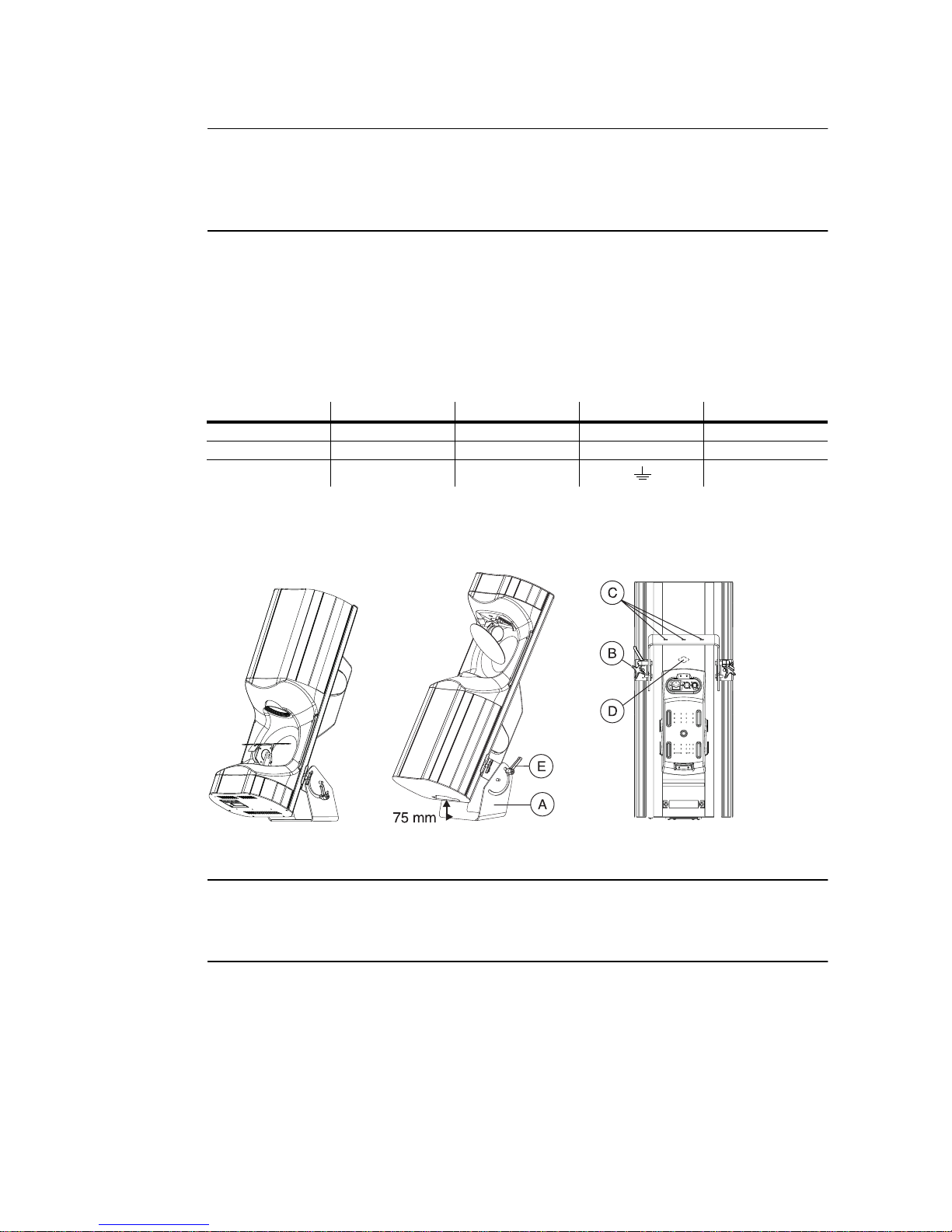

I

NSTALLATION

ý

Using the mounting bracket as a floor stand

WARNING

When standing the fi xtu r e wi th the l am p end down, the end panel m ust be a m i n-

imum of 75 mm (3 in) above the floor to provide adequate circulation.

1.

If standing the fixture with the mirror end up, loosen the mounting bracket and align the pointer with the last

index line : the bracket sha ll no t be p lac ed any farther from the end. Tighten the clamps securely. Loosen th e

swivel locks and set the angle to the extreme position, marked as “-”. Tighten both swivel locks.

2.

If standing the fixture with the mirror down, slide the mounting bracket to the mirror end and set the pointer

near the last index line; the exact position is not critical. Tighten the clamps securely. Loosen the swivel

locks and set the angle in between the 60° and 75° marks. Tighten both swivel locks.

3.

Stand the fixture on a stable platform away from publicly trafficked areas. Verify that the fixture is stable;

adjust the bracket if necessary.

Wire (EU) Wire (US) Pin Marking Screw (US)

