Page 1

JEM Glaciator X-Stream

SERVICE MANUAL

Revision A, 06-19-2017, Level 1

Page 2

Service manual

2 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Table of contents

General information .................................................................................................................3

Safety instructions .......................................................................................................................................3

Preventing electric shocks ...............................................................................................................4

Preventingburnsandre .................................................................................................................5

Preventing injuries .............................................................................................................................5

Preventing breathing problems ........................................................................................................ 6

Tools .............................................................................................................................................................. 6

Spare parts....................................................................................................................................................7

Product information .....................................................................................................................................7

Repair and maintenance ....................................................................................................... ...8

Heat exchanger calibration .........................................................................................................................8

Heat exchanger calibration - analog PCB ........................................................................................ 8

Heat exchanger calibration - digital PCB ....................................................................................... 11

Fluid pump speed calibration ..................................................................................................................14

Fluid sensor calibration ..................................................................................................................15

Refrigeration system..................................................................................................................................17

Refrigeration system check ............................................................................................................ 17

Temperature values .........................................................................................................................18

Rear fan diagnostics ..................................................................................................................................19

Sight glass level check ..............................................................................................................................19

Condensate drain .......................................................................................................................................20

Firmware updates.......................................................................................................................................20

Maintenance ............................................................................................................................21

Cleaning the product .................................................................................................................................21

Casework, fan, drip tray cleaning ................................................................................................... 21

Airltermaintenance ......................................................................................................................22

Heat exchanger cleaning .................................................................................................................22

Maintenance schedule ...............................................................................................................................23

Page 3

Service manual

3 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 1: Safety instructions

General information

This service manual contains information about how to

service JEM Glaciator X-Stream.

Safety instructions

Read the safety precautions in this

manual before installing, operating

or servicing this product.

Warning!

This product is not for household

use. It presents risks of injury due

to electric shock, burns, falls and

respiratory problems!

The following symbols are used to identify important

safety information:

Danger!

Hazardous voltage. Contact will

cause electric shock.

Caution!

Burn hazard. Hot surface. Do not

touch.

Caution!

Safety hazard. Risk of severe injury

or death.

Caution!

Fire hazard.

Read this manual before operating the machine, follow

the safety precautions listed below, and observe all

warnings in this manual and printed on the machine.

Use the machine only as described in this manual and

in accordance with local laws and regulations.

If you have questions about how to operate the

machine safely, or if you have followed the instructions

in this manual and the machine is malfunctioning,

please contact Martin™ Service.

Page 4

Service manual

4 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 2: Preventing electric shocks

Preventing electric shocks

• Always ground (earth) the machine electrically.

• Use only a source of AC power that complies with

local building and electrical codes, and that has

both overload and ground-fault protection.

• Before connecting the machine to power, check

that the voltage indicated on the machine’s serial

label matches your local AC power voltage. If your

AC power voltage does not match, do not use the

machine. Contact Martin™ Service for assistance.

• Before using the machine, check that all power

distribution equipment and cables are in perfect

condition and rated for the current requirements of

all connected devices.

• If the machine or any cables connected to it are

in any way damaged, defective, wet, or show

signs of overheating, stop using the machine

and contact Martin™ Service for assistance. If

the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

• Disconnect the machine from AC power before

servicing and when not in use as directed.

• This machine is not waterproof and must not

be exposed to wet outdoor conditions. Do not

immerse in water or any other liquid. Do not

expose to high-pressure water jets.

• Do not spill uid over or inside the machine. If

uid is spilled, disconnect AC power and clean

with a damp cloth. If uid is spilled onto electronic

parts, take the machine out of service and contact

Martin™ for advice.

• Do not remove the covers or attempt to repair a

faulty machine. Refer any service not described in

this manual to Martin™ Service.

• Do not operate the machine if any parts are

damaged, defective or missing.

• Moisture and electricity do not mix. Do not aim fog

output at electrical connections or devices.

