Page 1

Martin®

Sonic Horns

Go to Martin® Sonic Horns web page

Operator’s Manual

M3829

Page 2

Important

MARTIN ENGINEERING HEREBY DISCLAIMS ANY LIABILITY FOR: DAMAGE DUE TO

CONTAMINATION OF THE MATERIAL; USER’S FAILURE TO INSPECT, MAINTAIN AND TAKE

REASONABLE CARE OF THE EQUIPMENT; INJURIES OR DAMAGE RESULTING FROM USE OR

APPLICATION OF THIS PRODUCT CONTRARY TO INSTRUCTIONS AND SPECIFICATIONS

CONTAINED HEREIN. MARTIN ENGINEERING’S LIABILITY SHALL BE LIMITED TO REPAIR

OR REPLACEMENT OF EQUIPMENT SHOWN TO BE DEFECTIVE.

Observe all safety rules given herein along with owner and Government standards and regulations. Know

and understand lockout/tagout procedures as defined by American National Standards Institute (ANSI)

z244.1-1982, American National Standard for Personnel Protection - Lockout/Tagout of Energy Sources -

Minimum Safety Requirements and Occupational Safety and Health Administration (OSHA) Federal

Register, Part IV, 29 CFR Part 1910, Control of Hazardous Energy Source (Lockout/Tagout); Final Rule.

The following symbols may be used in this manual:

!

DANGER

Danger: Immediate hazards that will result in severe personal injury or death.

!

WARNING

Warning: Hazards or unsafe practices that could result in personal injury.

!

CAUTION

Caution: Hazards or unsafe practices that could result in product or property damages.

IMPORTANT

Important: Instructions that must be followed to ensure proper installation/operation of equipment.

NOTE

Note: General statements to assist the reader.

Page 3

Table of Contents

Section Page

List of Figures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Required accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Materials required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before Installing Sonic Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Installing Sonic Horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing sonic horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing restraining cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Connecting air supply to sonic horn. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

After Installing Sonic Horn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Every month. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Appendix A.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Table of Contents