brown black live “L” yellow or brass

blue white neutral “N” silver

yellow/green green ground green

Page 7

7

RoboScan Pro 918

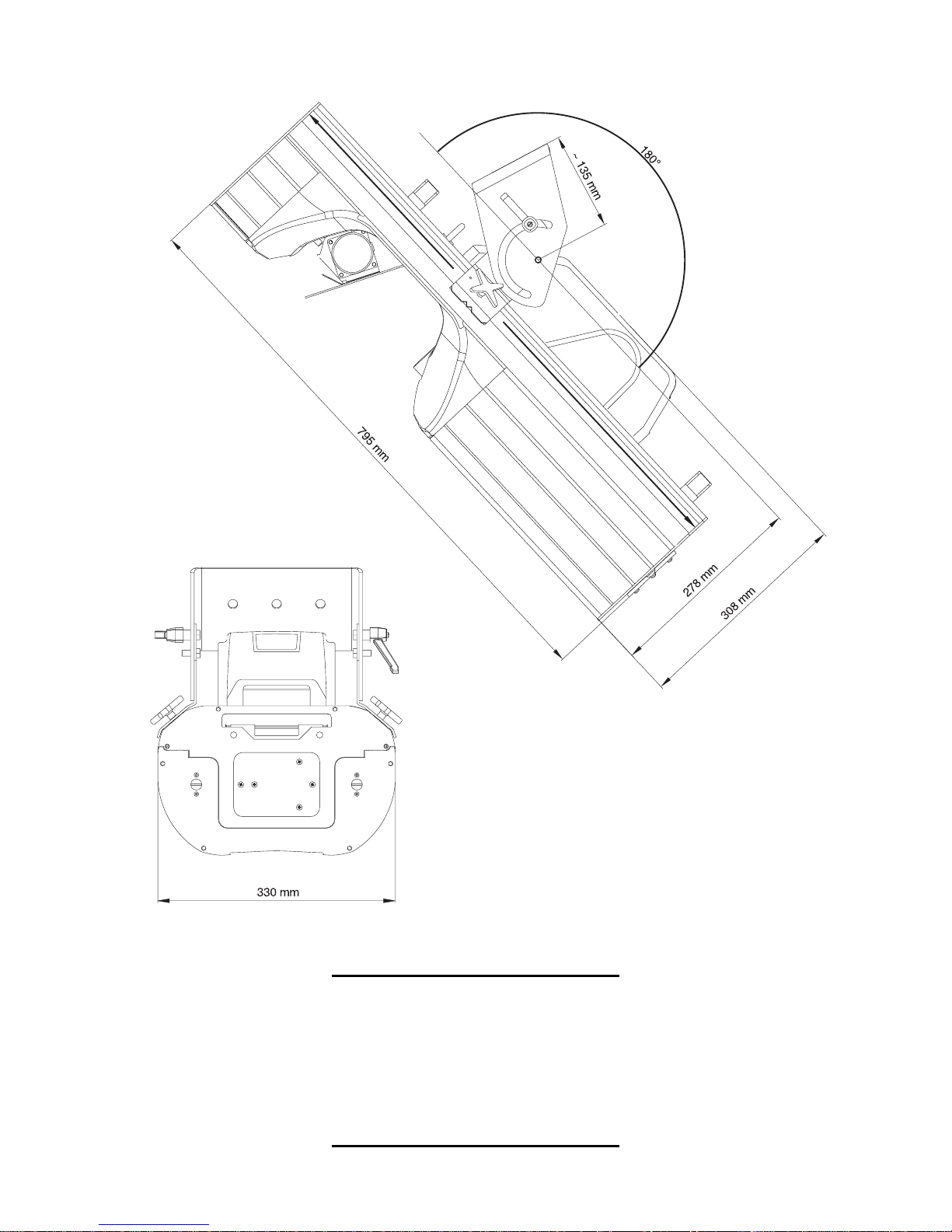

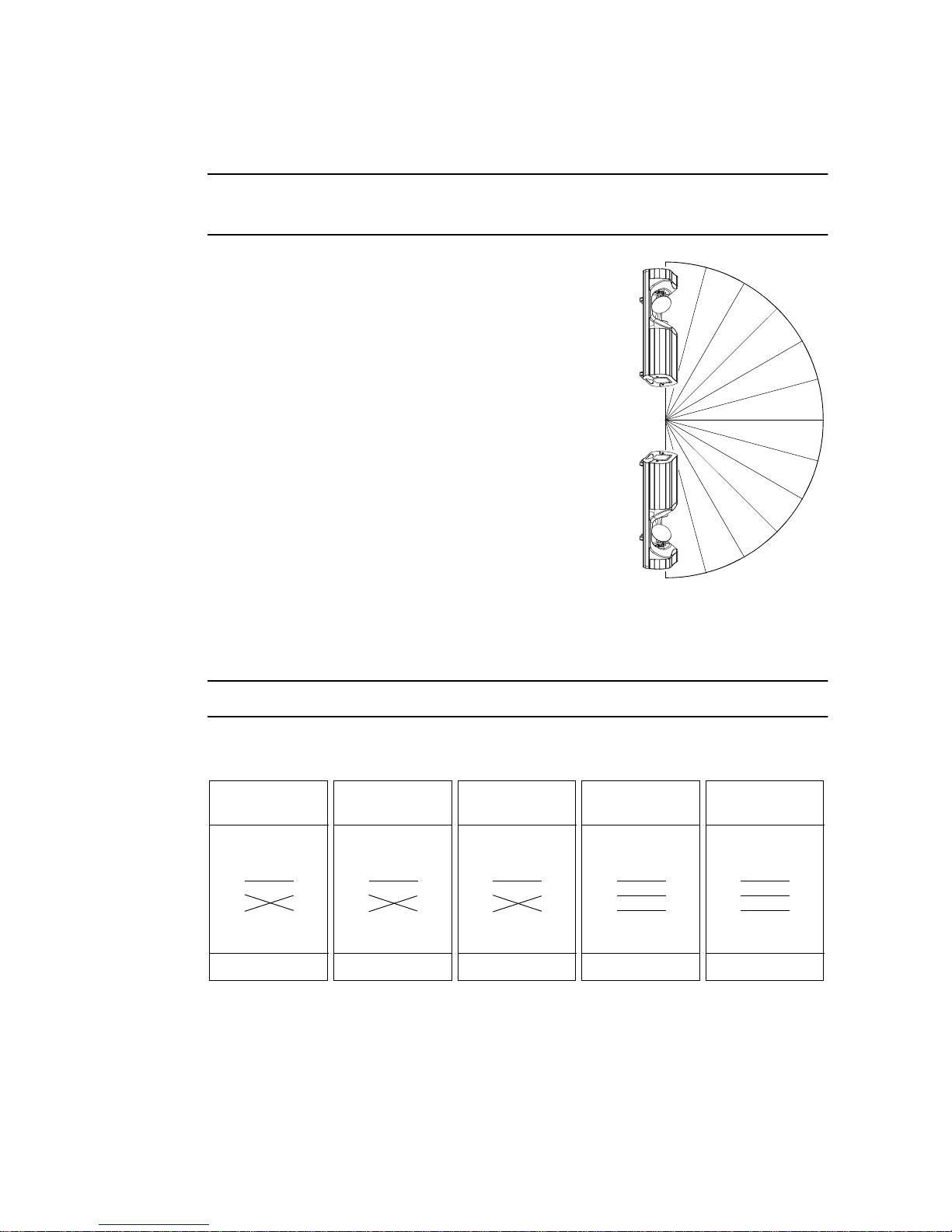

Rigging

The mounting bracket allows the Pro 918 to be rigged at any angle. The figure below shows the index position of the

balance point at different angles. Balancing the fixture makes it more stable and easier to work with, but it can be hung

out of balance if necessary.

WARNING!

Attach an approved safety cable to the eye hook.

1.

Loosen the clamps (B) on each side of the mounting bracket, slide the

bracket to the approximate position, and partially tighten the clamps.

2.

Loosen the swivel locks (E) and tilt the bracket to the desired angle.

Partially tighten the locks.

3.

Bolt rigging clamps that ca n bear at l east 10 times the we ight of the fi xture to the mounting bracket. 1 clamp may be bolted to the center hole

or 2 clamps may be bolted to the 2 outside holes (C). See page 31 for

clamps available from Martin.

4.

Verify that the structure can bear at least 10 times the weight of all

installed fixtures, clamps, cables, auxiliary equipment, etc.

5.

Block access below the work area. Working from a stable platform,

place the fixture on the rigging.

6.

Install a saf ety w ire tha t can bea r at leas t 10 time s the w eight of the fi xture. Use the e y e hook (D ) to fasten the safety wire to the fixt ure .

Never

use the carrying handles or mounting bracket for secondary attachment.

7.

Tighten the rigging clamp(s) securely to the structure.

8.

Fine-tune the position and the fully tighten the slide clamps and swivel

locks.

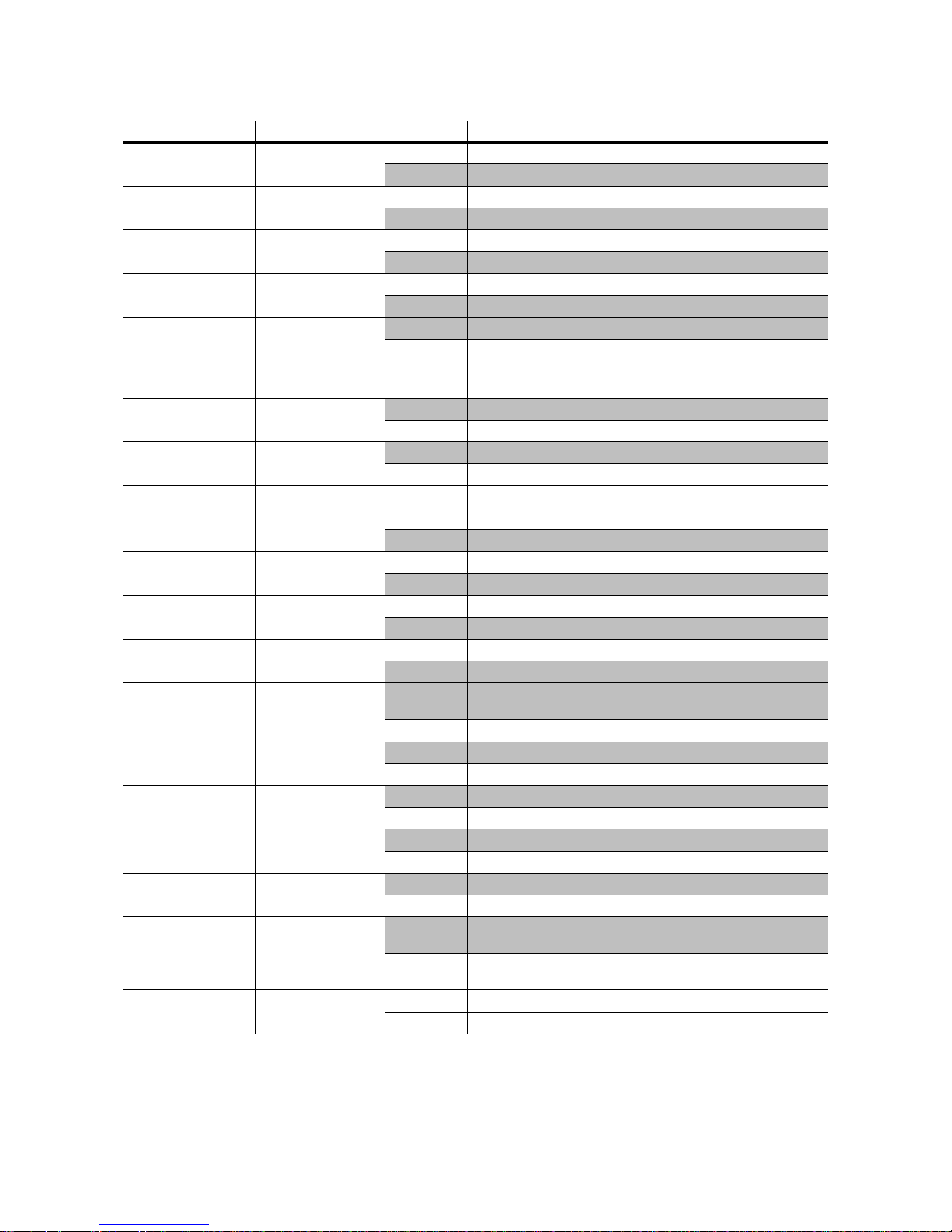

C

ONNECTING THE SERIAL LINK

The default pin-out is compatible with DMX-512.

The Pro 918’s 3-pin data sockets are configured for DMX controllers, i.e., pin 1 to shield, pin 2 to cold (-) and pin 3 to

hot (+). As many devices have 5-pin connecto rs or 3-pin connect ors with reversed polarity on pins 2 and 3, adap tor

cables may be required.

1.

Connect the controller’s data output to the RoboScan Pro 918’s data input. For a

• DMX controller with 5- pin output: use a cabl e with 5-pin male and 3-p in female connectors such as P/N 11820005.

Pins 4 and 5 are not used.

• DMX controller with 3- pin output: use a normal cable with 3-pin male and female connectors.

• Martin RS-485 Protocol controller: use a phase-reversing cable, such as P/N 11820006, with 3-pin male and female

connectors, or reconfigure the data sockets as described on page 19.

+

6

0

°

,

A

0

+45°, B2

+

3

0

°

,

C

0

+

1

5

°,

C

3

0°, D2

-

1

5

°,

E

0

>

+

7

5

°,

e

n

d

>

-

7

5

°,

e

n

d

-3

0

°

,

E4

-

4

5°, F4

-6

0

°

,

G2

Phase-Reversing

Cable

Male Female

1

2

3

1

2

3

3-pin to 3-pin

Connections

P/N 11820006

Phase-Reversing

Cable

Male Female

1

2

3

1

2

3

4

5

3-pin to 5-p in

Connections

P/N 11820002

Phase-Reversing

Cable

Male Female

1

2

3

4

5

1

2

3

5-pin to 3-p in

Connections

P/N 11820003

Straight

Cable

Male Female

1

2

3

4

5

1

2

3

5-pin to 3-p in

Connections

P/N 11820005

Straight

Cable

Male Female

1

2

3

1

2

3

4

5

3-pin to 5-pin

Connections

P/N 11820004

Page 8

8

Setup

2.

Continue the link: connect the output of the fixture closest to the controller to the input of the next fixture.

Use a phase-reversing cable when connecting a DMX-standard (pin 3 +) device to a Martin-standard (pin 3

-) device.

3.

Insert a male 120

Ω

XLR termination plug in the output of the last fixture on the link.

Tips for building a serial link

• Use shielded twisted-pair cable designed for RS-485 devices: standard microp hone cable cannot transmit DMX data

reliably over long runs. For links up to 300 meters (1000 ft.) long, you can use 24 AWG, low capacitance, 85-150 ohm

characteristic impedance, shielded cable with 1 or more twisted pairs. For runs up to 500 meters (1640 ft.) use 22 AWG

cable. Use an amplifier if the serial link exceeds 500 meters.

• Never use a “Y” connector to split the link. To split the serial link into branches use a splitter such as the Martin 4Channel Opto-Isolated RS-485 Splitter/Amplifier.

• Do not overload the link. Up to 32 devices may be connected on a serial link.

• Terminate the link by installing a termination plug in the output socket of the last fixture on the link. The termination

plug, which is simply a male XLR connector with a 120 ohm, 0.25 watt resistor soldered between pins 2 and 3, “soaks

up” the control signal so it does not reflect back down the link and cause interference. If a splitter is used, terminate

each branch of the link.