Page 5

Service manual

5 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 3: Preventingburnsandre

Figure 4: Preventing injuries

Preventingburnsandre

• Do not attempt to bypass thermostatic switches,

uid sensors or fuses.

• Replace fuses only with ones of the type and

rating specied in this manual for the machine.

• Provide a minimum free space of 500 mm (20 in.)

around the machine.

• Provide a minimum free space of 500 mm (20 in.)

around fans and air vents and ensure free and

unobstructed air ow to and around the machine.

• Do not operate the machine if the ambient

temperature (Ta) is below 5° C (41° F) or above

40° C (104° F).

Preventing injuries

• Check that all external covers are securely

fastened.

• Do not operate the machine with missing or

damaged covers or shields.

• In the event of an operating problem, stop using

the machine immediately and disconnect it from

power. Do not attempt to use a machine that is

obviously damaged.

• Do not modify the machine in any way not

described in this manual or install other than

genuine Martin™ parts.

• Refer any service operation not described in this

manual to a qualied technician.

• Fog output can cause condensation. Do not point

the output at smooth oors. Floors and surfaces

may become slippery. Check these frequently

and wipe dry as necessary to avoid any danger of

slipping.

• Ensure at least 2 m (6.6 ft.) visibility in areas

where fog is being produced.

• Fog uid contains food-grade glycols in solution

but may present health risks if swallowed. Do not

drink it. Store it securely. If eye contact occurs,

rinse with water. If uid is swallowed, give water

and obtain medical advice.

• This appliance is not intended for use by persons

(including children) with reduced physical sensory

or mental capabilities, or lack of experience

and knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

Page 6

Service manual

6 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 5: Safety instructions

Figure 6: Tools

Figure 7: ESD mat and wristband

Preventing breathing problems

• A machine can operate safely only with the fog

uid it is designed for. Use the machine only with

uids specied or you may cause the release of

toxic gases, presenting a severe health hazard.

You will also probably damage the machine.

• Do not create dense fog in conned or poorly

ventilated areas.

• Do not expose people with health problems

(including allergic and/or respiratory conditions

such as asthma) to fog output.

• Do not point fog output directly at a person’s face

or at face height.

Tools

Make sure that the tools below are available before you

start working on the product.

• Pozi-driver #0, 1, 2

• Epsilon 5 Programmer (P/N: 50502004)

• Slotted screwdriver #0

• Temperature calibration box (P/N: 92620005)

• Digital multimeter with probes

• Flashlight or work light.

Take the necessary precautions

to prevent static electricity from

damaging the product during

modication or repair.

Page 7

Service manual

7 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Product information

Before you start servicing the product, read and do the

following:

• Observe all safety precautions.

• Disconnect all cables and the mains power cord

from the machine where required.

• Place the machine on a at solid working surface.

• Lock the braking casters.

• MachinesproducedafterApril2012aretted

with digital mains PCBs and require different

maintenance procedures. Please note the

year of manufacture on your machines serial

number label for correct procedures.

Figure 8: Partnder:Layered

Figure 9: JEM Glaciator X-Stream

Spare parts

For an overview of the spare parts and spare part

numbers of JEM Glaciator X-Stream, refer to

martin.com.

1. Login with your user login details.

2. Search for “JEM Glaciator X-Stream”.

3. Clik “Partnder: Layered” (1).

For the latest user documentation and other

information for this and all Martin™ products, please

visit the Martin™ website at

martin.com.

If you have any questions about how to install, operate

or service the xture safely, please contact your

Martin™ distributor (see

www.martin.com/where-to for

details) or call the Martin™ 24-hour service hotline on

+45 8740 0000, or in the USA on 1-888-tech-180.

1

Page 8

Service manual

8 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Repair and maintenance

Heat exchanger calibration

The heat exchanger will require calibration after 1000

hours of operation or annually. This procedure will

take about 45 minutes to complete and requires the

temperature calibration box, available from Martin™.

