Page 1

MAC III™ Wash

USER MANUAL

Page 2

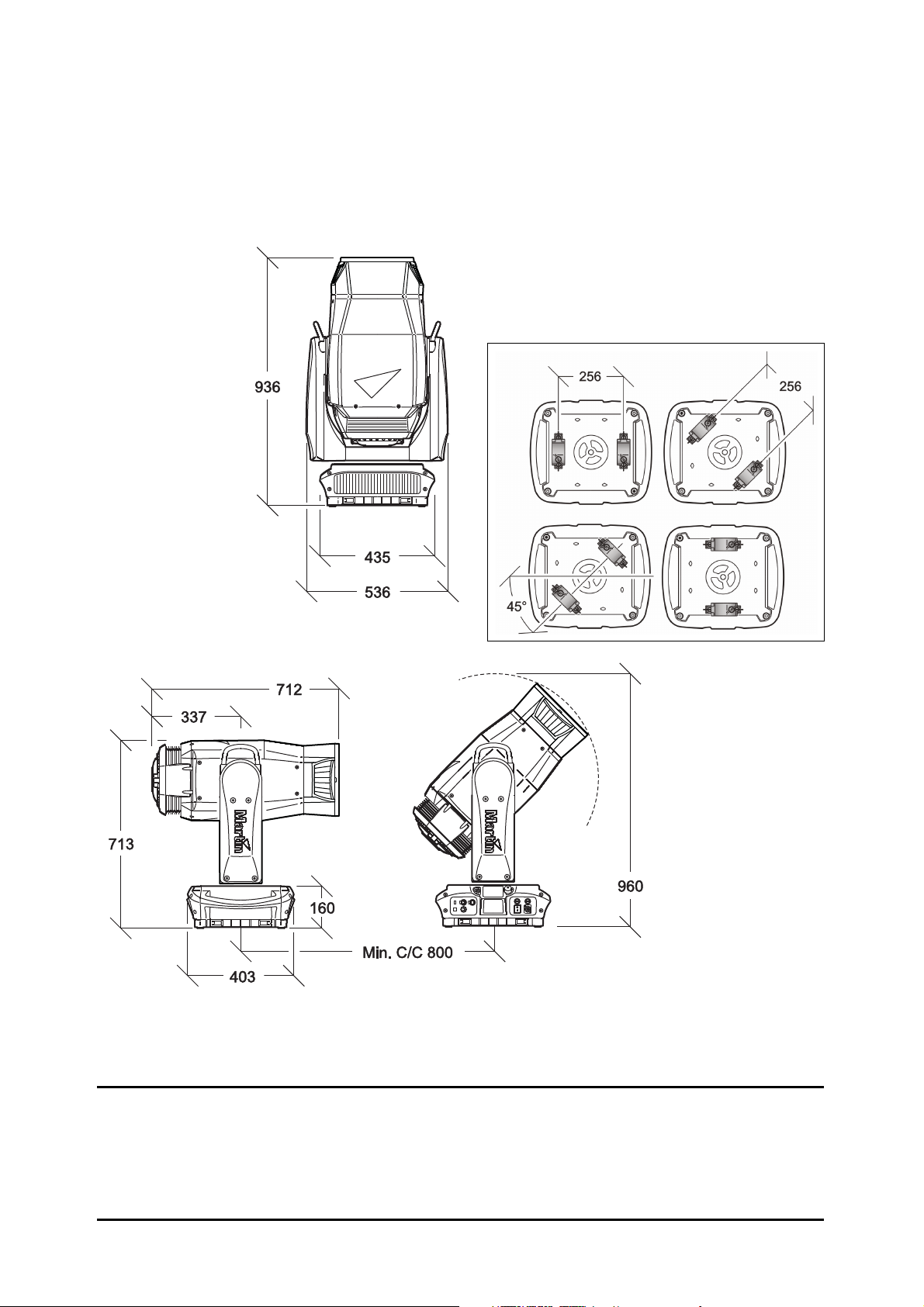

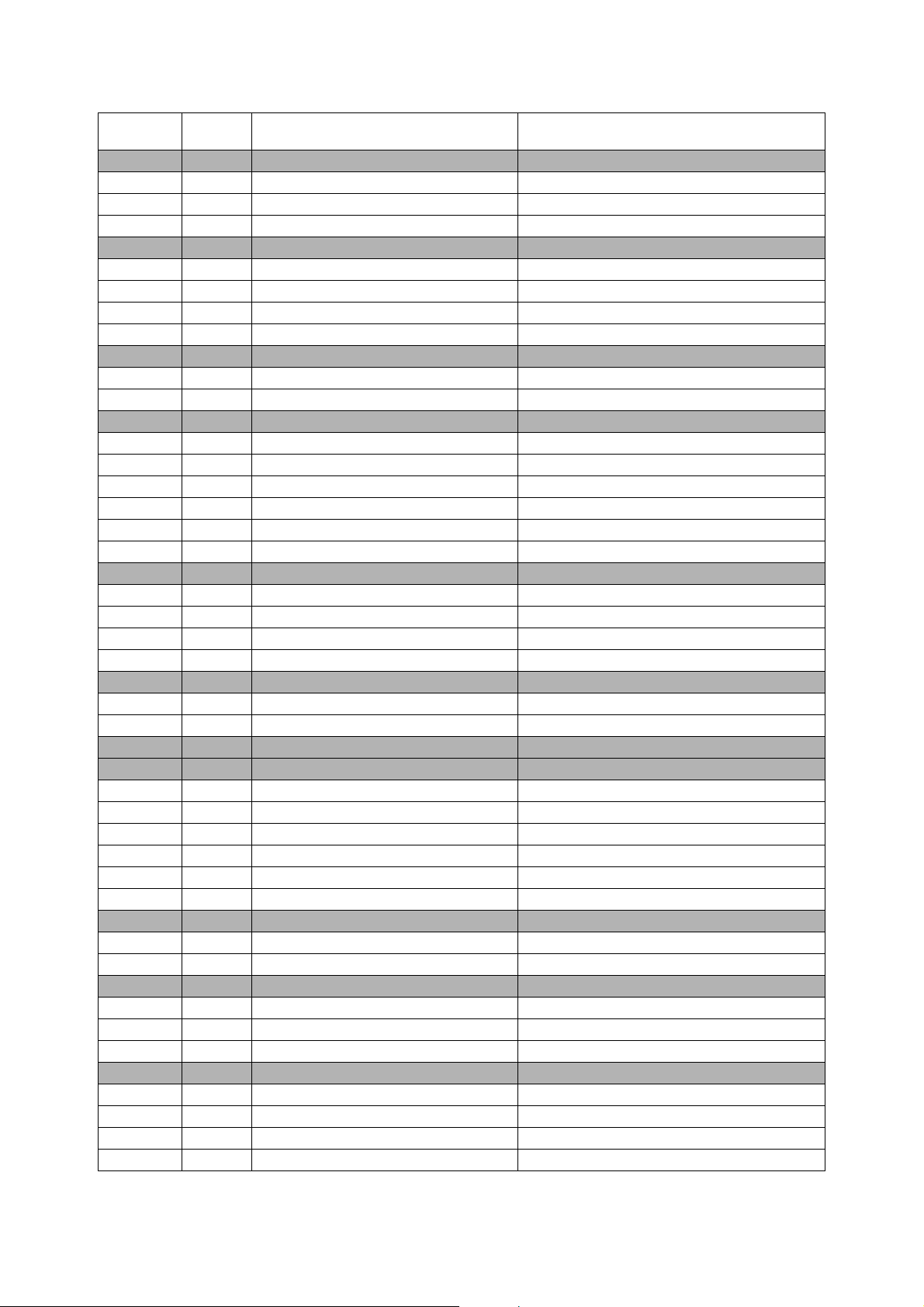

Dimensions

The minimum center-to-center

distance can be reduced if pan and

limits are set via the control menus

All measurements are expressed in millimeters

© 2012 Martin Professional A/S. Information subject to change without notice. Martin Professional A/S and all affiliated companies

disclaim liability for any injury, damage, direct or indirect loss, consequential or economic loss or any other loss occasioned by the

use of, inability to use or reliance on the information contained in this manual. The Martin logo, the Martin name and all other trade-

marks in this document pertaining to services or products by Martin Professional A/S or its affiliates and subsidiaries are trademarks

owned or licensed by Martin Professional A/S or its affiliates or subsidiaries.

P/N 35000266, Rev. B

Page 3

Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Applying power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

About the discharge lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Lamp replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DMX data link. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Physical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Control panel operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Setup Wizard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

DMX address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Fixture ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Personality – tailoring performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Factory settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fixture information readouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

DMX signal monitoring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Test sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Manual control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Adjusting settings via DMX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Resetting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Lamp on / off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Adjusting lamp power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Illuminating the display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Control menu setting overrides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Effects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Shutter and strobe effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Dimming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Cyan, Magenta, Yellow and CTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Color wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Internal barndoors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Iris . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Focus and zoom . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Pan and tilt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Followspot mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

RDM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Service and maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Tilt lock. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Service utilities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Software installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Replacing a color filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

MAC III Wash DMX protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Control panel menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Service and display messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Page 4

Safety Information

WARNING!

Read the safety precautions in this section before

installing, powering, operating or servicing this

product.

The following symbols are used to identify important safety information on the product and in this manual:

DANGER!

Safety hazard.

Risk of severe

injury or death.

Warning! Risk Group 3 (high risk) product according to EN 62471. Do not view the light output with

optical instruments or any device that may concentrate the beam.

This product is for professional use only. It is not for household use.

This product presents risks of severe injury or death due to fire and burn hazards, electric shock, lamp

explosion and falls.

Read this manual before installing, powering or servicing the fixture, follow the safety precautions listed

below and observe all warnings in this manual and printed on the fixture.

If you have questions about how to operate the fixture safely, please contact your Martin supplier or call the

Martin 24-hour service hotline on +45 8740 0000, or in the USA on 1-888-tech-180.

PROTECTION FROM ELECTRIC SHOCK

• Disconnect the fixture from AC power before removing or installing any cover or part – including the lamp

– and when not in use.

• Ensure that the fixture is electrically connected to ground (earth).

• Use only a source of AC power that complies with local building and electrical codes and has both

overload and ground-fault (earth-fault) protection.

• Use only a power input cable that is rated 20 A, hard usage type and heat-resistant to 90° C (194° F)

minimum. It must have three conductors and an outer cable diameter of 5 - 15 mm (0.2 - 0.6 in.). In North

America the cable must be 12 AWG minimum conductor size, SJT or better. In the EU the cable must be

2.5 mm², HAR compliant.

• Before using the fixture, check that all power distribution equipment and cables are in perfect condition

and rated for the current requirements of all connected devices.

• Isolate the fixture from power immediately if the power cable or power plug are in any way damaged,

defective or wet, or if they show signs of overheating.

• Do not expose the fixture to rain or moisture.

• Refer any service operation not described in this manual to an authorized Martin Service partner.

DANGER!

Refer to

manual before

installing,

powering or

servicing.

DANGER!

Hazardous

voltage. Risk of

severe or lethal

electric shock.

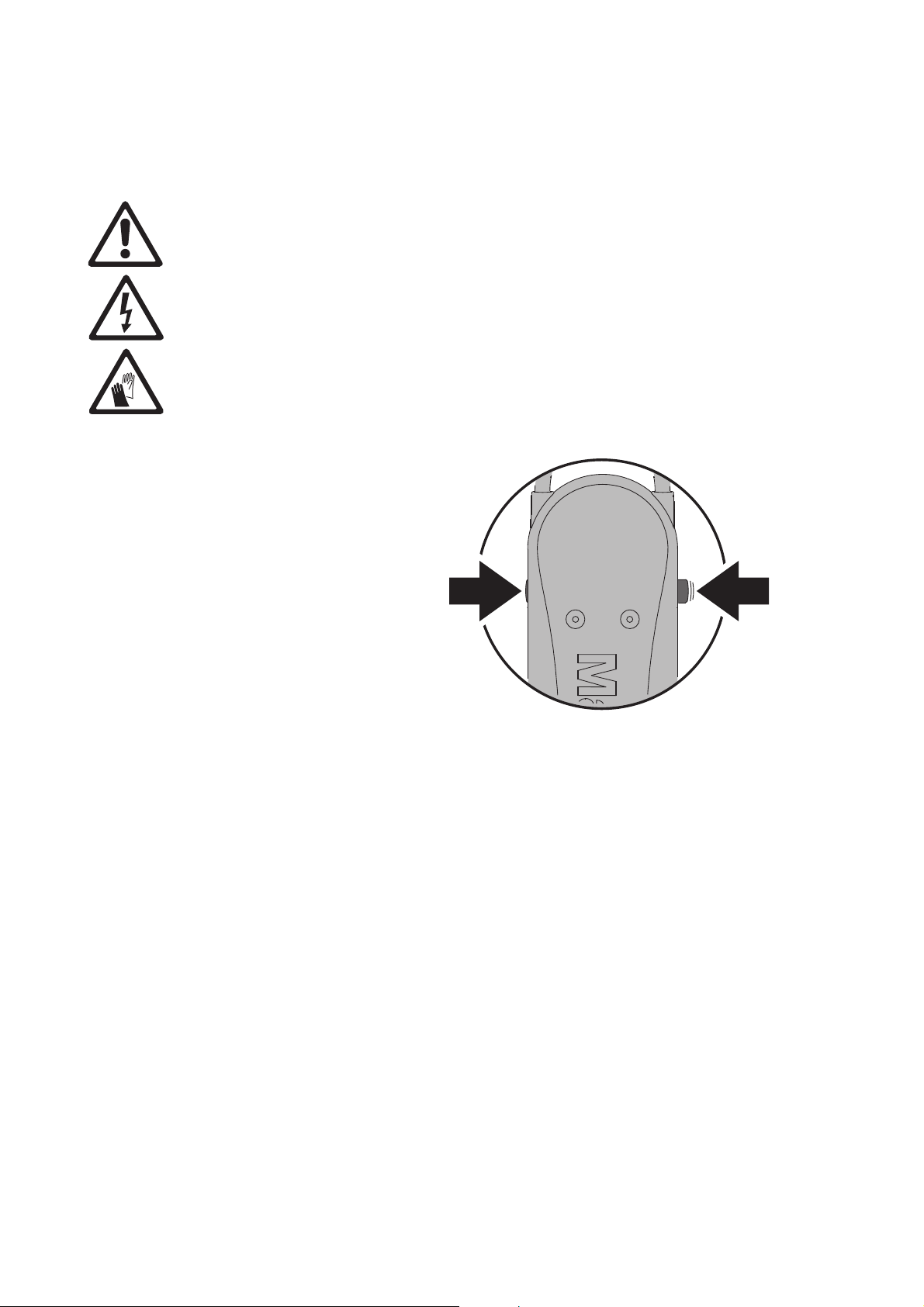

Warning!

Fire hazard.

Warning!

Burn hazard.

Hot surface. Do

not touch.

Warning!