Page 9

9

RoboScan Pro 918

section 3

CONTROL PANEL

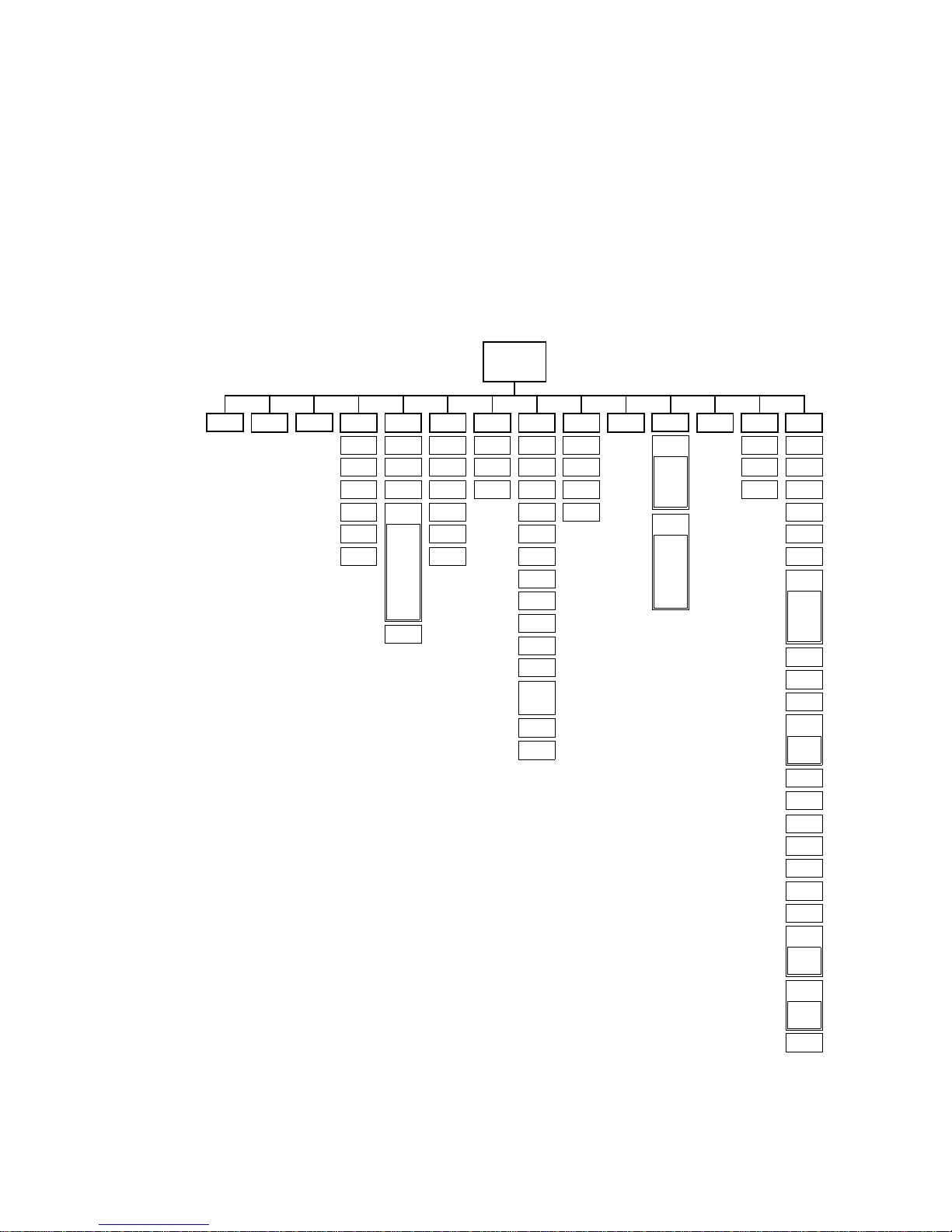

The 4-digit LED control panel allows you to set the address and personalities, read lamp hours and other information,

calibrate effects, c ontrol t he fixture manual ly, and run stand- alone te sts and d emo pr ograms. Most of these fu nctions

may be performed remotely via the serial link with the MPBB1 Uploader.

The display can be flipped for easy reading by pressing the >↑@ and >↓@ keys simultaneously. The intensity is adjustable

and the display can be set to go out 2 minutes after the last key-press.

The DMX or Martin address, depending on the protocol setting, and any error messages are displayed when the

RoboScan Pro 918 is turn ed on. To enter the menu, press >MENU@ï Use the >↑@ and >↓@ keys to move within the menu.

To select a funct ion or submenu, press >ENTER@. To escape a function or menu, press >MENU@.

G$GU

0$GU

7,0(

$G- &$/ 3$7, 9(5

36(7

0$1 G0;/ 3763 63(&

G(02

$GGUHVV2

0HVVDJHV

3R#+

53R+

/$#+

5/$+

/675

5/67

567

/#21

/R))

);

3$7,

&42)

&52)

5*2)

G#2) 6:$3

3,19

7,19

567

/#21

6+87

G,0

&2/4

&2/5

/R))

)JRE

5JRE

,5,6

35,62

3$1

7,/7

)2&8

)526

67&2

6+87

1111

(#63

&38

5384

G,63

)7< 3

G,63

G/2)

G5(6

$/21

G,17

G)2)

83/G

3&E7

$872

6&87

G0$&

02G(

)76 7

G,0

&2/4

&2/5

)JRE

5JRE

)2&8

,5,6

35,6

'(04

3$1

7,/7

)2&8

6(4

'(05

0,13

0$;3

0,17

0$;7

)2&8

6(4

G)6(

)$&7

&864

&865

&866

7(03

3&E

);

76(4

G02G

())E

75$&

02G(

&$/

)*2)

)22)

J02G

),;

6&5/

37

Page 10

10

Control Panel

P

ERSONALITY SETTINGS

* Setting may be overridden via DMX. See protoc o l for detai ls.

Personali ty Path Options Effect

(Default settings shaded.)

Pan/tilt speed

PTSP

FAST

Optimize mirror movement for speed.*

SLOW

Optimize mirror movement for smoothness.*

Pan/tilt swap

PATI/SWAP

ON

Map DMX pan control to tilt channel and vice versa.

OFF

Normal pan and tilt control.

Pan inverse

PATI/PINV

ON

Reverse DMX pan control, right Æ left.

OFF

Normal pan control, left

ÆÆÆÆ

right.

Tilt inverse

PATI/TINV

ON

Reverse DMX tilt control, down Æ up.

OFF

Normal tilt control, up

ÆÆÆÆ

down

Tracking algorit hm

SPEC/TRAC/MOdE

MOd1

Absolute delta value algorithm (for most controllers)

MOd2

Real delta value algorithm

Tracking samples

SPEC/TRAC/CAL

1-10

Tracking mode sample level - default is 6. Higher levels give

smoother movement but slower acceleration.

Fixture type

SPEC/FTYP

PRIS

Operate with rotating prism

.

FROS

Operate with optional variable frost.

Display On/Off

SPEC/dISP

ON

Display stays on.

OFF

Display goes out 2 minutes after last key press.

Display intensity

SPEC/dINT

10-100

Adjust display intensity.

DMX lamp off

SPEC/dLOF

ON

Enable DMX lamp off command.

OFF

Disable DMX lamp off command.*

DMX reset

SPEC/dRES

ON

Enable DMX reset command.

OFF

Disable DMX reset command.*

Automatic lamp on

SPEC/ALON

ON

Lamp strikes automatically within 90 seconds of power on.

OFF

Strike lamp from controller.

Automatic protocol

detection

SPEC/AUTO

ON

Enable automatic protocol detection.

OFF

Disable automatic protocol detection.

Shortcuts

SPEC/SCUT

ON

Color wheels and fixed-gobo wheel turn the shortest

direction.

*

OFF

Wheels turn same direction.*

DMX macros

SPEC/dMAC

ON

Enable DMX-selectable macros and pulsating effects.

OFF

Disable DMX-selectable macros and pulsating effects

Fixed gobo mode

SPEC/gMOd

FIX

Static gobo wheel steps between full positions

SCRL

Static gobo wheel scrolls continuously

Studio mode

SPEC/MOdE

NORM

Optimize effects for speed.

STUd

Optimize effects for silence.

Dimmer mode

SPEC/dMOd

NORM

Normal dimming curve.

TUNG

Simulated tungsten dimming curve.

Effects feedback

SPEC/EFFb

ON

Enable feedback on color wheels, fixed-gobo wheel, and

rotating-gobo index.

OFF

Disable feedback on color wheels, fixed-gobo wheel, and

rotating-gobo index.

Tilt motor select

SPEC/PT

NEW

For units after S/N 402908-0000 (selected automatically).

OLD

For units before S/N 40 2908-0000 (selected automatically).

Page 11

11

RoboScan Pro 918

P

ROTOCOL AND ADDRESS SELECTION

7KHý5RER6FDQý3URý äìåý KDVýéý'0;ýRSHUDWLQJýPRGHVñýRUý SURWRFROVñýDQGý Dý0DUWLQýPRGHïý7KHVHýDUHýGHVFULEHGýLQý PRUH

GHWDLOýRQýSDJH ìéï

(DFKýIL[WXUHýPXVWýEHýDVVLJQHGýLWVýRZQýFKDQQHOVýWRýUHFHLYHýLQVWUXFWLRQVýIURPýWKHýFRQWUROOHUïý7KHýDGGUHVVñýDOVRýNQRZQýDV

WKHýVWDUWýFKDQQHOñýLVýWKHýILUVWýFKDQQHOýXVHGïý$GGUHVVHVýDUHýLQGHSHQGHQWýRIýWKHýSK\VLFDOýRUGHUýRQýWKHýOLQNãýWKH\ýPD\ýEHýVHW

LQýDQ\ýFRQYHQLHQWýRUGHUïý7ZRý3URýäìåVý PD\ýVKDUHýWKHýVDPHýDGGUHVVâýKRZHYHUñýWKH\ýZLOOýUHFHLYHý WKHýVDPHýLQVWUXFWLRQV

DQGýLQGHSHQGHQWýFRQWUROýZLOOýQRWýEHýSRVVLEOHï

1.