This procedure is for qualied service personnel only

and only those competent should perform the task.

• For machines tted with analog PCBs

(manufactured before April 2012) follow the

procedure in “Heat exchanger calibration - analog

PCB” on page 8.

• For machines tted with digital mains PCBs utilize

the procedure in “Heat exchanger calibration digital PCB” on page 11.

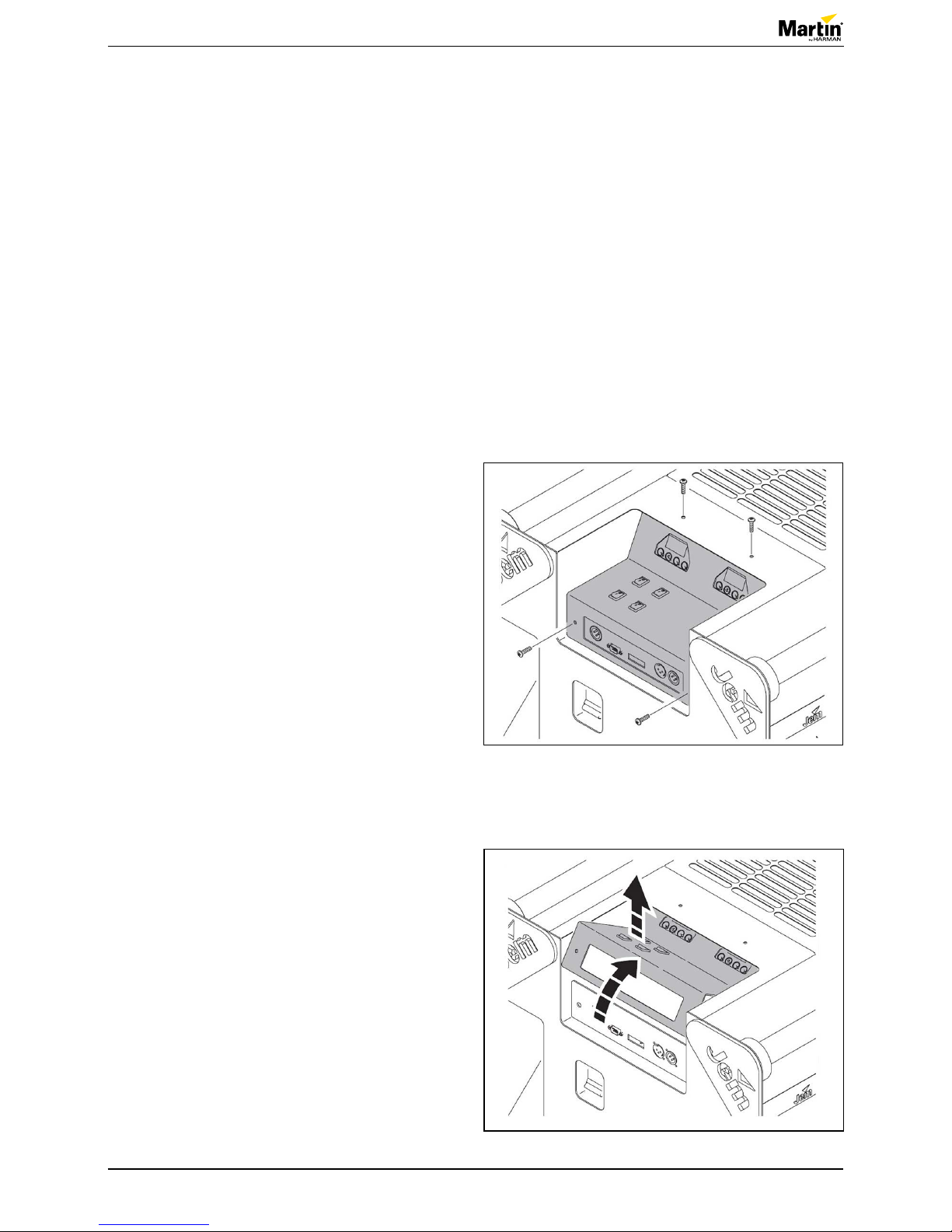

Heat exchanger calibration - analog PCB

1. Power off the machine.

2. Remove the control panel access cover (four M5

screws).

