Page 1

MAC 300

user manual

Page 2

table of

CONTENTS

Introduction ..........................................................................................................3

Lamp Installation..................................................................................................5

AC Power Connection..........................................................................................6

Data Connectio n............. ... .. ............................. ............... ............................. ........7

Rigging...... ... .. ............................. ............... ............................. ............... ...............8

Fixture Settings ....................................................................................................9

Operation ............................................................................................................15

Basic Service ......................................................................................................17

Troubleshooting.................................................................................................21

DMX Protocol.............. ................ ............................ ................ ............................22

Error Messages ..................................................................................................24

PCB Layout........................... .. .. ................................................................. .. .. .. .. .25

Accessories.............................................. .. .. .. ................................ .. .. .. .. .. ..........26

Specifications.....................................................................................................27

©1999 - 2000 Martin Professional A/S, Denmark.

All rights reserved. No part of this manual may be

reproduced, in any form or by any means, without

permission in writing from Martin Professional A/S,

Denmark.

Printed in Denmark.

P/N 35000075, Rev. C.

Page 3

3

Introduction

section 1

INTRODUCTION

Thank you for selecting the Martin MAC 300. The MAC 300 is an automated yoke-mounted Fresnel washlight

employing a 250 wa tt discharge lamp. It prov ides cyan, magenta, an d yellow (CMY) color mi xing, separate color

wheel with 6 replaceable d ichro ic fi lters, variab le fro st, strobe effects, fu ll-range dimm ing, and acc urate 16-b it mov ement. Efficient optics , attractiv e design, mo dular const ruction and nu merous other f eatures make the M AC 300 well

suited for any lighting application calling for color mixing and soft focus in a 250 watt fixture.

MAC 300 safety information

WARNING!

This product is for professional use only. It is not for household use.

This product presents risks of lethal or severe injury due to fire and heat, electric shock, ultraviolet radiation, lamp

explosion, and fal ls. Read this manual before powering or installing the fixture, follow the safety precautions listed

below and observe all warnings in this manual and printed on the fixture. If you have questions about how to operate

the fixture safely, please contact your Martin dealer or call the Martin 24-hour service hotline at +45 70 200 201.

To protect yourself and others from electric shock

• Disconnect the fixture from AC power before removing or installing the lamp, fuses, or any part, and when not in

use.

• Always ground (earth) the fixture electrically.

• Use only a source of AC power that complies with local building and electrica l codes and has both overload and

ground-fault protection.

• Do not expose the fix tu re to ra in or moisture.

• Refer any service operation not des cribed in this manual to a qualified techni cian.

To protect yourself and others from UV radiat ion and lamp explosion

• Never op er a te the fixture with missing or dam aged lenses and/ or covers.

• When replacing the lamp, allow the fixture to cool for at least 5 minutes befo re opening the fixture or removi ng the

lamp. Protect your hands and eyes with gloves and safety glasses.

• Do not stare directly into the light. Never look at an exposed lamp while it is lit.

• Replace the lamp if it becomes defective or worn out, or before usage exceeds 125 percent of the rated average life.

To protect yourself and others from burns and fire

• Never attempt to bypass the thermostatic switch or fuses. Always replace defective fuses with ones of the specified

type and rating.

• Keep all combustible materials (for example fab r ic, wood, paper) at least 0.4 meters (16 inches) away from the fixture. Keep flammable materials well away from the fixture.

• Do not illuminate surfaces within 0.4 meters (16 inches) of the fixture.

• Provide a minimum clearance of 0.1 meters (4 inches) around fans and air vents.

• Never place filters or other materials over the lens.

• The exterior of the fixture can reach temperatures up to 150° C (302° F). Allow the fixture to cool for at least 5 minutes before handling.

• Do not modify the fixture or install other than genuine Martin parts.

• Do not operate the fixture if the ambient temperature (Ta) exceeds 40° C (104° F).

To protect yourself and others from injury due to falls

• When suspending the fixture above ground level, verify that the structure can hold at least 10 times the weight of all

installed devices.

• Verify that all external covers and rigging hardware are securely fasten ed and use an ap proved means of seco nda ry

attachment such as a safety cable.

• Block access below the work area whenever installing or removing the fixture.

Page 4

Introduction

4

Unpacking

The MAC 300 comes with:

• 1 1/4-turn clamp mounting bracket

• 1 5-meter, 3-pin shielded XLR control cable

• 1 3-meter, 3-wire IEC power cable

• 1 user manual

The packing material is carefully designed to protect the fixture during shipment - always use it or a custom flight case

to transport the fixture.

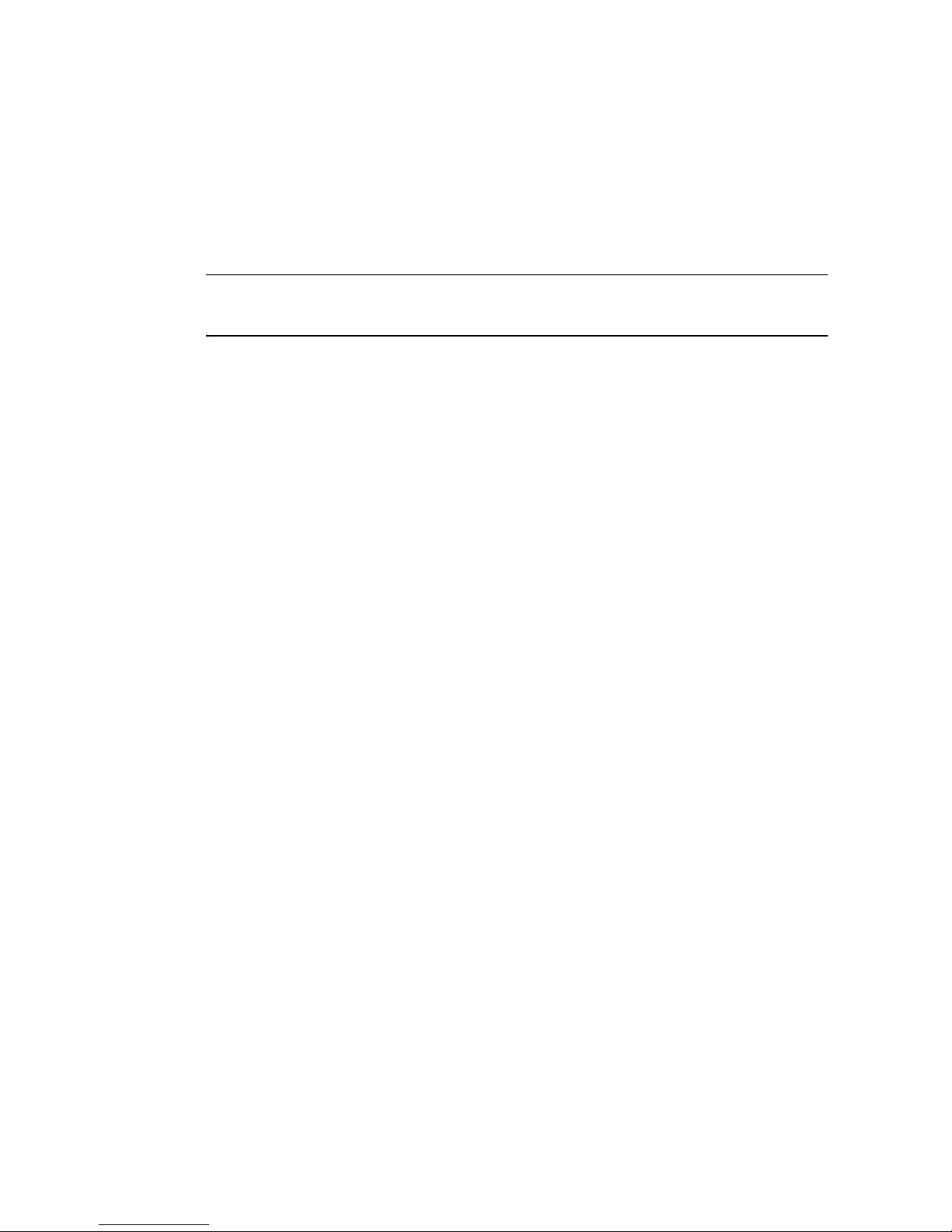

Main dimensions

Page 5

5

Lamp Installation

section 2

LAMP INSTALLATION

This section describes how to install a lamp.

