Page 1

MAC 250 Krypton/Entour

user manual

Page 2

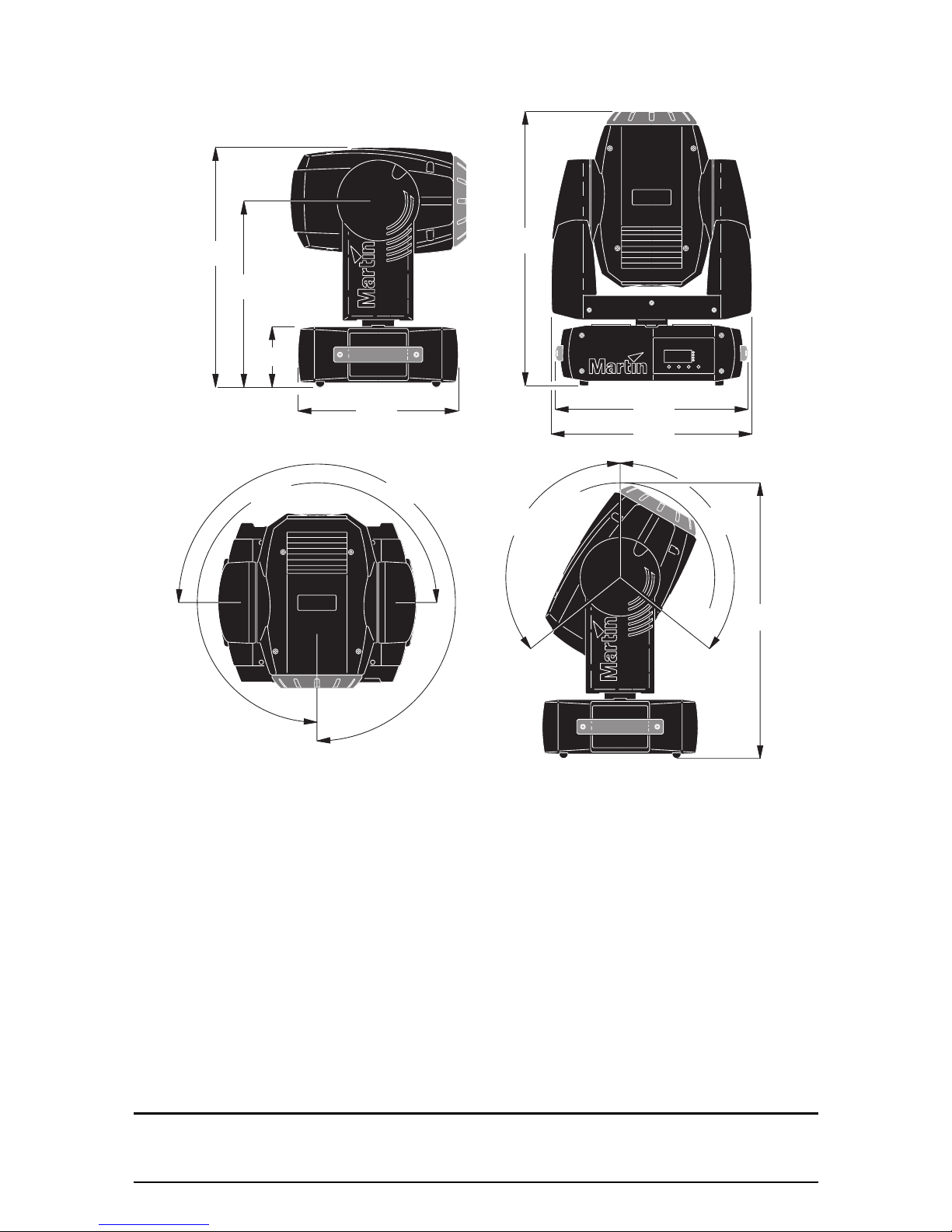

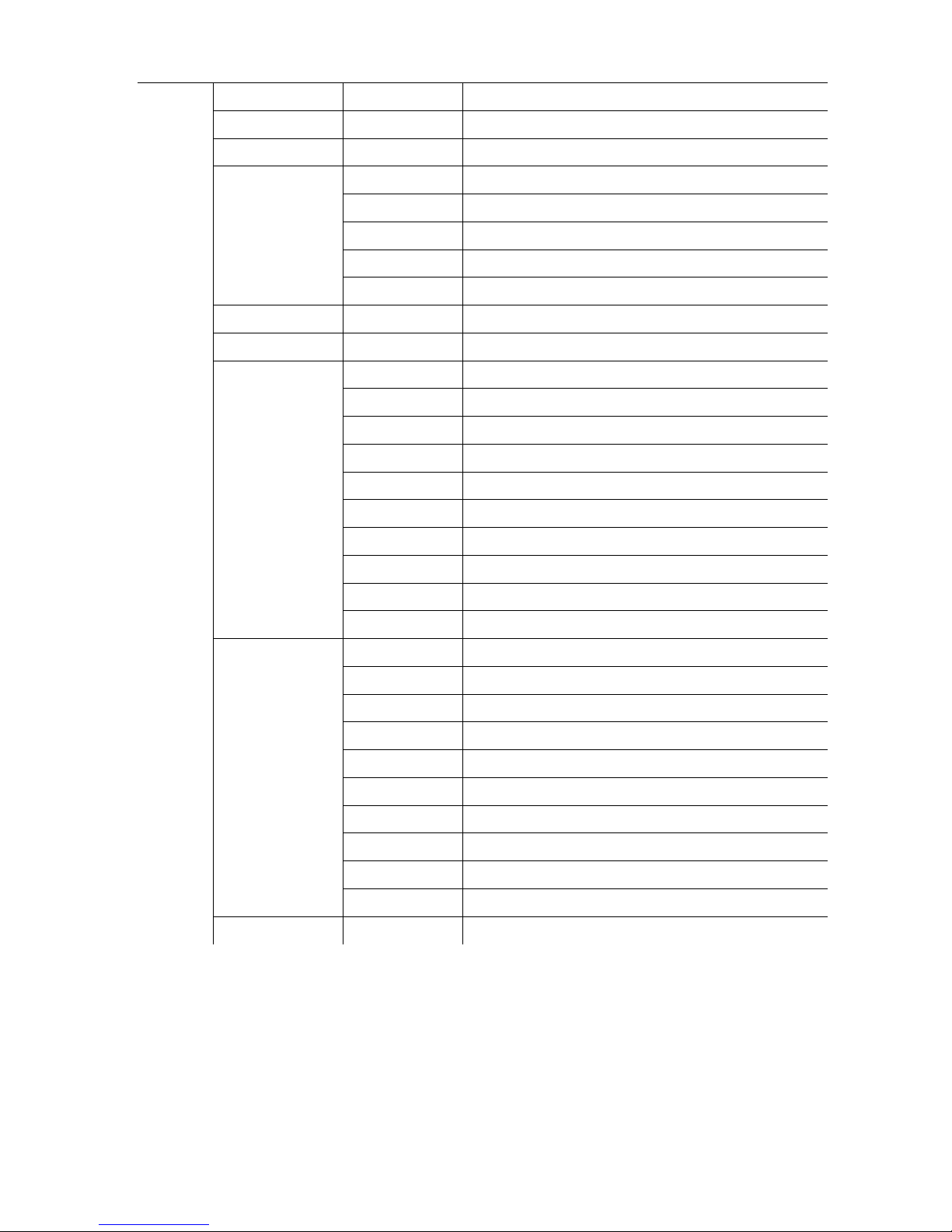

All measurements are expressed in millimeters

393

375

538

469

364

119

315

270°270°

560

270°

128.5°

128.5°

© 2003 Martin Professional A/S, Denmark. All rights reserved. No part of this manual may be reproduced, in any form or by any

means, without permission in writing from Martin Professional A/S, Denmark. Printed in Denmark.

P/N 35000126 Rev. D

Page 3

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

MAC 250 Krypton/Entour safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SETUP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AC power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Connecting the serial data link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Menu navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DMX Mode selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DMX Address selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tailoring performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Information readouts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Test and service utilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DMX-512 CONTROL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Lamp power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Effect position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Speed control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

OPTICAL CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Rotating gobos . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Fixed gobos (MAC 250 Entour only). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Color filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Prism. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Mounting the optional 14° lens (MAC 250 Entour only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Lamp replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Replacing fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Updating software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DMX PROTOCOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

MAC 250 Krypton DMX protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

MAC 250 Entour DMX protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

CONTROL MENU . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

CIRCUIT BOARD CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

SPECIFICATIONS - MAC 250 KRYPTON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

SPECIFICATIONS - MAC 250 ENTOUR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Page 4

4 MAC 250 Krypton/Entour

I

NTRODUCTION

Thank you for selecting the Martin MAC 250 Krypton or the MAC 250 Entour.

Features

Some of the many features include:

• efficient, 2000 hour, 250 watt discharge lamp

• 12 interchangeable dichroic colors

• 7 interchangeable indexed-rotation gobos

• interchangeable 3-facet rotating prism

• motorized focus

• full-range dimming

• fast blackout and strobe effects

• coated optics

• user-installable firmware

• switch-selectable power supply settings

The MAC 250 Entour additionally features:

• 10 fixed gobos

• Tilt locks

• Optional lens providing a 14° beam angle

For the latest firmware updates, documentation, and other information about this and all Martin Professional

products, please visit the Martin web site at http://www.martin.dk.

Please check the Martin web site at http://www.martin.dk for the latest product software and documentation.

Comments or suggestions regarding this document may be e-mailed to service@martin.dk or posted to

Martin Professional A/S

Olof Palmes Allé 18

DK-8200 Aarhus N, Denmark

Attn: Service Department

Please review the important safety precautions in this manual before installing and operating the fixture.

MAC 250 Krypton/Entour safety information

Warning! This product is for professional use only. It is not for household or residential use.

This product presents risks of lethal or severe injury due to fire and heat, electric shock, ultraviolet radiation,

lamp explosion, and falls. Read this manual before powering or installing the fixture, follow the safety

precautions listed below and observe all warnings in this manual and printed on the fixture. If you have

questions about how to operate the fixture safely, please contact your Martin dealer or call the Martin

24-hour service hot line at +45 70 200 201.

PROTECTION FROM ELECTRIC SHOCK

Warning! Always disconnect from mains supply before replacing the lamp.

• Disconnect the fixture from AC power before removing or installing the lamp, fuses, or any part, and when

not in use.

• Always ground (earth) the fixture electrically.

Page 5

Introduction 5

• Use only a source of AC power that complies with local building and electrical codes and has both overload

and ground-fault protection.

• Do not expose the fixture to rain or moisture.

• Refer any service operation not described in this manual to a qualified technician.

PROTECTION FROM UV RADIATION AND LAMP EXPLOSION

• Never operate the fixture with missing or damaged lenses and/or covers.

• When replacing the lamp, allow the fixture to cool for at least 15 minutes before opening the fixture or

removing the lamp. Protect your hands and eyes with gloves and safety glasses.

• Do not stare directly into the light. Never look at an exposed lamp while it is lit.

• Replace the lamp if it becomes defective or worn out, or before usage exceeds the maximum service life.

PROTECTION FROM BURNS AND FIRE

Danger! Intense heat. Avoid contact by persons and materials.

The exterior of the fixture can get very hot - up to 120° C (248° F). Allow the fixture to cool

for at least 45 minutes before handling.

Prolonged exposure to unshielded lamp can cause eye and skin burns.

• Never attempt to bypass the thermostatic switch or fuses. Always replace defective fuses with ones of the

specified type and rating.

• Keep all combustible materials (for example fabric, wood, paper) at least 1 meter (39 inches) away from the

fixture. Keep flammable materials well away from the fixture.

• Do not illuminate surfaces within 3 meters (10 feet) of the fixture.

