Page 1

TM

Extube

user manual

Page 2

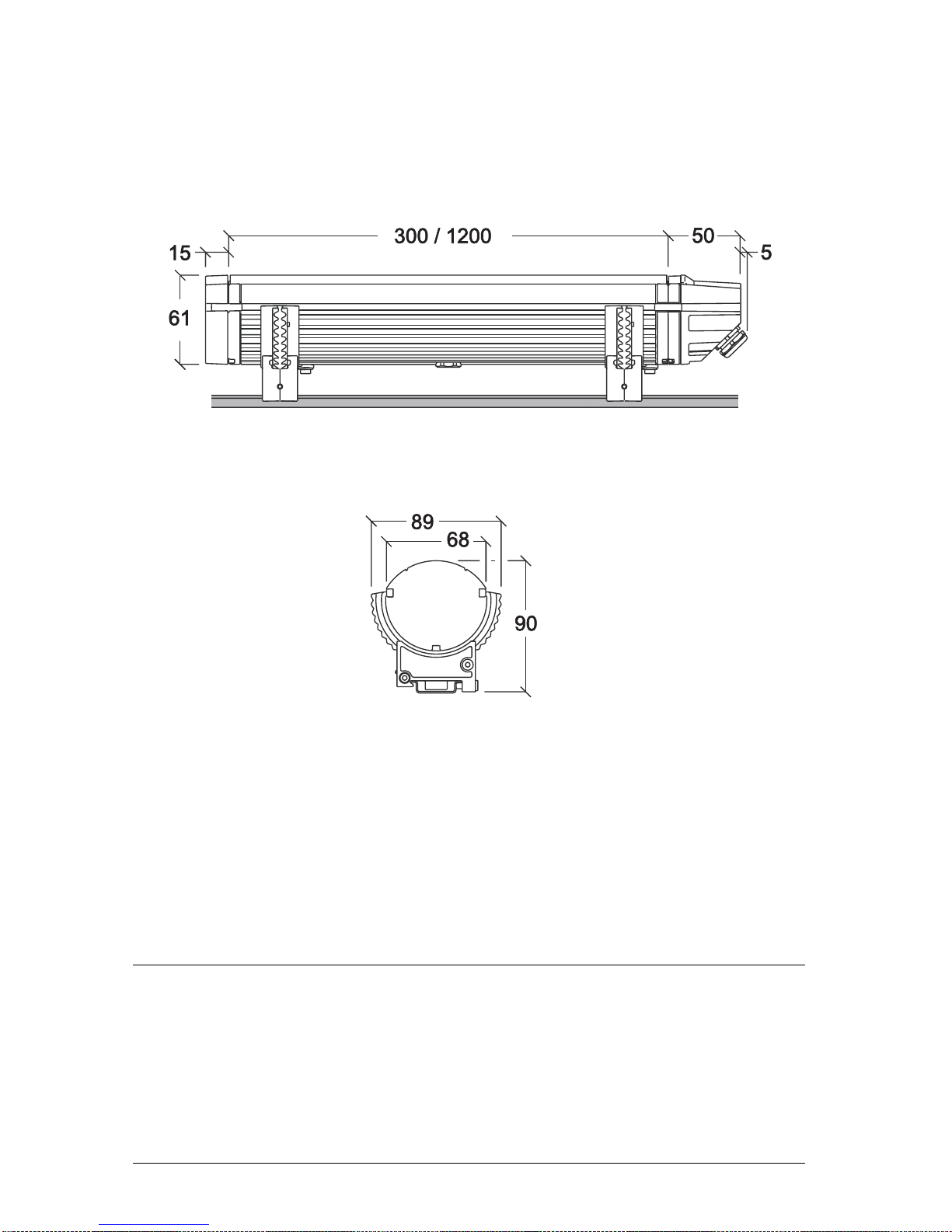

Dimensions

All dimensions are in millimeters

©2008 Martin Professional A/S. Information subject to change without notice. Martin

Professional A/S and all affiliated companies disclaim liability for any injury, damage, direct

or indirect loss, consequential or economic loss or any other loss occasioned by the use of,

inability to use or reliance on the information contained in this manual. The Martin logo, the

Martin name and all other trademarks in this document pertaining to services or products by

Martin Professional A/S or its affiliates and subsidiaries are trademarks owned or licensed

by Martin Professional A/S or its affiliates or subsidiaries.

P/N 35000212, Rev. A

Page 3

Safety Information

Warning! Read the safety precautions in this section before

installing, powering, operating or servicing this product.

The following symbols are used to identify important safety inf ormation on

the product and in this manual.

DANGER!

Safety hazard.

Risk of severe

injury or death.

Warning! Class 2M LED product. Do not look into the beam from a

distance of less than 40 cm (16 inches). Do not stare into the beam

for extended periods at a short distance. Do not view the beam

directly with optical instruments.

This product is for professional use only. It is not for household use.

This product presents risks of severe injury or death due to fire hazards,

electric shock and falls.

Read this manual before installing, powering or servicing the fixture,

follow the safety precautions listed below and observe all warnings in this

manual and printed on the fixture. Install and operate the fixture only as

described in this manual and in accordance with local laws and

regulations. Refer any operation not described in this manual to a

qualified technician.

Warning!

Hazardous

voltage. Risk of

lethal or severe

electric shock.

Warning!

LED light

emission. Risk

of eye injury.

Warning!

Fire hazard.

Warning!

Refer to user

manual.

If you have questions about how to operate the fixture safely, please

contact your Martin supplier or call the Martin 24-hour service hotline on

+45 8740 0000, or in the USA on 1-888-tech-180.

Safety Information 3

Page 4

PROTECTION FROM ELECTRIC SHOCK

• Shut down power to the entire installation at the power distribution board

and lock out power (by removing a fuse at the distribution board for

example), before removing any input cap, end cap, other cover or part.

Do not reapply power until all caps, retaining clips, cove rs and other

parts have been correctly installed.

• Shut down power to the installation when it is not in use.

• Connect the fixture electrically to ground (earth).

• Use only a source of AC power that complies with local building and

electrical codes and has both overload and ground-fault (earth-fault)

protection.

• Connect the fixture to AC power using an Extube input cap and the 13 A

power cable supplied pre-installed on the input cap only. The power

cable may not be changed by the user. If it is not suitable for your

installation, contact Martin for assistance in selecting and installing an

alternative power cable.