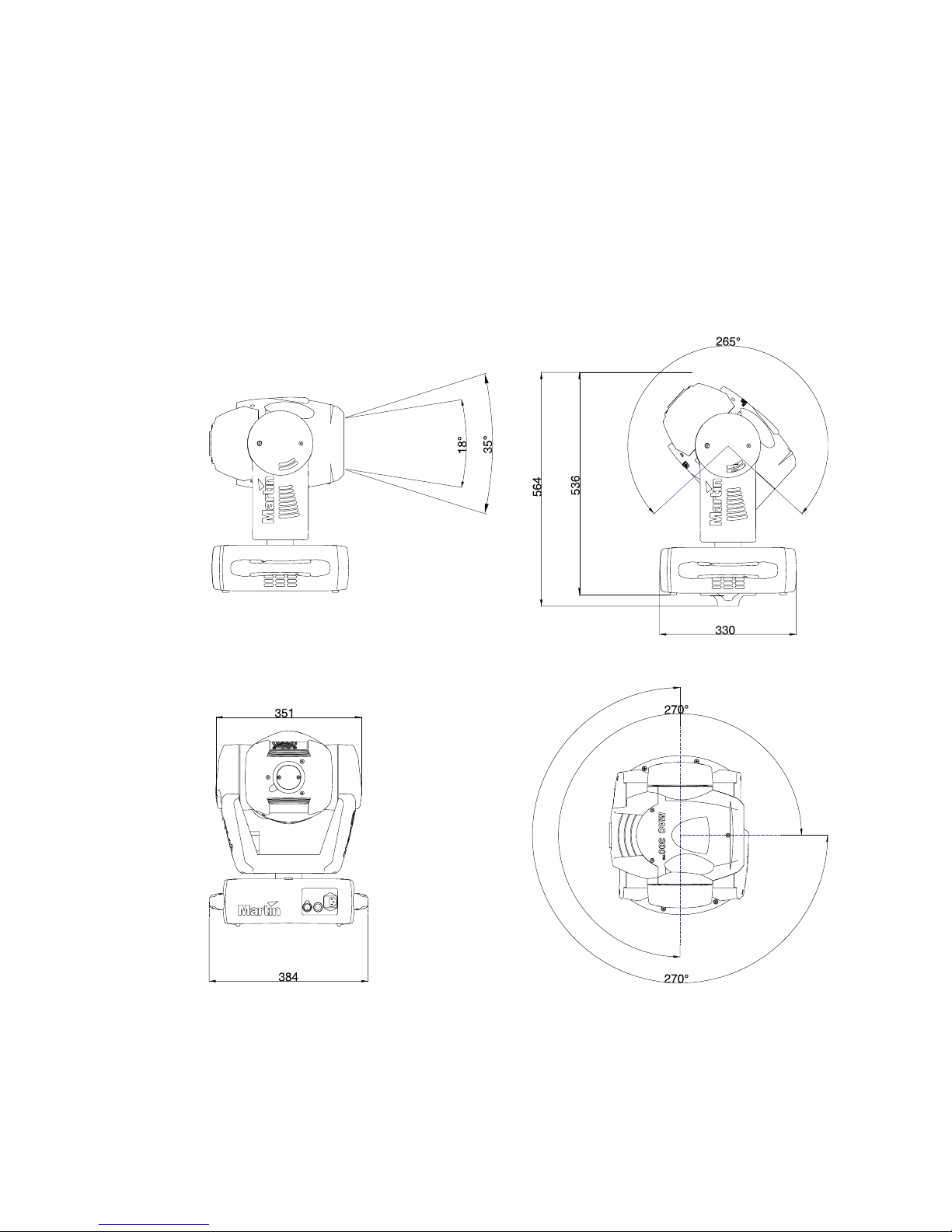

Compatible lamps

The lamps listed in the table below may be used wi th the MAC 30 0. Installing any other lamp may damage the fixture.

Installing or changing the lamp

WARNING!

Always d isconnect the fixture from A C powe r and allo w it to cool be f ore installin g

the lamp. To protect against lamp explosion, allow a hot lamp to cool for at least

5 minutes before removing the lamp socket.

1.

Remove the 2 Phill ips sc re ws fr om the lam p soc k et assem b ly. Pull the lamp and socket out of the h ead.

2.

Remove the old lamp, if any, from the socket.

3. Holding the new lamp by its ceramic base

(do not touch the glass), align the small pin with

the small hole and insert the lamp squarely into the socket. Make sure that the 4 small projections on the base contact the face of the socket.

4.

Clean the glass bulb with the cloth supplied with the lamp, particularly if your fingers touched the

glass. A clean, lint-free cloth wetted with alcohol may also be used.

5.

Gently insert the assembly, making sure the lamp fits through the opening in the reflector.

Replace the 2 screws.

6.

Please see “Optimizing reflector alignment” on page 19 to optimize light output.

Lamp

Replace

before Average life Color Temp. Output P/N

Osram HSD 250 2500 hr. 2000 hr. 6000K 68 lm/W 97010103

Philips MSD 250/2 2200 hr. 2000 hr. 6500K 72 lm/W 97010100

Philips MSD 200 2200 hr. 2000 hr. 5600K 67 lm/W 97010106

Figure 1: Lamp installation

reflector alignment screws

lamp soc ket assembly

Page 6

AC Power Connection

6

section 3

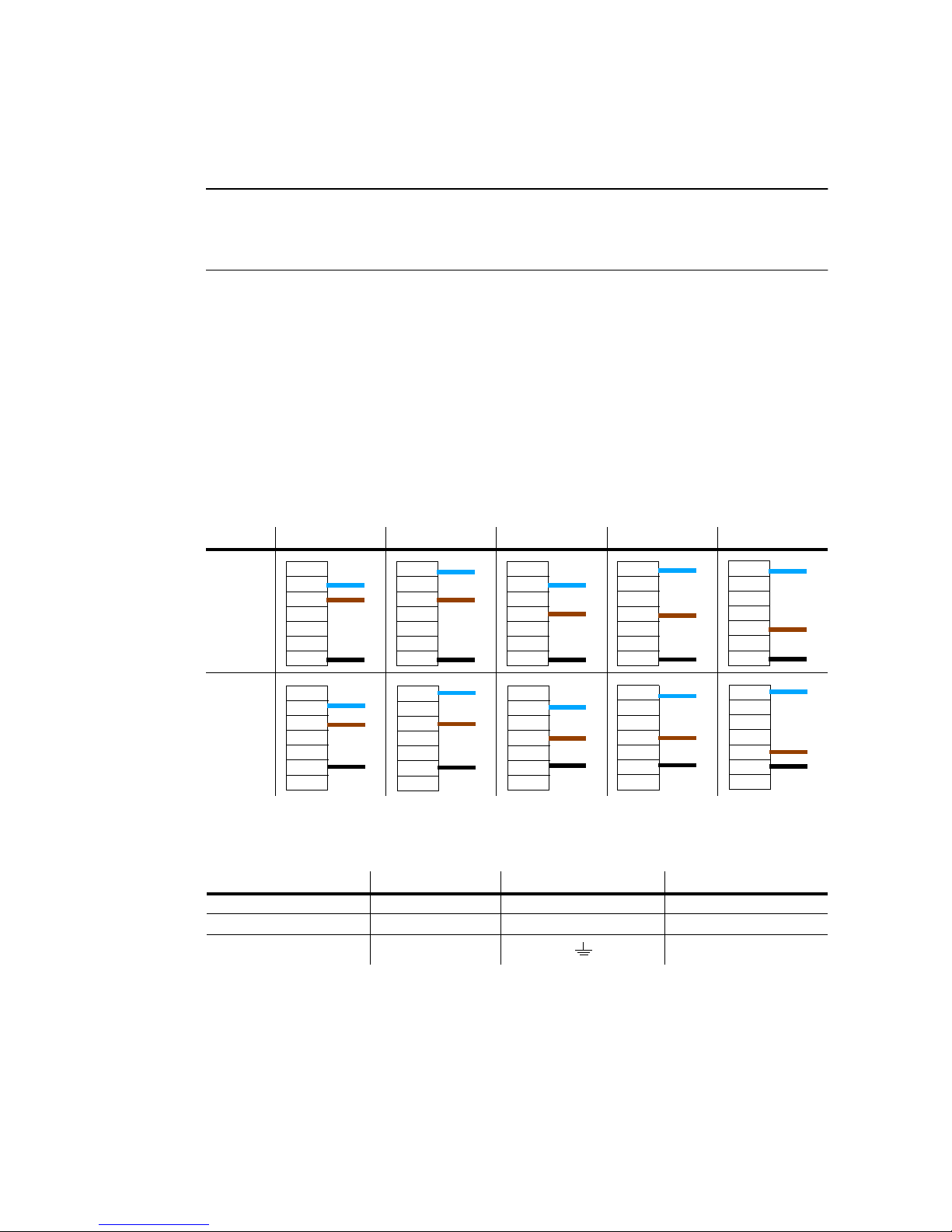

AC POWER CONNECTION

This section describes how to ta p the po wer supply fo r local co nditio ns and h ow to wi re the mai ns lead. Do n ot con nect

the MAC 300 to an electrical dimmer system: doing so can damage the electron ics.

WARNING!

For protection from dangerous electric shock, the fixture must be grounded

(earthed). The AC supply shall have overload and ground -fault protection.

Changing voltage and frequency settings

The factory settings are printed on the serial number label under the base. These settings must match the local AC

power supply as closely as possible! Operating at the incorrect power setting can result in poor light output, greatly

reduced lamp life, overheating and/or damage to the fixture.

1.

Disconnect the fixture from AC power. Unscrew and remove the cover from top of the base on the side

closest to the power inlet.

2.

Locate the 7-terminal connection block. Move the wires to the terminals that most closely match

local conditions as shown in Table 1. If the local voltage falls halfway between settings, use the

higher voltage setting. For example, use the 120 V setting if your voltage is 110 V.

3.

Replace the cover.

Wiring the mains lead

1.

Install a grounding-type cord cap on the mains lead. Connect the yellow/green wire to ground (earth),

the brown wire to live (hot), and the blue wire to neutral. Table 2 shows some possible pin identification

schemes; if you have any doubts about proper installation, consult a qualified electrician.

2.

Ver ify that the feed cable is undamaged and rated for the current requirements of all connected

devices.

100 V 120 V 210 V 230 V 250 V

50 Hz

60 Hz

Table 1: Voltage and frequency settings

Wire Pin Marking Screw (US)

brown live “L” yellow or brass

blue neutral “N” silver

yellow/green ground green

Table 2: Cord cap wiring

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

0 V

20 V

120 V

230 V

250 V

60 Hz

50 Hz

BLUE

BROWN

BLACK

Page 7

7

Data Connection

section 4

DATA CONNECTION

This section describes how t o connect fixtu res to a control ler. The MAC 300’s 3-pin XLR connectors are configure d

for use with DMX-512 controller s. To reconfigure them for use wi th Martin Protocol controllers, see “Chang ing the

XLR pin-out” on page 19.

XLR PIN-OUT

Pin 1: shield Pin 2: signal - Pin 3: signal +

Recommended cable

Use cable designed for RS-485 devices with low capacitan ce and a charact eristic impeda nce of 85 to 1 50 ohms. The

cable must be electrically shielded and have at least 1 pair of twisted wires. The minimum wire size is 0.2 mm

2

(24

AWG) for runs up to 300 meters (1000 ft.), and 0.322 mm

2

(26 AWG) for runs up 500 meters (1640 ft.).