Martin Engineering M3829-08/13 i Martin® Sonic Horns

Page 4

Figure Title Page

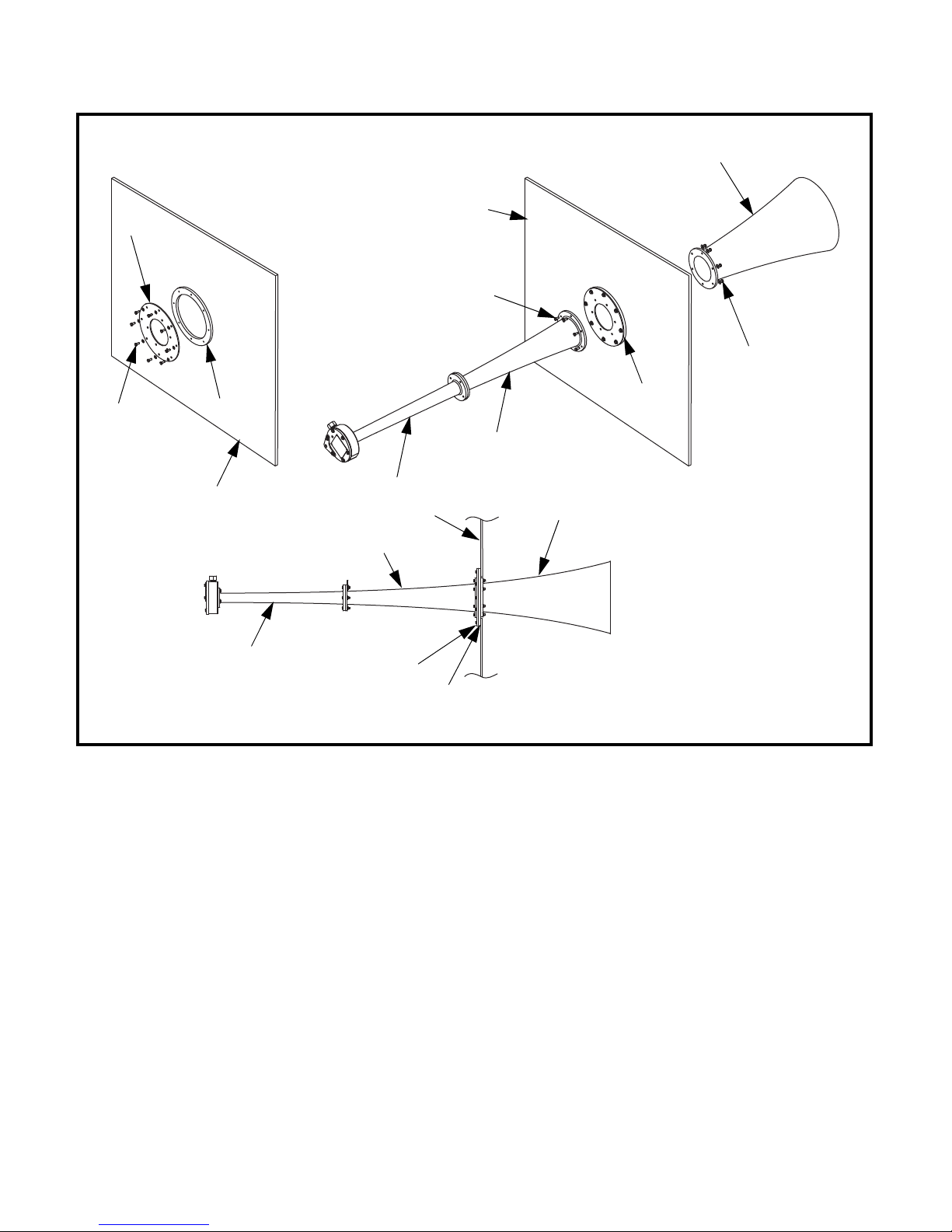

1 Flush Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Mid-Mount Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3 Installing Restraining Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4 Plumbing Detail for Normally-Closed Solenoid Valve . . . . . . . . . . . . . . . . . 8

5 Martin

6 Martin

7 Martin

®

75Hz Sonic Horn Assembly, P/N SH075-XXXXXXX . . . . . . . . . 14

®

230Hz Sonic Horn Assembly, P/N SH230-XXXXX . . . . . . . . . . . 16

®

75Hz Mega Horn Assembly, P/N SH075M-XXXXXX . . . . . . . . . 17

List of Figures & Tables

Table Title Page

List of Figures

List of Tables

I Martin® 75Hz Sonic Horn Assembly, P/N SH075-XXXXXXX . . . . . . . . . 15

II Martin

III Martin

®

230Hz Sonic Horn Assembly, P/N SH230-XXXXX . . . . . . . . . . . 16

®

75Hz Mega Horn Assembly, P/N SH075M-XXXXXX . . . . . . . . . 18

Martin Engineering M3829-08/13 ii Martin® Sonic Horns

Page 5

Introduction

General The Martin

generates intense sound waves and introduces vibration into vessels, transfer

chutes, gas ducts, and feed pipes to maintain material or gas flow.

This manual provides instructions for installing sonic horns on steel structures

only. For installations on other structures, call Martin Engineering or a

representative

®

Sonic Horn is a pneumatic bulk material-moving system that

.

Specifications See Appendix A for technical data specific to individual models.

Required

accessories

A sonic horn system requires additional accessories in order to be fully

operational. These accessories, which consist of solenoid valves, filters,

regulators, ball valves, air hoses, mounting plates, etc., can be purchased from

Martin Engineering. These accessories are packaged in kits for convenience

and are ordered separately from the sonic horn assembly. Contact Martin

Engineering or a representative to determine which kits are required for your

specific application.

References The following documents are referenced in this manual:

Introduction

• American National Standards Institute (ANSI) z244.1-1982, American

National Standard for Personnel Protection - Lockout/Tagout of Energy

Sources - Minimum Safety Requirements, American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

• Federal Register, Volume 54, Number 169, Part IV, 29 CFR Part 1910,

Control of Hazardous Energy Source (Lockout/Tagout); Final Rule,

Department of Labor, Occupational Safety and Health Administration

(OSHA), 32nd Floor, Room 3244, 230 South Dearborn Street,

Chicago, IL 60604.

• The National Electrical Code (NEC) Handbook, National Fire Protection

Association, 1 Batterymarch Park, P.O. Box 9101, Quincy MA 02269-9101.

• ICS 1-1988, General Standards for Industrial Control and Systems, and

250-1985, Enclosures for Electrical Equipment (1000 Volts Maximum),

National Electrical Manufacturers Association (NEMA), 2101 L Street

N.W., Washington, D.C. 20037.

Safety All safety rules defined in the above documents, and all owner/employer

safety rules, must be strictly followed when installing and servicing this

equipment.

Materials required Materials other than standard hand tools that are required to complete tasks

are listed where applicable.

Martin Engineering M3829-08/13 1 Martin® Sonic Horns

Page 6

Before Installing Sonic Horn

IMPORTANT

WARNING

!

WARNING

!

Before Installation

The delivery service is responsible for damage occurring in

transit. Martin Engineering CANNOT enter claims for

damages. Contact your transportation agent for more

information.

1. Inspect shipping container for damage. Report damage to delivery service

immediately and fill out delivery service’s claim form. Keep any damaged

goods subject to examination.

2. Remove sonic horn assembly from shipping container.

3. If you purchased accessories from Martin Engineering, they will be

packaged separately. Remove this equipment from its shipping container.

4. Take inventory of the equipment received. If anything is missing, contact

Martin Engineering or representative.

Before installing sonic horn, lock out/tag out any equipment

that is loading or unloading material from the vessel.

5. Turn off and lock out/tag out energy source to accessory equipment

according to ANSI standards (see “References”).

If equipment will be installed in an enclosed area, test gas level

or dust content before using a cutting torch or welding. Using

a cutting torch or welding in an area with gas or dust may

cause an explosion.

6. If using a cutting torch or welding, test atmosphere for gas level or dust

content.