Apply power to the RoboScan Pro 918. Press the [MENU] key and then press [↑] or [↓] until th e display

shows

PSET

. Press [ENTER].

2.

Press [↑] or [↓] until the desired protocol appears on the display. Press [ENTER] to confirm.

3.

Press [↑] or [↓] until the display shows

dAdr

(to set a DMX address) or

MAdr

(to set a Martin

address). Press [ENTER] to confirm.

4.

Press [↑] or [↓] to select a DMX address from 1 to 512 or a Martin address from 1 to 31. Press

[ENTER] to confirm.

5.

Press [MENU] to return to the main menu. Depending on the protocol selected, the DMX or Martin

address is displayed.

R

EADOUTS

Usage readouts (

TIME

)

Read the total number of power-on hours (Po H), power-on hours since last reset (RPoH), total lamp hours (LA H),

lamp hours since last reset (

RLAH), total number of lamp strikes (L STR), and the number of lamp strikes since last

reset (

RLST).

The resettable counters may be used to track overall usage and lamp life. To reset to zero, display the readout and then

press >↑@ for 5 seconds.

DMX value readouts (

dMXL

)

Read the DMX start code (STCO) and DMX values received for each effect. This is an easy way to check if the fixture is receiving the expected commands. This feature is not applicable in Martin mode.

Software version readouts (

VER

)

Read the version number of the CPU software (CPU), 2051 microprocessor (2051), an d display mod ule software

(

dISP). The CPU software version is also displayed for a moment at power up.

Temperature readouts (

SPEC/TEMP

)

Read temperature at the main printed circui t board (PCb) and in the effects section (FX) in C elsiu s. Temperatur es

below 25° C are shown as

-25; temperatures above 100° C are shown as +100.

The temperature sensors are calibrated at the factory and adjustment should not be necessary. The following procedure

calibrates the sensors if they give no or faulty readings.

1.

Allow the unit to cool to room temperature (powered off for at least 4 hours).

2.

Measure the room temperature in Celsius. (To convert F° to C°, subtract 32° and then multiply by 0.555.)

3.

Power up the unit and allow it to reset.

4.

Press the [MENU] an d [↓] keys at the same ti me and hold t hem f or 3 seconds until “25” sho ws in the disp la y.

5.

Press the [↑] and [↓] keys until the display shows the temperature measured.

6.

Press [ENTER] to save the setting.

Mode Martin DMX 1 DMX 2 DMX 3 DMX 4

Control Vector Tracking Tracking and/or Vector

Pan/tilt resolution 16 bit 8 bit 16 bit 8 bit 16 bit

Channels required 2 12

ìé

14

ìç

Page 12

12

Control Panel

M

ANUAL CONTROL

Manual control (

MAN

)

The manual control menu permits you to do the following without a controller:

• reset the fixture (RST)

• turn the lamp on and off (

L ON, LoFF)

• open, close, and strobe the shut ter at 3 speeds (

SHUT)

• control the dimm er (

dIM)

• move the color wheels to each position and scroll them at 3 speeds (

COL1, COL2)

• move the fixed-gobo wheel to each position (

Fgob)

• move the rotating-gobo wheel to each position and rotate the gobos at 3 speeds (

Rgob)

• control the focus (

FOCU)

• control the i ris (

IRIS)

• insert and rotate the prism (

PRIS) at 3 speeds, or, if a frost filter is installed, vary the frost (FROS)

• control pan and tilt (

PAN, TILT)

Adjustment (

AdJ

)

The adjustment menu provides manua l control for making mechanical adjustm ents. These should be performed by a

qualified technician. The menu allows you to reset the fixture (

RST), turn on and off the lamp (L ON, LoFF), con-

trol all effects (FX), and move the mirror to the hom e and extr eme positi ons (

PATI). The FX submenu allows you

to:

• open, close, and strobe the dimmer/shutter (

dIM)

• move the color and gobo wheels through their positions (

COL1, COL2, Fgob, Rgob)

• move the focus lens to its extreme position s (

FOCU)

• open and close the iris (

IRIS)

• insert and rotate the prism (

PRIS)

S

TAND-ALONE SEQUENCES

Demonstration programs (

dEMO

)

This menu offers 2 pr eprogram med demon strations . Demo 1 shows each effect individual ly and i n combin ation wit h

others. Pan and tilt are static. Demo 2 pans and tilts within a defined area and shows various effect combinations.

Before running demo 1, set the pan/tilt position (

PAN, TILT) to a good location for viewing the effects and then

focus (

FOCU) the beam. Select SEQ to run the demo. Demo 2 is similar but instead of def ini ng a home po sition, you

define an area such as a screen or wall by setting the minimum and maximum pan and tilt positions (

MINP, MAXP,

MINT, MAXT). Focus the beam in the center of the area.

Test sequences

Test sequence (TSEQ): Run a general test of al l effects.

Printed circuit board test (SPEC/PCBT): This menu provides 4 tests of the circuit board for service use: TI,

T2, T3, and LEd.

Factory test (SPEC/FTST): This menu provides an effects test (ETST), a movement test (M TST), and a sensor

test (

STST) used for quality control. The sensor test includes programs for testing sensors on the color and gobo

wheels (

COL1, COL2, Rgo b, and Fgob).

U

TILITIES

Calibration (

CAL

)

The calibration menu allows you to adjust the effects to achieve total uniformity between fixtures: it is not a substitute

for mechanical adjustment. Select dimmer/shutter (

d OF), color wheels (C1OF, C2OF), rotating-gobo wheel

(

RGOF), focus (FOOF), or fixed-gobo wheel (F GOF) and adjust the effect’s of fset with the arrow k e ys. Offsets are

adjustable from 1 to 255 for all effects except the fixed-gobo wheel, whic h is adjustable from 127 to 129. P ress

>ENTER@ýto save the calib ra tio n.

Page 13

13

RoboScan Pro 918

Reset default offsets (

SPEC/dFOF

)

Reset all calibrations to their factory defaults. Select dFOF and press [ENTER] when SURE is displayed, or press

>MENU@ to escape.

Reset default personality settings (

SPEC/dFSE/FACT

)

Return all personality settings (not calibrations) to their factory defaults. Select FACT and press [ENTER] when

LOAD is displayed.

Custom configurations (

SPEC/dFSE/CUS1, CUS2, CUS3

)

Save and load 3 sets of custom configurations. To save a custom configuration, adjust the settings as desired, go to

CUS1, CUS2, or CUS3 and press [ENTER] when SAVE is displayed. To load a custom setting, select it and

press [ENTER] when

LOAD is displayed.

Upload mode (

UPLd

)

Upload mode prepares th e RoboSc an Pro 918 to receive control software. It is norma lly engag ed auto maticall y when

using a Martin uploade r. In certain circumstances, however, you may have to set upload mode manually as described

under “Updating softwa re” on page 19.

Page 14

14

Operation

section 4

OPERATION

This section describes the RoboScan Pro 918’s controllable effects and the options for customizing them for your

application. Selecting options from the menu is described in the previous section.

M

ARTIN

RS-485

CONTROL

The Pro 918 may be controlled with the Martin 3032 controller with version 2.04 or later software. While the Pro 918

is not officially implemented in version 2.04, it may be set up and operated as a MAC 500.

For the fixture to respond, t he prot ocol se tting (

PSET) must be set to Martin (MART) or automatic proto col d etec-

tion (

SPEC/AUTO) must be enabled. If automatic protocol detection is enabled, send one dummy command

before sending real commands.

DMX-512

CONTROL

The Pro 918 has 4 DMX control modes wit h different channel requirement s and characteristics. Mode selection will

depend on the controller and your programming preferences.

Tracking control

Tracking is available in all 4 DMX modes. With tracking control, the controller calculates the positions along the path

between an effect’s starting point and it’s ending point. It uses the fade time t o calculate the change (delta ) of each

update or refresh, which the fixture “tracks.” For smooth movement with any fade time, the Pro 918 has a filter algorithm that looks at several position updates (samples), and calculates the ideal speed.

This algorithm is adjustable to compensate for controllers that calculate position changes unevenly. In most cases the

default settings work well.

If movement is not satisfactory there are 2 parameters that can be adjusted. The first is the calculation method used and

is selected under

SPEC/TRAC/MOdE. MOd1, the default, calculates speed based on the absolute value of the

change in DMX; it is the best choi ce with con trollers t hat calcul ate inte rmediate po sitions tha t are clos e to the lin e of

travel. MOd2 uses the real value of the DMX delta to calculate speed and is better if the intermediate positions stray

significantly from the line of travel.

The second parameter is the number of position updates used to calculate speed. The level is adjustable between 1 and

10 under

SPEC/TRAC/CAL. Increasing the number of samples increases the distance over which speed is calcu-

lated, making movement smoother but less r e sponsive to sudden changes.

The ideal settings for both parameters will vary from controller to controller: experiment for best results. The real

value algorithm (MOd2) is recommended when using the Pro 918 with the Martin Lighting Director system.

Vector control

With vector control, available in DMX modes 3 and 4, the fixture is given just 1 position - the end position - and a

speed, which is set on a separate channel. Fo r smooth movement, the fade time must be set to 0. With controllers that do

not have programmable fade times, vector control provides a way to set speed. Because the end point and speed are

known from the beginning, vector co ntrol resul ts in smooth m ovement regardless of the fade time or the c ontroller’s

processing power.

The speed channels allow vector control to be turned off, resulting in tracking control. In addition, they offer a “blackout speed,” described below, and overrides of the PTSP (pan/tilt speed) and SCUT (shortcuts) personality settings.

8-bit versus 16-bit pan/tilt resolution

With 8-bit pan/tilt resolution, the pan and tilt are divided into 256 equal increments. Finer position control and

smoother movement is provided in the 16-bit modes, which divide the full pan range into 6400 increments and the full

tilt range into 1280 increments.

S

TAND-ALONE CONTROL

The Pro 918 has test and demonstration sequences that can be run from the control panel. See page 12 for details.

Page 15

15

RoboScan Pro 918

C

ONTROLLABLE EFFECTS

All mechanical effects are reset to a “home” position when the fixture is powered up. They can also be rese t via DMX

if necessary. Accidental resets can be prevented by turning DMX Reset (

SPEC/dRES) off.