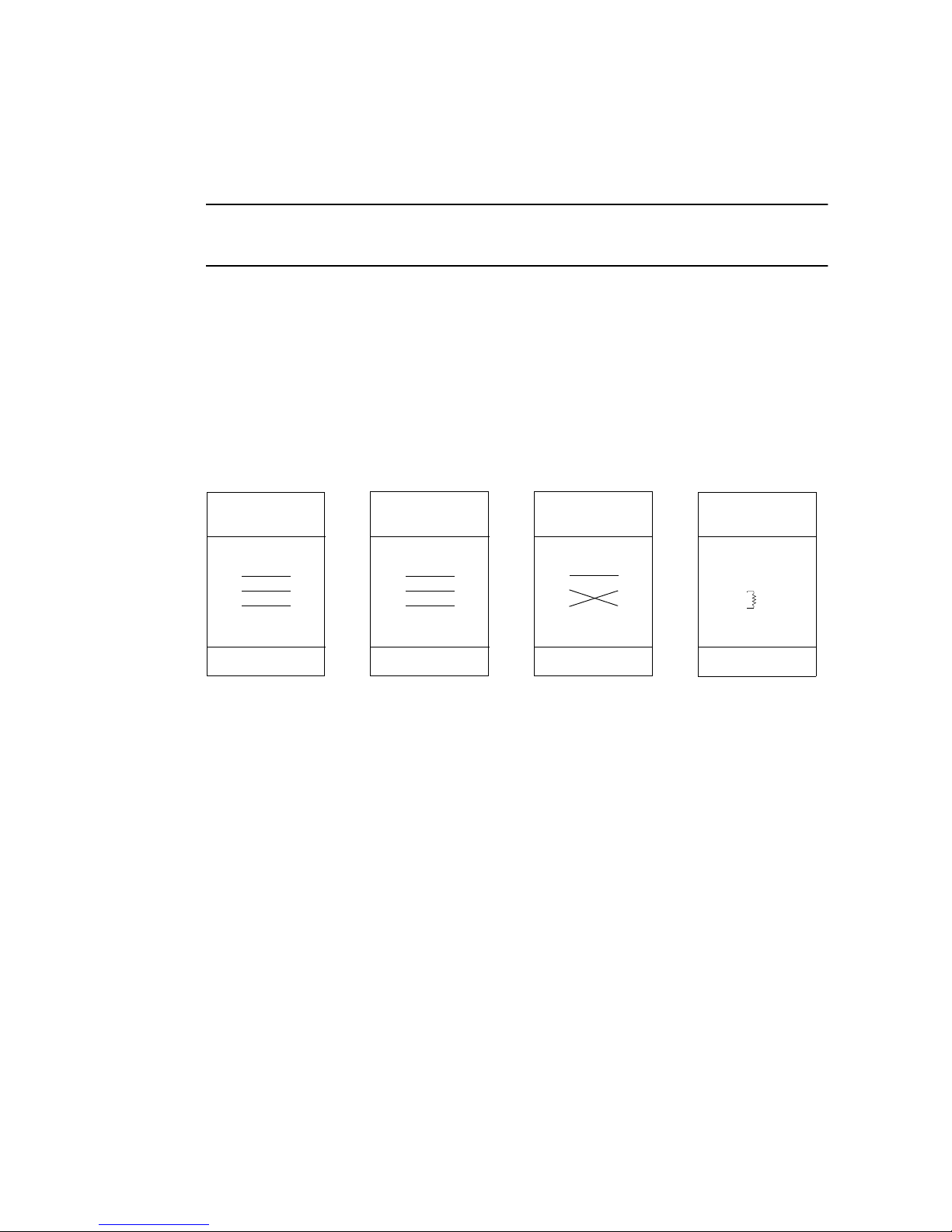

Adaptors

As many devices have 5- pin connectors and others have 3-pin connectors with reverse d si gnal polarity, adaptor cables

as shown below may be required. Insert a termination plug in the output of the last fixture on the link.

Building the data link

1. DMX controllers:

Connect a data cable to the controller’s data output. If controller has a 5-pin female

socket, use a 5-pin male to 3-pin female adaptor cable (P/N 11820005).

Martin RS-485 protocol controllers

: First, connect a 3-pin “swapper” cable (P/N 11820006) to the

controller’ s d ata out put; the n, conn ect a regu lar data cab le t o the swapper cable. Alternativel y, reconfigure the XLR pin-out as described on page19.

2.

If convenient, you may split the link into branches using a splitter such as the Martin 4-Channel

Opto-Isolated RS-485 Splitter/Amplifier. Do not use a “Y” connector to split the link.

3.

Lead the data cable from the controller to the first fixture. Plug the cable into the fixture’s data

input socket.

4.

Connect the output of the fixture closest to the controller to the input of the next fixture. If connecting to another type of fixture with reversed-polarity (pin 3 cold), insert a swapper cable

between the two fixtures.

5.

Continue connecting fixtures output to input. Up to 32 devices may be connected on a serial link.

If more fixtures are required, use another controller output, if available, or an RS-485 amplifier.

6.

Terminate the link

by inserting a male termination plug (P/N 91613017) into the data output of

the last fixture. A termination plug is simply an XLR connector with a 120 ohm, 0.25 W resistor

soldered across pins 2 and 3. If a splitter is used, each branch of the link must be terminated.

Phase-Reversing

Adaptor

Male Female

1

2

3

1

2

3

3-pin to 3-pin

P/N 11820006

Adaptor

Male Female

1

2

3

4

5

1

2

3

5-pin to 3-pin

P/N 11820005

Adaptor

Male Female

1

2

3

1

2

3

4

5

3-pin to 5-pin

Construct

Figure 2: Cable adaptors and termination

Male

1

2

3

Termination Plug

P/N 91613017

120

Page 8

Rigging

8

section 5

RIGGING

This section briefly describes how to install the MAC 300 on a truss.

Location and orientation

The MAC 300 may be installed in any orie n tatio n. It shall be located at least 0.4 meters (16 inches) away from the surface to be illuminated and any combustible materials. The lamp socket at the back of the head reaches temperatures up

to 150° C (302° F): the fixture should not b e located in publicly trafficked areas.

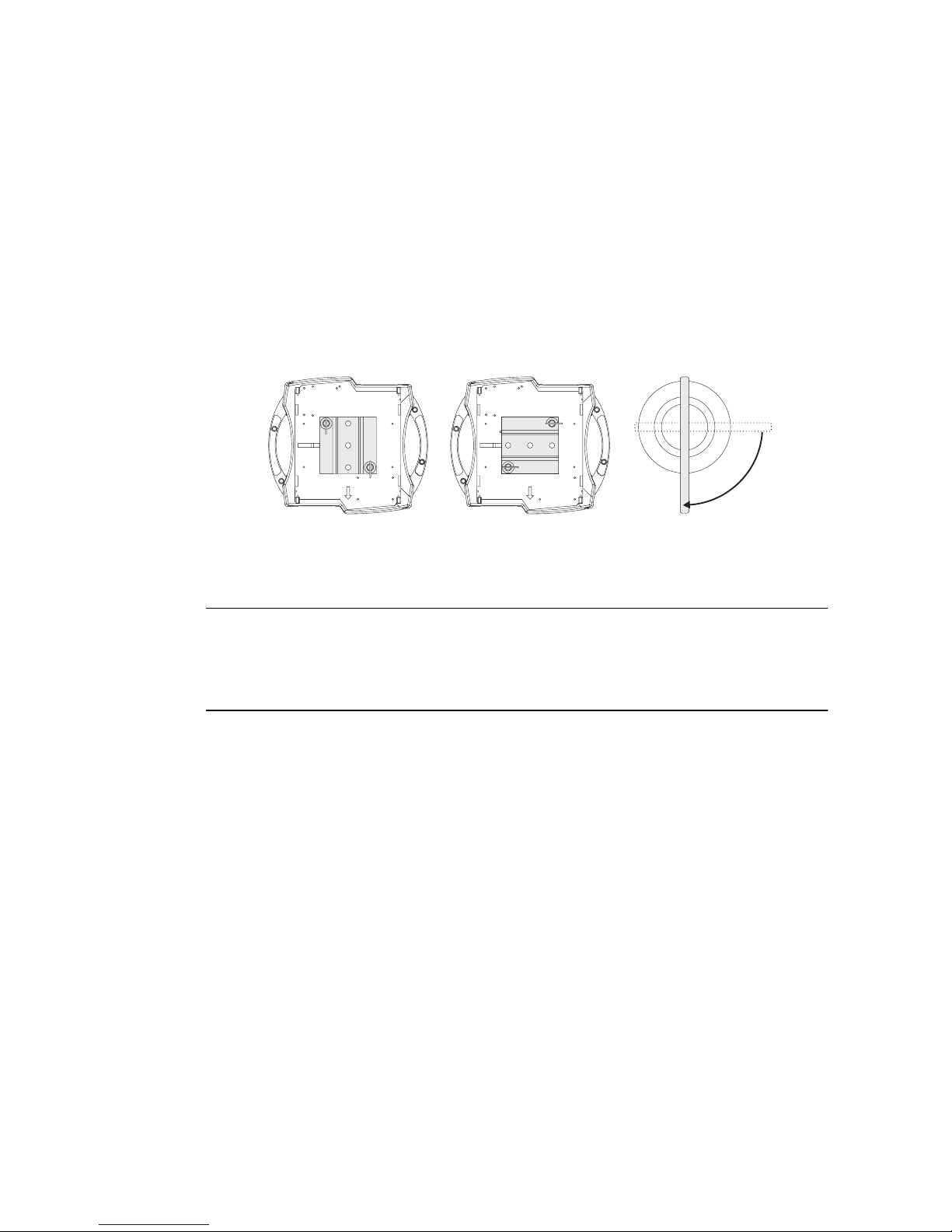

Rigging hardware

The MAC 300 inclu des a clamp m ounting brac ket to whic h 1 or 2 rigg ing clamps ( not include d) can be b olted with

locking 12 mm (1/2 in.) hardware. The clamp bracket fastens to the base with 1/4-turn fasteners. For clamps available

from Martin, see the list of accessories on page 26.

To hang the fixture on a truss

WARNING!