Risk of eye

injury. Safety

glasses must

be worn.

Warning!

Risk of hand

injury. Safety

gloves must be

worn.

Page 5

LAMP SAFETY

• Prolonged exposure to an unshielded discharge lamp can cause eye and skin burns. Do not stare directly

into the light output. Never look at an exposed lamp while it is lit.

• Do not operate the fixture with missing or damaged covers, shields, lenses or ultraviolet screens.

• A hot discharge lamp is under pressure and can explode without warning. Allow the fixture to cool for at

least 2 hours 45 minutes and protect yourself with safety glasses and gloves before handling a lamp or

servicing the fixture internals.

• Replace the lamp immediately if it becomes visually deformed, damaged or in any way defective

• Monitor hours of lamp use and lamp intensity and replace the lamp when it reaches the limit of its service

life as specified in this manual or by the lamp manufacturer.

• Install only an approved lamp.

• If the quartz envelope of a discharge lamp is broken, the lamp releases a small quantity of mercury and

other toxic gases. If a discharge lamp explodes in a confined area, evacuate the area and ventilate it

thoroughly. Wear nitrite gloves when handling a broken discharge lamp. Treat broken or used discharge

lamps as hazardous waste and send to a specialist for disposal.

PROTECTION FROM BURNS AND FIRE

• The exterior of the fixture becomes very hot – up to 170° C (338° F) – during use. Avoid contact by

persons and materials. Allow the fixture to cool for at least 2 hours 45 minutes before handling.

• Keep all combustible materials (e.g. fabric, wood, paper) at least 0.2 m (8 in.) away from the fixture. Keep

flammable materials well away from the fixture.

• Provide a minimum clearance of 0.1 m (4 in.) around fans and air vents.

• Do not illuminate surfaces within 2.5 m (100 in.) of the fixture.

• Position or shade the head so that the lens does not face the sun at any time during daylight hours. The

lens can focus the sun's rays inside the fixture, creating a potential fire hazard.

• Do not operate the fixture if the ambient temperature (Ta) exceeds 40° C (104° F).

• Do not modify the fixture in any way not described in this manual or install other than genuine Martin

parts. Do not stick filters, masks or other materials onto any lens or other optical component. Use only

Martin-approved accessories to mask or modify the light beam.

• Do not attempt to bypass a thermostatic switch or fuse. Replace defective fuses only if authorized by

Martin™ and with Martin™ service documentation for the product. Replace fuses with the same type and

rating only.

PROTECTION FROM INJURY DUE TO FALLS

• Do not lift or carry the fixture alone.

• Use two evenly spaced clamps to suspend the fixture from rigging structures. Do not use only one clamp.

• When clamping the fixture to a truss or other supporting structure at any other angle than with the yoke

hanging vertically downwards, use two half-coupler clamps. Do not use G-clamps, quick-trigger clamps or

any other type of clamp that does not completely encircle the supporting structure when fastened.

• When suspending the fixture, ensure that the supporting structure and all hardware used can hold at least

10 times the weight of all devices suspended from them.

• Do not use the handles in the base or the handles on the top of the yoke for hoisting or secondary

attachment.

• Install as described in this manual a secondary attachment such as a safety cable that is approved by an

official body such as TÜV as a safety attachment for the weight of all the fixtures it secures. The safety

cable must comply with EN 60598-2-17 Section 17.6.6 and be capable of bearing a static suspended load

ten times the weight of the fixture.

• Check that all external covers and rigging hardware are securely fastened.

• Block access below the work area and work from a stable platform whenever installing, servicing or

moving the fixture.

Safety Information 5

Page 6

Introduction

Thank you for selecting the Martin™ MAC III Wash™. This moving-head washlight features:

• CMY color mixing plus color wheel

• Variable CTO

• Internal barndoors with continuously variable opening and 110° rotation

• 1:4 linear zoom with no lumen drop or internal lens changes

• Fresnel lens

• Optional PC lens

• Full-range mechanical dimmer with four dimming curve options, plus mechanical shutter

•Iris

• 1500 watt high-output discharge lamp with semi-hot restrike (< 90 seconds)

• Backlit graphic display and battery power (mains power not required for fixture setup)

• 540° of pan and 268° of tilt with user-settable pan/tilt limits

• Electronic “flicker-free” ballast and auto-sensing switch-mode power supply.

For the latest firmware updates, documentation, and other information about this and all Martin Professional

products, please visit the Martin website at http://www.martin.com

Comments or suggestions regarding this document may be e-mailed to service@martin.dk or posted to:

Technical Documentation, Martin Professional A/S, Olof Palmes Allé 18, DK-8200 Aarhus N, Denmark.

Unpacking

The MAC III Wash is packaged in either a cardboard box or a flightcase that is designed to protect the

product during shipment. The following items are included:

• 1500 W discharge lamp (installed)

• 2 omega brackets for clamp attachment

• This user manual

Using for the first time

Before applying power to the fixture:

• Carefully review the safety information starting on page 4.

• Prepare a power cable (see “Power connection” on page 7).

• Check that the tilt lock is released (see “Tilt lock” on page 30).

• Check that the base is fastened securely so that the torque reaction when the head is panned does not

cause the fixture to move.

When powered up, check lamp alignment as described on page 10.

Packing

Important! Release the tilt lock before repacking in the flightcase.

The tilt lock must be released during transportation in the MAC III flightcase.

6 MAC III Wash user manual

Page 7

AC power

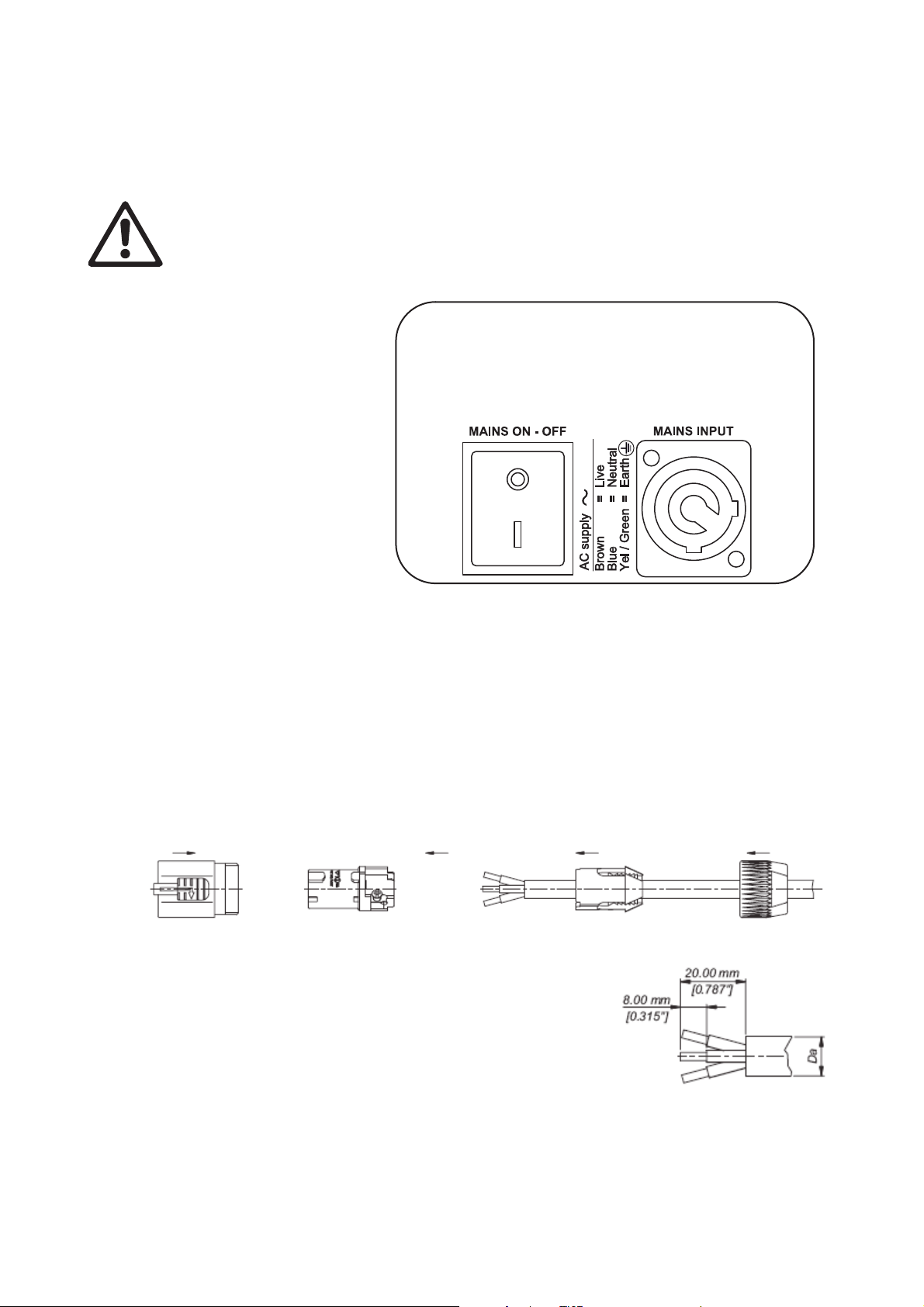

Figure 2: Power on/off switch and input connector

Chuck BushingHousing Insert

Cable end

Warning! For protection from electric shock, the fixture must be grounded (earthed). The AC mains

supply must be protected against overload with a fuse or circuit breaker and provide ground-fault

(earth-fault) protection.

The MAC III Wash features an

auto-sensing switch-mode

power supply that

automatically adapts to

200-240 V (nominal) AC power

at 50 or 60 Hz. It is protected

by fuses inside the fixture that

may only be replaced by

service technicians authorized

by Martin™ with Martin™

service documentation for the

MAC III Wash.

Power connection

Important! Connect the MAC III Wash

directly to AC power. Do not

connect it to a dimmer

system; doing so may

damage the fixture.

from mains before servicing.

- Déconnecter du secteur avant entretien.

- Disconnect

The MAC III Wash requires a power input cable with a Neutrik PowerCon NAC3FCA cable connector for AC

mains power input. The cable must meet the requirements listed under “Protection from electric shock” on

page 4.

Martin™ can supply either a suitable 3 m (9.8 ft.) power cable with PowerCon input connector installed or

the PowerCon input connector without a cable (see “Accessories” on page 56).

If you need to install a PowerCon connector on the power cable, see the next section.

Installing a power input connector

To install a Neutrik PowerCon NAC3FCA input connector on a power

cable, see illustrations above and right:

1. Slide the bushing over the cable.

2. Slide the white chuck over cables with a diameter (D

(0.2 - 0.4 in.), or the black chuck over cables with a diameter of 10 15 mm (0.4 - 0.6 in.).

3. Prepare the end of the cable by stripping 20 mm (0.8 in.) of the

cable’s outer jacket.

) of 5 - 10 mm

a

AC power 7

Page 8

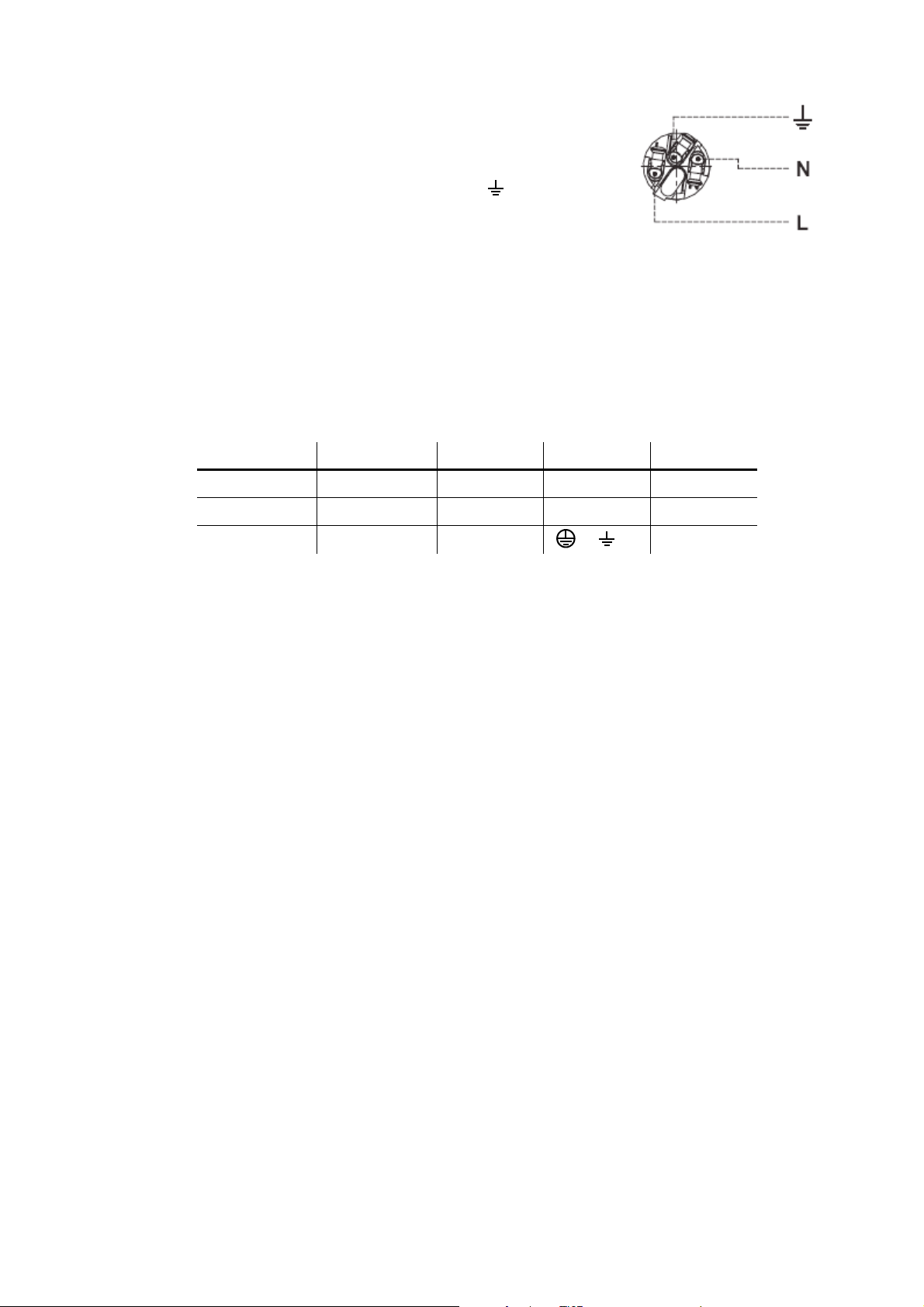

4. Strip 8 mm (1/3 in.) of insulation from the end of each wire.

Termina ls

5. Use a small flathead screwdriver to fasten the wires into the

connector terminals in the insert as follows:

• live wire into the terminal marked L

• neutral wire into the terminal marked N

• ground (earth) wire into the terminal marked .

6. Line up the raised key in the insert with the keyway in the housing,

then push the insert and chuck into the housing.

