Page 1

e

r u o

e

d ie e

D r O nT W l ’s Q

t

s e

h

o

t

p r.o

™

10/2008

Martin Door Manufacturing® Salt Lake City, Utah 84127-0437 USA www.martindoor.com Printed in the USA Copyright 2008 ©

AD-IM42-05

This instruction manual features “Low Risk” Martin

Finger Shield Garage Doors

See page 7 for IMPORTANT INSTALLATION,

MAINTENANCE & SAFETY INSTRUCTIONS

MARTIN RESIDENTIAL TORSION DRIVE OPENER

R

E

M

G

R

I

I

S

F

T

D

E

E

R

ISO 9001A8949

MARTIN DOOR MFG.

ISO 9001

Quality

Standard

DC4600 for torsion spring doors up to 15' (4600) High Or up to 500 lbs. (227kg)

INSTRUCTION MANUAL

Complies

with

U.L. 325

TM

DOOR OPENERS

ARTI

N

M

Page 2

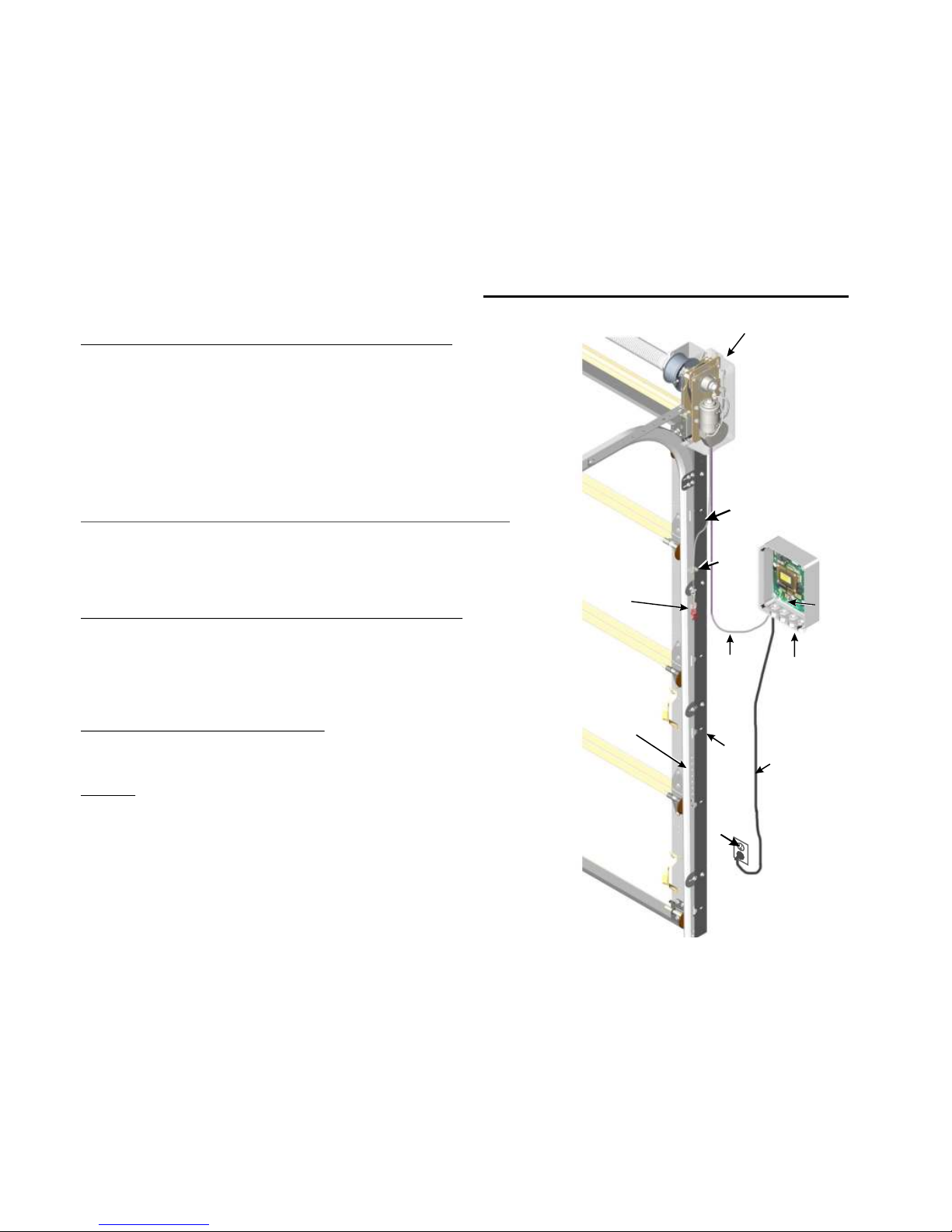

FIGURE 1

DC4600

CONTROL

BOX

ASSEMBLY

DC4600

MOTOR ASSEMBLY

RIGHT SIDE INSTALLATION

DC MOTOR

WIRING

HARNESS

POWER

CORD

6’(1800)

GROUNDED

WALL

OUTLET

CABLE

POST

BOWDEN

CABLE

PUSH BUTTON

EMERGENCY

RELEASE LEVER

AND MOUNTING

BRACKET

REVERSE

ANGLE

SHIELD

VERTICAL

TRACK

BOTTOM DOOR

SECTION

TOP DOOR

SECTION

COPYRIGHT © 2008 MARTIN DOOR

2

Motor Assembly See Figures 2a, 2b, 12, 47 and Step 1

DC Motor with Reduction Gear

Motor Pulley

Torsion-Shaft Pulley with Set Screws

Drive Belt

Drive Belt Tensioning Plate

Back Plate

Front Plate

Front and Back Motor Cover

Anti-torque Arm with Bolts, Spacer, Nut

Emergency Release Assembly See Figures 6a to 9b and Step 2

Emergency Release Lever with Bracket

Bowden Cable with Cable Post and D-Shackle

Screw Hook with Lock Nut

Chain Extension Package

Control Box Assembly See Figures 10a, 10b and Step 3

Control Box with Screws, Conduit Outlets

Control Box Lid With Screws and Push Button

Circuit Board with Transformer, etc.