Figure 10: Removing the cover

Figure 11: Lifting the cover

3. Lift the control panel access cover up.

Page 9

Service manual

9 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 12: Mains PCB

Figure 13: Disconnecting the thermocouple wires

4. Locate the mains PCB.

5. Disconnect the thermocouple wires from their

spade terminals, PL4 (1) and PL5 (2). See gure

12.

NOTE! If your machine was manufactured prior

to November 2006 these wires may be colored

green and yellow. Green is negative (-), and

yellow is positive (+).

6. Replace the thermocouple wires with the

calibration box leads.

NOTE! The correct orientation: Red is positive,

PL5 and black is negative, PL4.

7. Power on the calibration box.

8. Set the ramp button to off (LED ashing green)

and depress the VAR button (LED on steady red).

9. Use the variable slider to set the calibration point

to 11.5 mV.

10. Power on the machine.

Danger!

Take precaution to limit exposure to

live wires.

Figure 14: Replacing thermocouple wires

2 1

Page 10

Service manual

10 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

11. On the mains PCB, adjust potentiometer P1 until

the red heating LED on the PCB starts to ash.

See gure 16.

12. On the calibration box, turn ramp button on (LED

on steady green). The red LED on the PCB

should go off.

13. For verication, turn the ramp button off (LED

ashing green), and the red heating LED on the

PCB should start ashing again.

14. Adjust if necessary following directions from step

11.

15. Power off and disconnect the calibration box.

16. Replace the thermocouple wires onto the correct

terminals.

NOTE! Thermocouple wires are colored black/

white and white. Black/white is positive (+), PL5

and white is negative (-), PL4. See gure 13.

NOTE! If your machine was manufactured prior

to November 2006 these wires may be colored

green and yellow. Yellow is positive (+), PL5 and

green is negative (-), PL4.

Figure 15: Adjusting potentiometer

Figure 16: RedLEDisashing

Figure 17: Connecting a digitial multimeter

17. Connect a digital multimeter to the thermocouple

connectors. Positive to PL5 and negative to PL4.

18. Power on and set DMM to read mV DC.

19. Allow the machine to heat to the ready state.

DMM values should rise as machine heats.

20. DMM should read 11.5 mV when the machine

displays “RDY” and the red LED on the PCB turns

off.

21. Re-calibrate if necessary starting from step 7.

22. If no re-calibration is required, turn off and unplug

the machine.

23. Remove the DMM probes and replace the control

panel access cover and fasten the four M5

screws.

24. If re-calibration is not possible, the PCB may need

to be replaced. Contact Martin service for detailed

instructions to proceed.

Page 11

Service manual

11 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Heat exchanger calibration - digital PCB

1. Power off the machine.

2. Remove the control panel access cover (four M5

screws).

Figure 18: Removing the cover

Figure 19: Lifting the cover

Figure 20: Digital mains PCB

3. Lift the control panel access cover up.

4. Locate the digital mains PCB.

Page 12

Service manual

12 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 21: Disconnecting thermocouple wires

Figure 22: Replacing thermocouple wires

5. Disconnect thermocouple wires. See gure 20

and gure 21.

6. Replace the thermocouple wires with the

calibration box leads.

NOTE! The correct orientation: Red is positive,

PL5 and black is negative, PL4.

7. Power on the calibration box.

8. Set the ramp button to on (LED on green) and

depress the VAR button (LED on red).

9. Use the variable slider to set the calibration point

to 11.5 mV.

