Page 1

FiberSource QFX 150

user manual

Page 2

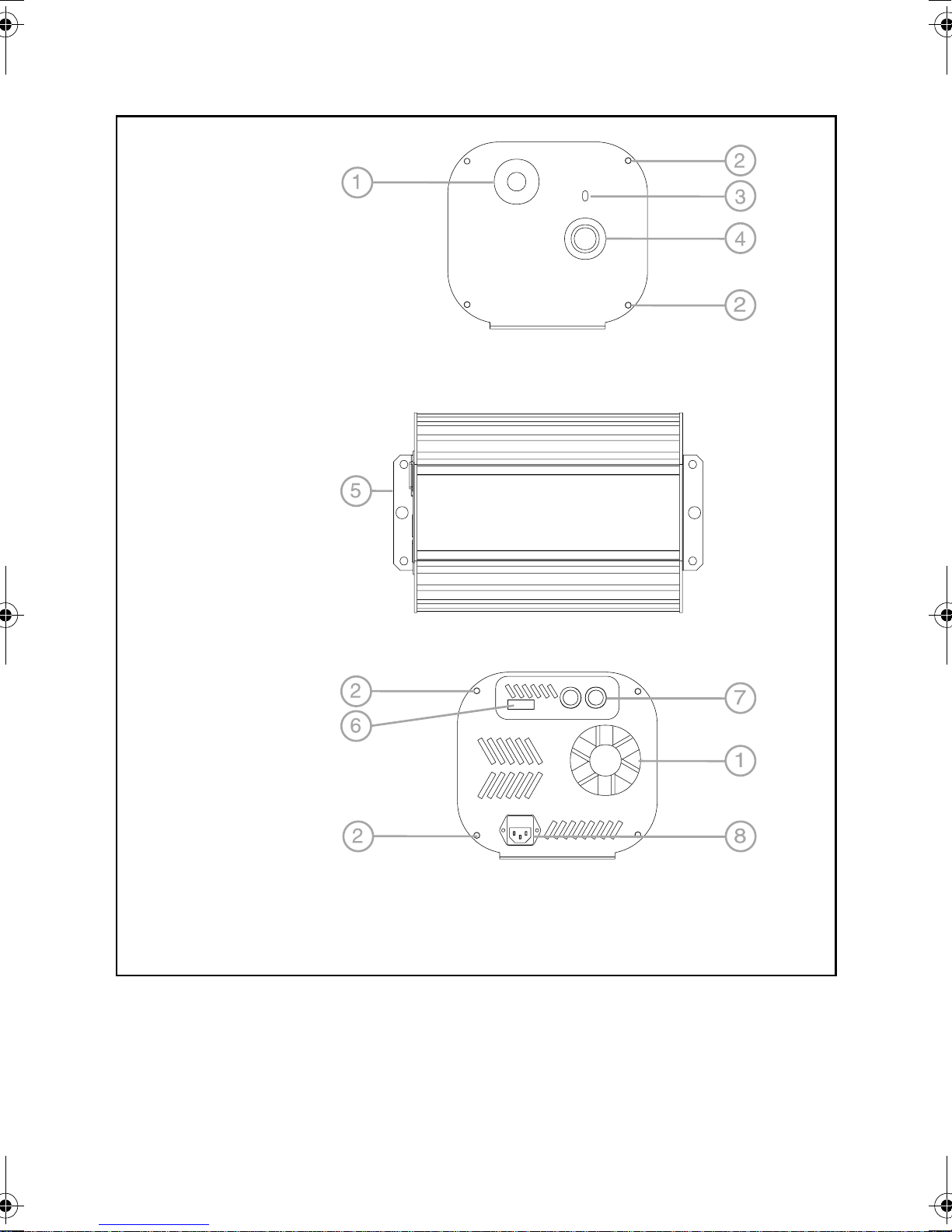

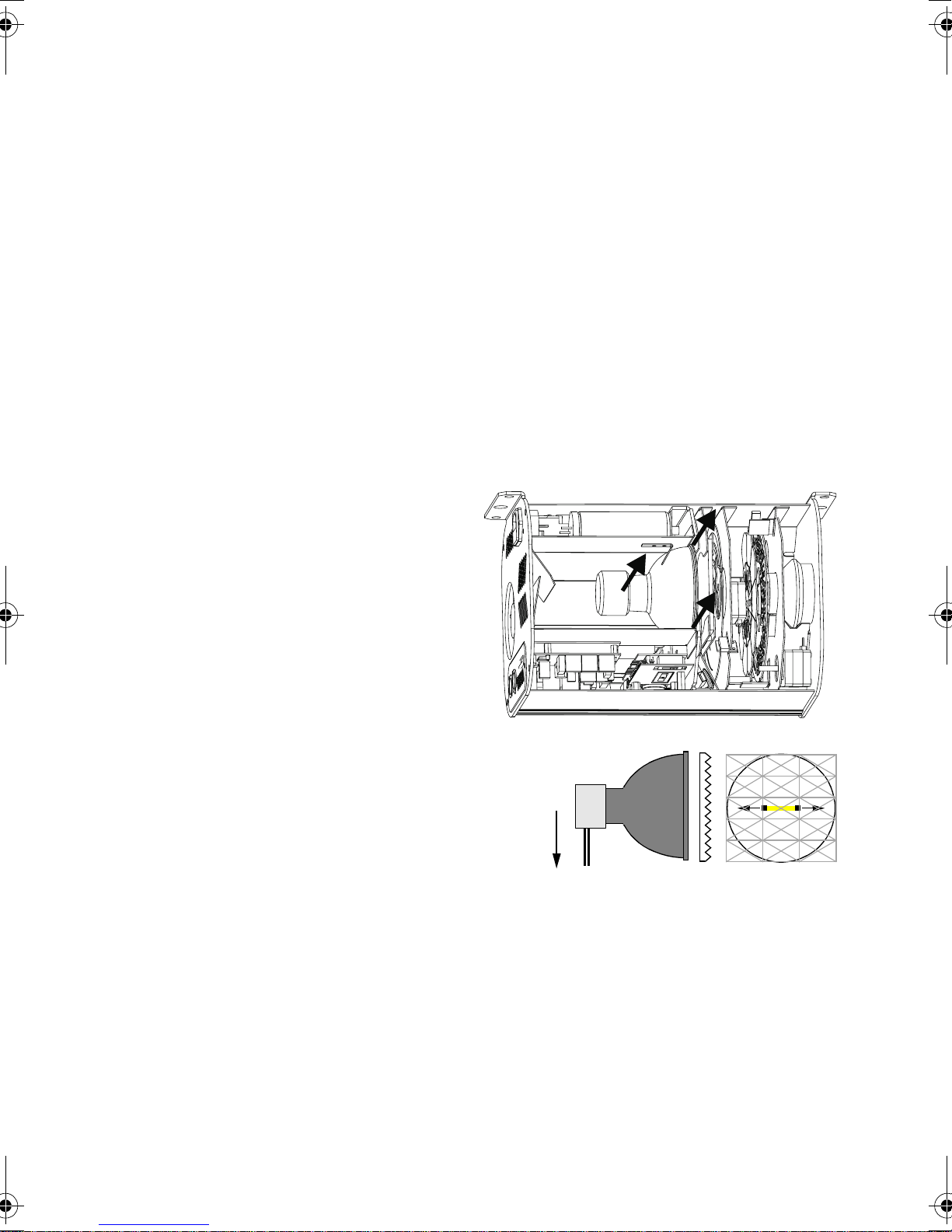

1 cooling fan

2 lamp access

cover screw

3 adaptor set screw

4 cable socket

5 mounting flang e

6 DIP-switch

7 data sockets

8 AC input & main

fuse

©1999 Martin Professional A/S, Denmark.

All rights reserved. No part of this manual may be

reproduced, in any form or by any means, without

permission in writing from Martin Professional A/S,

Denmark.

Printed in Denmark.

P/N 35000079, Rev. B

Page 3

I

NTRODUCTION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

L

AC

I

NSTALLATION

F

C

S

M

B

T

DMX

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AMP

POWER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

IBER OPTIC CABLE

ONTROLLER OPERATION

TAND-ALONE OPERATION

ASTER/SLAVE OPERATION

ASIC SERVICE

ROUBLESHOOTING

PROTOCOL

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

S

PECIFICATIONS

A

CCESSORIES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3

Page 4

NTRODUCTION

I

Thank you for selecting the Martin FiberSource QFX 150. This fiber optic lighting

fixture uses a long-life 150 watt discharge la mp and provides 4 colors plus white,

full-range dimming, and a variable-speed twinkle effect. It operates with DMX-512

controllers, in stand-alone mode, and in master/slave configuration.

1

SAFETY INFORMATION

Warning! This product is for professional use only. It is not for household use.

This produ ct prese nt s ris ks of le t hal or severe injur y due.

powering or installing the fixture, follow the safety precautions listed below and

observe all warnings in this manual and on the fixture. If you have questions about

how to operate the fixture safely, pl ease contact your Ma rtin dealer or call the

Martin 24-hour service hotline.

Read this manual

before

To protect yourself and others from electric shock

• Disconnect the fixture from power be for e re moving or installing the lamp, f uses, or

any part, and when not in use.

• Always ground (earth) the fixtu r e electrically.

• Use only a source of power that complies with local building and electrical codes

and has both overload and ground-fault protection.

• Do not expose the fixture to rain or moisture.

• Refer all service to a qualified technician.

