Page 1

MAC 2000 Wash

service manual

Page 2

1

MAC 2000 Wash Service Manual

PROCEDURES

Head procedures

CMYC belts and flags, replace . . . . 12

CMYC module, install . . . . . . . . . . . . 5

CMYC module, remove . . . . . . . . . . . 5

CMYC module, separate . . . . . . . . . 11

CMYC motors, replace . . . . . . . . . . 13

Color wheel 1 belt, replace . . . . . . . . 6

Color wheel 1 motor, replace . . . . . . . 6

Color wheel 2 belt, replace . . . . . . . . 6

Color wheel 2 motor, replace . . . . . . . 6

Color wheel module, install . . . . . . . . 7

Color wheel module, remove . . . . . . . 5

Color wheels, adjust . . . . . . . . . . . . . 7

Dimmer blades, replace & adjust . . . 10

Dimmer motor, replace . . . . . . . . . . 11

Effect fans, replace . . . . . . . . . . . . . . 7

Head side covers, remove and install 7

Heat filter assembly, remove & install 8

Heat filter, replace . . . . . . . . . . . . . . . 9

Left lamp fan, replace . . . . . . . . . . . . 7

Reflector, replace . . . . . . . . . . . . . . . . 9

Right lamp fan, replace . . . . . . . . . . . 8

Starter, replace . . . . . . . . . . . . . . . . . 9

Zoom belt, replace . . . . . . . . . . . . . . . 4

Zoom lens assembly, replace . . . . . . 5

Zoom module, install . . . . . . . . . . . . . 3

Zoom module, remove . . . . . . . . . . . . 3

Zoom motor, replace . . . . . . . . . . . . . 4

Zoom rail, replace . . . . . . . . . . . . . . . 5

Yoke procedures

Tilt belt, left, replace . . . . . . . . . . . . .14

Tilt belt, right, replace . . . . . . . . . . . .15

Tilt motors, replace . . . . . . . . . . . . . .16

Tilt motors, synchronize . . . . . . . . . .16

Yoke covers, remove . . . . . . . . . . . .14

Base procedures

Ballast fan, replace . . . . . . . . . . . . . 19

Base fans, replace . . . . . . . . . . . . . . 19

Electronic ballast, replace . . . . . . . . 19

Left pan motor, replace . . . . . . . . . . 20

Main PCB, replace . . . . . . . . . . . . . 18

Pan belt, replace . . . . . . . . . . . . . . . 17

Pan motors, synchronize . . . . . . . . . 21

Power supply, replace . . . . . . . . . . . 18

Right pan motor, replace . . . . . . . . . 20

Page 3

© 2002 Martin Professional A/S, Denmark. Updated December 23, 2002 2

INTRODUCTION

Risk of electrical shock

Removal of any cover exposes connectors

that carry lethal electric currents. While

working on a fixture under power:

• Make sure the fixture is electrically

grounded.

• Use a supply with ground-fault-interrupt protection.

• Never touch any connector that carries

voltage.

• Be careful with tools that conduct electricity.

Risk of UV radiation and

lamp explosion

Discharge lamps emit harmful ultraviolet

(UV) light that can cause eye and skin burns

through direct exposure. They also work

under high pressure that occasionally causes

them to explode. To eliminate the risk of

injury from the discharge lamp,

• Never operate the lamp with covers or

lenses removed.

• Do not look directly into the light.

Electrostatic discharge

Printed circuit boards (PCBs), individual

ICs, and Hall sensors can be damaged by

electrostatic discharge (ESD). To avoid

damaging these ESD sensitive parts:

• Ensure that you and your tools have the

same potential (ground) as the fixture

before and when handling any of the

above components.

• Store PCBs in antistatic (electrically

conducting) bags and store ICs in antistatic foam.

• Power off the fixture and allow capacitors do discharge before removing or

inserting components on the PCB.

Inductive loads

Power off the MAC 2000 Wash before

connecting or disconnecting step motors.

Failure to do so can damage the motor

drivers.

Threadlock

Threadlock is highly recommended on all

machine screws except self-tapping

(Taptite) screws to prevent loosening.

Threadlock should be reapplied if the

screws are removed.

Two types of threadlock are available from

Martin. For set screws, use Loctite 290, P/N

37020002. For all other screws, use Loctite

243, P/N 37021002. Both come in 10 ml

tubes.

Be careful to avoid getting any material on

shafts or axles. A needle and syringe makes

an idea application tool.

Long set screws: Start the screw and turn it

until it contacts the shaft. Back the screw 2

turns, apply a small drop or 2 of Loctite 290

to the threads, and then tighten the screw as

you normally would.

Short set screws: Back the set screw out of

the adaptor until 2 threads stick out of the

shaft. Apply a small drop or 2 of Loctite 290

to the threads, and then tighten the screw

within 60 minutes.

Other metric screws: Apply a drop of

Loctite 243 (blue) to 3 or 4 threads, or

spread a thin stripe with a syringe, before

starting the screw.

Self-tapping screws

The reuse of self-tapping “Taptite” screws

is not recommended as these screws are

designed to cut threads and can strip

existing threads when reinserted. Change to

metric hardware of the same size when

reinstalling parts originally held with

Taptites.

If installing a new part without threads, use

new self-tapping screws. Do not use old

taptites to cut new threads!

Lubrication

Silicone grease, P/N 37302002, “Silicon

grease, clear, 100g”, is used, for example, to

lubricate brass bushings inside of pulleys

and between moving metal plates such as

the motor bracket for color wheel 1 on the

MAC 2000 Wash.

Slides are generally lubricated with the high

viscosity silicone oil, P/N 37302005, “High

viscosity silicone oil, 200 ml, in applicator

bottle.”

Bearings are lubricated with P/N 37302004,

“Silicone oil, 200 ml, in applicator bottle”.

Comments

Your feedback is appreciated. Please send

your comments and suggestions for

improvements to:

Martin Professional

Olof Palmes Allé 18

DK 8200 Aarhus N, Denmark

Attn: Service

E-mail: service@martin.dk.

Always disconnect the fixture

from AC power before and while

servicing.

Page 4

© 2002 Martin Professional A/S, Denmark. Updated December 23, 2002 3

HEAD PROCEDURES

Zoom module, remove

1 Remove the top and bottom head

covers and the front lens. Fully back out

the thumbscrew for the lens retaining

wire.

2 Unplug cables from the outside row

of the left-side zoom module junction

print. Unplug the unlabeled 2-pin connector from socket 38.

3 Unplug the wires from the outside

row of the right-side zoom module junction print. Unplug connectors 42, 23,

and the unlabeled 2-pin fan plug from

the inside row.

4 Unplug the wires from the back row

of the CMYC module junction print and

the thermo-sensor, which is in front of

the junction print.

5 Unplug connector 16 from the dimmer junction print.

6 Remove the 4 zoom module fastening screws.

7 Pull the zoom module (and attached

color wheel module) up, out of the

head.

Zoom module, install

1 Lock the head in the horizontal, top

up position.

2 Place the ends of the wire bundles

outside of the head, forward of the

yoke.

3 Lower the module into the chassis,

working it past each “sticking point” in

turn. Fasten.

4 Reconnect the wires to the left and

right junction prints.

5 Plug connector 16 into the dimmer

junction print. (Fig. 4)

6 Insert the CMYC wire bundle into

the slot in the zoom module. Connect

The color wheel module remains

attached to the zoom module in

this procedure.