• Terminals inside the input cap are live when power is applied to the

power cable. Do not apply power to the cable unless the input cap is

installed on a fixture as described in this manual.

• Terminals inside the connector at the output end of the fixture are live

when power is applied to the fixture. Do not apply power to the fixture

unless an end cap is installed on the fixture as described in this manual.

• Before using the fixture, check that all power distribution equipment and

cables are in perfect condition, rated for the current requi rements of al l

connected devices, protected to IP67 or higher and of suitable type for

the location (including water, pollution, temperature and UV resistance).

• Isolate the fixture from power immediately if any cap, cable, seal, cover

or other component is damaged, cracked or deformed. Do not reapply

power until repairs have been completed.

• Do not expose any part of the fixture to a high-pressure water jet.

• Do not immerse the fixture in water or any other fluid, or install it in a

location where flooding may occur.

• Refer any service operation not described in this manual to an

authorized Martin Service partner.

4 Extube user manual

Page 5

PROTECTION FROM BURNS AND FIRE

• Do not operate the fixture if the ambient temperature (Ta) exceeds 40°

C (104° F).

• The exterior of the fixture becomes hot, up to 75° C (167° F) during

normal operation. Ensure that accidental physical contact with an

installed fixture is impossible.

• Allow the fixture to cool for 20 minutes before servicing.

• Keep combustible materials (for example fabric, wood, paper) at least

0.5 m (20 in.) away from the fixtu re’s front cover and light output. Keep

flammable materials well away from the fixture.

• Do not modify the fixture in any way not described in this manual or

install other than genuine Martin parts. Do not stick filters, masks or

other materials directly onto LEDs. Use only Martin approved

accessories to mask or modify the light beam.

• Do not attempt to bypass thermostatic switches or fuses. Replace

defective fuses with ones of the specified type and rating only.

• Install the fixture in a well ventilated area only. Provide a minimum

clearance of 10 cm (4 inches) and ensure unrestricted airflow around

the fixture.

PROTECTION FROM INJURY

• The LED emission presents a hazard to eyesight at distances from 4 cm

(1.6 inches) to 40 cm (16 inches) when the eye is exposed to the beam

for longer than 0.25 seconds.

• Do not look at LEDs from a distance of less than 40 cm (16 inches)

without suitable protective eyewear.

• Do not look at LEDs with a magnifying glass or any other optical

instrument that may concentrate the light output.

• Ensure that all external covers, components and installation fittings are

securely fastened.

• Block access below the work area and work from a stable platform

whenever installing, servicing or moving the fixture.

• Ensure that all supporting structures, surfaces, fasteners and lifting

equipment can bear the weight of all the devices they are intended to

support plus an adequate safety margin, and that they conform to local

building and safety regulations.

• Use a sufficient number of fasteners with sufficient corrosion resistance,

dimensions and strength to mount the DIN rail safely. Any nuts used

must be self-locking.

• If the fixture is to be installed in a location where it may cause injury or

damage if it falls, use a secondary means of attachment such as looped

safety wires passing around the fixture.

Safety Information 5

Page 6

Disposing of this product

Martin™ products are supplied in compliance with Directive 2002/96/EC of

the European Parliament and of the Council of the European Union on

WEEE (Waste Electrical and Electronic Equipment), as amended by

Directive 2003/108/EC, where applicable.

Help preserve the environment! Ensure that this product is recycled at the

end of its life. Your supplier can give details of local arrangements for the

disposal of Martin products.

Page 7

Contents

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Using for the first time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Physical installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Location and orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Mounting the fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Adjusting tilt angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Connections – general . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

AC power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Connecting to power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Control data link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Connecting the data link . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Fixture setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Setting up a fixture with a PC and MUM . . . . . . . . . . . . . . . . . . 23

Service and maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Software installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

DMX protocols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

RGB Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

RGBW Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

HSI Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

HSIC Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Page 8

8 Extube user manual

Page 9

Introduction

Thank you for selecting an Extube™, a compact LED-based

color-changing lighting fixture from Martin™. The Extube is available in

short 300 mm (11.8 inch) and long 1200 mm (47.2 inch) models. All

models can be plugged into each other end-to-end to form an unbroken

line of light. Each 300 mm fixture or 300 mm segment of a 1200 mm

fixture can be considered as one pixel that can be controlled separately

via DMX, or fixtures and segments can be controlled together as a group.

Diffuser filters that give wider beam angles are available.

This product features:

• Philips Rebel high-power LEDs

• RGBW (red, green, blue, white) color mixing, with RGB, RGBW, HSIC

(hue, saturation, intensity, color temperature) and HSI color control

options

• 100 W LED power and 1392 lumens total output (at very narrow beam

angle) from 1200 mm models

• 25 W LED power and 348 lumens total output (at very narrow beam

angle) from 300 mm models

• Four models available: one Very Narrow beam angle model with no

diffuser fitted, and Narrow, Medium and Wide beam angles with

corresponding diffuser filters installed

• DMX 512A control

• Remote configuration over the DMX data link using a PC with Martin

MUM software and a hardware interface (Martin DABS1 recommended)

• Cascading auto-addressing (automatic DMX address setting of fixtures

connected to the master fixture)

• Auto-sensing power supply unit with 100 - 120/200 - 240 V, 50/60 Hz

operating range

• Clamp mounting system on standard

• Rapid end-to-end connection system

For the latest firmware updates, documentation, and other information

about this and all Martin Professional products, please visit the Martin

website at http: //w w w.martin.com

Introduction 9

Page 10

Comments or suggestions regarding this user manual may be e-mailed to

service@martin.dk or posted to:

Service Department

Martin Professional A/S

Olof Palmes Allé 18

DK-8200 Aarhus N

Denmark

Unpacking

The following items are included with the Extube:

• Adjustable mounting bracket

• This user manual

Using for the first time

Before applying power to the fixture:

• Carefully review “Saf ety Information” on page 3.

• Check that the local AC power voltage is within the range listed on the

fixture’s serial number label.

• Install the fixture as described in this manual

10 Extube user manual

Page 11

Physical installation

Warning! Read "Safety Information" on page 3 before installing the

Extube.

Warning! The safety and suitability of lifting equipment, installation

location, anchoring method, mounting har dware and electrical

installation is the responsibility of the installer. All local safety

regulations and legal requirements must be observed when

installing and connecting the Extube. Installation must be carried

out by qualified professionals only.

