Page 1

RoboScan 812

user manual

Page 2

© 1998, 1999 Martin Professional A/S, Denmark.

All rights reserved. No part of this manual may be

reproduced, in any form or by any means, without

permission in writing from Martin Professional A/S,

Denmark.

Printed in Denmark.

P/N 35000052, Rev. C

Page 3

section 1

INTRODUCTION

Thank you for selecting the Martin RoboScan 812. It is designed and built to be bright, reliable and easy to use. With proper setup and maintenance, the RoboScan 812 will provide

years of trouble-free operation.

Read this manual before operating the RoboScan 812. Safety hazards or damage to the fixture may occur if it is handled or operated incorrectly. For your protection and other’s,

always follow the safety precautions listed below and observe the warnings in this manual

and printed on the fixture. If you have questions about how to operate and service the fixture, please contact your Martin dealer for assistance before proceeding. Refer any service

not described in this manual to a qualified Martin technician.

This manual covers the RoboScan 812 with software version 2.8 or higher. The latest information on the RoboScan 812 is always available from your dealer and the Martin web site

at http://www.martin.dk.

SAFETY PRECAUTIONS

• The RoboScan 812 is NOT for domestic use.

• For protection against dangerous electric shock, always ground (earth) the fixture

electrically, use only a source of AC power that complies with local building and electrical codes, and do not expose the fixture to rain or moisture. Disconnect the fixture

from AC power before removing any cover or part.

• Disconnect the fixture from AC power if the lamp blo ws. Allow the fixture to cool for

10 minutes before installing a new lamp.

• Do not illuminate surfaces within 30 cm (12 inches) of the fixture.

• Do not place filters or other objects over th e lens or mirror.

• Keep all combustible materials (for example fabric, wood, paper) at least 10 cm (4

inches) away from the fixture. Keep flammable mate ri al s wel l away from the fixture.

• Provide a minimum clearance of 10 cm (4 inches) around the fan and air vent.

• Do not operate the fixture if the ambient temperature exceeds 40° C (104° F).

• When suspending the fixture above ground level, verify that the structure can hold at

least 10 times the weight of all installed devices and secure the fixture with an

approved safety cable. Block access below the work area whenever installing or

removing the fixture.

• For protection against dangerous UV radiation, neve r operate the f ixture with missing

and/or damaged covers or lenses installed and do not stare into the light. Replace any

broken or cracked component immediately.

• Refer all service to a qualified technician.

3Introduction

Page 4

Features

• 150 watt discharge lamp

• 11 dichroic colors plus white

• 11 gobos plus open and blackout

• 175° pan movement

• 83° tilt movement

• Variable speed control on all functions

• Split color and gobo effects

• Variable strobe up to 7 Hz

• Remote lamp on/off (with Martin-protocol controllers)

• Coated precision optics

• Adjustable focus

• Controllable via Martin and DMX-512 controllers

• Preprogrammed stand-alone operation

• Music trigger using built-in microphone

• Power factor correction for low current consumption

• Efficient fa n cooling

• Overheating protection

4 RoboScan 812

Page 5

section 2

INSTALLATION

The RoboScan 812 is delivered fully adjusted from the factory; only a few setup steps are

necessary. Please follow them carefully to get the most out of your new equipment.

Unpacking

The packing material is carefully designed to protect the fixture during shipment - always

use it or a flight case to transport the fixture.

The RoboScan 812 comes complete with the following items:

• 150 W Martin Metal Halide discharge lamp

• 5 meters XLR-XLR cable

• mains cable

• mounting bracket and hardware

• this user manual

Installing a Plug on the Power Cord

WARNING!

For protection from dangerous electric shock, the fixture

must be grounded (earthed). The AC supply shall be fitted

with a fuse or circuit breaker and ground-fault protection.

The RoboScan 812 is delivered without a plug on the power cord. Following the manufacturer’s instructions, install an approved 3-prong grounding-type plug that fits your supply.

Connect the wires to the pins as listed below. The table shows some possible pin identification schemes; if the pins are not clearly identified, or if you have any doubts about proper

installation, consult a qualified electrician.