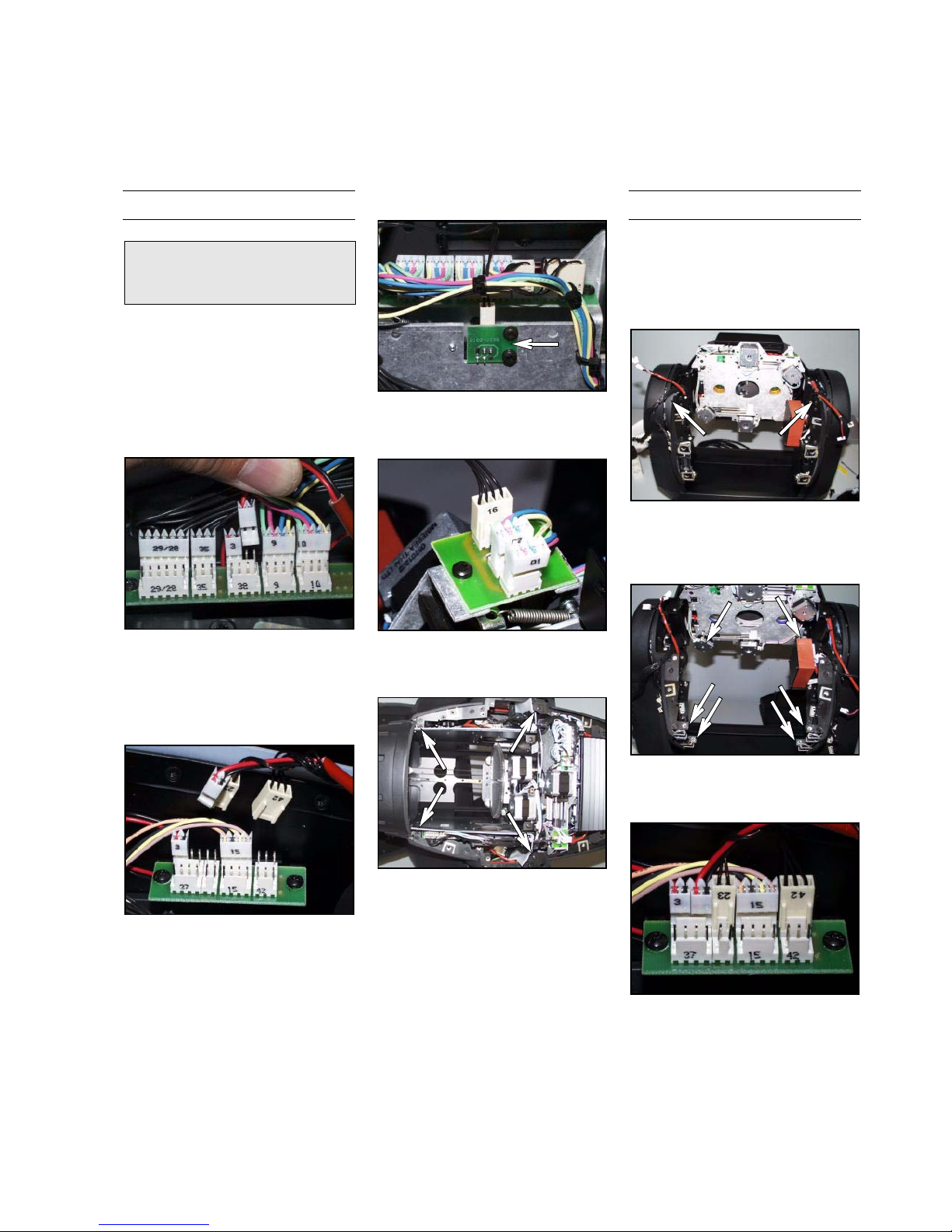

Fig. 1 Unplug left junction print

Fig. 2 Unplug right junction print

Fig. 3 CMYC thermo-sensor PCB

Fig. 4 Dimmer junction PCB

Fig. 5 Zoom module screws

Fig. 6 Place wires forward of yoke

Fig. 7 “Sticking points”

Fig. 8 Right junction connections

Page 5

4

MAC 2000 Wash Service Manual

the wires to the junction print. Secure

the bundle under the flexible tie.

Zoom belt, replace

1 Remove the zoom module. (p. 3)

2 Remove the belt clamp screws.

3 Loosen the set screws and remove

the belt clamp from the belt.

4 Flip the module over and loosen the

zoom motor screws. Push the motor in

to loosen and remove the old belt.

5 Pull the belt tension pulley forward

and loop the new belt over it as shown

in Fig. 12.

6 Lead the belt to the motor and loop

it over the gear. Loop the other end of

the belt over the front pulley.

7 Tighten the belt by moving the zoom

motor back until the tension pulley

starts to move. Tighten the motor

screws.

8 Place the belt clamp on the belt with

the set screws inside the loop and the

small bar between the belt and the

screws. Tighten the set screws.

9 Fasten the belt clamp to the lens

car.

10 Install the zoom module. (p. 3)

Zoom motor, replace

1 Remove the zoom module. (p. 3)

2 Unplug the motor wires and remove

the motor screws. Loosen the bracket

enough to remove the motor.

3 Transfer the gear to the new motor

with 0.6 mm (0.025 in.) clearance

between the motor and the gear.

Tighten the set screw.

4 Position the motor in the bracket

with the socket facing out. Tighten the

bracket screws. Start the motor screws

but do not tighten.

5 Place the belt over the gear. Push

the motor out to tighten the belt until the

tension pulley just begins to move.

Tighten the motor screws.