Contact your Martin supplier for assistance if you have any

questions about how to install this product safely.

Location and orientation

Warning! The Extube must be clamped onto a a DIN top-hat rail that

is securely anchored to a suitable flat surface. Ensure that the

supporting structure can bear the weight of all installed devices plus

an adequate safety margin.

Warning! If no diffuser filter is installed, make sure that it is

impossible for LEDs to be viewed from a distance of less than 40 cm

(16 inches).

If the diffuser front is installed, there is no eye hazard at any distance.

important! Make sure that there will be at least 10 cm (4 inches) of

free space and unrestricted airflow around the Extube.

The Extube can be installed outdoors. It has an IP rating of 65 and is

designed to withstand rain and other low-pressure water projections, but:

• Do not expose it to high-pressure water jets from any direction.

• Do not immerse it in water or any other fluid.

• Do not install it in a location where flooding may occur.

If installing in an enclosed area, make sure that water can drain awa y from

the installation area at lea st as fast as it can enter it.

The Extube requires free and unobstructed airflow around it to ensure

adequate cooling:

• Do not cover the fixture or locate it in an unventilated space.

• Allow 10 cm (4 inches) free space around the fixture.

Physical installation 11

Page 12

• Keep combustible materials (for example fabric, wood, paper) at least

2.5

0.5 m (20 in.) away from the fixture’s front cover and light output. Keep

flammable materials well away from the fixture.

The housing can reach temperatures up to 75° C (167° F). Restrict public

access or locate the fixture so that it cannot accidentally be touched.

Mounting the fixture

Warning! The Extube must be mounted on a top-hat profile 35 mm

(1.4 inch) DIN rail that is securely anchored to a surface. The

installation must conform to local electrical, building, safety and fire

regulations. If there is a danger that fixtures may cause injury or

damage if they fall, use a means of secondary attachment such as

safety cables looped around the fixtures.

Corrosion-resistant DIN rail can be ordered from Martin (see

"Accessories" on page 37).

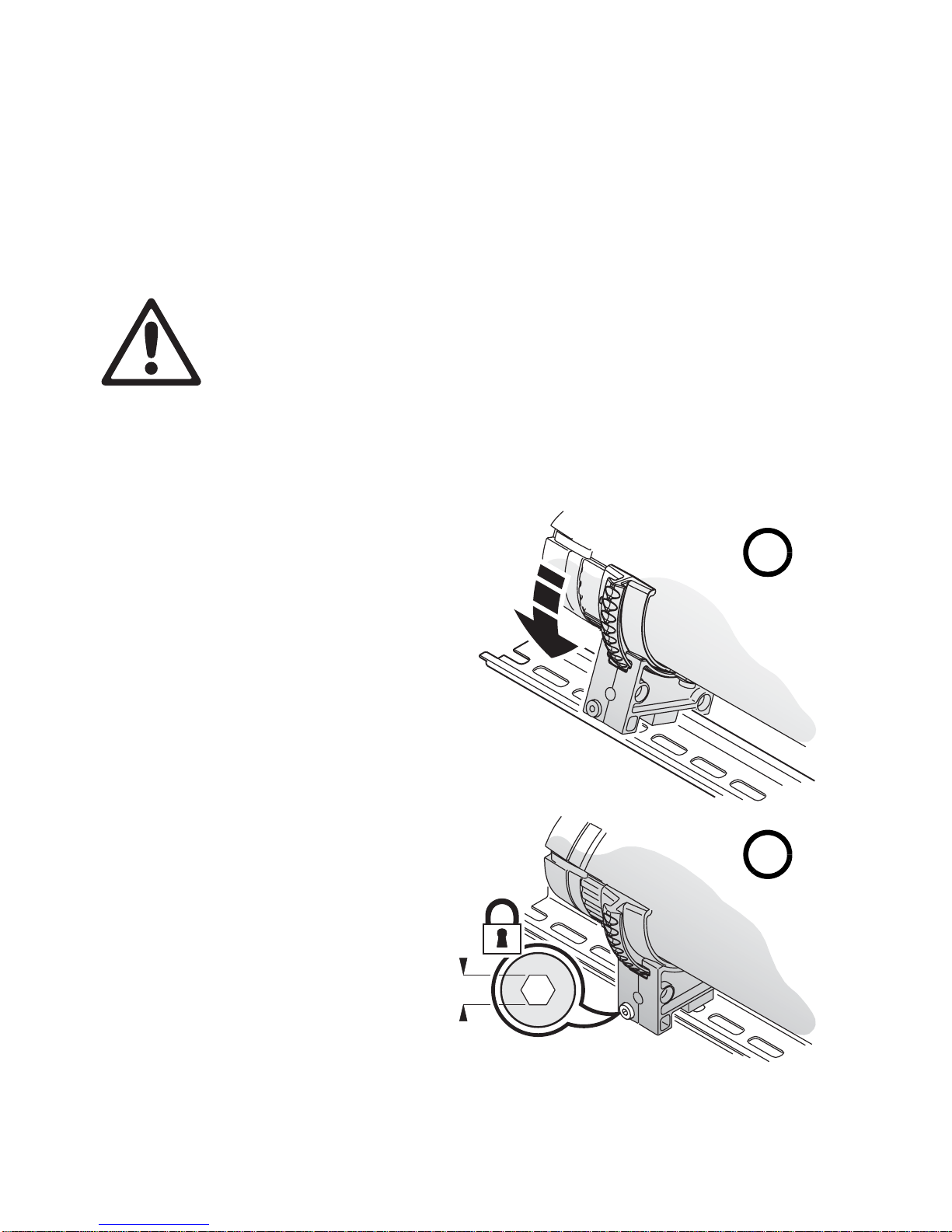

To mount the Extube on

a surface using 35 mm

DIN rail:

1. Fasten the DIN rail

securely to the

mounting surface.

A

2. See Figure 1. The

Extube mounting

bracket has a

hooked profile on

one side. Hook this

profile over the top

of the DIN rail and

swing the bracket

down (see A). Use a

2.5 mm Allen ke y to

tighten the mounting

clamp screw (see

B).

B

2.5

Figure 1: Mounting on DIN rail

12 Extube user manual

Page 13

Adjusting tilt angle

The Extube can be tilted through 90° (see Figure 2).