Martin Engineering M3829-08/13 2 Martin® Sonic Horns

Page 7

Installing Sonic Horn

NOTE

NOTE

NOTICE OF LIMITED LIABILITY: Due to possible presence of latent

structural defects in the apparatus of the purchaser, Martin Engineering

shall not be responsible for consequential damage to the purchaser’s

equipment and/or apparatus resulting from the application of a Martin

Product. Martin

by the purchaser or other circumstances beyond the control of Martin

Engineering. Liability is disclaimed for the structural soundness of

apparatus or equipment not supplied by Martin Engineering. Liability

shall be strictly limited to the replacement of the purchased product or

refund of the purchase price. To secure the integrity of the installation,

specify supervision by qualified personnel from Martin Engineering.

Engineering shall not be liable for improper installation

Installation

®

Installing sonic

horn

Sonic horns must be solidly mounted to the vessel and the horn must have

unrestricted flow. A variety of installation methods and mount plate designs

can be used to install sonic horns. This section will describe the installation

using the most common methods. If you are not sure how to install the sonic

horn for optimum performance and convenience, contact Martin Engineering

or a representative.

If you are unsure where to locate sonic horn(s) on your vessel,

contact Martin Engineering or your representative.

1. Mark location for each sonic horn on vessel. Make sure sonic horn is not

positioned where material can flow into horn.

Martin Engineering M3829-08/13 3 Martin® Sonic Horns

Page 8

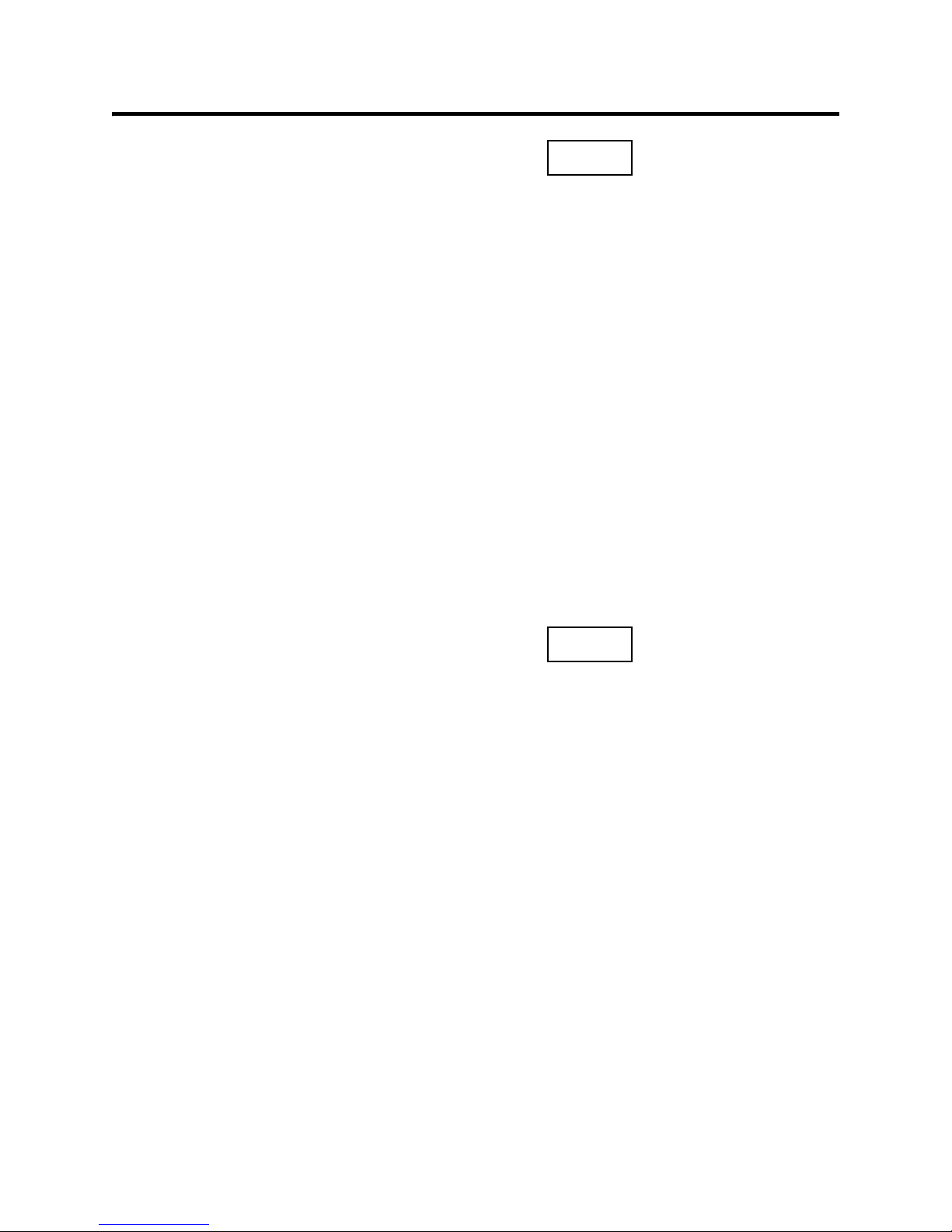

A

C

B

A. Vessel Wall

B. Cap Screw and Washer

C. Flange Ring

Installation

Figure 1. Flush Mount Installation

2. For flush mount installations:

a. Cut a hole in vessel using flange ring (C) as a template.

b. Tack weld flange ring (C) to vessel.

c. Attach sonic horn to flange ring (C) using cap screws and washers (B).

d. Weld flange ring (C) to vessel. Make a continuous weld around

perimeter of flange ring.