6 Plug in the motor wires.

7 Install the zoom module. (p. 3)

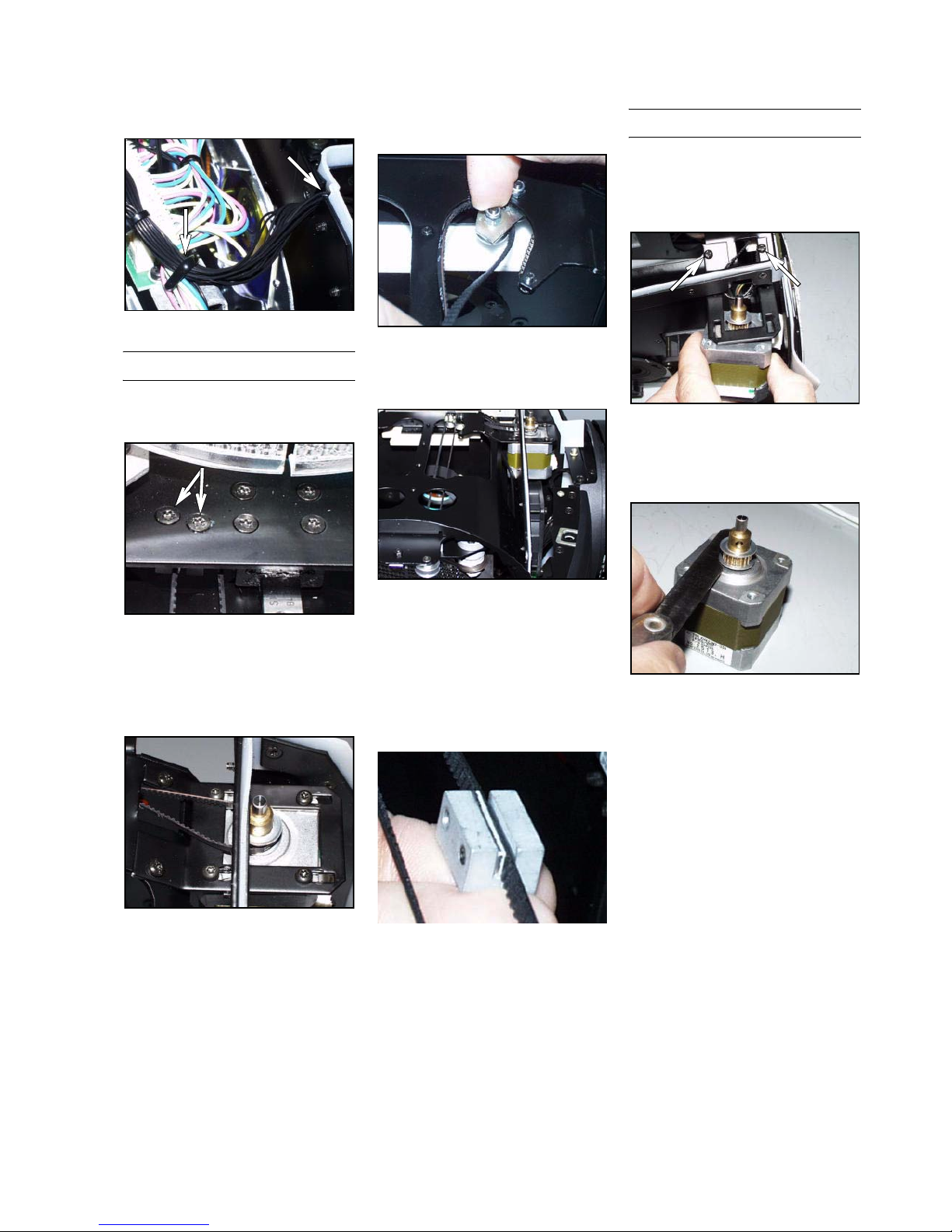

Fig. 9 CMYC wire bundle path

Fig. 10 Belt clamp screws

Fig. 11 Loosen the belt

Fig. 12 Loop belt over tensioner

Fig. 13 Zoom belt

Fig. 14 Belt clamp

Fig. 15 Loosen bracket to remove motor

Fig. 16 0.6 mm (0.025 in.)

Page 6

5

MAC 2000 Wash Service Manual

Zoom lens assembly, replace

1 Remove the zoom module. (p. 3)

2 Remove the belt clamp screws.

(Fig. 10)

3 Remove the 4 screws that fasten

the zoom car to the zoom slide. Do not

remove the slide from the rail.

4 Fasten the replacement zoom lens

assembly to the slide.

5 Fasten the belt clamp.

6 Install the zoom module. (p. 3)

Zoom rail, replace

1 Remove the zoom lens assembly.

(p. 5)

2 Separate the color wheel module

from the zoom module. (p. 5)

3 Remove the white plastic plate at

the back of the module.

4 Unscrew and remove the zoom rail.

5 Starting with the third hole from the

front, fasten the new zoom rail to the

zoom module with 5 M3x6 panhead

Torx screws, P/N 08050702.

6 Place the stand-off on the M3x12

panhead Torx screw and insert the

screw through the first hole in the rail.

Fasten with an M3 nut.

7 Install the zoom lens car stop. (Fig.

18)

8 Install the color wheel module. (p. 7)

9 Install the zoom lens assembly. (p.

5)

10 Install the zoom module. (p. 3)

CMYC module, remove

1 Remove the zoom module. (p. 3)

2 Remove the module fastening

screws: there are two on the top and

two on the bottom.

3 Slide the module forward as far as it

will go, then lift it out of the top of the

head.

CMYC module, install

1 Lock the head in the horizontal, top

up position.

2 Move the wire bundles forward and

out of the way.

3 Orient the module with the junction

print up and to the right. Lower the

module into the chassis at an angle.

Square the module with the flaps over

the chassis and slide it back as far as it

will go. Align the screw holes and fasten

at the top and bottom.

4 Install the zoom module. (p. 3)

Color wheel module, remove

1 Remove the top head shell.

2 Disconnect plugs 28/29, 9, and 10

from the inside row of the left-side zoom

module junction print. (Fig. 1)

When removing the zoom car, do

not remove the slide from the rail.

Fig. 17 Do not remove slide from rail

Fig. 18 Zoom lens car stop

Fig. 19 Zoom slide stop

Fig. 20 1 of 4 CMYC module screws

Fig. 21 Insert module at an angle

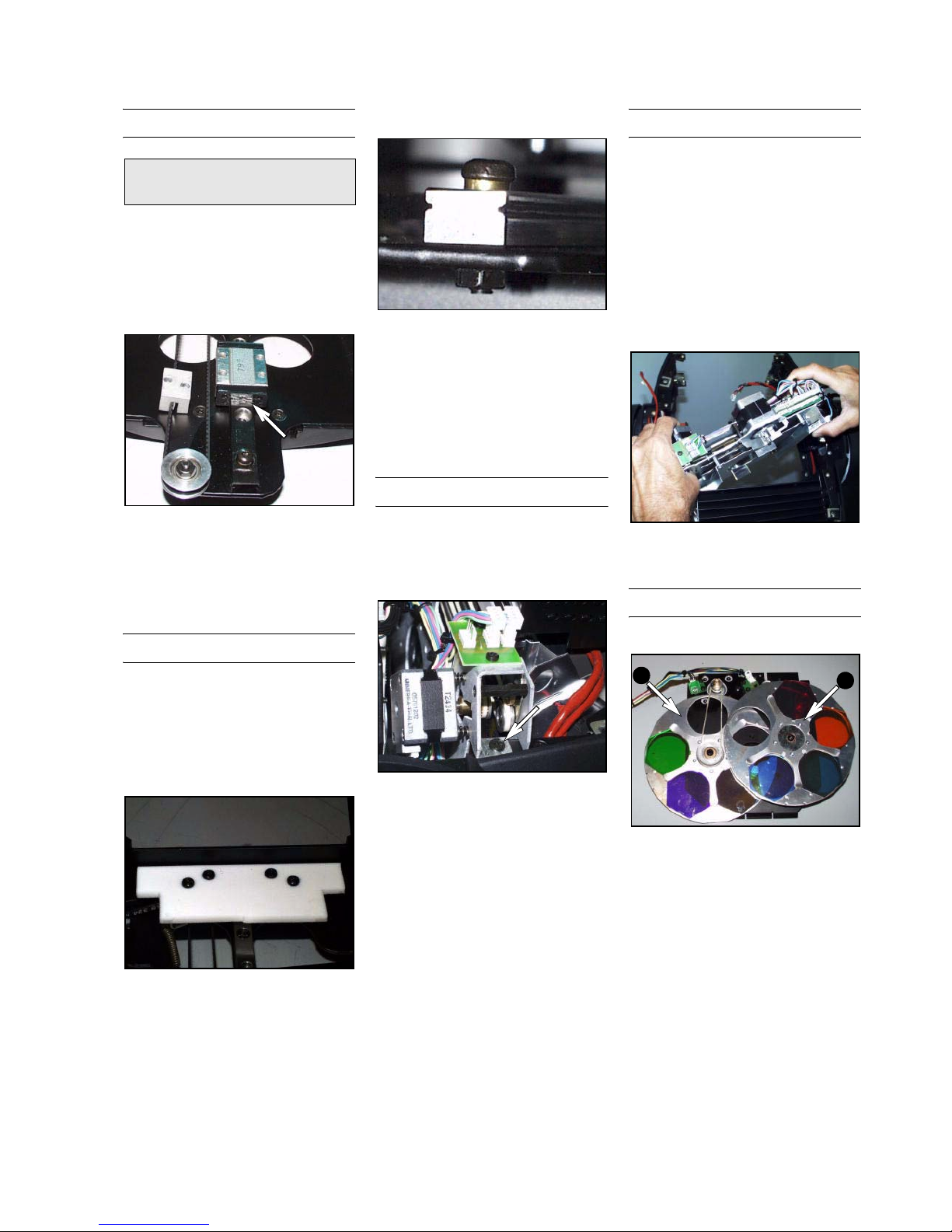

Fig. 22 Color wheels 1 & 2

2

1

Page 7

6

MAC 2000 Wash Service Manual

3 Remove the color module attachment screws and separate the color

wheel module from the zoom module.