Low Voltage DC Motor Wiring Harness

6’ (1830) Power Cord with 3-Prong Plug

Radio Control Assembly See Step 5

Radio Receiver with optional 4 cond. wire (blue, green red, white)

2-Button Transmitter (mini)

Options

2-Button Transmitter (mini)

3-Button Transmitter (keychain - micro)

4-Button Transmitter (mini)

Mounting Plate (Pocket) for Transmitter (mini)

Wireless Keyless Entry

Battery Back-up

Automatic Solenoid Lock with Side Lock Module

Door Bell Type Push Button with Wiring

Keyswitch

DOOR OPENER INCLUDES:

DC4600 - REGULAR LIFT

Page 3

COPYRIGHT © 2008 MARTIN DOOR

3

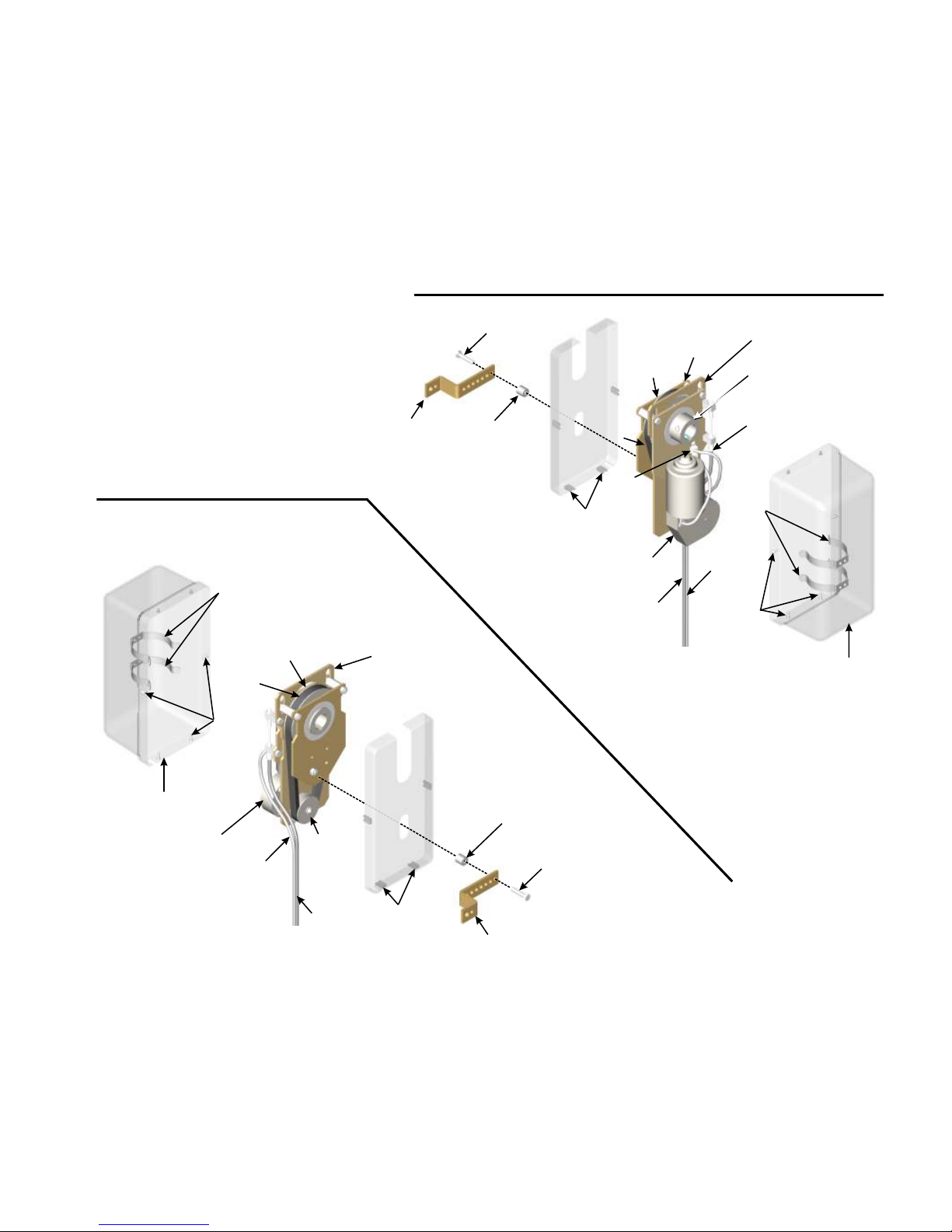

FIGURE 2a

LEFT SIDE INSTALLATION

FIGURE 2b

RIGHT SIDE INSTALLATION

DRIVE BELT

TENSIONING PLATE

DRIVE BELT

TORSION SHAFT

PULLEY

B

A

CK

P

A

T

L

E

BOWDEN

CABLE

FRONT COVER

MOTOR BARREL

CLIPS

DC MOTOR

WIRING

HARNESS

REDUCTION

GEAR

FRONT MOTOR COVER

BACK

M

OT R

O

V

E

R

C

O

MOTOR PULLEY

ANTI-TORQUE ARM

SPACER

HEX HEAD BOLT

B

A

CK

M

O

T

OR

CO

VER

SMALL

CLIPS

BACK PLATE

DRIVE BELT

TENSIONING PLATE

DRIVE

BELT

TORSION

SHAFT

PULLEY

MOTOR

COVER

SCREWS

TORSION SHAFT PULLEY

SET SCREWS

BOWDEN

CABLE

BOWDEN

CABLE

FRONT

COVER

MOTOR

BARREL

CLIPS

REDUCTION

GEAR

FRONT MOTOR COVER

MOTOR

ASSEMBLY

PLUG-IN

TERMINAL

DC

MOTOR

WIRING

HARNESS

DC

MOTOR

SPACER

HEX HEAD BOLT

SMALL

CLIPS

MOTOR

COVER

SCREWS

ANTI-TORQUE ARM

Page 4

2” (51)

FIGURE 8a

FIGURE 6a FIGURE 6b

FIGURE 8b

COPYRIGHT © 2008 MARTIN DOOR

FIGURE 9a

FIGURE 7a FIGURE 7b

FIGURE 9b

2” (51)

EMERGENCY RELEASE ASSEMBLY

BOWDEN

CABLE

CABLE

POST

OUTER

SHEATH

D SHACKLE

REVERSE

ANGLE

SHIELD

REVERSE

ANGLE

SHIELD

OPTIONAL

EXTENSION

CHAIN

D SHACKLE

AFTER

FASTENING,

BOWDEN

CABLE

HAS SLACK

BOWDEN CABLE FASTENED TO VERTICAL TRACK - REGULAR LIFT DOORS BOWDEN CABLE FASTENED TO DOOR JAMB - VERTICAL/HIGH LIFT DOORS

D SHACKLE

OPTIONAL

EXTENSION

CHAIN FOR

HIGH DOOR

HIGH LIFT

OR

VERTICAL

LIFT TRACK

LAG

SCREWS

CABLE

POST

OUTER

SHEATH

MARK HOLES

DOOR

JAMB

DOOR

JAMB

AFTER

FASTENING,

BOWDEN

CABLE

HAS SLACK

HIGH LIFT

OR

VERTICAL

LIFT TRACK

LAG

SCREWS

EMERGENCY RELEASE LEVER SCREW HOOK ON D SHACKLE EMERGENCY RELEASE LEVER SCREW HOOK ON EXTENSION CHAIN

REVERSE

ANGLE

SHIELD

LOCK NUT

D SHACKLE

SCREW

HOOK

REVERSE

ANGLE

SHIELD

EMERGENCY

RELEASE

LEVER AND

MOUNTING

BRACKET

EXTENSION

CHAIN

SCREW

HOOK

LOCK NUT

REVERSE

ANGLE

SHIELD

EMERGENCY

RELEASE

LEVER AND

MOUNTING

BRACKET

EMERGENCY

RELEASE

LEVER AND

MOUNTING

BRACKET

EMERGENCY

RELEASE

LEVER AND

MOUNTING

BRACKET

VERTICAL

TRACK

VERTICAL

TRACK

D SHACKLE

SCREW

HOOK

REVERSE

ANGLE

SHIELD

EXTENSION

CHAIN

SCREW

HOOK

VERTICAL

TRACK

VERTICAL

TRACK

VERTICAL

TRACK

VERTICAL

TRACK

VERTICAL

TRACK

4

ATTENTION! THE OPENER CANNOT LEARN IF THE DRIVE BELT TENSION SLIPS

OPTIONAL

EXTENSION

CHAIN FOR

HIGH DOOR

MARK

AND DRILL

7/32” (5)

