Page 1

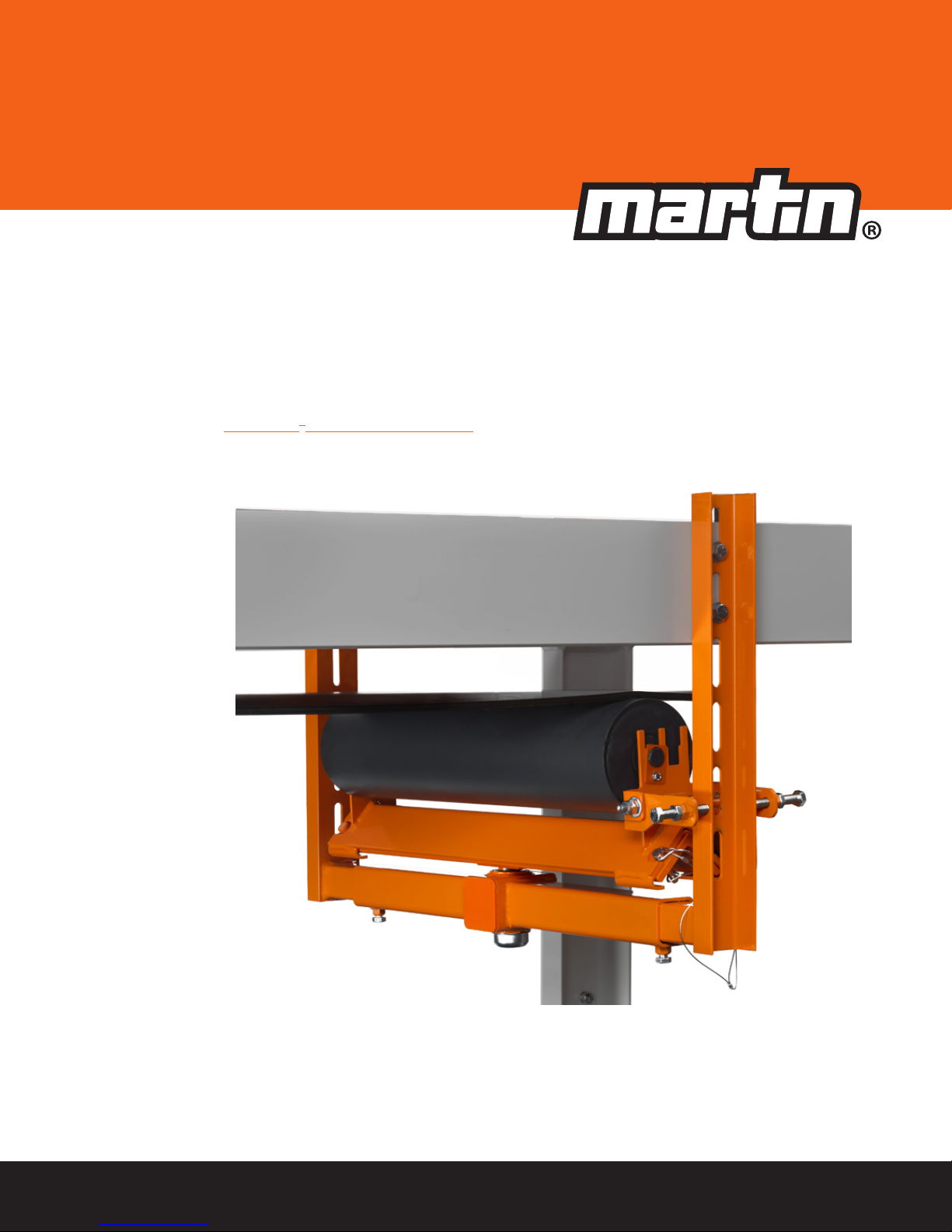

EVO®

Return Roller

Go to EVO® Return Roller web page

Operator’s Manual

M3796

Page 2

Important

MARTIN ENGINEERING HEREBY DISCLAIMS ANY LIABILITY FOR: DAMAGE DUE TO

CONTAMINATION OF THE MATERIAL; USER’S FAILURE TO INSPECT, MAINTAIN AND TAKE

REASONABLE CARE OF THE EQUIPMENT; INJURIES OR DAMAGE RESULTING FROM USE OR

APPLICATION OF THIS PRODUCT CONTRARY TO INSTRUCTIONS AND SPECIFICATIONS

CONTAINED HEREIN. MARTIN ENGINEERING’S LIABILITY SHALL BE LIMITED TO REPAIR

OR REPLACEMENT OF EQUIPMENT SHOWN TO BE DEFECTIVE.

Observe all safety rules given herein along with owner and Government standards and regulations. Know

and understand lockout/tagout procedures as defined by American National Standards Institute (ANSI)

z244.1-1982, American National Standard for Personnel Protection - Lockout/Tagout of Energy Sources -

Minimum Safety Requirements and Occupational Safety and Health Administration (OSHA) Federal

Register, Part IV, 29 CFR Part 1910, Control of Hazardous Energy Source (Lockout/Tagout); Final Rule.

The following symbols may be used in this manual:

!

DANGER

Danger: Immediate hazards that will result in severe personal injury or death.

!

WARNING

Warning: Hazards or unsafe practices that could result in personal injury.

!

CAUTION

Caution: Hazards or unsafe practices that could result in product or property damages.

IMPORTANT

Important: Instructions that must be followed to ensure proper installation/operation of equipment.

NOTE

Note: General statements to assist the reader.

Page 3

Table of Contents

Section Page

List of Figures and Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Materials required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Before Installing Return Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Installing Return Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Installing EVO® Return Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

After Installing Return Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Weekly Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table of Contents

Martin Engineering M3796-05/12 i EVO® Return Roller

Page 4

Figure Title Page

1EVO