Color wheel 1 belt, replace

1 Remove the top head shell.

2 Press the motor down to release

belt tension. Remove the old belt and

install a new one.

Color wheel 1 motor, replace

1 Remove the color wheel module. (p.

5)

2 Release belt tension and slip the

belt off the motor gear. (Fig. 24)

3 Remove the sensor print to access

the screw underneath. Remove the

screws that fasten the motor bracket to

the module plate.

4 Unhook the spring from the motor

bracket. (Fig. 28)

5 Transfer the gear (or install a new

one) to the shaft of the replacement

motor with 10 mm clearance between

the bottom of the gear and the face of

the motor. Tighten the set-screw. (No

further adjustment is required.)

6 Transfer the mounting bracket to the

new motor. Do not open the new motor!

7 Apply a drop or two of silicone

grease (P/N 37302002) to the motor

bracket. Attach the bracket to the plate

with metric screws and bushings.

8 Hook the tension spring onto the

motor bracket and connect the motor

wires.

9 Reinstall and connect the Hall sensor circuit board.

10 Reinstall the drive belt.

11 Install the color wheel module. (p. 7)

Color wheel 2 belt, replace

1 Remove the color wheel module. (p.

5)

2 Unscrew and remove the wheel.

3 Remove the old belt. Place the new

belt over the motor gear and the axle.

4 Reinstall the color wheel and loop

the belt onto the color wheel gear.

5 Place the open position over the

tension pulley, pull the pulley in, and

loop the belt over the pulley.

6 Install the color wheel module.

Color wheel 2 motor, replace

1 Remove the color wheel module.

2 Remove the belt from the tension

pulley and motor gear.

3 Unscrew and unplug the old motor.

4 Transfer the standoffs to the

replacement motor. Do not open the

new motor!

5 Transfer the gear (or install a new

one) to the shaft of the replacement

motor with 1.1 mm clearance between

the bottom of the gear and the face of

the motor and tighten the set-screw.

(No further adjustment is required.)

6 Place the motor on the plate with

the socket towards the other motor.

Fig. 23 Color module screws

Fig. 24 Release belt tension

Fig. 25 Motor bracket screws

Fig. 26 10 mm clearance

Fig. 27 Motor and bracket

Fig. 28 Color wheel 1 motor

Fig. 29 Color wheel 2 belt

Page 8

7

MAC 2000 Wash Service Manual

Fasten with 4 M3x6 mm countersunk

screws. Plug in the wires.

7 Loop the belt over the motor gear

and tension pulley. Verify that the wheel

turns smoothly without binding.

8 Install the color wheel module. (p. 7)

Color wheels, adjust

The color wheels are magnetically indexed

using a routine that does not require

mechanical adjustment.

If the wheels are not centered in the optical

path, the Hall sensor IC is probably bent out

of position. The problem can be solved by

entering a position offset in the calibration

menu. In extreme cases it may be necessary

to move the sensor IC.

Color wheel module, install

1 Insert the module in the head, mak-

ing sure that the bottom flaps straddle

the chassis plate. Fasten.

2 Connect plugs 28/29, 9, and 10 to

the inside row of the left-side zoom

module junction print. (Fig. 1)

Head side covers, remove

and install

1 Remove the screws that fasten the

cover: each cover has two screws.

2 Pull front covers straight out to

remove. The rear covers must be pulled

out 1 cm at the back before pulling

back.

3 When reinstalling the front covers,

verify that the air filter lies flat.

4 When reinstalling the rear covers, it

helps to tilt the head down.

Effect fans, replace

1 Remove the zoom module. (p. 3)

2 Unplug, unscrew, and remove the

defective fan.

3 Install the replacement fan with the

air-flow arrow pointing in. To avoid stripping the threads, use M4x30 metric

screws (P/N 008070410) instead of the

original taptites.

4 If replacing the left fan, connect the

plug to the front 2 pins of socket 38.

(Fig. 1)

5 If replacing the right fan, connect

the plug to the rear 2 pins of socket 37.

(Fig. 8)

6 Install the zoom module. (p. 3)

Left lamp fan, replace

1 Remove the zoom module (p. 3)

and CMYC module (p. 5). Remove the

left-rear side cover. (p. 7)

2 Cut the cable tie if required to

access the lower fan screw. Remove

the fan attachment screws.

3 Work the fan assembly free of the

reflector housing.

4 Remove the metal heat shield and

the ceramic insulation from the old fan.

5 Cut cable ties as required and free

the fan cable. Remove the fan.

6 Prepare the new fan. Cut a piece of

foil backing (P/N 33002002) to fit and

apply it to the back of the fan. Place a

40 cm (16 in.) length of sleeve over the

leads, cut the leads to length, and

install a 2-pole plug.

7 Install the insulation and heat shield

on the foil-backed side of the prepared

fan.

8 Work the fan assembly back into

place and fasten.

9 Lead the fan cable forward, through

the holes in the side chassis. Slide the

cable insulation fully back to the fan and

then retie the bundle above the starter.

10 Replace the cable tie at the bottom

fan screw.Keep the wires and thermo-

Fig. 30 Color wheel motors

Fig. 31 Bottom flaps straddle plate

Fig. 32 Apply foil to fan

Fig. 33 Fan heat shield and insulation

Fig. 34 Cable path

Page 9

8

MAC 2000 Wash Service Manual

switch clear of the fan to maintain maximum airflow.

Right lamp fan, replace

1 Remove the zoom module (p. 3)

and CMYC module (p. 5). Remove the

front and rear covers from the right side

of the head. (p. 7)

2 Remove the fan attachment screws.

3 Work the fan assembly free of the

reflector housing. Though the fit is tight,

it should not be necessary to loosen or

remove the reflector housing.

4 Unplug the thermo-switch.

5 Cut cable ties as required and

remove the old fan cable. Remove the

fan assembly from the head.

6 Prepare the new fan. Cut a piece of

foil backing (P/N 33002002) to fit and

apply it to the back of the fan. (Fig. 32)

Place a 40 cm (16 in.) length of sleeve

over the leads, cut the leads to length,

and install a 2-pole plug.

7 Remove the old fan from the heat

shield and install the new fan.

8 Lead the fan cable out through hole

1, in through hole 2, under the wire bundle, and out through hole 3 as shown in

Fig. 38.

9 Connect the thermo-switch leads.

10 Work the fan assembly into position,

align the screw holes, and fasten.

11 Pull slack in the fan cable towards

the front. Gather the fan cable together

with the cables labeled ‘42’ and ‘23’ and

tie at point 4 in Fig. 38 Wrap the black

wires around the fan cable a few times

to hold them together. Replace any

other cable ties that you removed.

12 Verify that the openings in the plate

around the fan are sealed with hightemperature polyester electrical tape.

13 Reassemble the head.

Heat filter assembly, remove

& install

1 Remove the zoom module (p. 3)

and CMYC module (p. 5).

2 Bend open the cable retention tabs

and move the cables out of the way.

3 Remove the four heat filter module

screws and remove the module.