7. Fasten the bushing to the housing using a wrench, applying a

torque of 2.5 Nm (1.8 lb.-ft).

Illustrations used by kind permission of Neutrik AG

Installing a cord cap (mains plug)

If you install a cord cap (mains plug) on the power cable to allow connection to power outlets, install a

grounding-type (earthed) plug, following the plug manufacturer’s instructions. Table 1 shows some possible

mains power pin and wire color identification schemes; if pins are not clearly identified, or if you have any

doubts about proper installation, consult a qualified electrician.

Wire color (USA) Wire color (EU) Pin Symbol Screw (US)

black brown live L yellow or brass

white blue neutral N silver

green yellow/green ground (earth) or green

Applying power

To apply power, first check that the tilt lock is released and that a power input cable is connected, then set

the power switch on the base (see Figure 2) to the “I” position.

Table 1: Cord cap connections

8 MAC III Wash user manual

Page 9

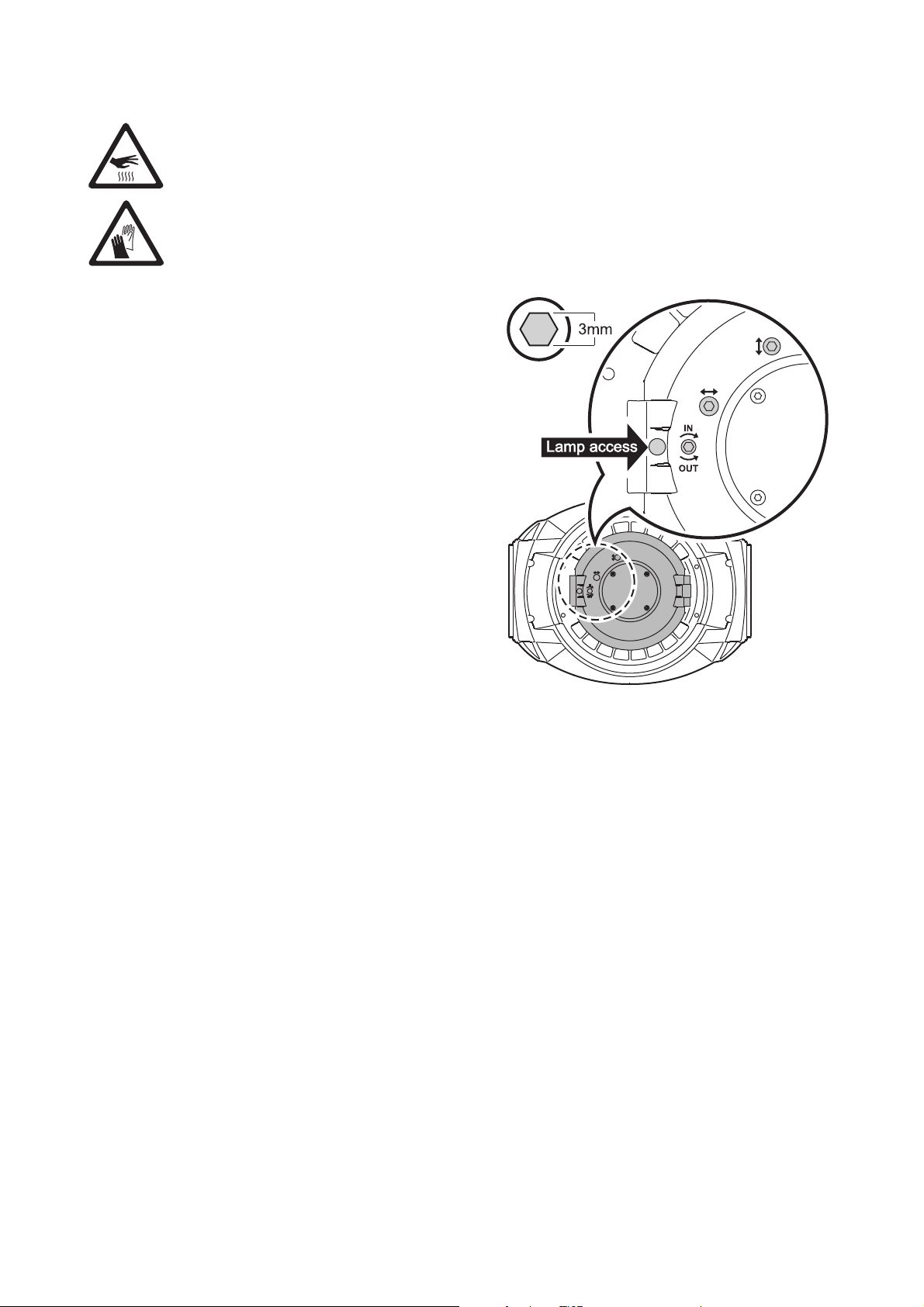

Lamp

Figure 2: Lamp removal / refitting

About the discharge lamp

The MAC III Wash is designed for use with an Osram Lok-it HTI 1500W/60/P50 - 7mm lamp. This highly

efficient single-ended discharge source provides a color temperature of 6000 K, a color rendering index

greater than 90, an average service life of 750 hours and semi-hot restrike, meaning that a hot lamp is ready

to strike again after 90 seconds.

Lamp power is automatically reduced to approximately 800 W after 10 seconds when the fixture is blacked

out in order to reduce cooling fan activity and power consumption. The lamp returns to 1500 W as soon as

the dimmer and/or shutter are opened.

Warning! Installing any other lamp may create a safety hazard or damage the fixture!

To reduce the risk of explosion, replace the lamp when it reaches the limit of its average service life, i.e.

when usage reaches 750 hours. Never exceed the lamp’s average service life by more than 10%. To read

lamp hours in the fixture’s display, refer to the section on lamp hours readouts on page 19. Replace the lamp

immediately if it is deformed or in any way defective.

For maximum service life, avoid powering the lamp off until it has warmed up for at least 5 minutes.

Lamp replacement

Warning! Wear safety glasses and gloves when handling lamps. The clear lamp bulb is integral with

the ceramic lamp base. Do not try to separate the bulb from the base.

Important! The lamp can be a stiff fit in its holder. Twist the lamp base a full 45° clockwise when

installing to ensure that the lamp contacts are fully engaged.

Replacement lamps are available from your Martin dealer requesting P/N 97010348.

The clear bulb must be perfectly clean. Do not touch it with your fingers. Clean the lamp with an alcohol

wipe and polish it with a dry cloth before installing, particularly if you accidentally touch the bulb.

To replace the lamp:

1. Disconnect the fixture from power and allow it to cool for at

least 2 hours 45 minutes.

2. Lock the head.

3. Release the screw on the lamp access cover and open the

cover.

4. Grasp the ceramic lamp base, twist it 45° counterclockwise

and withdraw the lamp from the fixture as shown in Figure 2.

5. The lamp base has two metal contacts, one narrow and one

wide, that fit into corresponding narrow and wide slots in the

lampholder. Line up the contacts on the replacement lamp’s

base with the corresponding slots in the lampholder, slide

the lamp into the fixture so that the contacts are fully

engaged in the slots, and then twist the lamp base a full 45°

clockwise until it locks into position with a noticeable click.

The lamp is a stiff fit and trying to strike a lamp that is not

correctly installed can cause damage that is not covered by

the product warranty, so ensure that the lamp is correctly

locked into position.

6. Close the lamp access cover and tighten the screw to

secure the cover before reapplying power.

7. After installing a new lamp, reset the lamp hour counter (see

the section on lamp hours readouts on page 19).

Lamp 9

Page 10

Lamp adjustment

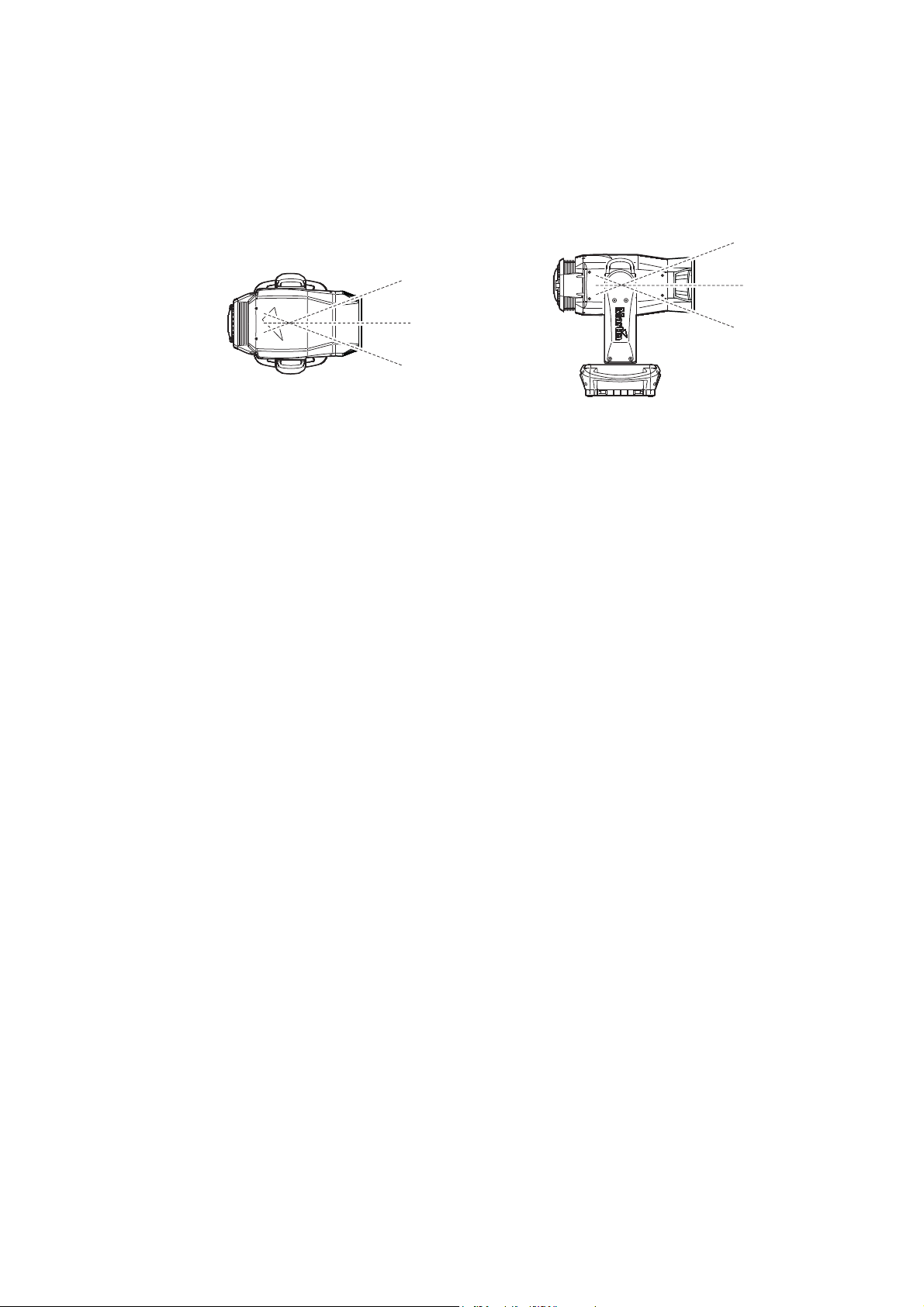

Figure 3: Lamp adjustment screws

Warning! Adjust the lamp with the fixture cool. The fixture may become hot during adjustment, so

wear heat-resistant safety gloves.

As well as being undesirable for aesthetic reasons, a significant hot-spot in the beam will focus extra heat

onto optical components and may cause damage that is not covered by the product warranty.

After fitting a new lamp, adjustment may be required to obtain an even beam.

To adjust the lamp:

1. If the fixture has been in use, allow it to cool for at least 2 hours 45 minutes to avoid the danger of burns,

and wear heat-resistant safety gloves.

2. Apply power, allow the fixture to reset, then set

zoom to narrow, turn on the lamp and open the

mechanical shutter.

3. Aim the fixture at an even surface and make

sure no further commands can be sent by

DMX.

4. See Figure 3. Screw the three lamp adjustment

screws in or out to obtain the most even beam.

10 MAC III Wash user manual

Page 11

DMX data link

The MAC III Wash has 5-pin locking XLR sockets for DMX and RDM input and output. The default pin-out on

both sockets is:

• pin 1 to shield

• pin 2 to DMX and RDM data 1 cold (-)

• pin 3 to DMX and RDM data 1 hot (+)

Pins 4 and 5 are not used by the fixture but are bridged between input and output sockets. These pins can

therefore be used as a pass-through connection for an additional data signal if required.

Tips for reliable data transmission

• Use shielded twisted-pair cable designed for RS-485 devices: standard microphone cable cannot transmit

control data reliably over long runs. 24 AWG cable is suitable for runs up to 300 meters (1000 ft). Heavier

gauge cable and/or an amplifier is recommended for longer runs.

• To split the serial link into branches, use a splitter such as the Martin 4-Channel Opto-Isolated RS-485

Splitter/Amplifier.

• Do not overload the link. Up to 32 devices may be connected on a serial link.

• Install a DMX termination plug on the last fixture on the link.

To connect the data link

1. Connect the DMX data output from the controller to the MAC III Wash’s data input (male XLR) socket.

2. Run the data link from the MAC III Wash’s data output (female XLR) socket to the data input of the next

fixture.

3. Terminate the data link by connecting a 120 Ohm, 0.25 Watt resistor between the data 1 hot (+) and cold

(-) conductors (and between data 2 hot and cold if used) at the data output of the last fixture on the link.

If a splitter is used, terminate each branch of the link.