Block access below the work area before proceeding.

Always fasten a safety cable to the reinforced attachment point in the base.

The 1/4-turn fasteners are locked only when turned fully clockwise.

1.

V erify t hat the clam ps are in goo d cond ition and c an bear at l east 10 t imes the w eig ht of th e fixt ure . Bol t

clamps to the bracket with a grade 8.8 (minimum) M12 bolt and lock nut, or as recommended by the

clamp manufacturer, through the 13 mm holes in the clamp mounting bracket.

2.

Align the clamp mounting bracket with any 2 key slots on the base. Insert both locking pins into

the slots and turn both levers a full 1/4 turn clockwise to lock.

3.

Ver ify that the structure can bear at least 10 times the weight of all installed fixtures, clamps,

cables, auxiliary equipment, etc.

4.

Working from a stable platfor m, clamp the fixture to the structure.

5.

Install a safety cable that can bear at least 10 times the weight of the fixture securely to the

structure and anchor the cable to the dedicated attachment point in the base. The attachment

point is designed to fit a carabiner clamp.

Figure 3: Clamp mounting bracket

Page 9

9

Fixture Settings

section 6

FIXTURE SETTINGS

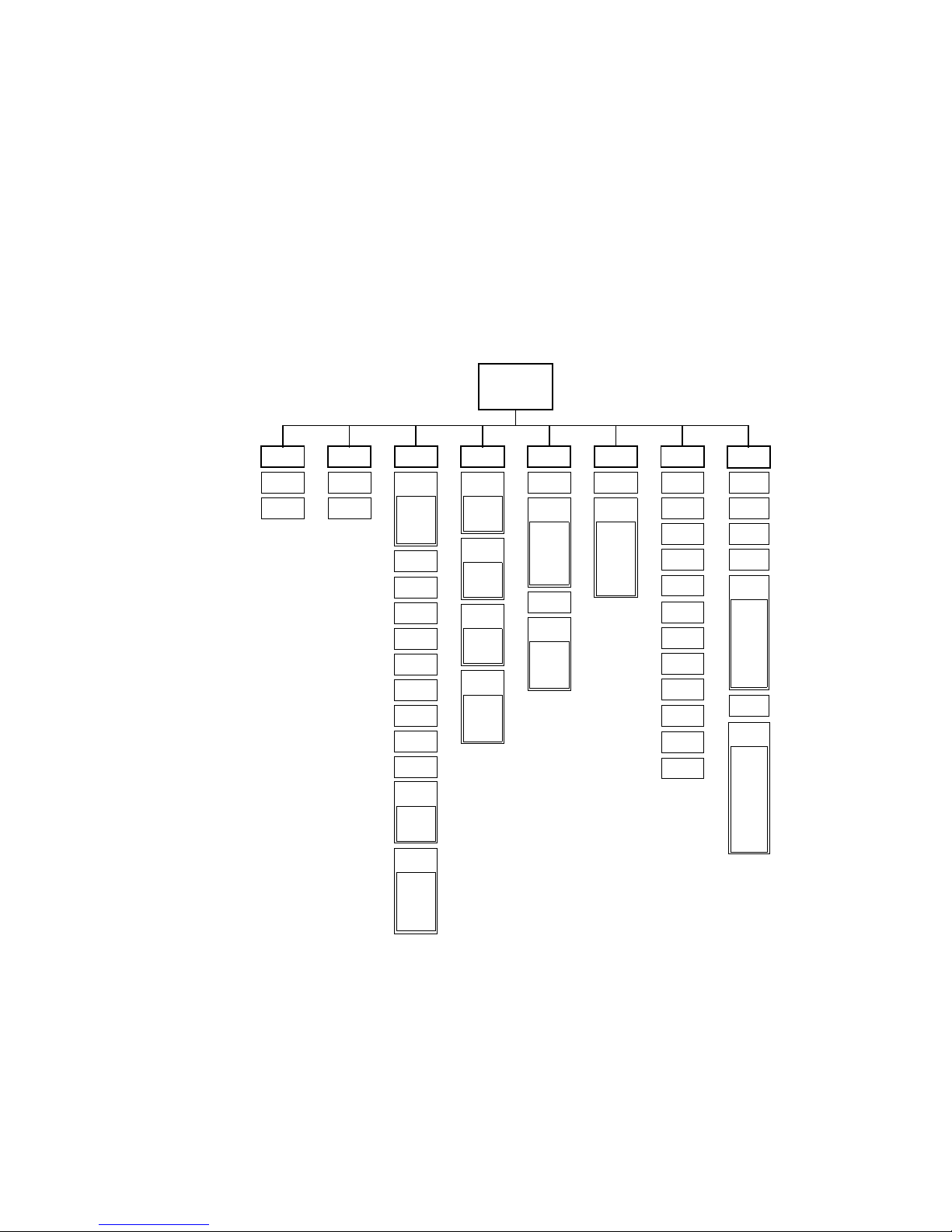

This section describes how to set the address and personalities, read lamp hours, DMX values, and other information;

calibrate effects, control the fixture manually, and run test and demo programs from the 4-digit LED control panel.

Functions that do not require feedback can also be performed remotely via the serial link using the MPBB1 Uploader.

Please refer to the MPBB1 manual.

Menu navigation

The DMX or Martin address, depending on the mode, and any error messages are displayed after the MAC 300 resets.

To enter the menu, press [MENU]. Use the [↑] and [↓] keys to move within the menu . To select a function or submenu,

press [Enter]. To escape, press [MENU].

SWAP

PINV

TINV

PSET

AdJ

CAL

VER

AddR MANTESTPERS

Address/

Messages

DMX

RST

L ON

LOFF

HEAd

PATI

P OF

T OF

C OF

M OF

Y OF

dFOF

d OF

RST

L ON

SHUT

dIM

YEL

LOFF

FROS

PAN

TILT

dISP

ALON

dINT

UPLd

PCb

AUTO

SCUT

dIM

COL

CYAN

MAG

YEL

dEMO

MINP

MAXP

MINT

MAXT

dFSE

FACT

CUS1

CUS2

CUS3

UTIL

dMOd

EFFb

MART

INFO

HRS

TOTL

RSET

DMXL

STCO

SHUT

...

E SP

L HR

TOTL

RSET

L ST

TOTL

RSET

TSEQ

PTSP

MOdE PATI

dLOF

dRES

FEbA

CPU

FEbA

dISP

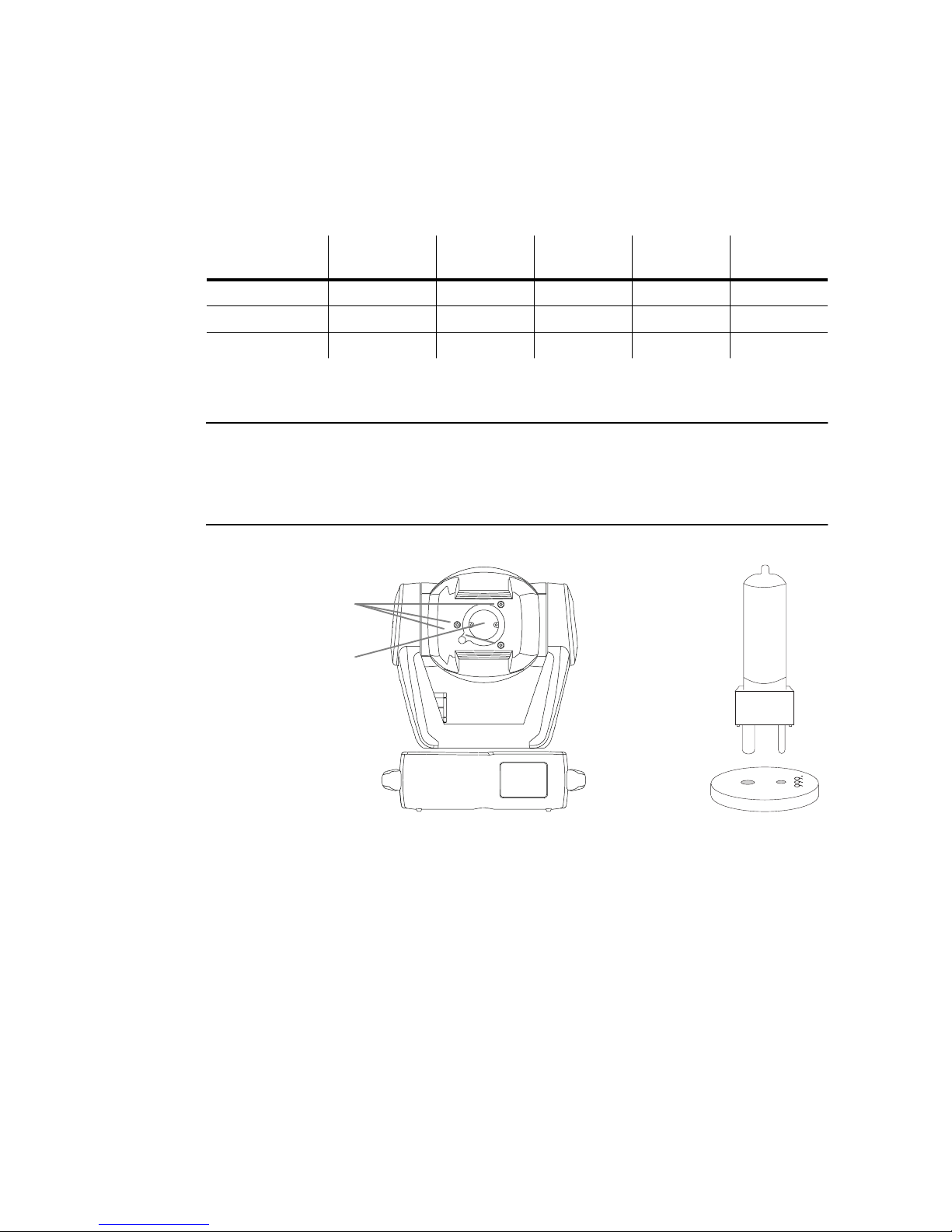

Figure 4: MAC 300 menu

TRAC

MOdE

CAL

GO

CYAN

MAG

COL

FROS

FACT

ETST

MTST

STST

Page 10

Fixture Settings

1 0

Personality settings

The MAC 300’ s person ality setting s are shown in Table 3; they are described as well in the following sectio n. To select

a personality setting:

1.