Figure 23: Replacing thermocouple wires

10. On the mains PCB move the temperature

calibration “TCAL” jumper to the calibration

position, by moving over one position.

11. Power on the machine.

Danger!

Take precaution to limit exposure to

live wires.

12. The machine should be in calibration mode;

indicated by a ashing red and green LEDs on the

mains PCB.

13. Count to ten and remove the TCAL jumper all

together. The LEDs should ash slowly.

14. Turn the machine off.

15. Replace the TCAL jumper back to its original pin

positions.

16. Power off and disconnect the calibration box from

the mains PCB.

Page 13

Service manual

13 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 24: Replacing the thermocouple wires

17. Replace the thermocouple wires to the mains

PCB.

NOTE! The thermocouple wires are colored black/

white and white. Black/white is positive (+) PL5,

and white is negative (-) PL4.

18. Connect a digital multimeter to the thermocouple

connectors. Positive to PL5 and negative to PL4.

19. Power on and set DMM to read mV DC.

20. Allow the machine to heat to the ready state.

NOTE! DMM values should rise as machine

heats.

21. DMM should read 11.5 mV when the machine

displays “RDY” and the red LED on the PCB turns

off and green turns on.

22. Re-calibrate if necessary starting from step 7.

23. If no re-calibration is required, turn off and unplug

the machine.

24. Remove the DMM probes and replace the control

panel access cover and fasten the four M5

screws.

25. If re-calibration is not possible, the PCB may need

to be replaced.

Contact Martin service or replace utilizing “PCBA

power HFGX, 230V 50/60Hz, Tiny 44 – P/N:

62020130”.

Page 14

Service manual

14 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

4. Locate the mains PCB.

5. Power on the machine and allow the machine to

heat up.

Danger!

Take precaution to limit exposure to

live wires.

6. Set the fog output level to one (1) on the left side

LCD display.

7. Turn dipswitch S2 to ON for pump ramp override.

Fluid pump speed calibration

For older machines (manufactured before April 2012)

tted with an analog mains PCB pump speed re-

calibration is necessary annually or after every 1000

service hours. The below procedure will take about 45

minutes and is intended for qualied service personnel

only. Newer machines (produced after April 2012) do

not require this procedure.

1. Power off the machine.

2. Remove the control panel access cover (four M5

screws).

Figure 25: Removing the cover

Figure 26: Lifting the cover

3. Lift the control panel access cover up.

Figure 27: Mains PCB

Page 15

Service manual

15 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 29: Turning pot P2 on

11. Turn pot “P2” on the mains PCB until the voltage

to the pump reads 90 V DC.

12. Check the fog ow output at the front of the

machine.

NOTE! A smooth ow should be visible. If not

quite enough, adjust slightly higher.

13. The pump is now calibrated.

14. Power off and unplug the machine.

15. Remove the DMM probes and close the control

panel access cover replacing the four M5 screws.

16. Turn off dipswitch S2.

Figure 28: Placing the probes

8. Turn on DMM and set to measure volts DC.

9. Place the probes across the pump positive (PL6)

and negative (PL9) terminals.

10. Press the “Fog” on button on the control panel.

Figure 30: Fluid sensor PCB

Fluid sensor calibration

The machine utilizes an electronic uid sensor that

periodically needs calibration. We recommended that

you perform this task every 1000 hours or annually.

This procedure should take about 30 minutes and

requires a, Pozi-drive #2, slotted driver #0, and a DMM.

1. Ensure the uid reservoir is lled and place the

uid inlet tubing (with sensor) into the uid.

2. Remove the left side maintenance cover by

removing the four M5 screws.

3. Gently remove the ground wire, and set aside.

4. Locate the uid sensor PCB.

NOTE! It is on the front side of the machine just

behind the uid compartment.

Page 16

Service manual

16 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Figure 31: ConnectingDMMtouidsensor

Figure 32: Turning the potentiometer

Figure 33: Turning the potentiometer

5. Connect the DMM to the uid sensor PCB placing

the positive lead onto “TP1” and the negative lead

onto “ground”. See gure 31 and gure 33.