DMX data link 11

Page 12

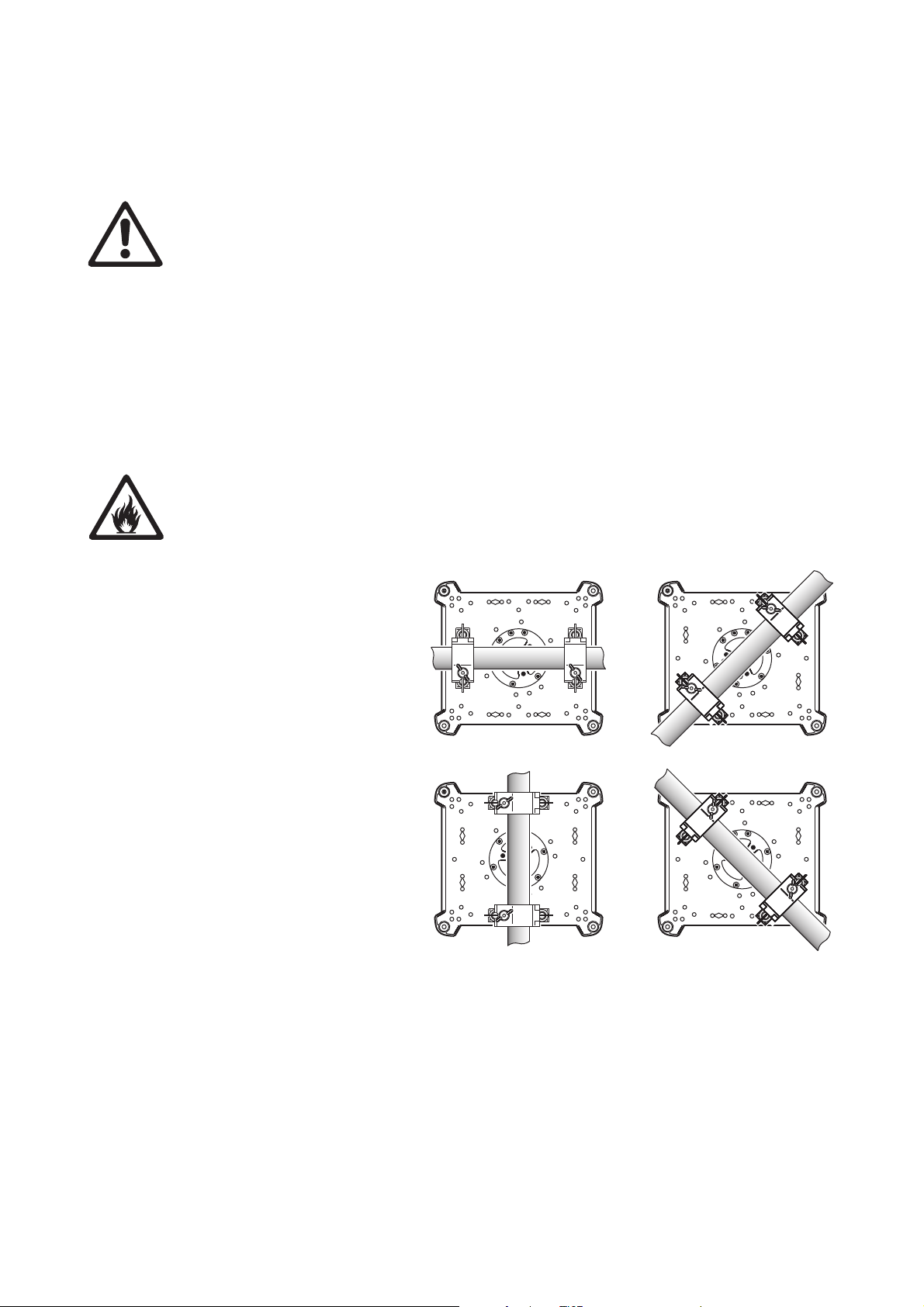

Physical installation

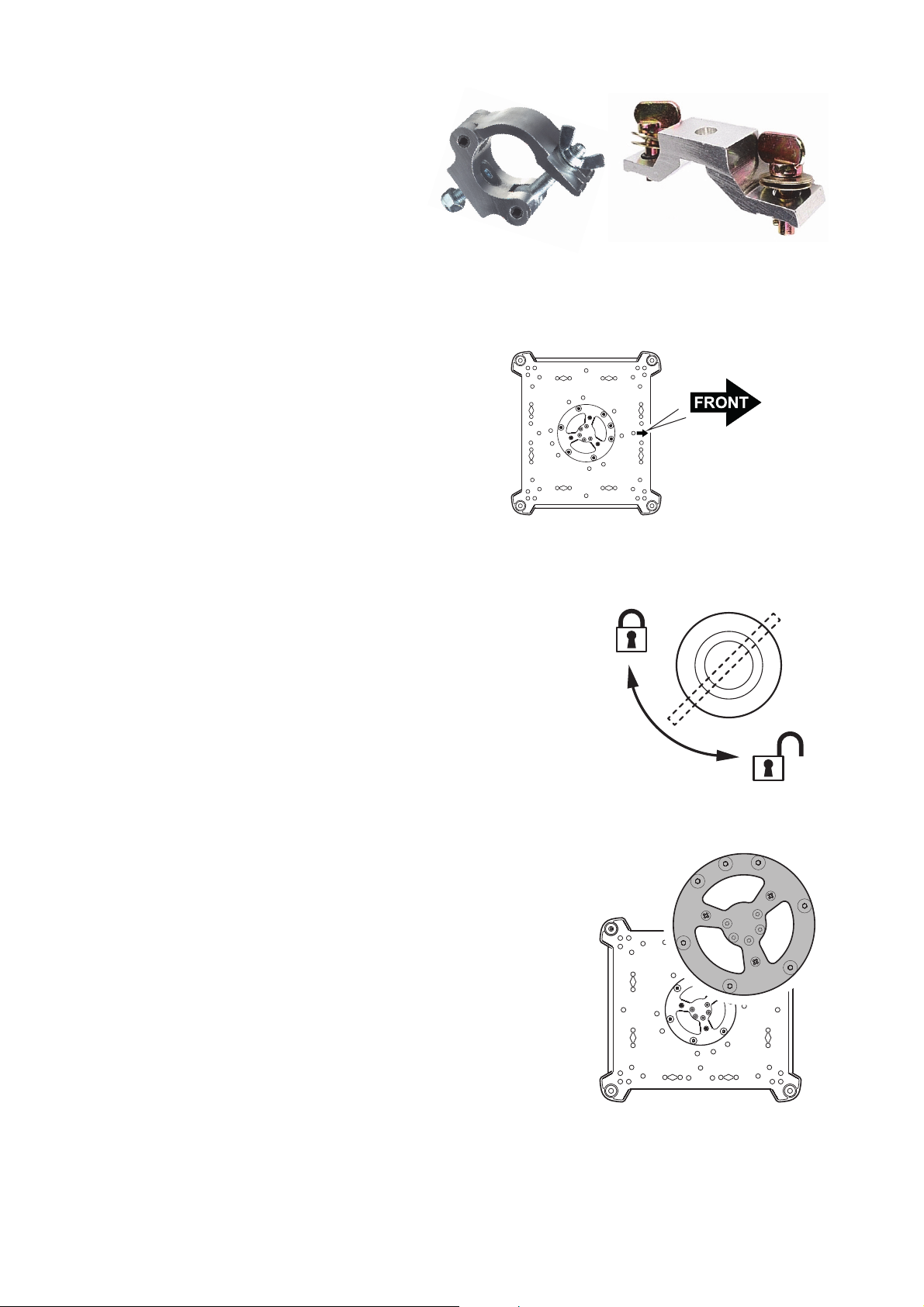

Figure 4: Clamp bracket positions

Warning! The MAC III Wash has a powerful pan motor. The torque reaction when the head is panned

suddenly can cause the base to move if the fixture is standing unsecured on a surface. Do not apply

power to the MAC III Wash unless the base is securely fastened to a surface or to rigging hardware.

Warning! Use 2 clamps to rig the fixture. Do not hang the fixture from only one clamp. Lock each

clamp with both 1/4-turn fasteners. Fasteners are locked only when turned fully clockwise.

Warning! When suspending the fixture above ground level, secure it against failure of primary

attachments by attaching a safety wire that is approved as a safety attachment for the weight of the

fixture to the attachment point in the base. Do not use the carrying handles for secondary

attachment.

Warning! When clamping the fixture to a truss or other structure at any other angle than with the

yoke hanging vertically downwards, use two clamps of half-coupler type. Do not use any type of

clamp that does not completely encircle the structure when fastened.

Warning! Position or shade the head so that the lens does not face the sun at any time, even for a

few seconds, during daylight hours. The MAC III Wash’s lens can focus the sun's rays inside the

fixture, creating a potential fire hazard and causing internal damage.

Important! Do not point the output from other lighting fixtures at the MAC III Wash from a distance of

less than 3 m (10 ft.), as intense illumination can damage the display.

The MAC III Wash can be fastened to

a surface such as a stage or clamped

to a truss in any orientation. Clamps

must be half-coupler type (see Figure

5) unless the fixture is installed with

the yoke hanging vertically

downwards. The mounting points allow

the clamp brackets to be fastened

parallel, perpendicular or at 45° to the

front, as shown Figure 4.

Pan and tilt range can be limited via

the control panel to allow fixtures to be

installed close to each other or to

obstacles with no risk of collision (see

PAN/TILT SETTINGS on page 16).

Clamping the fixture on a truss

1. Check that the rigging clamps are

undamaged and can bear at least

10 times the weight of the fixture.

Check that the structure can bear

at least 10 times the weight of all

installed fixtures, clamps, cables,

auxiliary equipment, etc.

12 MAC III Wash user manual

Page 13

2. Bolt each clamp securely to a

Figure 5: Martin rigging hardware

Half-coupler Omega clamp

rigging clamp attachment bracket

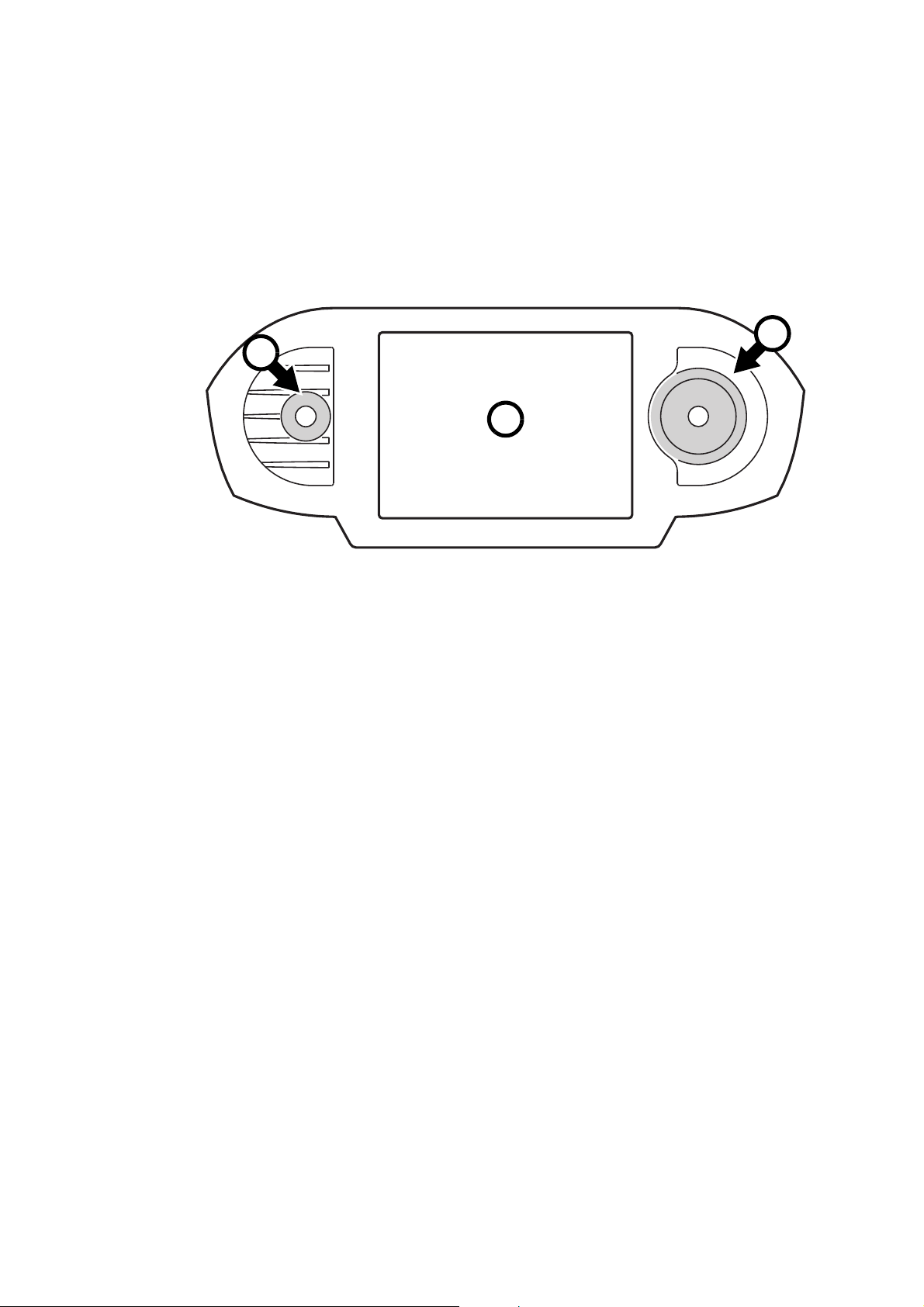

Figure 6: Front of fixture

Figure 7: Locking 1/4-turn fasteners

Figure 8: Safety cable attachment

point

clamp bracket with an M12 bolt

(minimum grade 8.8) and lock nut.

3. See Figure 6. Note the position of

the arrows on the bottom of the base

that indicate the front of the fixture.

4. Align a clamp with 2 mounting points in the base. See

Figure 7. Insert the fasteners into the base and turn both

levers a full 90° clockwise to lock. Install the second clamp.

5. Block access under the work area. Working from a stable

platform, hang the fixture on the truss with the arrows

marked FRONT printed on the base of the fixture facing

towards the area to be illuminated. Tighten the rigging

clamps.

6. See Figure 8. Install a safety wire that is approved as a

safety attachment for the weight of the fixture by looping it

through the safety attachment wheel on the bottom of the

base.

7. Check that the tilt lock is released. Check that there are no

combustible materials within 0.2 m (8 in.) or surfaces to be

illuminated within 2.5 m (100 in.) of the fixture, and that there

are no flammable materials nearby.

8. Check that there is no possibility of heads or yokes colliding

with other fixtures. Note that pan and tilt range on the MAC III

Wash can be restricted by setting minimum and maximum

limits via the control menus. This feature allows fixtures to be

installed closer together or closer to obstacles.

9. Check that other lighting fixtures cannot project light at the

MAC III Wash from a distance of less than 3 m (10 ft.), as

intense illumination can damage the MAC III Wash’s display.

90°

Physical installation 13

Page 14

Control panel operations

C

B

Figure 9: Display and control panel

A

You can configure individual fixture settings such as the MAC III Wash’s DMX address, read out data,

execute service and view the event log using the fixture’s backlit graphic display and control panel. The

control menu overview starting on page 44 gives a complete list in table form of the menus and commands

available.

After a pause while the fixture boots and resets, the DMX address and any status messages (see page 49)

appear in the graphic display A when the MAC III Wash is powered on.

Using the control panel

Click (i.e. press once) the jog wheel B once to enter the menus. Rotate the jog wheel to scroll up and down

menus and click the jog wheel once to make a selection. Rotating the jog wheel faster gives high-speed

scrolling.

Once you have made a selection, either click the jog wheel to save it or press the Escape button C to

cancel. If you save the selection, Saving... is displayed for 1 second. If you cancel, the menu returns to the

previously saved value. Press the Escape button to step backwards through the menus.

The jog wheel and Escape button continue to function while the Saving... message is displayed.

Status LED on jog wheel

An LED in the center of the jog wheel indicates fixture status depending on the color displayed and DMX

status depending on whether the LED flashes or lights constantly:

• GREEN: All fixture parameters normal.