An on-the-fly position correctio n system a utomatic ally corrects th e positio n of the color wheels, fixed-gobo wheel, and

rotating gobos. This feature can be disabled by turning Effects Feedback (

SPEC/EFFb) off.

The Studio Mode setting (SPEC/MOdE) allows operation to be optimized for speed (NORM) or quietness

(

STUd).

Lamp

With the default setting, the lamp remains off until a “lamp on” command is sent from the controller. Note: A strong

surge of electric current is drawn for an instant when striking a discharge lamp. Striking many lamps at once may cause

a voltage drop large enough to prevent lamps from striking or trip the main circuit breaker. If sending “lamp on ” commands to multiple fixtures, program a sequence that strikes lamps one at a time at 5 second i nt ervals.

The Pro 918 automatically strikes the lamp within 90 seconds of being powered on if the Automatic Lamp On

(SPEC/ALON) setting is turned on. A delay determined by the address staggers lamp strikes to prevent excessive

current draw.

Lamp power can be turned off from the controller. Be careful: it is not possible to strike the lamp within 8 minutes of

having switched it off. Accidental lamp off commands can be prevented by turning DMX Lamp Off (SPEC/

dLOF

) to off.

Pan and tilt

The mirror pans 180° and tilts 72°. Movement may be optimized for speed by setting the pan/tilt speed (PTSP) per-

sonality to

FAST, or for smoothness by setting it to SLOW. The setting may be overridden on the speed channel in

vector mode. Setting the movement speed to “blackout” in vector mode causes the shutter to black out the light while

the mirror is moving.

The pan and tilt channels (DMX) can be inverted and/or swapped using the pan/tilt (PATI) menu.

Color wheels

The Pro 918 has 2 9- posi tio n-pl us-o pen color w hee ls, yi eld ing a

total of 100 possi ble combinations. In th e standard configuration the wheels combine in 67 useful ways that can be called on

1 DMX channel. The filters on color wheel 1 are easily replaceable, allowing you to configure the color wheel to suit your

taste. See page21 for details .

Both wheels can be scrolled, allowing for split color effects,

snapped to fixed positions, and continuously rotated in both

directions at different speeds. The 67 co lors can be called randomly on DMX channel 4.

The shortcuts (

SPEC/SCUT) setting determines whether

the wheels take the shortest path to the next position or turn in

one direction only. The setting may be overridden on the speed

channel in vector mode.

Setting the color speed to “blackout” in vector mode causes the shutter to black out the light while the wheels are moving.

Focus

The beam may be focused f rom 2 meters (6.5 feet) t o infinity. Depending on model, the beam angle is 17° or 23.5°.

Iris

The iris closes from full open down to 10 percent . There are 6 variable/rand om pulsa tin g iri s effects callab le on cha nnel 9. These can be disabled by switching DMX Macros (

SPEC/dMAC) off.

Color wheel 1

P

i

n

k

3

1

2

B

lu

e

1

0

1

C

y

a

n

4

0

1

P

u

r

p

le

5

0

2

Yellow 604

M

a

g

e

n

t

a

5

0

7

B

lu

e

1

1

1

G

r

e

e

n

2

0

2

R

e

d

3

0

1

Page 16

16

Operation

Fixed (static) gobos

The fixed-gobo wheel provides 9 met al gobos p lus an open position. It has 2 operating modes. In “fixed” mode (

SPEC/

gMOd/FIX

), the wheel steps between fixed positions and

shakes at variable speeds. In “scroll” mode (

SPEC/gMOd/

SCRL

), the wheel scrolls continuou sly, shakes at 1 speed, a nd

rotates at variable speed.

Setting the fixed-gobo speed to “blackout” in vector mode causes

the shutter to black out the light while the wheel turns from one

position to another. The Shortcuts (

SPEC/SCUT) setting

determines whether the gobo wheel takes the shortest path to the

next position or turns in one direction only. The setting may be

overridden on the speed channel in vector mode.

Rotating gobos

The Pro 918 has 5 rotating gobo positions. Gobos may be rotated

in both directions at varying speeds or indexed to any position.

The function and gobo are selec ted on channe l 5 and the velocity

or index position a re selected on channel 6. Sett ing the rotat inggobo speed to “blackout” in vector mode causes the shutter to

black out the light while the wheel turns from one position to

another and, if indexing is selected, while the gobo rotates

between positions.

To change the gobos, see “Changin g r otating gobos” on page 20.

Rotating prism / variable frost

The 3-facet prism can rotate in both directions at varying speeds.

There are 8 preprogrammed macros th at combine the prism wi th

rotating gobos on ch annel 10. These can be disabled by switching

DMX Macros (

SPEC/dMAC) off. Setting the prism speed to

“blackout” in v ect or m ode cau ses th e sh utt er to black out the light

while the prism moves in and out.

An optional frost filter may be in stalle d in pla c e of t he rota ting p rism to provide a variable frost ef fect . If t he fro st filter

is installed, the fixture type personality (

SPEC / FTYP) must be set to “FROS” to enable the frost variation of the

protocol.

Dimmer / shutter

The mechanical dimmer/shut ter system provides smooth, high-resolution 10 0 percent dimming, “instant” open and

blackout, random and variable strobe effects up to 23 Hz, and random and variable pulses in which the di mmer snaps

open and slowly dims or snaps cl osed and slowly opens. The pulse and rando m strobe effects can be disabled by

switching DMX Macros (

SPEC/dMAC) off.

The Dimmer Mode (SPEC/dMOd) setting allows you to select between linear or simulated tungsten fade curves.

The fade time must be 0 to simulate tungsten dimming.

Fixed gobos

Rotating gobos

Page 17

17

RoboScan Pro 918

section 5

BASIC SERVICE AND MAINTENANCE

The RoboScan Pro 918 operates under challenging conditions presented by heat, humidity, dust, and touring. It

requires regular cleanin g and lub rication to k eep pe rforming at its peak . The mai ntenanc e schedule will depe nd hea v ily

on the application and should be discussed with your Martin technician. This section describes basic maintenance.

Refer any service procedure not described here to a qualified technician.

IMPORTANT!

Excessive dust, grease, and smoke fluid buildup degrades performance and

causes overheating and damage to the fixture that is not covered by the war-

ranty. If you do not feel completely competent to perform the service, consult

qualified service personnel.

A

CCESSING PARTS

WARNING!

Disconnect the fixture from AC power before removing any cover.

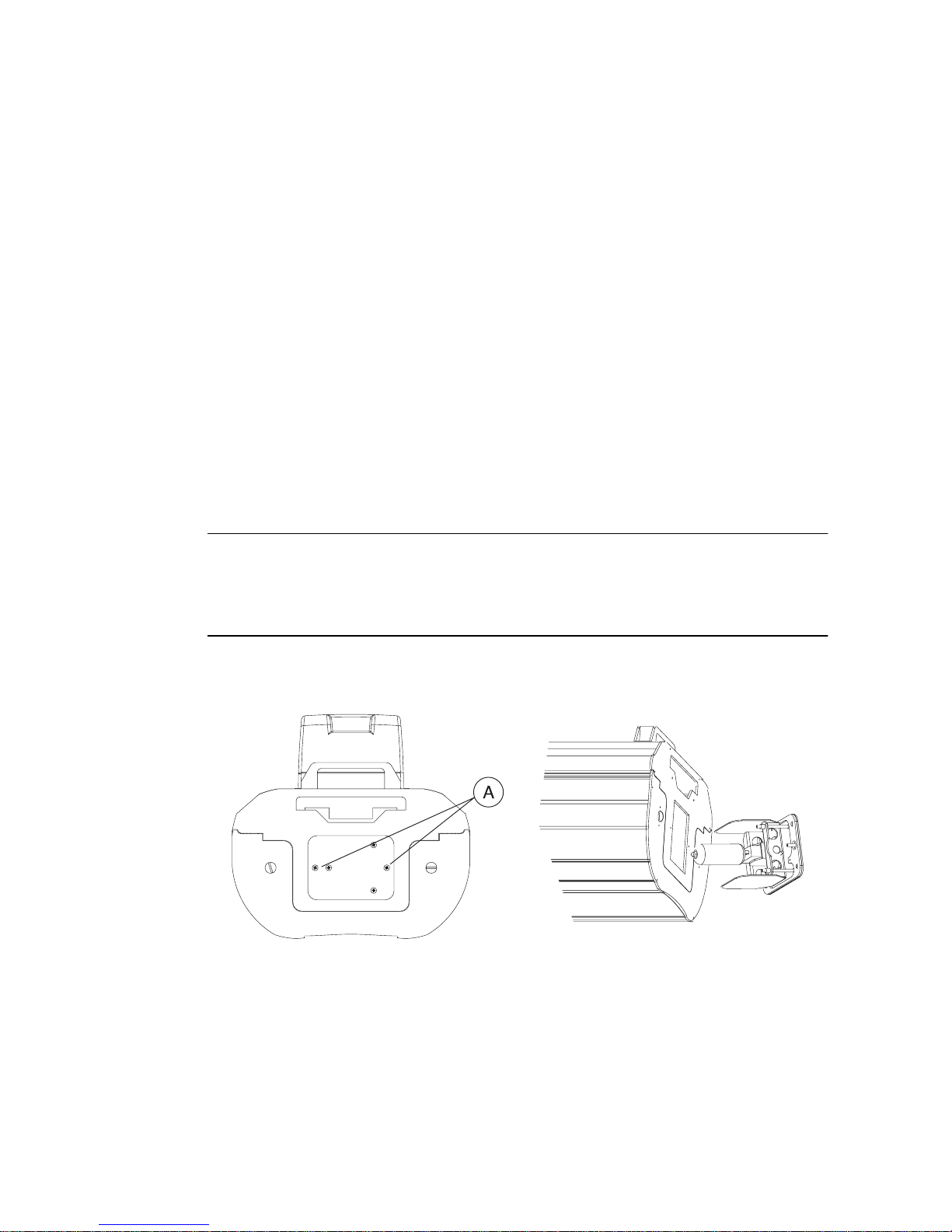

Effects section

1.