To adjust the tilt angle:

1. See Figure 3. Insert a 4 mm Allen key in the holes next to the

mounting clamp screws on the mounting brackets of all interconnected

fixtures. Engage the Allen key in the screw inside each hole, apply a

little inwards pressure and twist a quarter-turn clockwise to release the

tilt lock.

Figure 2: Tilt range

2. Adjust the fixture(s) to the desired tilt angle.

3. Re-insert the Allen key and twist a quarter-turn counter-clockwise to

reapply the tilt lock.

Figure 3: Releasing the tilt lock

Physical installation 13

Page 14

4. Check that the tilt lock is applied

on all the mounting brackets.

See Figure 4. A small button on

the opposite side of the

mounting bracket to the tilt lock

screw indicates whether the tilt

lock is applied or not.

Figure 4: Tilt lock indicato r

14 Extube user manual

Page 15

Connections – general

See Figure 5. The Extube must be connected to power and control data

by plugging an Extube input cap into the input en d of the fixture.

Input cap End cap

DMX control data in

Power in

Figure 5: Connecting fixtures to data and power

A second Extube can be plugged into the output end of this fixture, a third

Extube can be plugged into the output end of the second fixture, and so

on until the connected fixtures reach the maximum permitted length (see

"Maximum interconnected length per power input" on page 36).

Warning! Do not exceed the maximum length specified for a line of

Extube fixtures connected to each other and supplied with power via

one input cap, or you will overload the power cable and other

components and create a serious safety risk.

If another Extube is not plugged into the output end of a fixture, an end

cap must be installed as shown in Figure 5.

Input and end caps are supplied in Extube Connection Kits that must be

ordered separately. Each kit contains one input cap with 1.8 m (71 in.)

power and data cable tails, plus one end cap. Kits are available with

standard EU wire colors for EU markets and with standard US wire colors

for US markets (see "Accessories" on page 37 for deta i l s).

Connections – general 15

Page 16

When installing

input and end

caps, use the clips

provided with the

caps to secure

them to the fixture.

Clips are installed

by pressing them

into the slots

provided in fixtures

and end caps (see

Figure 6). Clips

can be released b y

levering them

outwards at one

end with a small

flat-blade

screwdriver.

Figure 6: Input and end cap clips

Warning! Do not apply power to an installation unless all input caps

and end caps are installed and secured with two clips per cap.

See Figure 7. It is possible to create a gap in a line of Extube fixtures (to

pass a door, window or corner, for example) but keep the fixtures

connected to each other by using an Extube Extension Kit that is available

as an accessory. Fixtures connected to each other using an extension kit

can be controlled together as a group.

Extension

End capInput cap End cap

InputOutput

Figure 7: Extension kit

Extension kits are available with 250 mm (9.8 in.) or 2 m (78 in.) cable

lengths in EU versions for EU markets and US versions for US markets

(see "Accessories" on page 37 for details).

16 Extube user manual

Page 17

AC power

Warning! Read “Safety Information” on page 3 before attempting to

install this product. Lock out power to the entire installation before

working on cables an d connections or removing any cover.

Electrical installation must be carried out by qualified professionals

only.

For protection from dangerous electric shock, the fixture must be

grounded (earthed). The AC mains power distribution system must

be fitted with both current overload and ground-fault (earth-fault)

circuit breakers, as well as a means to isolate fixtures from power

and lock out power during service.

Important! Do not connect the Extube to an electrical dimmer

system. Doing so can damage the electronics.

If you require help in planning or dimensioning the power distribution

system, please contact your Martin supplier for assistance.

If there is a break or cut at any point in a cable (for example at a

connection point), and if this is exposed to water, moisture can be drawn

up the inside of the cable due to the vacuum effect of temperature

fluctuations during operation. Ensure that the fixture is protected from the

entry of water via the power cable by using IP65-rated connectors or

junction boxes, or by protecting connectors with weatherproof housings.

The Extube does not have a power on/off switch. Power is applied to the

fixture as soon as it is connected to power.

AC mains power voltage and frequency

The Extube accepts AC power at 100 - 120 and 200 - 240 V nominal, at

50 or 60 Hz. Do not connect the fixture to power at any other voltage or

frequency.

Current and fuse ratings

See "Typical Power and Current" on page 36 for details of current drawn

by Extube fixtures.

Extube 300 mm fixtures are protected by a 1 amp slow-blow primary fuse

and 1200 mm fixtures are protected by four 1 amp slow-blow fuses. Fuses

are located internally on the power PCB and are not user-serviceable. If

you suspect that a fuse has blown, please contact your Martin supplier for

assistance.

AC power 17

Page 18

Connecting to power

An Extube fixture or group of fixtures must be supplied with power via the

13 A power cable installed on an Extube power input cap.

Details of standard US and EU conductor identification systems are given

in Table 1.

Wire color

(US system)

black brown live L yellow or

white blue neutral N silver

green yellow/green ground

Warning! Terminals inside the input cap are live when power is

applied to the power cable. Terminals inside the connector at the

output end of the fixture are live when power is applied to the fixture.

Do not apply power to the power cable unless the input cap is

installed on the fixture and an end cap is installed either on the

fixture or on the last fixture in a line of interconnected fixtures.

To connect to power:

Wire color

(EU system) Conductor Symbol Screw (US)

brass

green

(earth)

Table 1: Conductor identification

1. Lock out power to the installation.

2. Install an end cap on the fixture or on the last fixture in a line of

fixtures.

3. Connect the power cable on the input cap to the power distribution

circuit as follows:

- Connect the green wire (US models) or yellow/green wire (EU

models) to ground (earth)

- Connect the white wire (US models) or blue wire (EU models) to

neutral

- Connect the black wire (US models) or brown wire (EU models) to

live.

4. Install the input cap on the fixture you want to supply with power , check

that all installation work is completed and carry out appropriate tests

and safety checks before applying power to the installation.

18 Extube user manual

Page 19

Power plug

If you decide to fit the supplied power cable with a plug that is suitable for

your AC mains power outlets, install a grounding-type (earthed) pl ug that

is rated 13 A minimum, following the plug manufacturer’s instructions.

Table 1 shows some possible pin identification schemes; if pins are not

clearly identified, or if you have any dou bts about proper installation,

consult a qualified electrician. Ensure that all connections are sufficiently

protected from water.