• AMBER: Warning active (service interval exceeded, for example). If ERROR MODE in the control menus

is set to Normal, the warning message will be shown in the display. If ERROR MODE is set to Silent, the

display must be activated with the jog wheel to display the warning message.

• RED: Error detected. If ERROR MODE is set to Normal, the error message will be shown in the display. If

ERROR MODE is set to Silent, the display must be activated with the jog wheel to display the error

message.

• FLASHING: No DMX signal detected.

• LIGHTS CONSTANTLY: Valid DMX signal detected.

If an error has been detected and the LED is red when the fixture is powered off, the LED will continue to

flash red slowly. This feature allows easy identification of fixtures that require service intervention even if

fixtures are disconnected from power.

Martin flightcases for the MAC III Wash contain a small window through which the status LED is visible.

14 MAC III Wash user manual

Page 15

Battery power

The display and control panel are powered by the MAC III Wash’s onboard battery. This gives access to the

most important functions in the control panel – including DMX addressing – when the fixture is not

connected to AC power.

To activate the display when the fixture is not connected to power, press the Escape button. The display

extinguishes after 10 seconds with no jog wheel activity and the control panel is de-activated after 1 minute

with no jog wheel activity. Press the Escape button again to re-activate.

Mains power indicator

When the fixture is connected to AC mains power, a ‘battery recharging’ icon appears in the display. When

the battery is fully charged, the battery icon is replaced a mains plug icon.

Status indicators in display

The status indicators on the right of the display have the following functions:

• LAMP lights green when the lamp is powered.

• ETHERNET lights green when the MAC III Wash is correctly connected to an Ethernet network (at the

moment there is no provision for direct connection to Ethernet).

• DMX lights green when the MAC III Wash is receiving a valid DMX signal.

• PAN /T ILT lights yellow when pan/tilt limits have been activated (see page 16) and lights orange when

Followspot mode is enabled (see “Followspot mode” on page 24).

Shortcuts pop-up

If you hold the Escape button pressed in for 2 - 3 seconds, a pop-up window with shortcuts to important

commands appears. Select a command and click the jog wheel to activate, or press Escape to cancel.

• RESET resets the whole fixture

• LAMP ON/OFF strikes or douses the lamp.

• ROTATE DISPLAY rotates the MAC III Wash display.

• FOLLOWSPOT MODE calls up the followspot menu.

• EVENT LOG calls up the event log menu.

Settings stored permanently

The following settings are stored permanently in the fixture memory and are not affected by powering the

MAC III Wash off and on or by updating the firmware:

• DMX address

• Fixture ID

• All personality settings (pan/tilt and pan/tilt limit, linked zoom/focus, lamp cooling, fan clean mode,

dimming curve, DMX lamp off, DMX reset, parameter shortcuts, all display settings, error mode)

• Factory settings

• Fixture info (resettable power-on, lamp-on, lamp strikes, and air filter counters)

• All Service settings (adjust, calibration, firmware)

These settings can be returned to factory defaults using the control menus or via DMX.

Setup Wizard

The SETUP WIZARD menu gives quick access to the most frequently required items in the control menus.

DMX address

The DMX address, also known as the start channel, is the first channel used to receive instructions from the

controller. For independent control, each fixture must be assigned its own control channels. If you give two

MAC III Washs the same address, they will behave identically. Address sharing can be useful for diagnostic

purposes and symmetrical control, particularly when combined with the inverse pan and tilt options.

DMX addressing is limited to make it impossible to set the DMX address so high that you are left without

enough control channels for the fixture in the 512 channels available in one DMX universe.

Control panel operations 15

Page 16

DMX address setting

To set the fixture’s DMX address:

1. Press the jog wheel to enter the main menu.

2. Rotate the jog wheel to scroll down to DMX ADDRESS, then click the jog button. Rotate the jog wheel to

scroll to the desired address and click the jog button to save.

3. Press the Escape button to step back to the main menu.

Fixture ID

The MAC III Wash lets you set a four-digit ID number to ease identification of the fixtures in an installation.

When a fixture is powered on for the first time, it displays its DMX address by default. As soon as you set an

ID number other than 0000 in FIXTURE ID, the MAC III Wash will display this ID number by default.

To let you distinguish easily between ID numbers and DMX addresses, the ID number is always displayed

with four digits and DMX address is displayed with between one and three digits.

Personality – tailoring performance

The MAC III Wash provides several options that let you optimize the fixture for different applications in the

PERSONALITY menu:

• The PAN/TILT SETTINGS menu gives three options:

- PAN/TILT CONTROL lets you swap and/or invert pan and tilt and activate the pan and tilt limits you

define in PAN & TILT LIMIT SETTINGS (see below).

- MOVE ON RESET lets you choose if you want pan and tilt to move when the fixture resets or not. Pan

and tilt movement can be a useful visual sign that fixtures in a rig are powering up and resetting.

- PAN & TILT LIMIT SETTINGS lets you define minimum and maximum limits for both pan and tilt

angles, making it possible to install fixtures close to obstacles such as other fixtures with no risk of

collision. Settings are based on the following principles:

Pan range for pan limit purposes runs from 0° to 360° clockwise as seen looking at the fixture from

the bottom of the base towards the yoke, as if the fixture was hanging downwards underneath you.

Tilt range is +134° and -134° either side of 0°, which is the head straight up position with the front

glass pointed directly away from the base.

The light beam points fully forward (the front of the fixture is indicated by the arrows printed under the

base) when pan is set to 90° or 450° and tilt is set to +90°.

Selecting Inside keeps pan and tilt inside the limits you set – i.e. angles define a ‘safe zone’.

Selecting Outside keeps pan and tilt outside the limits you set – i.e. angles define a ‘no-go zone’.

Limits are not activated until the head is panned and tilted into its safe zone or out of its no-go zone.

When pan/tilt limits are active, the PAN/TILT light at the bottom right of the display lights yellow.

16 MAC III Wash user manual

Page 17

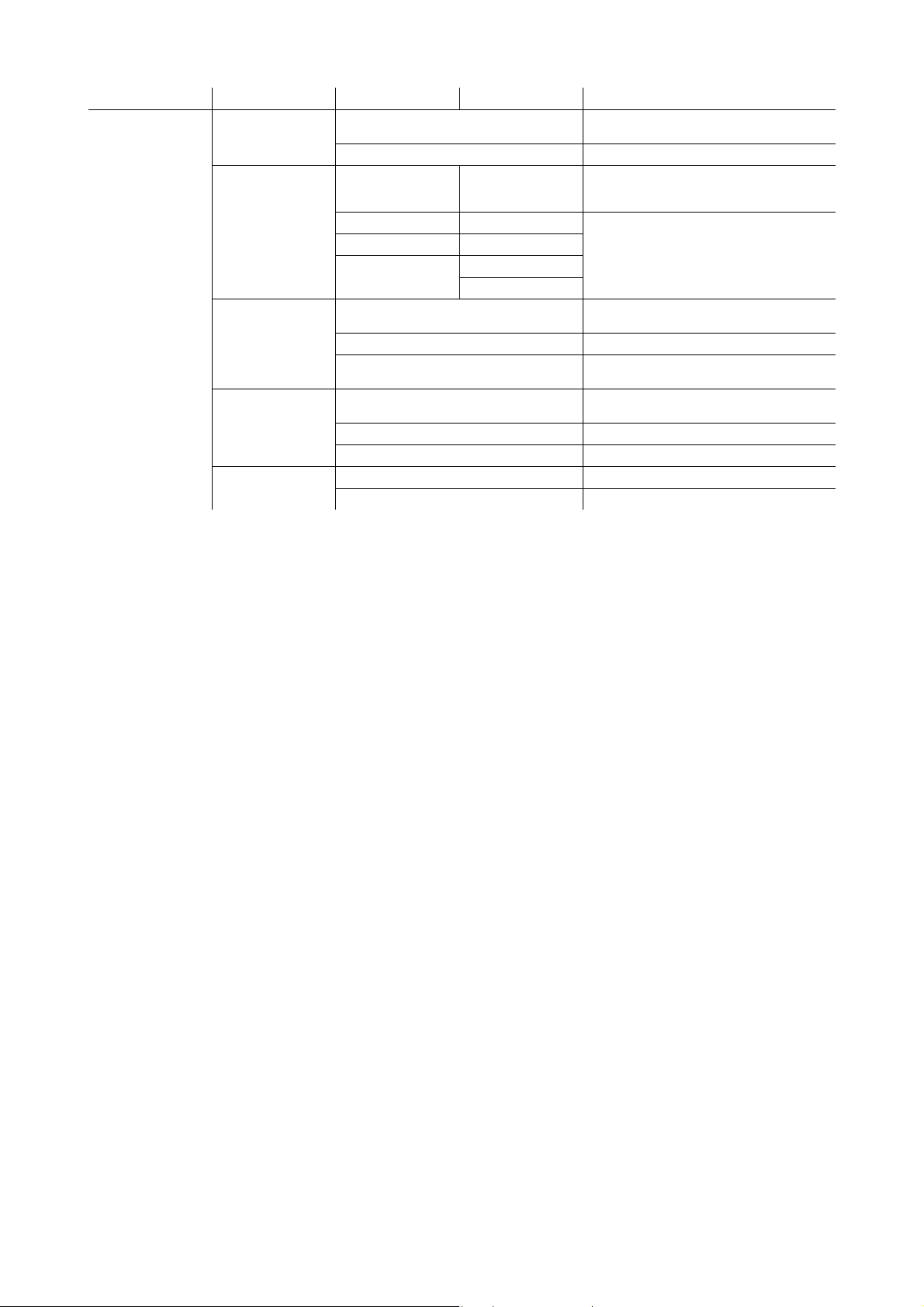

See Figure 10. To limit pan so that it stays inside a safe zone 20° either side of fully forward and limit tilt so

Figure 10: Pan/Tilt limit settings

+72°

+90°

+108°

Tilt safe zone

Inside, min. +72°, max. +108°

Pan safe zone

Inside, min. +70°, max. +110°

Safe zone

+70°

+90°

+110°

Safe zone

that it stays inside a safe zone 18° either side of fully forward, for example:

1. Set PAN MINIMUM to 70°.

2. Set PAN MAXIMUM to 110°.

3. Set TILT MINIMUM to +72°.

4. Set TILT MAXIMUM to +108°.

5. Set P/T LIMIT AREA to Inside.

Important! Regardless of the pan and tilt limits you set, when you power the fixture off, the head will sink under

gravity to the nearest rest position (e.g. with the lens pointing vertically downwards if the fixture is

hanging in a rig, or to one side if the fixture is standing fastened to a horizontal surface). When you

power the fixture on, the head will not move until the fixture receives a pan or tilt command. When a

command is received, if the head’s rest position is outside its pan/tilt limits, the head will move

slowly until it is within its limits. This feature reduces the risk of damage caused by a collision.

Pan and tilt limits can quickly be returned to the factory default setting (all limits at 0°, pan/tilt limits disabled)

by setting DEFAULT LIMIT SETTINGS to On and clicking with the jog wheel to confirm.

• SPEED SETTINGS lets you set PAN & TILT SPEED to Normal, Fast (optimized for speed) or Slow

(optimized for smooth movement – useful in long-throw applications). Likewise, you can set EFFECT

SPEED to Normal, Fast or Slow. You can also set effect speed to Follow P/T speed, in which effects will

always use whatever speed is set for pan and tilt.

• The FANS menu gives the following cooling fan options:

- FAN CLEAN gives three options for automatically clearing dirt from fans:

Off sets fans to normal operation with no fan cleaning function.

Auto sets fans to normal operation, but if a fan error is detected, the fan that has reported an error

speeds up to 100% for a short period and then returns to normal operation. If the fan error is still

detected after three attempts at cleaning, the fan returns to normal operation but continues to report a

fan error. This feature works independently for each of the fans. Attempts at cleaning are reset to zero

if the fixture is reset or if FAN CLEAN MODE is updated.

Forced sets all fans to 100% speed until another FAN CLEAN MODE setting is selected.

This feature does not eliminate the need to inspect and clean cooling fans at regular intervals (see

“Cleaning” on page 36).

FAN MODE allows you to set fans to Always on or Follow lamp off mode, in which fan operation is

-

disabled when the lamp is powered off.

Control panel operations 17

Page 18

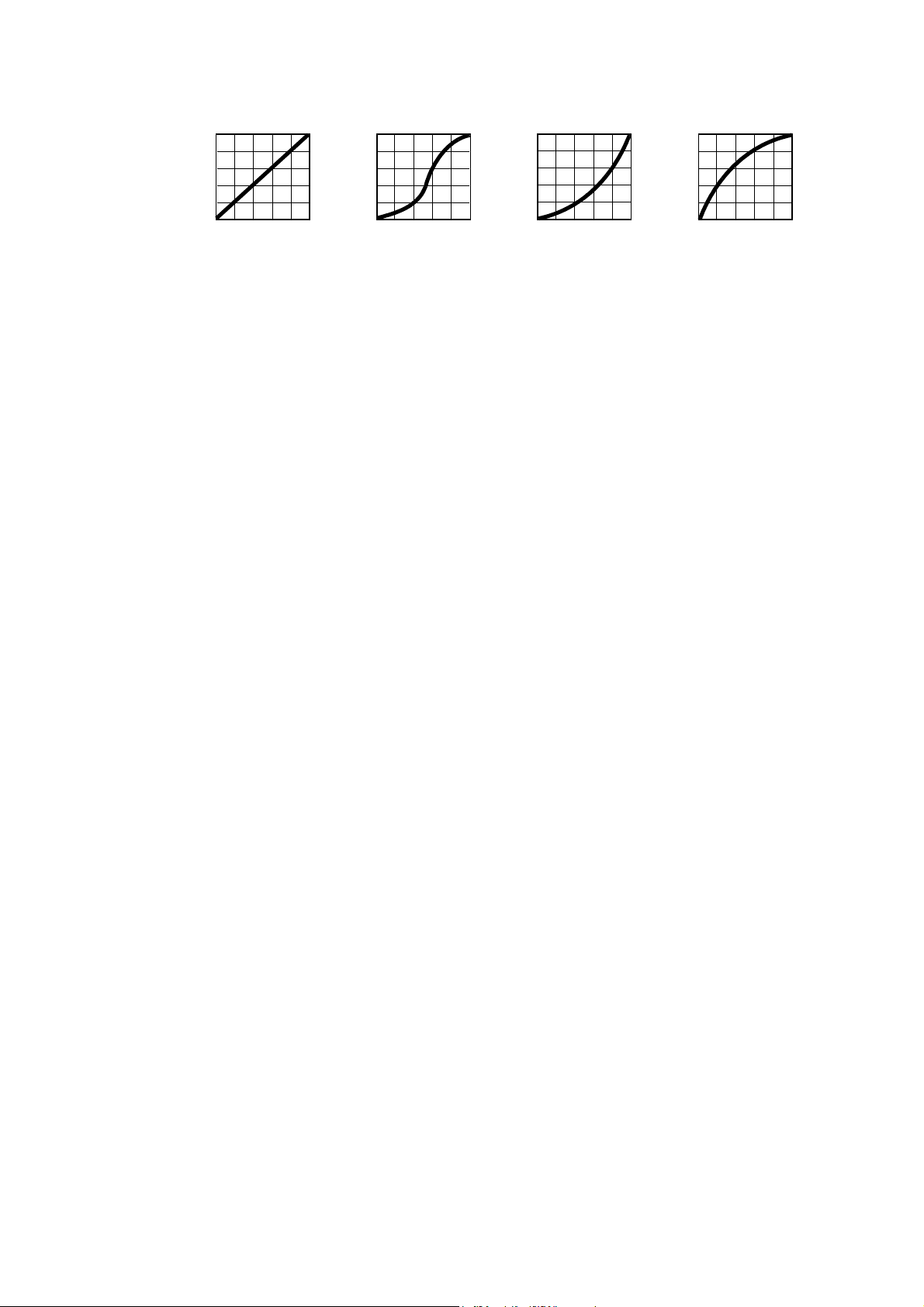

• DIMMING CURVE provides four dimming options (see Figure 11):

Output

DMX %DMX %DMX %DMX %

Output

Output

Output

Optically linear VRMS linear Square law Inverse square law

Figure 11: Dimming curve options

- Optically linear – the increase in light intensity appears to be linear as DMX value is increased.