Wire Pin Marking Screw color

brown live “L” yellow or brass

blue neutral “N” silver

yellow/green ground green

5Installation

Page 6

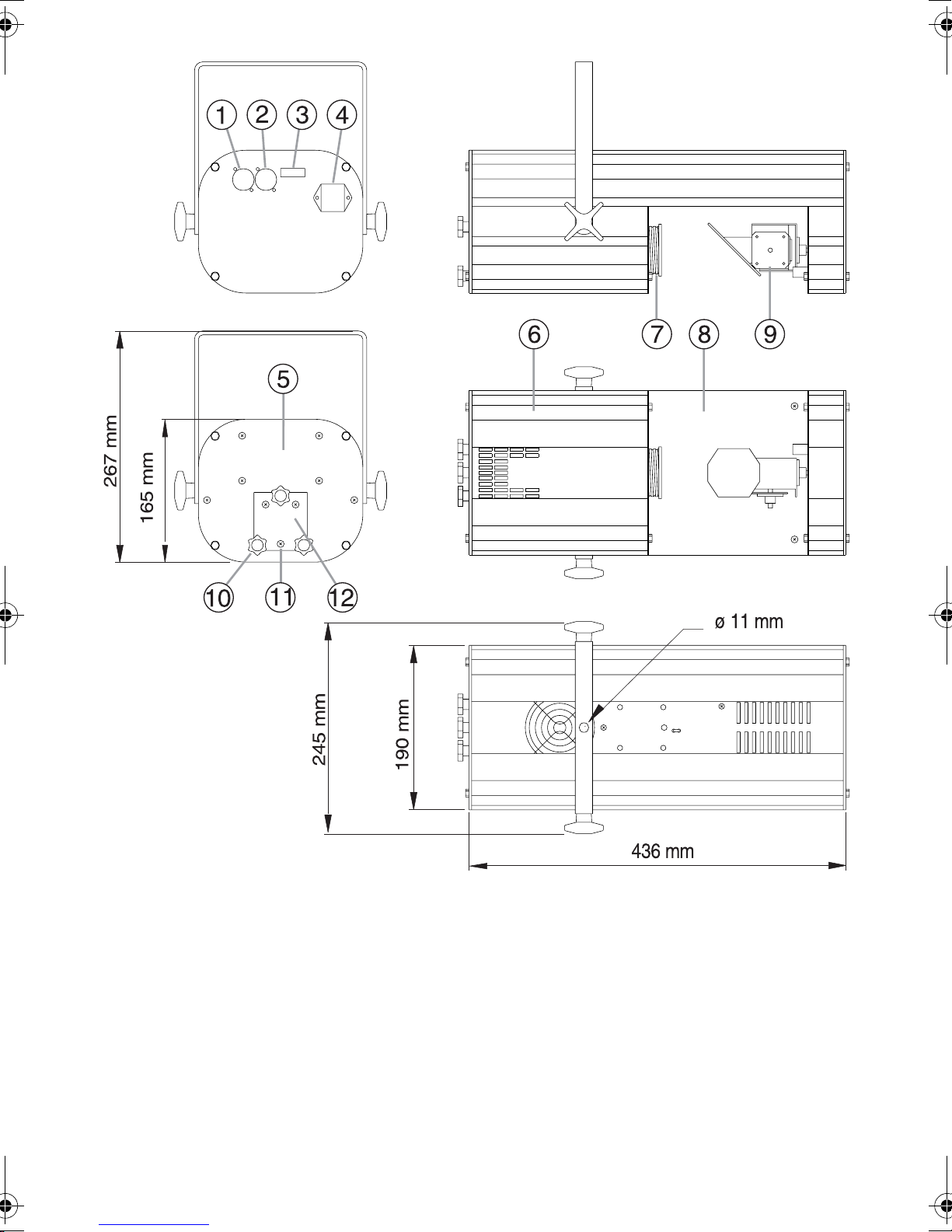

Checking voltage and frequency settings

The RoboScan 812 voltage setting must be within 5% of the AC mains supply. The voltage

setting may be adjusted to local conditions. The frequency (50 or 60 Hz depending on

model), however, must match your supply. Check the settings printed on the label near the

mains input. See page 13 to change the voltage setting if necessary.