Disconnect the fixture from AC power.

2.

Turn the locking pins (A) on the back plate 1/2 turn.

3.

Pull the cover back and off.

4.

To replace the cover, position the rails on the cover in

the grooves and slide the cover forward. Push the

locking pins (A) all the way in to lock.

Printed circuit board

1.

Disconnect the fixture from AC power.

2.

Remove the 4 screws (B) from the front cover plate

(C) with one hand on the section to prevent it from falling. Gently tilt the plate away from the body to access

the printed circuit board. Removing the wires is not necessary for most service procedures.

3.

Thread the screws carefully when replacing the cover. Aluminum threads are easily stripped if screws are

overtightened or cross-threaded.

Ballast, transformer, and mains filter fuse

The ballast (E), transformer (F), and mains filter circuit

board (G) are accessed by removing the cover (D) from the

top of the RoboScan Pro 918.

1.

Disconnect the fixture from AC power.

2.

Remove the 4 screws from the plastic ballast/transformer cove r (D) and lift it off.

Page 18

18

Basic Service and Maintenance

C

HANGING VOL TAG E AND FREQUENCY SETTINGS

Operating at the wrong setting can result in poor output, greatly reduced lamp life, overheating and fixture damage.

EU version

1.

Make sure the fixture is isolated from AC power. Access the transformer and ballast as described above.

2.

On the transformer (F), move the BROWN wire to the terminal listed for your voltage. The terminal numbers

are printed in front of the connection tabs.

3.

On the ballast (E), move the BROWN wire to the terminal listed for your voltage and frequency.

4.

Replace the cover.

US version

IMPORTANT!

Fixtures wired for 100 or 120 volt operation shall have a 10 ampere main fuse

(P/N 05020025). R eplace th is with a 6.3 ampe re fu se (P/ N 050 20 020) if re w iring

for 230 or 250 volt operation.

1.

Make sure the RoboScan Pro 918 is isolated from AC power. Access the transformer and ballast as described abo ve.

2.

Find the correct transformer setting for your AC supply in the table above. The

colors refer to the wires that enter the connection block at the bottom. The figure

to right shows the transformer connection block as seen from the top. On the

transformer (F), move the BROWN wire to the correct terminal.

3.

On the ballast (E), move the BROWN wire to terminal 7 (60 Hz), or terminal 10

(50 Hz). The other terminals are not used because the ballast is fed 230 volts

from the transformer.

4.

Replace the cover.

Local AC Supply Transformer Magnetic Ballast

Frequency Voltage Setting Terminal Setting Terminal

50 Hz 200-210 V

210 V 4

200 V / 50 Hz 7

50 Hz 210-220 V

230 V / 50 Hz 10

50 Hz 220-235 V

230 V 6

50 Hz 235-240 V

245 V / 50 Hz 12

50 Hz 240-260 V 250 V 8

60 HZ 200-217 V 210 V 4 208 V / 60 Hz 4

60 HZ 217-240 V 230 V 6 227 V / 60 Hz 7

Local AC Supply Transformer Ballast

Frequency Voltage Setting Terminal Setting Terminal

60 Hz

98 - 105 V 100 V red 227 V / 60 Hz

7

118 - 126 V 120 V orange 227 V / 60 Hz

220 - 240 V 230 V yellow 227 V / 60 Hz

240 - 260 V 250 V green 227 V / 60 Hz

50 HZ

99 - 105 V 100 V red 230 V / 50 Hz

10

118 - 126 V 120 V orange 230 V / 50 Hz

220 - 240 V 230 V yellow 230 V / 50 Hz

240 - 260 V 250 V green 230 V / 50 Hz

250 V

230 V

120 V

100 V

US version transformer

connections

Page 19

19

RoboScan Pro 918

R

EPLACING FUSES

The RoboScan Pro 918 has 5 fuses. The main fuse is located in the power inlet and may be replaced wit hout openin g

the fixture. Note: The main fuse may need to be replaced with one of another value when rewiring the fixture for operation at a different AC voltage. The fuses for each of the 3 low-voltage power supplies are located on the printed circuit

board. If one of the circuit board LEDs does not light, one of these fuses may be blown. To replace:

1.

Access the printed circuit board as described above.

2.

Locate and replace the defective fuse with a time-delay fuse of the same rating. Fuse locations are shown

on the PCB layout diagram and their values are listed in the specifications.

The fifth fuse is located on the mains filter and power protectio n circuit board, located between the ballas t and the AC

power inlet. If this fuse is bl own there will be no power to th e transforme r and the fixture will appear dead, but there

will still be mains voltage on the ballast. To replace the fuse:

1.

Make sure the RoboSc an Pro 918 is isolat ed from AC power. Access the main s filter c ircuit bo ard fuse a s

described abov e .

2.

Remove the fuse with tweezers or a similar tool.

Replace only with a special fast-acting fuse of the

same rating (P/N 05021010).

3.

Replace the ballast/transformer cover.

C

HANGING THE

XLR

PIN-OUT

This procedure r everses the signal pola rity of pins 2 an d 3 on the

XLR connectors so that the fixture can be conne cted directly to

Martin RS-485 protocol devices. Optionally, a phase-reversing

cable may be used.

1.

Access the printed circuit board as described above.

2.

Position the jumpers on PL 233 and PL 234 for the desired XLR pin-out as shown.

U

PDATING SOFTWARE

The latest software for the RoboScan Pro 918 is available from your Martin dealer and the Martin Professional web

site. Please r ead the update notes bundled with the software. Up date software is uploaded to t he RoboScan P ro 918

using a Martin uploader such as the MBPP1.

Normal upload

Connect the uploader to the fixture just like a controller. Under normal conditions, software can be install ed from a

remote locatio n - th ere is no need t o set t he Ro boSca n Pro 918 to boot mode. P lease refer to t he up load er manua l f or

further instructions.

Boot mode upload

If the data is corrupted during transmission, a check-sum error (CSER) will occur and after 15 seconds the fixture will

automatically switch to boot mode (

UPLd) and be ready for a boot-mod e upload as described below and in the

uploader manual.

If a software upload to the RoboScan Pro 918 is interrupted, the fixture must be powered off for at least 10 seconds

before a new upload can be attempted. When powered on, a check-sum error will occur and it will automatically go

into boot mode, ready for a second upload attempt. Select boot mode upload on the uploader.

If there is no functional software in memory, the fixture must be set to boot mode manually before starting the upload.

If the control panel works, select

UPLd from the SPEC menu and confirm when SURE is displayed by pressing

[ENTER].

If the control panel does not work, boot mode can be engaged by moving jumper PL12 1 on the main circu it board t o

pins 1 and 2 as follows.

1.

Access the printed circuit board as described above.

DMX pin-outMar tin pin-out

(default)

PL234

PL233

PL234

PL233

Page 20

20

Basic Service and Maintenance

2.

Move jumper PL121 to pins 1 and 2 (hard boot setting) as

shown. See also the circuit board layout diagram on page 30.

3.

Apply power to the RoboScan Pro 918 and proceed with the

upload as described in the uploader manual.

4.

After the upload, disconnect the fixture from AC power, move

the jumper back to the normal setting, and replace the circuit board section.

C

USTOM GOBOS

For best focus, custom gobos fo r th e Rob oSca n Pr o 918 sh ou ld be mad e wit h the artwork reversed on the c oated side.

See page 31 for gobo specifications.

Chrome-coated glass gobos are no t recommended: they absorb more heat than enhan ced aluminum gobos and are

likely to break or oxidize. The lifetime of chrome gobos is extremely short in the Pro 918; but, if used, their lifetime

can be extended somewhat by inserting the gobos with the coated side towards the lamp.

C

HANGING ROTATING GOBOS

Without tools

1.

Remove the effects section cover.

2.

Turn the gobo wheel so you can reach the desired gobo. Turn the color wheel until the open position is over

the gobo.

3.

Push the gobo and retaining spring out of the back of the holder. Avoid letting the spring and gobo fall into

the effects compartment.

4.

Insert the new gobo. See below for proper orientation.

5.

Insert the retaining spring with the bend facing out, away from the gobo. Working through the open position

in the color wheel, push the gobo and spring all the way down into the gobo holder.

With needlenose pliers

1.

Remove the effects section cover as described above.

2.

Tur n the gobo wheel until the easiest access to the desired gobo position is obtained. Tur n the color wheel

until the open position is over the gobo position.

3.

Turn the gobo holder until you can see the tab on the holder retaining spring.

4.

Grip the tab on the retaining spring with a pair of small (needlenose) pliers. Place your index finger over the

spring to prevent it from falling into the fixture. Open the spring and remove it from the gobo holder.

5.

Remove the gobo holder from the bearing by pulling it forwards towards the mirror.

6.

Push the gobo and gobo retaining spring out of the holder.

7.

Insert the new gobo. See below for proper gobo orientation.

8.

Insert the retaining spring with the bend facing out, away from the gobo. Push the gobo and spring all the

way down into the gobo h older.

9.

Replace the gobo holder in the bearing. Do not force the holder into the bearing: it will go in easily if it is

installed straight.

10.

Grip the retaining ring by the tab with the pliers. Place your thumb on the back of the gobo holder to press it

all the way down in the bearing and use your index finger to hold the other end of the spring on the holder.

Open the spring and place it in the groove.

PIN 1

È

PL121 PL121

PIN 1

È

hard boot settingnormal setting

Page 21

21

RoboScan Pro 918

Gobo orientation

When installing coated glass gobos, the coated side should face out towards the mirror for best focus. Glass gobos may

be inserted with the coated side towards the lamp if requir ed for proper projection.

Te xtured glass gobos must be installed with the smooth side facing the lamp.

Text and image gobos, for correct projection, must be installe d with the image facing the mirror.

C

HANGING COLOR FILTERS

1.

Remove the effects section cover as described above.

2.

Manually turn color wheel 1 so the desired filter is accessible.

3.

Using a soft cloth or gloves, gently tilt the outside edge of the filter towards the mirror and remove.

4.

To place a filter in the wheel, insert the plastic holder between the spring cl ip - with th e protru din g tab facing

the lamp - until it snaps into place.