2 Conveyor Products Warning Label, P/N 23395 . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Pinch Point Warning Label, P/N 30528 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4EVO

®

Return Roller, UCRR-007000-XXX . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

®

Return Roller Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

List of Figures and Tables

List of Figures

List of Tables

Table Title Page

I Part Numbers for EVO® Return Roller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Martin Engineering M3796-05/12 ii EVO® Return Roller

Page 5

Introduction

DANGER

!

DANGER

!

General The EVO

for safe, quick, and simple one-sided servicability and roll replacement. The

track-mounted design reduces the risk of injury and allows replacement of the

roll in a matter of seconds.

®

Return Roller is a pivoting track-mounted return idler that allows

References The following documents are referenced in this manual:

• American National Standards Institute (ANSI) z244.1-1982, American

National Standard for Personnel Protection - Lockout/Tagout of Energy

Sources - Minimum Safety Requirements, American National Standards

Institute, Inc., 1430 Broadway, New York, NY 10018.

• Federal Register, Volume 54, Number 169, Part IV, 29 CFR Part 1910,

Control of Hazardous Energy Source (Lockout/Tagout); Final Rule,

Department of Labor, Occupational Safety and Health Administration

(OSHA), 32nd Floor, Room 3244, 230 South Dearborn Street,

Chicago, IL 60604.

Materials required Only standard hand tools are required to install and service this equipment.

Introduction

Safety All safety rules defined in the above documents and all owner/employer safety

rules must be strictly followed when working on the belt cleaner.

Do not touch or go near the conveyor belt or conveyor

accessories when the belt is running. Your body or clothing

can get caught and you can be pulled into the conveyor,

resulting in severe injury or death.

Before installing, servicing, or adjusting the conveyor

equipment, turn off and lock out/tag out all energy sources to

the conveyor and conveyor accessories according to ANSI

standards. Failure to do so could result in serious injury or

death.

Martin Engineering M3796-05/12 1 EVO® Return Roller

Page 6

DANGER

!

WARNING

!

WARNING

!