Releasing the Pan/Tilt Lock

The pan/tilt assembly (9) floats in a special rubber mount to reduce noise when operating

the pan and tilt motors. In order to protect the pan/tilt assembly from damage during shipment, it is secured with two plastic straps and a locking thumbscrew. These must be

removed before using the RoboScan!

It is strongly recommended that the pan/tilt assembly be locked for transportation by replacing the thumbscrew in position A over the pan/tilt assembly.

1. Cut and remove the two plastic straps.

2. Remove the thumbscrew over the pan/tilt assembly and store it in the

threaded hole, labelled B, on the pan/tilt plate.

3. Carefully remove the surface protection foil and war ning notice from the

mirror.

Installing the Mounting Bracket

Use the 11 mm hole in the center of the mounting bracket to fasten a clamp (not included),

or to permanently bolt the fixture in place, with a grade 8.8 (minimum) M10 bolt and lock

nut. For safety, verify that the structure can support at least 10 times the weight of all

installed fixtures, clamps, cables, auxiliary equipment, etc., and always use an approved

means of secondary attachment suc h as a safe ty cable to prevent falls.

The mounting bracket may also be used as a floor stand.

1. Inser t the two black plastic hand wheels into the bracket holes.

2. Place a plastic spacer on each hand wheel, between the bracket and the

casing, and screw the hand wheels into the fixture.

3. Turn or tilt the RoboScan to the desired position and tighten the hand

wheels.

6 RoboScan 812

Page 7

Setup for Controller Operation

Connect the Serial Link

The RoboScan 812 may be used with DMX and Martin protocol controllers. The RoboScan

812’s XLR connections are configured for Martin protocol controllers such as the 3032.

When connecting a RoboScan 812 to any DMX-standard device, you must swap pins 2 and

3 with a phase-reversing cable.

1. Connect the controller’s data output to the RoboScan 812’s input (2). If using

a Martin-standard controller, use a direct 3-pin to 3-pin cable such as the one

provided. If using a DMX controller, use a phase-reversing cable, either 3-pin

to 3-pin, or 5-pin to 3-pin, depending on the output of the controller.

2. Continue the link: connect the output (1) of the fixture closest to the controller to the input of the next fixture. Use a direct cable when connecting

same-standard fixtures. Use a phase-reversing cable only when connecting a DMX-standard fixture to a Martin fixture with pin 2 hot. Up to 32 fixtures may be connected on a serial link.

3. Insert a male 120 Ω XLR ter mination plug in the output of the last fixture

on the link. The termination plug is simply a 3-pin male XLR plug with a

120 Ω resistor soldered between pins 2 and 3. The termination plug is

required for error-free communication.

3-pin to 3-pin

Phase Reversing

Cable

Connections

Male Female

1

2

3

P/N 11820006

1

2

3

5-pin to 3-pin

Phase Revers ing

Cable

Connections

Male Female

1

2

3

4

5

P/N 11820003

1

2

3

3-pin to 5-pin

Phase Reversing

Cable

Connections

Male Female

1

2

3

P/N 11820002

1

2

3

4

5

Set the Address

When using the RoboScan 812 with a controller, you must set the DIP-switch (3) to the start

channel, also known as the address, which is the first channel the controller uses to send

instructions to the RoboScan 812.

For independent control, each fixture must have its own address and control channels. Two

or more RoboScan 812s may have the same address; however, they will receive the same

instructions and behave identically.

7Installation

Page 8

Martin mode: The RoboScan 812 uses 1 channel to communicate with the controller. The

address may be any channel between 1 and 32.

DMX mode: The RoboScan 812 may be operated in tracking or vector mode; see the DMX

protocol for details. It uses 5 consecutive DMX channels in tracking mode and 7 consecutive DMX channels in vector mode. The factory default is tracking mode. The address may

be any channel up to 508 within the controller’s range (506 if 7 channels are used).

Example: 4 RoboScans using tracking mode (5 channels) may be addressed as follows:

12345678910111213141516171819

812 No. 1

Address: 1

812 No. 2

Address: 6

812 No. 3

Address: 11

812 No. 4

Address: 16

20

Use the following procedure to set a Martin or DMX address.

1. Select an available address within the controlle r’s range.

2. Look up the DIP-switch setting on page 19. You can also calculate it by

subtracting pin values until the total of the values equals the address.

Start with the highest pin value that can be subtracted and work down

until there is no remainder. The table below shows the pin values.

3. Set the DIP-switch (3) by flipping ON the pins found in step 2.

pin 1 2 3 4 5 6 7 8 9 10

value

1

2

4

8

16

32

64

128

256

OFF

.

Example: Channel 6

Pins 2 and 3 ON

channel

- value of pin 3

remainder

- value of pin 2

remainder 0

On

8 RoboScan 812

Example: Channel 82

Pins 2, 5 and 7 ON

6

-4

2

-2

10234 51 86 7 9

channel

- value of pin 7

remainder

- value of pin 5

remainder

- value of pin 2

remainder 0

On

82

- 64

18

- 16

- 2

10234 51 86 7 9

2

Page 9

section 3

OPERATION

Stand-Alone Operation

The RoboScan 812 may be operated without a controller in stand-alone mode. In this mode,

the fixture performs a random sequence that is triggered by the beat of the music or automatically at a set speed. The DIP-switch must be set to th e desired stand-alone mode before

applying power. Settings for the different modes are shown below.

1. With the fixture powered off, set the DIP-switch (3) for the desired mode.

Pins not listed must be switched off.

2. Apply power to the RoboScan 812 to run the sequence.

Stand-Alone Modes

Description Pins Switched ON

Random sequence, wide pan/tilt, auto trigger 2, 10

Random sequence, wide pan/tilt, music trigger 1, 2, 10

Random sequence, narrow pan/tilt, auto trigger 2, 3, 10

Random sequence, narrow pan/tilt, music trigger 1, 2, 3, 10

Lamp ON 8, 10

Lamp OFF 7, 10

Adjustment sequence (for service use and lamp adjustment) 5, 10

L.E.D. chase auto-trig (for service use only) 4, 10

L.E.D. chase music-trig (for service use only) 1, 4, 10

Controller Operation

Getting Started

The RoboScan 812 may be used with DMX-512 and Martin protocol controllers; it automatically determines which protocol is in use. Protocol auto-detection can be reactivated if

necessary by switching on all ten DIP-switches and then resetting the address.

1. Connect the RoboScan 812 to the controller and set the address.

2. Switch on and configure the controller.

3. Apply power to the RoboScan. After a short reset procedure it will

respond to the controller.

9Operation

Page 10

Controllable Effects

Lamp

After switching on the RoboScan 812, the lamp remains off until a “lamp on” command is

sent from the controller. If using a Martin protocol controller, the lamp may also be turned

off via the controller. This feature is not implemented in the DMX protocol - to turn off the

lamp you must power off the fixture.

It's important to note that the lamp is a cold restrike type: it must be cold before striking is

possible. The lamp must cool for approximately 5 minutes before it can be turned on again.

Pan/Tilt

The moving mirror allows you to pan the beam 175° and tilt it 83°. Movement speed may

be adjusted with the controller fade time (DMX tracking mode and Martin controllers) or

on a separate channel (DMX vector mode).

Color Wheel

The RoboScan 812 has 13 positions on the color wheel: 11 with saturated dichroic colors,

open white, and blackout. The wheel can be positioned between 2 colors to split the beam.

The speed of the color and gobo wheels may be adjusted with the controller fade time

(DMX tracking mode and Martin controllers) or on a separate channel (DMX vector mode).

Selecting color strobe causes the color wheel to change between any 2 adjacent colors or

between white and black. The strobe speed is variable.

Gobos

The RoboScan 812 has 11 gobos on the gobo wheel plus open and blackout. Selecting gobo

strobe causes the gobo wheel to change between any 2 adjacent gobos or between full open

and black. The strobe speed is variable.

Random Sequence

The RoboScan 812 may be set to perform a preprogrammed sequence with automatic or

music trigger.

Focus

Focus may be adjusted manually from 1 meter to infinity by turning the threaded lens bar rel

(7). Screwing the lens in increases the focus distance; screwing it out decreases the distance

at which the image is focused.

10 RoboScan 812

Page 11

section 4

SERVICE AND MAINTENANCE

WARNING!

Read the procedures carefully. If you do not feel completely

competent to perform the service, consult qualified service

personnel for assistance.

Disconnect the fixture from power before removing any cover.

Changing the Lamp

Martin 150 W

Metal Halide Osram HTI 150 GE CSS 150

Martin P/N

Average Life

Color Temp.

Output

The three lamps shown above may be used in the RoboScan 812. Installing any other lamp

may damage the fixture. The lamp holder is adjusted at the factory; i f further alignment is

necessary, the procedure is described on page 12.

1. Remove the 3 thumbscrews (10) securing the lamp-socket assembly to the

rear of the RoboScan. Gently pull out the assembly.

2. If changing the lamp, remove the old lamp from the socket.

3. Holding the new lamp in a clean cloth (do not touch the glass), carefully

insert it firmly and squarely into the lamp socket.

4. If your fingers touch the glass, clean the bulb with a clean, lint-free cloth

wetted with alcohol.

97010107 97010108 97010104

2000 h 750 h 1000 h

5000K 6500K 5000K

900 lm 1200 lm 900 lm

5. Replace the lamp-socket assembly and tighten the thumbscrews.

11Service and Maintenance

Page 12

Adjusting the Lamp

The RoboScan 812 comes fully adjusted from the factory, however, readjustment of the

lamp may improve performance. The lamp is adjusted by turning the 3 screws (11) on the

lamp access plate (12). Turning these clockwise pulls the lamp back towards the rear and

vice versa. Keep adjustments small to avoid pulling the lamp so far off center that it hits the

reflector.

1. Set up the RoboScan 812 so th at you can access the lamp-access plate (12)

and, if adjusting the lamp without a controller, the DIP-switch (3).

2. With controller: Turn on the RoboScan 812 and allow the lamp to warm

up for 5 minutes. From the controller, select white light with the open

gobo and position the beam on a flat, white surface. Focus the beam.

Without controller: Flip DIP-switch pins 1, 5 and 10 on. Flip all other

pins off. Apply power to the RoboScan 812. After it has reset, the fixture

produces a white light with an open gobo for adjustment purposes. Wait

approximately 5 minutes for the lamp to reach full brightness. Position

the fixture and/or mirror so the light shines on a flat, white surface and

focus the beam.

3. If there is an off-center “hot spot,” the lamp is not centered in the reflector. Pull the hot spot into the center of the field with small adjustments of

one or more of the screws (11). Note: the Martin Metal Halide lamp is

nearly as large as the reflector opening - very little side to side adjustment is possible or necessary.

4. If the light is significantly brighter in the center of the field than it is at the

edge, the lamp is too far forward in the reflector. Pull the lamp in by turning all three screws clockwise 1/4-turn at a time until the light is evenly

distributed.

5. If the light is brighter around the edge than it is in the center, or if light

output is low, the lamp is too far back in the reflector. “Push” the lamp out

by turning the screws counterclockwise 1/4-turn at a time until the light is

bright and evenly distributed.

6. If you have made large sideways adjustments, disconnect the fixture from

AC power, allow it to cool, and remove the lamp assembly to ensure that

the lamp is still placed squarely in the socket.

12 RoboScan 812

Page 13

DMX Mode Selection

7 channel vector mode

PL11

654321

5 channel tracking mode

fan connector

jumper

The DMX mode is set with a jumpe r on the cir cuit board inside the unit. The factory default

is tracking mode. Follow the procedure below to change the mode.

WARNING!

Make sure the fixture is disconnected from AC power.

1. Remove the cover (6) above the lamp. Remove the cover (8) above the circuit

board.

2. Locate connector PL11 on the circuit board: refer to the label inside the

chassis. On one or two of the pins there is a black clip - a jumper - that

creates an electrical connection when placed over 2 pins.

3. Place the jumper on pins 4 and 5 to enable 7-channel vector mode.

Remove the jumper to enable 5-channel tracking mode. You can store

the jumper by placing it sideways on one of the pins.

4. Reassemble the fixture.

Selecting Voltage

The voltage and frequency settings must match the local AC power supply! Operating at the

incorrect setting can result in poor light output, shortened lamp life, overheating and damage to the fixture. The factory setting is printed on the serial number label next to the mains

input. If the voltage is not within 5 percent of the local supply, then the ballast and transformer must be rewired.

Model Selectable Voltages Frequency

RoboScan 812 EU 230 V / 240 V / 250 V 50 Hz

RoboScan 812 US 100 V / 110 V / 120 / 220 V 50 or 60 Hz*

* The RoboScan 812 US may also be used with a 100 V, 50 Hz supply when wired for 120

V, 60 Hz operation.

13Service and Maintenance

Page 14

WARNING!

Make sure the fixture is disconnected from AC power.

RoboScan 812 US

1. Remove the cover above the lamp. (6)

2. Remove the cover (8) above the circuit board.

3. Locate the connection block next to the circuit board. Right beside it is a

label indicating the proper terminal for each voltage.

4. With a small screwdriver, loosen the screw in the terminal that holds the

BROWN wire. Remove the brown wire. Tighten the screw. Note: The

BLACK wire must always be connected to the 220 V terminal.

5. Loosen the screw for the terminal closest to the supply voltage and insert

the BROWN wire. Tighten the screw.

6. Remove the end plate (5) to access the ballast.

7. To set the frequency, move the GREY wire on the ballast to the “230-50”

(50 Hz) or “230-60” (60 Hz) terminal. The wire is released and locked by

inserting a small screwdriver in the square hole next to the terminal and

prying back the spring.

8. Tug lightly on the GREY wire to make sure that it is connected securely.

9. Reassemble the unit before connecting to AC power.

RoboScan 812 EU

Transformer

50 Hz AC Supply

218 - 234 V 230 V 230 V

235 - 240 V 230 V 240 V

241 - 244 V 250 V 240 V

245 - 260 V 250 V 250 V

1. Remove the cover above the lamp. (6)

2. Remove the cover (8) above the circuit board.

3. Move the BROWN transformer wire to the transformer setting shown

above. Do not move the WHITE and BLUE wires from terminal 1.

Setting

Ballast

Setting

4. Remove the end plate (5) to access the ballast.

14 RoboScan 812

Page 15

5. Remove the GRAY wire from the ballast terminal: insert a screwdriver in

the small hole under the terminal and release the spring with a clockwise

turn.

6. Open the spring for the correct ballast terminal and insert the GRAY wire.

The terminals are marked on the side of the ballast.

7. Reassemble the unit before connecting to AC power.

Replacing the Fuse

The holder for the main fuse is built in to the mains input socket (4). If the fuse blows

repeatedly, the fixture requires servicing by a qualified technician. Never replace the fuse

with one of a different rating!

1. Unplug the mains cable from the input socket.

2. Pry open the fuse holder and remove the fuse.

3. Replace the fuse with one of the same type and rating. The fuse rating is

listed on serial number label on the end plate.

4. Close the fuse holder and replace the mains cable.

15Service and Maintenance

Page 16

appendix a

DMX 512 PROTOCOL

The RoboScan 812 supports tracking and vector mode. In tracking mode, speed is determined by the controller’s fade time. In vector mode, speed is determined by a value programmed on a separate DMX channel. For smooth movement in vector mode, the

controller’s fade time must be set to 0, i.e., the position must bump fr o m the current value to

the next. If the RoboScan 812 is set to run vector mode, tracking mode can be enabled by

programming the speed channels to 0.

DMX

Channel

1

2

DMX

V alues Percent Effect

Strobe, SA, Reset, Lamp ON

0 - 10

11 - 74

75 - 138

139 - 170

171 - 202

203 - 235

236 - 255

0 - 15

15 - 30

30 - 45

45 - 60

60 - 75

75 - 90

90 - 105

105 - 120

120 - 135

135 - 150

150 - 165

165 - 180

180 - 184

185 - 189

190 - 194

195 - 199

200 - 204

205 - 209

210 - 214

215 - 219

220 - 224

225 - 229

230 - 234

235 - 239

240 - 255

0 - 4

4 - 29

29 - 54

55 - 67

67 - 79

80 - 92

93 - 100

0 - 6

6 - 12

12 - 18

18 - 24

24 - 29

29 - 35

35 - 41

41 - 47

47 - 53

53 - 59

59 - 65

65 - 71

71 - 72

73 - 74

75 - 76

76 - 78

78 - 80

80 - 82

82 - 84

84 - 86

86 - 88

88 - 90

90 - 92

92 - 94

94 - 100

No strobe

Gobo strobe (fast ! slow)

Color strobe (fast ! slow)

Remote Auto trig

Remote Music trig

Reset fixture

Lamp power ON

Color

black ! white

white ! color 1

color 1 ! color 2

color 2 ! color 3

color 3 ! color 4

color 4 ! color 5

color 5 ! color 6

color 6 ! color 7

color 7 ! color 8

color 8 ! color 9

color 9 ! color 10

color 10 ! color 11

color 11

color 10

color 9

color 8

color 7

color 6

color 5

color 4

color 3

color 2

color 1

white

black

16 RoboScan 812

Page 17

Gobo

0 - 15

15 - 30

30 - 45

45 - 60

60 - 75

75 - 90

90 - 105

105 - 120

120 - 135

135 - 150

150 - 165

165 - 180

0 - 6

6 - 12

12 - 18

18 - 24

24 - 29

29 - 35

35 - 41

41 - 47

47 - 53

53 - 59

59 - 65

65 - 71

3

180 - 184

185 - 189

190 - 194

195 - 199

200 - 204

205 - 209

210 - 214

215 - 219

220 - 224

225 - 229

230 - 234

235 - 239

240 - 255

71 - 72

73 - 74

75 - 76

76 - 78

78 - 80

80 - 82

82 - 84

84 - 86

86 - 88

88 - 90

90 - 92

92 - 94

94 - 100

closed ! open

open ! gobo 1

gobo 1 ! gobo 2

gobo 2 ! gobo 3

gobo 3 ! gobo 4

gobo 4 ! gobo 5

gobo 5 ! gobo 6

gobo 6 ! gobo 7

gobo 7 ! gobo 8

gobo 8 ! gobo 9

gobo 9 ! gobo 10

gobo 10 ! gobo 11

gobo 11

gobo 10

gobo 9

gobo 8

gobo 7

gobo 6

gobo 5

gobo 4

gobo 3

gobo 2

gobo 1

open

closed

4

0

127

255

5

0

127

255

60

1 - 255

1 - 100

70

1 - 255

1 - 100

0

50

100

0

50

100

0

0

Pan

Max Left

Neutral

Max Right

Tilt

Max Up

Neutral

Max Down

Movement Speed (vector mode only)

Tracking mode enabled

Speed (fast ! slow)

Color / Gobo speed (vector mode only)

Tracking mode enabled

Speed (fast ! slow)

17DMX 512 Protocol

Page 18

appendix b

TECHNICAL SPECIFICATIONS

RoboScan 812 EU / US

Dimensions:

• Length:.........................................................................................436 mm (17.2" )

• Height incl./excl. bracket:..................................267 mm / 165 mm (10.5" / 6.5")

• Width incl./excl. bracket:.....................................245 mm / 190 mm (9.6" / 7.5")

• Weight incl. bracket (EU model):................................................9.4 Kg (20.7 lb)

• Weight incl. bracket (US model):..............................................10.5 Kg (23.1 lb)

Electrical

• Power and current consumption: ..............................170 W, 1 A at 230 V, 50 Hz

• AC voltage and frequency (EU model): ............................230/240/250 V, 50 Hz

• AC voltage and frequency (US model): .....................100/110/120/220 V, 60 Hz

• Fuse:................ ...................... ....................... .................3.15 AT (EU) / 4AT (US)

Compatible Lamps

• Martin Metal Halide 150 (standard)..............................................P/N 97010107

• Osram HTI 150..............................................................................P/N 91010108

• GE Lighting CSS 150....................................................................P/N 91010104

Photometric

• Beam angle:.... ..............................................................................................15.5°

18 RoboScan 812

Page 19

appendix c

DIP-SWITCH TABLE

This table shows DIP-switch settings for channels 1- 511. To find a setting, locate the channel in the table. Follow the row to the left to find the settings for pins 1 through 5; follow the

column to the top to find the settings for pins 6 through 9. A “0” indicates the pin is turned

off and a “1” indicates the pin is turned on. Pin 10 is always switched OFF when using the

RoboScan 812 with a controller.

Example: The table shows the setting for channel 212 is 00101 for pins 1 - 5 and 0110 for

pins 6 - 9. Pins 3, 5, 7, and 8 are set to on; pins 1, 2, 4, 6, 9, and 10 are set to off.

DIP-Switch Setting

0 = OFF

1 = ON

#1 #2 #3 #4 #5

0 0 0 0 0 32 64 96 128 160 192 224 256 288 320 352 384 416 448 480

1 0 0 0 0 1 33 65 97 129 161 193 225 257 289 321 353 385 417 449 481

0 1 0 0 0 2 34 66 98 130 162 194 226 258 290 322 354 386 418 450 482

1 1 0 0 0 3 35 67 99 131 163 195 227 259 291 323 355 387 419 451 483

0 0 1 0 0 4 36 68 100 132 164 196 228 260 292 324 356 388 420 452 484

1 0 1 0 0 5 37 69 101 133 165 197 229 261 293 325 357 389 421 453 485

0 1 1 0 0 6 38 70 102 134 166 198 230 262 294 326 358 390 422 454 486

1 1 1 0 0 7 39 71 103 135 167 199 231 263 295 327 359 391 423 455 487

0 0 0 1 0 8 40 72 104 136 168 200 232 264 296 328 360 392 424 456 488

1 0 0 1 0 9 41 73 105 137 169 201 233 265 297 329 361 393 425 457 489

0 1 0 1 0 10 42 74 106 138 170 202 234 266 298 330 362 394 426 458 490

1 1 0 1 0 11 43 75 107 139 171 203 235 267 299 331 363 395 427 459 491

0 0 1 1 0 12 44 76 108 140 172 204 236 268 300 332 364 396 428 460 492

1 0 1 1 0 13 45 77 109 141 173 205 237 269 301 333 365 397 429 461 493

0 1 1 1 0 14 46 78 110 142 174 206 238 270 302 334 366 398 430 462 494

1 1 1 1 0 15 47 79 111 143 175 207 239 271 303 335 367 399 431 463 495

0 0 0 0 1 16 48 80 112 144 176 208 240 272 304 336 368 400 432 464 496

1 0 0 0 1 17 49 81 113 145 177 209 241 273 305 337 369 401 433 465 497

0 1 0 0 1 18 50 82 114 146 178 210 242 274 306 338 370 402 434 466 498

1 1 0 0 1 19 51 83 115 147 179 211 243 275 307 339 371 403 435 467 499

0 0 1 0 1 20 52 84 116 148 180 212 244 276 308 340 372 404 436 468 500

1 0 1 0 1 21 53 85 117 149 181 213 245 277 309 341 373 405 437 469 501

0 1 1 0 1 22 54 86 118 150 182 214 246 278 310 342 374 406 438 470 502

1 1 1 0 1 23 55 87 119 151 183 215 247 279 311 343 375 407 439 471 503

0 0 0 1 1 24 56 88 120 152 184 216 248 280 312 344 376 408 440 472 504

1 0 0 1 1 25 57 89 121 153 185 217 249 281 313 345 377 409 441 473 505

0 1 0 1 1 26 58 90 122 154 186 218 250 282 314 346 378 410 442 474 506

1 1 0 1 1 27 59 91 123 155 187 219 251 283 315 347 379 411 443 475 507

0 0 1 1 1 28 60 92 124 156 188 220 252 284 316 348 380 412 444 476 508

1 0 1 1 1 29 61 93 125 157 189 221 253 285 317 349 381 413 445 477 509

0 1 1 1 1 30 62 94 126 158 190 222 254 286 318 350 382 414 446 478 510

1 1 1 1 1 31 63 95 127 159 191 223 255 287 319 351 383 415 447 479 511

#90000000011111111

#80000111100001111

#70011001100110011

#60101010101010101

19DIP-Switch Table

Loading...

Loading...