To protect yourself and others from UV radiation and lamp

explosion

• Do not operate th e fixture without a fiber optic cable inserted.

• When replacing the lamp, allow the fixture to cool for at least 5 minutes before

opening. Protect your hands and eyes with gloves and safety glasses.

• Never look at a lamp while it is lit.

• Replace the lamp when it becomes defective or worn out, or before usage exceeds

110 percent of the rated average life.

4 Introduction

Page 5

To protect yourself and others from burns and fire

• Never attempt to bypass the thermostatic switch or fuses. Always replace defective

fuses with ones of the speci fied type and rating.

• Keep all combustible materials (for example fabric, wood, paper) at least 0.1 meters

(4 inches) away from the fixture. Keep flammable materials well away from the

fixture.

• Provide a minimum clearan ce of 0.1 meters (4 inches) around fans and air vents.

• Allow the fixture to cool before handling.

• Do not modify the fixture or install other than genuine Martin parts.

• Do not operate the fixture if the ambient t emperature (Ta) exceeds 40° C (104° F).

To protect yourself and others from injury due to falls

• When suspending the fixture above ground level, verify that the structure can hold

at least 10 times the weight of all installed devices.

• Verify that all external covers and rigging hardware are securely fastened and use an

approved means of secondary attachment such as a safety cable.

• Block access below the work area whenever installing or removing the fixture.

UNPACKING

The packing material is carefully designed to protect the fixture during shipment always use it to transport the fixture.

The FiberSource QFX 150 comes with:

• Osram HQI-R 150 W lamp

• 3 m power cable w/ 3-pin IEC female cord cap

• 4 dichroic color filters

•user manual

Introduction 5

Page 6

AMP

L

The FiberSource QFX 150 is designed for use with the Osram HQI-R 150 lamp. Do

not install any other type of lamp.

Warning! Disconne ct the fixt ure from p ower and allow i t to co ol before

opening.

Impor tant! Turn the lamp so that the arc is horizo ntal.

2

To install or position the lamp

1 Remove the 4 lamp access

cover screws and pull off the

access cover, which is

indicated by the arrow on the

rear panel.