• Provide a minimum clearance of 0.1 meters (4 inches) around fans and air vents.

• Never place filters or other materials over the lens.

• Do not modify the fixture or install other than genuine Martin parts.

• Do not operate the fixture if the ambient temperature (Ta) exceeds 40° C (104° F). Protection from injury

due to falls

• Do not lift or carry the fixture alone.

• When suspending the fixture, verify that the structure can hold at least 10 times the weight of all installed

devices.

• Verify that all external covers and rigging hardware are securely fastened and use an approved means of

secondary attachment such as a safety cable.

• Block access below the work area whenever installing or removing the fixture.

Page 6

6 MAC 250 Krypton/Entour

S

ETUP

Unpacking

The MAC 250 Krypton/Entour comes with:

• MSD 250/2 lamp (factory installed)

• 3-meter, 3-wire IEC power cable

• user manual

• 1/4-turn clamp mounting bracket

• 5-meter, 3-pin shielded XLR control cable

The MAC 250 Entour also comes with an extra 14° lens.

The packing material or flightcase is carefully designed to protect the fixture during shipment - always use it

to transport the fixture.

When installing the MAC 250 Entour model you may find it useful to lock the

head in place using the tilt locks.

AC power

Warning! For protection from electric shock, the fixture must be grounded

(earthed). The power supply shall have overload and

ground-fault protection.

Important! Verify that power supply settings match the local AC supply

before use.

The MAC 250 Krypton/Entour is factory configured for 230 V / 50 Hz operation. If your AC power supply is

different, the fixture must be configured for the local voltage and frequency. Always use the settings that are

closest to your AC supply.

Page 7

Setup 7

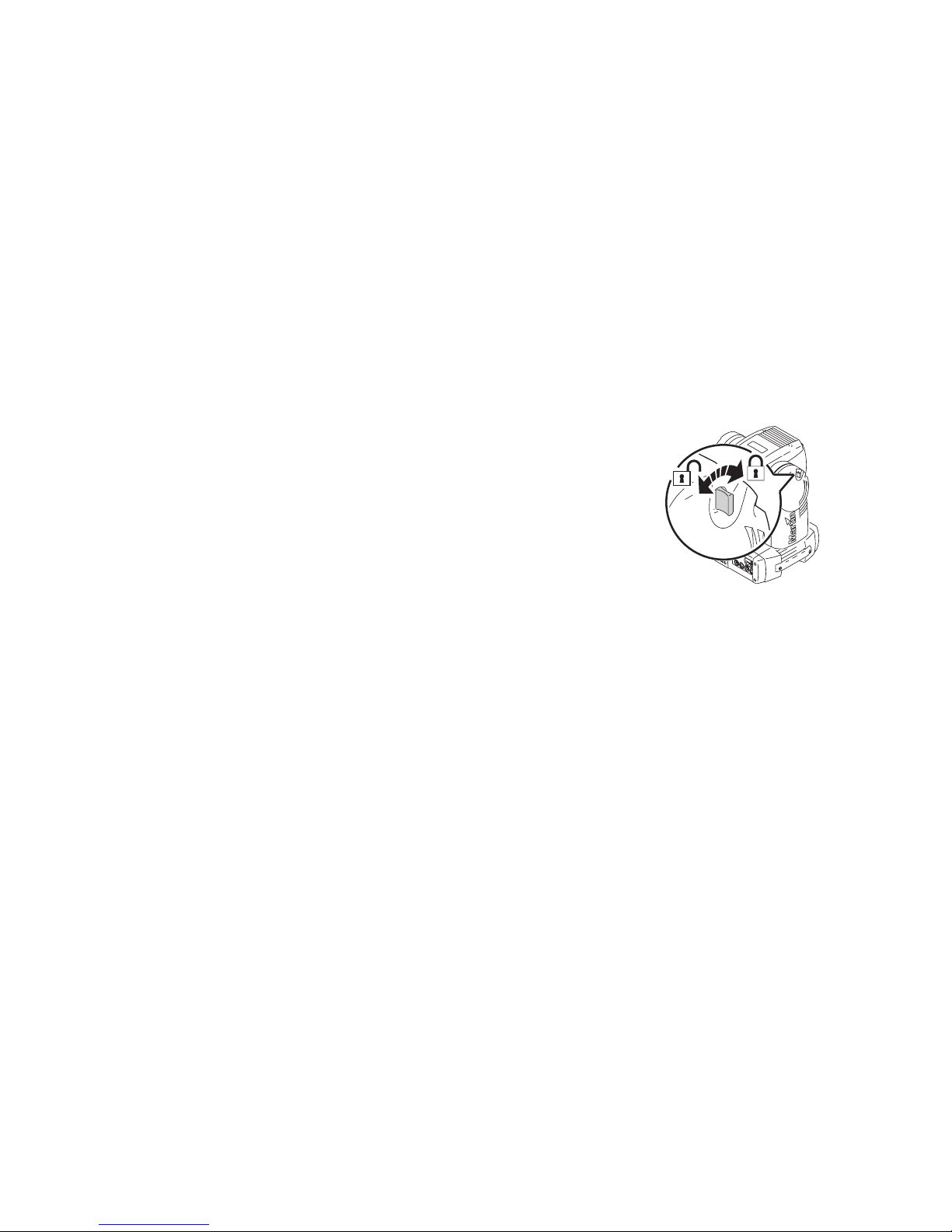

CONFIGURING FOR LOCAL AC POWER

1 Disconnect the fixture from power.

2 Remove the 2 Phillips screws in the access cover directly behind the power and data connectors. Lift off the

cover.

3 Locate the selection switches.

4 Move the voltage switch to the setting that most closely matches the local AC voltage. If your voltage falls

halfway between 2 settings, select the higher voltage. For example, if the AC voltage is 220 V, use the 230

V setting instead of 210 V.

5 Move the frequency switch to the setting that matches the local AC frequency: 50 or 60 Hz.

6 Replace the cover.

INSTALLING A PLUG ON THE POWER CABLE

The power cable must be fitted with a grounding-type cord cap that fits your power distribution system.

Consult an electrician if you have any doubts about proper installation.

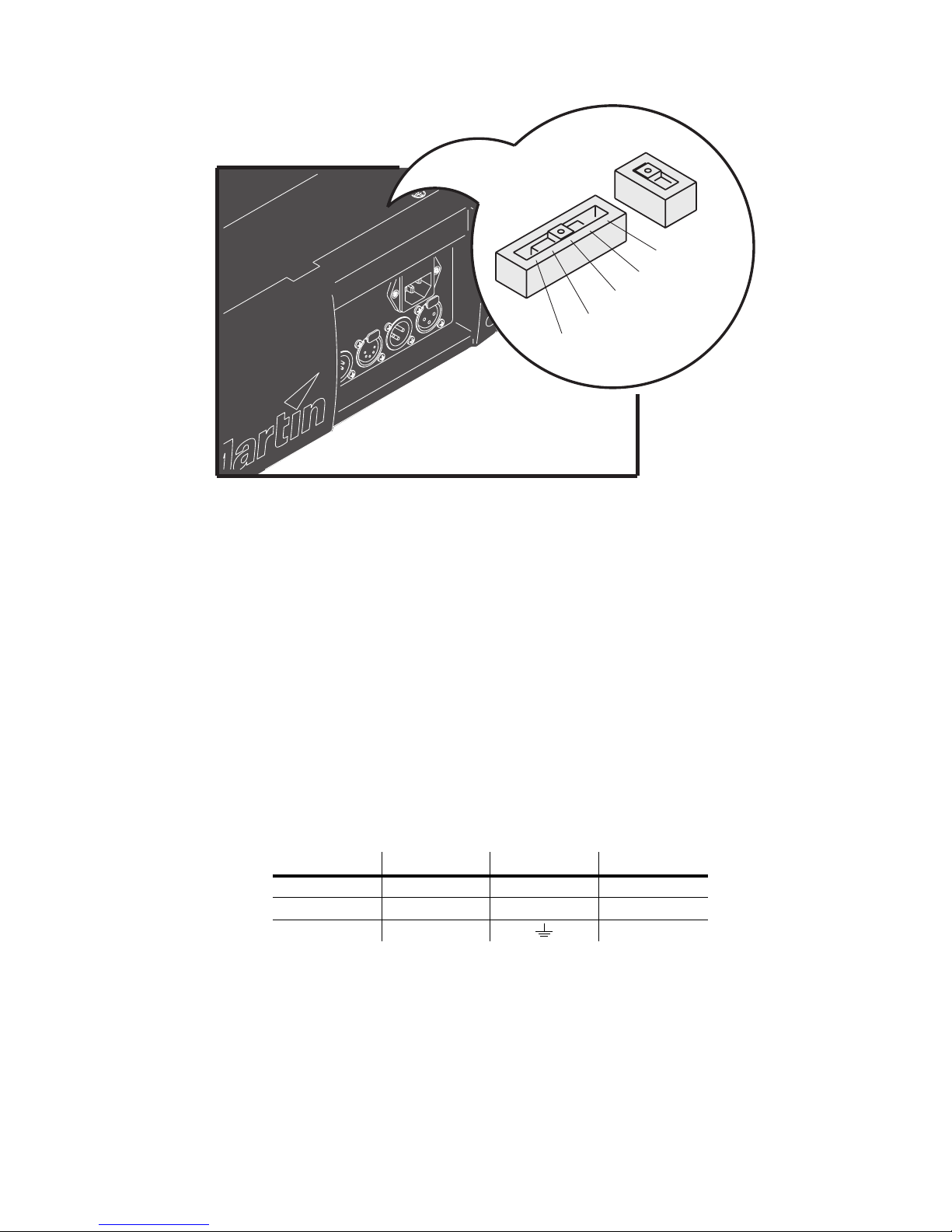

• Following the cord cap manufacturer’ s instructions, connect the yellow and green wire to ground (earth), the

brown wire to live, and the blue wire to neutral. The table below shows some pin identification schemes.

APPLYING POWER

Warning! The power cables must be undamaged and rated for the electrical requirements of all

connected devices.

Important! Powering through a dimmer system can damage the fixture.

1 Verify that the supply cable is undamaged and rated for the current requirements of all connected devices.

2 Plug the prepared power cable into the AC socket and a grounded AC power supply.

Wire Pin Marking Screw color

brown live “L” yellow or brass

blue neutral “N” silver

yellow/green ground green

Table 1: Plug wiring

50

60

120

100

210

230

250

Figure 1: Power supply settings

Voltage

Frequency

Page 8

8 MAC 250 Krypton/Entour

Installation

LOCATION AND ORIENTATION

The MAC 250 Krypton/Entour may be installed in any orientation. It can be fastened directly to a suitable

surface, hung with a rigging clamp, or placed directly on a level surface.

For safe operation, install the MAC 250 Krypton/Entour in a location where:

• the fixture is at least 1 meters (39 inches) away from combustible materials

• the fixture is protected from rain and moisture

• there is at least 0.1 meters (4 inches) clearance around the fan and control panel

• there are no flammable materials nearby

RIGGING OR MOUNTING THE MAC 250 KRYPTON/ENTOUR

Warning! Block access below the work area before proceeding.

The MAC 250 Krypton/Entour can be placed on stage or clamped to a truss in any orientation. The

Fast-Lock system enables quick and easy fastening of the clamp brackets in 4 positions.