Introduction

If this equipment will be installed in an enclosed area, test the

gas level or dust content before using a cutting torch or

welding. Using a torch or welding in an area with gas or dust

may cause an explosion resulting in serious injury or death.

Before using a cutting torch or welding the chute wall, cover

the conveyor belt with a fire retardant cover. Failure to do so

can allow the belt to catch fire.

Remove all tools from the installation area and conveyor belt

before turning on the conveyor. Failure to do so can cause

serious injury to personnel or damage to the belt and

conveyor.

Martin Engineering M3796-05/12 2 EVO® Return Roller

Page 7

Before Installing Return Roller

IMPORTANT

WARNING

!

DANGER

!

The delivery service is responsible for damage occurring in

transit. Martin Engineering CANNOT enter claims for

damages. Contact your transportation agent for more

information.

1. Inspect shipping container for damage. Report damage to delivery service

immediately and fill out delivery service’s claim form. Keep any damaged

goods subject to examination.

2. Remove EVO

3. If anything is missing contact Martin Engineering or a representative.

Before installing equipment, turn off and lock out/ tag out all

energy sources to the conveyor and conveyor accessories

according to ANSI standards. Failure to do so could result in

serious injury or death.

4. Turn off and lock out/tag out energy source according to ANSI standards

(see “References”).

®

Return Roller assembly from shipping container.

Before Installation

If this equipment will be installed in an enclosed area, test the

gas level or dust content before using a cutting torch or

welding. Using a torch or welding in an area with gas or dust

may cause an explosion resulting in serious injury or death.

5. If using a cutting torch or welding, test atmosphere for gas level or dust

content. Cover conveyor belt with fire retardant cover.

Martin Engineering M3796-05/12 3 EVO® Return Roller

Page 8

Installing Return Roller

A. Cap Screw, Washers, and Nut (2 used) B. Hanger Tube C. Pivoting Weldment

Installing EVO®

Return Roller

Installation

90°

C

L

1. Remove existing return idler and mounting brackets.

2. Mark holes for hanger tubes opposite of each other and perpendicular to

belt.

3. Drill or torch holes into stringer.

4. Install hanger tube (B) on far side stringer using cap screws, washers, and

nuts (A), but do not tighten.

5. Slide pivoting weldment (C) onto hanger tube (B).

Martin Engineering M3796-05/12 4 EVO® Return Roller

Page 9

6. Install lanyard and snap lock pin (E) on hanger tube (D).

A. Cap Screw, Washers, and Nut (2 used)

D. Hanger Tube

C. Pivoting Weldment

E. Snap Lock Pin and Lanyard

F. Set Screws (4 used)

G. Rotating Weldment H. Roll Assembly J. Handle

7. Slide hanger tube (D) into pivoting weldment (C).

8. Attach hanger tube (D) to stringer using cap screws, washers, and nuts

(A), but do not tighten.

9. Center pivoting weldment (C) on belt and tighten set screws (F).

Installation

10. Slide roll assembly (H) on rotating weldment (G). Make sure handle (J)

11. Insert snap lock pin (E) into rotating weldment to secure roll assembly.

12. Rotate roll assembly into position and lower handle (J).

Martin Engineering M3796-05/12 5 EVO® Return Roller

is located on operator side of conveyor.

Page 10

NOTE

J. Handle L. Cap Screw (2 used)K. Nut (2 used)

Installation

Do not tighten cap screws (L) into hanger bar. Handle (J) must

be able to be raised when replacing roll.

13. Loosen nuts (K) and adjust cap screws (L) to hold roll assembly

perpendicular to belt.

14. Tighten nuts (K).

15. Raise entire assembly up into belt 1 inch and tighten all cap screws and

nuts.

Martin Engineering M3796-05/12 6 EVO® Return Roller

Page 11

After Installing Return Roller

WARNING

!

DANGER

!

DANGER

!