HOLES

Page 5

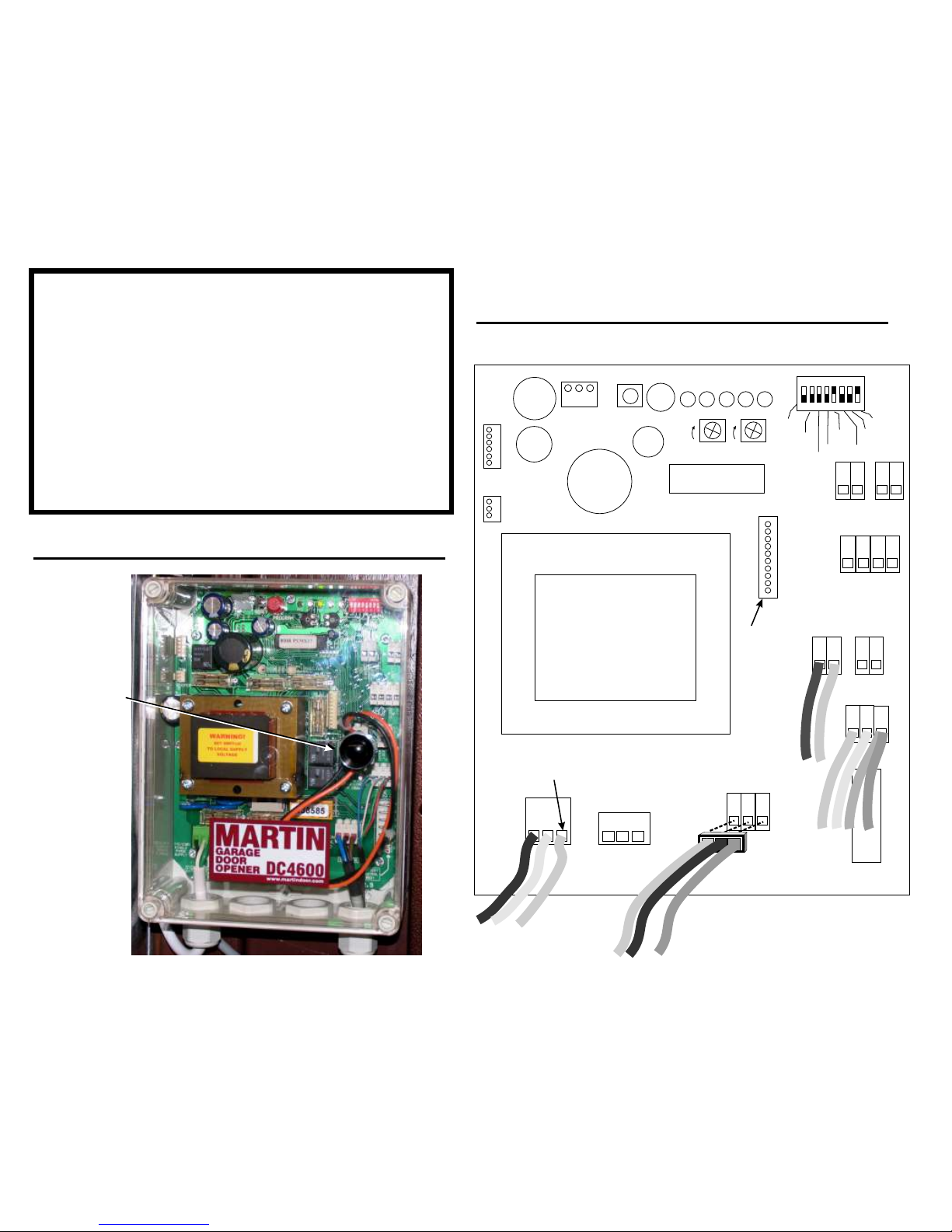

DC 4600 CONTROL BOX ASSEMBLY

FIGURE 10b

12 V

2 WIRE

PHOTO

EYE

COM

MOT

24V

GND

MARTIN

DC 4600

LD1 LD2 LD3 LD4 LD5

ACK SFTY PWR CLSNG OPNG

ON APEM

1 2 3 4 5 6 7 8

INC

STD

SAFETY

12 V

PHOTO

EYE

I/LOCK

O/RIDE

LIGHT

MODE

PROGRAM

RESET

CLOSE

SENSITIVITY

MAX POWER

N/C

BEEPER

TEST

RX

SKT

GND

DATA

+5V

V2

RL5

RL6

COPYRIGHT © 2008 MARTIN DOOR

5

G

reen

LIGHT

lackB

h

W ite

The Martin DC4600 Intelligence

FIGURE 10a

OPEN

STOP

COM

CLOSE

ACCESSORY

DOCK

GROUND

DC 4600 CIRCUIT BOARD

PUSH

BUTTON

GND LIVE N

Wh tei

115/230 V

SINGLE

PHASE

SUPPLY

DC MOTOR

M2 S1 M1

INTER

LOCK

COM

SAFETY

COM

15V

eOrang

COM

MODULE SOCKET

24V

RLY

GND

Red

Gr ene

h tW ie

Blue

AUTO

MOTOR

POLARITY

STOP

BUTTON

O/RIDE

SAFETY

MODE

1. The open limit is set automatically as the garage door reaches

opened position allowed by the cable drums or optional bumper springs.

The close limit is set automatically as the garage door touches the floor.

2. The opener’s computer will memorize the limits after two complete

cycles, during which time the motor may run slower than normal.

3. After the two complete cycles the garage door will “soft start” and “soft

stop” as it opens and closes.

4. The opener’s computer will reverse the closing door if it contacts an

obstruction 1”(25) high or more above the floor.

5. The opener’s computer will stop the door if it contacts an object in the

open cycle.

the fully

Blue

Br now

Black

INC

Black

CYCLE SW

ACCESSORY

RADIO

TRANSFORMER

Page 6

PREPARATION

Correct all “High Risk” areas on the garage door

before installation of the new Martin Torsion Drive

Opener. If unable to correct, replace garage door with

a new Martin Garage Door. See Back Page

Decide if the Motor Assembly will be mounted to the

right side or left side of the garage door.