6. Power on the machine.

Danger!

Take precaution to limit exposure to

live wires.

7. Turn on and set the DMM to read mV DC, 2V

NOTE! The sensor should read 2.20 mV. If the

reading is higher or lower than 2.20 mV, the PCB

requires calibration.

8. If no calibration is necessary, proceed to step 12.

9. To re-calibrate, locate and turn the potentiometer

“P01” in the direction that will allow the uid

sensor to settle at 2.20 mV using a slotted driver

#0.

NOTE! Clockwise will increase the reading and

counter-clockwise will decrease the reading.

10. When the DMM reads 2.20 mV, remove the uid

sensor from the uid bottle.

NOTE! The reading on the DMM will climb to 2.45

- 2.51 mV and the red LED on the top of the uid

sensor PCB will illuminate; indicating “uid out”.

11. Place the uid sensor back into the uid, the DMM

should now read 2.20 mV and the red LED should

turn off. The sensor is calibrated correctly.

12. If the sensor was successfully calibrated, power

off and unplug the machine. If calibration was

unsuccessful proceed to step 15.

13. Replace the left side maintenance cover, ensuring

the grounding wire is rmly connected and tighten

the four M5 screws.

14. Secure the uid reservoir back in the uid

compartment.

15. If calibration was unsuccessful, the uid sensor

PCB is likely faulty. Replace it with “Loom uid

sensor c/w wire &h, P/N: 11862026”.

Page 17

Service manual

17 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Abbreviation Value

AI No function at present

TA Ambient temperature

EO Evaporator outlet

EO Evaporator inlet

CO Condenser output

CI Condenser input

Figure 34: Abbreviations

TA EO EI CO CI

Figure 35: Record your readings

Refrigeration system

The refrigeration system of the machine is a closed

loop refrigeration system and requires no preventative

or periodic maintenance for the lifetime of the product.

Should a component fail or a refrigeration leak be

suspected, immediately contact Martin Service.

Please contact Martin™ Service if you require service

or support with the refrigeration system. A system

check of the refrigeration system can be reviewed to

determine that the system is operating with optimal

performance. Please see the following section for the

details of this procedure.

Refrigeration system check

1. To check the status of the refrigeration system at

any time, use the ICE menu by putting S3 down

(dipswitch 12).

2. The left hand panel will now display the name of

the sensor on the left hand display, while the right

hand display will show the temperature value.

3. Use the scroll keys on the right hand display to

move through the available values.

NOTE! These values represent the temperatures

at specic locations within the refrigeration

system.

Follow the procedure below, notating the values of

each sensor and compare to the values on page 18.

1. Turn the machine on.

2. Ensure the ICE button is ON.

3. Ensure STANDBY is ON.

4. Turn switch S3 ON - DO NOT FIRE THE

MACHINE.

5. Leave the machine for 30 minutes to stabilize.

6. Scroll through the ICE menu and record your

readings in the table to the right.

Page 18

Service manual

18 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

TA EO EI CO CI

15 -39 -42 57 17

16 -38 -41 57 18

18 -37 -39 60 20

20 -35 -38 62 22

22 -34 -37 63 24

24 -33 -36 66 26

26 -33 -36 66 28

28 -33 -34 58 28

30 -33 -34 58 28

Figure 36: Record your readings

TA EO EI CO CI

Figure 37: Ice no/no fog (tick over) after 40 minutes

TA EO EI CO CI

15 -14 4 71 27

16 -12 6 72 28

18 -10 8 73 30

20 -10 11 75 33

22 -10 11 77 34

24 -8 12 80 37

26 -7 12 81 38

28 -6 12 81 39

30 -6 13 81 42

Figure 38: Fog on level 20 after 5 minutes

7. Now re the machine at full output (S3 off, set to

Level 20, Fog ON) for 5 minutes.