- VRMS linear (S-curve) – light intensity control is finer at low levels and high levels and coarser at

medium levels. This curve emulates the RMS voltage dimming characteristics of an incandescent lamp

such as the tungsten halogen lamp of the Martin™ MAC TW1™.

- Square law – light intensity control is finer at low levels and coarser at high levels.

- Inverse square law – light intensity control is coarser at low levels and finer at high levels.

• FOCUS TRACKING sets focus to automatically self-adjust when you use the zoom effect (see

“Zoom/focus linking” on page 24).

• FOLLOWSPOT MODE enables pan, tilt, or pan and tilt movement to be unlocked so that the head of the

fixture can be directed by hand using a user-supplied handle (see “Followspot mode” on page 24). In

followspot mode the motors can be applied as a brake to pan, tilt, or both pan and tilt movement to prevent

head movement when the fixture is not “manned”; in this case DMX or menu-based control over pan and

tilt is still disabled.

• AUTOMATIC LAMP ON gives three lamp strike options:

- When set to Off, the lamp remains off until a “lamp on” command is received via DMX.

- When set to On, the lamp strikes automatically after the fixture is powered on.

- When set to DMX, the lamp strikes automatically when the fixture begins to receive DMX data, and

lamp power is shut down 15 minutes after the fixture stops receiving DMX data. Automatic lamp strikes

are staggered to prevent all lamps from striking at once. The delay is determined by the fixture address.

No matter what the AUTOMATIC LAMP ON setting is, the lamp can be struck by sending a lamp on

command via DMX on channel 21.

• DMX LAMP OFF and DMX RESET define whether the lamp can be powered off, or whether fixture or

individual effects can be reset by sending a DMX command on channel 21. If either of these settings are

set to Off, you can override this setting and cut lamp power or reset effects by applying a special

combination of DMX values (see “MAC III Wash DMX protocol” on page 40).

• PARAMETER SHORTCUTS determines whether the color wheel takes the shortest path between two

positions (shortcuts enabled), crossing the open position if necessary, or always avoid the open position

(shortcuts disabled).

• DISPLAY determines whether the display remains on permanently, or goes into sleep mode 2, 5 or 10

minutes after the last movement of the jog wheel or Escape button.

• DISPLAY INTENSITY lets you define the brightness of the backlit graphic display. Select Auto for

automatic adjustment to match the ambient light level, or manually set the intensity to a level from 0% to

100%.

• DISPLAY ROTATION lets you rotate the display manually through 0°, 90°, 180° or 270° so that it can be

read easily no matter how the fixture is oriented. If set to Auto, the MAC III Wash senses its orientation

and rotates the display automatically.

• ERROR MODE enables or disables error warnings. If set to

if the fixture needs to report an error. If set to Silent with LED, the fixture does not light the display with

error warnings but error messages can still be read when the display is activated manually. In both

Normal and Silent with LED modes, the status LED in the jog wheel lights amber to indicate a warning

and red to indicate an error.

Normal, the display is activated and lights up

Factory settings

FACTORY SETTINGS lets you restore the fixture’s default setup options. Effect calibration is not affected,

18 MAC III Wash user manual

so any effects that have been re-calibrated will not be returned to factory calibration settings.

Page 19

Fixture information readouts

The following fixture information can be called up in the display:

• FIRMWARE VERSION displays the currently installed fixture software version.

• POWER ON TIME provides two counters:

- The TOTAL POWER ON counter is not user-resettable and displays total hours powered on since

manufacture.

- The RESETTABLE POWER ON counter is user-resettable and displays the number of hours the fixture

has been powered on since the counter was last reset.

• LAMP ON TIME provides two counters and a user-settable lamp lifetime warning:

- The TOTAL LAMP ON counter is not user-resettable and displays total hours the lamp has been

powered on since manufacture.

- The RESETTABLE LAMP ON counter is user-resettable and displays the number of hours the lamp

has been powered on since the counter was last reset.

- SET TIME ALERT lets you define the number of hours before an LTI M lamp lifetime service warning

appears in the display.

• LAMP STRIKES provides two counters:

- The TOTAL LAMP STRIKES counter is not user-resettable and displays the total number of lamp

strikes since manufacture.

- The RESETTABLE LAMP STRIKES counter is user-resettable and displays the number of lamp strikes

since the counter was last reset.

• AIR FILTERS provides an alert feature for service interventions:

- The RESETTABLE AIR FILTER counter displays the total number of hours the fixture has been

powered on since the alert timer was last cleared.

- SET TIME ALERT lets you set the number of hours from 1 to 750 you want the fixture to be powered on

before a service alert appears in the display. If you set this figure to 0, the time alert is disabled.

- CLEAR RESETTABLE AIR FILTER lets you reset the resettable air filter counter to zero after

completing service work.

• MAC ID displays the fixture’s factory-set MAC (Media Access Control) address.

• SERIAL NUMBER displays the fixture’s factory serial number.

• RDM UID displays the fixture’s factory-set unique ID for identification in RDM systems.

• FAN SPEED provides separate status readouts from the fixture’s cooling fans.

• TEMPERATURE provides a fixture temperature status readout.

• POWER UNIT provides the following readouts:

- MAINS VO LTAGE displays a mains power voltage readout measured at the fixture’s mains power input.

- LAMP VO LTAGE, LAMP CURRENT and LAMP WATTAGE display readouts measured at the fixture’s

lamp terminals.

LAMP STATE gives a lamp status readout.

-

- IGNITER STATE gives an igniter (starter) lamp status readout.

- INTENSITY indicates current lamp intensity.

• EVENT LOG VIEWER lets you view event logs in the fixture’s display panel. See “Event log” on page 31.

DMX signal monitoring

The MAC III Wash provides data on the DMX signal it is receiving in the DMX LIVE menu. This information

can be useful for troubleshooting control problems.

RATE displays the DMX refresh rate in packets per second. Values lower than 10 or higher than 44 may

result in erratic performance, especially when using tracking control.

QUALITY displays the quality of the received DMX data as a percentage of packets received. Values much

below 100 indicate interference, poor connections, or other problems with the serial data link that are the

most common cause of control problems.

START CODE displays the DMX start code. Packets with a start code other than 0 may cause irregular

performance.

The remaining options under DMX LIVE display the DMX values in a range from 0 - 255 that are being

received on each channel, starting with channel 1 (Strobe/shutter).

Control panel operations 19

Page 20

Test sequence

TEST SEQUENCE activates effects in sequence, allowing you to test them quickly without a DMX

controller:

ACTION lets you start, pause, and stop the sequence.

REPEAT sets the current test to repeat when finished.

Status readouts for the current test sequence are displayed below the ACTION and REPEAT commands.

Manual control

The MANUAL CONTROL menu lets you reset the fixture, strike or douse the lamp, apply effects and move

pan and tilt manually.

Service

The SERVICE menu is covered under “Service and maintenance” on page 30.

20 MAC III Wash user manual

Page 21

Adjusting settings via DMX

Certain fixture settings and parameters can be adjusted from the DMX controller on channels 20 and 21.

Commands sent via DMX override any settings entered in the fixture’s onboard control menus. However, to

reset the fixture, reset individual effects or cut power to the lamp via DMX if DMX Reset or DMX Lamp Off

are disabled in the control menus, certain conditions must be met (see the notes in the DMX Protocol table

in this manual).

Note also that a lamp off command sent by DMX must be applied for 5 seconds before it executes.

These requirements are a safeguard to help you avoid resetting the fixture or powering the lamp off

accidentally.

Resetting

Either the entire fixture or individual effects can be reset to their initial positions. Resetting individual effects

can allow on-the-fly recovery if an effect loses its correct position, for example, without having to reset the

entire fixture.

Lamp on / off

The lamp can be struck and doused from the DMX controller.

A peak of electric current that is many times the operating current is drawn for a fraction of a second when

striking a discharge lamp. Striking many lamps at once may cause a voltage drop large enough to prevent

lamps from striking or draw enough current to trip electronic circuit breakers. If sending lamp-on commands

to multiple fixtures, program a sequence that strikes lamps one at a time.

Adjusting lamp power

If full light output is not required, the power supplied to the lamp by the ballast can be reduced. Reducing

lamp power reduces heat output and therefore reduces noise from the cooling fans. It also reduces power

consumption, and it helps reduce the gradual fall in output that occurs over the lifetime of a discharge lamp.

Lamp power can be to set to 1500 W (full power), 1200 W, 1100 W, 1000 W or 900 W via DMX using the

ballast output control commands available on channel 21.

If the shutter and/or dimmer are closed for longer than 10 seconds, lamp power is automatically switched to

900 W. When the shutter is opened again, the lamp returns to full power.

Illuminating the display

The fixture’s display panel can be brought out of sleep mode with a DMX command. This makes it possible

to read the fixture’s DMX address while the fixture is installed in the rig.

After being illuminated in this way, the display will return to sleep mode according to the setting entered in

the onboard control menus.

Control menu setting overrides

The following fixture settings can be adjusted via DMX, overriding the settings entered in the onboard

control menus. See under “Control panel operations” on page 14 for details of these parameters.

• Dimming curve

• Parameter shortcuts

• Zoom/focus linking

• Pan/tilt limits

• Calibration offsets

Adjusting settings via DMX 21

Page 22

Defining calibration offsets via DMX

255

192

128

64

0

+5%

+2.5%

0

-2.5%

-5%

Effect channel

value

Adjustment

value

Figure 12: Offset adjustment values

The ”Fixture adjustments/calibration (menu override)”

DMX channel allows effect offsets to be adjusted and

stored in the fixture from the DMX controller.

To adjust an effect offset:

1. Set the effect to a DMX value from 0 to 255 on its own

DMX channel (for example, set Cyan to 192 on channel

4).

2. Send a ‘Store’ command for the effect on the Fixture

Adjustment/Calibration channel.

The MAC III Wash now reads the value on the effect

channel (192 for Cyan in the example above), translates it

to an adjustment value of between -5% and +5% as shown

in Figure 12 (+2.5% Cyan adjustment in the example

above) and stores that offset in memory.

See ”Fixture adjustments/calibration (menu override)” on

page 43 for details of the offsets that can be adjusted

using this method.

Effect offsets stored in memory are not affected by

powering the fixture off and on or by updating the fixture

software. To return all offsets to their factory defaults, send

a DMX value from 245 to 249 on the ”Fixture

adjustments/calibration (menu override)” channel 21 or

apply LOAD FACTORY SETTINGS in the FAC TORY

SETTINGS menu in the fixture’s control panel.

22 MAC III Wash user manual

Page 23

Effects

Figure 13: Color wheel

1

2

3

4

5

6

7

Wheel seen from

lamp side

Color filters

1. Blue 101 - P/N 46404500

2. Green 203 - P/N 46404510

3. Orange 311 - P/N 46404520

4. NB half minus green - P/N 46404541

5. Yellow 610 - P/N 46404530

6. Deep blue (Congo) - P/N 46404550

7. Red 310 - P/N 46404560

8. Open

This section gives details of the effects that can be controlled via DMX. See “MAC III Wash DMX protocol”

on page 40 for details of the channels used to control them.

Where fine control is available, the main control channel sets the first 8 bits (the most significant byte or

MSB), and the fine channels set the second 8 bits (the least significant byte or LSB) of the 16-bit control

byte. In other words, the fine channel works within the position set by the coarse channel.

Shutter and strobe effects

The MAC III Wash’s mechanical shutter provides regular or random strobe and pulse effects with variable

speed from 2 Hz to 10 Hz approximately.

To ensure total blackout, the mechanical dimmer also deploys if the shutter is closed for more than 5

seconds.

Dimming

The MAC III Wash’s mechanical dimmer provides smooth, high-resolution 100 percent fading. 16-bit fine

control of the dimmer is available.

To ensure total blackout, the mechanical shutter also deploys by default if the dimmer is reduced to 0% for

more than 5 seconds (this function can be disabled under

menu).

SHUTTER BLACKOUT in the PERSONALITY control

Cyan, Magenta, Yellow and CTO

The amount of cyan, magenta, yellow and CTO (color temperature control orange) applied to the MAC III

Wash’s light output can be varied from zero to 100%. Color temperature can be varied from 6000 - 3200 K.

Color wheel

The MAC III Wash features a color wheel with 7 interchangeable dichroic color filters and an open position.

Color filters can be applied as split colors or in full-color steps. The color wheel can also be scrolled

continuously, applying the color filters in sequence with control of color wheel speed and direction. Color

filters can also be applied at random at fast, medium or slow speed.

Effects 23

Page 24

The MAC III Wash and MAC III AirFX use the same color wheel, but the wheel is installed facing in opposite

directions in the two fixtures. The fixtures’ firmware takes this difference into account, so that color filter

selection via DMX is identical in the two fixtures.

Internal barndoors

The internal barndoors in the MAC III Wash comprise a twin-blade system with independent control of each

blade. The entire barndoor assembly can be rotated through 110°. The width of the aperture obtained with

the barndoors can be modified using the iris. Using barndoors opening and rotation in combination with the

iris gives full control of beam shape and angle.

Iris

The iris can be set to a static diameter, or regular and random pulsing effects can be set with variable

speed.

Focus and zoom

The focus lens focuses the beam from approximately 2 meters (6.5 feet) to infinity.

The separate zoom lens varies the focused beam angle from approximately 11.5° to 55° with the standard

lens installed.

Zoom/focus linking

Focus can be linked to zoom so that it automatically adjusts to match changes in zoom angle.

Linked zoom/focus works within 3 distance ranges:

• Near (5 - 10 meters)

• Medium (10 - 20 meters)

• Far (20 meters - infinity)

To link zoom and focus, select a distance range using the Fixture Control/Settings DMX channel or FOCUS

TRACKING in the PERSONALITY menu in the control panel. Then adjust focus to obtain the required

degree of sharpness. Linking is now enabled and focus will auto-adjust.