The Torsion Tube/Shaft protrudes 5”(130) beyond the

lock-on/side bearing bracket. (Motor Assembly side

clearance requires an extra 4.5”(114) beyond the end

of the tube/shaft.) See Figure 12, 13

A qualified electrician should install a grounded

electrical outlet within 5’(1520) of the Control Box

Assembly location according to local codes.

See Figure 1

Make sure the garage door is properly balanced, the

moving steel parts properly lubricated, and the jambs

waxed where the garage door rubs. The door should

work free and easy as it opens and closes. Please call

a trained Martin Dealer if you have a problem or do not

understand.

The garage door should be at least 5’(1520) high.

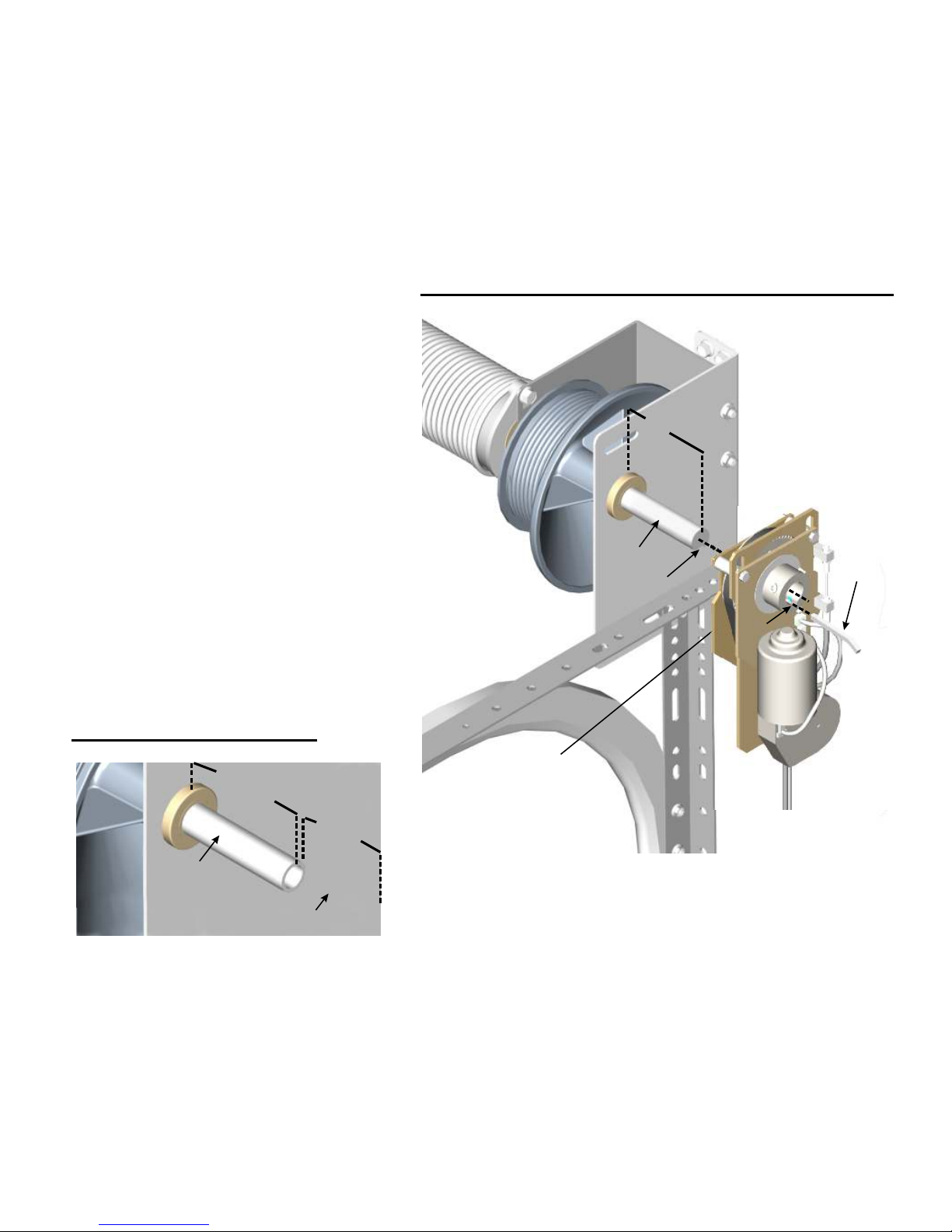

FIGURE 12 (Solid Shaft)

FIGURE 13 (Torsion Tube)

5”

(130)

TORSION SHAFT

PULLEY

SOLID

SHAFT

SOLID

SHAFT

KEY-WAY

SOLID

SHAFT

KEY

KEYWAY

6

COPYRIGHT © 2008 MARTIN DOOR

TORSION

TUBE

5”

(130)

4 ½ ”

(114)

SIDE CLEARANCE

DC MOTOR

Page 7

THE FOLLOWING ITEMS ARE HELPFUL TO COMPLETE A SATISFACTORY MARTIN GARAGE DOOR AND OPENER INSTALLATION:

Hammer

Level (magnetic)

Hacksaw

Wire Cutters

18’ (5500) Measuring Tape

Socket Wrench set for 7/16” (11), and 9/16” (14) with 3” (76) Extension

Regular and Phillips Screwdriver

End Wrench set for 13/32”(10), 7/16” (11), and 9/16” (14)

10/40 Motor Oil Lubricant

Wax Lubricant (paraffin, candle, etc.)

Cordless Drill with 1/8“ (3), 13/64” (5), 1/4” (6) Bits

plus 1/4” and 3/8” (6 and 10) Masonry Bits

Step Ladder (not shown)

Pencil

Punched Angle Opener Hanger: 8' X 1-1/4" X 1-1/4" (2440 X 32 X 32)

Needle Nose Plier and Wire Stripper.

NOTE: Bolts, lock nuts and lag screws for fastening the punched angle are

furnished with the door opener hardware fasteners.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

2.

3.

6.

9.

WAX LUBE

10/4

0

O

MT

O R

OIL

11.

10.

4.

1.

7.

M

T

R

S

A

O

D

A

G

E

R

O

G

ITAR

M

N

14.

8.

6.

5.

13.

ALL MEASUREMENTS IN

PARENTHESIS ( ) ARE

MILLIMETERS IN THIS

INSTRUCTION MANUAL.

!

IMPORTANT

INSTALLATION INSTRUCTIONS

Do not install this opener or any other opener on "HIGH RISK" garage doors that may cause severe injury, entrapment or death!

See back page for serious injuries which may occur if “HIGH RISK” areas are left uncorrected.

Martin Finger Shield Garage Doors are “Low Risk”.

Untrained or Negligent Installing, Adjusting and Servicing can be Dangerous! The

garage door springs and related parts can cause serious injury or death! IF YOU ARE

UNSURE, CALL A TRAINED MARTIN DOOR DEALER!

Garage door should be balanced and easy to open and close by hand.