8. After 5 minutes, keep the machine ring and

record your readings (S3 ON) in the table to the

right.

Temperature values

The temperatures specied in the tables to the right

are only a guide. These temperatures will vary from

machine to machine.

These temperatures can be used for reference and

diagnostic assistance when servicing/repairing the

machine.

If your measurements are within the range, then no

action is necessary. If your measurements are not

within range, contact Martin™ Support.

Page 19

Service manual

19 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Rear fan diagnostics

The rear fans should be visually and audibly checked

for operation every 250 hours for correct operation. The

rear fans are what propel the fog from the machine and

are vital to operation.

To verify fan operation simply operate the machine

manually from the control panel.

1. Turn on “ICE” and “Standby” then allow the

machine to get to its ready state.

2. Once ready, set fog output at 10 on the left hand

display and density to “Hi” on the right hand

display.

NOTE! The fan speed should be low and the fan

noise should match that speed.

3. Set density to “Nor”, the fan speed and noise

should increase.

4. Set the density to “Lo”, the fan should now be

operating at full speed.

If the fan speeds do not change or the fan is not

running at all, contact Martin™ Support for service and

support.

Sight glass level check

Inside of the uid compartment is a sight glass

for visual indication of the refrigeration’s systems

operation. Check this sight glass every 1000 hours

or annually, alongside the refrigeration system check,

“Refrigeration system check” on page 17.

1. Open the uid compartment door and locate the

sight glass.

NOTE! A ashlight or work light may be necessary

to better illuminate the space.

2. With the machine powered on and in its ready

state but not producing fog, observe the sight

glass.

There will be visible liquid level rising and falling in

the sight glass.

3. There is no dened level but the rising and falling

should time with the expansion valve opening/

closing, which can be audibly observed by the

clicking/surging noise the machine’s emits,

approximately every 10-15 seconds.

4. If no level is seen and clicking noise is more

frequent than normal, a possible refrigeration leak

is possible. Contact Martin™ Service for service

and support.

Page 20

Service manual

20 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Condensate drain

When operating the machine for long periods, there will

always be a buildup of condensation in the evaporator

unit. This will drain into the drip tray, which should be

emptied and cleaned regularly.

For installation purposes, a drain hose can be tted into

the condensate drain hole.

A visual inspection of the condensate drain should be

performed every 500 hours or semi-annually. When

performing an inspection, it is only necessary to verify

that waste water is properly draining from the drain

hole or drain hose.

Caution!

Isolate the machine from power and

allow it to cool completely before

performing the following procedure.

1. If the drain hose or drain hose appears to be

clogged, clear the obstruction.

2. Use a small slotted screwdriver or an awl and

simply dislodge any debris out of the way of the

hole or clear the hose.

3. If an obstruction cannot be cleared contact

Martin™ Service.

Firmware updates

The factory installed rmware version is indicated on

the serial number label or the current rmware version

is displayed upon powering on of the JEM Glaciator

X-Stream as well.

The most current rmware can be found on the service

webpage for the JEM Glaciator X-Stream.

In most cases rmware updates are not necessary nor

required. Please contact Martin Support for questions

about updating rmware on the JEM Glaciator

X-Stream.

If rmware updates are required, a programmer will be

required and is available from Martin™ by Harman as

“Epsilon 5 Programmer: P/N: 5050200”.

Page 21

Service manual

21 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Maintenance

Read the user manual before performing service or

maintenance on the product.

Failure to respect service and maintenance schedules

may cause damage that is not covered by product

warranties.

Cleaning the product

Casework, fan, drip tray cleaning

Excessive dust, fog uid, and dirt build-up will degrade

performance and cause overheating and damage

to the machine that is not covered by the product

warranty. To maintain adequate cooling, dust must

be cleaned from the outer casing and air vents of the

machine periodically.

Caution!

Isolate the machine from power and

allow it to cool completely before

cleaning.