Press [Menu] as required to reach the ma in menu. Navigate to

PERS

and press [Enter].

2.

Navigate to the desired setting and press [Enter].

3.

Select the desired option with the arrow keys and press [Enter].

Custom personal ity configurations

Three sets of custom personality configurations can be stored for later recall. To create and use a custom configuration:

1.

Set the personalities as desired.

2.

Navigate to

PERS

/

dFSE

and press [Enter].

3.

Select

CUS1, CUS2

, or

CUS3

and press [Enter].

4.

Select

SAVE

to create a custom configuration or

LOAd

to recall. Press [Enter].

5.

To load the factory default personality settings, navigate to

PERS

/

dFSE

/

FACT

and press

[Enter].

Personality Path Options Effect

(Default setting shaded, * indicates DMX override)

Pan/tilt swap

PATI/SWAP

ON

Map DMX pan control to tilt channel and vice versa.

OFF

Normal pan and tilt control.

Pan inverse

PATI/PINV

ON

Reverse DMX pan control (right Æ left).

OFF

Normal pan control (left

ÆÆÆÆ

right).

Tilt inve rse

PATI/TINV

ON

Reverse DMX tilt control (down Æ up).

OFF

Normal tilt control (up

ÆÆÆÆ

down).

Pan/tilt speed

PTSP

FAST

Optimize movement for speed.*

SLOW

Optimize movement for smoothness.*

DMX lamp off

dLOF

ON

Enable DMX lamp off command.

OFF

Disable DMX lamp off command.*

DMX reset

dRES

ON

Enable DMX reset command.

OFF

Disable DMX reset command.*

Automatic lamp on

ALON

ON

Lamp strikes automatically within 90 seconds of power on.

OFF

Lamp remains off until “lamp on” command is sent.

Display on/off

dISP

ON

Display stays on.

OFF

Display goes out 2 minutes after last key press.

Display intensity

dINT 10-100

Adjust display intensity.

Dimmer mode

dMOd

NORM

Normal dimming.

TUNG

Simulated tungsten dimming.

Shortcuts

SCUT

ON

Color and CMY wheels turn the shortest direction.

*

OFF

Wheels turn same direction.*

Effects feedback

EFFb

ON

Enable feedback on color and CMY wheels.

OFF

Disable feedback on color and CMY wheels.

Tracking algorithm

TRAC/MOdE

MOd1

Absolute delta value algorithm (for most controllers)

MOd2

Real delta value algorithm

Tracking samples

TRAC/CAL 1-10

Tracking samples. Increase if pan/tilt is not smooth.

Table 3: Personality settings

Page 11

11

Fixture Settings

Adjusting the LED display

Invert

T o flip the display ve rtic ally, press the up-arrow [↑] and down-arrow [↓] keys simultaneously.

Adjust int ensity

T o adjust the displa y int ens ity, set

PERS/dINT

to a level between 10 and 100.

Blacko ut

T o bla c ko u t the dis p la y 2 min ut es afte r the las t ke y-press, toggle

PERS/dISP

to

OFF

.

Protocol selection

The MAC 300 can be control led with DM X-51 2 and Mar ti n RS- 485 proto col cont rol ler s. Wh en us ed wit h DMX co ntrollers, there are 4 control protocols to choose from. The control option - DMX mode 1, 2, 3, 4; or Martin - must

match the controller setup.

DMX mode summary

The DMX modes are summarized above. Mode 4 provides full control; it is recommended unless channels are limited.

To select a protocol

Automatic protocol detection

Automatic protocol detection allows the MAC 300 to detect the controller type - DMX-512 or Martin RS485 - and

respond accordingly. If it is a DMX controller, the MAC 300 uses the control option se lected above.

The default setting is

OFF

. To turn it on, navigate to the

PSET

sub menu, select

AUTO

, press [Enter], select ON,

and press [Enter].

123456789

1234567891011123456789101112345678910111213

shutter

dimmer

cyan

magenta

yellow

color wh.

frost

pan coarse

tilt coarse

shutter

dimmer

cyan

magenta

yellow

color wh.

frost

pan coarse

pan fine

tilt coarse

tilt fine

shutter

dimmer

cyan

magenta

yellow

color wh.

frost

pan coarse

tilt coarse

p/t speed

fx speed

shutter

dimmer

cyan

magenta

yellow

color wh.

frost

pan coarse

pan fine

tilt coarse

tilt fine

p/t speed

fx speed

Mode 1

tracking control

8-bit pan/tilt

9 channels

Mode 2

tracking control

16-bit pan/tilt

11 channels

Mode 3

tracking & vector control

8-bit pan/tilt

11 channels

Mode 4

tracking & vector control

16-bit pan/tilt

13 channels

Press To

[Menu] As required Display main menu

[↑], [↓]

As required

Select

PSET

[Enter] Once Display sub menu

[↑], [↓]

As required

Select

MOdE

[Enter] Once Display currently selected control mode

[↑], [↓]

As required

Select protocol (

dMX1, dMX2, dMX3, dMX4, MART)

[Enter] Once

Save setting.

MOdE

is displayed.

[Menu] Once Display main menu

[Menu] Once Display current address

Table 4: Setting a protocol

Page 12

Fixture Settings

1 2

Address selection

The address, also kn own as t he start c hannel, is the first c hannel use d to re ceive i nstructi ons from th e contro ller. The

address set on the fixture must match the address set on the controller.

When selecting DMX addresses, b e su re to allo w the nu mber of c ha nne l s required for the protoc ol . If an y of t he co ntrol channels for one fixture overlap any of the ch annels for another fixt ure, then one of t he fixtures will receive the

wrong instructions and respond incorrectly. Two MAC 300s may share the same address, however, if they are to

respond identically: they will receive the same instructions so individual control will be impossible.

Note: Whether the MAC 300 displays a DMX or Martin address at the to p of the menu depends on the protocol

selected.

To set a DMX address

To set a Mar tin address

The MAC 300 uses 2 Martin RS-485 channels.

Press To

[Menu] As required Display main menu

[↑]

As required

Select

AddR

[Enter] Once Display address sub menu

[↑]

As required

Select

DMX

[Enter] Once Display current DMX address

[↑], [↓]

As required Select desired DMX address

[Enter] Once

Save the ne w addre ss .

DMX

is displayed.

[Menu] Once Display main menu

[Menu] Once

Display current address for the

PSET

setting.

Table 5: Selecting a DMX address

Press To

[Menu] As required Display main menu

[↑]

As required

Select

AddR

[Enter] Once Display address sub menu

[↑]

As required

Select

MART

[Enter] Once Display current Martin address

[↑], [↓]

As required Sel ect desired Martin address

[Enter] Once

Save the ne w addre ss .

MART

is displayed.

[Menu] Once Display main menu

[Menu] Once

Display current address for the

PSET

setting.

Table 6: Selecting a Martin address

Page 13

13

Fixture Settings

Readouts

The MAC 300 has counters to track usage, maintenance intervals, lamp life, etc. One set of counters shows total

(

TOTL

) accumulated usage and canno t be reset. Anoth er set shows usage since the cou nter was reset (

RSET

). To

reset one of these counters, navigate to the readout and press [↑] for 5 seconds.

Hours used

To read the accumulated total number of hours the fixture has been on, navigate to

INFO

/

HRS

/

TOTL

and press

[Enter]. To read the number of hours since the counter was last reset, navigate to

INFO

/

HRS

/

RSET

and press

[Enter]. To reset this counter, navigate to the readout and press [↑] for 5 seconds.

Lamp hours

To read the accumulated total number of lamp hours, navigate to

INFO

/ L HR /

TOTL

and press [Enter]. To read

the number of lamp hours since the counter was last reset, navigate to

INFO

/ L HR /

RSET

and press [Enter]. To

reset this counter when installing a new lamp, navigate to the readout and press [↑] for 5 seconds.

Lamp strikes

To read the accumulated total number of lamp strikes, navigate to

INFO

/ L ST /

TOTL

and press [Enter]. To read

the number of lamp strikes since the cou nt er was last reset, nav iga te to

INFO

/ L ST /

RSET

and press [Enter]. To

reset this counter when installing a new lamp, navigate to the readout and press [↑] for 5 seconds.

Software version

Navigate to the sub menu under

INFO

/

VER

to read the version number of the CPU software (

CPU

), feedback cir-

cuit software (

FEBA

), and display module software (

dISP

).

Utilities

Upload mode

The software upload mode is engaged automatically by the MPBB1 Uploader. Engage upload mode manually only if

automatic upload fails. To do so, navigate to

UTIL

/

UPLd

and press [Enter]. Press [Enter] again when

SURE

is

displayed to confirm, or press [Menu] to escape. See also “Updating software” on page 19.

Demonstration program

The demonstration m enu allo ws you to run a preprogra mmed stand- alone progr am. Befo re running the demo, set the

minimum and maximum pan and tilt positions (

MINP, MAXP, MINT, MAXT

) to a good location for viewing the

effects. Select

GO

and press [Enter] to run the demo. Press [Menu] to stop the pr ogram.

Test programs

Test sequence

Navigate to

TEST

/

TSEQ

and press [Enter] when

RUN

is displayed to perform a general fixture test. Press [Menu]

to stop the program.

DMX log

The DMX log provides a quick way to check if the fixture is receiving DMX instructions correctly. The log displays

the start code (

STCO

), which must be 0, and the DMX values received on each control channel.

To read a value, navigate to

TEST

/

DMXL

and press [Enter]. Scroll to an effect channel and press [Enter] to read

the DMX value receiv ed. Look up the val ue’s function in the DMX protocol to see if it correspo nds to the effect’s

behavior.