2 To remove the lamp, place a

hand under it and pull it out. Do

not lift by the ceramic base

alone. Squeeze the sides of the

lamp plug and pull it out.

3 To position the lamp, turn it so the wires,

where they exit the lamp base, point

towards the ground when the fixture is

installed

burning posi tion.

4 To install a lamp, plug in the connector

and then place the reflector rim in the

slot. Gently press the lamp between the

springs until it snaps into place.

5 Remove and turn the diffusion filter 90°, if necessary, so the long sides of the

prisms align with the arc.

6 Check the power setting as described in the next section before replacing the

lamp access cover.

.

This puts the arc in its ideal

Turn lamp so wires

point towards

ground and arc is

horizontal.

Align long edge of

diffuser prisms

with arc.

6 Lamp

Page 7

AC

Warning! For pro te ct io n from electric shock, the fixture must be ground e d

Import ant! Install fuse and ve rify th at power supply set tings match l ocal

POWER

The FiberSource QFX 150 has 10 switch-selectable power supply settings. Always

use the setting that is closest to the local AC supply.

(eart hed). T he power supply sh all have overload an d groundfault protection.

AC supply before use.

3

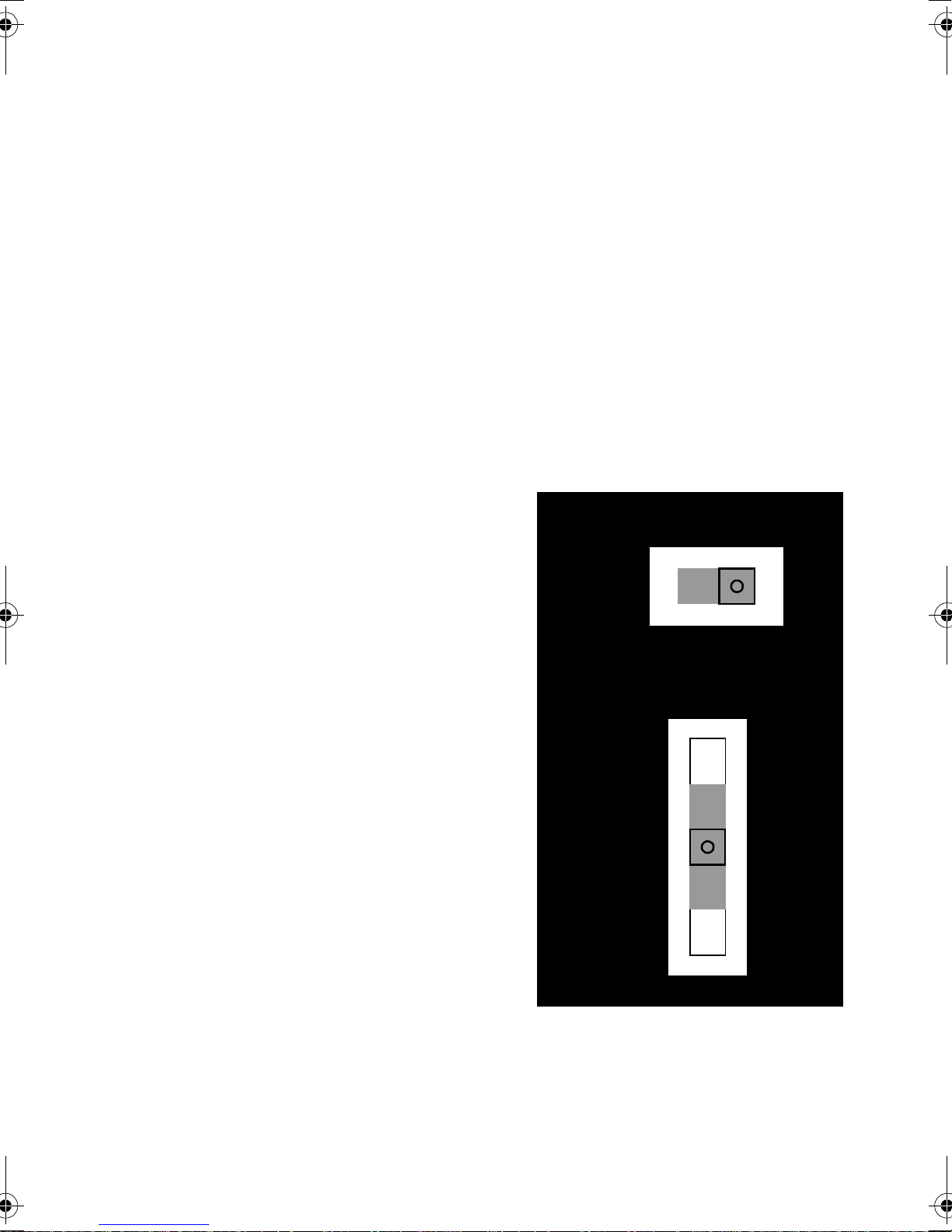

To check or change the voltage

setting

1 Disconnect the fixture from power.

Remove the lamp access cover.

2 Set the 5-position switch to the

setting closest to the A C v o ltage. Use

the higher setting if the voltage is

halfway between 2 settings. For

example, use the 230 V setting

instead of the 210 V setting for

operation with 220 V power.

3 Set the 2-position switch to the AC

frequency (50 / 60 Hz).

4 Replace the cover and apply a new

power setting label to the serial

number label.