4 Installation is the reverse.

Fig. 35 Tie bundle at bottom screw

Fig. 36 Thermo-switch connections

Fig. 37 Right lamp fan assembly

Fig. 38 Right fan cable path

1

2

3

4

Fig. 39 Move wires out of way

Fig. 40 Module attachment screws

Page 10

9

MAC 2000 Wash Service Manual

Heat filter, replace

1 Remove the heat filter assembly. (p.

8)

2 Remove the damaged filter(s).

Clean and degrease the metal plates

with an alcohol cleaner.

3 Apply a dab of red, high temperature silicone adhesive about the size of

a 1 mm ball on each corner of the heat

filter holder. Place the middle frame on

the holder and align the screw holes.

4 Place the heat filter glass inside the

middle frame with the coated side down

(towards the lamp) and with the long

edge parallel to the bent sides of the filter holder. (To find the coated side, hold

the filter up to a source of light. When

the coated side is up, the edges of the

glass have a reddish tint. When the

coated side is down, the edges have a

more gray or black appearance.

5 Place the top frame over the glass

and fasten with four screws (4.2x13

self-tap, Torx, black).

6 Remove any excess glue that

extends beyond the metal corners and

clean the glass.

7 Reinstall the heat filter assembly.

Allow the glue to harden for at least 12

hours before use.

Reflector, replace

1 Remove the heat filter assembly. (p.

8)

2 Remove the outer screws from the

reflector spring clips, loosen the inner

screws, and turn the clips away from

the rim.

3 Remove the reflector and install the

the replacement, carefully aligning the

opening with the lamp.

4 Secure the reflector with the spring

clips. Tighten all 8 screws and verify

that the reflector cannot turn.

5 Reassemble.

Starter, replace

1 Remove the zoom module (p. 3),

CMYC module (p. 5), and the front and

rear left-side head covers (p. 7).

2 Remove the lamp.

3 Turn the lamp in/out adjustment

screw fully counterclockwise.

4 Pry the lamp socket assembly off

the lamp access plate.

5 Remove the starter wires from the

lamp socket terminals.

6 Loosen the wire clamp at the base

of the lamp access plate by removing

one of the push-on fasteners.

7 Pull the wires back to the starter,

cutting cable ties as you go.

Fig. 41 Apply adhesive

Fig. 42 Insert glass filters

Fig. 43 Install top frame

Fig. 44 Turn clips to free reflector

Fig. 45 Turn fully CCW

Fig. 46 Pry out the adjustment plate

Fig. 47 Loosen the cable clamp

Page 11

10

MAC 2000 Wash Service Manual

8 Unscrew, unplug, and remove the

starter.

9 Plug in the replacement starter and

fasten it to the bracket with the lamp

wires towards the front and bottom.

Lead the wires up, through the hole in

the top of the chassis, and towards the

back as shown in Fig. 48.

10 Place a 30 cm (12 in.) length of 6

mm sleeve (P/N 15802007) on each

lamp wire. Insert the lamp wires through

the hole under the thermo-switch and

pull them out at the back. Adjust the

sleeve as shown in Fig. 49.

11 Lead the wires up through the hole

in the lamp access plate and then to

either side. The lamp wires are not

polarized.

12 Connect the lamp wires to the lamp

socket terminals. Make sure the connections are secure.

13 Snap the lamp socket and adjustment assembly back into place.

14 Gather the white lamp wires

together with the black and blue starter

wires and tie them to the chassis at

point 1 in Fig. 51 Tie the wires that lead

to the back at point 2.

15 Tie the wires under the left fan as

shown in Fig. 52. Keep the wires and

thermo-switch clear of the fan to maintain maximum airflow.

16 Adjust the wires for a neat lead at

the lamp socket.

17 Place the cable clamp over both

screws and secure with a push-on fastener. (Fig. 47)

18 Reassemble the fixture and install

the lamp.

19 Adjust the lamp as described in the

user manual

Dimmer blades, replace &

adjust

1 Remove the CMYC module. (p. 5)

2 Remove the heat shield on the back

(lamp side) of the module.

3 Remove the V-shaped plate over

the top dimmer.

4 Loosen the shaft adaptor set screws

and remove the dimmer blades.

Remove any nicks or burrs from the

motor shaft with fine sandpaper.

5 Install a dimmer blade on the top

motor with a 1.5 mm gap between the

module plate and the inside (black) face

of the blade (Fig. 56). Slightly tighten a

set screw.

6 Install a dimmer blade on the bottom motor with a distance of 7 mm from

the module plate to the outside face of

the shaft adaptor (Fig. 57). Slightly

tighten a set screw to hold the position.

Fig. 48 Starter screws

Fig. 49 Lamp wires with sleeve

Fig. 50 Lamp wires at access plate

Fig. 51 Tie starter wires

1

2

Fig. 52 Cable ties at left fan

Fig. 53 Heat shield

Fig. 54 V-plate over top dimmer

Fig. 55 Remove burrs

Page 12

11

MAC 2000 Wash Service Manual

7 Connect a 4-pole motor extension

cable to dimmer junction PCB, and

cable 16 in the head or the dimmer output on the PCB. Apply power and cancel pan/tilt reset from the control panel.

8 When the reset is complete, select

UTIL>AdJ>HEAd>dIM>AdJ (dimmer

adjustment position) from the menu.

Press each blade against its stop and

tighten the set screws.

9 Select STRO (strobe) from the

menu and check dimmer movement.

10 Switch off the fixture and disconnect the motor extension cable.

11 Reinstall the V-shaped plate and the

heat shield.

12 Reassemble.

Dimmer motor, replace

1 Remove the dimmer blade as

described under “Dimmer blades,

replace & adjust” on page 10.

2 Unplug and remove the motor.

3 Place the spacer on the face of the

replacement motor and install with the

plug oriented as shown. Connect.

4 Install and adjust the dimmer blade.

(p. 10)

CMYC module, separate

1 Remove the CMYC module. (p. 5)

2 Remove the heat shield (Fig. 53)

and the V-plate over the top dimmer

blade (Fig. 54).

3 From the dimmer side of the module, remove the 8 screws that fasten the

module plate to the stand-offs.

4 Unplug the dimmer motors, the light

sensor (41), the cyan and magenta

motors, and the microswitches on the

dimmer half of the module.

5 Separate the module into 2 parts.

6 Assembly is the reverse.

Fig. 56 Top blade spacing: 1.5 mm

Fig. 57 Bottom blade spacing: 7 mm

Fig. 58 Press blade against stop

Fig. 59 Dimmer motor orientation

Fig. 60 Stand-off screws

Fig. 61 Unplug light sensor

Fig. 62 Unplug microswitches

Fig. 63 Separate into 2 parts

Page 13

12

MAC 2000 Wash Service Manual

CMYC belts and flags,

replace

1 Remove and separate the CMYC

module. (p. 11)

2 Place the module half that needs

servicing on a clean surface with the filters up.

3 Starting with the top set of filters

(cyan or yellow), release tension and lift

the belt off the pulleys.

4 Gently pry the drive rail out of its clip

on one end. Pull the rail lengthwise out

of the other clip.

5 Lift the drive rail, filters, and belt out

of the assembly.

6 If you need to remove the bottom

set of filters (magenta or CTC), first

remove the idle rail for the top filters.

Then repeat steps 3, 4, and 5 to

remove the bottom filters.

7 If replacing the belt or filters, unlock

and remove the belt clamp from each

slide. Remove the belt.

8 Clean the rails and lubricate with a

drop of high viscosity silicone oil.

9 Slide the flags onto the rail with the

coated (text true) sides facing each

other.

10 Magenta and CTC only: Clamp

the belt to the inside slot of the Y slide.