AC power 19

Page 20

Control data link

Extube fixtures must be connected via a data link to allow DMX control.

The following considerations must be taken into account when planning

the data link:

• RS-485 data cable designed for exterior use is required for outdoor

installations. RS-485 cable has low capacitance and a characteristic

impedance of 85 to 150 Ohms. It is electrically shielded and has at least

1 twisted pair of conductors. The minimum recommended wire size is

0.25 mm

(22 AWG) for run s up 500 meters (1640 ft). CAT 5e network cable

designed for direct burial can be used in outdoor installations, but you

are recommended to run it inside conduit.

• CAT 5e network cable is suitable for the control data link in indoor

installations. Installation-type cable is acceptable for fixed installations.

Flexible patch-type cable with good bend and torsion recove ry is

required in movable installations (Martin patch cables are

recommended).

• Long parallel runs of AC power and control data cables may cause

interference on the data link and must be avoided. Even if not required

by law, use separate conduits for power and data cables.

2

(24 AWG) for runs up to 300 meters (1000 ft.) and 0.32 mm2

• The maximum permitted control data cable length before a control

signal amplifier is required is 500 meters (1640 ft.). An optically isolated

amplifier-splitter such as the Martin RS-485 Opto-Splitter (P/N

90758060) must be used to extend a link beyond this length.

• If you want to control more than one single line of interconnected

Extubes, yo u must either use one DMX output from your controller for

each line of fixtures or use an optically isolated amplifier-splitter such as

the Martin RS-485 Opto-Splitter to split the data link into one branch for

each line of Extubes. The Martin Opto-Splitter all ows you to split a link

into four branches.

• Each link or branch of a link must be terminated by installing an end cap

on the last fixture.

• One DMX universe has 512 DMX control channels availabl e. If

individual control of the fixtures in an installation is required, each fixture

must be given its own channels until the limit of 512 is reached. At this

point, a new DMX universe must be created.

• The number of fixtures that can be individually controlled in one DMX

universe depends on the number of DMX channels they use. if Extubes

are set to HSI mode, for example, each fixture requires 3 DMX

channels. The total number of Extubes that can be linked in one DMX

universe will therefore be 512/3 = 170.

20 Extube user manual

Page 21

When planning DMX cable layout, remember that the maximum

current-carrying capacity of cables and fixtures limits the length of the line

of fixtures that can be connected via one input cap (see "Installation" on

page 36).

Data connection pinouts

XLR connection

XLR connectors are suitable if the DMX controller has XLR output

sockets. DMX cable is recommended for the data link in this case. XLR

pin numbers are normally marked on connectors. Connectors must be

wired using the standard XLR DMX pin-out:

• Pin 1: Cable shield

• Pin 2: DMX Data 1 - (cold)

• Pin 3: DMX Data 1 + (hot)

To avoid ground/earth loop interference, ensure that the DMX cable shield

does not come into contact with the shell or body of XLR connectors.

RJ-45 connection

RJ-45 connectors are suitable if the DMX controller has RJ-45 output

sockets. CAT 5e network cable is recommended in this case. RJ-45 cable

connector pins are numbered from the left looking at the face of the

connector with the locking clip on top (see Figure 8). Connectors must be

wired according to the 568-B system using the standard RJ-45 pin-out for

DMX applications:

• Pin 1 (White/orange): DMX data hot (+)

• Pin 2 (Orange): DMX data cold (-)

• Pins 7 (White/brown) and 8

(Brown): Common

Pins 3 and 6 are available for Data 2

connections in DMX 512-A or

similar systems. They must be

Pin 1 Pin 8

wired as follows:

• Pin 3 (White/green): Available for

Data 2 hot (+)

Figure 8: RJ-45 cable

connector pins

• Pin 6 (Green): Available for Data

2 cold (-)

Pins 4 and 5 are not used in currently available lighting control systems

but can be wired as follows:

• Pin 4 (Blue)

• Pin 5 (White/blue)

Control data link 21

Page 22

Connecting the data link

Warning! Lock out power to the entire installation before working on

cables and connections or removing any cover.

Warning! Make sure that data connections are totally protected from

water , or moisture may be dra wn up the inside of the cable due to the

vacuum effect from the heat generated during operation.

The Extube is supplied with a 1.8 meter (5 ft.10 in.) data cable tail for data

connection. The cable contains both input and output conductors that are

identified as follows:

• 1 x shield = data input and output common

• 2 x white wires = data input and output hot (+)

• 1 x green wire = data input cold (-)

• 1 x brown wire = data output cold (-)

To connect a fixture to the data link:

1. Connect the conductors in the fixture’s cable tail to the data link

respecting the above color code. If required, install input and output

connectors on the data cable respecting the pinouts described in “Data

connection pinouts” on page 21. Standard procedure is to use a male

connector on a fixture’s cab le tail for data input and a female connector

for data output. Do not connect the shield conductor to ground (earth)

or allow it to come into contact with a connector shell, as this may

cause interference.

2. Protect connectors in a weatherproof housing if they are not totally

weatherproof.

22 Extube user manual

Page 23

Fixture setup

Setting up a fixture with a PC and MUM

The Martin MUM (Multi-Utility Manager) application allows you to program

and configure Martin lighting products from a laptop and features an

intuitive GUI (graphic user interface). Refer to the MUM user manual for

instructions on installing and starting the MUM application.

Using MUM, you can connect to and set up one Extube fixture or one

interconnected line of fixtures at a time.

To connect a PC with MUM to an Extube:

1. Obtain the MUM application, a DABS1 adaptor and interface cables.

These are available as a set from Martin, P/N 90758090.

2. Connect the DABS1 adaptor to y our PC using the USB cable supplied

in the set.

3. Connect the DABS1 adaptor to the Extube or line of Extubes using an

XLR connector connected to the Extube data input cable.

4. Apply power to the Extube and start the MUM application. MUM will

automatically detect an Extube if it is powered on and correctly

connected. It will also retrieve information and current settings from

the fixture and display them.

Communication between MUM and fixtures

When there is a connection to a fixture:

• The Reconnect button at the bottom of every window in MUM lets you

re-initialize communicat ion with the f ixture or establish communication if

you connect to a new Extube.

• The Refresh button retrieves and displays fresh fixture information.

• The Close button closes the MUM application.