250 V

230 V

210 V

100 V

120 V

50Hz

60Hz

AC po wer 7

Page 8

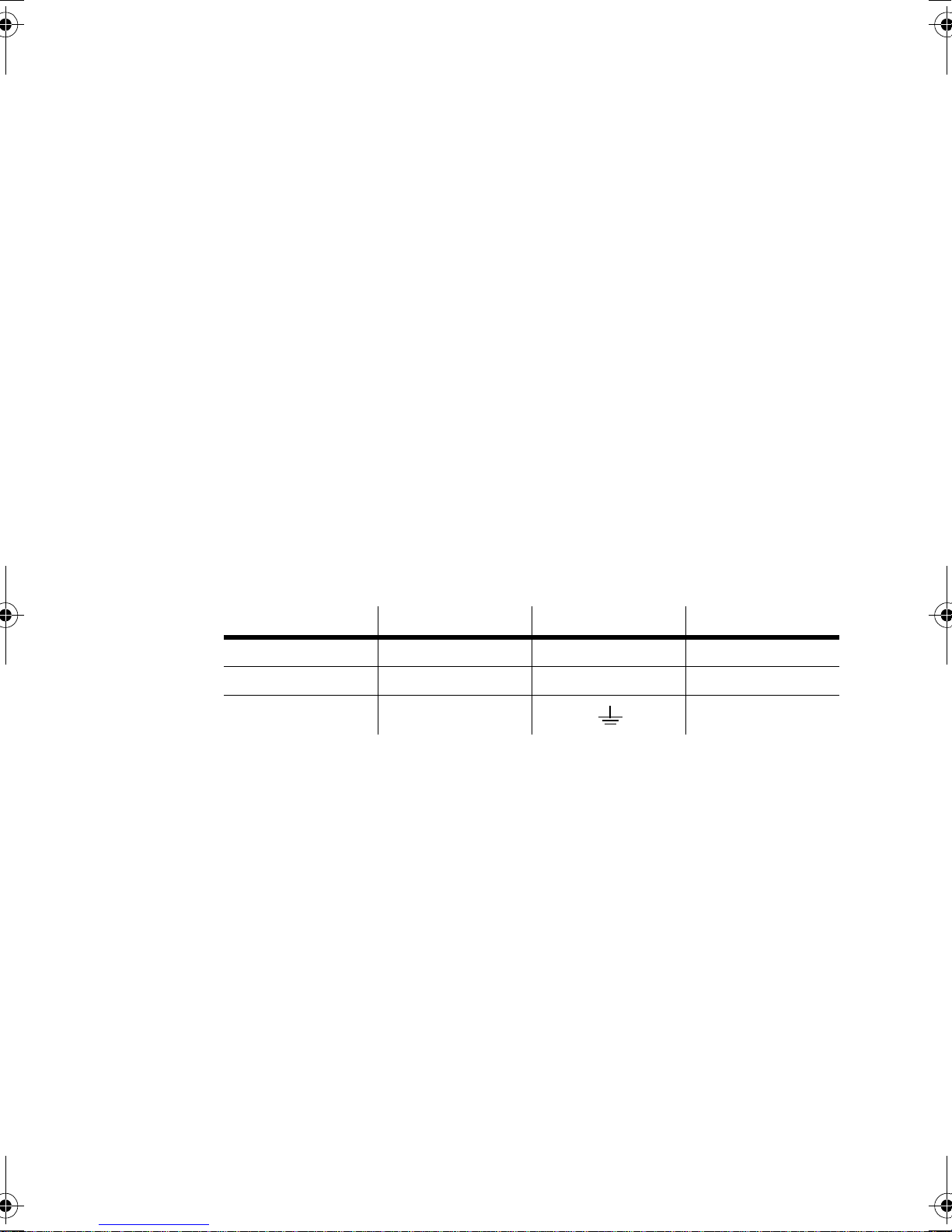

To install the main fuse

Fuses are provided for 1 00 - 130 V and 200 - 250 V o peratio n.

specified for the operating voltage.

1 Locate the bag containing the fuse for your AC voltage. Insert the fuse in the

fuse holder. The holder may be packed with the other fuse.

2 Remove the label covering the mains input socket.

3 Insert the fuse holder in t he empty slot in the mains input socket. See a lso “To

replace the main fuse” on page 20.

Use only the fuse

To install a plug on the power cable

The power cable must be fitted with a grounding-type cord cap that fits your power

distribution system. Consult an electrician if you have any doubts about proper

installation.

Important! Verify that the feed cables are undamaged and rated for the

current r equir ements of all conne cted d evices before use .

• Following the cord cap manufacturer’s instructions, connect the yellow and

green wire to ground (earth), the br own wire to live, and the blue wire to neut ral.

The table below shows some pin identification schemes.

Wire Pin Marking Screw color

brown live “L” yellow or brass

blue neutral “N” silver

yellow/green ground green

8 AC power

Page 9

NSTALLATION

I

The FiberSour ce QFX 150 can b e fastened directly through the 4 rubber washers in

the mounting flanges, or hun g with 2 rigging clamps (not in cluded) fastened

through the 13 mm holes.

INSTALLATION REQUIREMENTS

For optimum performance an d ease of service, install the fixture such that

• The long axis is horizontal as

shown in A to right. This

positions the lamp electrodes

for maximum lamp life. Do not

install as shown in B.

4

• The minimum clearance around

the fans and air vents at both

ends is 10 cm (4 in.) and

circulation is adequate keep the

air around the fixture at 40° C

(104° F) or below.

• The DIP-switch is acc essible and there is room to insert cables.

• The lamp access panel can be removed.

• All safety requirements are met.

To install the FiberSource QFX 150

Wa rning! Always u se a secu re mea ns of se condar y atta chment when

hanging t he fixt ure with clamps.

1 Verify that the fasteners or clamps can bear 10 times the fixture’s weight. Verify

that the structure can support 10 times the weight of all installed fixtures,

clamps, cables, auxiliary equipment, etc.

2 Block access belo w th e work area.

3 If fastening directly, place a metal washer over each rubber washer. The metal

washer must be as wide as the rubber washer, or wider , to insure a secure hold.