Pan and tilt

16-bit pan and tilt control is available on channels 17 plus 18 (pan) and 19 plus 20 (tilt).

Maximum and minimum pan and tilt limits can be set using the control panel (see “Personality – tailoring

performance” on page 16) and via DMX.

Followspot mode

The MAC III Wash features a followspot mode in which the fixture ignores any pan, tilt, or pan and tilt

commands sent via DMX or the control menu, releasing the head for use as a followspot.

In followspot mode, the pan and/or tilt motors can be engaged or disengaged using commands in the

control menu. If motors are engaged, they act as a brake to pan, tilt, or both pan and tilt movement to

prevent the head from moving when it is not being held in place, but DMX or menu-based control over pan

and tilt is still disabled (see “Personality – tailoring performance” on page 16 and “Control panel menus” on

page 44).

Followspot handles can be custom-made by the user to suit the user’s own preferences and requirements.

Followspot handles safety precautions

Warning! It is the user’s responsibility to ensure that the followspot handles and any mounting

brackets are safe and that the fixture is kept in followspot mode at all times while handles are

installed to avoid collision between the followspot handles and the yoke.

Warning! Intermediate brackets for permanent mounting on the back of the MAC III Wash head must

be constructed so that they will not touch the yoke at any point in the head’s tilt range!

24 MAC III Wash user manual

Page 25

Warning! Screws used to fasten any item to the rear of the head may only be fastened into the holes

Figure 14: Dimensions for followspot handles

(arrowed in Figure 14) provided in the rear head cover. Do not attempt to fasten any item to the rear

of the head by any other method. Screws must not protrude more than 15 mm (0.6 inches) into the

rear head cover, or there is a danger that they may damage electrical insulation inside the head and

create a risk of serious or lethal electric shock for the operator.

Warning! Followspot handles must be thermally insulated so that it is impossible for the operator to

suffer discomfort or a burn injury.

Followspot handles use and construction

The MAC III Wash’s rear head cover is a magnesium alloy casting. Magnesium alloy is prone to galvanic

corrosion when steel screws are fastened into it and has a relatively low resistance to mechanical wear on

threads. Self-tapping screws fastened into magnesium alloy should be left there permanently.

If you are going to switch between using the MAC III Wash as a manually-controlled followspot and as a

DMX-controlled moving head from time to time, you will need to install and remove followspot handles. In

this case, we recommend that you fabricate two intermediate mounting brackets in a suitable material for

repeated installation and removal of screws, fasten the brackets permanently to the rear head cover, and

use these brackets as mounting points for the followspot handles.

If followspot handles are going to be installed permanently, there is no need for intermediate brackets.

The design of the brackets and followspot handles is left up to the user to match user requirements, but the

following points must be noted:

• Intermediate mounting brackets must be as light as possible in order to minimize the effect of their extra

weight on the balance of the head. It may be best to make them in aluminium.

• Four holes (arrowed in Figure 14) are

provided in the fixture’s rear head cover

for fastening followspot handle

mounting brackets. Use regular M6

machine screws for attachment but

ensure that screws are the correct

length: the portion of the screw that

goes into the rear head cover must have

a length of between 12 mm (0.47 in.)

and 15 mm (0.6 in.).

• The rear head cover becomes very hot.

Ensure that handles are insulated well

enough to avoid discomfort or burn

injuries for the followspot operator.

• A handle must only be fitted after

followspot mode is enabled and tilt is

performed manually. Always remove

any handle that is fitted before

disengaging followspot mode.

Besides being constructed so that they

will not foul the yoke at any point in the tilt

range, mounting brackets must match the

dimensions shown in Figure 14.

Dimensions in Figure 14 are shown in

millimeters:

• 216.8 mm = 8.53 in.

• 230.7 mm = 9.08 in.

• 78.9 mm = 3.11 in.

Effects 25

Page 26

RDM

The MAC III Wash can communicate using RDM (Remote Device Management) in accordance with ESTA’s

American National Standard E1.20.

RDM is a bi-directional communications protocol for use in DMX512 control systems, it is the open standard

for DMX512 device configuration and status monitoring.

The RDM protocol allows data packets to be inserted into a DMX512 data stream without adversely

affecting existing non-RDM equipment. The RDM protocol allows a console or dedicated RDM controller to

send commands to and receive messages from specific fixtures.

RDM ID

Each MAC III Wash has an RDM UID that makes it uniquely addressable. This can be found in the control

panel menus under FIXTURE INFORMATION. RDM UID shows the fixture’s factory-set unique ID for

identification in RDM systems.

RDM communication

The MAC III Wash will respond to:

1. ”MAC III Wash supported standard commands” (see page 27).

2. ”MAC III Wash supported manufacturer specific commands” (see page 28).

26 MAC III Wash user manual

Page 27

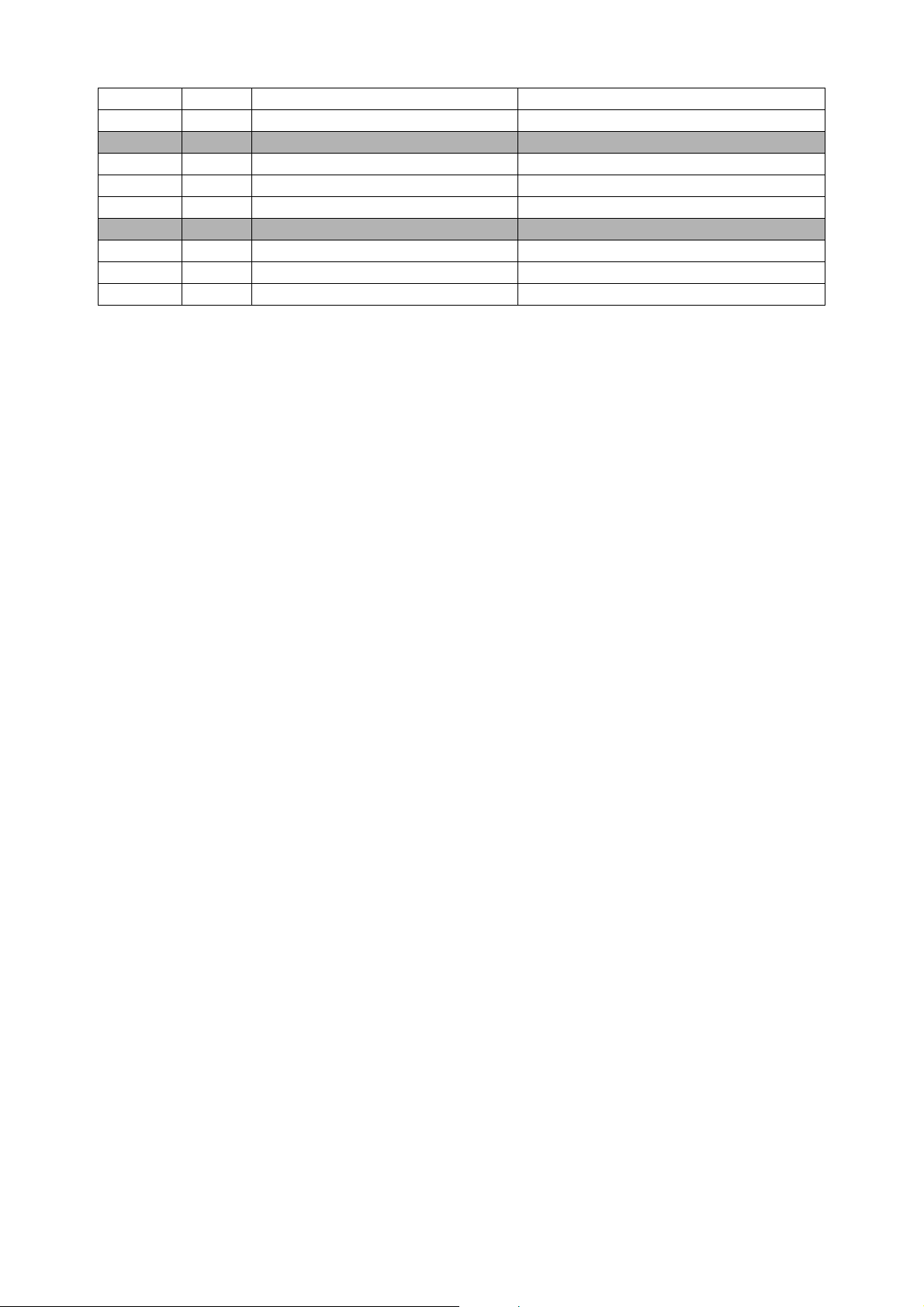

MAC III Wash supported standard commands

GET

allowed

QUEUED_MESSAGE

STATUS_MESSAGES

STATUS_ID_DESCRIPTION

SUPPORTED_PARAMETERS

PARAMETER_DESCRIPTION

DEVICE_INFO

DEVICE_MODEL_DESCRIPTION

MANUFACTURER_LABEL

DEVICE_LABEL

FACTORY_DEFAULTS

SOFTWARE_VERSION_LABEL

DMX_PERSONALITY

DMX_PERSONALITY_DESCRIPTION

DMX_START_ADDRESS

SLOT_DESCRIPTION

SENSOR_DEFINITION

SENSOR_VALUE

DEVICE_HOURS

LAMP_HOURS

LAMP_STRIKES

LAMP_STATE

LAMP_ON_MODE

DEVICE_POWER_CYCLES

DISPLAY_INVERT

DISPLAY_LEVEL

PAN_INVERT

TILT_INVERT

PA N_ T I LT _S WA P

IDENTIFY_DEVICE

PERFORM_SELFTEST

SELF_TEST_DESCRIPTION

SET

allowed RDM parameter ID’s (slot 21-22) Notes

Category – Network Management

DISC_UNIQUE_BRANCH

DISC_MUTE

DISC_UN_MUTE

Category - Status Collection

CLEAR_STATUS_ID

Category - RDM Information

Category – Product Information

Category - DMX512 Setup

Category – Sensors See “RDM accessible onboard sensors” on page 28

Category – Dimmer Settings Reserved for future use

Category – Power/Lamp Settings

Category - Display Settings

Category – Configuration

Category – Control

RESET_DEVICE

RDM 27

Page 28

RDM accessible onboard sensors

The following onboard sensors are RDM accessible:

LAMP R FAN

LAMP L FAN

BOTTOM FAN

FAN SPEED

TEMPERATURE

POWER UNIT

CMY FAN

TOP FAN

MAINBOARD FAN

POWER FAN 1

POWER FAN 2

UI PCB

CHARGER PCB

BATTERY

FAN PCB

CMY PCB

ZOOM FOCUS PCB

PAN/ T I LT PC B

POWER UNIT PCB

POWER UNIT CAPACITOR

MAINS VOLTAGE

LAMP VOLTAGE

LAMP CURRENT

LAMP WATTAGE

MAC III Wash supported manufacturer specific commands

GET

allowed

DMX_LAMP_OFF

DMX_RESET

EFFECT_SPEED

EFFECT_SHORTCUTS

LAMP_HOUR_WARNING_HOURS Data range is 0 - 750 hours

AIR_FILTER_HOUR Data range is 0 - 750 hours

AIR_FILTER _HOUR_WARNING_HOURS Data range is 0 - 750 hours

DIMMER_CURVE

FOCUS_TRACKING

DISPLAY_AUTO_OFF

PAN_TILT_SPEED

PAN_TILT_MOVE_ON_RESET

PAN_TILT_LIMITATION

PAN_LIMITATION_MINIMUM

PA N_ L I M ITAT I O N_ M A XI M U M

TILT_LIMITATION_MINIMUM

TILT_LIMITATION_MAXIMUM

PAN_TILT_LIMITATION_AREA

FOLLOW_SPOT_MODE

SET

allowed RDM parameter ID’s (slot 21-22) Notes

Category – DMX protocol settings

Fixture behavioral settings

Fixture pan/tilt settings

Fixture followspot settings

FOLLOW_SPOT_MODE_LOCK_TOGGLE

28 MAC III Wash user manual

Page 29

FOLLOW_SPOT_MODE _LOCK_PAN

FOLLOW_SPOT_MODE _LOCK_TILT

Fixture cooling settings

LAMP_COOLING

FAN_CLEAN

FAN_MODE

Fixture other settings

SERIAL_NUMBER

LICENSE_KEY

EVENT_LOG_USER_EVENT_TRIGGER

RDM 29

Page 30

Service and maintenance

Figure 15: Tilt lock

Warning! Disconnect the fixture from power and allow to cool for 2 hours 45 minutes before

removing any cover.

Important! Excessive dust, smoke fluid, and particulate buildup degrades performance, causes

overheating and will damage the fixture. Damage caused by inadequate maintenance is not covered

by the warranty.

This section lists service and maintenance operations that may be carried out by the user. Refer any

operation that is not described here to a qualified Martin technician.

The MAC III Wash requires routine cleaning. The schedule depends heavily on the operating environment.

It is essential to follow the cleaning guidelines given later in this section.

Tilt lock

Important! Release the tilt lock before

operating the fixture.

The tilt position of the head can

be locked at various angles for

service. Push the lock in

towards the yoke in one

direction to lock the head and

back in from the other side to

unlock the head.

There is no pan lock on the

MAC III Wash.

Important! Release the tilt lock before

packing the fixture in the

flightcase.

Service utilities

The SERVICE menu in the main menu provides utilities for technicians rigging or servicing the fixture:

• PAN/TILT FEEDBACK lets you disable feedback to the fixture software from the pan, tilt and effects

positioning systems. If feedback is set to On and a pan, tilt or effect position error is detected, the shutter

closes and the effect resets. This feature can be disabled by setting feedback to Off.

The Off setting is not saved when the fixture is powered off, and the system will be re-enabled the next

time the fixture starts. If a pan/tilt position error occurs and the system cannot correct pan/tilt position

within 10 seconds, feedback is automatically disabled.

• ADJUST is for use at the factory and by authorized Martin Service technicians only. This menu allows

dimmer, shutter, pan and tilt positions to be adjusted after replacement of components, etc. To adjust the

default positions of all the MAC III Wash’s effects, use the CALIBRATION menu instead.

Important! Do not enter the ADJUST menu without service documentation from Martin.

• CALIBRATION sets effects to their factory default positions or lets you set new default positions for

calibration purposes. See ”Calibration” later in this chapter for full details.

• UPDATE FIRMWARE, updates the firmware (fixture software). For a detailed guide to updating the

firmware, see ”Software installation” later in this chapter.

• EVENT LOG gives access to the fixture’s log. See next section.

30 MAC III Wash user manual

Page 31

Event log

The MAC III Wash monitors performance, any errors or warnings, temperatures, etc. and stores data in an

ongoing service event log that can be viewed in the fixture’s display or downloaded to a USB memory

device and viewed on a PC.