Lay the flag pair one the rails with the Y

filter on top. Skip to step 12.

11 Cyan and yellow only: Clamp

the belt to the inside slot of the X

slide. Position the flag pair in the mod-

ule with the X filter on top. Skip to step

13.

12 Install the idle rail for the top flag

set.

13 Arrange the belt and make sure the

ends are outside the rail clips. Center

the rail on the clips and snap it into the

clips on each end. Work the belt onto

the pulleys.

14 Set the filters an equal distance

from the clip using any convenient

spacer.

Fig. 64 Color flag order

Fig. 65 Gently pry out drive rail

Fig. 66 Remove flags, rail, & belt

Fig. 67 Remove clamp from slide

Fig. 68 Clamp belt to inside of Y slide

Fig. 69 Y filter on top

Y

X

Fig. 70 Clamp to inside of X slide

Fig. 71 X filter on top

X

Y

Fig. 72 Equal distance

Page 14

13

MAC 2000 Wash Service Manual

15 Clamp the belt in the outside slot

of the slide for the bottom filter.

16 Verify that the flags slide smoothly

in opposite directions and that the bottom flag engages the microswitch. If the

flag does not fully engage the switch,

remove the clamp from the bottom

slide, move the filter 1 tooth closer to

the microswitch, and re-clamp.

17 Reassemble and install the module.

CMYC motors, replace

1 Remove and separate the CMYC

module. (p. 11)

2 Unplug and remove the old motor.

3 Measure the position of the gear

along the motor shaft. Transfer the gear

to the replacement motor or install a

new one.

4 If replacing the cyan or magenta

motors, place the motor heat shield

under the module plate.

5 Orient the motor as shown with 3

springs between the motor and the

plate. Fasten.

6 Reassemble the fixture.

Fig. 73 Clamp belt in outside slot

Fig. 74 Flag must engage microswitch

Fig. 75 Magenta motor

Fig. 76 Cyan motor

Fig. 77 Yellow motor

Fig. 78 CTC motor

Fig. 79 Flag motor suspension

Page 15

© 2002 Martin Professional A/S, Denmark. Updated December 23, 2002 14

YOKE PROCEDURES

Yoke covers, remove

Remove yoke covers in the following order:

1 outer arm covers

2 inner arm covers

3 front and back base covers

4 top base cover

Installation is the reverse.

Tilt belt, left, replace

On the left side, the wiring is easiest to

disconnect at the head.

1 Disconnect the fixture from AC

power.

2 Remove the zoom module. (p. 3)

Remove the inside and outside covers

from the left side of the yoke.

3 Cut the cable ties that bind the bundle of black motor and sensor wires to

the lamp and ground wires. Pull the

bundle of black wires out of the head.

4 Disconnect the black and blue lamp

wires from top of the connection block

and pull them into the head.

5 Disconnect the ground wires and

pull the shorter wire into the head.

6 Unhook the motor springs and

loosen the hex-socket motor screws.

Push the motor up and remove the belt

from the motor gear.

7 Unlock the head and support it

under the left side.

8 Remove the circlip from the tilt bearing.

9 Remove 3 screws from each side of

the left tilt arm.

10 Work the arm off of the tilt bearing,

pulling straight, and place a new belt on

the large gear.

11 Work the arm back into position and

align the screw holes. Fasten.

12 Install the tilt axle circlip.

13 Place the belt on the motor gear.

Install the tension springs. Tighten the

hex-socket motor screws.

14 Pull the lamp and ground wires

through the yoke bearing. Connect the

lamp wires to the connection block.

Fasten both ground wires to the top of

the arm with a locknut.

15 Feed the black wire bundle into the

head. Tie the wires neatly together,

leaving some slack, with 3 or 4 cable

Fig. 80 Remove arm covers first

Fig. 81 Disconnect lamp wires

Fig. 82 Disconnect ground wires

Fig. 83 Loosen motor screws

Fig. 84 Support the head

Fig. 85 Remove circlip

Fig. 86 Remove arm screws

Fig. 87 Pull arm off bearing

Page 16

15

MAC 2000 Wash Service Manual

ties. Tie the bundle to the arm above

the motor.

16 Install and connect the zoom module. (p. 3)

17 Synchronize the tilt motors. (p. 16)

Tilt belt, right, replace

On the right side, the wiring is easiest to

disconnect at the yoke.

1 Remove the inside and outside covers from the right arm of the yoke.

2 Remove the yoke base covers.

3 Unplug all wires that lead down from

the head from the connection print at

the base of the yoke.

4 Remove the tilt timing wheel.

5 Unhook the belt tension springs,

loosen the hex head motor screws, and

take the belt off the motor gear. (Fig.

83)

6 Unlock and support the head under

the right side. (Fig. 84)

7 Remove the circlip from the tilt axle.

(Fig. 85)

8 Remove the 6 yoke arm screws.

(Fig. 86) Pull the arm straight back off

the axle. Remove the old belt and place

the new one over the large gear.

9 Work the arm back into position and

align the screw holes. Fasten.

10 Install the tilt axle circlip.

11 Place the belt on the motor gear and

install the tension springs. (Fig. 88)

Tighten the hex-socket motor screws.

12 Install the timing wheel.

13 Plug the wires back into the sockets

on the connection print shown in Fig. 92

14 Synchronize the tilt motors.

Fig. 88 Attach springs

Fig. 89 Tie bundle to arm

Fig. 90 Unplug bundle at yoke

Fig. 91 Remove arm

38 16

32 42 10 9

87

28/29

65

43

21

PL42PL38PL

37

PL 36 PL 35

PL 29 PL 28PL 41PL 30

PL 23 PL 22PL 24

PL 17 PL 16PL 18

PL 11 PL 10PL 12

PL 5 PL4PL 6

PL40PL34PL

33

PL 32 PL 31

PL 26 PL 25PL 39PL 27

PL 20 PL 19PL 21

PL 14 PL 13PL 15

PL 8 PL7PL 9

PL 2 PL1PL 3

33160020-A

38 16

32 42 10 9

87

28/29

65

43

21

23 36 30 37 22

32 41 21 20

31 19 18

26/27 17 15

34 14 13

24 12 11

Pan Lock Side

PL42PL38PL

37

PL 36 PL 35

PL 29 PL 28PL 41PL 30

PL 23 PL 22PL 24

PL 17 PL 16PL 18

PL 11 PL 10PL 12

PL 5 PL4PL 6

23 36 30 37 22

32 41 21 20

31 19 18

26/27 17 15

34 14 13

24 12 11

PL40PL34PL

33

PL 32 PL 31

PL 26 PL 25PL 39PL 27

PL 20 PL 19PL 21

PL 14 PL 13PL 15

PL 8 PL7PL 9

PL 2 PL1PL 3

33160020-A

Fig. 92 Yoke base connections

Page 17

16

MAC 2000 Wash Service Manual

Tilt motors, synchronize

1 Remove the outer arm cover from

the left or right side of the yoke.

2 With the power off, loosen both

motor gear set screws.

3 Apply power and allow the fixture to

reset.

4 From the control panel (MAN >

TILT), move the head the minimum

required to access and tighten one of

the set screws.

5 Move the head again and tighten

the second set screw.

6 Replace the yoke cover.

Tilt motors, replace

Steps in parenthesis are for the right, tilt

sensor, side only.

1 Remove the outside and inside arm

covers from the side of the yoke to be

serviced.

2 (Remove the timing wheel.)

3 Unhook the motor springs and

loosen the hex-socket motor screws.

(Fig. 83) Push the motor up and remove

the belt from the motor gear.

4 Remove the hex-socket motor

screws and remove the motor and

bracket. Unplug the motor. (Unplug the

tilt sensor).

5 Remove the bracket from the old

motor.

6 Transfer the gear to the new motor

or install a new one with a distance of

7.5 mm (0.3 in.) face of the motor to the

inside face of the shaft adaptor. Tighten

a set screw slightly to fix the position.

7 Fasten the motor bracket to the new

motor as shown using 3 new M5 x 16

mm hex head taptite screws, P/N

08091005. (Used taptites are not suited

for cutting new threads.)

8 Position the motor assembly on the

arm without pinching any wires and

start the hex-socket screws.

9 Plug in the motor wires. (Connect

the tilt sensor.)

10 Place the belt on the motor gear and

install the tension springs. (Fig. 88)

Tighten the hex-socket motor screws.

Move the head through its tilt range a

couple of times and verify that the belt

does not rub against the yoke.

11 (Install the timing wheel and verify

that it turns freely.)

12 Synchronize the tilt motors. (p. 16)

13 Replace the yoke covers.

Synchronize the tilt motors with a

front lens installed (for balance)

and with the head as close to vertical as possible.

Fig. 93 Remove motor and bracket

Fig. 94 Tilt motor orientation

Page 18

© 2002 Martin Professional A/S, Denmark. Updated December 23, 2002 17

BASE PROCEDURES

Pan belt, replace

1 Remove the covers from the top of

the base.

2 Remove all yoke covers. (p. 14)

3 Unplug all wires from the connection

PCB that lead up through the pan shaft.

Disconnect the lamp power and ground

wires from the yoke and cut cable ties

as required to free them.

4 Cut the cable ties around the wire

bundle at the top of the pan shaft.

5 Remove the pan gear screws with a

short or angled Pozidriv 2 screwdriver.

6 Remove the yoke attachment

screws with a 4 mm hex key. Before

removing the last screw, turn the yoke

to the center of the pan range, with the

bottom of the yoke parallel to the main

PCB.

7 Note how the pan stop screw aligns

with the edge of the power supply PCB.

The pan gear must be in the same position when you reinstall the yoke.

8 Lift the yoke off the base and have a

helper feed the wires through the yoke

opening. Set the yoke and head aside.

9 Remove the pan timing wheel.

Unhook the springs and loosen the

motor bracket screws.

10 Remove the belt.

11 To ensure that the new belt will be

properly tensioned, remove the springs

and loosen the opposite pan motor.

12 Install the replacement belt on both

motors and the pan gear. Hook the

springs onto both motors and verify that

the belt tension is the same on each

side before tightening the motors.

13 Install the timing wheel.

14 Turn the pan gear to the center of

the pan range. (Fig. 96)

15 Lock the head horizontally with the

top up. Have a helper feed the wires

into the yoke as you place the yoke on

the pan shaft. The front of the head

must face the front of the base

16 Align the holes in the yoke and pan

shaft. Install the hex socket yoke

attachment screws in the holes at the 2,

6, and 10 o’clock positions. (Fig. 95)

17 Install the pan gear screws in the

holes at the 12, 4, and 8 o’clock positions. (Fig. 95) Apply Loctite 480 to

these screws and be very careful to

avoid stripping the plastic threads.

18 Reconnect the lamp and ground

wires. Connect the other wires as

shown on the label. (Fig. 92) The unlabeled 2-pin connector in the pan-lockside bundle is plug 30.

19 Install cable ties as required to manage the wires.

20 Form a collar around the wire bundle at the top of the pan shaft with 2

cable ties (P/N 13104003, “Strap, black,

3.6x140mm”). Position the collar so that

the slack is about the same at the top

and bottom of the shaft. (Fig. 95)

21 Synchronize the pan motors. (p. 21)

22 Install yoke and base covers.

Fig. 95 Pan shaft detail

2

4

10

12

6

8

Fig. 96 Stop aligns with power supply

Warning! To prevent the head

from working loose, always use

threadlock on the yoke attachment

screws.

Fig. 97 Motor bracket screws

Fig. 98 Check belt tension

Fig. 99 Plug 30

Page 19

18

MAC 2000 Wash Service Manual

Main PCB, replace

See the electrostatic discharge precautions

on page 2.

1 Remove the front top base cover.

2 Remove the top screws from the

front side cover and swing the cover

down to expose the main PCB.

3 Disconnect all wires from the PCB.

4 Remove the nuts along the top edge

with a 5.5 mm socket wrench. Lift the

top edge of the PCB over the screws

and then lift the bottom edge out of the

track.

5 Check the jumper caps on the

replacement board. The normal positions are as follows:

6 Connect the blue, brown, and black

high voltage wires to the PCB as shown

on the connection label.

7 Install the PCB on the front cover.

8 Connect the 2-wire electronic ballast

dimmer cable to PL215. (The ballast

end is shown in Fig. 104.)

9 Connect the large unlabeled 4-pin

plug at the bottom of the PCB. Follow

the lead from the right base fan (next to

the control panel) and connect it to

PL57. Connect the left base fan to

PL55. Connect the 4-pin lead from the

control panel to PL33.

10 Connect the rectangular 8-pin plug

from the power supply to the socket at

the top of the PCB.

11 Connect the remaining wires as

shown on the connection label.

12 Upload software if required and

reinstall the covers.

Power supply, replace

1 Verify that the fixture is discon-

nected from AC power.

2 Remove the front top base cover.

3 Disconnect the blue and brown

wires at the top of the power supply

PCB and unplug the 8-pin connector on

the right.

4 Remove the front side cover and

disconnect the blue, black, and brown

wires so you can get to the nuts at the

bottom of the power supply.

5 Remove 2 nuts from the top and 3

nuts from the bottom of the circuit board

with a 5.5 mm socket wrench and

extension. You may also need a 5.5 mm

open-end wrench to hold the stand-offs.

Remove the power module.

6 Install and fasten the replacement.

7 Connect the brown wire to PL101

and the blue wire to PL102. These

wires are slightly heavier than the

brown and blue wires going to the relay.

8 Plug in the 8-pin connector.

9 Reconnect the brown, black, and

blue lamp power wires to the main PCB

as shown on the connection label.

10 Reinstall the covers.

Jumper Default position

write enable

boot normal

data receive/send

Fig. 100 DMX, control panel, and fan

connection

Fig. 101 PCB connections

Fig. 102 AC input

brown

blue

Page 20

19

MAC 2000 Wash Service Manual

Electronic ballast, replace

1 Verify that the fixture is discon-

nected from AC power.

2 Remove the ballast bracket screws

from the bottom.

3 Remove the top cover from the ballast side of the base. Remove the top

screws from the rear side cover and tilt

the cover down.

4 Disconnect the blue and black wires

from ballast terminals X300 and X301.

5 Disconnect the ballast dimmer wire.

6 Remove 6 small screws that fasten

the ballast on top and bottom.

7 Disconnect the brown and blue

mains wires from terminals X1 and X2.

8 Connect the brown mains wire to

the live terminal (X1) and the blue

mains wire to the neutral terminal (X2)

on the replacement ballast.

9 Fasten the ballast to the bracket.

10 Connect the brown starter wire to

the “+” terminal (X300) and the blue

starter wire to the “-” terminal (X301).

11 Connect the dimmer wire. (Fig. 104)

12 Fasten the ballast bracket to the

base.

13 Check the ballast fan connection.

Install the covers.

Ballast fan, replace

1 Remove the ballast as described in

the previous procedure.

2 Disconnect the ballast fan cable

from PL59 on the main PCB. Cut ties as

required to free the cable.