Fasten with 4 suitable fasteners 4 - 5 mm (5/32 - 3/16 in.) in diameter.

Installation 9

Page 10

4 If clamping, bolt the clamps securely to the flang es with grade 8.8 (minimum)

M12 bolts and lock nuts, or as recommended by the clamp manufacturer,

through the 13 mm holes. Install a safety cable that can hold at lea st 10 times

the weight of the fixture through one of the small holes and around the truss or

pipe. Remove a rubber washer if necessary to thread the safety cable.

5 Verify t hat the fixture is located at least 0.1 meters (4 in.) from any combustible

materials. Verify that the clearance around the fan and air vents is at least 0.1

meters (4 in.). Verify that there are no flammable materials nea rby.

10 Installation

Page 11

IBER OPTIC CABLE

F

The FiberSource male adaptor for 50 - 300 strand cables, P/N 91611016 (not

included), is tapered to fit fiber optic cables 8.3 - 19.3 mm (5/16 - 3/4 in.) in

diameter. With cables over 8.3 mm in diameter, the adaptor must be shortened for

proper fit and maximum light output. Please follow the instructions included with

the fiber adaptor.

CABLE CONNECTION

The following guidelines provi de a starting point for estimating your needs. Light

transmission through fiber-optic cable depends on its quality and results will vary

depending on the type of cable used.

5

SIDE-EMITTING CABLE

With 1 fixture, best results are had when the fiber optic cable is 10 m (33 ft.) or

shorter. The length may be increased to 15 m (50 ft.) by looping the cable and

illuminating both ends. With 2 fixtures, one at each end of the cable, lengths up to

30 m (100 ft.) can be achieved.

END-EMITTING CABLE

Light output de creases with length: keep the ca ble as short as possible. Th e

maximum recommende d length is 25 meters. Cut the ligh t emitting end of the f i bers

with a sharp knife for maximum output.

To install fiber optic cable

1 Install the cable in the fiber adaptor according to the instructions packaged

with the adaptor.

2 Insert the adaptor fully into the fiber optic cable socket.

3 Tighten the set screw with a 2 mm (5/64 in.) Allen wrench.

Fi b er optic cable 11

Page 12

ONTROLLER OPERATION

C

This Fibe rSource QFX 150 ma y be operated wi th any DMX-512 protoc ol

controller.

DATA CONNECTION

A reliable data connection begins with the right cable. Standard microphone cable

cannot transmit DMX data reliably over long runs. For best results, use cable

specifically designed for RS-485 applications. Your Martin dealer can supply high

quality cable in various lengths.

The FiberSource QFX 150’s data sockets are wired pin 1 to ground, pin 2 to signal (cold), an d pin 3 to signal + (ho t). Thi s is the stan dard pi n assignme nt for DMX

devices.

6

One or more adapt or cables m ay b e req uired to conn ect t he fixture to the c ontro ller

and other devices because many devices have 5-pin connectors and others may have

reversed signal polarity, that is, pin 2 hot and pin 3 cold.

5-pin to 3-pin

Adaptor

Male Female

1

2

3

4

5

P/N 11820005

1

2

3

To connect the data link

3-pin to 5-pin

Adaptor

Male Female

1

2

3

P/N 11820004

1

2

3

4

5

3-pin to 3-pin

Phase-Reversing

Adaptor

Male Female

1

2

3

P/N 11820006

1

2

3

1 Connect a data cable to the controller’s data output. If controller has a 5-pin

output, use a 5-pin male to 3-pin female adaptor cable (P/N 11820005).

2 Lead the data cable from the controller to the first fixture and plug the cable

into the data input.

12 Controller operation

Page 13

3 Connect the output of the fixture closest to the

Male XLR

1

2

3

Male

P/N 91613017

120

T ermination Plug

controller to the input of the next fixture. If

connecting to a fixture with reversed-polarity (pin 3

cold), insert a phase-reversing cable between the two

fixtures.

4 Continue connecting fixtures output to input. Up to

32 devices may be connected on a serial link.

5 Terminate the link by inserting a male termination

plug (P/N 91613017) into the data output of the last

fixture. A termination plug is simply an XLR

connector with a 120 ohm, 0.25 W resistor soldered

across pins 2 and 3.

ADDRESS SELECTION

A control address must be set using the DIP-switch on the rear panel. The control

address, also known as the start cha nnel, is the first channel used to rec eive

instructions from the controller. The FiberSource QFX 150 uses 5 DMX channels.

Import ant! Disconnec t the fixtu re from power before changing the D IP-

To set the address

Each fixture must be assigned its own address and non-overlapping control

channels for individual control . Two FiberSource QFX 150s may share the same

address, but they will respond identically and individual control will not be

possible.

switch setting. C hanges take effect after the fixtur e has been

turned o ff and back on.

1 Select an address for the fixture between 1 and 508 on your controller.

2 Look up the DIP-switch setting for the address on page 14.

3 Disconnect the fixture from power.

4 Set pins 1 through 9 to the ON (1) or OFF (0) position as listed in the table.

5 Set pin 10 to the OFF positio n.

Controller operation 13

Page 14

DIP-SWITCH ADDRESS TABLE

Find the address in the table below. Read the settings for pins 1 - 5 to the left and

read the settings for pins 6 - 9 ab ove the address. “0” means OF F and “1” means

ON.

Impor tant! Pin 10 must be OFF for controller operat ion.