Locks should be disabled and pull down ropes should be removed.

Locate the control box/push button within sight of door, at min. height of 5' (1520) so

small children cannot reach it, and away from all moving parts of door.

Emergency release lever should be installed and adjusted to about 6' (1830) above

the floor. Monthly check that the lever angle is correct. See page 4, 9

Risk of electrical shock is explained in Step 3. Do not connect opener to source of

power until instructed to do so.

Entrapment and warning labels should be installed next to the control box/push

button.

Where possible install opener 7’(2135) or more above the floor.

IMPORTANT

MAINTENANCE & SAFETY INSTRUCTIONS

Monthly, check the opener's down cycle safety reverse. The door must reverse when it contacts

a 1 1/2" (38) high object (or a 2X4 board laid flat) on the floor. A closing door must also reverse

if the optional photo eyes are interrupted.

Always keep the moving door in sight and away from people and objects until it is

completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR

Do not allow children to operate or play with the garage door opener controls. Keep all

remote control transmitters away from children.

The emergency release should only be used when garage door is in the closed position.

Weak or broken springs may cause door to fall if released in the open position, increasing

the risk of severe injury or death. Use caution when using the release with door open.

Monthly visually check the lift cables, spring assembly, hardware, etc. for wear and stability.

If the Safety Reverse or any other part of the garage door and opener system do not work

properly, or if you do not understand, call a trained Martin Door Dealer.

TO REDUCE THE RISK OF SEVERE INJURY OR

DEATH, READ AND FOLLOW ALL INSTRUCTIONS

SAVE THESE IMPORTANT INSTRUCTIONS

15.

COPYRIGHT © 2008 MARTIN DOOR

7

Page 8

FIGURE 18 (Solid Shaft)

INSTALLATION INSTRUCTIONS FOR

MARTIN RESIDENTIAL TORSION DRIVE DOOR OPENERS

THESE INSTRUCTIONS ARE INTENDED FOR PROFESSIONAL GARAGE DOOR OPENER

INSTALLERS. READ THROUGH THE COMPLETE INSTRUCTION, MANUAL,

SPECIFICATIONS AND APPLICABLE OPTIONAL INSTRUCTIONS BEFORE BEGINNING.

STEP 1

INSTALLING THE MOTOR ASSEMBLY

Study "PREPARATION” on page 6 and “INTELLIGENCE” on page 5.

Install back motor cover on torsion tube. See Step 8

Slide the motor assembly on the torsion tube/shaft. If the torsion shaft is solid, align the key-

ways and insert the key provided. See Figures 12, 17, 18

Decide what holes to use and where the anti-torque arm will be fastened to the horizontal track

angle (the arm may be reversed for convenience), bearing bracket, etc. and to the back plate of

the motor assembly with the 10mm hex head bolt and 1/2”(13) spacer. Fasten the 10mm hex

head bolt and 1/2”(13) spacer through the back motor cover into the back plate of the motor

assembly. See Figures 2a, 2b, 14, 15, 17

Position motor assembly close to horizontal track angle, plumb, level and square (vertically).

Fasten tight the long and short end of the anti-torque arm.

Tighten the three 10mm set screws, in the torsion-shaft pulley, of the motor assembly with

allen wrench provided. Do not use a manual rachet or power allen wrench driver. Tighten

as tight as necessary by hand only.

COPYRIGHT © 2008 MARTIN DOOR

FIGURE 17 (Torsion Tube)

FIGURE 14 FIGURE 15

8

TORSION

TUBE

SOLID

SHAFT

SOLID

SHAFT

KEY

ANTI-TORQUE ARM

ANTI-TORQUE ARM

ANTITORQUE

ARM

HORIZONTAL

TRACK

ANGLE

ALLEN

WRENCH

10 MM HEX

HEAD BOLT

1/2” (13)

SPACER

1/2” (13)

SPACER

1/2” (13)

SPACER

10 MM HEX

HEAD BOLT

1/2” (13)

SPACER

BACK

MOTOR

COVER

BACK MOTOR

COVER

BACK

MOTOR

COVER

FRONT

MOTOR

COVER

SET

SCREW

Page 9

REVERSE

ANGLE

SHIELD

SCREW

HOOK

EMERGENCY

RELEASE

LEVER AND

MOUNTING

BRACKET

VERTICAL

TRACK

BOWDEN

CABLE

D SHACKLE

VERTICAL

TRACK

MARK

AND DRILL

7/32” (5)

HOLES

MARK

AND DRILL

7/32” (5)

HOLES

2” (51)

BOWDEN

CABLE

CABLE

POST

OUTER

SHEATH

D

SHACKLE

REVERSE

ANGLE

SHIELD

EXTENSION

CHAIN

3”(76)

FOR DC7000CH

FIGURE 21

STEP 2

INSTALLING THE EMERGENCY RELEASE ASSEMBLY

Fasten the cable post which is fastened to the outer sheath of the bowden cable

to the vertical track or track bracket, etc., with the two flat head 7/32" (5) screws

and nuts provided. (If fastened to the jamb, use optional 2 1/2”(64) long hex head

lag screws.) Allow at least 2" (51) slack to the outer sheath of the bowden cable.

Mark and drill two 7/32" (5) holes. See Figures 6a to 7b, 21

Place screw hook in D-shackle at end of bowden cable or at the end of the

extension chain. See Figures 8a to 9b, 21

The Emergency Release Lever should be about 5’ - 6' (1830) above the floor. If

the Bowden cable is not long enough, a short piece of chain (optional) should be

used.

Mark and drill two 7/32” (5) holes in the vertical track or track bracket, etc., with

the emergency release lever at an 85° angle, never less than 90°. Fasten

emergency release lever with mounting bracket using two 7/32” (5) flat head

screws and nuts provided. See Figures 8a to 9b, 20a, 20b, 21

The Bowden Cable should be taut when the emergency release lever is at an 85°

angle. Adjust the screw hook as necessary, then tighten the lock nut. Push the

emergency release lever down. Drill new holes and remount if required.

When the emergency release lever (RED) is pushed down, the drive belt

tensioning plate moves, tightening the drive belt on the motor and torsion shaft

pulley. The garage door opener will not function without proper drive belt

tension. The computer cannot learn if drive belt slips. Pushing the

emergency release lever up or down, disconnects or connects the garage door

opener to the garage door. The garage door should be closed when

connecting or disconnecting the Emergency Release Lever. Following a

power outage etc, disconnect the power from the control box for 30

seconds. After reconnecting the power, open and close garage door two or

more complete cycles (door may run slow). The computer should restore the

original open and close positions without a calibration reset. See Step 4 for

calibration reset

Note: The emergency release lever is first set at an 85° angle before

engaging, because the chain, cable, belt, etc. will slightly stretch

during the first few cycles. NEVER ALLOW THE EMERGENCY

RELEASE LEVER TO BE MORE THAN 90° WHEN DISENGAGED

WITH THE BOWDEN CABLE TAUT. CHECK DRIVE BELT FOR

PROPER TENSION AFTER ONE MONTH OF USE.