Martin Engineering M3829-08/13 4 Martin® Sonic Horns

Page 9

D

F

C

G

E

D

G

I

D

F

G

B

A

A

B

A. Section A

B. Section B

C. Section C

D. Vessel Wall

E. Cap Screw and Washer

F. Fla nge Ri n g

G. Flange Plate

H. Cap Screw

I. Nut and Washer

H

C

Installation

3. For mid-mount installations:

Martin Engineering M3829-08/13 5 Martin® Sonic Horns

Figure 2. Mid-Mount Installation

a. Cut a hole in vessel using flange ring (F) as a template.

b. Tack weld flange ring (F) to vessel.

c. Attach flange plate G) to flange ring (F) using cap screws and

washers (E).

d. Weld flange ring (F) to vessel. Make a continuous weld around

perimeter of flange ring.

e. Place sections A and B of sonic horn on the outside of the flange plate

(G) and place section C on the inside of the flange plate. Attach both

sections to flange plate and to each other using cap screws (H) and

washers and nuts (I).

Page 10

Installing

WARNING

!

A.

B.

C.

D.

D-ring

Vessel Wall

Wire rope

Cable clamp

E. Bracket

D

D

A

B

C

D

E

E

D

restraining cable

Installation

Always install restraining cable to secure sonic horn to vessel.

Without restraining cable, sonic horn could fall and cause

injury.

Do not use restraining cable to mount sonic horn to vessel wall.

Purpose of restraining cable is to keep sonic horn from falling

should it come loose from vessel wall, not as primary means of

securing sonic horn to wall.

1. Weld D-ring (A) onto vessel wall (B) with 1/4-in. (6-mm) field weld.

2. Insert one end of wire rope (C) through D-ring (A) on vessel, making a

Martin Engineering M3829-08/13 6 Martin® Sonic Horns

3. Route wire rope (C) through brackets (E) and back to D-ring on vessel.

4. Insert wire rope (C) through D-ring (A) on vessel, making a 3-in.

5. To fasten each wire loop:

Figure 3. Installing Restraining Cable

3-in. (76-mm) loop.

(76-mm) loop.

a. Clamp wire rope with one cable clamp (D) as close to loop as possible.

Place another cable clamp 1-3/4 in. (44 mm) from first clamp.

b. Leave at least 1 in. (25 mm) of wire rope on dead end.

c. Gradually tighten nuts alternately and evenly to 15 ft-lbs.

Leave 2 to 3 in. (51 to 76 mm) slack in wire rope.

Page 11

Connecting air

IMPORTANT

IMPORTANT

IMPORTANT

WARNING

!

supply to sonic

horn

Depending upon the application, a receiver tank may be

needed to supply amount of air required to effectively operate

sonic horns. For more information contact Martin

Engineering or a representative.

Installation

Do not use a lubricated air supply for sonic horns.

1. Apply pipe sealant to all fittings.

2. See Figure 4. Connect 1” lockout ball valve to compressed air source with

desired length of 1” pipe. Look at arrow on side of ball valve to make sure

flow is correct.

3. Connect air filter/regulator to 1” lockout ball valve with desired length of

1” pipe. Look at arrow on side of air filter/regulator to make sure flow is

correct.

4. Connect 1” to 3/4” reducer to air filter/regulator with desired length of

1” pipe.

5. Connect 3-way electrical solenoid valve to 1” to 3/4” reducer with 6” long

3/4” pipe nipple. See Figure 4 for solenoid connections.

6. Connect 3/4” lockout ball valve to solenoid valve using desired length of

3/4” pipe.

7. Connect sonic horn sound generator to 3/4” lockout ball valve using

braided stainless steel hose.

For electrical solenoid valve installations, design and wire

electrical solenoid controls according to NEC Handbook.

Electrical push buttons, timers, and programmable

controllers are available through Martin Engineering.

8. For electrical solenoid valve installations, if using electrical solenoid

controller, install according to instructions provided with controller.

Do not exceed 80 psi (5.52 bar) maximum working pressure.

Minimum recommended pressure for most applications is

60 psi (4.14 bar), but lower pressures can be used. Make sure

air supply is filtered and regulated.