1. Thoroughly wipe chute wall clean above tensioner.

2. Place Conveyor Products Warning Label (P/N 23395) on outside chute

wall visible to belt cleaner operator.

Failure to remove tools from installation area and conveyor

belt before turning on energy source can cause serious injury

to personnel and damage to belt.

After Installation

Do not touch or go near conveyor belt or conveyor accessories

when conveyor belt is running. Body or clothing can get

caught and pull body into conveyor belt, causing severe injury

or death.

3. Turn on conveyor belt for 1 hour, then turn off.

Before installing, servicing, or adjusting the conveyor

equipment, turn off and lock out/tag out all energy sources to

the conveyor and conveyor accessories according to ANSI

standards. Failure to do so could result in serious injury or

death.

4. Make sure all fasteners are tight. Tighten if necessary.

Martin Engineering M3796-05/12 7 EVO® Return Roller

Page 12

Weekly Maintenance

IMPORTANT

NOTE

DANGER

!

WARNING

!

DANGER

!

Weekly Maintenance

Read entire section before beginning work.

Maintenance inspection should be performed no less than

weekly. Some applications may require more frequent

maintenance inspections.

Before installing, servicing, or adjusting the conveyor

equipment, turn off and lock out/tag out all energy sources to

the conveyor and conveyor accessories according to ANSI

standards. Failure to do so could result in serious injury or

death.

1. Remove any material from return roller.

2. Make sure all fasteners are tight. Tighten if necessary.

3. Lubricate pivot bearings as necessary.

4. Wipe all labels clean. If labels are not readable, contact Martin

Engineering or a representative for replacements.

5. Remove equipment from service if there is any indication it is not

functioning properly. Call Martin Engineering or a representative for

assistance. Do NOT return equipment to operation until the cause of the

problem has been identified and corrected.

Failure to remove tools from maintenance area and conveyor

belt before turning on energy source can cause serious injury

to personnel and damage to belt.

6. Remove all tools from maintenance area.

Do not touch or go near conveyor belt or conveyor accessories

when conveyor belt is running. Body or clothing can get

caught and pull body into conveyor belt, causing severe injury

or death.

7. Start conveyor belt.

Martin Engineering M3796-05/12 8 EVO® Return Roller

Page 13

Part Numbers

This section provides part numbers for the EVO® Return Roller Assemblies.

Please reference part numbers when ordering parts.

EVO® Return

Roller Assembly

EVO® Return Roll Assembly: 24 to 72 in. (600 to 1800-mm) belts:

P/N UCRR-007000-XXX.

Part Numbers

Martin Engineering M3796-05/12 9 EVO® Return Roller

Page 14

5

14

9

7

15

11

12

13

3

8

4

6

19

18

21

2

10

20

22

17

1

16

A

A

Section A–A

Part Numbers

Figure 1. EVO® Return Roller, P/N UCRR-007000-XXX* (Sheet 1 of 2)

*First XX indicates belt width in inches; Next X indicates stringer type: E = EVO® Stringer, S = Standard Stringer;

Add an F to end of part number for frame only (no roller included).