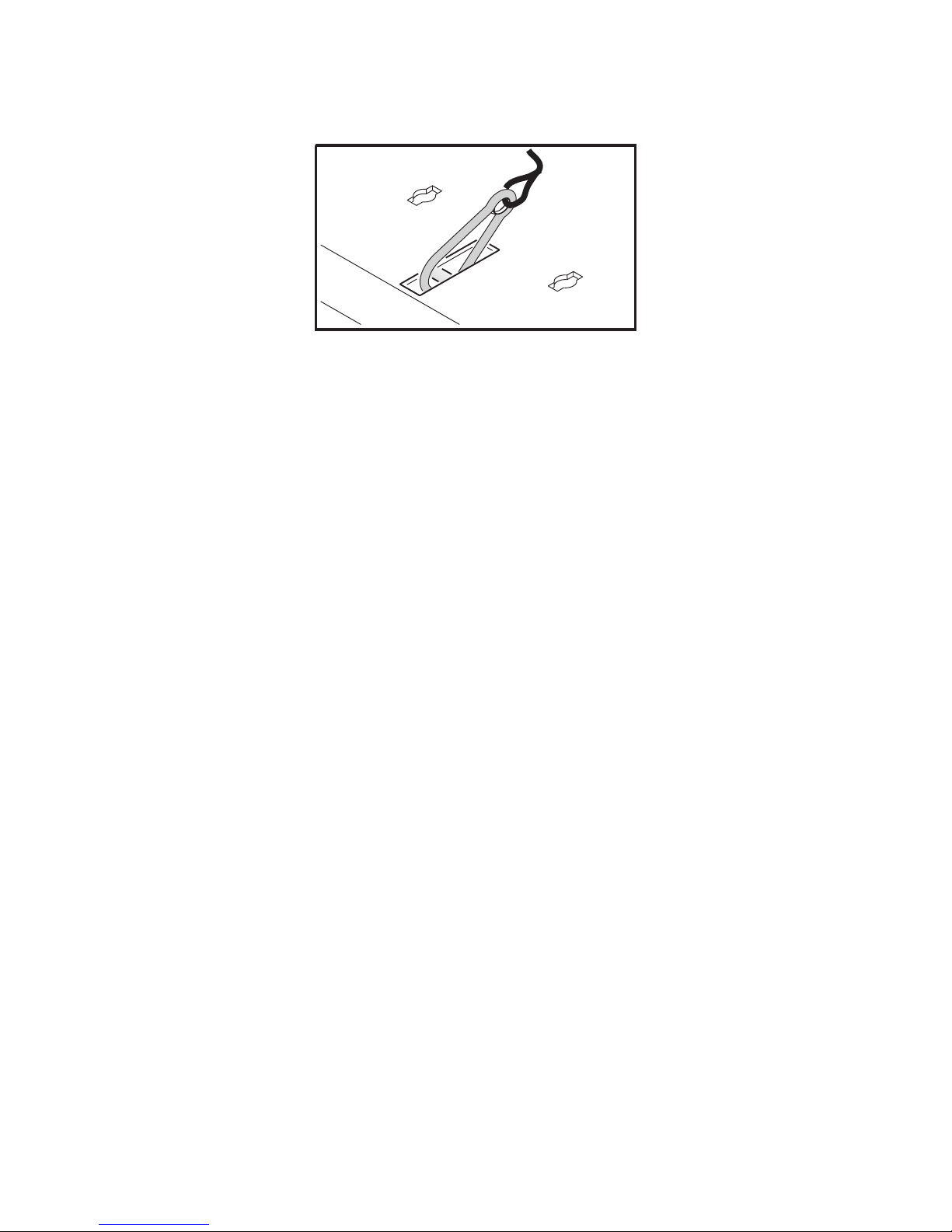

The MAC 250 Krypton/Entour includes an omega clamp mounting bracket to which 1 or 2 rigging clamps

(not included) can be bolted. The clamp mounting bracket fastens to the base as shown with 1/4-turn

fasteners.

Warning! Attach an approved safety cable to the attachment point provided in the base. Never use

the carrying handles for secondary attachment. Always use an approved safety cable.

The 1/4-turn fasteners are locked only when turned fully clockwise.

1 Verify that the clamps are in good condition and can bear at least 10 times the weight of the fixture. Bolt

clamps to the bracket with a grade 8.8 (minimum) M12 bolt and lock nut, or as recommended by the clamp

manufacturer, through the 13 mm holes in the clamp mounting bracket.

2 Align the clamp mounting bracket with any 2 key slots on the base. Insert both locking pins into the slots and

turn both levers a full 1/4 turn clockwise to lock.

3 Verify that the structure can bear at least 10 times the weight of all installed fixtures, clamps, cables,

auxiliary equipment, etc.

4 Working from a stable platform, clamp the fixture to the structure.

Figure 2: Clamp mounting bracket

Page 9

Setup 9

5 Install a safety cable that can bear at least 10 times the weight of the fixture securely to the structure and

anchor the cable to the dedicated attachment point on the base. The attachment point is designed to fit a

carabiner clamp.

6 Verify that there are no combustible materials or surfaces to be illuminated within 1 meter (39 inches) of the

fixture, and that there are no flammable materials nearby.

Connecting the serial data link

The MAC 250 Krypton/Entour has locking 3-pin and 5-pin data input and output sockets that are

wired for use with DMX devices with pin 1 to shield, pin 2 to cold (-) and pin 3 to hot (+).

Important! Never connect more than 1 data input and 1 data output.

1 Connect the controller’s output to the fixture’s data input.

2 Connect the output of the fixture closest to the controller to the input of the next fixture. If connecting a

fixture with pin 3 hot to a fixture with pin 3 cold, use a phase-reversing adaptor.

3 To terminate the link, insert a male 120 Ω XLR termination plug in the output of the last fixture.

TIPS FOR BUILDING A SERIAL LINK

• Use shielded twisted-pair cable designed for RS-485 devices: standard microphone cable cannot transmit

DMX data reliably over long runs. For links up to 300 meters (1000 ft.) long, you can use 24 AWG, low

capacitance, 85-150 ohm characteristic impedance, shielded cable with 1 or more twisted pairs. For runs up

to 500 meters (1640 ft.) use 22 AWG cable. Use an amplifier if the serial link exceeds 500 meters.

• Never use a “Y” connector to split the link. To split the serial link into branches use a splitter such as the

Martin 4-Channel Opto-Isolated RS-485 Splitter/Amplifier.

• Do not overload the link. Up to 32 devices may be connected on a serial link.

• Terminate the link by installing a termination plug in the output socket of the last fixture on the link. The

termination plug, which is simply a male XLR connector with a 120 ohm, 0.25 watt resistor soldered

between pins 2 and 3, “soaks up” the control signal so it does not reflect back down the link and cause

interference. If a splitter is used, terminate each branch of the link.

Page 10

10 MAC 250 Krypton/Entour

C

ONTROL

P

ANEL

You set the address and personalities, read out data, and execute service utilities from the control panel.

Settings can also be changed remotely via the serial link with the Martin MP-2 uploader.

See also the control menu table starting on page 40.

Menu navigation

The DMX address and any error messages are displayed after the fixture resets. To enter the menu, press

[menu]. Use the [up] and [down] keys to move within the menu. To select a function or submenu, press

[enter]. To escape a function or menu, press [menu].

DMX Mode selection

The fixture has two DMX operating modes, 16-bit and 16-bit Extended. 16-bit Extended mode uses 17 DMX

channels, three more than the 14 DMX channels than standard 16-bit mode requires. 16-bit Extended mode

provides more precise control of the dimmer color, and focus settings. The DMX mode is selected using the

PSET option in the fixture control menu (see “Control menu” on page 40).

SETTING THE DMX MODE

1 Apply power to the MAC 250 Krypton/Entour. Press [menu] to enter the main menu.

2 Select PSET using the [up] and [down] keys. Press [enter].

3 Select 16BT for standard 16-bit mode, or 16EX for 16-bit extended mode.Press [enter].

4 Press [menu] to return to the main menu.

DMX Address selection

For independent control, each fixture must be assigned its own address and non-overlapping control

channels. Two MAC 250 Krypton/Entours can share the same address if they are to respond identically:

they will receive the same instructions and individual control will not be possible.

SETTING THE DMX ADDRESS

1 Apply power to the MAC 250 Krypton/Entour. Press [menu] to enter the main menu.

2 Select AddR using the [up] and [down] keys. Press [enter].

3 Select an address (start channel) from 1 to 500 using the [up] and [down] keys. Press [enter]. Press [menu]

to return to the main menu.

Tailoring performance

MOVEMENT

The MAC 250 Krypton/Entour provides the three menus with options for optimizing movement to suit

different applications.

•

PATI, the pan and tilt invert menu, allows you to swap the pan and tilt channels (SWAP>ON), invert pan

movement (

PINV>ON), and invert tilt movement (TINV>ON). These options can be useful in situations

Page 11

Control Panel 11

where you want some fixtures to mirror the performance of others with the same DMX address, or when

fixtures are not oriented as programmed.

•

PTSP, the pan/tilt speed menu, provides 3 settings: FAST, NORM and SLOW. NORM is best for

most applications.

FAST provides better performance in applications where speed is most important.

•

SCUT, the shortcuts setting which can be found under the PERS (personality) menu, determines whether

the color and gobo wheels scroll past open when changing positions. When set to

ON, the wheels can “take

a shortcut” and scroll through open when this is the shortest path to the next position. The wheels do not

scroll past open when

SCUT is set to OFF.

DISPLAY

The display menu (PERS>dISP) determines whether the display remains lit or not. Select ON to have

the display remain lit, or OFF to extinguish the display two minutes after the last key press.

To flip the display for easier reading, press [up] and [down] simultaneously.

The display intensity setting (

PERS>dINT) controls display brightness. You can select AUTO for

automatic dimming of the display using the built-in light sensor, or manually select an intensity level from 10

to 100.

LAMP POWER

There are two settings that modify lamp control: Automatic Lamp On (PERS>ALON) and DMX Lamp-Off

(

PERS>DLoF).

There are three options for automatic lamp control: ON, OFF, and DMX. When ALON is OFF, the lamp

remains off until a lamp-on command is received from the controller. When

ALON is ON, the lamp strikes

automatically after the fixture is powered on. When

ALON is set to DMX, the lamp strikes automatically

when the fixture receives DMX data, and it extinguishes automatically 15 minutes after DMX data is lost.

When ALON is either ON or DMX, lamp strike timing is determined by the fixture address to prevent all

lamps from striking at once.

The DMX Lamp-Off setting effects how the lamp can be turned off. When

dLOF is ON, lamp power can be

switched off by sending a DMX value from 248 to 255 on channel 1 for five seconds. When

dLOF is OFF,

the lamp-off command will not work unless special conditions are met. Refer to the DMX protocol.

RESET

The fixture can be reset from the controller if DMX reset (PERS>dRES) is set to 5SEC. If DMX reset is

OFF, this command will not work unless special conditions are met. Refer to the DMX protocol.

DEFAULT SETTINGS

The fixture can be reset to its factory default settings by selecting dFSE>FACT>LOAd.

Information readouts

POWER-ON HOURS

Read the total number of hours the fixture has been on since fabrication (INFO>TIME>HRS>TOTL),

and the number of hours on since the counter was last reset (

INFO>TIME>HRS>RSET). This can be

used to track maintenance intervals. Press [up] for 5 seconds while displayed to reset.

LAMP HOURS

Read the total number of lamp hours since fabrication (INFO>TIME>L HR>TOTL), and the number

of lamp hours since the counter was last reset (

INFO>TIME>L HR>RSET). Reset this counter after

installing a new lamp. Press [up] for 5 seconds while displayed to reset.

Page 12

12 MAC 250 Krypton/Entour

LAMP STRIKES

Read the total number of lamp strikes (INFO>TIME>L ST>TOTL), and the number of lamps strikes

since the counter was last reset (

INFO>TIME>L ST>RSET). Reset this counter when installing a

new lamp. Press [up] for 5 seconds while displayed to reset.

FIRMWARE VERSION

INFO>VER

displays the firmware version number. The firmware version is also displayed briefly at

startup.