9. Anchor all pipes and wires to prohibit movement.

Martin Engineering M3829-08/13 7 Martin® Sonic Horns

Page 12

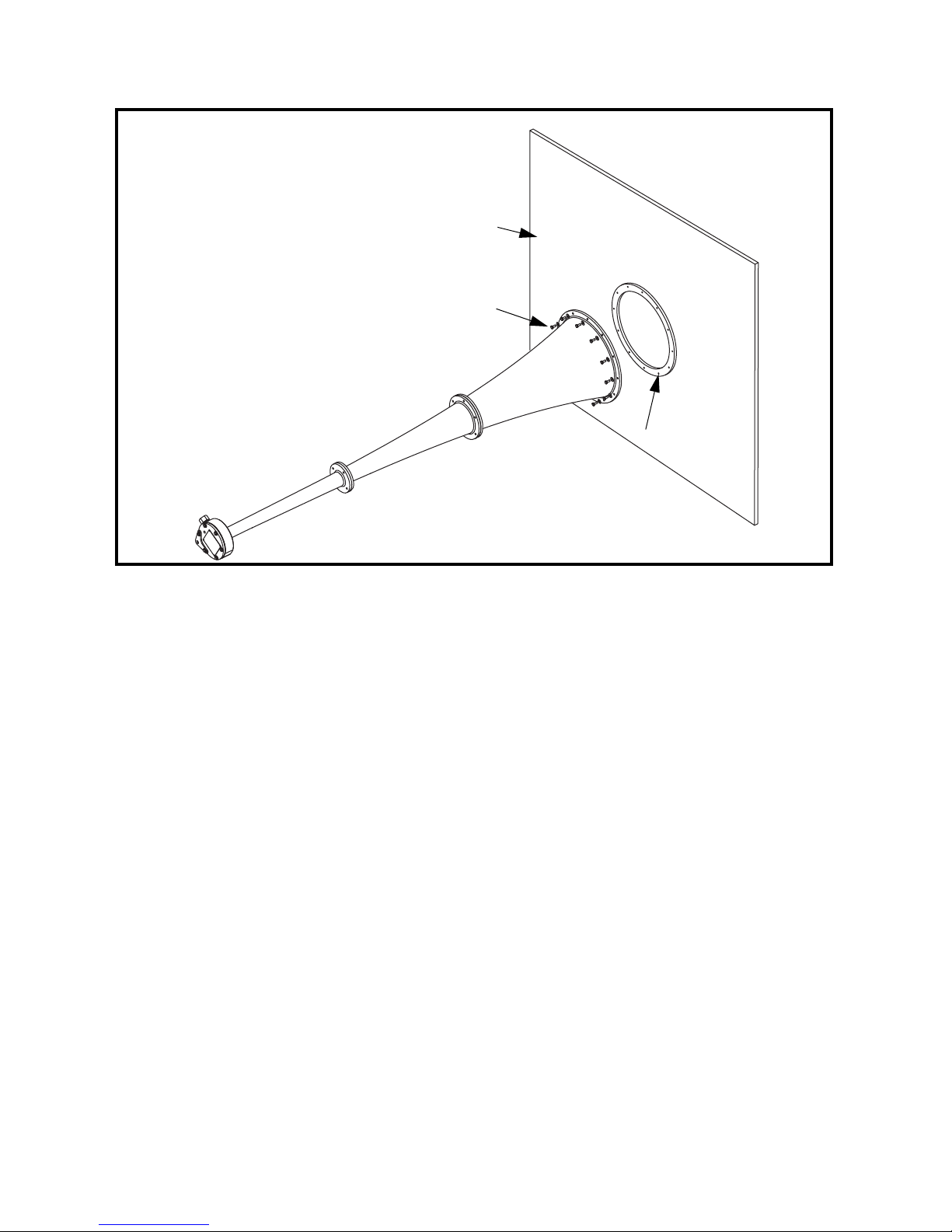

From PLC or timer

To sound generator

Open to

atmosphere

From

air supply

Electrical Signal Line

(supplied by others)

60 to 80 psi (supplied by others)

Electrical Power Supply

(supplied by others)

Compressed Air Supply

B

A

E

D

H

C

G

F

1” pipe for less than 100’

1” pipe reduced to 3/4”

Installation

Figure 4. Plumbing Detail for Normally-Closed Solenoid Valve

Item

AMartin

B Braided Stainless Steel Hose 3/4” 38795-5

C 3-Way Solenoid Valve (normally closed) 38794-XXX

D Lockout Valve 1” 32284-04

E Filter Regulator Unit 38736

F Air Supply Pipe 1” 103005 or by others

G Lockout Valve 3/4” 32284-02

H Controller/PLC

* Contact MARTIN ENGINEERING for Recommendation.

** Contact MARTIN ENGINEERING for breakdown of parts contained in assemblies and kits.

Martin Engineering M3829-08/13 8 Martin® Sonic Horns

®

Sonic Horn

Description

Assembly & Kit

Part Numbers**

SH075-XXXXXXX &

SH230XXXXX

*

Page 13

After Installing Sonic Horn

WARNING

!

WARNING

!

Sonic horns produce intense sound waves. Use ear protection

to avoid impairment or loss of hearing.

Do not exceed 80 psi (5.52 bar) maximum working pressure.

Minimum recommended pressure for most applications is

60 psi (4.14 bar), but lower pressures can be used. Make sure

air supply is filtered and regulated.

1. Turn on air supply and open ball valves.

2. Sound sonic horn five times to ensure proper operation.

3. If sonic horn sounds properly, continue to operate as needed. If problems

occur, see “Troubleshooting.”

4. If sonic horn does not sound, see “Troubleshooting.”

5. Check system for air leaks. If leaking, see “Troubleshooting.”

After Installation

Martin Engineering M3829-08/13 9 Martin® Sonic Horns

Page 14

WARNING

!

Maintenance

Maintenance

Do not open door/port or enter vessel before turning off

compressed air source, locking out controls, and purging line

pressure.