Martin Engineering M3796-05/12 10 EVO® Return Roller

Page 15

Item Description Part No. Qty

1 Pivoting Weldment UCRR-007030-XX** 1

2 Telescoping Tube Weldment Table I 2

3 Bearing Roller 38505-01 2

4 Rotation Weldment UCRR-007020-XX** 1

5 Sliding Weldment UCRR-007010-XX** 1

6 Roll RR-D6-XX** 1

7 Extended Length Grease Fitting 1/8 NPT 38517 1

8 Plug 3 x 3 37302 1

9 Plug 3 x 3 with Hole 37302-2 1

10 Locking Kit Table I 1

11 Pin Cotter 1/8 x 1-3/4 ZP 14210 1

12 Cap Dust 38515-S 1

13 Washer Flat O.D. 1.75 I.D. 1.015 38513 1

14 Seal Bearing 38516-S 1

15 Nut Hex Slotted 38514 1

Part Numbers

16 Screw HHC 1/2-13NC x 1 ZP 13842 4

17 Pin Snap Lock 3/8 x 1-3/4 ZP 37126 1

18 Washer Flat 1/4 Wide ZP 15073 2

19 Tie Tab TMI-TT-100P 2

20 Clip Cable 28112 2

21 Screw Tapping HWH 1/4-20NC x 3/8 ZP 38608 2

22 Cable 1/16 Galvanized 102249 2

23 (NS) Label Kit UCRR-007070 1

24 (NS) Hardware Kit Table I 1

25 (NS) Operator’s Manual M3796 1

**XX indicates belt width in inches.

Figure 1. EVO® Return Roller, P/N UCRR-007000-XXX (Sheet 2 of 2)

Martin Engineering M3796-05/12 11 EVO® Return Roller

Page 16

Table I. Part Numbers for EVO® Return Roller

Part Number Item 2

UCRR-007000-24X 34743-03

UCRR-007000-36X 34743-01

UCRR-007000-42X 34743-01

Part Numbers

Part Number Item 11 Item 25

UCRR-007000-XXE UCRR-007060-E UCRR-007050-E

UCRR-007000-XXS UCRR-007060-S UCRR-007050-S

UCRR-007000-48X 34743-01

UCRR-007000-54X 34743-01

UCRR-007000-60X 34743-02

UCRR-007000-72X 34743-02

Martin Engineering M3796-05/12 12 EVO® Return Roller

Page 17

Lock out and/or tag out all energy sources to

Cierre y/o rotule todas las fuentes de energía al

Label P/N 23395

conveyor system and loading system before

performing any work on conveyor or conveyor

accessories. Failure to do so could result in

severe injury or death.

sistema transportador y al sistema de carga antes

de realizar cualquier trabajo en el transportador

o sus accesorios. El no hacerlo puede resultar

en heridas serias o muerte.

ADVERTENCIA

WARNING

!

!

Label P/N 30528

WARNING

!

ADVERTENCIA

!

pellizcar!

¡

Usted se puede

Pinch point!