Quality control and service tests

The

PCB

and

FACT

menus, under

TEST

, contain tests for factory and service use. The factory effects test

(

TEST

/

FACT

/

ETST

) drives all effects at 10 percent over their maximum speed.

Page 14

Fixture Settings

1 4

Manual control

The manual control menu (

MAN

) permits limited operation from the control panel.

• T o reset the fixture, select

RST

.

• To turn the lamp on or off, select

L ON

or

LoFF

.

• To open, close, and strobe the shu tter at 3 speeds, select

SHUT

.

• To control the dimmer, select

dIM

.

• To move the color wheel to each position and scroll it at 3 speeds, select

COL

.

• To control the CMY mix, select

CYAN, MAG

, and

YEL

.

• To insert the frost filter, select

FROS

.

• To control pan and tilt, select

PAN

and

TILT

.

Adjustment control and calibration

The adjustment menu (

AdJ

) provides the following functions:

• Reset the fixture (

RST

)

• Turn on and off the lamp (

L ON, LoFF

)

• Disable pan/tilt feedback (

FEbA

)

• Control effects in the head (

HEAd

)

• Move the head to the home and extreme positions (

PATI

)

• Calibrate effects (

CAL

)

Head effects adjustment

The head submenu (

AdJ

/

HEAd

) provides manual control when makin g mechanical adjust ments, which must be

performed by a qualified technician. It allows the technician to:

• Open, close, and strobe the dimmer/shutter

• Move the color wheel to the open, sensor, and full color positions

• Move the CMY wheels to the open, sensor, and full positions

• Insert and remove the frost filte r

Calibratio n

The calibration submenu (

AdJ

/

CAL

) allows you to adjust the effects for uniformity between fixtures: it is not a

substitute for mechanical adjustment. To reset all calibrations to their factory defaults, select

dFOF

and press [Enter]

when

SURE

is displayed, or press [MENU] to escape.

1.

Select the effect to calibrate: pan (

P OF

), tilt (T OF), dimmer/shutter (d OF), cyan (

CYOF

), magenta

(

MAOF

), or yellow (

YEOF

).

2.

Calibrate the effect using the arrow keys until it matches the other units. Offsets are adjustable

from 1 to 255.

3.

Press [Enter] to save the calibration.

Page 15

15

Operation

section 7

OPERATION

This section describes the MAC 300’s controllable effects and how personality settings affect their behavio r. Selecting

personalities from the control panel is described in the previous section.

Martin RS-485 control

The MAC 300 will be controllable with the Martin 3032 controller when version 2.07 of the 3032 software is released.

To respond to the controller, either Martin mode must be selected or automatic protocol detection must be enabled.

DMX-512 control

The MAC 300 may be op e r at ed with USITT DMX512 co ntrollers in 4 different modes that mix ve c to r and /o r tr ac k i ng

control with 8-bit or 16-bit pan/tilt resolution in different combinations.

Tracking versus vector control

With tracking control the time it takes an effect to move from one position to another is controlled by programming a

fade time on the controller. The controller divides the move into steps and updates the fixture with small changes at the

rate required to achieve the fade. The MAC 300 fo llows or “trac ks” the changes, and averages them with a digital filter

algorithm to ensure smooth movement at all speeds.

With vector control you set the fade speed on a separate speed channe l. Thi s provi des a way t o fade effec ts with con-

trollers that do not have programmable fade times. With controllers that send slow or irregular tracking updates, vector

control provides smoother movement, particularly at slow speeds.

Tracking control can be enabled in vector mode by setting one or both of the speed channels to “tracking speed.” When

setting a fade speed, though, the controller fade time must be 0, i.e., the position snaps from one value to the next.

Vector control also provides a special “blackout speed” and o verrid e s of th e shortcut and pan/tilt speed personalit y se ttings.

8-bit versus 16-bit pan/tilt resolution

With 8-bit pan/tilt resolution, pan and tilt are divided into 256 equal increments. Finer position control and smoother

movement is provided in the 16-bit modes, which divide pan i nto 40,192 positions and tilt into 39,424 positions.

Controllable effects

All mechanical effects are reset to a home position when the fixture i s powered up and th ey can also be reset fro m the

controller. The DMX Reset function (

PERS/dRES

), when set to off, prevents accidental resets by adding the

requirement that each CMY channel be set to a DMX value from 230 to 232.

An on-the-fly position correction system automatically corrects the position of the CMY wheels and the color wheel.

Though this feature can be disabled by turning Effects Feedback (

PERS/EFFb

) off, doing so is not recommended.

Lamp

With the default setting, the lamp remains off until a “lamp on” command is sent from the controller. Note: A peak of

electric current that can be man y times the operating curren t is drawn for an instant when striking a disc harge lamp.

Striking many lamps at once may cause a voltage drop large enough to prevent lamps from striking or draw enough

current to trip circuit breakers. If sending “lamp on” commands to multiple fixtures, program a sequence that strikes

lamps one at a time at 5 second in tervals.

The MAC 300 automatically strikes the lamp within 90 seconds of being powered on only if the Automatic Lamp On

setting (

PERS/ALON

) is turned on. A delay determined by the fixture address staggers lamp strikes to prevent

excessiv e cu r r e nt dr a w.

The lamp can be turned off from the controller. Note: the lamp cannot be restruck for 8 minutes after being turned off.

Accidental “lamp off” commands can be prevented by turning the DMX Lamp Off setting (

PERS/dLOF

) off.

Page 16

Operation

1 6

Dimmer / shutter

The mechanical dimmer/shut ter system pr ovides full, high-resolu tion dim ming, and ran dom or variabl e strobe effects

up to 14 Hz.

The Dimmer Mode (

PERS

/

dMOd

) setting allows you to sel ect betw een linear o r simulate d tungsten fade curves.

For simulated tungsten dimming, the fade time must be set to 0.

CMY subtractive color mixing

The CMY color mixing system is based on grad uated cya n, magent a, and yello w color fil ters. A contin uous range of

colors may be achieved by varying the amount of each filter from 0 to 100%. Random CMY color mixing at three

speeds can be selected on DMX channel 6.

The Shortcuts setting (

PERS/SCUT

) determines whether or not the CMY wheels always take the shortest path to

the next position; this setting may be o ver ridden on the speed channel in vector mode.

Color

The color wheel provides a 5500 to 2900K color temperature correction (CTC) filter, a UV filter, and 4 saturated dichroic color filters. The filters are replaceable; please see “Changing color filters” on page 18, and additional colors are

available from Martin; please see “Accessories” on page 26.

The wheel can be scrolled continuously - allowing for split color effects - or in steps, and rotated continuously in both

directions at different speeds.

The Shortcuts setting (

PERS/SCUT

) determines whether or not the wheel always takes the shortest path to the

next position; this setting ma y be overridden on the speed ch annel in vector mode. Setting the effects speed to “blackout” causes the shutter to black out the light while the wheel is moving.

Frost

The variable frost filter softens and widens the beam. The beam field angle is 18° with no frost applied and increases to

35° with the frost applied fully.

Pan and tilt

The yoke pans 540° an d th e he a d tilts 2 6 5°. Mo vem en t ma y b e op tim ize d fo r sp eed by settin g the pan/tilt speed setting

(

PERS

/

PTSP

) to

FAST

, or for smoothness by setting it to

SLOW

. This setting may be overridden on the speed

channel in vector mode. Setting the speed to “blackout” causes the shutter to close while the head is moving.

The pan and tilt channels can be inverted and/or swapped in DMX mode with the pan/tilt personality settings (

PERS

/

PATI

).

Page 17

17

Basic Service

section 8

BASIC SERVICE

The MAC 300 operates under challenging conditions presented by heat, humidity, dust, and touring. Excessive dust,

grease, and smoke fluid buildup degrades performance and causes overhe ating and damage that is not covered by the

warranty. The fixture requires regular maintenance to keep performing at its peak. The schedule will depend on the

application and sh ould be d iscussed wit h your Mar tin distr ibutor. Refer any service that you are not qua lified t o perform to a professional technician.

WARNING!

Removing co v er s exposes dangerous live ele ctrical circu its , hot su rfaces, and a

lamp under high pressure. Procedures requiring the removal of any cover shall

be performed by professional users or technicians only. Disconnect the fixture

from AC power and allow it to cool before removing any cover.

Cleaning

Optical components

Use care when cleaning optical components. The surface on dichroic filters is achieved by means of special multi-layer

coatings and even sma ll scrat ches may be visible. Residues f rom cleani ng fluid s can bak e onto com ponents an d ruin

them.

1.

Allow the components to cool completely.

2.

Wash dirty lenses and filters with isopropyl alcohol. A generous amount of regular glass cleaner

may also be used, but no residues may remain.

3.

Rinse with distilled water. Mixing the water with a small amount of wetting agent such as Kodak

Photoflo will help prevent streaking and spotting.

4.

Dry with a clean, soft and lint-free cloth or blow dry with compressed air.

Fans

To maintain adequate cooling it is important that the fans be cleaned of dust and dirt periodically. Use a soft brush, vacuum, or compressed air.

Figure 5: Opening the head (base and yoke not shown)

Page 18

Basic Service

1 8

Changing color filters

Handle color filters by their edges as much as possible and be careful not to chip the edges.

1.

Disconnect the fixture from AC power and allow it to cool.

2.

Remove the top cover from the head as shown in Figure 5.

3.

Rotate the color wheel until the filter is aligned with the access hole in the chassis plate.

4.

Gently tilt the filter out of the clips as shown in Figure 6 and remove.

5.

Installation is the reverse. Turn the filter so that the coated side faces the lamp.

Replacing fuses

Power sup ply f use s

The fuses for each of the 3 low-voltage power supplies are located on th e printed circuit board. If one of the circuit

board LEDs does not light, one of these fuses may be blown.

1.

Disconnect the fixture from AC power. Remove the 2 Philips screw s from the plastic cover on the arm

opposite the side with the visible motor and pull off the cover.

2.

Locate and replace the defective fuse with one of the same rating. The fuses are shown on the

PCB layout diagram; their values are listed on page 27.