Turn off and lock out/tag out energy source according to ANSI standards

(see “References”).

Every month 1. Inspect all connections from air supply to sonic horn for leaks and

deterioration. If connections are leaking, seal all fittings with pipe sealant

and tighten. Replace any deteriorating connections. Make sure hoses do

not flex more than 1/4 inch (6 mm).

2. Make sure all pipes and wires are anchored to prohibit movement. Secure

as needed.

3. Inspect sonic horn for material buildup. Remove buildup as necessary.

4. Inspect electrical solenoid valve, lockout ball valve, and air filter/

regulator for proper operation. If not operating correctly, replace.

5. Inspect sound generator for correct operation; If not operating correctly

see “Troubleshooting.”

Martin Engineering M3829-08/13 10 Martin® Sonic Horns

Page 15

Troubleshooting

If sonic horn will not sound, find possible cause(s) in appropriate chart below

and follow steps in “Solution” column. If after doing so you are still

experiencing problems, contact Martin Engineering or a representative.

Problem: Sonic Horn Will Not Sound

Cause Solution

Compressor source. Make sure compressor is on and air line has pressure.

Ball valves open. Check that ball valves are fully open.

Filter/Regulator. Factory-set at zero. Rotate clockwise to increase.

Check plumbing air flow direction (indicated with an

arrow).

Solenoid plumbing. Make sure plumbing is correct.

Check for leaks.

Check plumbing direction.

Solenoid electrical. Make sure wiring is connected.

Check that voltage is correct.

Check for signal.

Troubleshooting

Blocked discharge—

horn makes high-pitched sound.

Titanium diaphragm worn. Replace diaphragm.

Sound generator worn. Return to Martin Engineering for refurbishing.

Remove blockage.

Martin Engineering M3829-08/13 11 Martin® Sonic Horns

Page 16

Part Numbers

SECTION A MATERIAL

D: Ductile Iron

S: Stainless Steel

SECTION B CONSTRUCTION

C: Cast

F: Fabricated

SECTION B MATERIAL

D: Ductile Iron

S: Stainless Steel

SECTION B FLANGE

0: No Flange

(N/A with cast sections)

1: With Flange

SOUND GENERATOR

D: Ductile Iron

S: Stainless Steel

Blank: No Generator

SH230-X X X X X

NOMENCLATURE

Section A Material

Section B Construction

Section B Material

Section B Flange

Sound Generator

SECTION B MATERIAL

D: Ductile Iron

S: Stainless Steel

SECTION B STYLE

0: Straight

9: 90 Degree Elbow

SECTION C CONSTRUCTION

C: Cast

F: Fabricated

SECTION C MATERIAL

D: Ductile Iron

S: Stainless Steel

M: Mild Steel

SECTION C FLANGE

0: No Flange

(N/A with cast sections)

1: With Flange

SOUND GENERATOR

D: Ductile Iron

Blank: No Generator

SH075M-X X X X X X

NOMENCLATURE

Section B Material

Section B Style

Section C Construction

Section C Material

Section C Flange

Sound Generator

Part Numbers

NOMENCLATURE

Section A Material

Section B Material

Section B Style

Section C Construction

Section C Material

Section C Flange

Sound Generator

This section provides product names and corresponding part numbers for

®

Martin

Sonic Horns and related equipment. Please reference part numbers

when ordering parts. Part numbers for accessory equipment not listed here are

available from Martin Engineering or representative.

SH075-X X X X X X X

SECTION A MATERIAL

D: Ductile Iron

S: Stainless Steel

SECTION B MATERIAL

D: Ductile Iron

S: Stainless Steel

SECTION B STYLE

0: Straight

9: 90 Degree Elbow

SECTION C CONSTRUCTION

C: Cast

F: Fabricated

SECTION C MATERIAL

D: Ductile Iron

S: Stainless Steel

M: Mild Steel

SECTION C FLANGE

0: No Flange

(N/A with cast sections)

1: With Flange

SOUND GENERATOR

D: Ductile Iron

S: Stainless Steel

Blank: No Generator

Martin Engineering M3829-08/13 12 Martin® Sonic Horns

Page 17

Recommended Spare Parts

Description Part No. Qty*

Sound Generator Body Assembly

Sonic Horn Diaphragm/Gasket Kit

*Recommended quantity for two years of operation.

Accessories Martin

Martin

Martin

Martin

38770 (Standard Horn)

38770-M (Mega Horn)

38798 (Standard Horn)

38798-M (Mega Horn)