• Remove dust from the air vents with a soft brush,

cotton swab, vacuum, or compressed air.

• Remove contaminants from the fans with a soft

brush, cotton swab, vacuum, or compressed air.

If utilizing compressed air, do not allow the fans

to spin uncontrollably by placing a screwdriver

or similar object in the blades to temporarily lock

them in place.

• Clean fog uid residues from the fog output of the

machine using a damp cloth.

• Clean the outer casing with a damp cloth only.

• Clean the drip tray using water and a mild

detergent.

Figure 39: Read the user manual

Page 22

Service manual

22 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Airltermaintenance

The machine uses a washable synthetic ber lter in

the air intake for the condenser unit (located at the top

of the machine). This can be removed for cleaning by

removing the ventilation grill above it (four M5 screws).

Caution!

Isolate the machine from power and

allow it to cool completely before

performing the following procedure.

Use the following guidelines for when to check the lter.

• Under normal conditions (clean and dry

environment), inspect and clean/replace the lter

every 250 hours.

• Under severe conditions (dirty and/or damp

environment), inspect and clean/replace the lter

every 150 hours.

The lter can either be replaced or cleaned. To clean

the lter, simply wash with warm water and a mild

detergent, and allow to air dry. If replacing the lter, it

can be ordered from Martin™ by Harman using P/N:

“56210020 – Filter, HFG-2 Condenser”.

Heat exchanger cleaning

For optimum performance while providing longevity

of the heat exchanger, we recommend that you

utilize JEM Pro Clean Supreme cleaning solution.

Applying JEM Pro Clean Supreme uid on a regular

basis reduces clogging and further extends the life of

Martin™ fog and haze machines.

Using JEM Pro Clean Supreme every 200 hours, or

once a month (depending on usage), will prolong the

life of the heat exchanger.

1. Connect JEM Pro Clean Supreme uid to the uid

inlet of the machine

2. Allow the machine to heat.

3. When fully ready, activate the machine or remote

for approximately 30-45 minutes.

4. When completed, replace cleaning uid with

appropriate uid heavy fog uid.

NOTE! Cleaning procedure should be used if the unit

is to be stored for 30 days or more. Ensure there is no

uid in the uid tube when placing in storage.

Figure 40: Airltermaintenance

Page 23

Service manual

23 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Part description Service period recommendation Service description

General service

Cleaning

As needed or every 150-250 hours See page 21

Airltermaintenance

As needed or every 150-250 hours See page 22

Firmware updates

As required See page 20

Fog system

Heat exchanger calibration

Every 1000 hours or annually See page 8

Heat exchanger cleaning

Every 200 hours or monthly See page 22

Fluid pump speed calibration*

Every 1000 hours or annually See page 14

Fluid sensor calibration

Every 1000 hours or annually See page 15

Refrigeration system

Refrigeration system

Lifetime See page 17

Refrigeration system check

Every 1000 hours or annually See page 17

Rear fan diagnostics

Every 250 hours See page 19

Sight glass level check

Every 1000 hours or annually See page 19

Condensate drain

Every 500 hours or annually See page 20

* Not required for machines produced after April 2012.

Maintenance schedule

Page 24

Service manual

24 of 24JEM Glaciator X-Stream - Revision A, 06-19-2017, Level 1

Information subject to change without notice. Harman Professional Denmark ApS disclaims liability for

any injury, damage, direct or indirect loss, consequential or economic loss or any other loss occasioned

by the use of, inability to use or reliance on the information contained in this document.

©2017 Harman Professional Denmark ApS. All rights reserved. Martin® and JEM® are registered

trademarks of Harman Professional Denmark ApS registered in the United States and/or other countries.

Features,specications,andappearancearesubjecttochangewithoutnotice.

Harman Professional Denmark ApS • Olof Palmes Allé 18 • 8200 Aarhus N • Denmark • www.martin.com

Loading...

Loading...