Fixture setup 23

Page 24

Communicating with segments

A segment consists of either a single 300 mm Extube or a 300 mm section

of a 1200 mm Extube. Depending on how you set up the installation,

segments can be controlled separately or put into groups.

If you are connected to a line of two or more interconnected fixtures, MUM

lets you select which segment to communicate with and gives you

information about segments. In the example below:

a. MUM is communicating with segment 1.

b. The installation ranges from 1 to 14 segments, i.e. there are 14

segments in total.

c. Use the arrows to scroll between segments.

a

b

C

24 Extube user manual

Page 25

Fixture information

The Fixture info window identifies the fixture and software version

installed.

The Fixture info window also displays information about the number of

hours the fixture has been powered on and the number of hours LEDs

have been active. In both cases, one non-resettable counter shows the

total number of hours since manufacture and one resettable counter

shows the number of hours since it was lest reset.

The Extube’s software monitors operation. If it detects an error , it displa ys

diagnostic information in the Fixture info window.

The segment information above the Reconnect button tells you which

segment MUM is retrieving fixture information from. You can use the

segment selection arrows to scroll between segments and retrieve

information from all the segments you have connected to.

Fixture setup 25

Page 26

Fixture settings

The Fixture settings window lets you select DMX modes (i.e. color

control options), group segments into pixels, and set DMX addresses.

DMX mode

The Fixture settings window lets you select a DMX mode (RGB, RGBW,

HSI or HSIC color control) for the fixtures or pixels in your installation. It is

possible to set different pixels to different DMX modes by scrolling

between pixels using the scroll arrows and changing the DMX mode

setting for each pixel.

Individual and grouped control of segments

The Fixture settings window lets you control 300 mm Extubes or 300 mm

segments of 1200 mm Extubes individually, or put them into groups that

behave identically and are controlled as one pixel.

For example, if you select 1 in the Segments/Pixel box, each 300 mm

segment in the line of fixtures is controlled individually as one pixel that is

300 mm long.

If you select 3 in the Segments/Pixel box, the 300 mm segments are put

into groups of three segments. You then control each group as one pixel

that is 900 mm long.

Note that you cannot set different segments within one pixel to different

DMX modes.

26 Extube user manual

Page 27

DMX address setting – general

The DMX address, also known as the start channel, is the first of the DMX

channels used to receive instructions from the controller. For individual

control, each pixel must have its own channels. Thus, if a pixel has DMX

address 1 and uses 3 channels because it is set to RGB mode, it will use

channels 1 - 3. The DMX address of the next pixel must be set to 4, and

so on.

The Extube features ‘cascading’ auto-addressing. This means that once

you have connected MUM to the first Extube in an interconnected line and

set that first fixture’s DMX address, you can automatically set the DMX

addresses of all the pixels in that line.

DMX address setting in single lines of Extubes

If you intend to use a DMX controller to operate one Extube or one line of

interconnected Extubes only, and you want all the segments to behave

identically, leave DMX address set to 1, enter the total number of

segments in your installation in the Segments/Pixel box, select Enable

auto configure all segments, and click on Auto co nfigure now. You can

now control one pixel containing all the segments in your installation. You

will use DMX channels 1 - 3 or 1 - 4 (depending on the DMX mode you

have selected) on your controller to control all the segments together.

If you intend to use a DMX controller to operate one line of interconnected

Extubes only but you want individual control of pixels , leav e DMX address

set to 1, enter 1 in the Segments/Pixel box, select Enable auto

configure all segments, and click on Auto configure now. You can no w

control all the segments in your installation separately as individual pixels .

You will use 3 or 4 (depending on the DMX mode you have selected) DMX

channels per segment, starting at channel 1 on your control l e r.

DMX address setting in multiple lines of Extubes and in mixed

installations

If you intend to use one DMX controller to control more than one line of

interconnected Extubes – or to control a mixed installation containing

Extubes and other fixtures – you will need to set the DMX addresses on

all fixtures for which individual control is required.

If you set the DMX address of the first segment you are connected to,

select Enable auto configure all segments and then click on Auto

configure now, the first Extube you are connected to automatically

calculates and sets the DMX addresses of all the segments connected to

it starting with the first segment’s DMX address and then adding

addresses in ascending order.

For example , if your installation consists of 10 interconnected segments

set to two segments per pixel (giving you five segments), with all

segments in RGBW mode (so that they use 4 DMX channels), and the

Fixture setup 27

Page 28

first segment has DMX address 101, auto configuring will set the DMX

address of the first pixel to 101, the next pixel to 105, the next pixel to 109,

and so on until the last pixel is set to DMX address 117. The last pixel will

use channels 117 to 120 and channel 121 will be available for other

fixtures.

Monitoring fixture parameters

PCB voltage data and LED and PCB temperatures for each segment

MUM communicates with can be displayed in MUM’s Monitor window.

28 Extube user manual

Page 29

LED Test

The Extube’s LEDs can be activated with out a DMX controller for test

purposes in MUM’s LED Test window.

Auto test all starts colors fl ashing in sequence. Flash speed can be

adjusted.

Fixture setup 29

Page 30

Service and maintenance

Warning! Read “Safety Information” on page 3 before carrying out

serv ice or m ain tenan ce wor k on the Ext ube. Lock out power to the

entire distribution system before servicing or opening any

cover.

Important! Excessive dirt and dust buildup degrades performance,

causes overheating and will damage the fixture. The Extube requires

cleaning at intervals that depend on the environment in which it is

installed. Damage caused by inadequate cleaning is not covered by

the product warranty.

The Extube, its power input cap with installed cable, and its end cap are

not user-serviceable. All service apart from cleaning, software renewal

and the installation work described in this manual must be carried out by

the Martin Service organization or its authorized agents.

It is Martin policy to use the best quality materials available to ensure

optimum performance and the longest possible component lifetimes.

Howev er , optical components in all lighting fixtures are subject to wear and

tear over the life of the fixture, resulting in gradual changes in color

rendition, for example. The extent of wear and tear depends heavily on

operating conditions and environment, so it is impossible to specify

precise lifetimes for optical components. LEDs will eventually require

replacement if their characteristics are affected by wear and tear after an

extended period of use and if you require fixtures to perform within very

precise optical and color parameters. The expected lifetime (to 50% of

initial output level) of the Extube’s LEDs is minimum 20 000 hours at full

intensity.