DIP-Switch Setting

0 = OFF

1 = ON

#1 #2 #3 #4 #5

00000 326496128160192224256288320352384416448480

10000 1336597129161193225257289321353385417449481

0 1 0 0 0 2 34 66 98 130 162 194 226 258 290 322 354 386 418 450 482

11000 3356799131163195227259291323355387419451483

00100 43668100132164196228260292324356388420452484

1 0 1 0 0 5 37 69 101 133 165 197 229 261 293 325 357 389 421 453 485

01100 63870102134166198230262294326358390422454486

11100 73971103135167199231263295327359391423455487

0 0 0 1 0 8 40 72 104 136 168 200 232 264 296 328 360 392 424 456 488

10010 94173105137169201233265297329361393425457489

01010 104274106138170202234266298330362394426458490

1 1 0 1 0 11 43 75 107 139 171 203 235 267 299 331 363 395 427 459 491

00110 124476108140172204236268300332364396428460492

10110 134577109141173205237269301333365397429461493

0 1 1 1 0 14 46 78 110 142 174 206 238 270 302 334 366 398 430 462 494

11110 154779111143175207239271303335367399431463495

00001 164880112144176208240272304336368400432464496

1 0 0 0 1 17 49 81 113 145 177 209 241 273 305 337 369 401 433 465 497

01001 185082114146178210242274306338370402434466498

11001 195183115147179211243275307339371403435467499

0 0 1 0 1 20 52 84 116 148 180 212 244 276 308 340 372 404 436 468 500

10101 215385117149181213245277309341373405437469501

01101 225486118150182214246278310342374406438470502

1 1 1 0 1 23 55 87 119 151 183 215 247 279 311 343 375 407 439 471 503

00011 245688120152184216248280312344376408440472504

10011 255789121153185217249281313345377409441473505

0 1 0 1 1 26 58 90 122 154 186 218 250 282 314 346 378 410 442 474 506

11011 275991123155187219251283315347379411443475507

00111 286092124156188220252284316348380412444476508

1 0 1 1 1 29 61 93 125 157 189 221 253 285 317 349 381 413 445 477 509

01111 306294126158190222254286318350382414446478510

11111 316395127159191223255287319351383415447479511

#90000000011111111

#80000111100001111

#70011001100110011

#60101010101010101

14 Controller operation

Page 15

CONTROLLABLE EFFECTS

LAMP POWER AND RESET

The lamp on command is on channel 1, the address channel.

controller operation, the lamp remains off until a lamp-on command is sent.

A peak of electric current many times the operating current is drawn briefl y when

striking a lamp. Striking many discharge lamps at once may cause a voltage drop

that prevents lamps from striking or trips circuit breakers. When striking multiple

fixtures, space lamp on comman ds at 5 second intervals.

The lamp can be turned off as well, but then it must be allowed to cool for several

minutes before it can be turned back on. To prevent acc idental lamp off commands,

this command only works when the dimmer is closed (ch. 2 < 3) and the twinkle

effect is rotating s lowly CCW (ch. 4 > 252). If a hot lamp does not strike, send the

lamp off command and wait several minutes before trying again.

All effects reset to their home position s when the fixture i s powered up. There is

also a reset command on channel 1. To prevent accidental resets, the command must

be sent for 5 seconds.

When set up for

DIMMER

The intensity of the light is controlled from full-off to full-on on channel 2.

COLOR

The color wheel is control led o n channel 3 . You can program split-color effects with

continuous scroll, stick to full color posi tions usi ng stepped scroll, and rotate the

wheel continuously. The speed at which colors fade from one position to another

can be controlled on channel 5, the speed channel.

TWINKLE

The speed and direction of the twinkle effect is controlled on channel 4. When

stopped, the effect wheel returns to its hom e position where t here is a removable

section. The light output can be made more uniform if the twinkle effect is not used

by removing this section.

FADE SPEED

Channel 5 controls the speed of the color wheel, allowing you to achieve variable

fades on controller s without cross-faders. If your control ler has cross-faders, an d

you use them, then set channel 5 to 0 (tracking), for best results.

Controller operation 15

Page 16

TAND-ALONE OPERATION

S

CONTROL OPTIONS

The FiberSource QFX 150 can be opera ted without a controller in stand-alone

mode. This mode provides various combinations of color and twinkle effect that are

selected usin g DIP-switch pins 1 - 7.

The twinkle effect may by set to off, slow, medium , or fast usi n g DIP-s w itc h pins 1

and 2. If the twinkle effect is not required, a section o f the effect wheel can be

removed to increase the uniformity of the output: refer t o “To remove or replace the

twinkle wheel section” on page 19.

The speed at which the color wheel moves from one color to the next may be set to

snap, slow, medium, or fast using DIP-switch pins 3 and 4. This setting has no effect

if white or color 1 is selected.

7

The color or colors are selected using DIP-switch pins 5, 6, and 7. You can select

white, color 1 (position 1), a range of colors, and continuous rotation. If continuous

color wheel rotation is selected, then the color change speed must be slow, medium,

or fast.

If a range of colors is selected, the color wheel holds at pos ition 1 for 1 second,

moves to position 2 at the selected change speed, holds for 1 second, and so on.

When the last p ositi on is reached, th e colo r wheel reverses direction. Col ors can be

arranged in any order as described under “To change color filters” on page 19.

To set stand-alone behavior

1 Disconnect the fixture from power.

2 Set DIP-switch pins 1 - 7 on or off as shown in the table below to achieve the

desired combination of effects.

3 Set pins 8 and 9 to off. Set pin 10 to on.

4 Apply power to the fixture.

The option setting wi ll take effect and the lamp will automatically strike. Note,

howeve r, that a hot lamp must cool for several minutes before it can be restruck. If

the lamp does not strike, disconnect the fixture from power for several minutes to

reduce strain on the starter while the lamp cools.

16 Stand-alone operation

Page 17

Import ant! D IP-switch pi n 10 must be ON for stand- alone op eration .