SEE FIGURES 8a to 9b, 20a, 20b, 21

FIGURE 20a 85°

COPYRIGHT © 2008 MARTIN DOOR

9

FIGURE 20b 90°

BOWDEN CABLE AND EMERGENCY RELEASE LEVER FASTENED

TO VERTICAL TRACK - REGULAR LIFT DOORS SEE PAGE 4 FOR

OTHER MOUNTING OPTIONS

ATTENTION! THE OPENER COMPUTER CANNOT LEARN

IF THE DRIVE BELT SLIPS

New Installation After One Month

1/16” THREADS SHOWING1/16” THREADS SHOWING

THE DRIVE BELT MAY NEED

TO BE TIGHTENED IF:

1. The opener does not

instantly turn off when

the door is fully open

or closed.

2. The door opener reverts

to continuous “slow

speed” learning mode.

3. The door can be easily

moved by hand with

the opener off.

4. The opener computer

loses its program.

5. The newly installed

opener has been used

for one month.

6. The door has been

opened and closed more

than 5000 times (cycles).

Page 10

STEP 3

INSTALLING THE CONTROL BOX ASSEMBLY

Fasten the control box to the wall about 5' (1520) from the ground with screws.

The holes are in the corner pillars, which are outside the water resistant gasket of

the control box. See Figures 1, 24 Because the push button is mounted in the

control box lid, the control box should be mounted within sight of the garage door,

clear of all moving garage door parts.

ATTENTION! The control box is water resistant. Do not drill holes in the control

box! Route all wires through the conduit outlets at the bottom of the control

box. Dress wiring tight and straight, using ties, staples or other means.

See Figures 23, 24

Temporarily fasten the control box lid to the left or right side, above or below the

control box to prevent it from hanging by the push button wires during the setup

process. See Figures 23, 24 The push button should only be used when the

garage door area is free of people or any obstructions.

Plug the three wire low voltage DC motor wiring harness, if not plugged in, into the

terminal block at the bottom right hand side of the circuit board that is marked "DC

Motor". See Figures 10b, 26a, 26b. Plug the opposite end into the three way

terminal in the motor assembly. See Figures 2b, 27. Do not cut or shorten excess

wiring. Coil excess wire and tie away from moving parts.

See Figure 28

FIGURE 25

COPYRIGHT © 2008 MARTIN DOOR

FIGURE 28

FIGURE 23 FIGURE 24

10

FIGURE 27

FIGURE 26a

FIGURE 26b

Page 11

FIGURE 30

***STEP 3 CONTINUED***

The control box assembly includes a 6’(1800) power cord with a

three prong plug. The third prong is ground. To reduce the risk of

electric shock do not alter or change plug or outlet in any way. Do not

try to conceal or staple the power cord or try to rout it through a door

way, window, wall, ceiling, floor, etc. The power cord must be routed

away from moving parts.

Also see “WARNING” On page 12.

Wait until Step 4 before plugging the power cord into the grounded

electrical outlet.

DO NOT PINCH WIRING! The door opener will not work properly

with damaged wiring.

DIP Switch Positions. See Figure 10b, 30, 31

Observe the factory set positions of each dip switch in the upper

right hand corner of the circuit board.

Sw1 Safety Mode Off/Normally Closed

Sw2 Standard Safety Off (On for photo-eyes, etc.)

Sw3 12 Volt Photo-eye Off (On for photo-eyes, etc.)

Sw4 Auto Close Off (N/A in North America)

Sw5 Inter-Lock Over-Ride On (Off for inter-lock lock-out switch)

Sw6 Lighting Mode Off (On eliminates light delay timer)

Sw7 Motor Polarity On/Off (as required)

Sw8 Stop Button Over-Ride On

See Figures 30, 31

COPYRIGHT © 2008 MARTIN DOOR

11

ACK = Acknowledge

SFTY = Safety

PWR = Power

CLSNG = Closing

OPNG = Opening

L.E.D. = Light Emitting Diode

Abbreviations

RLY = Relay

V = Volt

N = Neutral

COM = Common

GND = Ground

TX = Transmitter

RX = Receiver

FIGURE 31

ON APEMs

1 2 3 4 5 6 7 8

STD

SAFETY

12 V

PHOTO

EYE

I/LOCK

O/RIDE

LIGHT

MODE

N/C

AUTO

MOTOR

POLARITY

STOP

BUTTON

OVER-RIDE

SAFETY

MODE

***CLEARING SERVICE DUE REMINDER INSTRUCTIONS***

At 1500 cycles, the opener may turn on a “service due reminder”

(delay to close). To disable do the following:

Turn off the power (or press and hold the reset button)

Press and hold the case lid button

Turn on the power (or release the reset button)

Release the case lid button after ACK flashes three times

Note the two confirmation ACK flashes

Page 12

FIGURE 40

STEP 4

CONNECTING OPENER TO POWER

(All basic and accessory wiring should be completed)

Plug the 6’(1830) power cord into a 10 amp minimum, grounded electrical outlet. Observe the L.E.D.

Light #3 PWR illuminates at top of circuit board. If no outlet is available or if power will be wired in direct,

contact a qualified electrician. Notice that the power cord wires are connected into the green “main”

terminal at the bottom of the circuit board. Observe LIVE, N, and GND. See Figures 10a, 10b, 40

WARNING! To help prevent electrocution, death, fire, etc, the installation of wiring and approved

grounded electrical outlet must be done in accordance with local electrical and building codes. DO

NOT USE AN EXTENSION CORD. DO NOT USE A 3-PRONG TO 2-PRONG PLUG ADAPTER.

Also see “The Control Box ” on page 11.

Push emergency release lever up to disconnect opener from garage door.

Manually open garage door about 3' (915).

Push emergency release lever down to reconnect opener to garage door. Press push button.

COPYRIGHT © 2008 MARTIN DOOR

12

Note: The door may move slow while the computer learns the open and close limits.

Following power outage etc., disconnect power from the control box assembly with the door

closed.Reconnect power. If the door performs incorrectly after three cycles, perform a calibration reset

with the door closed.

Calibration Reset

Press and hold reset button.

Press and hold program button.

Release reset button. Wait and observe that the L.E.D. #1 ACK blinks.

Release Program Button. Observe that the L.E.D. #1 ACK blinks

twice, confirming Calibration Reset. See Figure 41

The computer cannot learn if the drive belt slips. See Step 2

IF DOOR OPENS:

and LED light #5 OPNG illuminates

Press push button to stop door

Unplug power cord or turn off power

Push emergency release lever up

Manually close garage door

Push emergency release lever down

Plug in power cord or turn on power

Press push button to open door

Open and close door two complete cycles

IF DOOR CLOSES:

Press push button to stop door

Unplug power cord or turn off power

Push Emergency Release Lever up

Manually close garage door

Push emergency release lever down

Move dip switch #7 to the opposite position

Warning! Never move dip switch #7 with power on.