L

AMP REPLACEMENT

Discharge lamps operate under high pressure. As the lamp ages, the glass envelope becomes more fragile . To reduce

the risk of the lamp exploding, wh ich may cause damage t o the fixture, do n ot exceed the rated average life by mo re

than 25 percent. The procedure for installing the lamp is described on page 5. After installing the lamp, reset the lamp

usage counters as described under “Readouts” on page 11.

O

PTIMIZING LAMP ALIGNMENT

1.

Disconnect the fixture from AC power and allow to cool.

2.

Make a preliminary adjustment: remove the lamp assembly and turn the 3 lamp adjustment screws with a 3

mm Allen wrench to position the lamp socket plate a distance of 38 mm (1.5”, outside measurement) from

the access pl ate as shown below.

3.

Replace the lamp assembly.

4.

Apply power to the fixture and allow it to reset.

Coated Glass

:KHQýDQýREMHFWýLVýKHOGýXSýWRýWKHýXQFRDWHGýVLGHñý

WKHUHýLVýDýVSDFHýEHWZHHQýWKHýREMHFWýDQGýLWVý

UHIOHFWLRQïý7KHýHGJHýRIýWKHýJRERýFDQýEHýVHHQý

ZKHQýORRNLQJýWKURXJKýWKHýXQFRDWHGýVLGHïý

Coated side towards mirrorUncoated side towards lamp

:KHQýDQýREMHFWýLVýKHOGýXSýWRýWKHýFRDWHGýVLGHñýWKHUHýLVý

QRýVSDFHýEHWZHHQýWKHýREMHFWýDQGýLWVýUHIOHFWLRQïý7KHý

HGJHýRIýWKHýJRERýFDQQRWýEHýVHHQýZKHQýORRNLQJý

WKURXJKýWKHýFRDWHGýVLGHï

Textured side towards mirror

Structured Glass

Smooth side towards lamp

Image Gobos

Correct image towards mirrorReversed image towards lamp

Page 22

22

Basic Service and Maintenance

5.

Using either a controller or the control panel, strike the lamp and focus the light on a flat surface.

6.

Center the hot-spot (the b rightest part of the beam) usin g the 3 ad justm ent scre w s. Turn one screw at a time

to drag the hot-spot diagonally across the projected image. If you cannot detect a hot-spot, adjust the lamp

until the light is even.

7.

To reduce a hot-spot, pull the lamp in by turning all three screws clockwise 1/4-turn at a time until the light is

evenly distributed.

8.

If the light is brighter around the edge than it is in the center, or if light output is low, the lamp is too far back

in the reflector. “Push” the lamp out by turning the screws counterclockwise 1/4-turn at a time until the light

is bright and evenly distributed.

C

LEANING

Optical components

Be very careful when cleaning the optical components. The colored surface on the dichroic filters is achieved by means

of special multi-layer coatings and even small scratches may be visible. Residues from cleaning fluids can bake onto

components and ruin them.

1.

Allow the components to cool completely.

2.

Wash dir ty lenses and filters with isopropyl alcohol. A generous amount of regular glass cleaner may also

be used, but no residues may remain.

3.

Rinse with distill ed water. Mixing the water with a small amount of wetting agent such as Kodak Photoflo will

help prevent streaking and spotting.

4.

Dry with a clean, soft and lint-free cloth or blow dry with compressed air.

Fans

To ensure pr oper cooling of the fixture, it is imp ortant tha t the fans are free of du st. Vacuum or gently wipe the fans

clean if they are dirty.

L

UBRICATION

The focus mechanism slides on 2 metal pi ns that must b e lubricated periodica lly. Check the focus mechanism whenever the fixture is open for service and lubricate the slides if movement is rough. Lubricate the rotating-gobo bearings

if movement is rough on slow rot a tion or if they become noisy.

1.

Fill a syringe with Martin P/N 37302003, “Silicone oil, 500 ml,” or P/N 37302004, “Silicone oil, 200 ml, in

applicator bottle.”

2.

Apply a few drops of oil to both slides. The oil will be distributed by the action of the focus mechanism. Be

careful not to get oil on other parts.

3.

Apply a few drops of oil to each rotating-gobo bearing from the lamp side of the wheel. Remove excess

lubricant and be careful not to get oil on other parts.

Page 23

23

RoboScan Pro 918

appendix a

DMX PROTOCOL

DMX Channel Start code = 0

DMX1 DMX2 DMX3 DM X4

Value Percent Function

1

Note: If the DMX reset (dRES) and/or DMX

lamp off (dLOF) commands are turned off in

the menu, they can be enabled by setting

color wheel 1 to cyan 401(144-148) and

color wheel 2 red 308 (157-160).

0 - 19

20 - 49

50 - 72

73 - 79

80 - 99

100 - 119

120 - 127

128 - 147

148 - 167

168 - 187

188 - 190

191 - 193

194 - 196

197 - 199

200 - 202

203 - 207

208 - 217

218 - 227

228 - 237

238 - 247

248 - 255

0 - 7

8 - 19

20 - 28

29 - 31

31 - 39

39 - 47

47 - 50

50 - 58

58 - 65

66 - 73

74 - 75

75 - 76

76 - 77

77 - 78

78 - 79

80 - 81

82 - 85

85 - 89

89 - 93

93 - 97

97 - 100

Shutter, Strobe, Reset, Lamp On/Off

Shutter closed

Shutter open

Strobe, fastÆslow

Shutter open

Opening pulse, fast Æslow

Closing pulse, fast Æslow

Shutter open

Random strobe, fast

Random strobe, medium

Random strobe, slow

Shutter open

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

Shutter open

Reset fixture, see note

Shutter open

Lamp power on

Shutter open

Lamp power off: time > 5 seconds, see note

2

0 - 255 0 - 100

Dimmer

Closed Æ open

3

0 - 16

16 - 32

32 - 48

48 - 64

64 - 80

80 - 96

96 - 112

112 -128

128 - 144

145 - 148

149 - 152

153 - 156

157 - 160

161 - 164

165 - 168

169 - 172

173 - 176

177 - 180

181 - 184

185 - 215

216 - 245

246 - 255

0 - 6

6 - 13

13 - 19

19 - 25

25 - 31

31 - 38

38 - 44

44 - 50

50 - 56

57 - 58

58 - 60

60 - 61

62 - 63

63 - 64

65 - 66

66 - 67

68 - 69

69 - 71

71 - 72

73 - 84

85 - 96

96 - 100

COLOR 1

Continuous scroll

White Æ Blue 111

Blue 111 Æ Red 301

Red 301 Æ Magenta 507

Magenta 507 Æ Green 202

Green 202 ÆYellow 604

Yellow 604 Æ Purple 502

Purple 502 Æ Blue 101

Blue 101 Æ Pink 312

Pink 312 Æ Cyan 401

Fixed color positions

Cyan 401

Pink 312

Blue 101

Purple 502

Yellow 604

Green 202

Magenta 507

Red 301

Blue 111

White

Continuous rotation

CW, fast Æ slow

CCW, slow Æ fast

Enable alternate color functions.

Page 24

24

DMX Pro tocol

4

0 - 16

16 - 32

32 - 48

48 - 64

64 - 80

80 - 96

96 - 112

112 -128

128 - 144

145 - 148

149 - 152

153 - 156

157 - 160

161 - 164

165 - 168

169 - 172

173 - 176

177 - 180

181 - 184

185 - 215

216 - 245

246 - 248

249 - 251

252 - 255

0 - 255

0 - 6

6 - 13

13 - 19

19 - 25

25 - 31

31 - 38

38 - 44

44 - 50

50 - 56

57 - 58

58 - 60

60 - 61

62 - 63

63 - 64

65 - 66

66 - 67

68 - 69

69 - 71

71 - 72

73 - 84

85 - 96

96 - 97

98 - 98

99 - 100

0 - 100

COLOR 2: Normal Functions

Continuous scroll

White ÆCTC 3200-4100

CTC 3200-4100 Æ CTC 3200-5600

CTC 3200-5600 Æ Blue 104

Blue 104 Æ Blue 108

Blue 108 Æ Green 206

Green 206 Æ Red 308

Red 308 Æ Yellow 603

Yellow 603 Æ CTC 5500-2900

CTC 5500-2900 Æ CTC 5500-4200

Fixed color positions

CTC 5500-4200

CTC 5500-2900

Yellow 603

Red 308

Green 206

Blue 108

Blue 104

CTC 3200-5600

CTC 3200-4100

White

Continuous rotation

CW, fast Æ slow

CCW, slow Æ fast

Random color

Fast

Medium

Slow

Alternate Functions

(Channel 3 set from 246 to 255.)

67 different colors in following order:

white, purple, pink, magenta, red, orange, yellow, green,

cyan, blue, black

5

0 - 55

56 - 75

76 - 95

96 - 115

116 - 135

136 - 155

156 - 175

176 - 195

196 - 215

216 - 235

236 - 255

0 - 22

22 - 29

30 - 37

38 - 45

45 - 53

53 - 61

61 - 69

69 - 76

77 - 84

85 - 92

93 - 100

Rotating Gobo Selection

Open gobo

Indexing - set position on channel 6

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Continuous rotation - set velocity on channel 6

Gobo 5

Gobo 4

Gobo 3

Gobo 2

Gobo 1

6

нэрэмлз

ìëæ

млеэрэлии

0 - 2

3 - 127

128 - 252

253 - 255

нэрэйд

èí

инэрэмнн

нэрэм

мэрэинэ

инэрэде

ддэрэмнн

Rotating Gobo Index and Rotation

(Select mode and gobo on channel 5.)