Cleaning

Regular cleaning is essential for fixture life and performance. Buildup of

dust and dirt degrades the fixture’s light output and cooling ability.

Cleaning schedules will vary greatly depending on the operating

environment. It is therefore impossible to specify precise cleaning intervals

for the Extube. Inspect fixtures within their first few weeks of operation to

see whether cleaning is necessary. Chec k again at frequent intervals. This

procedure will allow you to assess cleaning requirements in your particular

situation. If in doubt, consult your Martin dealer about a suitable

maintenance schedule.

30 Extube user manual

Page 31

Warning! The Extube is IP65 rated. This means that it will withstand

water projections, but do not e xpose it to high-pressure water jets or

immerse it in water or any other liquid.

Clean the Extube’s housing and front glass with a soft cloth dampened

with a solution of water and a mild detergent such as car shampoo. Take

care not to damage seals and wiring during cleaning. Do not use products

that contain solvents, abrasiv es or caustic agents for cleaning, as they can

cause surface damage to the fixture and its front cover.

Software installation

It may be necessary to upload new software (i.e. firmware) to the Extube if

you believe that the product has a software-related fault or if you wan t to

update to a newer version. Software updates are availab le from the Martin

website (http://www.martin.com) and can be installed via the DMX data

link with the following items:

• The Martin Uploader application, version 5.0 or later , downloadable free

of charge from the Support area of the Martin website.

• The Extube main CPU software update file, downloadable free of

charge from the Support area of the Martin website (this file can be

downloaded automatically from within the Ma rtin Uploader application)

• A Martin Universal USB-DMX Interface or similar PC/fixture hardware

interface and a Windows PC (if you have a Martin MP-2 Uploader

device, it can also be used).

To install new software:

1. Connect the uploader hardware to an Extube fixture’s data input

connector. The software will be uploaded to that fixture and all Extube

fixtures that are powered on and connected via the DMX link.

2. Upload the fixture software as described in the uploader’s help file or

user documentation.

3. Disconnect the uploader hardware and reconnect the fixture to the

DMX link.

4. Cycle power off and on. Check that the fixture operates correctly. If it

does not, cycle power off and on again and check that the fixture now

operates correctly. If it still does not, repeat the upload procedure.

Service and maintenance 31

Page 32

DMX protocols

RGB Mode

Start code = 0

Channel Value Percent Function

1

2

3

RGBW Mode

Channel Value Percent Function

1

2

0 - 255 0 - 100%

0 - 255 0 - 100%

0 - 255 0 - 100%

Start code = 0

0 - 255 0 - 100%

0 - 255 0 - 100%

Red

Intensity 0

Green

Intensity 0 →100%

Blue

Intensity 0 →100%

Red

Intensity 0

Green

Intensity 0 →100%

→100%

→100%

3

4

32 Extube user manual

0 - 255 0 - 100%

0 - 255 0 - 100%

Blue

Intensity 0

White

Intensity 0

→100%

→100%

Page 33

HSI Mode

Channel Value Percent Function

Start code = 0

Hue

1

0 - 255 0 - 100

Red

→ Orange → Amber→

Yellow

Blue

Magenta → Red

→ Green → Cyan →

→ Indigo → Violet →

2

3

In HSI mode, white color temperature is fixed at 5500 K.

HSIC Mode

Channel Value Percent Function

1

0 - 255 0 - 100

0 - 255 0 - 100%

Start code = 0

0 - 255 0 - 100

Saturation

Zero (white)

Intensity

Intensity 0

Hue

Red → Orange → Amber→

Yellow

Blue

→ Indigo → Violet →

Magenta → Red

→ Full

→100%

→ Green → Cyan →

2

3

4

In HSIC mode, a DMX value of 191 (75%) must be sent on channel 4 to

obtain a white color temperature of 5500 K.

Saturation

0 - 255 0 - 100

0 - 255 0 - 100%

0 - 255 0 - 100

DMX protocols 33

Zero (white)

Intensity

Intensity 0

Color Temperature Control

2000 - 10 000 K

→ Full saturation

→100%

Page 34

Troubleshooting

Problem Probable cause(s) Remedy

Fixture is completely

dead.

One or more fixtures

responds incorrectly

to control or does not

respond at all.

LEDs cut out

intermittently.

No power to fixture. Check power and connections.

Primary fuse blown.

Fault on DMX link.

Incorrect fixture addressing.

Fixture defective.

Other device on DMX link

defective.

Fixture is too hot.

Isolate fixture from power. Contact

Martin for service.

Inspect connections and cables.

Correct poor connections. Repair

or replace damaged cables.

Check fixture is set to correct DMX

mode.

Check number of channels

required by fixture’s DMX mode

and check fixture addresses.

Have faulty fixture serviced by

Martin service technician.

Bypass devices on DMX link until

the faulty device has been

identified.

Have faulty device tested and

serviced by Martin service

technician or device supplier.

Ensure free airflow around fixture.

Clean fixture.

Check that ambient temperature

does not exceed maximum

permitted level.

Contact Martin for service.

Table 2: Troubleshooting

34 Extube user manual

Page 35

Specifications

Physical

Length. . . . . . . . . . . . . . . . . . . . . . . . . .300 mm (11.8 in.) / 1200 mm (47.2 in.),

. . . . add 70 mm (2.8 in.) if end cap and power input module installed

Width. . . . . . . . . . . . . . . . . . . . . . . . 89 mm (3.5 in.) including mounting bracket

Height . . . . . . . . . . . . . 90 mm (3.5 in.) including mounting bracket and DIN rail

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .300 mm model: 750 g (26.5 oz.)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1200 mm model: 3 kg (6.6 lbs.)