0 = OFF

1 = ON

Effect Setting

no twinkle 0 0 0 0 1

slow twinkle 1 0 0 0 1

medium twinkle 0 1 0 0 1

fast twinkle 1 1 0 0 1

snap color change 0 0 0 0 1

slow color change 1 0 0 0 1

medium color change 0 1 0 0 1

fast color change 1 1 0 0 1

white 000001

color 1 100001

color 1 - 2 010001

pin 1

pin 2

pin 3

pin 4

pin 5

pin 6

pin 7

pin 8

pin 9

pin 10

color 1 - 4 110001

color 1 - 6 001001

color 1 - 8 101001

color 1 - 9 0 11001

continuous rotation* 111001

* Continuous rotation is not available when snap co lor ch an ge is sel ect ed.

Stand-alone operation 17

Page 18

ASTER/SLAVE OPERATION

M

Several FiberSource QFX 150s may be connected together for synchronous

operation without a controller. They are connected together and one, the maste r, is

set up in stand-alone mode and sends cont rol instructio ns to the others. Up t o 32

fixtures can be can be connected and operated this way.

Impor tant Verify that al l slave fixture s are set as des cribed. Damag e can

be caus ed if t here is more than 1 device (ma ster f ixture or

controller) sendin g cont rol signal s on the seri al data link.

8

To connect and set fixtures for master/slave operation

1 Disconnect all fixtures from power.

2 Plug a 3-pin XLR data cable into the OUT socket of the first fixture and the IN

socket of the next fixture.

3 Continue connecting fixtures output to input. Up to 32 FiberSource QFX 150s

may be connected.

4 Terminate the data link on

both ends. Insert a female

termination plug (P/N

91613018) into the IN socket

of the first fixture . Insert a

male termination plug (P/N

91613017) into the OUT

socket of the last fixture. A

termination plug is an XLR

connector with a 120 ohm,

0.25 W resistor soldered

across pins 2 and 3.

5 Select any one fixture to be the master. Set the desired stand-alone options

using the master’s DIP-switch as described on page 16.

6 On all other fixtures (slaves), set DIP-switch pin 1 to the ON position; set all

other DIP-switch pins to the OFF position.

Male

Male XLR

1

2

120

3

P/N 91613017

Female

Termination PlugTermination Plug

Female XLR

1

2

120

3

P/N 91613018

7 Apply power to the fixtures.

18 Master/slave operation

Page 19

ASIC SERVICE

B

The FiberSource QFX 150 requires simple routine maintenance. The maintenance

schedule de pends he avily on the op erating environm ent; pleas e consul t a Marti n

service technician for recommendations.

Any service procedure not described here should be referred to a qualified

technician.

Warning! Disconnect the f ixture from power before re moving any cover.

Import ant! Excessive du st, gre ase, and sm oke fl uid buildup degr ades

performance and causes overheati ng and damage t o the fixture

that is not covered by the war ranty.

9

To change color filters

1 Disconnect the fixture from power. Remove the lamp access cover.

2 Turn the color wheel by hand until the desired filter is accessible.

3 Using a soft cloth or gloves, gently tilt the outside edge of the filter back

towards the lam p to unlock. Remove filter.

4 To place a filter in the wheel, insert the plastic holder between the spring clip

with the protruding tab facing forwards until it snaps into place.

5 Replace the lamp access cover before applying power.

To remove or replace the twinkle wheel section

The twinkle wheel has a removable section for uniform light ou tp ut when the effect

is not used.

1 Disconnect the fixture from power. Remove the lamp access cover.

2 Turn the twinkle wheel by hand until the removable section is aligned with the

cable socket. Turn the color wheel so that the open position is aligned with the

cable socket.

3 Support the twinkle wheel with one hand and unlock the removable section by

pulling the outside e dge ba ck towards the lamp. Grasp the section and pull it

up and out.

4 To replace the section, turn the wheel to the open position and slide the section

between the wheel and the spring clip, with the heads of the screws towards

Basic service 19

Page 20

the cable socket. Center the section and then supp ort the wheel wi th a fing er

from the front as you press the 2 screw hea ds through the wheel.

5 Replace the lamp access cover before applying power.

To clean optical components

Use care when cleaning optical components. The surface of the color filters is

fragile and small scratches may be visible.

1 Disconnect the fixture from power and allow it to cool com pletely. Remove the

lamp access cover.

2 Blow or vacuum away loose dust. Remove residues from filters with a soft cloth

or cotton swabs wetted with isopropyl alcohol. Regular glass cleaner may also

be used, but no residues may remain.

3 Rinse with distilled water. Mixing the water with a small amount of wetting

agent such as Kodak Photoflo will help prevent streaking and spotting.

4 Dry with a clean, soft and lint-free cloth or blow dry with co mp ressed ai r.

To clean the fan and air vents

To maintain adequate cool ing, dust must be cleaned from the fan and ai r vents

periodically.

1 Disconnect the fixture from power.

2 Remove dust and dirt from the fan blades and vent grills using a soft brush,

cotton swab, vacuum, or compressed air.

To replace the main fuse

1 Unplug the mains cable from the input socket. Pry open the fuse holder as

shown.

2 Remove the defective fuse and replace it with one of the same type and rating.

3 Replace the fuse holder in the mains input socket.

20 Basic service

Page 21

To replace the secondary fuse

1 Disconnect the fixture from power.

2 Remove one screw by the DIP-switch and one screw by the data IN socket.

3 Pull the circuit board assembly out until you can access the fuse, which is

located behind the data IN socket.

4 Remove the defective fuse and replace it with one of the same type and rating.

5 Replace the circ uit board assembly before applying power.

Basic service 21

Page 22

ROUBLESHOOTING

T

Problem Probable cause(s) Remedy

10

Fixture is completely dead.

Fixture resets correctly but does

not respond to the co ntroller.

Fixture fails to reset correctl y.

No power to fixture.

Primary fuse blown. Replace fuse.

Secondary fuse blown. Replace fuse.

The controller is not connected. Connect controller.

Reversed data signal polarity.

Bad data link c onnection

Data link no t terminated.