3.

Replace the cover before applying power.

Figure 6: Color filter removal and positioning

Uncoated side towards stageCoated side towards lamp

When an object is held up to the coated side there is no

space between the object and its reflection. The back edge

of the filter cannot be seen when looking through the coated

side.

When an object is held up to the uncoated side there is

a space between the object and its reflection. The back

edge of the filter can be seen when looking through the

uncoated side.

Page 19

19

Basic Service

Main fuse

The main fuse holder is built in to the mains input socket. Never replace the fuse with one of a different rating!

1.

Unplug the mains cable from the input socket. Pry open the fuse holder and remove the fuse.

2.

Replace the fuse with one of the same type. The fuse rating is listed on serial number label.

3.

Close the fuse holder and replace the mains cable.

Changing the XLR pin-out

The signal polarity of the XLR connectors can be reversed,

allowing the fixture to be connected directly to those Martin

devices with reversed polarity (pin 3 -). Optionally, a phasereversing cable may be used.

1.

Disconnect the fixture from AC power. Remove the 2

Philips screws from the cover on the arm opposite

the side with the visible motor and pull off the cover.

2.

Position the jumpers on PL 233 and PL 234 for

the desired XLR pin-out as shown.

3.

Replace the cover before applying power.

Optimizing reflector alignment

The MAC 300 reflector is aligned at the factory. Due to differences between lamps, however, fine adjustment may

improve performance.

1.

Strike the lamp and shine the light on a flat surface.

2.

See Figure 1. Center the hot-spot (the brightest part of the beam) by turning the 3 adjustment

screws one at a time with a 3 mm Allen wrench. If there is no hot-spot, adjust the reflector until

the light is even.

3.

To reduce a hot-spot, “push” the reflector out by turning all 3 screws counterclockwise 1/4-turn at

a time until the light is evenly distr ibuted.

4.

If the light is brighter around the edge than it is in the center, or if light output is low, the lamp is

too far back in the reflector. “Pull” the reflector in by turning the screws clockwise 1/4-turn at a

time until the light is bright and evenly distributed.

Updating software

The latest CPU control software for the MAC 300 is available from your Martin dealer and the Martin web site. This

software is uploaded to the MAC 300 using the Martin MPBB1 Uploader. The display module and feedback system

software are not updated this way.

Normal upload

Update software is uploaded usin g a M artin uploader such as the MPBB1. The uploader is connected to th e fixt ure ju st

like a controller. Under normal conditions, software can be installed from a rem ote l oc atio n - the re is n o ne e d to se t t he

MAC 300 to boot mode. Please refer to the uploader manual for further instructions.

Boot mode upload

If the data is corrupted during transmission, a check-sum error (

CSER

) occurs and after 15 seconds the fixture

switches to boot mode (

UPLd

) and is ready for a boot mode upload as described in the uploader manual.

If a software upload is interrupted, the fixture must be turned off for at least 10 seconds before a new upload can be

attempted. When powered on, a check-sum error occurs and the fixture goes into boot mode, ready for a second upload

attempt. Select boot mode upload on the uploader.

If there is no functional softwa re in m e mory, the fixture must be set to boot mode manually. If the control panel works,

select

UPLd

from the

UTIL

menu and confi r m w he n

SURE

is displayed by pressing [ENTER].

DMX pin-out

PL234

PL233

Martin pin-out

PL234

PL233

Figure 7: XLR jumpers

(default)

Page 20

Basic Service

2 0

If the control panel does not work, boot mode can be engaged by

moving jumper PL 121 on the main circ uit board t o pins 1 an d 2 as

follows.

1.

Disconnect the fixture from AC power. Remove the plastic cover from the arm opposite the side with the visible

motor.

2.

Move jumper PL121 to pins 1 and 2 (hard boot setting). See also the diagram on page 25.

3.

Perfor m a boot-mode upload as described in the uploader manual.

4.

Disconnect the fixture from AC power. Move the hard boot jumper back to the normal setting and

replace the cover.

Changing lenses

A wide angle diffusion “lens” is available for the MAC 30 0. The diffuser gives the MAC 300 a 59° beam angle. If the

frost filter is fully applied , th e bea m an gle is 6 7° . Ph oto m e tric da ta fo r thi s op tio n is av ai lab le a t h ttp://www .m art in. dk /

service/Photometrics/MAC300-wide.htm.

The kit may be ordered by P/N 91610016, “Wide angle diffuser lens kit for MAC 300." To change lenses:

1.

Disconnect the fixture from AC power. Remove the top head cover.

2.

From the outside of the bottom head cover, remove the screw that holds the lens in place.

Remove the lens.

3.

Install the new lens in the same position as the old one, in the inside lens slot.

4.

Replace the screw to secure the new lens. Replace the top head cover.

PIN 1

È

PL121 PL121

PIN 1

È

hard boot settingnormal setting

Figure 8: Hard boot jumper

Page 21

21

Troubleshooting

section 9

TROUBLESHOOTING

Problem Probable cause(s) Remedy

One or more of the

fixtures is completely

dead.

No power to fixture.

Check that power is switched on and

cables are plugged in.

Primary fuse blown. Replace fuse.

Secondary fuse(s) blown (located

on PCB inside base).

Check fuses on PCB and replac e.

Fixtures reset correctly

but all respond

erratically or not at all to

the controller.

The controller is not connected. Connect controller.

XLR pin-out of the controller does

not match pin-out of the first fix ture

on the link (i.e. signal is reversed).

Install a phase-reversing cable between

the controller and the first fixture on the

link.

Fixtures reset correctly

but some respond

erratically or not at all to

the controller.

Bad data link connection

Inspect connections and cables. Correct

poor connections. Repair or replace dam-

aged cables.

Data link not terminated wi th

120Ω

termination plug.

Insert termination plug in output jack o f

the last fixture on the link.

Incorrect addressing of the fix-

tures.

Check address and protocol settings.

One of the fixtures is d ef ectiv e a nd

disturbs data transmission on the

link.

Bypass one fixture at a time until normal

operation is regained: unplug both con-

nectors and connect them directly

together. Have the defective fixture ser-

viced by a qualified techni cian.

XLR pin-out on fixtures does not

match (pins 2 and 3 reversed).

Install a phase-reversing cable between

the fixtures or swap pins 2 and 3 in the fix-

ture that behaves erratically.

An effect fails to reset

correctly.

The effect requi res mechanic al

adjustment.

Contact Martin technician for service.

No light and “LERR”

error message

displayed.

The ballast and transformer settings do not match local AC voltage and frequency.

Disconnect fixture. Check ballast and

transformer settings and correct if neces-

sary.

Lamp missing or blown Disconnect fixture and replace lamp.

Lamp cuts out

intermittently.

Fixture is too hot.

Allow fixture to cool.

Reduce ambient room temperature.

Recalibrate temperature sensors.

The ballast and transformer set-

tings do not match local AC voltage and frequency.

Check ballast and transformer settings

and correct if necessary.

Table 7: Troubleshooting

Page 22

DMX Protocol

2 2

appendix a

DMX PROTOCOL

DMX1 DMX2 DMX3 DMX4 Value Percent Function

Start code = 0

1

Note: To override (DMX) Reset or Lamp

Off = OFF, set all 3 CMY channels to a

value from 230 to 232.

0 - 19

20 - 49

50 - 72

73 - 79

80 - 99

100 - 119

120 - 127

128 - 147

148 - 167

168 - 187

188 - 190

191 - 193

194 - 196

197 - 199

200 - 202

203 - 207

208 - 217

218 - 227

228 - 237

238 - 247

248 - 255

0 - 7

8 - 19

20 - 28

29 - 31

31 - 39

39 - 47

47 - 50

50 - 58

58 - 65

66 - 73

74 - 75

75 - 76

76 - 77

77 - 78

78 - 79

80 - 81

82 - 85

85 - 89

89 - 93

93 - 97

97 - 100

Shutter , Str o be, Reset, Lamp On/Off

Shutter closed

Open

Strobe, fast to slow

Open

Opening pulse, fast to slow

Closing pulse, fast to slow

Open

Random strobe, fast

Random strobe, medium

Random strobe, slow

Open

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

Open

Reset, see note

Open

Lamp on

Open

Lamp off: time > 5 seconds, see note

2 0 - 255 0 - 100

Dimmer

Closed to open

3 0 - 255 0 - 100

Cyan

White to full cyan

4 0 - 255 0 - 100

Magenta

White to full magenta

5 0 - 255 0 - 100

Yellow

White to full yellow

6

0 - 179

0

26

52

78

104

130

156

180 - 183

184 - 187

188 - 191

192 - 195

196 - 199

200 - 203

204 - 207

208 - 226

227 - 245

246 - 248

249 - 251

252 - 255

0 - 70

0

10

20

31

41

51

61

71 - 72

72 - 73

74 - 75

75 - 76

77 - 78

78 - 80

80 - 81

82 - 88

89 - 96

96 - 97

98 - 98

99 - 100

Color

Continuous scroll

White

CTC 5500-2900K

Pink 312

UV

Red 308

Green 206

Blue 108

Stepped scroll

Blue 108

Green 206

Red 308

UV

Pink 312

CTC 5500-2900K

White

Continuous rotation

CW, fast to slow

CCW, slow to fast

Random CMY color

Fast

Medium

Slow

Page 23

23

DMX Protocol

7 0 - 255 0 - 100

Frost

Open (off) to full

8 0 - 255 0 - 100

Pan

Left to right (128 = neutral)

- 9 - 9 0 - 255 0 - 100

Pan Fine (LSB)

Left to right (128 = neutral)

9109100 - 2550 - 100

Tilt

Up to down (128 = neutral)

- 11 - 11 0 - 255 0 - 100

Tilt Fine (LSB)

Up to down (128 = neutral)

- - 10 12

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

Pan/Tilt Speed

Tracking control

Vector speed, fast to slow

Tracking, PTSP SLOW (override FAST)

Tracking, PTSP FAST (override SLOW)

Blackout while moving

- - 11 13

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 2

3 - 251

252 - 255

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

0 - 1

1 - 98

99 - 100

Effects Speed

Dimmer, CMY filters

Tracking control

Vector speed, fast to slow

Tracking, SCUT OFF (overrides ON)

Tracking, SCUT ON (overrides OFF)

Vector speed, fast

Color wheel

Tracking control

Vector speed, fast to slow

Tracking, SCUT OFF (overrides ON)

Tracking, SCUT ON (overrides OFF)

Blackout while moving

Frost

Tracking control

Vector speed, fast to slow

Vector speed, fast

DMX1 DMX2 DMX3 DMX4 Value Percent Function

Page 24

Error Mess age s

2 4

appendix b

ERROR MESSAGES

Display readout Appears if... What to do

AUTO (Automatic protocol detection error)

... automatic protocol detection is

enabled and there is no control input.