Dynamic Effects

Color mixing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RGBW

Red. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 100%

Green . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 100%

Blue. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 100%

White. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .0 - 100%

Control and Programming

Color control modes . . . . . . . . . . . . . . . . . . . . . . . . . . RGB, RGBW, HSI, HSIC

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . DMX

DMX channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/4

Grouped pixel control options. . . . 1 x 3 (all as one group) on 300 mm models,

. . . . . . . . . . . . 1 x 12 (all as one group) or 4 x 3 on 1200 mm models

DMX address setting . . . . . . . . . . .Auto-addressing and Martin MUM software

26-bit control (internal) . . . . . . . . . . . . . . RGBW, RGB, HSI, HSIC color mixing

Protocol. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .USITT DMX512-A

Receiver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . RS-485

Firmware update. . . . . . . . . . . . . . . . . . . . . . . . . . . . Serial upload via DMX link

Photometric Data

Light source . . . . . . . . . . . . . . . . . . . . . . . . .Luxeon Rebel high power emitters

Total LED power . . . . . . . . . . . . . . . . . . . . . . 25 W approx. on 300 mm models,

Color temperature control. . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 000 - 10 000 K

Total output per 300 mm segment (balanced white, 5600 K)

Very narrow (19° half-peak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .348 lm

Narrow (27° half-peak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .324 lm

Medium (34° half-peak) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .301 lm

Wide (40° half-peak). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .259 lm

For full photometric data please see www.martin.com

. . . . . . . . . . . . . . .100 W approx. on 1200 mm models

Specifications 35

Page 36

Construction

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminum

Finish . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clear anodized, black or white

End covers . . . . . . . . . . . . . . . . . . . . . . . . . . . UV-resistant clear polycarbonate

Mounting brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PA6 nylon

Protection rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . IP 65

Installation

Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Any

Vertical aiming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+/- 90°

Mounting points . . . . . . . . . . . . . . . . . . . . Mounting brackets or 35 mm DIN rail

Maximum interconnected length per power input

100 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 m

110 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 m

120 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13 m

208 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22 m

230 V, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 m

240 V, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 m

Connections

Power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 m cable tail

Data connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 m cable tail

Fixture-to-fixture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Quick plug-in system

Electrical

AC power . . . . . . . . . . . . . . . . . . . . . . . .100-120/200-240 V nominal, 50/60 Hz

Power supply unit . . . . . . . . . . . . . . . . . . Integrated, auto-sensing multi-voltage

Typical Power and Current

300 mm models

100 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.4 A, PF 0.992

110 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.3 A, PF 0.992

120 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.3 A, PF 0.990

208 V, 60 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.2 A, PF 0.980

230 V, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.2 A, PF 0.980

240 V, 50 Hz. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 W, 0.2 A, PF 0.980

36 Extube user manual

Page 37

1200 mm models

100 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 1.4 A, PF 0.992

110 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 1.2 A, PF 0.992

120 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 1.2 A, PF 0.990

208 V, 60 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 0.7 A, PF 0.980

230 V, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 0.6 A, PF 0.980

240 V, 50 Hz . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128 W, 0.6 A, PF 0.980

Measurements made at Ta (ambient temperature) 25° C (77° F).

Measurements made at nominal voltage. Allow for a deviatio n of +/- 10% .

Thermal

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Convection

Maximum ambient temperature (Ta max.) . . . . . . . . . . . . . . . . . 40° C (104° F)

Minimum ambient temperature (Ta min.) . . . . . . . . . . . . . . . . . . . . 5° C (41° F)

Maximum surface temperature, steady state, Ta=40° C. . . . . . . 75° C (167° F)

Approvals

EU safety . . . . . . .EN 60598-1, EN 60598-2-1,

. . . . . . . . . . . . . . . . IEC/EN 60825-1

EU EMC . . . . . . . . . . . .EN 55 015, EN 55 103,

. . . . . . . . . . . . . . . . . . .EN 61 000-3

US safety . . . . . . . . . . . . . . . . . . . . . . UL 1598

Canadian safety . . . .CAN/CSA C.22.2 No. 250

Included Items

Brackets for mounting on DIN rail

User manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 35000212

Accessories

Po wer connection kit (input cap with 1.8 m cable tails + end cap)

EU type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610086

US type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610087

250 mm Extension Kit (output cap, cable and input cap)

EU type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610094

US type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610096

2000 mm Extension Kit (output cap, cable and input cap)

EU type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610095

US type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610097

Four 300 mm diffusers, Narrow. . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610098

Four 300 mm diffusers, Medium. . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610099

Four 300 mm diffusers, Wide . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91610100

DIN rail set (ten 2 m lengths) . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 91602009

Specifications 37

Page 38

Ordering Information

Extube 300 mm, Aluminum, Narrow. . . . . . . . . . . . . . . . . . . . . . .P/N 90352200

Extube 300 mm, Aluminum, Medium . . . . . . . . . . . . . . . . . . . . . .P/N 90352300

Extube 300 mm, Aluminum, Wide . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352400

Extube 300 mm, Aluminum, no diffuser . . . . . . . . . . . . . . . . . . . .P/N 90352500

Extube 300 mm, Black, Narrow . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352201

Extube 300 mm, Black, Medium. . . . . . . . . . . . . . . . . . . . . . . . . .P/N 9035 2301

Extube 300 mm, Black, Wide . . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352401

Extube 300 mm, Black, no diffuser. . . . . . . . . . . . . . . . . . . . . . . .P/N 90352501

Extube 300 mm, White, Narrow . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352202

Extube 300 mm, White, Medium . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352302

Extube 300 mm, White, Wide. . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352402

Extube 300 mm, White, no diffuser . . . . . . . . . . . . . . . . . . . . . . .P/N 90352502

Extube 1200 mm, Aluminum, Narrow. . . . . . . . . . . . . . . . . . . . . .P/N 90352210

Extube 1200 mm, Aluminum, Medium . . . . . . . . . . . . . . . . . . . . .P/N 90352310

Extube 1200 mm, Aluminum, Wide . . . . . . . . . . . . . . . . . . . . . . .P/N 90352410

Extube 1200 mm, Aluminum, no diffuser . . . . . . . . . . . . . . . . . . .P/N 90352510

Extube 1200 mm, Black, Narrow . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352211

Extube 1200 mm, Black, Medium. . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352311

Extube 1200 mm, Black, Wide . . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352411

Extube 1200 mm, Black, no diffuser. . . . . . . . . . . . . . . . . . . . . . .P /N 90352511

Extube 1200 mm, White, Narrow . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352212

Extube 1200 mm, White, Medium . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352312

Extube 1200 mm, White, Wide. . . . . . . . . . . . . . . . . . . . . . . . . . .P/N 90352412

Extube 1200 mm, White, no diffuser . . . . . . . . . . . . . . . . . . . . . .P/N 90352512

Custom colors are available by special order – please contact your Martin

distributor for details.

Specifications subject to change without notice.

38 Extube user manual

Page 39

Page 40

Loading...

Loading...