Plug in power cord or turn on power

Press push button to open door

Open and close door two complete cycles

FIGURE 41

THE DRIVE BELT MAY NEED TO BE TIGHTENED IF:

1. The opener does not instantly turn off when

the door is fully open or closed.

2. The door opener reverts to continuous “slow

speed” learning mode.

3. The door can be easily moved by hand with

the opener off.

4. The opener computer loses its program.

5. The newly installed opener has been used

for one month.

6. The door has been opened and closed more

than 5000 times (cycles).

Page 13

STEP 5

RADIO CONTROL AND EXTRA PUSH BUTTON

Radio Receiver

Remove the cover. Mount the receiver on the wall, next to the control

box assembly. See Figure 33

Route the receiver wires up through the conduit outlet in the control

box and plug the three labeled wires to the terminals marked 24V, RLY,

and GND. The terminal is marked ACCESSORY RADIO.

See Figure 32

Connect the blue wire to 24V, white wire to RLY, green and red wire to

GND. See Figure 32

To Program first transmitter press and hold button TA1 on receiver

circuit board. See Figure 33

After three or four seconds the LED will blink for about ten seconds.

During the ten seconds press and hold transmitter button until the

LED illuminates. Release transmitter button and observe that the LED

turns off. Test transmitter. See Figure 33

To delete the transmitter memory in the receiver, press and hold

button TA1 ten seconds. The LED will blink a few times and then

illuminate. Release the button.

Antenna

The 315 MHZ receiver antenna wire on the radio receiver is about

13”(340) long and can have multiple arrangements for the best

distance. In a normal installation the distance from the transmitter to

the antenna wire should be 50’ to 150’(15240 to 45720). Do not

lengthen or shorten the antenna wire.

NOTE: The Distance from the transmitter to the antenna may be

reduced by electrical interference or spherical disturbances in the

area, various lights or transformers in and out of the garage, automatic

sprinkler system timers, various audible or inaudible sounds, noise,

radio signals in the area, concrete, steel or lead in and around the

garage, antenna wire touching metal, etc.

External Push Button

Fasten additional white w/ black stripe and white wires to Case Button

terminal, in parallel with existing box cover lid push button wires.

Fasten other end of wires to the external push button. See Figure 32

COPYRIGHT © 2008 MARTIN DOOR

FIGURE 33

FIGURE 32

13

TA1

LED

ANTENNA

WHITE, RED, GREEN, BLUE WIRES

3 24V

2 RLY

1 GND

ACCESSORY

RADIO

CYCLE SW

COM

CASE

BUTTON

PUSH

BUTTON

TO CONTROL BOX

LID PUSH BUTTON

NC

1

N

O

1

C

OM1

I

N1

I

N2

Page 14

FIGURE 34

***STEP 5 CONTINUED***

TRANSMITTERS

THE BATTERY:

Pry transmitter apart using a small coin to expose battery. The 3 Volt #CR2032 battery is

shown. Battery may last 4 to 5 years. See Figure 34

TRANSMITTER MOUNTING CHOICES:

Transmitter can be carried alone, attached to a key chain, attached to the visor clip or

attached using the optional mounting plate. See Figures 34, 35, 36

MULTIPLE TRANSMITTERS:

Each transmitter has been factory programmed with different private security codes. For

your information there are 284 trillion different codes. 2-channel transmitters have 2

different codes. 4-channel transmitters have 4 different codes. Additional transmitters

that come with the opener or are purchased separately as accessories have their own

different codes that must be changed to match your first transmitter.

Connect the programming tine to both transmitters. See Figures 36, 37, 38 and 39

Press and hold button on your present transmitter. Indicator light will illuminate. While still

holding the 1st transmitter button, press and hold the button on the new or second

transmitter. Code transfer will occur in approximately 2 seconds when the indicator light

will blink and then illuminate on the new transmitter. See Figure 39

The 315 MHz transmitters are “Home Link” compatible. Follow instructions furnished in the

automobile owners manual for non-rolling code applications.

TRANSMITTER OPERATION:

Press button until garage door begins to move. The indicator light on the transmitter will

illuminate. Press button at any time during travel to stop the garage door.

FIGURE 35

FIGURE 36

FIGURE 37

SNAP VISOR CLIP INTO SOCKET

FIGURE 38 FIGURE 39

FCC Certified: This device complies with Part 15 of the FCC rules. Operation is subject to the following two conditions: (1) This device may not

cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the equipment.

MINI

TRANSMITTER

PRESENT

TRANSMITTER

NEW OR SECOND

TRANSMITTER

PRESENT

TRANSMITTER

NEW OR SECOND

TRANSMITTER

INDICATOR

LIGHT

MARTIN MARTIN

MARTINMARTIN

PRESENT

TRANSMITTER

NEW OR SECOND

TRANSMITTER

INDICATOR

LIGHT

MARTIN

COIN

VISOR CLIP COVER

(REMOVE SMALL

COVER TO EXPOSE

VISOR CLIP SOCKET)

VISOR CLIP SOCKET

PROGRAMMING

TINE

MINI TRANSMITTER

BACK

BATTERY

(#CR2032)

MINI TRANSMITTER

FRONT

CIRCUIT BOARD

3 BUTTON MICRO

TRANSMITTER

(OPTIONAL)

4 BUTTON MINI

TRANSMITTER

(OPTIONAL)

M RT N

A I

SCREW

MOUNTING PLATE

POCKET (OPTIONAL) MAY BE

USED AS A WALL CONTROL ETC.

MINI

TRANSMITTER

PROGRAMMING

TINE

PROGRAMMING

TINE

PROGRAMMING

TINE

MARTIN

TRANSMITTER

COPYRIGHT © 2008 MARTIN DOOR

14

Page 15

FIGURE 44

STEP 6

TESTING THE GARAGE DOOR OPENER SYSTEM

Press the push button to open door. Observe that LED #5

OPNG illuminates as the garage door opens. The garage door

will stop when it reaches the full open position allowed by the

cable drums or optional bumper springs. Press the push button to

close the door. Observe that LED #4 CLSNG illuminates as the

garage door closes. The garage door will stop when it reaches

the floor. If OPNG or CLSNG light does not go out when door

stops, the belt tension may need to be adjusted (Max Power and

Close Sensitivity may also need adjusting). See Figure 43

Open and close garage door two more complete cycles.

Observe the movement of the garage door as the computer

memorizes the open and close position. You may notice that

LED #1 ACK illuminates from time to time. The garage door

opener system now provides “soft start” and “soft stop” as the

door opens and closes. See Figure 43

Do Not touch the following settings unless you are sure.