3 Remove the fan from the ballast

bracket.

4 Transfer the grill to the replacement

fan. Install the fan on the ballast bracket

with the air flow arrow pointing towards

the ballast and the fan lead on the side

of the fan closest to the PCB.

5 Lead the fan wires across the base

and connect to PL59. Replace the cable

ties.

6 Reinstall the ballast as described in

the replacement procedure.

Base fans, replace

1 Remove the top base covers.

Remove the left or right side cover and

handle. Remove the top screw from the

other end of the front cover and tilt the

cover down to access the main PCB.

2 Unplug the fan from the main PCB

and cut ties as required to free the

cable.

3 Unscrew the fan and remove the

grill. Lift the fan up and pull the fan bottom-first out of the opening.

4 The air flow arrow for both fans

points into the base. If replacing the

right fan (closest to the control panel)

orient it so the wires enter at 9 o’clock,

seen from the outside. If replacing the

left fan (closest to the power switch),

turn it so the wires are on top. Insert the

fan top-first into the base.

5 Connect and tie the fan cable.

6 Place the grill over the fan. Check

that the fan wires are not pinched and

then fasten.

7 Install all covers.

Fig. 103 Ballast bracket screws

Fig. 104 Ballast dimmer connection

Fig. 105 Ballast screws

Fig. 106 Ballast AC connection

Fig. 107 Ballast fan orientation

Fig. 108 Remove fan bottom first

Fig. 109 Fan grill installation

Page 21

20

MAC 2000 Wash Service Manual

Right pan motor, replace

1 Remove the top base covers and

the right side cover. Flip the front cover

down to access the main PCB.

2 Unscrew and remove the fan and

grill. You may not have to disconnect

the fan if there is enough slack in the

wire to move the fan out of the way.

3 Loosen and push back the v-shaped

air deflector.

4 Remove the timing wheel and

unplug the position sensor. Unplug the

pan motor.

5 Unhook the belt tension springs.

6 Remove 2 of the 3 hex-head motor

attachment screws.

7 Remove all 4 motor bracket screws.

(Fig. 97) Take the pan belt off the motor

gear and lower the motor.

8 Working through the fan opening,

remove the third motor screw.

9 Move the bracket out of the way and

remove the motor.

10 Remove the gear from the shaft of

the old motor.

11 Cut threads in the new motor before

installing. Use a 5 mm tap or new 5 mm

taptites (P/N 08091005). Do not cut the

threads with used taptites.

12 Orient the motor in the base as

shown.

13 Align the motor and bracket and,

working from the top, fasten with 2 M5 x

16 hex cap screws. Install the third

screw through the fan opening.

14 Install the 4 bracket screws and

washers loosely so the bracket can

slide.

15 Place the gear on the motor shaft

and visually align it with the large gear.

Tighten one set-screw slightly to hold

this position.

16 Work the belt into position on all 3

gears.

17 Install the belt tension springs and

then tighten the bracket screws. The

motor is not intended to float.

18 Connect the motor and the pan sensor wires. Install the timing wheel.

19 Fasten the air deflector in position.

20 Install the fan and grill. (Fig. 109)

21 Install the right side cover but leave

the front panel open for the next step.

22 Synchronize the pan motors. (p.

21). Remember to tighten the set

screws on the right motor.

Left pan motor, replace

The pan lock bridge must be removed in

order to remove the left pan motor.

1 Follow steps 1 - 5 of the ballast

replacement procedure on page 19.

2 Move the ballast out of the way and

remove the 3 pan-lock bridge screws.

3 Remove both top base covers, the

left side cover, and the front side cover.

4 Follow steps 1 - 5 of the power supply replacement procedure on page 18.

5 Remove the pan-lock bridge

screws. Remove the stand-off using a 2

mm hex key to hold the screw. Remove

the pan-lock bridge.

Fig. 110 Air deflector screws

Fig. 111 Motor attachment screws

Fig. 112 Remove 3rd screw

Fig. 113 Right motor orientation

Fig. 114 Bridge for pan lock

Fig. 115 Bridge screws

Fig. 116 Screws and stand-off

Page 22

21

MAC 2000 Wash Service Manual

6 Loosen the hex socket screw that

fastens the power supply mounting

plate to the chassis.

7 Remove the left fan.

8 Loosen and push back the v-shaped

air deflector. (Fig. 110)

9 Unplug the motor. Remove the belt

tension springs. Remove 2 of the 3 hexhead motor attachment screws (Fig.

111)

10 Remove all 4 motor bracket screws.

(Fig. 97) Take the pan belt off the motor

gear and lower the motor.

11 Working through the fan opening,

remove the third motor screw. (Fig.

112)

12 Move the bracket out of the way and

remove the motor.

13 Cut threads in the new motor before

installing. Use a 5 mm tap or new 5 mm

taptites (P/N 08091005). Do not cut the

threads with used taptites.

14 Position the new motor in the base

with the plug towards the power switch.

15 Align the motor and bracket and,

working from the top, fasten with 2 M5 x

16 hex cap screws. Lower and turn the

assembly to install the third screw.

16 Install the 4 bracket screws and

washers loosely so the bracket can

slide.

17 Place the gear loosely on the motor

shaft. Work the belt onto the gears and

then install the tension springs. Tighten

the motor bracket screws so that the

motor is securely fastened and does not

float.

18 Align the motor gear with the pan

gear and tighten both set screws.

19 Connect the motor wire.

20 Move the air deflector back into

place and fasten. (Fig. 110)

21 Install the pan lock bridge.

22 Tighten the hex-socket screw that

fastens the power supply mounting

plate to the chassis. (Fig. 117)

23 Install the stand-off for the power

supply PCB.

24 Install and fasten the power supply.

Connect the brown wire to PL101 and

the blue wire to PL102. These wires are

slightly heavier than the brown and blue

wires going to the relay. (Fig. 102)

25 Connect the 8-pin plug to the power

module.

26 Reconnect the brown, black, and

blue wires to the main PCB as shown

on the connection label.

27 Install the fan and grill.

28 Install the left side cover but leave

the front and back covers open.

29 Connect the brown starter wire to

the “+” terminal (X300) and the blue

starter wire to the “-” terminal (X301) on

the ballast. Connect the ballast dimmer

wire. (Fig. 104)

30 Fasten the ballast bracket from the

bottom. (Fig. 103)

31 Apply power and reset the fixture.

Verify that all three fans in the base are

running.

32 Synchronize the pan motors. If you

synchronize the right motor make sure

the set screws on the left motor are

tight.

Pan motors, synchronize

1 If the fixture is mounted sideways,

move it to a level surface.

2 Remove the top front base cover

and open the front side cover.

3 Verify that the belt is tensioned

evenly on both sides of the pan gear. If

the belt is loose, loosen the motor

bracket screws and allow the springs to

tension the belt. Retighten the screws

so that the motor bracket is securely

fastened.

4 Loosen the set screws on either the

left or right pan motor gear. The right

motor is easiest to access if the front

cover is open.

5 Apply power and allow the fixture to

reset. Using either a controller or the

control panel, turn the yoke as required

to access and tighten the set screws.

6 To test, turn off pan/tilt feedback

(UTIL > FEbA > OFF) and turn the timing wheel by hand. When synchronized,

both motors will step together smoothly.

When unsynchronized or improperly

tensioned, the movement may be jerky

and sometimes only one motor will

step.

7 Close the base.

Fig. 117 Loosen screw

Fig. 118 Left motor orientation

Use caution while working in the

base with the power on: there are

dangerous voltages present.

Fig. 119 Best access on right side

Loading...

Loading...