Test and service utilities

DMX READOUT

The DMX log (dMXL) menu provides useful information for troubleshooting control problems.

RATE displays the DMX refresh rate in packets per second. Values lower than 10 or higher than 44 may

result in erratic performance, especially when using tracking control.

qUAL displays the quality of the received DMX data as a percentage of packets received. Values much

below 100 indicate interference, poor connections, or other problems with the serial data link that are the

most common cause of control problems.

STCO displays the DMX start code. Packets with a start code other than 0 may cause irregular

performance.

The remaining options under

dMXL display the DMX values received on each of the 13 channels, from

SHUT (shutter, channel 1) to EFSP (effect speed, channel 13). If the fixture does not behave as expected,

reading the DMX values can help you troubleshoot the problem.

MANUAL CONTROL

The manual control menu (MAN) provides commands for turning the lamp on (LON), turning the lamp off

(

LoFF), and resetting the fixture (RST). It also permits you to position and move individual effects.

EFFECTS TEST

The test sequence (TSEQ>RUN) runs through all effects to provide a quick check of fixture performance.

Note: the test sequence does not automatically strike the lamp. Use

MAN>LON and MAN>LoFF to

control lamp power. Press [menu] to stop the test.

FEEDBACK TOGGLE

Magnetic sensors monitor the positions of the color wheel, gobo wheel, and rotating gobos. If they detect an

error, the shutter closes while the effect resets. This feature can be disabled by turning effects feedback off

(

UTIL>EFFb>OFF).

ADJUSTMENT POSITIONS

The adjustment menu (UTIL>AdJ) provides commands for positioning effects during mechanical

adjustment.

EFFECT CALIBRATION

With the calibration menu (UTIL>CAL), effect positions can be fine-tuned with a software-defined offset

value to compensate for small misalignments or differences between fixtures.

The default offset command (

UTIL>dFOF) erases any offsets stored in memory.

CIRCUIT BOARD TEST

UTIL>PCBT

executes a routine designed for testing the main circuit board. For service use only.

Page 13

Control Panel 13

UPLOAD MODE

The upload mode command (UTIL>UPLd) prepares the fixture for a software update. This command is

not necessary, however, as upload mode is engaged automatically by the uploader.

Page 14

14 MAC 250 Krypton/Entour

DMX-512

CONTROL

The MAC 250 Krypton/Entour is compatible with USITT DMX512 controllers.

The full protocol is available in “DMX protocol” on page 33.

The fixture has two DMX operating modes, 16-bit and 16-bit Extended. 16-bit Extended mode uses 17 DMX

channels, three more than the 14 DMX channels than standard 16-bit mode requires. 16-bit Extended mode

provides more precise control of the dimmer color, and focus settings. All other functions are identical. See

“DMX protocol” on page 25.This section briefly describes the DMX-controllable effects. The DMX mode is

selected using the PSET option in the fixture control menu (see “Control menu” on page 40).

Lamp power

LAMP-ON

Unless automatic lamp strike is enabled, lamp power remains off until a lamp-on command is sent from the

controller.

Note: A peak of electric current that can be many times the operating current is drawn for an instant when

striking a discharge lamp. Striking many lamps at once may cause a voltage drop large enough to prevent

lamps from striking or draw enough current to trip circuit breakers. If sending lamp-on commands to multiple

fixtures, program a sequence that strikes lamps one at a time at 5 second intervals.

LAMP-OFF

The lamp can be turned off from the controller by sending the lamp-off command on channel 1 for 5

seconds. The lamp cannot be restruck for 8 minutes after being turned off. Note that the

lamp-off command may be disabled by the DMX Lamp-Off personality setting (PERS/dLOF).

Effect position

RESET

If an effect loses its indexing and fails to move to programmed positions, the fixture can be reset from the

controller by sending the “Reset” command on channel 1 for 5 seconds. Note that the DMX reset feature

may be disabled by the DMX Reset personality setting (PERS/dRES).

DIMMER / SHUTTER

The mechanical dimmer/shutter system provides full, high-resolution dimming, “instant” open and blackout,

random and variable strobe effects, and random and variable pulses in which the dimmer snaps open and

slowly dims or snaps closed and slowly opens. Shutter, strobe, and pulse effects are selected on channel 1.

The intensity level is selected on channel 2. 16-bit Extended mode provides fine tuning of the intensity level

on channel 3.

COLOR

The color wheel can be scrolled continuously - allowing for split color effects - or in steps, and rotated

randomly or continuously in both directions at different speeds. 16-bit Extended mode provides finer tuning

on channel 5 of the color setting selected on channel 4.

ROTATING GOBOS

The MAC 250 Krypton/Entour has 7 indexed-rotation gobo positions plus an open position. Gobos can be

indexed (positioned at a defined angle), rotated continuously, or rotated and shaken (bounced). The gobo

and the type of movement are selected on channel 4 (channel 6 in 16-bit Extended mode) and the index

Page 15

DMX-512 control 15

angle or rotation speed are selected on channel 5 (channel 7 in 16-bit Extended mode). Fine tuning of this

index position or rotation is available on channel 6 (channel 8 in 16-bit Extended mode).

The gobo wheel can also rotate continuously in both directions at variable speed.

FIXED GOBOS (MAC 250 ENTOUR ONLY)

The MAC 250 Entour provides an additional wheel with 10 fixed gobo positions (plus open). The gobo and

the type of movement are selected on channel 7 (channel 9 in 16-bit Extended mode). The gobo wheel can

also rotate continuously in both directions at variable speed.

FOCUS

The beam may be focused from approximately 2 meters (6.5 feet) to infinity using channel:

• 7 in 16-bit mode on the MAC 250 Krypton

• 9 in 16-bit Extended mode on the MAC 250 Krypton

• 8 in 16-bit mode on the MAC 250 Entour

• 10 in 16-bit Extended mode on the MAC 250 Entour

ROTATING PRISM

The prism is controlled using channel:

• 8 in 16-bit mode on the MAC 250 Krypton

• 10 in 16-bit Extended mode on the MAC 250 Krypton

• 9 in 16-bit mode on the MAC 250 Entour

• 11 in 16-bit Extended mode on the MAC 250 Entour

The prism may be inserted and removed from the light path. It rotates in both directions at varying speeds.

PAN AND TILT

Head pan and tilt are controlled on channels

• 9-12 in 16-bit mode on the MAC 250 Krypton

• 12-15 in 16-bit Extended mode on the MAC 250 Krypton

• 10-13 in 16-bit mode on the MAC 250 Entour

• 13-16 in 16-bit Extended mode on the MAC 250 Entour

The course control channel sets first 8 bits (the most significant byte or MSB), and the fine channel sets the

second 8 bits (the least significant byte or LSB) of the 16-bit control byte. In other words, the fine channel

fine-tunes the position set by the course channel.

Speed control

The speed control channels are:

• 13 & 14 in 16-bit mode on the MAC 250 Krypton

• 16 & 17 in 16-bit Extended mode on the MAC 250 Krypton

• 14 & 15 in 16-bit mode on the MAC 250 Entour

• 17 & 18 in 16-bit Extended mode on the MAC 250 Entour

TRACKING CONTROL

Tracking control for pan/tilt and the various effects is enabled by setting the speed channels to 0.

With tracking control, the speed at which effects move is determined by the cross-fade time between two

positions or scenes. The controller divides the move into steps and updates the fixture with small changes

at the rate required to achieve the fade. The fixture “tracks” the changes and averages them with a digital

filter algorithm to provide smooth movement.

Page 16

16 MAC 250 Krypton/Entour

VECTOR CONTROL

Alternatively, with vector control, movement speed is determined by the selected speed values on the speed

channels.This provides a way to control speed on controllers without cross-faders. Vector control also

provides smoother movement, particularly at slow speeds, with controllers that send slow or irregular

tracking updates.

When using vector control, the cross-fade time must be 0.

BLACKOUT

When “blackout while moving” is selected on the speed channels, the shutter closes when the effect moves

to make the transition invisible. The shutter opens when the movement is complete.

PERSONALITY OVERRIDES

The following channel provide tracking values that allow you to override the pan/tilt speed personality

setting (PTSP in the control menu)

• 13 in 16-bit mode on the MAC 250 Krypton

• 16 in 16-bit Extended mode on the MAC 250 Krypton

• 14 in 16-bit mode on the MAC 250 Entour

• 17 in 16-bit Extended mode on the MAC 250 Entour

The following channel provide tracking values that allow you to override the shortcuts setting (SCUT in the

control menu).

• 14 in 16-bit mode on the MAC 250 Krypton

• 17 in 16-bit Extended mode on the MAC 250 Krypton

• 15 in 16-bit mode on the MAC 250 Entour

• 18 in 16-bit Extended mode on the MAC 250 Entour

Page 17

Optical configuration 17

O

PTICAL CONFIGURATION

GOBO ORIENTATION

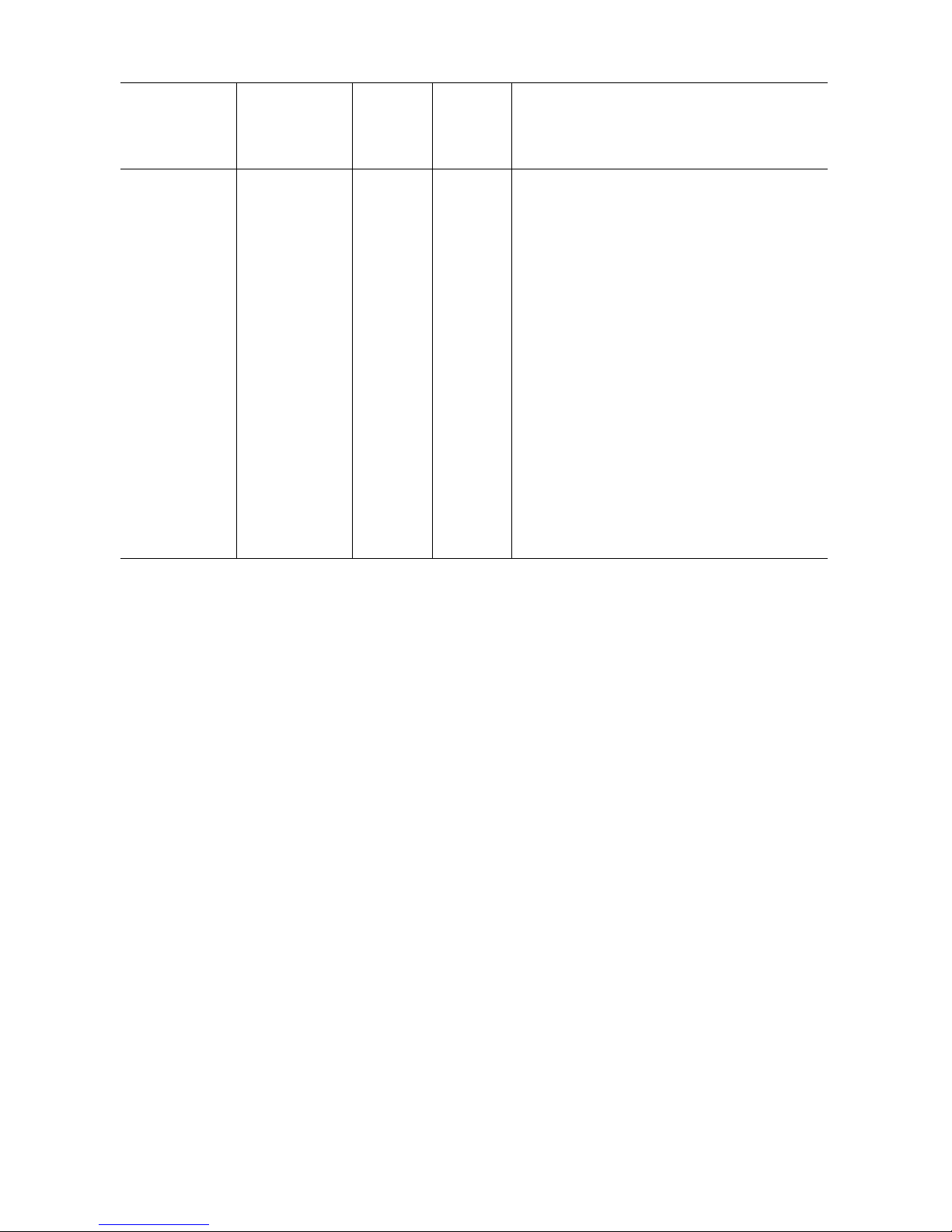

Figure 3 shows the correct orientation for different gobo types. When in doubt, install gobos with the more

reflective side towards the lamp.

CUSTOM GOBOS

For optimum performance, custom glass gobos for the MAC 250 Krypton/Entour should be made with the

text, logo, and similar artwork reversed on the coated side. Gobo types and dimensions are specified in on

“Gobos” on page 47.

Rotating gobos

The MAC 250 Krypton/Entour accepts up to eight metal or glass gobos with an outside diameter of 22.5 mm

and a maximum image diameter of 17 mm.

Coated Glass Gobos

Coated side towards stageUncoated side towards lamp

When an object is held up to the

uncoated side there is no space

between the object and its

reflection. The back edge of the

gobo cannot be seen when

looking through the coated side.

When an object is held up to the

coated side there is a space

between the object and its reflection.

The back edge of the gobo can be

seen when looking through the

uncoated side.

Textured side towards stage

Textured Glass Gobos

Smooth side towards lamp

Metal Gobos

Reflective side towards lamp Black side towards stage

Image/text Gobos

Reversed image towards

lamp

True image towards stage

Figure 3: Gobo orientation

Page 18

18 MAC 250 Krypton/Entour

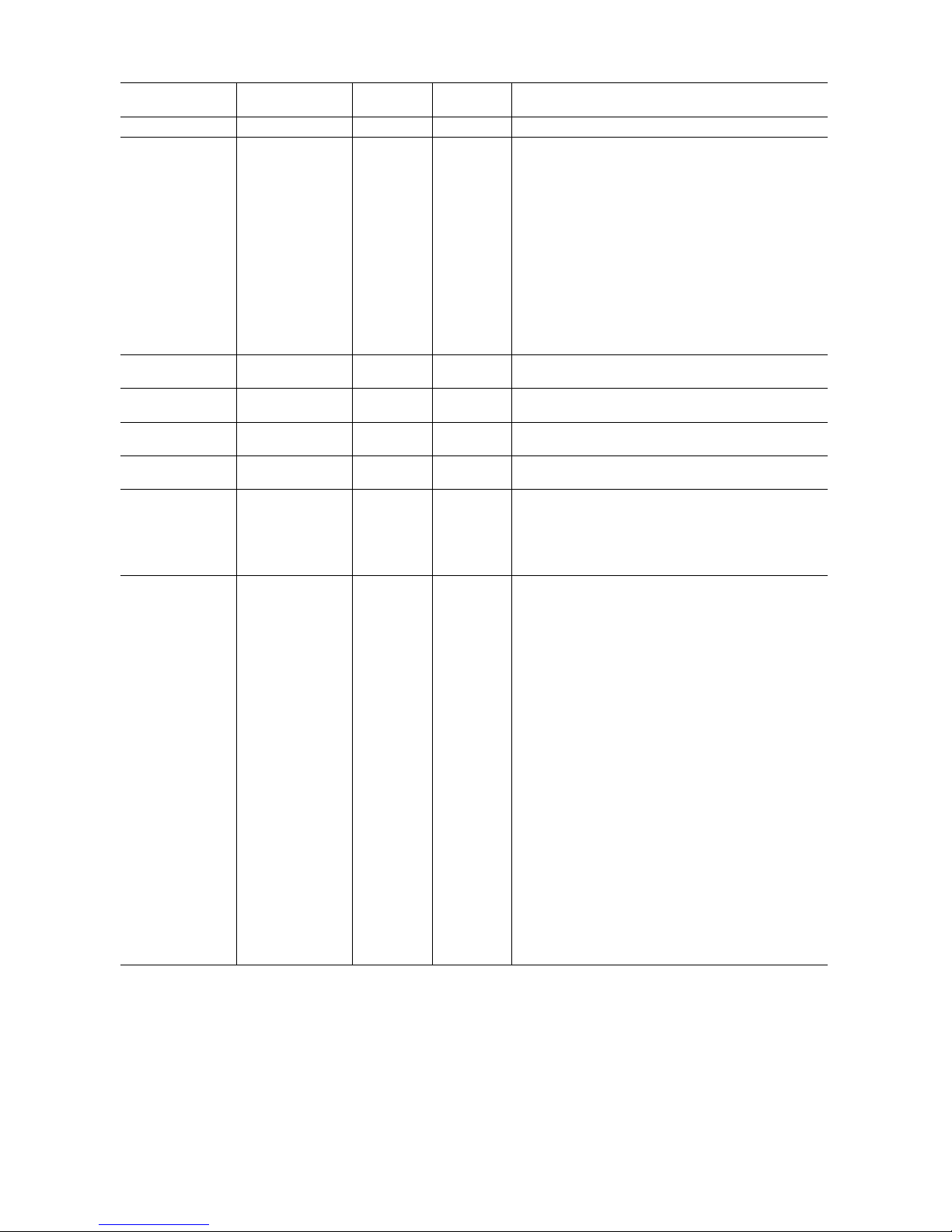

STANDARD ROTATING GOBO CONFIGURATION

The MAC 250 Krypton/Entour provides 7 gobos as shown below.

REPLACING A GOBO

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow it to cool

for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

1 Disconnect the fixture from AC power and allow it to cool.

2 Remove the top cover of the fixture head using a flathead screwdriver to loosen the four quarter-turn

screws. The top and bottom cover look the same, but the top cover is found by checking if the text on the

back of the head is oriented correctly (top) or not (bottom) as illustrated here.

3 Turn the gobo wheel to access the desired position.

Position Gobo

1 Eclipse

2 Fat bar

3Fan

4 Happy Yins

5 Twisted triangle

6 Splash

7 Aflobet

Table 2: Rotating gobos

Figure 3: MAC 250

1

2

3

4

5

7

6

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

Page 19

Optical configuration 19

4 Remove the gobo holder from the gobo wheel.

5 Squeeze the ends of the retention spring together and remove. Push the gobo out from the back and

remove.

6 Orient the gobo as shown in “Gobo orientation” on page 17 and insert the replacement gobo into the holder.

Secure the gobo with the retention spring.

7 Insert the gobo holder back in the gobo wheel using a small flathead screwdriver to lift the retaining blades.

8 Replace the cover before applying power.

Page 20

20 MAC 250 Krypton/Entour

Fixed gobos (MAC 250 Entour only)

The MAC 250 Entour provides 10 fixed gobo positions (plus open).

REPLACING A FIXED GOBO

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow it to cool

for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

1 Disconnect the fixture from AC power and allow it to cool.

2 Remove the top cover of the fixture head using a flathead screwdriver to loosen the four quarter-turn

screws. The top and bottom cover look the same, but the top cover is found by checking if the text on the

back of the head is oriented correctly (top) or not (bottom) as illustrated here.

3 Turn the gobo wheel to access the desired position.

1

2

3

4

5

6

7

8

9

10

.

Position Gobo

1 Oriental fire

2Wiggles

3 Pear drops

4 Brush strokes

5 Lashes

6 Splash

7 Crazed

8 Dibs

9 Sharp breakup (large)

10 Zeds-a-leaping

Table 3: Fixed gobos

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

Page 21

Optical configuration 21

4 Push and slide the gobo out of position

5 Insert the replacement gobo into the holder. Secure the gobo with the retention feather. You may find it

easiest to do this with the assistance of a flathead screwdriver.

6 Replace the cover before applying power.

Color filters

STANDARD CONFIGURATION

The MAC 250 Krypton/Entour provides 12 dichroic color filters as shown below.

12

11

10

9

8

7

6

5

4

3

2

1

Position Color

1

CTC

2

Yellow 603

3

Blue 104

4

Pink 312

5

Green 206

6

Blue 108

7

Red 301

8

Magenta 507

9

Blue 101

10

Orange 306

11

Dark green

12

Purple 502

Figure 5: MAC 250

Page 22

22 MAC 250 Krypton/Entour

REPLACING A COLOR FILTER

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow it to cool

for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

1 Disconnect the fixture from AC power and allow it to cool.

2 Remove the top cover. The top and bottom cover look the same, but the top cover is found by checking if

the text on the back of the head is oriented correctly (top) or not (bottom).Remove the top cover of the

fixture head using a flathead screwdriver to loosen the four quarter-turn screws. The top and bottom cover

look the same, but the top cover is found by checking if the text on the back of the head is oriented correctly

(top) or not (bottom) as illustrated here.

3 Turn the color wheel to access the desired color filter. Press the

filter forwards slightly to release it and then grasp it by the edges

and remove.

4 To insert a filter, slide it under the retention spring until it snaps into

place.

5 Replace the top cover before applying power.

Prism

The standard 3-facet prism can be replaced with optional five- and nine-facet prisms. See “Accessories” on

page 48 for part numbers. See:

• Replacing the prism in a MAC 250 Entour below, or

• “Replacing the prism in a MAC 250 Krypton” on page 24.

REPLACING THE PRISM IN A MAC 250 ENTOUR

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow it to cool

for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

1 Disconnect the fixture from AC power and allow it to cool.

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

A

B

Figure 4: Filter replacement

Page 23

Optical configuration 23

2 Remove the top cover. The top and bottom cover look the same, but the top cover is found by checking if

the text on the back of the head is oriented correctly (top) or not (bottom).Remove the top cover of the

fixture head using a flathead screwdriver to loosen the four quarter-turn screws. The top and bottom cover

look the same, but the top cover is found by checking if the text on the back of the head is oriented correctly

(top) or not (bottom) as illustrated here.

3 Using a flathead screwdriver, remove the two retaining plates (only one - at position A - is illustrated here)

holding the prism module in place. Disconnect the cables (at positions marked B) from the PCBs on the

prism module.

4 Lift the prism module out of the fixture.

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

A

B

Page 24

24 MAC 250 Krypton/Entour

5 Using a Philips screwdriver, remove the half-circle shaped plate that holds the prism into place (as indicated

in this illustration).

6 Remove the rubber belt to free the prism and replace it with a compatible rotating prism (contact your Martin

dealer for a list of available prisms).

7 Replace the rubber drive belt over the rotating prism and screw the half-circle shaped plate into place. The

prism should be able to rotate freely.

8 Reinsert the prism module into the fixture, reattach the leads (these are numbered) to the PCBs, and screw

the retaining plates into place.

9 Replace the top cover using a flathead screwdriver to tighten the four quarter-turn screws.

10 Connect the fixture to AC power.

REPLACING THE PRISM IN A MAC 250 KRYPTON

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow it to cool

for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

1 Disconnect the fixture from AC power and allow it to cool.

2 Remove the top cover. The top and bottom cover look the same, but the top cover is found by checking if

the text on the back of the head is oriented correctly (top) or not (bottom).Remove the top cover of the

fixture head using a flathead screwdriver to loosen the four quarter-turn screws. The top and bottom cover

look the same, but the top cover is found by checking if the text on the back of the head is oriented correctly

(top) or not (bottom) as illustrated here.

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

Page 25

Optical configuration 25

3 Using a flathead screwdriver, remove the two retaining plates (only one - at position A - is illustrated here)

holding the prism module in place. Disconnect the cables (at positions marked B) from the PCBs on the

prism module.

4 Lift the prism module out of the fixture.

5 Using a Philips screwdriver, remove the half-circle shaped plate that holds the prism into place (as indicated

in this illustration).

6 Remove the rubber belt to free the prism and replace it with a compatible rotating prism (contact your Martin

dealer for a list of available prisms).

A

B

B

Page 26

26 MAC 250 Krypton/Entour

7 Replace the rubber drive belt over the rotating prism and screw the half-circle shaped plate into place. The

prism should be able to rotate freely.

8 Reinsert the prism module into the fixture, reattach the leads (these are numbered) to the PCBs, and screw

the retaining plates into place.

9 Replace the top cover using a flathead screwdriver to tighten the four quarter-turn screws.

10 Connect the fixture to AC power.

Mounting the optional 14° lens (MAC 250 Entour only)

The MAC 250 Entour is supplied with an optional 14° lens. Mounting optional 14 degree lens. to mount the

lens:

1 Disconnect the fixture from AC power and allow it to cool.

2 Lock the head in top side up position. Remove the top cover of the fixture head using a flathead screwdriver

to loosen the four quarter-turn screws. The top and bottom cover look the same, but the top cover is found

by checking if the text on the back of the head is oriented correctly (top) or not (bottom) as illustrated here.

3 Locate the effect module and remove the wire connectors (located at position B). Using a flat head

screwdriver, remove the screws (located at the positions marked A) and lift the tabs. Lift the effect module

out of the fixture.

Minimum

dist

ance to flammMinimum

dist

ance to flamm

Minimum

dist

ance to illumina

Maximum

ambient te

Exterior surface to

B

A

A

Page 27

Optical configuration 27

4 Remove the three Phillips screws and lift the plate off the effect module.

5 Remove the four Phillips screws.

6 Lift the lens module plate off the effect module.

7 Remove the three Torx 10 screws holding the lens in place.

Page 28

28 MAC 250 Krypton/Entour

8 Place the 14° lens between the standard lens and the plate and replace the three Torx 10 screws.

9 Perform these steps in reverse, returning the components to their correct positions and replacing all the

covers, before applying power to the fixture.

Page 29

Service 29

S

ERVICE

The MAC 250 Krypton/Entour requires regular maintenance to keep performing at their peak. Excessive

dust, grease, and smoke fluid buildup degrades performance and causes overheating and damage that is

not covered by the warranty. The maintenance schedule will depend on the application and should be

discussed with your Martin distributor. Refer any service that is not described here to a professional

technician.

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). Disconnect the fixture from AC power and allow the it to

cool for at least 45 minutes before handling.

Do not removing covers while the fixture is powered on as this exposes dangerous live

electrical circuits, hot surfaces, and a lamp under high pressure.

Lamp replacement

Lamp life will vary; the rated life is an average figure that is based on the manufacturer’s test cycle. For

maximum lamp life, avoid excessive strikes and always allow the lamp to burn for at least 5 minutes before

turning it off.

To reduce the risk of lamp explosion, which may damage the fixture, never exceed the lamp’s rated life

(2000 hours) by more than 25 percent.

Replace the lamp when:

• it strikes with difficulty or not at all, or is in any other way defective

• usage exceeds the manufacturer’s “replace before” hours. See Table 5.

COMPATIBLE LAMPS

A Philips MSD 250/2 lamp is included installed. The MAC 250 Krypton/Entour lamp options are shown in the

table below. Installing any other lamp may damage the fixture.

INSTALLING A LAMP

Danger! Intense heat. Avoid contact by persons and materials. The exterior of the fixture can get

very hot - up to 120° C (248° F). When replacing the lamp, disconnect the fixture from AC

Lamp Average life Color Temp.

Osram HSD 250/78 3000 hr 7800K

Philips MSD 250/2 2000 hr 9000K

GE CSD 250/2 2000 hr 9000K

Table 5: Lamp comparison

Page 30

30 MAC 250 Krypton/Entour

power and allow it to cool for at least 45 minutes before proceeding. Wear safety goggles

to protect your eyes.

1 Locate the lamp access cover at the back of the fixture head and remove the Phillips screws.

2 Pull out the lamp socket.

3 If changing the lamp, remove the old lamp from the socket.

4 Holding the new lamp by its ceramic base (do not touch the glass), align the small pin on the lamp with the

small hole in the socket and insert the lamp squarely. Make sure that the 4 small projections on the base

contact the face of the socket.

5 Clean the glass bulb with the cloth supplied with the lamp, particularly if your fingers touched the glass. A

clean, lint-free cloth wetted with alcohol may also be used.

6 Insert the lamp into the fixture with as little twist in the lamp wires as possible.

7 Align the screw holes and fasten the lamp access plate with 2 screws.

8 If replacing the lamp, reset the lamp hour and lamp strike counters as described on page 11.

9 Strike the lamp (after setup is complete) and adjust it for optimum performance by turning the 3 adjustment

screws one at a time until the brightest part of the beam is centered.

10 Adjust the lamp position if necessary by turning the 3 lamp adjustment screws to the middle of their range

using a 3 mm Allen wrench.

Cleaning

OPTICAL COMPONENTS

Use care when cleaning optical components. The surface on dichroic filters is achieved by means of special

multi-layer coatings and even small scratches may be visible. Residues from cleaning fluids can bake onto

components and ruin them.

1 Allow the components to cool completely.

2 Wash dirty lenses and filters with isopropyl alcohol. A generous amount of regular glass cleaner may also

be used, but no residues may remain.

3 Rinse with distilled water. Mixing the water with a small amount of wetting agent such as Kodak Photoflo will

help prevent streaking and spotting.

4 Dry with a clean, soft and lint-free cloth or blow dry with compressed air.

3

#2

mm

Figure 5: Lamp installation

Page 31

Service 31

FAN

To maintain adequate cooling it is important that the fan be cleaned regularly. It can be cleaned with a soft

brush, vacuum, or compressed air.

Lubrication

Use only silicone lubricant, Martin P/N 37302003 (500 ml) or P/N 37302004 (200 ml, in applicator bottle).

No other lubricant is approved for use. When applying lubricant, always remove excess and do not get oil

on other parts.

1 Check the focus mechanism and apply a drop of lubricant to the 3 metal slides if movement is rough.

2 Lubricate the rotating-gobo bearings if movement is rough on slow rotation or if they become noisy. Apply a

few drops of oil to each bearing from the lamp side of the wheel.

Replacing fuses

MAIN FUSE

The main fuse holder is built in to the mains input socket. Never replace the fuse with one of a different

rating!

1 Unplug the mains cable from the input socket.

2 Pry open the fuse holder and remove the fuse.

3 Replace the fuse with one of the same type and rating. The fuse rating is listed on serial number label.

4 Close the fuse holder and replace the mains cable.

POWER SUPPLY FUSES

There are two fuses for the low-voltage power supplies located on the printed circuit board. If one or more of

the green LEDs on the PCB does not light, one of these fuses may be blown. If all three LEDs are lit, the

low-voltage power supplies are functioning correctly.

Have the fixture serviced by a Martin service technician if the problem persists.

1 Disconnect the fixture from AC power.

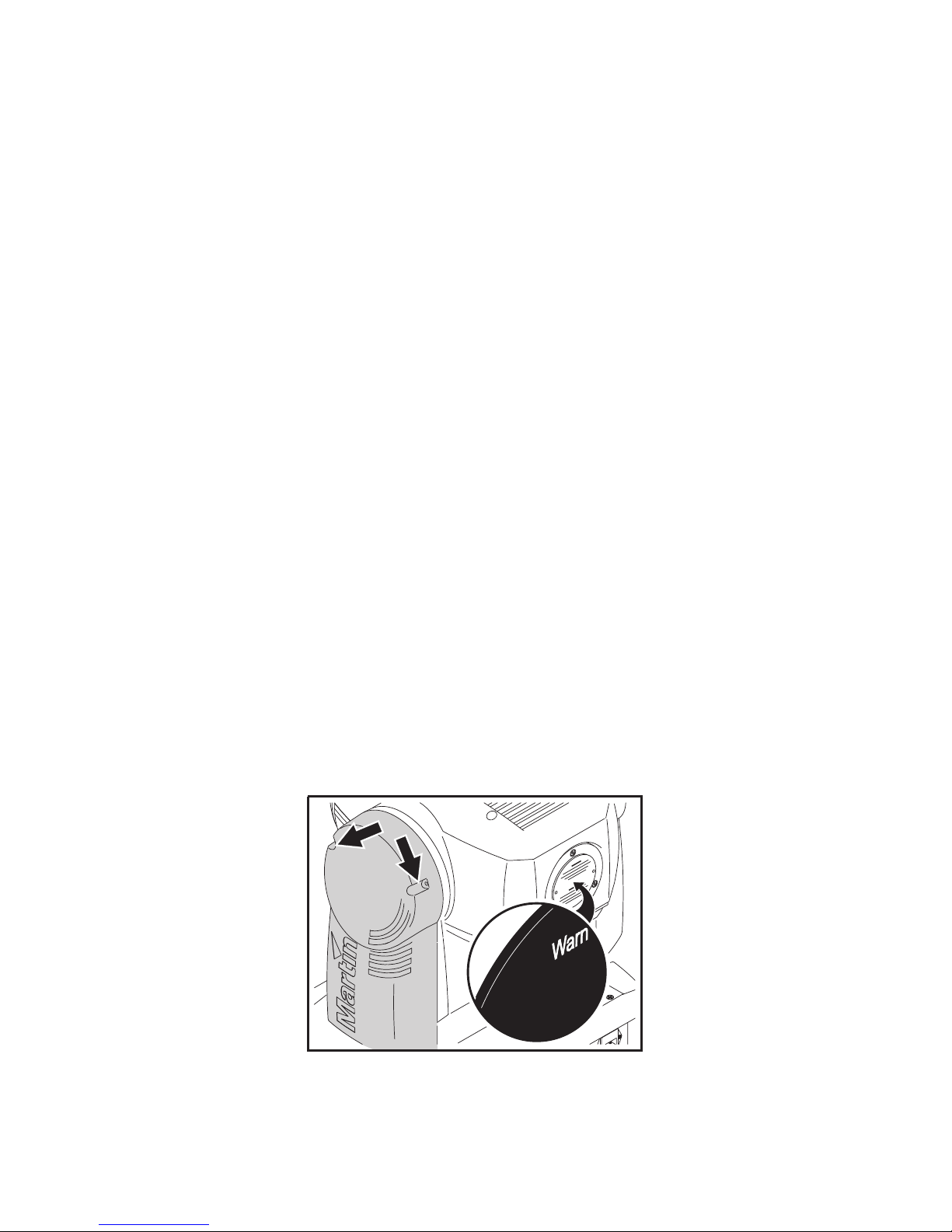

2 Remove the left-side yoke cover (when looking at the head in the text in the upright position from the back

as indicated in the illustration) to access the PCB.

3 Carefully remove and check the two fuses located in the bottom of the PCB (see “Circuit board connections”

on page 46). Replace as necessary with fuses of the same size and rating (see page 47).

4 Re-attach the yoke cover.

Minimum distance to flammMinimum distance to flamm

Minimum distance to illumina

Maximum ambient te

Exterior surfaceto

Page 32

32 MAC 250 Krypton/Entour

Updating software

The latest MAC 250 Krypton/Entour firmware is available from the support area of the Martin web site at

www.martin.dk. It can be installed via the serial data link using a supported Martin uploader such as the

MP-2, or via a LightJockey 4064 ISA DMX interface.

Note: Intermediate control systems such as the Martin Lighting Director (MLD) and the Martin Matrix must

be bypassed when updating fixture software via the DMX link. These systems do not relay the update code

correctly because it is not a DMX-compliant signal.

NORMAL UPDATE

To update fixture software, connect an upload device to the fixture just like a DMX controller and perform a

DMX mode upload as described in the uploader’s documentation. There is no need to isolate the MAC 250

Krypton/Entours from other types of fixtures on the serial link.

When the upload is completed (and when booting up) the MAC 250 Krypton/Entour performs a check-sum

test of the flash memory and then resets. If the firmware is corrupted a check-sum error (

CSER) occurs. A

few seconds later the fixture displays

UPLd and is ready for a new DMX-mode upload.

In the unlikely event that a software upload is interrupted, the fixture must be powered off for at least 10

seconds to force the check-sum test. You can repeat the DMX-mode upload as soon as

UPLd is

displayed.

BOOT SECTOR UPDATE

If the normal update procedure fails or the software update notes call for a boot-sector update, install new

software as follows.

1 Disconnect the fixture from AC power.

2 Remove the left-side yoke cover (when looking at the head in the text in the upright position from the back

as indicated in the illustration) to access the PCB.

3 The boot sector jumper is located next to the plug for the control

panel data cable. Move the jumper to the Init setting. Verify that

the Flash Write jumper is in the Enable position. See the

diagram in “Circuit board connections” on page 46.

4 Apply power and perform a boot-mode upload as described in

the uploader manual.

5 Disconnect the fixture from AC power. Move the jumper back to

the Lock setting.

6 Re-attach the yoke cover.

Minimum distance to flammMinimum distance to flamm

Minimum distance to illumina

Maximum ambient te

Exterior surface to

InitLock

front

Page 33

DMX protocol 33

DMX

PROTOCOL

This chapter contains:

• “MAC 250 Krypton DMX protocol” on page 34

• “MAC 250 Entour DMX protocol” on page 37

Page 34

34 MAC 250 Krypton/Entour

MAC 250 Krypton DMX protocol

16 Bt

(16 Bit Mode)

16 Ex

(16 Bit Extended) Value Percent Function

1

1

If DMX Reset is disabled in the menu,

a reset command can only be

executed if the CTC filter is selected,

the prism is on (not rotating) and the

open gobo is selected.

A 5 second delay can be given to the

reset command from the fixture menu

under, dRES.

2

If DMX Lamp Off is disabled in the

menu, a lamp off command can only

be executed if the CTC filter is

selected, the prism is on (not rotating)

and the open gobo is selected.

0 - 19

20 - 49

50 - 72

73 - 79

80 - 99

100 - 119

120 - 127

128 - 147

148 - 167

168 - 187

188 - 190

191 - 193

194 - 196

197 - 199

200 - 202

203 - 207

208 - 217

218 - 227

228 - 237

238 - 247

248 - 255

0 - 7

8 - 19

20 - 28

29 - 31

31 - 39

39 - 47

47 - 50

50 - 58

58 - 65

66 - 73

74 - 75

75 - 76

76 - 77

77 - 78

78 - 79

80 - 81

82 - 85

85 - 89

89 - 93

93 - 97

97 – 100

Shutter, Strobe, Reset, Lamp On/Off

Shutter closed

Shutter open

Strobe, fast → slow

Shutter open

Opening pulse, fast → slow

Closing pulse, fast → slow

Shutter open

Random strobe, fast

Random strobe, medium

Random strobe, slow

Shutter open

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

Shutter open

Reset fixture

Shutter open

Lamp on

Shutter open

Lamp off

22

0 - 255 0 – 100

Dimmer

Closed → open

3

0-255 0-100

Dimmer Fine (Lowest Significant Byte)

Closed → open

34

0

11

22

33

44

55

66

77

88

99

110

121

132

143

156 – 159

160 – 163

164 – 167

168 – 171

172 – 175

176 – 179

180 – 183

184 – 187

188 – 191

192 – 195

196 – 199

200 – 203

204 – 207

208 – 226

227 – 245

246 – 248

249 – 251

252 – 255

0

4

9

13

17

22

26

30

35

39

43

47

52

56

61 – 63

63 – 64

64 – 65

66 – 67

67 – 68

69 – 70

70 – 72

72 – 73

74 – 75

75 – 76

77 – 78

78 – 79

80 – 81

82 – 88

89 – 96

96 – 97

98 – 98

99 – 100

Color

Continuous Scroll: full color positions:

White

CTC

Yellow 603

Blue 104

Pink 312

Green 206

Blue 108

Red 301

Magenta 507

Blue 101

Orange 306

Dark green

Purple 502

White

Stepped Scroll

White

CTC

Yellow 603

Blue 104

Pink 312

Green 206

Blue 108

Red 301

Magenta 507

Blue 101

Orange 306

Dark green

Purple 502

Continuous Rotation

CW, fast → slow

CCW, slow → fast

Random color

Fast

Medium

Slow

5 0 - 255 0 - 100 Color (Lowest Significant Byte)

Page 35

DMX protocol 35

46

0 - 4

5 - 10

11 - 1 5

16 - 20

21 - 25

26 - 30

31 - 35

36 - 42

43 - 50

51 - 58

59 - 65

66 - 73

74 - 81

82 - 89

90 - 96

97 - 104

105 - 119

120 - 134

135 - 149

150 - 164

165 - 179

180 - 194

195 - 209

210 - 232

233 - 255

0 - 2

2 - 4

4 - 6

6 - 8

8 - 10

10 - 12

12 - 14

14 - 16

17 - 20

20 - 23

23 - 26

26 - 29

29 - 32

32 - 35

35 - 38

38 - 41

41 - 46

47 - 52

53 - 58

59 - 64

65 - 70

70 - 76

76 - 82

82 - 91

91 - 100

Rotating Gobo selection and shake

Indexing: set position on channel 5 in 16 bt mode or

channel 6 in 16 Ex mode

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation: set rotation speed on channel 5 in 16 bt

mode or channel 6 in 16 Ex mode

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation with shake, slow → fast: set rotation speed

on channel 5 in 16 bt mode or channel 6 in 16 Ex

mode

Gobo 7, Shake slow → fast

Gobo 6, Shake slow → fast

Gobo 5, Shake slow → fast

Gobo 4, Shake slow → fast

Gobo 3, Shake slow → fast

Gobo 2, Shake slow → fast

Gobo 1, Shake slow → fast

Continuous scroll

CW slow → fast

CCW fast → slow

57

0 - 255

0 - 2

3 - 127

128 - 252

253 - 255

0 - 100

0 - 1

1 - 50

50 - 98

99 - 100

Gobo rotation (active when you select gobo on

channel 4 in 16 bt mode or channel 5 in 16 Ex mode)

Index position 0 - 395

Continuous rotation (direction and speed)

No rotation

CW, slow → fast

CCW, fast → slow

No rotation

6 8 0 – 255 0 - 100 Gobo Rotation ((Lowest Significant Byte)

79

0 - 255 0 - 100

Focus

Infinity → 2 meters

10 0 - 255 0 - 100 Focus (Lowest Significant Byte)

811

0 - 19

20 - 79

80 - 89

90 - 149

150 - 215

216 - 220

221 - 225

226 - 230

231 - 235

236 - 240

241 - 245

246 - 250

251 - 255

0 - 7

8 - 31

31 - 35

35 - 58

59 - 84

84 - 86

87 - 88

89 - 90

91 - 92

93 - 94

95 - 96

96 - 98

98 - 100

Prism

Prism off

Rotating prism, CCW fast à slow

No rotation

Rotating prism, CW slow à fast

Prism off

Prism/Gobo Macros

Macro 1

Macro 2

Macro 3

Macro 4

Macro 5

Macro 6

Macro 7

Macro 8

912

0 - 255 0 - 100

Pan

Left → right (128 = neutral)

10 13

0 - 255 0 - 100

Pan Fine (Lowest Significant Byte)

Left → right

11 14

0 - 255 0 – 100

Tilt

Left → right (128 = neutral)

12 15

0 - 255 0 – 100

Tilt Fine (Lowest Significant Byte)

Left → right

Page 36

36 MAC 250 Krypton/Entour

13 16

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

Pan/Tilt Speed

Tracking

Fast → slow

Tracking, PTSP NORM (menu override)

Tracking, PTSP FAST (menu override)

Blackout while moving

14 17

0 - 2

3 - 245

246 - 251

252 - 255

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 245

246 - 248

249 - 251

252 - 255

0 - 2

3 - 245

246 - 251

252 – 255

0 - 251

252 - 255

0 - 1

1 - 96

96 - 98

99 - 100

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

0 - 96

96 - 97

98 - 98

99 - 100

0 - 1

1 - 96

96 - 98

99 - 100

0 - 98

99 - 100

Effects Speed

Dimmer, focus

Tracking mode

Fast → slow

Tracking

Maximum speed

Color

Tracking mode

Speed, fast → slow

Tracking, SCUT OFF (control menu override)

Tracking, SCUT ON (control menu override)

Blackout while moving

Gobo selection

Normal (no blackout)

Normal, SCUT OFF (control menu override)

Normal, SCUT ON (control menu override)

Blackout while moving

Indexed gobo rotation (only if gobo type = indexed)

Tracking mode

Fast à slow

Tracking

Blackout while moving

Prism

Normal (no blackout)

Blackout while moving

Page 37

DMX protocol 37

MAC 250 Entour DMX protocol

16 Bt

(16 Bit Mode)

16 Ex

(16 Bit Extended) Value Percent Function

1

1

If DMX Reset is disabled in the menu,

a reset command can only be

executed if the CTC filter is selected,

the prism is on (not rotating) and the

open gobo is selected.

A 5 second delay can be given to the

reset command from the fixture menu

under, dRES.

2

If DMX Lamp Off is disabled in the

menu, a lamp off command can only

be executed if the CTC filter is

selected, the prism is on (not rotating)

and the open gobo is selected.

0 - 19

20 - 49

50 - 72

73 - 79

80 - 99

100 - 119

120 - 127

128 - 147

148 - 167

168 - 187

188 - 190

191 - 193

194 - 196

197 - 199

200 - 202

203 - 207

208 - 217

218 - 227

228 - 237

238 - 247

248 - 255

0 - 7

8 - 19

20 - 28

29 - 31

31 - 39

39 - 47

47 - 50

50 - 58

58 - 65

66 - 73

74 - 75

75 - 76

76 - 77

77 - 78

78 - 79

80 - 81

82 - 85

85 - 89

89 - 93

93 - 97

97 – 100

Shutter, Strobe, Reset, Lamp On/Off

Shutter closed

Shutter open

Strobe, fast → slow

Shutter open

Opening pulse, fast → slow

Closing pulse, fast → slow

Shutter open

Random strobe, fast

Random strobe, medium

Random strobe, slow

Shutter open

Random opening pulse, fast

Random opening pulse, slow

Random closing pulse, fast

Random closing pulse, slow

Shutter open

Reset fixture

Shutter open

Lamp on

Shutter open

Lamp off

22

0 - 255 0 – 100

Dimmer

Closed → open

3

0-255 0-100

Dimmer Fine (Lowest Significant Byte)

Closed → open

34

0

11

22

33

44

55

66

77

88

99

110

121

132

143

156 – 159

160 – 163

164 – 167

168 – 171

172 – 175

176 – 179

180 – 183

184 – 187

188 – 191

192 – 195

196 – 199

200 – 203

204 – 207

208 – 226

227 – 245

246 – 248

249 – 251

252 – 255

0

4

9

13

17

22

26

30

35

39

43

47

52

56

61 – 63

63 – 64

64 – 65

66 – 67

67 – 68

69 – 70

70 – 72

72 – 73

74 – 75

75 – 76

77 – 78

78 – 79

80 – 81

82 – 88

89 – 96

96 – 97

98 – 98

99 – 100

Color

Continuous Scroll: full color positions:

White

CTC

Yellow 603

Blue 104

Pink 312

Green 206

Blue 108

Red 301

Magenta 507

Blue 101

Orange 306

Dark green

Purple 502

White

Stepped Scroll

White

CTC

Yellow 603

Blue 104

Pink 312

Green 206

Blue 108

Red 301

Magenta 507

Blue 101

Orange 306

Dark green

Purple 502

Continuous Rotation

CW, fast → slow

CCW, slow → fast

Random color

Fast

Medium

Slow

5 0 - 255 0 - 100 Color (Lowest Significant Byte)

Page 38

38 MAC 250 Krypton/Entour

46

0 - 4

5 - 10

11 - 1 5

16 - 20

21 - 25

26 - 30

31 - 35

36 - 42

43 - 50

51 - 58

59 - 65

66 - 73

74 - 81

82 - 89

90 - 96

97 - 104

105 - 119

120 - 134

135 - 149

150 - 164

165 - 179

180 - 194

195 - 209

210 - 232

233 - 255

0 - 2

2 - 4

4 - 6

6 - 8

8 - 10

10 - 12

12 - 14

14 - 16

17 - 20

20 - 23

23 - 26

26 - 29

29 - 32

32 - 35

35 - 38

38 - 41

41 - 46

47 - 52

53 - 58

59 - 64

65 - 70

70 - 76

76 - 82

82 - 91

91 - 100

Rotating Gobo selection and shake

Indexing: set position on channel 5 in 16 bt mode or

channel 6 in 16 Ex mode

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation: set rotation speed on channel 5 in 16 bt

mode or channel 6 in 16 Ex mode

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Rotation with shake, slow → fast: set rotation speed

on channel 5 in 16 bt mode or channel 6 in 16 Ex

mode

Gobo 7, Shake slow → fast

Gobo 6, Shake slow → fast

Gobo 5, Shake slow → fast

Gobo 4, Shake slow → fast

Gobo 3, Shake slow → fast

Gobo 2, Shake slow → fast

Gobo 1, Shake slow → fast

Continuous scroll

CW slow → fast

CCW fast → slow

57

0 - 255

0 - 2

3 - 127

128 - 252

253 - 255

0 - 100

0 - 1

1 - 50

50 - 98

99 - 100

Gobo rotation (active when you select gobo on

channel 4 in 16 bt mode or channel 5 in 16 Ex mode)

Index position 0 - 395

Continuous rotation (direction and speed)

No rotation

CW, slow → fast

CCW, fast → slow

No rotation

6 8 0 – 255 0 - 100 Gobo Rotation ((Lowest Significant Byte)

79

0 - 7

8 - 15

16 - 23

24 - 31

32 - 39

40 - 47

48 - 55

56 - 63

64 - 71

72 - 79

80 - 87

88 - 95

96 - 105

106 - 115

116 - 125

126 - 135

136 - 145

146 - 155

156 - 165

166 - 175

176 - 185

186 - 195

196 - 205

206 - 230

231 - 255

0 - 3

3 - 6

6 - 9

9 - 12

13 - 15

16 - 18

19 - 22

22 - 25

25 - 28

28 - 31

31 - 34

35 - 37

38 - 41

42 - 45

45 - 49

49 - 53

53 - 56

57 - 60

61 - 65

65 - 69

69 - 73

73 - 76

77 - 80

81 - 90

91 - 100

Gobo Wheel 2 (static). Selection and Shake

Open gobo

Gobo 1

Gobo 2

Gobo 3

Gobo 4

Gobo 5

Gobo 6

Gobo 7

Gobo 8

Gobo 9

Gobo 10

Open

Gobo Shake

Gobo 10 - Shake, slow → fast

Gobo 9 - Shake, slow → fast

Gobo 8 - Shake, slow → fast

Gobo 7 - Shake, slow → fast

Gobo 6 - Shake, slow → fast

Gobo 5 - Shake, slow → fast

Gobo 4 - Shake, slow → fast

Gobo 3 - Shake, slow → fast

Gobo 2 - Shake, slow → fast

Gobo 1 - Shake, slow → fast

Open Gobo - Shake, slow → fast

Continuous Rotation

CW slow → fast

CCW fast → slow

Page 39

DMX protocol 39

810

0 - 255 0 - 100

Focus

Infinity → 2 meters

11 0 - 255 0 - 100 Focus (Lowest Significant Byte)

912

0 - 19

20 - 79

80 - 89

90 - 149

150 - 215

216 - 220

221 - 225

226 - 230

231 - 235

236 - 240

241 - 245

246 - 250

251 - 255

0 - 7

8 - 31

31 - 35

35 - 58

59 - 84

84 - 86

87 - 88

89 - 90

91 - 92

93 - 94

95 - 96

96 - 98

98 - 100

Prism

Prism off

Rotating prism, CCW fast à slow

No rotation

Rotating prism, CW slow à fast

Prism off

Prism/Gobo Macros

Macro 1

Macro 2

Macro 3

Macro 4

Macro 5

Macro 6

Macro 7

Macro 8

10 13

0 - 255 0 - 100

Pan

Left → right (128 = neutral)

11 14

0 - 255 0 - 100

Pan Fine (Lowest Significant Byte)

Left → right

12 15

0 - 255 0 – 100

Tilt

Left → right (128 = neutral)

13 16

0 - 255 0 – 100

Tilt Fine (Lowest Significant Byte)

Left → right

14 17

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

Pan/Tilt Speed

Tracking

Fast → slow

Tracking, PTSP NORM (menu override)

Tracking, PTSP FAST (menu override)

Blackout while moving

15 18

0 - 2

3 - 245

246 - 251

252 - 255

0 - 2

3 - 245

246 - 248

249 - 251

252 - 255

0 - 245

246 - 248

249 - 251

252 - 255

0 - 2

3 - 245

246 - 251

252 – 255

0 - 251

252 - 255

0 - 1

1 - 96

96 - 98

99 - 100

0 - 1

1 - 96

96 - 97

98 - 98

99 - 100

0 - 96

96 - 97

98 - 98

99 - 100

0 - 1

1 - 96

96 - 98

99 - 100

0 - 98

99 - 100

Effects Speed

Dimmer, focus

Tracking mode

Fast → slow

Tracking

Maximum speed

Color

Tracking mode

Speed, fast → slow

Tracking, SCUT OFF (control menu override)

Tracking, SCUT ON (control menu override)

Blackout while moving

Gobo selection

Normal (no blackout)

Normal, SCUT OFF (control menu override)

Normal, SCUT ON (control menu override)

Blackout while moving

Indexed gobo rotation (only if gobo type = indexed)

Tracking mode

Fast à slow

Tracking

Blackout while moving

Prism

Normal (no blackout)

Blackout while moving

Page 40

40 MAC 250 Krypton/Entour

C

ONTROL MENU

Options displayed in bold represent the default settings.

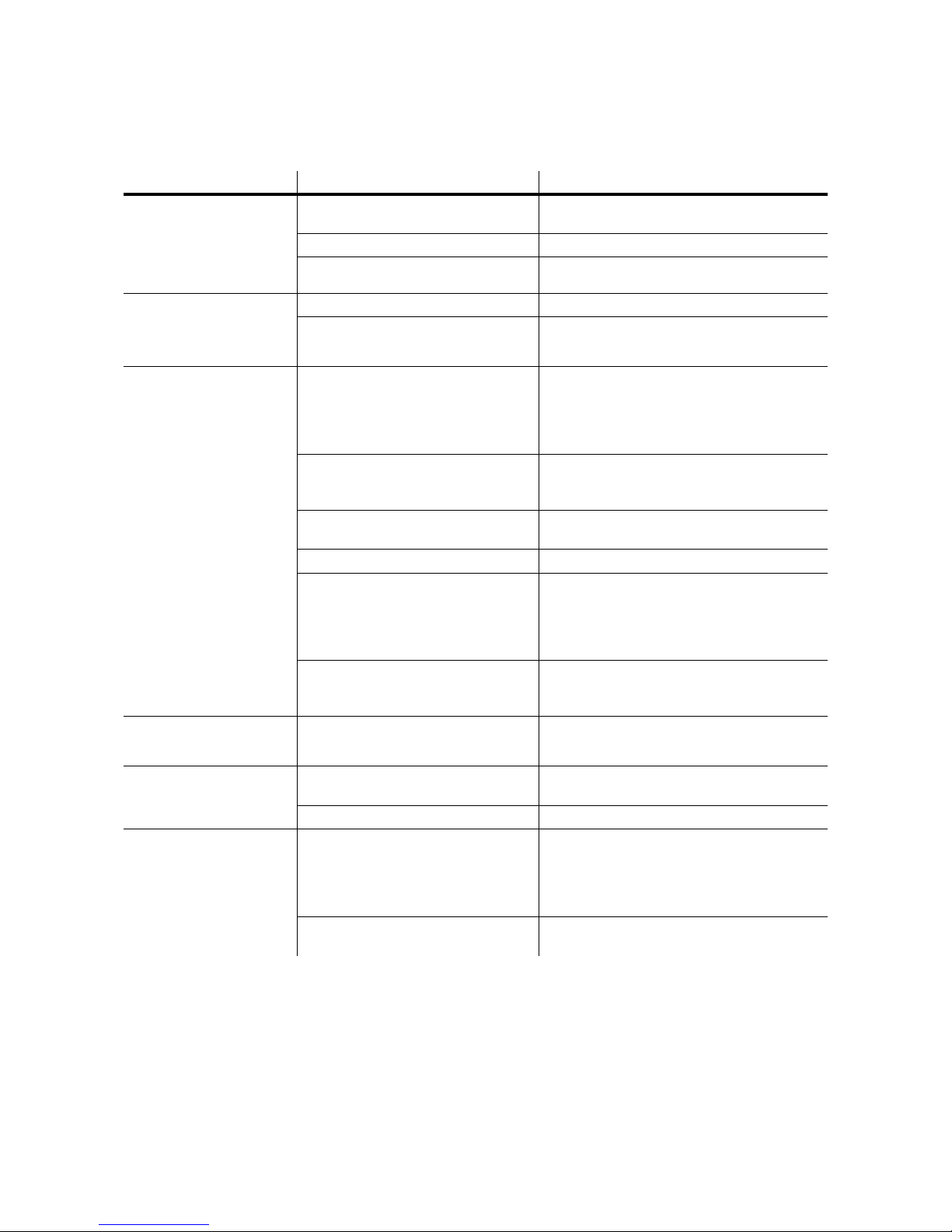

Menu Item Options Notes (Default settings in bold print)

AddR - 1-512 DMX address

PSET 16BT 16 Bit

16EX 16 Bit extended

PATI SWAP ON Map DMX pan control to tilt channel and vice versa.

OFF Normal pan and tilt control

PINV ON Reverse DMX pan control, right → left

OFF Normal pan control, left → right

TINV ON Reverse DMX tilt control, down → up

OFF Normal tilt control, up → down

PTSP NORM Default pan/tilt speed

FAST Maximum pan/tilt speed (position may be less precise)

SLOW Minimum pan/tilt speed

PERS dISP ON Display remains on

2 MN Display extinguishes 2 minutes after last key press

10MN Display extinguishes 10 minutes after last key press

dINT AUTO Automatic display dimming

10-100

Set display intensity manually

dLOF ON Enable DMX lamp off command

OFF Disable DMX lamp off command

dRES ON Enable DMX reset command

OFF Disable DMX reset command

5SEC Reset from Controller

ALON ON Lamp strikes automatically within 90 seconds of power on

OFF No automatic lamp strike

dMX Lamp strikes if DMX is present, douses 15 mins. after it’s

missing

SCUT

ON

Effect wheels turn shortest distance

OFF Effect wheels do not cross open position

dICU DIM1 0-100%

DIM2 Tungsten

dFSE FACT LOAD Return all personality settings (not calibrations) to factory