Part Numbers

Figure 2. Conveyor Products Warning Label, P/N 23395

Martin Engineering M3796-05/12 13 EVO® Return Roller

Figure 3. Pinch Point Warning Label, P/N 30528

Page 18

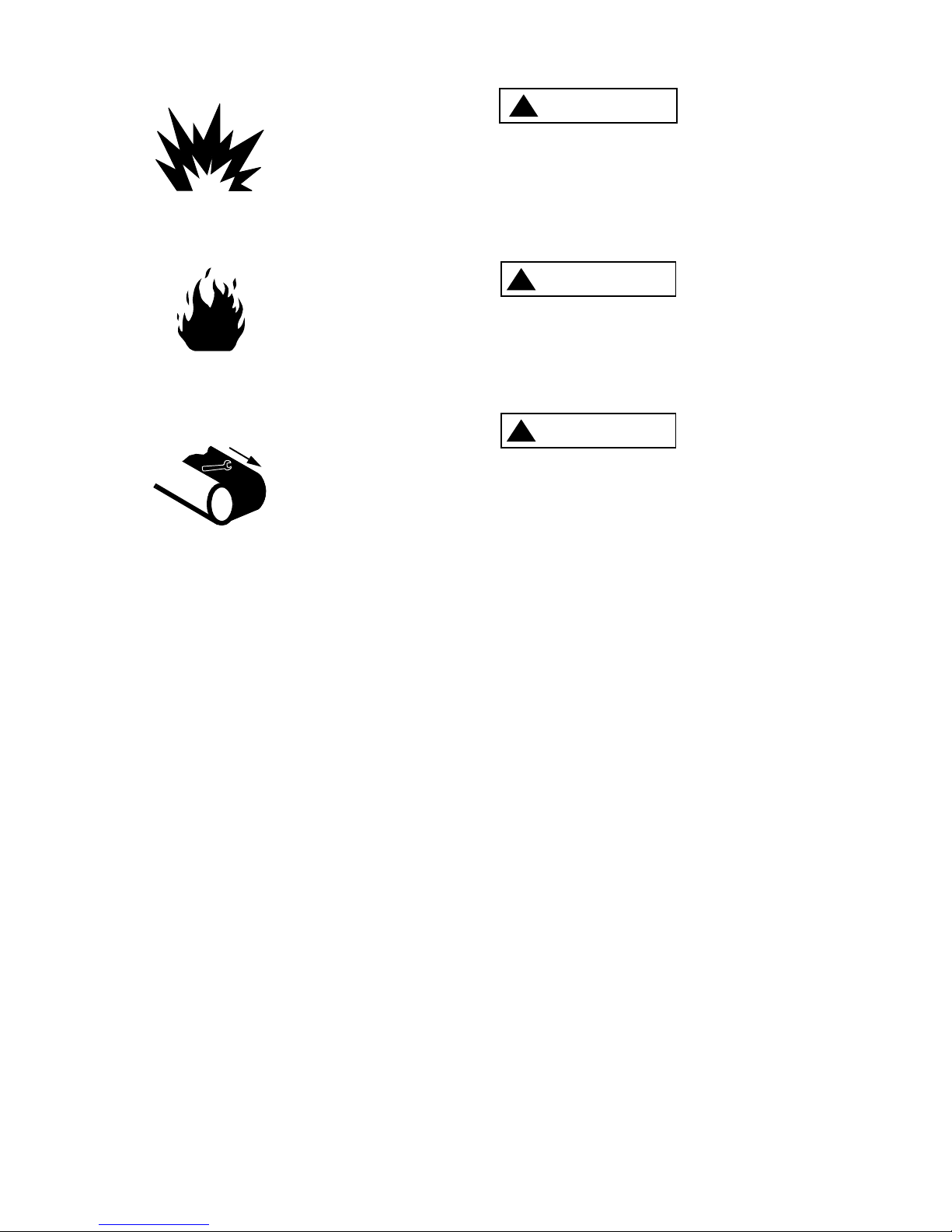

Dim. B

29.50

(749)

Dim. A

Standard Stinger

Dim. A

EVO

®

Stinger

5.20

(132)

3.00

(76)

Ø6.00

(152)

Part Numbers

Figure 4. EVO® Return Roller Dimensions

Part Number

UCRR-007000-24X 36 (914) 29 (737)

UCRR-007000-36X 48 (1219) 37 (940)

UCRR-007000-42X 54 (1372) 43 (1092)

UCRR-007000-48X 60 (1524) 47 (1194)

UCRR-007000-54X 66 (1676) 55 (1397)

UCRR-007000-60X 72 (1829) 51 (1295)

UCRR-007000-72X 84 (2134) 61 (1549)

Dim. A

in. (mm)

Dim. B

in. (mm)

Martin Engineering M3796-05/12 14 EVO® Return Roller

Page 19

Any product, process, or technology described here may be the subject of intellectual property rights reserved by

Martin Engineering Company. Trademarks or service marks designated with the ® symbol are registered with the U.S.

Patent and Trademark Office and may be proprietary in one or more countries or regions. Other trademarks and

service marks belonging to Martin Engineering Company in the United States and/or other countries or regions may

be designated with the “TM” and “SM” symbols. Brands, trademarks, and names of other parties, who may or may

not be affiliated with, connected to, or endorsed by Martin Engineering Company, are identified wherever possible.

Additional information regarding Martin Engineering Company’s intellectual property can be obtained at

www.martin-eng.com/trademarks

.

Page 20

Martin Engineering USA

One Martin Place

Neponset, IL 61345-9766 USA

800 544 2947 or 309 852 2384

Fax 800 814 1553

www.martin-eng.com

Form No. M3796-05/12 © Martin Engineering Company 2011, 2012

Loading...

Loading...