Power cycle reports are created automatically each time the fixture is powered up. The fixture stores up to

25 power cycle reports in memory. If the memory is full, the oldest report is deleted each time a new report

is generated.

A power cycle report lists three types of data:

1. General data, settings 2. Events 3. Dynamic Content

General data, settings displays fixture information and lists current settings.

Events is only displayed if any warnings, errors or changes in settings occur, and lists these with the

amount of time that has passed since they occurred.

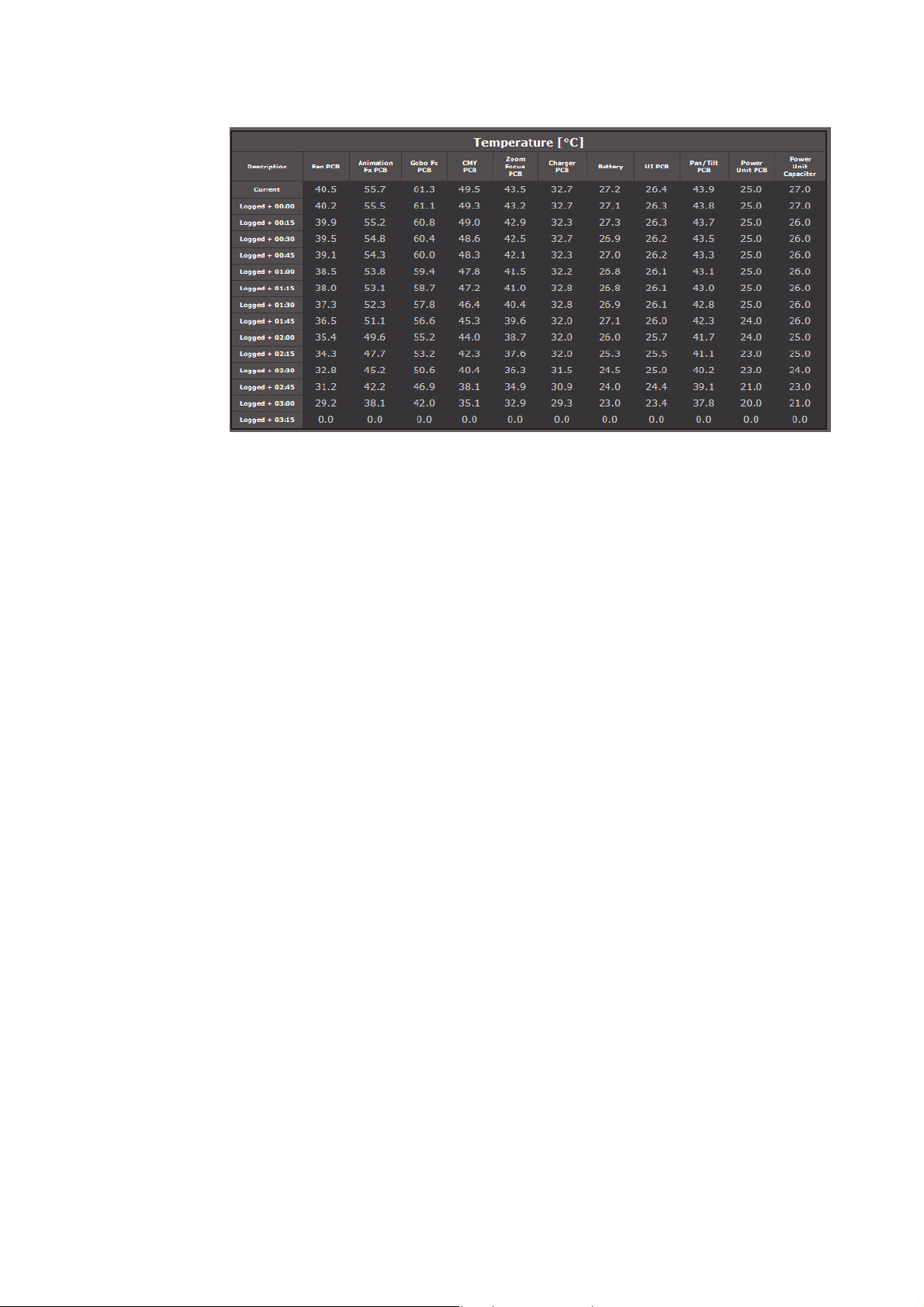

Dynamic content displays technical data for the fixture that is intended to help troubleshooting. It is only

displayed if warnings or errors are listed in the Events section. Dynamic content is updated automatically

with current data — and the old data is saved to the event log — every 15 minutes for up to 10 hours. The

oldest data is then replaced by new data. If an error or warning occurs, data is updated immediately.

Dynamic content can also be updated manually. This can be useful if a fixture does not behave as expected,

for example, but the fixture is not showing an error or a warning. the user can check that the DMX start code

is zero to eliminate poor data transmission as a possible cause of the problem. To renew the dynamic

content in the current power cycle report with the current data:

•select SERVICE

• send the RDM command EVENT_LOG_USER_EVENT_TRIGGER.

To delete all previous power cycle reports in the event log from memory, select SERVICE → EVENT LOG →

Clean Event Log in the control panel.

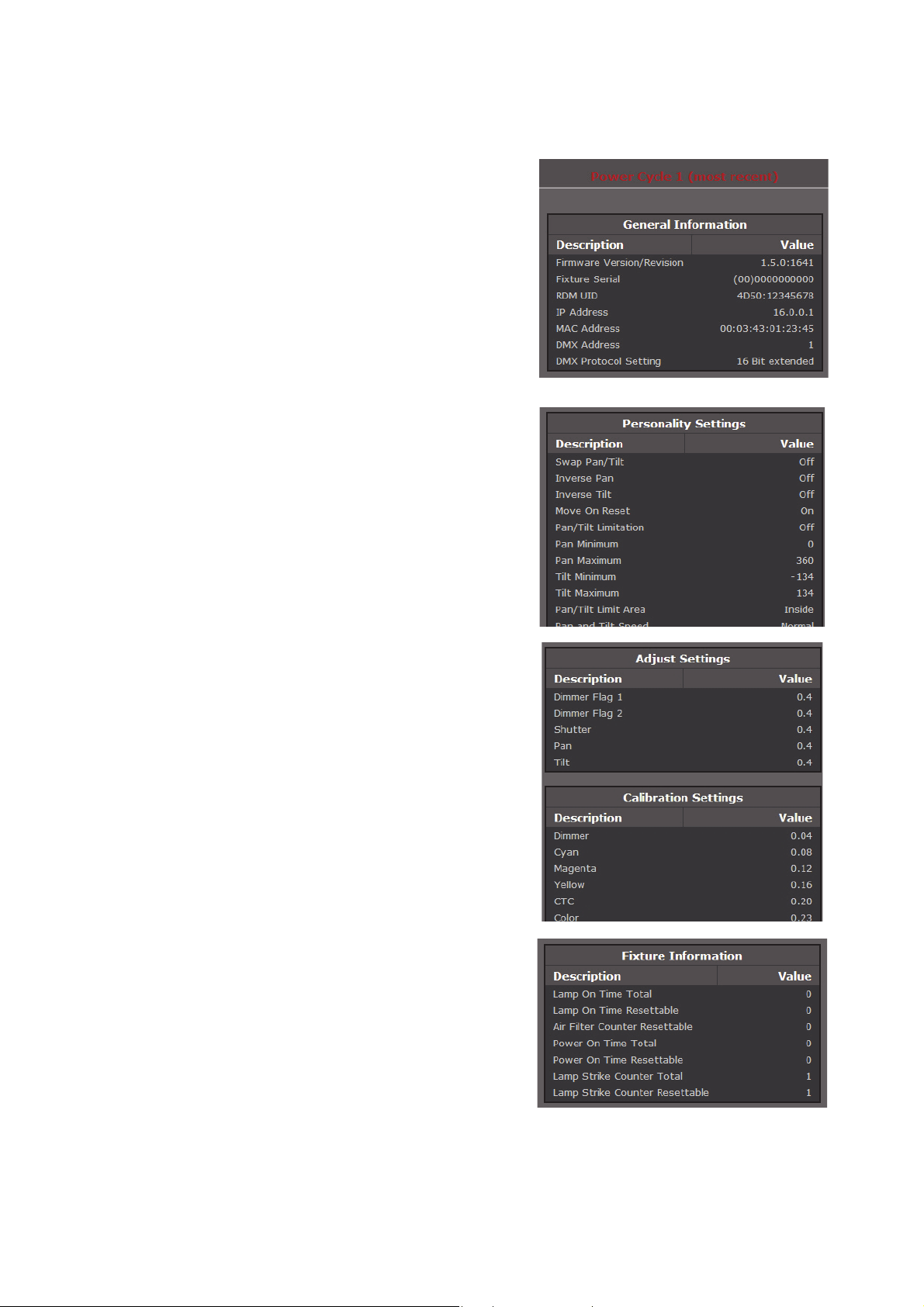

General Information

Personality Settings

Adjust Settings

Calibration Settings

Fixture Information

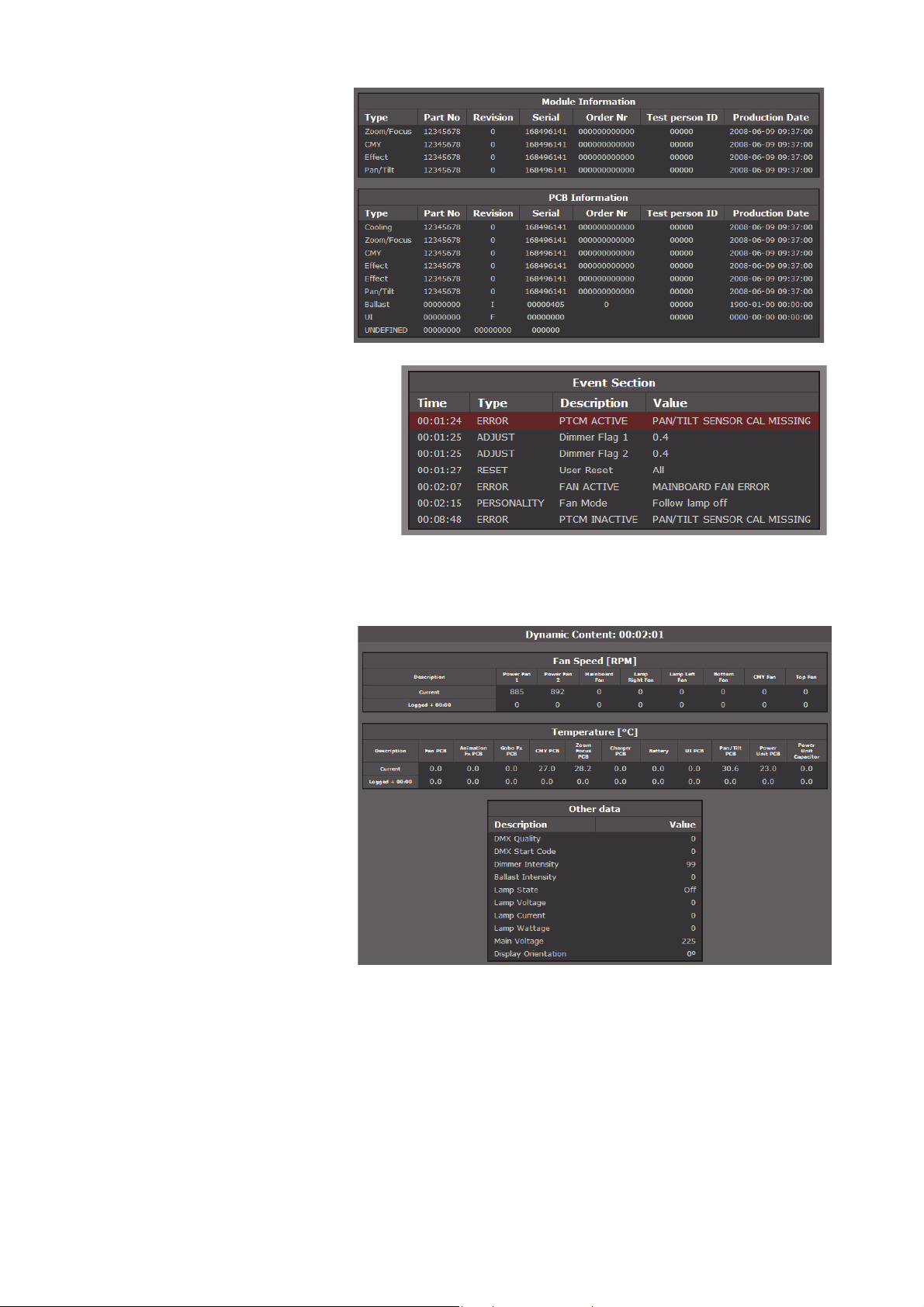

Module Information

PCB Information

→ EVENT LOG → EVENT LOG TRIGGER in the control panel, or

Errors, warnings, changes in

settings

Fan speeds

Temperatures

Other data

Viewing the event log in the fixture’s display panel

To view the event log in the fixture’s display panel, select FIXTURE INFORMATION → EVENT LOG

VIEWER in the control panel.

The EVENT LOG VIEWER displays all the power cycle reports in memory and supplementary information

about any event you scroll to. Use the jog wheel to scroll through the power cycle reports. As you scroll and

highlight each event, details of the event are shown at the bottom of the display:

• TIME gives the time after power up that the event occurred.

• DESCRIPTION gives type of event.

• VALU E gives either the value of a new personality setting (e.g. On/Off) or the long description of an error

code (e.g. FOER = focus error).

Viewing power cycle reports on a PC

To view the current and most recent power cycle reports on a PC:

1. Insert a USB memory device in the fixture’s USB port to open the USB device pop-up window.

2. Select Download Event Log and wait for the log file to be saved to the USB device.

3. Remove the USB memory device, and carry out this procedure with other fixtures if required.

4. Connect the USB memory device to a PC. Logs are stored in the root directory of the memory device in

a folder called EVENT LOGS MAC III SERIES using the naming convention LOG MACIII

XXXXXXXXXX.xml (where XXXXXXXXXX is the serial number of the fixture). The XML files can be

viewed using any web browser that supports XSLT 1.0 such as Internet Explorer 6, Firefox 3, Google

Chrome 1, Opera 9, Apple Safari 3 or later versions.

5. Double-click on the event log to open it in your web browser.

Service and maintenance 31

Page 32

Event log structure when viewed in a web browser

The effects in the example screenshots below may differ slightly from the effects in the MAC III Wash.

The title Power Cycle is displayed in red if that power cycle report includes an error.

Event log XML files are divided into boxes:

• General information lists the most important

information held by the fixture.

• Personality Settings lists the fixture’s settings at

power up.

• Adjustment Settings displays the fixture’s factory

adjustment settings at power up. These settings

should only be changed by Martin Service or its

authorized agents.

• Calibration Settings displays the fixture’s calibration

settings at power up. These settings can be changed

by the user (see ”Calibration” on page 34).

• Fixture Information displays data from the fixture’s

timers when it was last powered up.

32 MAC III Wash user manual

Page 33