Force Setting: MAX POWER is factory set at one o’clock. Force

can be slightly increased by turning screw clockwise 10 degrees

at a time. See Figure 10b, 43

Sensitivity Setting: CLOSE SENSITIVITY is factory set at one

o’clock. Sensitivity can be increased by turning screw clockwise

10 degrees at a time. See Figure 10b, 43

Place a 1 1/2”(38) high object (or a 2X4 laid flat) on the floor,

under the door. When the closing door contacts the object, it

should stop, reverse, and automatically return to the open

position. See Figure 44

If the door does not reverse, the drive belt may be slipping. After

correcting drive belt tension and the door still does not reverse,

call a trained Martin Door dealer. See Step 2

STEP 7

INSERT INSTRUCTION MANUAL INTO PACKET

Fold and Insert instruction manual into the packet located on the

#3 door section of the Martin garage door or mount to the wall.

An Important safety/instruction label is included with opener

package. This label and the instruction manual must be fastened

inside your garage where they can be easily seen. Fasten them

next to the wall control box. Peel off the protective backing, and

press onto smooth, clean surface. Tacks or additional adhesive

may be necessary. DO NOT REMOVE OR PAINT OVER ANY

LABELS. See Figures 45, 46

COPYRIGHT © 2008 MARTIN DOOR

15

FIGURE 43

FIGURE 46

!

8/2001

AD-01IM-03

INSTRUCTION MANUAL

For all Residential Garage Doors up to 12’ (3700) High.

GGARA E

DOOR

N

OPE ER

S

IN T

RUC

TION

L

MANUA AND

NWARI NG

L EAB L

T F

L A PMAR IN INGER SHIE D G RAGE DOOR AND O ENER SYSTEM

S A IN TRUCTION M NUALS AND WARNING LABEL

T E (FAC ORY PACKAG D AND MOUNTED)

CONTROL

BOX

ASSEMBLY

AND PUSH

BUTTON

MOTOR ASSEMBLY

TM

DOOR OPENERS

ARTI

N

M

FIGURE 45

A KET P C

(F T M N E )AC ORY OU T D

L DFO D AN

IN T SER

IN UC N STR TIO

MANU AL

INTO KET PAC

1 1/2”(38) HIGH OBJECT

FOR DOOR REVERSAL TEST

Page 16

O

O

BACK M

T

R

R al

C

O

VE (O

p

tio

n )

FRONT

COVER

MOTOR

BARREL

CLIPS

MOTOR

BARREL

PEGS

HOLES

CLIPS

IMPORTANT MAINTENANCE & SAFETY INSTRUCTIONS

Monthly, check the opener's down cycle safety reverse. The door must reverse when it

contacts a 1 1/2" (38) high object (or a 2X4 board laid flat) on the floor. A closing door must

also reverse if the optional photo eyes are interrupted.

Always keep the moving door in sight and away from people and objects until it is

completely closed. NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

NEVER go under a stopped, partially open door.

Do not allow children to operate or play with the garage door controls. Keep the remote

control away from children.

SAVE THESE IMPORTANT INSTRUCTIONS

If the Safety Reverse or any other part of the garage door and opener system do not work

properly, or if you do not understand, call a trained Martin Door Dealer.

The emergency release should only be used when garage door is in the closed position.

Weak or broken springs may cause door to fall, if released in the open position, increasing

the risk of severe injury or death. Use caution when using the release with door open.

Monthly visually check lift cables, spring assembly, hardware, etc. for wear and stability.

KEEP GARAGE DOOR PROPERLY BALANCED. See garage door owner’s manual. An

improperly balanced door increases the risk of severe injury or death. Call a trained Martin

Door Dealer to repair lift cables, spring assemblies and other hardware.

!

TO REDUCE THE RISK OF SEVERE INJURY OR

DEATH, READ AND FOLLOW ALL INSTRUCTIONS

STEP 8

INSTALLING THE FRONT MOTOR COVER (OPTIONAL)

The front cover has two motor barrel clips, which fasten over the motor

barrel. Position the front cover with the clips touching the motor barrel,

then with a hand over the clip area, firmly push the front cover until the

clips fasten to the motor barrel. Fit the two pegs

located in the top edge of the back cover into the

two holes located in the top edge of the

front cover. Fasten front and back

cover together with the small

screws into the small clips.

See Figures 2a, 2b, 47

FIGURE 47

INTERLOCK CIRCUIT WIRING

A pair of “Interlock” terminals is provided for a pass door switch or a key switch

(lock-out switch) to be interlocked to the opener, to prevent the garage door from

opening if the “Interlock” terminals are open circuit.

See Figure 10b, 48a

Interlock O/RIDE, DIP switch No. 5 is normally set to ON. If you want to add an

interlock device, move switch No. 5 to OFF. See Figure 10b, 48b

A slide lock switch may be installed and connected into the interlock terminals.

However this may not be necessary because the opener will detect the obstruction

and stop the garage door if the slide lock is left in the lock position.

FIGURE 48a

SW5 TO “OFF” POSITION

INTER

LOCK

COM

FIGURE 48b

ON APEMs

1 2 3 4 5 6 7 8

I/LOCK

O/RIDE

COPYRIGHT © 2008 MARTIN DOOR

16

Page 17

17

FIGURE 49

SAFETY CIRCUIT WIRING

(Photo-eyes required for U.L. 325 compliance)

If the garage door is to be operated without any safety devices then the STD SAFETY, DIP switch NO.

2 and 3 should be OFF. If a device such as a photo-eye or safety edge is installed then the STD

SAFETY DIP Switch NO. 2 should be set to the ON position. This provides a safety STOP and

RE-OPEN control of the garage door if the safety circuit becomes active while the garage door is

closing. See Figure 49, 50

Connect the relay contact wires to the SAFETY terminals at the top right hand side of circuit board. If

extra Photo-eyes, or other safety devices are added, wire them all in series. See Figure 10b, 50

Connect the 24-volt photo-eye power wires to the accessory radio terminal. This 24-volt supply may

also be used to power accessories such as a magnetic loop detector, safety edge, etc. An overload

circuit will trip if the options load exceeds 200mA. See Figures 10b, 50

Each time the safety circuit is activated LED LD2 will illuminate. This is useful when testing the

operation of photo-eyes, etc. without operating the garage door. See Figure 10b, 51

In Europe it is necessary to arrange for the safety circuit to be monitored for both an open circuit and a

short circuit in which case the circuit must include an 8.2 K resistor at the furthest point in the external

circuit. DIP switch No.1 should be set to ON which is the position marked “RES” for resistive. If the

safety circuit is interrupted while the door is operating with the auto close DIP switch No. 4 set to ON,

then timer will reset during each interruption of safety circuit while the door is open. The auto-close

function is not operational for North America.

OPTIONAL LIGHTING

For optional light, connect wires to the orange LIGHT terminal at the bottom of the circuit board.

The lighting wires should be rated at 10 Amps (lights - 250 watts maximum). See Figure 52

DIP switch No. 6 should be set to the OFF position if the light is required to turn on when the door

is operated and turn off three minutes from the last operation.

DIP switch No. 6 should be set to the ON position if the light is required to turn ON when the door

is opened, and turn OFF when the door is closed.

For qualified electricians only: A garage ceiling light may be wired to turn on/off by the door

opener. The door opener and ceiling light must be powered by the same circuit breaker. