Page 1

RoboColor III

user manual

P/N 35000050, Rev. B. © 1996 - 1999 Martin Professional A/S, Denmark

Page 2

NTRODUCTION

I

Congratulations on your choice of the RoboColor III system, designed and

manufactured by Martin Professional. The RoboColor III is a high performance,

automated color changing system, providing exciting possibilities for lighting

designers in many applications. The rugged construction combined with the

choice of high quality components ensures th at your RoboColor III system will

perform reliably for many years to come.

SAFETY PRECAUTIONS

The RoboColor III is NOT for domestic use.

• Read user manual before use.

• For protection against dangerous electric shock, always ground (earth) the system

electrically, use only a source of AC power that complies with local building and

electrical codes, and do not expose the system to rain or mois ture.

• Disconnect the system from AC power before removing any cover or part.

• Disconnect the system from A C po wer if the lamp blo ws. Allow the heads to cool

for 15 minutes before installing a new lamp.

• Do not illuminate surfaces within 30 cm (12 inches) of the heads.

• Do not place filters or other objects over the lenses.

• Keep all combustible materials (for example fabric, wood, paper) at least 30 cm

(12 inches) away from the heads. Keep flammable materials well away from the

heads.

• Provide a minimum clearance of 10 cm (4 inches) around the fans an d air vents.

• Do not operate the system if the ambient temperatu r e exceeds 40° C (104° F).

• When suspendin g t he system above ground level, verify that the structure can

hold at least 10 times the weight of all installed devices, and secure the fixtures

with approved safety cables. Block access below the work area whenever

installing or removing the syste m.

• For protection against dangerous UV radiation, never operate the system with

missing and/or damaged covers or lenses, and do not stare into the light. Replace

any broken or cracked component immediately.

• Refer all service to a qualified technician.

2 Introduction RoboColor III

Page 3

ETTING

S

The RoboColor III system consists of the RoboColor III heads, whic h are the

color changing spotlights, and the RoboColor III controller, which drives the

heads. You can connect up to four heads to one controller.

Important! Do NOT connect RoboColor III heads directly to the mains supply.

Connect them only to a RoboColor III controller.

U

P

UNPACKING

The RoboColor III system includes the following items:

• RoboColor III heads with Martin 150 W Metal Halide discharge lamps

• Mounting bracket

• Fittings for mounting bracket (two lever handles and two metal washers)

• RoboColor III controller

• 5 meter XLR-XLR cable

• User manual

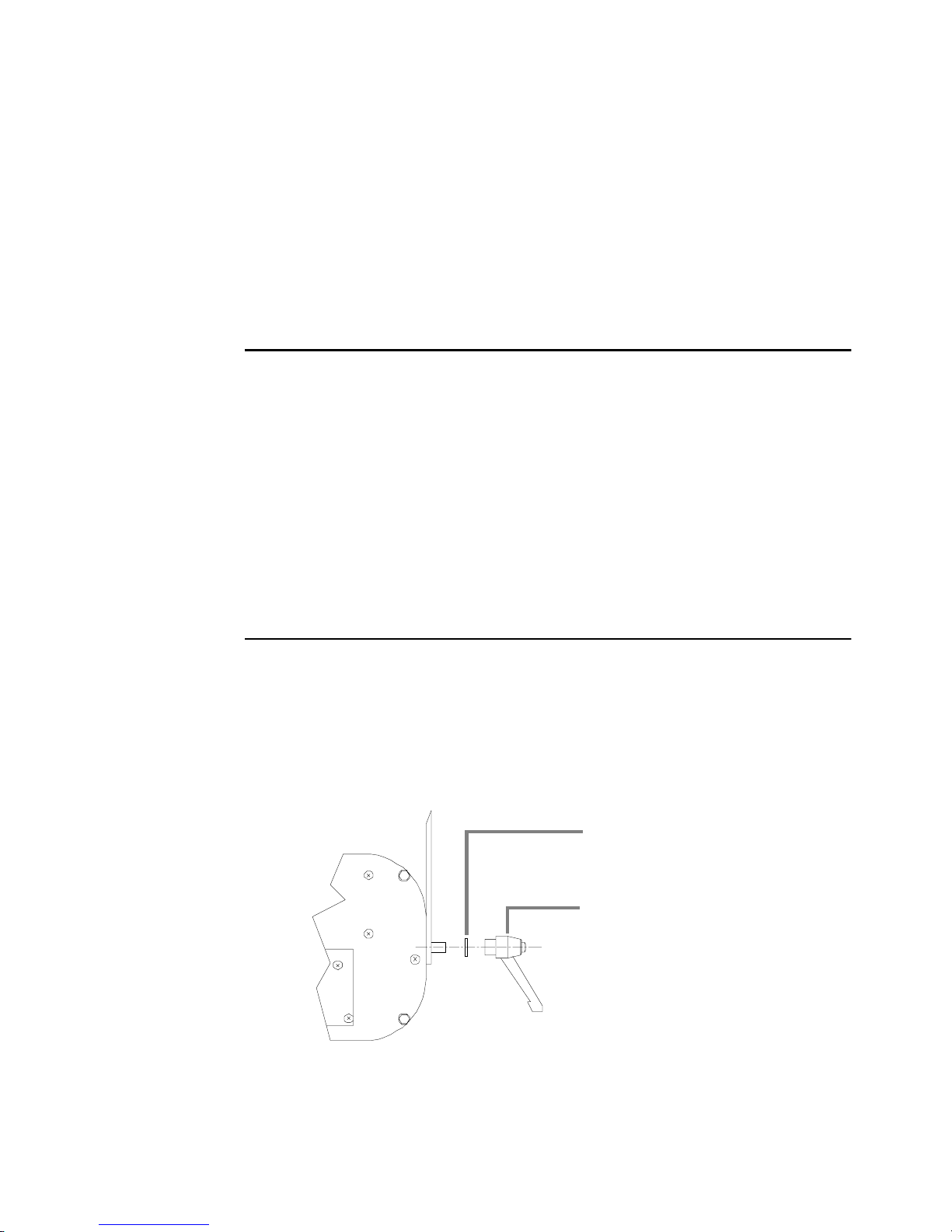

PREPARING HEADS

Secure the mounting bracket

• The mounting bracket is already fitted onto the head. Secure it with the two

metal washers and lever handles supplied.

First, fit the metal

washer.

Then, secure

the lever handle.

User Manual Setting Up 3

Page 4

Check voltage setting

Important! The voltage setting of the heads must match your local AC mains

supply.

The RoboColor III head is supplied in a 50 Hz or 60 Hz version. It is not possible

to rewire from 50 Hz to 60 Hz, or vice versa.

• The factory setting is printed on a label on the back of the head. Check the

setting against the table below and rewire if necessary, following the

instructions on page 15.

50 Hz Model 60 Hz Model

Mains supply Ballast tapping Mains supply Ballast tapping

210V - 235V 230V 200V - 215V 210V

235V - 245V 240V 215V - 225V 220V

245V - 255V 250V 225V - 235V 230V

PREPARING THE CONTROLLER

Install a mains plug

Warning! For protection from da ng erous el ec tri c sh ock, th e fix tu re must

be grounded (ear thed) . The AC main s supply sh all be have a

fuse or circuit breaker, and ground-fault protection.

The controller may be supplied without a plug on the mains cable. You will have

to fit a plug that conforms to your local mains outlet before you can connect the

unit to AC power. The double insulated mains cable contains three wires.

1 Connect the BROWN wire to the LIVE pin.

2 Connect the BLUE wire to the NEUTRAL pin.

3 Connect the YELLOW/GREEN wire to the EARTH pin.

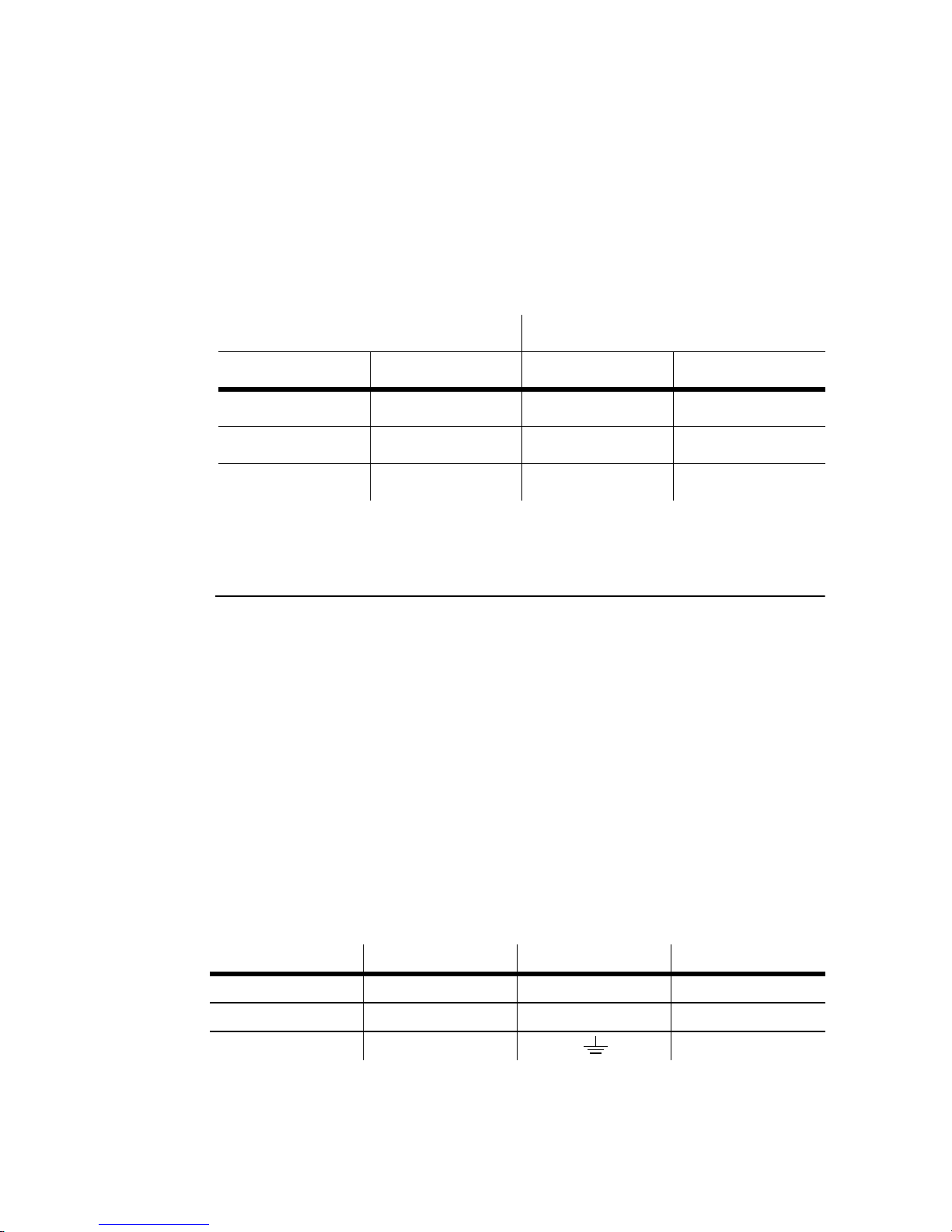

Wire Pin Marking Screw color (US)

brown live “L” yellow or bra s s

blue neutral “N” silver

yellow/green ground green

4 Setting Up RoboColor III

Page 5

Check voltage setting

Important! The contr ol ler’s volta ge se tting must match your local mains supply.

The factory setting is printed on a label on the back of the controller. Check the

setting against the table below and rewire if necessary, following the instructions

on page 15.

Mains Supply Transformer Setting

210 - 240V 230V

240 - 255V 250V

CONNECTING THE SYSTEM

You can use any DMX or Martin lighting controller to operate the RoboColor III

system. Control data is transmitted from the lighting controller via XLR data

cables to the data input on the RoboColor III controller. The RoboColor III

controller’s data output sends the data fur ther to addition al units: up to 32

RoboColor III systems can be connected on the same data link.

The RoboColor III can also be operated without a lighting controller in standalone mode. In this mode, the system runs built-in sequences that are

automatically or music triggered depending on the mode selected. A special

master/slave feature allo ws several RoboColor III systems to synchronize (via the

data link) in stand-alone mode. These features are further described later.

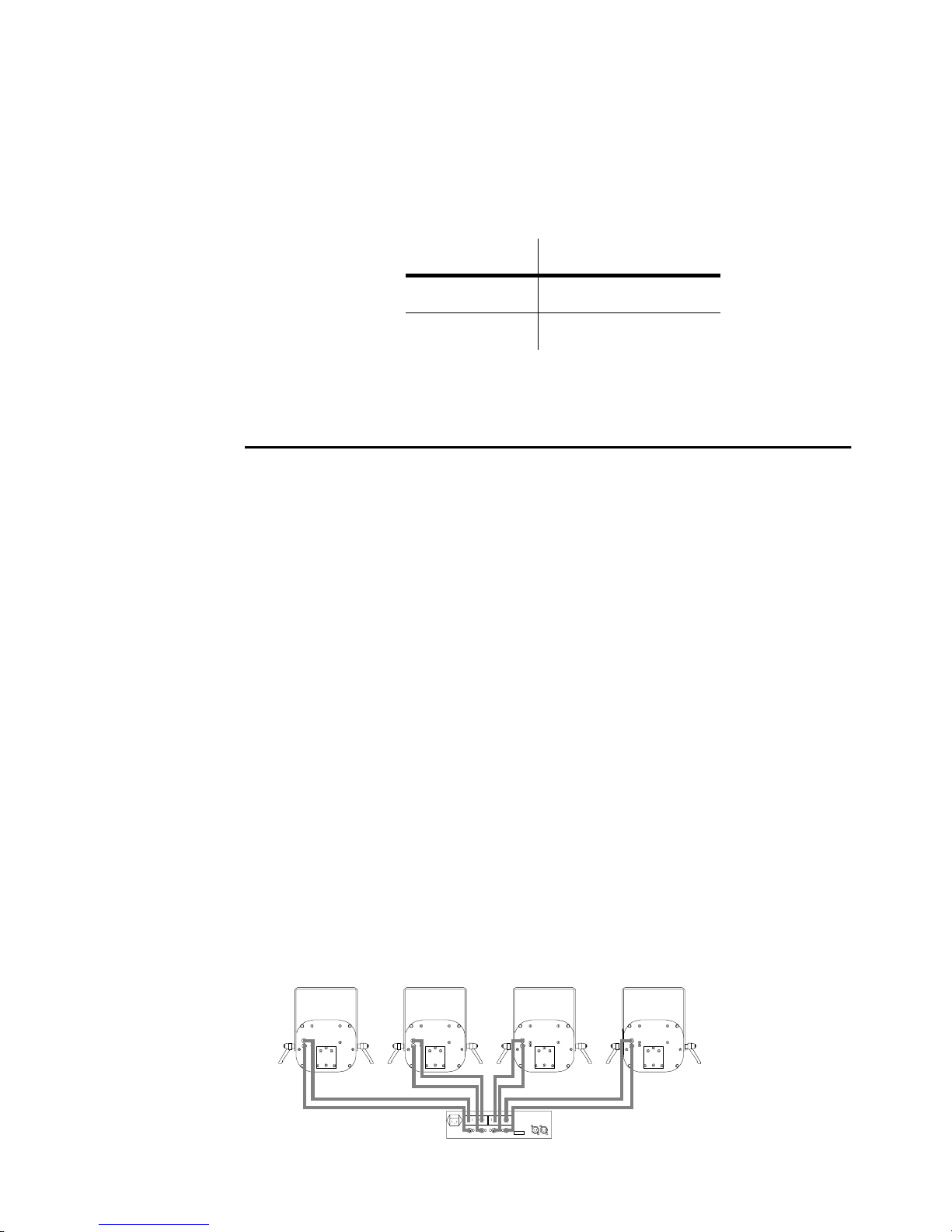

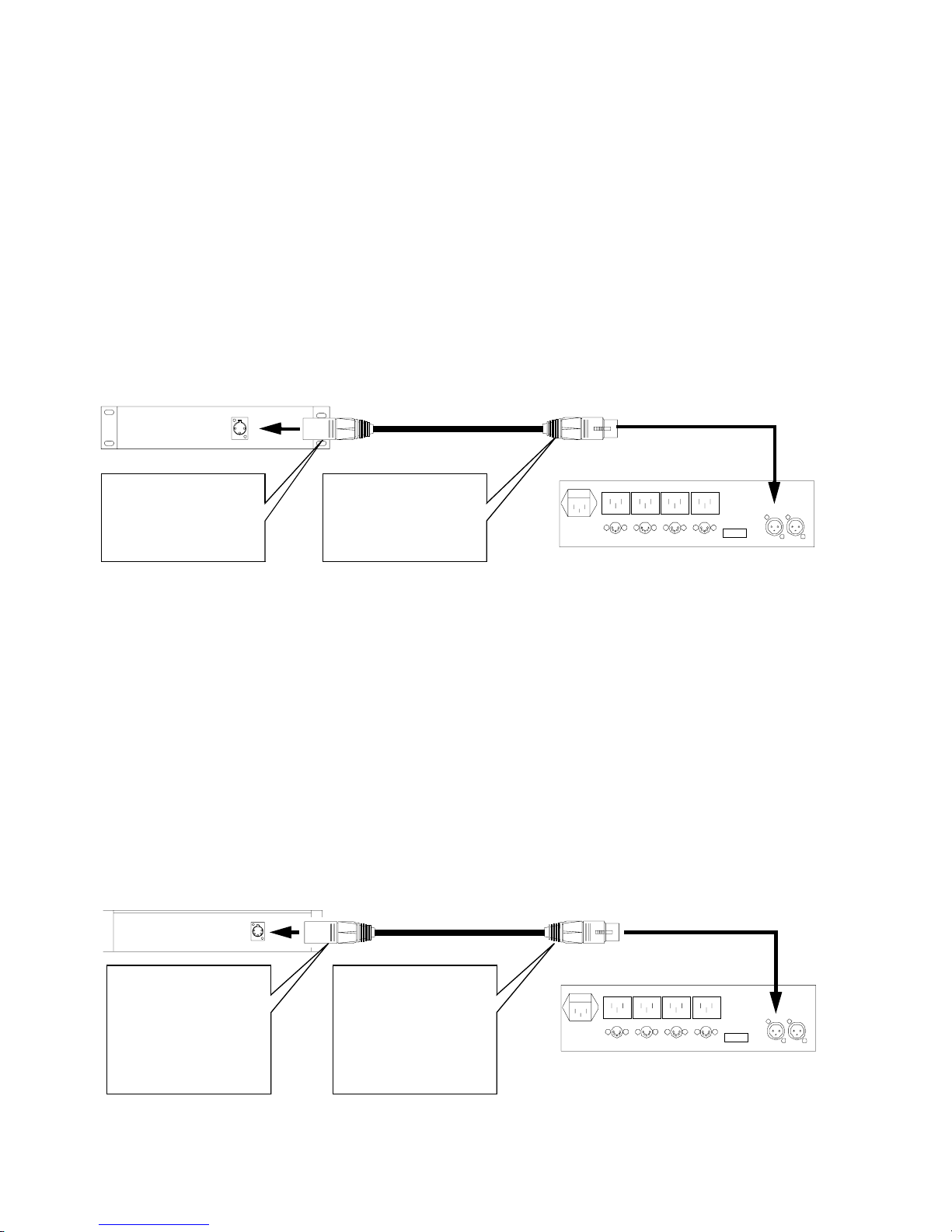

Connect the RoboColor III controller to the heads

The motor and lamp cables of each hea d mus t be conn ected to the RoboCol or III

controller. Connect each pair of cables to sockets of the same group (1, 2, 3 or 4)

on the RoboColor III controller as shown below.

Important! To avoid damaging the controller, make sure that it is disconnected

from AC power before connecting the heads.

User Manual Setting Up 5

Page 6

Connect the lighting controller

Once all heads have been connected to the RoboColor III controller, connect the

RoboColor III controller to the lighting controller . The procedure is the same for a

Martin RS-485 or DMX 512 controller, but you may need a 5-to-3-pin adapter

cable if using a DMX 512 controller.

1 Connect the data output on your lighting controller to the data input on the

RoboColor III controller.

MARTIN CONTROLLER: Use the XLR-XLR or DSUB-XLR cable supplied with

the controller.

Martin Lighting Controller

with 3 pin XLR output.

3 pin XLR male:

Pin 1: GND (screen)

Pin 2: Signal (+)

Pin 3: Signal (-)

DMX CONTROLLER: Most DMX controllers have 5-pin XLR sockets for data

output. Use a 5-pin to 3-pin phase-reversing adaptor, such as P/N 11820003,

as shown below. Th is adaptor connects pin 2 on one end to pin 3 on the other

end, and vice versa, to correct the difference in polarity between the

RoboColor III system and the DMX controller.

Note: The RoboColor III controller also has an option to swap the XLR pin

connections, making phase-reversing cables unnecessary. See page 18.

DMX Lighting Controller

with standard 5 pin XLR output.

3 pin XLR female:

Pin 1: GND (screen)

Pin 2: Signal (+)

Pin 3: Signal (-)

RoboColor III Controller

with 3 pin XLR in and output.

5 pin XLR male:

Pin 1: GND (screen)

Pin 2: Signal (-)

Pin 3: Signal (+)

Pin 4: N/C

Pin 5: N/C

6 Setting Up RoboColor III

3 pin XLR female:

Pin 1: GND (screen)

Pin 2: Signal (+)

Pin 3: Signal (-)

RoboColor III Controller

with 3 pin XLR in and output.

Page 7

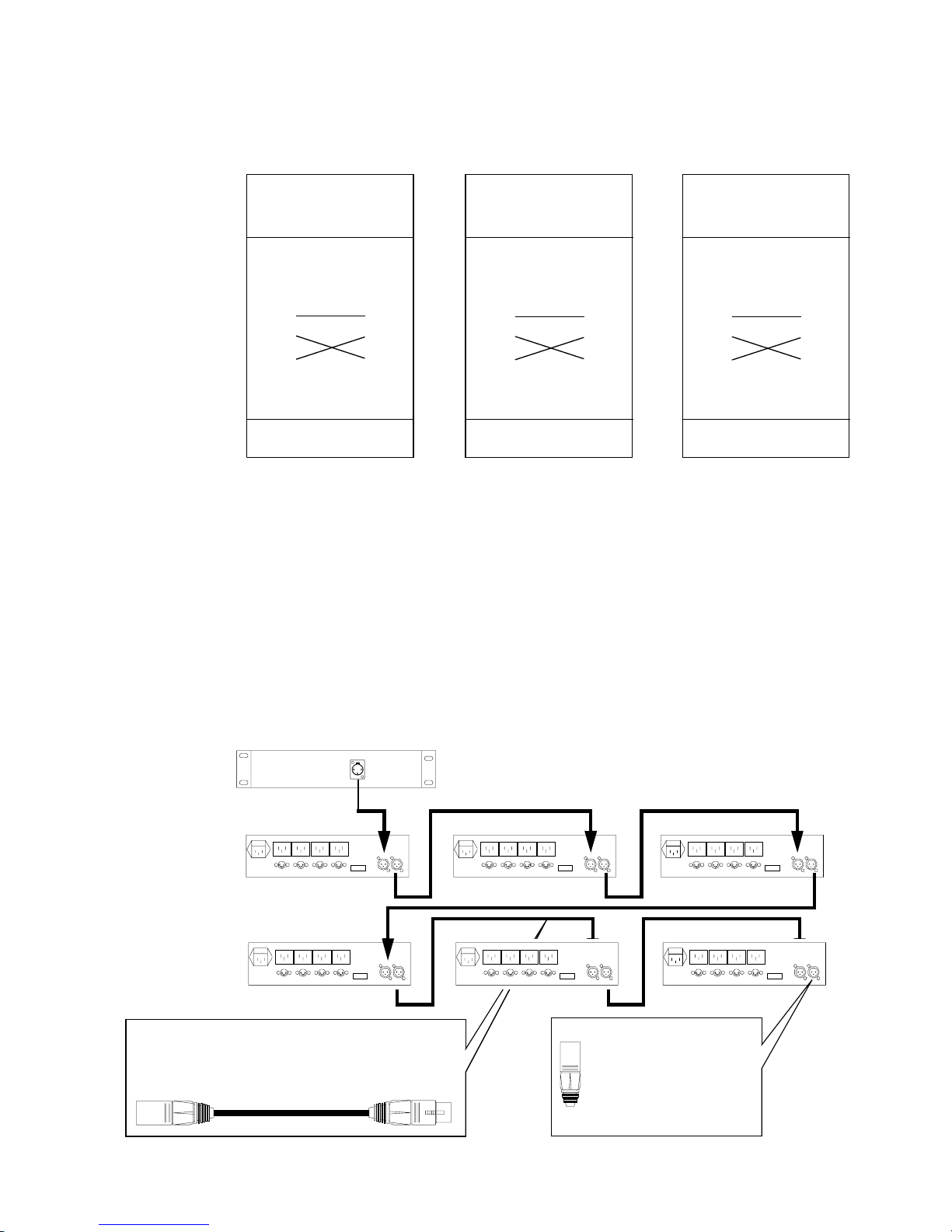

2 Connect th e data output of the first

of the next device. Use the XLR-XLR cable supplied when connecting to

another RoboColor III controller or fixture with Martin polarity (pin 3 cold).

Use a phase-reversing cable when connecting to a DMX device (pin 3 hot).

RoboColor III controller

to the data input

3-pin to 3-pin

Phase-Reversing

Cable

Connections

Male Female

1

2

3

1

2

3

P/N 11820006

3 Continue the link this way, connecting output to input (daisy-chaining), until

all units are linked together.

4 Finally, insert a male XLR termination plug in the output socket of the last

unit on the link. Use a 3 pin XLR male plug wit h a 120

and 3 (supplied with all Martin controllers).

3-pin to 5-pin

Phase-Reversing

Cable

Connections

Male Female

1

2

3

1

2

3

4

5

P/N 11820002

5-pin to 3-pin

Phase-Reversing

Cable

Connections

Male Female

1

2

3

1

2

3

4

5

P/N 11820003

ΩΩΩΩ

resistor between pin 2

Important! Failure to use a termination plug can cause communication errors

between the lighting controller and the units.

Lighting controller

RoboColor III controll ers

Use 3 pin XLR/XLR data cables to connect

the units. Pin 1 = screen, pin 2 = signal (+),

pin 3 = signal (-).

Insert a termination

plug in the last unit

on the data link.

User Manual Setting Up 7

Page 8

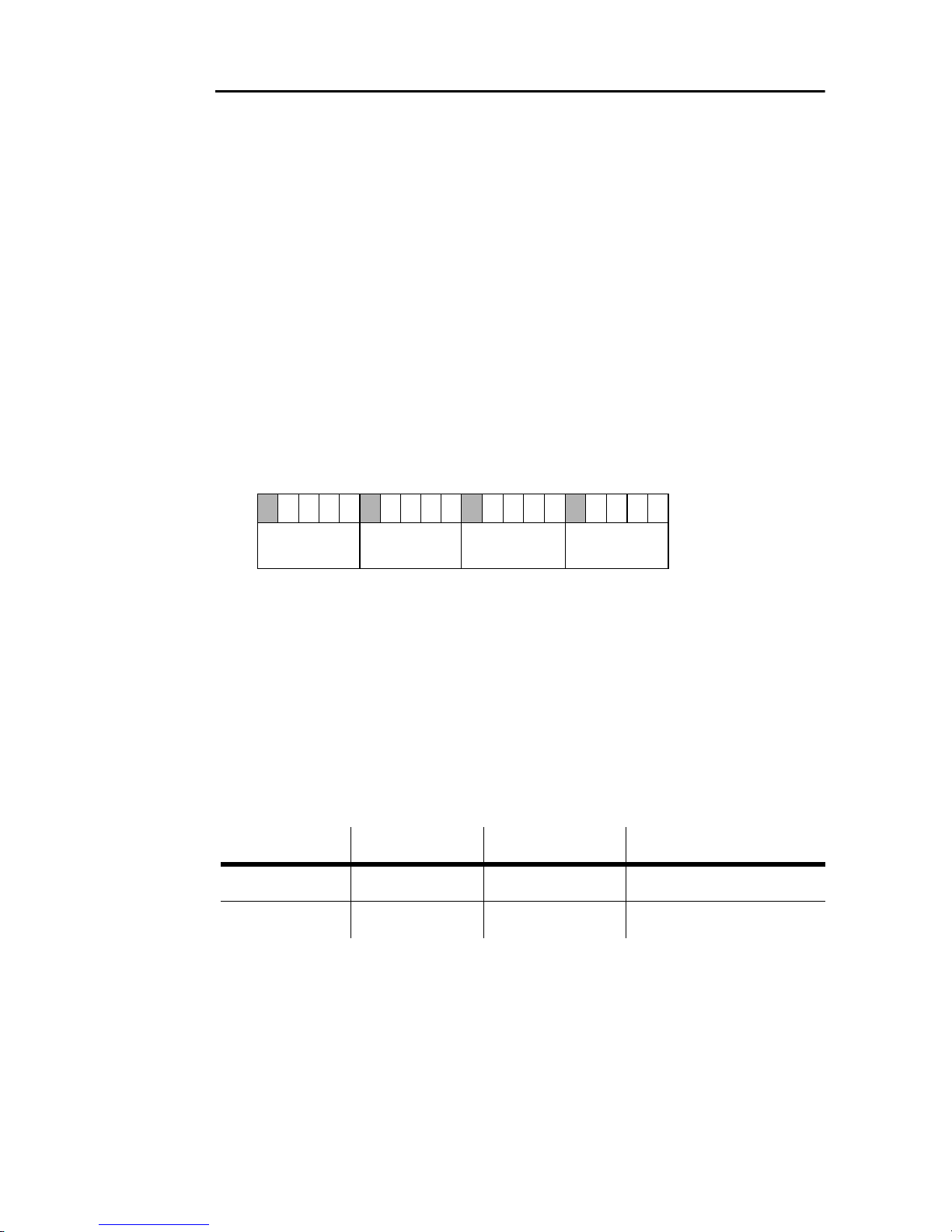

ADDRESSING THE SYSTEM

When using the RoboColor III with a l ighting cont roller, you must set the DIPswitch to the start channel, also known as the address, which is the first channel

the controller uses to send instructions to the RoboColor III system.

For independent control, each RoboColor III system must have its own address

and non-overlapping control channels. If two or more RoboColor III systems have

the same address they will receive the same instructions and behave identically.

Martin mode

: The RoboColor III uses 1 channel to communicate with the

controller. The address may be any channel between 1 and 32.

DMX mode

: The RoboColor III uses 5 consecutive DMX channels in tracking

mode (DMX mode 1) and 6 consecutive DMX channels in vector mode (DMX

mode 2).

The factory default is DMX mode 1.

Example: 4 RoboColor III systems using DMX mode 1 may be addressed as

follows:

12345678910111213141516171819

System 1

Address: 1

Set a Martin address

1 Select an available address from 1 to 32.

2 Look up the DIP-switch setting on page 9.

3 Set the DIP-switch by flipping ON the pins found in step 2.

System 2

Address: 6

System 3

Address: 1 1

20

System 4

Address: 16

4 Set DIP-switch pins 7 - 10 to OFF.

Set a DMX address

DMX Mode Color Control DMX Channels PL113 Jumper Setting

1 default Tracking 5 Channels No Jumper

2 Tracking/Vector 6 Channels Pin 1 and 2

1 Select an available address from 1 to 507 within the lighting controller’s

range.

2 Look up the DIP-switch setting on page 9.

3 Set the DIP-switch by flipping ON the pins found in step 2.

4 Set DIP-switch 10 to OFF.

8 Setting Up RoboColor III

Page 9

DIP-SWITCH TABLE

This table shows DIP -switc h sett ing s fo r chan nels 1 - 5 11. To find a settin g , loc ate

the channel in the table. Follow the row to the left to find the settings for pins 1

through 5; follo w the co lumn to the to p to f ind the setting s for pins 6 through 9 . A

“0” indicates the pin i s turn ed off and a “1” indic ates the p in is tu rned on.

Pin 10

is always switched OFF when using the RoboColor III with a lighting controller.

Example: The table shows the setting for channel 212 is 00101 for pins 1 - 5 and

0110 for pins 6 - 9. Pins 3, 5, 7, and 8 are set to on; pins 1, 2, 4, 6, 9, and 10 are

set to off.

',306ZLWFK#6HWWLQJ

3# #2))

4# #21

&4 &5 &6 &7 &8

3 3 3 3 3 65 97 <9 45; 493 4<5 557 589 5;; 653 685 6;7 749 77; 7;3

4 3 3 3 3 4 66 98 <: 45< 494 4<6 558 58: 5;< 654 686 6;8 74: 77< 7;4

3 4 3 3 3 5 67 99 <; 463 495 4<7 559 58; 5<3 655 687 6;9 74; 783 7;5

4 4 3 3 3 6 68 9: << 464 496 4<8 55: 58< 5<4 656 688 6;: 74< 784 7;6

3 3 4 3 3 7 69 9; 433 465 497 4<9 55; 593 5<5 657 689 6;; 753 785 7;7

4 3 4 3 3 8 6: 9< 434 466 498 4<: 55< 594 5<6 658 68: 6;< 754 786 7;8

3 4 4 3 3 9 6; :3 435 467 499 4<; 563 595 5<7 659 68; 6<3 755 787 7;9

4 4 4 3 3 : 6< :4 436 468 49: 4<< 564 596 5<8 65: 68< 6<4 756 788 7;:

3 3 3 4 3 ; 73 :5 437 469 49; 533 565 597 5<9 65; 693 6<5 757 789 7;;

4 3 3 4 3 < 74 :6 438 46: 49< 534 566 598 5<: 65< 694 6<6 758 78: 7;<

3 4 3 4 3 43 75 :7 439 46; 4:3 535 567 599 5<; 663 695 6<7 759 78; 7<3

4 4 3 4 3 44 76 :8 43: 46< 4:4 536 568 59: 5<< 664 696 6<8 75: 78< 7<4

3 3 4 4 3 45 77 :9 43; 473 4:5 537 569 59; 633 665 697 6<9 75; 793 7<5

4 3 4 4 3 46 78 :: 43< 474 4:6 538 56: 59< 634 666 698 6<: 75< 794 7<6

3 4 4 4 3 47 79 :; 443 475 4:7 539 56; 5:3 635 667 699 6<; 763 795 7<7

4 4 4 4 3 48 7: :< 444 476 4:8 53: 56< 5:4 636 668 69: 6<< 764 796 7<8

3 3 3 3 4 49 7; ;3 445 477 4:9 53; 573 5:5 637 669 69; 733 765 797 7<9

4 3 3 3 4 4: 7< ;4 446 478 4:: 53< 574 5:6 638 66: 69< 734 766 798 7<:

3 4 3 3 4 4; 83 ;5 447 479 4:; 543 575 5:7 639 66; 6:3 735 767 799 7<;

4 4 3 3 4 4< 84 ;6 448 47: 4:< 544 576 5:8 63: 66< 6:4 736 768 79: 7<<

3 3 4 3 4 53 85 ;7 449 47; 4;3 545 577 5:9 63; 673 6:5 737 769 79; 833

4 3 4 3 4 54 86 ;8 44: 47< 4;4 546 578 5:: 63< 674 6:6 738 76: 79< 834

3 4 4 3 4 55 87 ;9 44; 483 4;5 547 579 5:; 643 675 6:7 739 76; 7:3 835

4 4 4 3 4 56 88 ;: 44< 484 4;6 548 57: 5:< 644 676 6:8 73: 76< 7:4 836

3 3 3 4 4 57 89 ;; 453 485 4;7 549 57; 5;3 645 677 6:9 73; 773 7:5 837

4 3 3 4 4 58 8: ;< 454 486 4;8 54: 57< 5;4 646 678 6:: 73< 774 7:6 838

3 4 3 4 4 59 8; <3 455 487 4;9 54; 583 5;5 647 679 6:; 743 775 7:7 839

4 4 3 4 4 5: 8< <4 456 488 4;: 54< 584 5;6 648 67: 6:< 744 776 7:8 83:

3 3 4 4 4 5; 93 <5 457 489 4;; 553 585 5;7 649 67; 6;3 745 777 7:9 83;

4 3 4 4 4 5< 94 <6 458 48: 4;< 554 586 5;8 64: 67< 6;4 746 778 7:: 83<

3 4 4 4 4 63 95 <7 459 48; 4<3 555 587 5;9 64; 683 6;5 747 779 7:; 843

4 4 4 4 4 64 96 <8 45: 48< 4<4 556 588 5;: 64< 684 6;6 748 77: 7:< 844

&<3333333344444444

&;3333444433334444

&:3344334433443344

&93434343434343434

User Manual Setting Up 9

Page 10

SWITCHING ON

Having connected and addressed all units, you may now start operating these

from the lighting controller. The RoboColor III controller does not have a power

switch, hence the unit is switched ON when mains power is applied.

NOTE:

detection mode in order to determine wheth er a Martin RS-485 or DMX 512

controller is connected. To ensure correct protocol auto-detection, switch the

lighting controller on before switching on the RoboColor III controller.

If you are using a Martin controller then please refer to the controller’s manual for

further instructions. If you are using a DMX 512 controller then please refer to the

DMX 512 protocol listed in appendix A. All remotely controllable functions are

briefly de scribed starting on page 11.

After switching on, the RoboColor III controller defaults to auto-

MASTER/SLAVE OPERATION

Master/slave stand-alone operation means that you can have one RoboColor III

system

Additional systems

(i.e. switch 1 = ON) , can then be connected as if the master system were a normal

lighting controller. All RoboColor III system will then perform the same

programs fully s ynchroni zed. To ensure error free commun ication b etween the

master and the slave systems you will have to insert a female XLR termination

plug (120Ω) in the free input socket of the master system and a male XLR

termination plug (120Ω) in the free outpu t soc ket of th e las t slave system on the

data link.

(master system)

(slave systems)

acting as a controller whe n set to stand-alone mode .

, which all need to have DIP-switch setting 1

See page 20 for stand-alone DIP-switch settings.

Important! Set one, and only one, RoboColor III system to stand-alone mode,

otherwise damage may occur to the units.

FOCUS

When the h eads ar e in th eir final positions and powered on, yo u can adjust the

focus obj e ctive to achieve a sharp beam.

10 Setting Up RoboColor III

Page 11

ONTROLLABLE

C

This section briefly describes the various functions that can be remotely

controlled via the serial data input on the RoboColor III system.

BLACKOUT

The default position of the color wheel is the blackout position. This means that

no light is emitted from the unit until the wheel is moved from this position.

COLORS

Each RoboColor III head has 11 dichroic colors plus wh ite, all placed on a color

wheel. You can selec t these colors individually on any of the heads.

COLOR SPLIT EFFECTS

By placing the color wheel be tween two adjacent colors, color split effects can be

achieved.

COLOR SCROLLING

When switching from one color to another you can reduce the speed to emphasize

the scrolling effect.

UNCTIONS

F

COLOR STROBE

Strobe between two adjacent colors is achieved by first selecting a color and then

activating the strobe. The color wheel will then strobe betwe en the col or selected

and the next color on the wheel. E.G. to make a black/white strobe, select the

blackout position on the color wheel and activate the strobe. You can adjust the

strobe rate to a desired frequency .

STAND-ALONE

The built-in stand-alone programs can be activated from the controller.

User Manual Controllable Functions 11

Page 12

ERVICE AND

S

M

AINTENANCE

GENERAL MAINTENANCE

Warning! D isconne ct the syste m from AC power before r emoving any

cover.

To ensure optimum performance from the RoboColor III system, it is important to

keep the heads clean. Dirty lenses and filters reduce the brightness and diffuse the

beam. A fan blo cked by du st ma y p rovoke overh eat ing a nd cau se th e t her mos tat

to cut out the lamp intermittently. Thanks to the mechanical construction of the

RoboColor III, maintenance and cleaning can be done easily and requires no

special tools.

The RoboColor III controller should not require any maintenance.

Clean the optics

1 To access the optical components

inside head, remove the screws as

shown and then lift and remove

the bottom cover.

2 Use only a clean, soft and lint-free

cloth to clean the color filters. You

may need to wet t he cloth in a nonaggressive glass cleaning liquid if

the filters are greasy. Use the

same cloth to clean the focus

objective.

Clean the cooling fan

• For adequate cooling of the

head, the fan must be free of

dust. Clean the fan if the air

flow seams to be reduced.

The fan is located at the top of

the unit as per the following

figure. It is easiest to clean

the fan using compressed air.

Remove the 4 screws.

Then lift and remove the cover.

Use compressed air

to clean the fan.

12 Service and Maintena nce RoboColor I II

Page 13

LAMP REPLACEMENT

Warning! Disconnect the fixture from AC power before removing any cover.

To reduce the risk of the lamp shattering, never exceed the average lamp life,

listed below, by more than 25%. Disconnect the system from AC power if the

lamp blows. Allow the heads to cool for 15 minutes before installing a new lamp.

The RoboColor III comes with the Martin 150 W Metal Halide lamp installed.

The Osram HTI 150 and GE CSS 150 may be used as well.

lamp may damage the fixture.

P/N 97010107 97010108 97010104

Average Life 2000 h 750 h 1000 h

Color Temp. 5000K 6500K 5000K

Martin 150 W

Metal Halide Osram HTI 150 GE CSS 150

Installing any other

Output 900 lm 1200 lm 900 lm

To change the lamp

1 Remove the 3 thumbscrews that

secure the access plate of the lamp

socket assembly at the rear of the

head and withdraw the lamp socket

assembly.

2 Remove the old lamp from the

socket.

3 Holding the new lamp in a clean c loth

(do not touch the glass), carefully

insert it firmly and squarely into the

lamp socket.

4 If your fingers touch the glass, clean the bulb with a clean, lint-free cloth

wetted with alcohol.

5 Replace the lamp-socket assembly and tighten the thumbscrews.

Do not touch the

glass

Remove

screws.

Withdraw lamp socket assembly.

User Manual Service and Maintenance 13

Hold only by the

ceramic base.

Page 14

Optimizing the lamp for maximum output

The lamps are adjusted at the factory, however, fine adjustment of the lamp

assembly may be necessary to achieve maximum light output and a minimum hotspot.

1 The lamp housing access plate is held in place by 3 screws. Another 3

screws, shown below, are used to adjust the lamp-hol der. Turn ing these

clockwise pulls the lamp towards the rear of the lamp housing and vice versa.

2 Select the 'Lamp Adjustment' DIP-switch setting by switching ON DIP-switch

number 8 and 10, and apply power to the system. After finishing the reset the

heads will produce white beams.

3 Move the head so the spot is projected on a flat surface. Focus the beam.

4 If there is an off-center “hot spot,” the lamp is not centered in the reflector.

Pull the hot spot into the center of the field with small adjustments of one or

more of the s crews.

the reflector opening - very little side to side adjustment is possible or

necessary.

5 If the light is significantly brighter in the center of the field than it is at the

edge, the lamp is too far forward in the reflector. Pull the lamp in by turning all

three screws clockwise 1/4-turn at a time until the light is evenly distributed.

6 If the light is brighter around the edge than it is in the center, or if light output

is low, the lamp is too far back in the reflector. “Push” the lamp out by turning

the screws counterclockwise 1/4-turn at a time until the light is bright and

evenly distributed.

7 If you have made large sideways adjustments, disconnect the fixture from AC

power, allow it to cool, and remo ve th e lamp assembly to ensure that the lamp

is still placed squarely in the socket.

Note: the Martin Metal Ha lide lamp is near ly as large as

14 Service and Maintena nce RoboColor I II

Page 15

VOLTAGE SETTINGS

It is essential that the voltage and frequency setting of your RoboColor III system

matches the mains supply. Otherwise damage may occur.

Warning! Disconnect the fixture from AC power before removing any cover.

To change the controller voltage setting

Transformer

NEUTRAL.

Do NOT remove

BLUE wire.

230V

250V

1 Access the transformer by removing the top cover.

2 On the transformer, move the BROWN wire to the correct voltage terminal. If

the mains voltage is between 210 and 240 volt use the 230 volt tap. If the

voltage is between 240 and 255 volt then use the 250 volt tap.

3 Re-assemble the unit.

To change the head voltage setting

1 Remove 6 screws from the back of the unit, as shown, and carefully withdraw

the entire rear assembly.

User Manual Service and Maintenance 15

First, remove

these 6 screws.

Page 16

2 On the ballast, move the BLACK wire to the correct voltage terminal. Use the

following table to select the correct voltage setting.

3 Re-assemble the unit.

Ballast

230V/50Hz

240V/50Hz

250V/50Hz

220V/60Hz

210V/60Hz

230V/60Hz

50 Hz Version

50 Hz Model 60 Hz Model

Mains supply Ballast tapping Mains supply Ballast tapping

210V - 235V 2 30V 200V - 215V 210V

235V - 245V 2 40V 215V - 225V 220V

245V - 255V 2 50V 225V - 235V 230V

Ballast

60 Hz Version

FUSES

Should the RoboColor III system cease to work it may be due to a blown fuse.

This section describes how to replace the fuses.

To replace the primary fuse

• The primary fuse is located inside the IEC mains input socket at the rear of

the controller. Use a small screwdriver to pry open the fuse holder and

replace the fuse with one of the same size and rating. The fuse rating is also

printed on the serial number label.

Mains fuse

6.3AT/250V (slow

IEC mains input

socket.

16 Service and Maintena nce RoboColor I II

Page 17

To replace the secondary fuse

1 Access the circuit board as described earlier.

2 Replace the fuse with one of the same size and rating.

DMX MODE

• You can switch between DMX modes 1 and 2 by setting or removing the

jumper between pin 1 and 2 on PL113 as shown.

F202, 3.15AT/250V (slow blow)

Set jumper between

pin 1 and 2 to

1

PL113

enable extended

DMX mode

(mode 2).

CPU SOFTWARE

The RoboColor III control software can be updated when new features become

available. Software can be supplied by your Martin deal er as P/N 62122026.

Please check with yo ur Mart in de aler to find out if the so ftware upg rade re quire s

any mechanical changes to the RoboColor III system.

To update software

Important! To avoid damaging the CPU by electrostatic discharges, touch the

heat sink of the v olta ge re gula tor (IC102 ) before and when removin g

or inserting the CPU.

1 Access the circuit board as described earlier.

2 Remove the existing CPU (IC101) from the PCB.

User Manual Service and Maintenance 17

Page 18

3 Place the new CPU in the IC socket, ensuring that all pins enter the socket

correctly, and that the CPU is correctly oriented. Then press it firmly into the

socket.

Heat sink of IC102.

CPU (IC101).

XLR PIN-OUT

If the RoboColor III is operated via a DMX controller, you can change the XLR

pin-out to eliminate the need for phase-reversing cables. This can be done inside

the RoboColor III controller by moving two jumpers as shown below.

Reversed: Non-Reversed

-

3

+

2

Pin 2 =

Pin 3 =

-

3

+

2

Pin 2 =

Pin 3 =

+

+

-

Jumpers for swapping

+ and - signals on

data in and output.

18 Service and Maintena nce RoboColor I II

Page 19

DMX P

DMX channel

1

2 - 5

ROTOCOL

Value FunctionMode 1 Mode 2

Strobe, Stand-Alone, Reset

0 - 74

75 - 138

139 - 170

171 - 202

203 - 255

0 - 15

16 - 30

31- 45

46 - 60

61 - 75

76 - 90

91 - 105

106 - 120

121 - 135

136 - 150

151 - 165

166 - 180

No function

Strobe on (Fast Æ Slow)

Remote Stand-alone auto-trigger

Remote Stand-alone music-trigger

Reset

Color Whee l (Head 1, 2, 3, 4)

Blackout Æ White

White Æ Color 1

Color 1 Æ Color 2

Color 2 Æ Color 3

Color 3 Æ Color 4

Color 4 Æ Color 5

Color 5 Æ Color 6

Color 6 Æ Color 7

Color 7 Æ Color 8

Color 8 Æ Color 9

Color 9 Æ Color 10

Color 10 Æ Color 11

(Head 1 - 4)

-6 0

181 - 184

185 - 189

190 - 194

195 - 199

200 - 204

205 - 209

210 - 214

215 - 219

220 - 224

225 - 229

230 - 234

235 - 239

240 - 255

1 - 255

Color Wheel “Snaps” (Hea d 1 - 4)

Color 11

Color 10

Color 9

Color 8

Color 7

Color 6

Color 5

Color 4

Color 3

Color 2

Color 1

White

Blackout

Color Spe ed

Tracking

Speed (fast Æ slow)

User Manual DMX Protocol 19

Page 20

TAND-ALONE

S

The following table provides a description of the stand-alone sequences selectable

via the DIP-switch.

DIP-Switches ON Step Description

All Protocol auto- det e ct (D MX51 2 / Martin RS-485)

2, 10 Stand Alone Sequence - Auto-trigge r

1, 2, 10 Stand Alone Sequence - Music-trigger

2, 3, 10 Stand Alone Sequence - Auto-trigger (Head 1 - 4 same color)

1, 2, 3, 10 Stand Alone Sequence - Music-trigger (Head 1 - 4 sam e co lor)

8, 10 Lamp Adjust (color = white)

S

EQUENCES

(1), 5, 10

Toggle DIP-switch #1 to

advance through seq uence.

4, 10 LED Chase - Auto-trigger

1, 4, 10 LED Chase - Music-trigger

Adjustment sequence #1

1 Color Adjust Position #1

2 Color Adjust Position #2

20 Stand-alone Sequences RoboColor III

Page 21

ROUBLESHOOTING

T

Problem Probable cause(s) Suggested remedy

None of the RoboColor IIIs

respond to the lighting

controller.

One or more of the Ro boColor

IIIs does not respond to the

lighting controller or responds

erraticall y.

The lighting c ontroller is

disconnected from the data link.

Use of incorrect ca ble between

the contro ller and the f irst

RoboColor III system on the

data link.

Bad data link connection. Check connections/cables in the

Data link not terminated with

termination plug.

Incorrectly addre ssing (D IPswitch setting) of the RoboColor

III controller.

One or more RoboColor III

controllers are set to stand-alone

mode, thus transmi tt in g on the

link.

Connect th e l ighting controller.

If using a DMX controller with

standard 5-pin ou tput socket,

remember to us e a 5 to 3-pin

adapter cable that swaps pin 2

and 3, between the light ing

controller an d the first

RoboColor III system on the

data link.

data link and corre ct

accordingly.

Insert term ination plug in th e

last unit on the data link.

Ensure th at all lights are

addressed in compliance with

the lighting controller

configuration.

Set the DIP-switch on the

RoboColor III controller to the

correct address.

There is no power to th e

RoboColor IIIs.

The RoboColor III c ontrollers

have failed in the protocol autodetection.

One of the units on the link is

defective and disturbs data

transmission.

Apply power.

Switch off the RoboColor III

controllers and then back on

again. In gener al, switch on the

lighting controller before the

RoboColor III controllers.

By-pass one unit at a ti m e until

normal operation is regained.

Do this by unplugging the XLR

in and out connectors and then

connect them directly toge ther.

User Manual Troubleshooting 21

Page 22

Problem Probable cause(s) Suggested remedy

No light emission from som e or

all RoboColor III heads.

The RoboColor III system

appears to be completely dead

(no reset when switchin g on).

Lamp is cutting out

intermittently.

The lamp is on but the color

wheel is on blackout position.

Change color via lighting

controller.

No lamp inserted. Insert lamp.

Malfunctioning lamp. Replace lamp.

No lamp strike due to too low

mains

voltage.

Measure m ains voltage and

check against ballast and

transformer ta ppi ngs. Correct

tappings if necessary.

Head cables not connected to

RoboColor III controller.

Connect cabl es. Remember to

switch off the RoboColor III

controller first.

Mains fuse blown. Replace mains fuse.

PCB fuse(s) blown. Replace PCB fuse(s).

Ambient temperature is too

Reduce room te mperature.

high.

Fan speed is reduced due to fan

Clean fan.

covered by dirt and dust.

Incorrect ballast and transformer

tappings.

Measure m ains voltage and

check against ballast and

transformer ta ppi ngs. Correct

tappings if necessary.

22 Tr oubleshooting RoboColor III

Page 23

PECIFICATIONS

S

ELECTRICAL DATA (SYSTEM WITH 4 HEADS)

• Power consumption:.....................................................................................680 W

• Current consumption:......................................................... 3.7 A @ 230 V / 50Hz

• Power factor:.......................................................................................................0.8

COMPATIBLE LAMPS

• Martin 150 W Metal Halide............................................................. P/N 97010107

• Osram HTI 150................................................................................P/N 97010108

• GE CSS 150..................................................................................... P/N 97010104

PHOTOMETRIC DATA

• Beam angle (standard):......................................................................................17

• Beam angle (optional): ......................................................................................25

THERMAL DATA

• Max ambient temperature:............................................................................ 40° C

°

°

MECHANICAL DATA

•Weight

(single RoboColor III head)

267mm

10.5"

165mm

6.5"

208mm

8.2"

:................................................... 6 kg (13 lb)

∅

11mm

300mm

11 . 8"

User Manual Specifications 23

190mm

7.5"

Page 24

Olof Palmes Allé 18 8200 Aarhus N Denmark Tel.: +45 8740 0000

0DUWLQ#3URIHVVLRQDO#$26

www.martin.dk

Loading...

Loading...