Indexing

Index CCW from default

Default index

Index CW from default

Continuous rotation

Static

CW, slow Æ fast

CCW, fast Æ slow

Static

DMX Channel Start code = 0

DMX1 DMX2 DMX3 DM X4

Value Percent Function

Page 25

25

RoboScan Pro 918

7

gMOd

=

FIX

0 - 9

10 - 19

20 - 29

30 - 39

40 - 49

50 - 59

60 - 69

70 - 79

80 - 89

90 - 102

103 - 119

120 - 136

137 - 153

154 - 170

171 - 187

188 - 204

205 - 221

222 - 238

239 - 255

0 - 4

4 - 8

8 - 11

12 - 15

16 - 19

20 - 23

24 - 27

27 - 31

31 - 35

35 - 40

40 - 47

47 - 53

54 - 60

60 - 67

67 - 73

74 - 80

80 - 87

87 - 93

94 - 100

Fixed Gobos

Fixed gobo positions

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Gobo 8

Gobo 9

Gobo shake, fast

ÆÆÆÆ

slow

Gobo 9

Gobo 8

Gobo 7

Gobo 6

Gobo 5

Gobo 4

Gobo 3

Gobo 2

Gobo 1

7

gMOd

=

SCRL

0 - 180

0

20

40

60

80

100

120

140

160

180

181 - 183

184 - 186

187 - 189

190 - 192

193 - 195

196 - 198

199 - 201

202 - 204

205 - 207

208 - 231

232 - 255

0 - 70

0

8

16

24

31

39

47

55

63

70

71 - 72

72 - 73

73 - 74

74 - 75

75 - 76

77 - 78

78 - 79

79 - 80

80 - 81

82 - 91

92 - 100

Fixed Gobos

Continuous scroll

Full positions:

Open

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Gobo 8

Gobo 9

Gobo shake

Gobo 9 shake

Gobo 8 shake

Gobo 7 shake

Gobo 6 shake

Gobo 5 shake

Gobo 4 shake

Gobo 3 shake

Gobo 2 shake

Gobo 1 shake

Continuous rotation

CW, fast Æ slow

CCW, slow Æ fast

8

0 - 255 0 - 100

Focus

Infinity Æ 2 meters

9

0 - 199

200 - 215

216 - 229

230 - 243

244 - 246

247 - 249

250 - 252

253 - 255

0 - 78

78 - 84

85 - 90

90 - 95

96 - 96

97 - 98

98 - 99

99 - 100

Iris

Open Æ close

Close

Opening pulse, fast Æslow

Closing pulse, fast Æslow

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

DMX Channel Start code = 0

DMX1 DMX2 DMX3 DM X4

Value Percent Function

Page 26

26

DMX Pro tocol

10

Fixture type = prism (default)

0 - 19

20 - 79

80 - 89

90 - 149

150 - 215

216 - 220

221 - 225

226 - 230

231 - 235

236 - 240

241 - 245

246 - 250

251 - 255

0 - 7

8 - 31

31 - 35

35 - 58

59 - 84

84 - 86

87 - 88

89 - 90

91 - 92

93 - 94

95 - 96

96 - 98

98 - 100

Prism

Prism out

Prism in, CCW rotation, fast Æ slow

Prism in, no rotation

Prism in, CW rotation, slow Æ fas t

Prism out

Rotating prism and gobo macros

Macro 1

Macro 2

Macro 3

Macro 4

Macro 5

Macro 6

Macro 7

Macro 8

10

Fixture type = frost (optional) 0 - 255 0 - 100

Variab le Frost

1RýIURVWýÆýIXOOýIURVW

11

0 - 255 0 - 100

Pan Coarse (16-bit MSB)

/HIWэЖэULJKWэхмлеэ эQHXWUDOф

-12-12

0 - 255 0 - 100

Pan Fine (16-bit LSB )

/HIWýÆýULJKWý

12 13 12 13

0 - 255 0 - 100

Tilt Coarse (16-bit MSB)

8SэЖэGRZQэхмлеэ эQHXWUDOфэ

-14-14

0 - 255 0 - 100

Tilt Fine (16-bit LSB )

8SýÆýGRZQý

- - 13 15

нэрэл

экэрэлйи

лйзэрэлйе

лйдэрэлим

лилэрэлии

нэрэм

мэрэдз

дзэрэдж

деэрэде

ддэрэмнн

Pan/Tilt Speed

Tracking mode

Fast Æ slow

Tracking at slow speed, overrides PTSP FAST

Tracking at fast speed, overrides PTSP SLOW

Blackout while moving

- - 14 16

нэрэл

экэрэлйи

лйзэрэлйе

лйдэрэлим

лилэрэлии

нэрэл

экэрэлйи

лйзэрэлйе

лйдэрэлим

лилэрэлии

0 - 245

лйзэрэлйе

лйдэрэлим

лилэрэлии

0 - 251

252 - 255

0 - 2

3 - 245

246 - 255

нэрэм

мэрэдз

дзэрэдж

деэрэде

ддэрэмнн

нэрэм

мэрэдз

дзэрэдж

деэрэде

ддэрэмнн

нэрэдз

дзэрэдж

деэрэде

ддэрэмнн

нэрэде

ддэрэмнн

нэрэм

мэрэдз

дзэрэмнн

Effects Speed

Dimmer, iri s , focus and gobo indexing

Tracking mode

Fast Æ slow

Tracking with shortcuts disabled, overrides SCUT ON

Tracking with shortcuts enabled, overrides SCUT OFF

Maximum speed

Color 1, color 2, and fixed gobo if

gMOd = SCRL

Tracking mode

Speed, fast Æ slow

Tracking with shortcuts disabled, overrides SCUT ON

Tracking with shortcuts enabled, overrides SCUT OFF

Blackout while moving

Fixed gobo if gMOd = FIX

Normal (as set on effect channel), no blackout

Normal, shortcuts disabled, overrides SCUT ON

Normal, shortcuts enabled, overrides SCUT OFF

Blackout while moving

Rotating gobo and prism

Normal (as set on effect channel), no blackout

Blackout while moving

Gobo shake speed if

gMOd = SCRL

Fast

Speed, fast Æ slow

Fast

DMX Channel Start code = 0

DMX1 DMX2 DMX3 DM X4

Value Percent Function

Page 27

2

index ccw index cw

c

s

c

f

closing

230

←

243

I

RIS

open

0

close

199

closed

200 215

opening

216

←

229

I

RIS

P

ULSE

o

f

o

s

random

10 20 30 40 50 60 70 80 90

019

closed

20 49

open

S

TROBE

O

P

E

N

80

←

99

D

IMMER

P

ULSE

opening closing

128 187

R

ANDOM

S

TROBE

med slow

R

ND

PULSE

217208

R

ESET

237228

L

AMP

O

N

255248

S

HUTTER

fast

147 148 168167

L

AMP

O

FF

*

O

P

E

N

O

P

E

N

O

P

E

N

O

PEN

50

←

72

open close

f

*

100

←

119

238247

O

PEN

> 5 sec.

227218

128

←

continuous ccw 2523 continuous cw

→

127

st

M

ODE

T

E

FFECTS

S

PEED

216

R

OTATING

G

OBO

S

ELECTION

156

G 5

175

C

H

. 4

A

LT

D

IMMER

closed open

C

ONTINUOUS

C

OLOR

S

CROLL

(

WHEEL

1)

white blue 111

red 301

magenta 507

green 202

yellow 604 purple 502 blue 101 pink 312 cyan 401

S

TEPPED

S

CROLL

C

ONTINUOUS

R

OTATION

cw ccw

255246

145

185

←

215

R

ND

C

OLO

R

C

ONTINUOUS

C

OLOR

S

CROLL

(

WHEEL

2)

white ctc+ ctc++ blue 104 bl ue 10 8 green 206 red 308 yellow 603 ctc-- ctc-

0

Alternate function (e na ble on ch. 3) 67 colors: white, purple, pink, magenta, red, orange, yellow, green, cyan, blue, black

0

O

PEN

127

56 76

G 2

G 1

75 95 96

G 3

115 116

G 4

135 136

G 5

155 176 195 196 215 216

G 2

235 236

G 1

255

S

TEPPED

S

CROLL

C

ONTINUOUS

R

OTATION

cw ccw

I

NDEXED

G

OBO

S

ELECTION

G

OBO

R

OTATION

128 255

55

S

TATIC

G

OBO

S

CROLL

(

STEPPED

)

open

09

G 1

10 19

G 2

20 29

G 3

30 39

G 4

40 49

G 5

50 59

G 6

60 69

G 7

70 79

G 8

80 89

G 9

90 102

S

TATIC

G

OBO

S

HAKE

G 9

103 119

G 8

120 136

G 7

137 153

G 6

154 170

G 5

171 187

G 4

188 204

G 3

205 221

G 2

222 238

G 1

239 255

F

OCUS

infinity 2 meters

P

RISM

out

019

19

ccw rotation

20

←

79

stop

80

89

cw rotation

out

150

215

M

ACROS

1212345678

221 226 231 236 241 246 251

P

AN

left right

T

ILT

F

INE

(LSB)

up down

3 fast slow 245

T

P

AN

/T

ILT

S

PEED

3 fdimmer, iris, focus, and gobo indexing

no changefixed gobos

no changerotating prism and gobo

3

colors

245 S F

«·»

251

T 245

0

O

PEN

G 4 G 3

245

0

149 153 157161 165 169173 177 181

P

AN

F

INE

(LSB)

left right

T

ILT

up down

1

3

4

5

6

7

8

9

10

11

1212

1212 1313

-1414

13 15

14 16

--

3142

s

*

876 432105

216

→

245

185

←

215 216

→

245 f

ms

90

→

149

RoboScan Pro 918 DMX Protocol

Start code = 0

Implemented from CPU software version 1.0

←

* Set ch. 3 + ch. 4 as shown to override disabled function.

T = tracking mode (0-2 & 246-251)

S = normal pan/tilt or shortcuts off (246-248)

F = fast pan/tilt or shortcuts on (249 -251)

«·»

= blackout speed (252-255)

←

=

variable speed, points to fast

st

←←←←←←←←←

←

0 14416 32 48 64 80 96 112 128

0 14416 32 48 64 80 96 112 128

fs

25 50 75 100 125 150 175 200 225 250

L

I

GHT

C

OLO

R

G

OBO

S

E

F

F

ECT

S

P/T

S

P

EED

-

T

S

T

F

T

S

T

F

T

S

T

F

«·»

«·»

«·»

position 9 1 2 3 4 5 6 7 8

145 149 153157 161 165169 173 177181

987

*

432105

S

TATIC

G

OBO

S

CROLL

(

CONTINUOUS

)

open

0

G 1

20

G 2

40

G 3

60

G 4

80

G 5

100

G 6

120

G 7

140

G 8

160

G 9

180

G

OBO

S

HAKE

C

ONTINUOUS

R