• Verify that controller is connected

properly and sending data.

LERR (Lamp error) ... the lamp doesn’t ignite within 10

minutes of receiving the ‘Lamp ON’

command.

• Check the lamp

• Check voltage and frequency settings

MERR (Memory error) ... the EEPROM memory cannot be

read.

• Contact service technician.

CSER (Check-sum error) ...a software upload is unsuccessful. • Reload software, see page 19.

**** ... there is no communication between

the control panel and motherboard.

This appears briefly when switching on

the fixture.

• Check fuses.

• Check cable between control panel

and motherboard.

• Reinstall software.

• Contact service technician.

ShER (Short error) ... the fixture detects the lamp is ON

but no ‘Lamp ON’ command has been

received. This can occur if the lamp

relay is stuck.

• The fixture may be operated but

remote lamp on/off may be effected.

• Contact service technician.

Hot (Hot lamp) ... you attempt to strike the lamp within

8 minutes after having switched it off.

The fixture will store the ‘Lamp ON’

instruction and strike the lamp once the

8 minutes period has elapsed.

• Wait until the lamp strikes.

FbEP (Feedback error pan)

FbET (Feedback error tilt)

FbER (Feedback error pan/tilt)

...pan (FbEp), tilt (FbET) or both

(FbER) feedback circuits are malfunctioning.

• The fixture will still operate, though

with reduced maximum speed to prevent the fixture from losing track of its

position.

• Contact service technician.

PAER (Pan time-out)

TIER (Tilt time-out)

...the pan or tilt indexing circuit is malfunctioning.

• After the time-out the fixture will work

normally.

• Contact service technician.

COER (Color wheel time-out)

CYER (Cyan wheel time-out)

MAER (Magenta wheel time-out)

YEER (Yellow wheel time-out)

...the magnetic-indexing circuit malfunctions or the effect wheel is misaligned.

• After the time-out, the effect in question stops in a random position.

• Contact service technician.

Page 25

25

PCB Layout

appendix c

PCB LAYOUT

Hard boot

jumper

XLR jumper

Fan

Switch

Color

wheel

Cyan

Magenta

Yellow

Dimmer

Frost

Pan

Tilt

Hall sensor

Link

Light sensor

AC input

Fan

Opto1

Opto2

Display

Brown

Red

Page 26

Accessories

2 6

appendix d

ACCESSORIES

• Wide angle diffuser lens: ..........................................................................................................................91610016

• Flight case, 4 x MAC 25 0/3 0 0:......... .........................................................................................................91510005

• Flight case, 2 x MAC 25 0/3 0 0:......... .........................................................................................................91510004

• MPBB1 Uploader:............................ ... ......................................................................................................90758410

• G-clamp: ................................................................................................................................................... 91602003

• Half-coupler clamp: ................................ ... .... ...........................................................................................91602005

Color filte rs

Filter P/N Filter P/N

Blue 101 46404301 Purple 502 46404314

Blue 102 46404326 Purple 509 46404338

Blue 103 46404327 Red 301 46404315

Blue 104 46404302 Red 304 46404339

Blue 105 46404328 Red 305 46404340

Blue 106 46404303 Red 308 46404316

Blue 107 46404325 Red 309 46404341

Blue 108 46404320 Yellow 601 46404317

Blue 111 46404304 Yellow 602 46404342

Cyan 401 46404305 Yellow 603 46404318

CTC 5500-2900K 46404306 Yellow 604 46404319

CTC 5500-3400K 46404324 Green 201 46 404329

CTC 5500-4200K 46404307 Green 202 46 404310

CTC 3200-5600K 46404308 Green 203 46 404330

CTC 3200-4100K 46404309 Green 204 46 404321

Magenta 501 46404333 Green 205 46 404331

Magenta 504 46404334 Green 206 46 404311

Magenta 505 46404335 Green 208 46 404332

Magenta 507 46404312 Orange 302 46404322

Pink 303 46404336 Orange 306 46404323

Pink 307 46404337 1/2 Minus Green 46404343

Pink 312 46404313 UV-transmitter 46404344

Page 27

27

Specifications

appendix e

SPECIFICATIONS

Physical

• Length....................................... ....................................................................................................330 mm (13.0 in.)

• Width............................................................................................................................................384 mm (15.1 in.)

• Maximum height (full tilt)............................................................................................................536 mm (21.1 in.)

• Approximate weight........................................................................................................................... 21 kg (46 lbs)

Compatible lamps

• Osram HSD 250...................................................................................................2000 hr., 6000K, 250 W, 68 lm/W

• Philips MSD 250/2..............................................................................................2000 hr., 6500K, 250 W, 68 lm/W

• Philips MSD 200.................................................................................................2000 hr., 5600K, 200 W, 66 lm/W

Perf orm anc e

• Light output (MSD 250/2, no effects applied).......................................................................................4765 lumens

Thermal

• Maximum ambient temperature (Ta) ................................................................................................. 40° C (104° F)

• Maximum lamp-socket temperature ............................................................................................... 150° C (302° F)

• Maximum shell surface temperature ................................................................................................ 90° C (194° F)

Control and programming

• Data pin-out............................................................................................... pin 1 shield, pin 2 cold (-), pin 3 hot (+)

• Receiver ..................................................................................................................................Opto-isolated RS-485

• Protocols................................................................................................. USITT DMX-512 (1990), Martin RS-485

• DMX Channels...................... ... .... .... ............................................... ... .... .... ......................................................9 - 13

Connections

• AC input........... .............................................................................................. .... .... ... ........ 3-pr ong IEC male socket

• Data input................................................................................................................ locking 3-pin XLR male socket

• Data output...........................................................................................................locking 3-pin XLR female socket

Fuses

• Fuse 01 (primary)........................................... .... ... .... ............................................... .... ... ..6.3 A / 250 V time-delay

• Fuse F601 ................................ ................................................ ... .... ... ...............................5.0 A / 250 V time-delay

• Fuse F602 .......................... ............................................... .... .... ... ......................................4.0 A / 250 V time-delay

• Fuse F603 .......................... ............................................... .... .... ... .................................. 0.315 A / 250 V time-delay

Design standards

• Canadian safety..........................................................................................................................CSA C22.2 NO 166

• EU EMC.........................................................................................................................EN 50 081-1, EN 50 082-1

• EU safety.....................................................................................................................EN 60598-1, E N 60598-2-17

• US safety................. .... ............................................... .... ... .... .......................................................... ..ANSI/UL 1573

Installation

• Orientation........................................... .......................... ................................................................................ ...... any

• Minimum distance to combustible materials...................................................................................... 0.4 m (16 in.)

• Minimum distance to illuminated surfaces......................................................................................... 0.4 m (16 in.)

• Minimum clearance around fans and air vents...................................................................................... 0.1 m (4 in.)

Page 28

B

fast slowT

P

AN/TILT SPEED

2

10 20 30 40 50 60 70 80 90

closed open

S

TROBE

R

ANDOM STROBE

med slow

R

ESET

L

AMP

O

N

S

HUTTER

fast

L

AMP

OFF*

←

*

> 5 sec.

M

ODE

T

E

FFECTS SPEED

D

IMMER

closed open

full

F

ROST

P

AN

T

ILT FINE

(LSB)

up down

fdimmer, CMY

←

color wheel

←

«·»

T

PAN F

INE

(LSB)

left right

T

ILT

1

3

4

5

7

8

99

991010

-1111

10 12

11 13

--

3142

MAC 300 DMX Protocol

Start code = 0

Implemented from CPU software version 0.1

* Set CMY from 230 to 232 to override disabled function.

T = tracking mode (0-2 & 246-251)

S = normal PTSP or shortcuts off (246-248)

F = fast PTSP or shortcuts on (249 -251)

«·»

= blackout speed (252-255)

←

=

variable speed, points to fa s t

25 50 75 100 125 150 175 200 225 250

L

I

G

H

T

P

/

T

S

P

E

E

D

-

TST

F

TST

F

TST

F

«·»

O

PEN

O

PEN

O

PEN

O

PEN

M

AGENTA

0% 100%

C

YAN

0% 100%

Y

ELLOW

0% 100%

RND.

CMY

C

ONTINUOUS COLOR SCROLL

S

TEPPED SCROLLCONTINUOUS ROTATION

cw

←

ccw

→

G

(26) CTC

6

off

25 50 75 100 125 150 175 200 225 250

25 50 75 100 125 150 175 200 225 250

fms

10 20 30 40 50 60 70 80 90

10 20 30 40 50 60 70 80 90

C

O

L

O

R

*

*

*

(0) white

left

up

right

down

RUVPKCTW

(52) pink (78) UV (104) red (130) green (156) blue

frost

←

T f

120°130° 90°100° 70°80° 60° 30° 10°40° 20°10° 40°30° 80°50° 90° 120°100°0° 130°60° 70° 110°20°50°110°

B

M

90° 120° 150° 210° 240°180°240° 180°210° 150° 120° 60° 30°90° 60° 0° 30°

Page 29

Page 30

Unit C6, Hastingwood Trading Estate

35, Harbet Road, London, N18 3HU

Phone 020 8803 7400 email office@gradav.co.uk

FAX 020 8803 5060 Web www.gradav.co.uk

Loading...

Loading...