®

Sonic Horn Mounting Flange Kit: P/N 38800-XXXXXXXXX

®

Sonic Horn Air Line Kit: P/N 38793-XXX

®

Sonic Horn Manifold Plumbing Kit: P/N 38927

®

Sonic Horn Controller: P/N 38901-S

15% of Total Number of

Sonic Horns

40% of Total Number of

Sonic Horns

Part Numbers

Martin Engineering M3829-08/13 13 Martin® Sonic Horns

Page 18

1

5,8

4

3

5,6

7

2

9

1

5,8

4

3

5,6

7

2

SH075-XX9XX1X

SH075-XX0XX1X

Part Numbers

10 (NS) D-ring 32265 1

11 (NS) Cable Clamp 32264 4

12 (NS) Wire Rope 1/4 100258 12 ft

13 (NS) Operator’s Manual M3829 1

14 (NS) Hardware Kit (Items 5–12) 39129 1

Figure 5. Martin® 75Hz Sonic Horn Assembly, P/N SH075-XXXXXXX

Item Description Part No. Qty

1 75 Hz Section A Table I 1

2 75 Hz Section B Table I 1

3 75 Hz Section C Table I 1

4 Sound Generator Assembly Table I 1

5 Washer Compression 5/16 SS 38698 13

6 Screw, HHC 5/16-18NC

7 Screw, HHC 5/16-18NC

8 Nut Hex 5/16-18NC SS 37723 10

9 Safety Cable Clip 38797 2

X 1-1/4 SS 38697 3

X 1-1/2 SS SP04436-30 10

NS = Not Shown

Martin Engineering M3829-08/13 14 Martin® Sonic Horns

Page 19

Table I. Martin® 75Hz Sonic Horn Assembly, P/N SH075-XXXXXXX

Assembly

Part No.

SH075-DXXXXXX 38771-P SH075-D0XXXXX 38772-P

SH075-SXXXXXX 38771-SS SH075-S0XXXXX 38772-SS

Assembly

Part No.

SH075-XXXCD1X 38773-P SH075-XXXXXXD 38770

SH075-XXXCS1X 38773-SS SH075-XXXXXXS 38770-SS

SH075-XXXFM0X 38773-F0

SH075-XXXFM1X 38773-F1

SH075-XXXFS0X 38773-FC0

SH075-XXXFS1X 38773-FC1

Item 1

Part No.

Item 3

Part No.

Assembly

Part No.

SH075-D9XXXXX 38777-P

SH075-S9XXXXX 38777-SS

Assembly

Part No.

Item 2

Part No.

Item 4

Part No.

Part Numbers

Martin Engineering M3829-08/13 15 Martin® Sonic Horns

Page 20

1

4,6

3

4,5

6

2

8

Part Numbers

Figure 6. Martin® 230Hz Sonic Horn Assembly, P/N SH230-XXXXX

Item Description Part No. Qty

1 230 Hz Section A Table II 1

2 230 Hz Section B Table II 1

3 Sound Generator Assembly Table II 1

4 Washer Compression 5/16 SS 38698 9

5 Screw, HHC 5/16-18NC

6 Screw, HHC 5/16-18NC

7 Nut Hex 5/16-18NC SS 37723 6

8 Safety Cable Clip 38797 1

9 (NS) D-ring 32265 1

10 (NS) Cable Clamp 32264 4

11 (NS) Wire Rope 1/4 100258 12 ft

12 (NS) Operator’s Manual M3829 1

13 (NS) Hardware Kit (Items 4–11) 39129 1

NS = Not Shown

Table II. Martin® 230Hz Sonic Horn Assembly, P/N SH230-XXXXX

Assembly

Part No.

SH230-DXXXX 38778-P SH230-XCD0X 38779-P SH230-XXXXD 38770

SH230-SXXXX 38778-SS SH230-XCS0X 38779-SS SH230-XXXXS 38770-SS

Item 1

Part No.

X 1-1/4 SS 38697 3

X 1-1/2 SS SP04436-30 6

Assembly

Part No.

SH230-XFS0X 38779-FSS0

SH230-XFS1X 38779-FSS

Item 2

Part No.

Assembly

Part No.

Item 3

Part No.

Martin Engineering M3829-08/13 16 Martin® Sonic Horns

Page 21

1

4,7

3

4,5

6

2

8

1

4,7

3

4,5

6

2

SH075M-XX9XX1X

SH075M-XX0XX1X

Part Numbers

Figure 7. Martin® 75Hz Mega Horn Assembly, P/N SH075M-XXXXXX

Item Description Part No. Qty

1 75 Hz Section B Table III 1

2 75 Hz Section C Table III 1

3 Sound Generator Assembly 38770-M 1

4 Washer Compression 5/16 SS 38698 10

5 Screw, HHC 5/16-18NC

6 Screw, HHC 5/16-18NC

7 Nut Hex 5/16-18NC SS 37723 6

8 Safety Cable Clip 38797 1

9 (NS) D-ring 32265 1

10 (NS) Cable Clamp 32264 4

11 (NS) Wire Rope 1/4 100258 12 ft

12 (NS) Operator’s Manual M3829 1

13 (NS) Hardware Kit (Items 4–11) 39129 1

X 1-1/4 SS 38697 4

X 1-1/2 SS SP04436-30 6

NS = Not Shown

Martin Engineering M3829-08/13 17 Martin® Sonic Horns

Page 22

Table III. Martin® 75Hz Mega Horn Assembly, P/N SH075M-XXXXXX

SH075M-D0XXXX 38772-P SH075M-XXCD1X 38773-P

SH075M-S0XXXX 38772-SS SH075M-XXCS1X 38773-SS

SH075M-D9XXXX 38777-P SH075M-XXFM0X 38773-FO

Part Numbers

SH075M-S9XXXX 38777-SS SH075M-XXFS0X 38773-FCO

Assembly

Part No.