Incorrect address setti ng. Check DIP-switch settings.

One of the fixtures is

transmitting as a master or is

defective.

An effect requires mechanical

adjustment.

Check tha t po wer is swi tche d on

and cables ar e pl ugged in.

Install a phas e-reversing cable

between the cont roller and the

fixture.

Inspect connections and cables.

Repair or replac e damaged

cables.

Insert termination plug in output

of the last fixture on the l ink.

Bypass one fixture at a time

until normal ope ra tion is

regained: unplug both cables

from fixture and connect them

directly together. Contact

Martin technician for service.

Contact Ma rtin technician for

service.

No light.

Lamp cuts out intermittently or

burns out too quickly.

22 Troubleshooting

Lamp too hot to strike . All ow lamp to cool.

Power settings do not match AC

supply.

Defective lamp. Replace lamp.

Fixture is too hot. Allow fixture to c ool .

Power settings do not match AC

supply.

Defective fan.

Check AC setting.

Check set tings.

Contact Ma rtin technician for

service.

Page 23

DMX

Channel Value Percent Function

PROTOCOL

0 - 89

90 - 119

1

120 - 149

150 - 199

200 - 249

250 - 255

0 - 35

35 - 46

47 - 58

59 - 78

78 - 98

98 - 100

Reset and lamp power

No function

Reset (time > 5 sec.)

No function

Lamp on

No function

Lamp off (w/ Ch. 2 < 3 & Ch. 4 > 252)

A

2

3

0 - 255 0 - 100

0 - 144

0

16

32

48

64

80

96

112

128

144

145 - 185

145 - 148

149 - 152

153 - 156

157 - 160

161 - 164

165 - 168

169 - 172

173 - 176

177 - 180

181 - 185

0 - 56

0

6

12

18

25

31

37

44

50

56

57 - 72

57 - 58

58 - 59

60 - 61

61 - 63

63 - 64

65 - 66

66 - 67

68 - 69

69 - 70

71 - 72

Dimmer

Closed to Open

Color Wheel

Continuous scroll

Open

Color 1 (blue 108)

Color 2 (green 206)

Color 3 (yellow 603)

Color 4 (red 308)

Color 5 (-)

Color 6 (-)

Color 7 (-)

Color 8 (-)

Color 9 (-)

Stepped scroll

Color 9 (-)

Color 8 (-)

Color 7 (-)

Color 6 (-)

Color 5 (-)

Color 4 (red 308)

Color 3 (yellow 603)

Color 2 (green 206)

Color 1 (blue 108)

Open

186 - 220

221 - 255

4

5

0 - 1

2 - 125

126 - 131

132 - 255

0 - 2

3 - 5

6 - 255

73 - 86

87 - 100

0

0 - 49

49 - 51

52 - 100

0

1

2 - 100

Continuous rotation

CW, fast to slow

CCW, slow to fast

Twinkle Wheel

Stop/Open

CW, slow to fast

Stop

CCW, fast to slow

Color Speed

Tracking (speed function off)

Fast speed with shortcut enabled

Fast to slow, shortcut disabled

DMX protocol 23

Page 24

NO F

UNCTION

hold 5 seconds

L

A

M

P

C

OLOR SPEED

S

TEPPED COLOR SCROLL

C

ONTINUOUS ROTATION

fast CW slow

T

WINKLE

slow

9876 432105

R

ESET

L

AMP ON

D

IMMER

slow CCW fast

stop

fast CCW slow

Implemented from software version 1.0

NO F

UNCTION

O

F

F

Page 25

PECIFICATIONS

S

PHYSICAL

Length: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 330 mm (13.0 in)

Width: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213 mm (8.4 in)

Height: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199 mm (7.8 in)

Weight: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.4kg (lbs)

SOURCE

Osram HQI-R 150 (include d): . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150 W, 6000 hr. , 420 0K

CONTROL

Control options: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .DMX-512, stand-alone, master/slave

DMX channels: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Data I/O: . . . . . . . . . . . . . . . . . locking 3-pin XLR, pin 1 shi el d, pin 2 col d (-), pin 3 hot (+)

Recommended cable: . . . 24 AWG (min.), low capacitance, 85-150 Ω shielded twisted pair

INSTALLATION

Orientation: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .horizontal

Minimum distance to combustible materials: . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1 m (4 in)

Minimum clearance around fan and air vents: . . . . . . . . . . . . . . . . . . . . . . . . . . .0.1 m (4 in)

B

AC SUPPLY

Power supply options: . . . . . . . . . . . 100/120/210/230/250 V, 50/60 Hz (switch-selecta ble)

Maximum power and curren t: . . . . . . . . . . . . . 205W, 1.9A @ 120V; 195W, 1.0A @ 230V

FUSES

2

Primary fuse: . . . . . . . . . . . . . . . . . . . . . . . . . . . . T 3.15 A, high I

Secondary fuse: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . T 2.0 A, 250 V, P/N 05020009

CONSTRUCTION

Housing: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . sheet steel and aluminum

Finish: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . black, electrostatic powder coating

Protection factor: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IP 20

t, 250 V, P/N 05020013

Specifications 25

Page 26

CCESSORIES

A

Male adapto r for 50 - 300 strand cables with installation materi al s: . . . . . . .P/N 91611016

G-clamp: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91602003

Half-coupler clamp: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91602005

Accessory color filter, blue 111: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327015

Accessory color filter, blue 101: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327016

Accessory color filter, cyan 401: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327017

Accessory color filter, green 202: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327018

Accessory color filter, yellow 604: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327019

Accessory color filter, red 301: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327021

Accessory color filter, pink 312: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327022

Accessory color filter, magenta 507: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327023

Accessory color filter, purple 502: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327025

Accessory color filter, green 204: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327034

Accessory color filter, orange 306: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 62327035

C

26 Accessories

Loading...

Loading...