Item 1

Part No.

Assembly

Part No.

Item 2

Part No.

Martin Engineering M3829-08/13 18 Martin® Sonic Horns

Page 23

Appendix A

Martin® Sonic Horns Specifications

Appendix A

Martin Engineering M3829-08/13 A-1 Martin

®

Sonic Horns

Page 24

30.13

(765)

30.13

(765)

92.07

(2339)

29.26

(743)

3/4 NPT

Inlet

19.00

(483)

22.06

(560)

51.32

(1304)

38.63

(981)

8.50

(216)

19.00

(483)

SH075–XX9XX1X

SH075–XX0XX1X

Appendix A

Martin® 75Hz Sonic Horn Dimensions, P/N SH075-XXXXXXX

Martin Engineering M3829-08/13 A-2 Martin

®

Sonic Horns

Page 25

Martin® 230Hz Sonic Horn Dimensions, P/N SH230-XXXXX

3/4 NPT

Inlet

Section A

14.26

(362)

12.50

Appendix A

(317)

Section B

10.69

(272)

27.50

(699)

Martin Engineering M3829-08/13 A-3 Martin

®

Sonic Horns

Page 26

SH075M–X9CX1D

SH075M–X0FX0D

Section B

30.13

(765)

63.14

(1604)

30.13

(765)

16.33

(415)

Section C

Appendix A

Martin® 75Hz Mega Horn Dimensions, P/N SH075M-XXXXXX

38.63

(981)

8.50

(216)

34.45

(875)

22.06

(560)

Section B

Section C

Martin Engineering M3829-08/13 A-4 Martin

®

Sonic Horns

Page 27

Martin® 75Hz Sonic Horn Specifications

Fundamental Frequency (Hertz) 75 Hz

Output Power Level (Decibels) 147 dB

Section A Section B Section C

Cast Ductile Iron Cast Ductile Iron Cast Ductile Iron

Material*

Stainless Steel Stainless Steel Stainless Steel

Mild Steel

Diaphragm Material Titanium

Max Operating Temperature (Cast Ductile Iron) 1200°F (650°C)

Max Operating Temperature (Stainless Steel) 1600°F (870°C)

Weight 190 lbs (86.2 kg)

Air Consumption 80 SCFM @ 80 PSI (38 l/s @ 6.21 bar)

*Sonic Horn can be any combination of listed materials.

Cast Ductile Iron is ASTM A-240. Stainless Steel is ASTM A-395 60-40-18.

Martin® 230Hz Sonic Horn Specifications

Fundamental Frequency (Hertz) 230 Hz

Output Power Level (Decibels) 150 dB

Appendix A

Section A Section B

Material*

Cast Ductile Iron Cast Ductile Iron

Stainless Steel Stainless Steel

Diaphragm Material Titanium

Max Operating Temperature (Cast Ductile Iron) 1200°F (650°C)

Max Operating Temperature (Stainless Steel) 1600°F (870°C)

Weight 54 lbs (24.6 kg)

Air Consumption 80 SCFM @ 80 PSI (38 l/s @ 6.21 bar)

*Sonic Horn can be any combination of listed materials.

Cast Ductile Iron is ASTM A-240. Stainless Steel is ASTM A-395 60-40-18.

Martin Engineering M3829-08/13 A-5 Martin

®

Sonic Horns

Page 28

Martin® 75Hz Mega Horn Specifications

Fundamental Frequency (Hertz) 75 Hz

Output Power Level (Decibels) 160 dB

Appendix A

Material*

Diaphragm Material Titanium

Max Operating Temperature (Cast Ductile Iron) 1200°F (650°C)

Max Operating Temperature (Stainless Steel) 1600°F (870°C)

Weight 130–190 lbs (59–86 kg)

Air Consumption 100 SCFM @ 80 PSI (47 l/s @ 6.21 bar)

*Sonic Horn can be any combination of listed materials.

Cast Ductile Iron is ASTM A-240. Stainless Steel is ASTM A-395 60-40-18.

Section B Section C

Cast Ductile Iron Cast Ductile Iron

Stainless Steel Stainless Steel

Mild Steel

Martin Engineering M3829-08/13 A-6 Martin

®

Sonic Horns

Page 29

Any product, process, or technology described here may be the subject of intellectual property rights reserved by

Martin Engineering Company. Trademarks or service marks designated with the ® symbol are registered with the U.S.

Patent and Trademark Office and may be proprietary in one or more countries or regions. Other trademarks and

service marks belonging to Martin Engineering Company in the United States and/or other countries or regions may

be designated with the “TM” and “SM” symbols. Brands, trademarks, and names of other parties, who may or may

not be affiliated with, connected to, or endorsed by Martin Engineering Company, are identified wherever possible.

Additional information regarding Martin Engineering Company’s intellectual property can be obtained at

www.martin-eng.com/trademarks

.

Page 30

Martin Engineering USA

One Martin Place

Neponset, IL 61345-9766 USA

800 544 2947 or 309 852 2384

Fax 800 814 1553

www.martin-eng.com

Form No. M3829-08/13 © Martin Engineering Company 2011, 2013

Loading...

Loading...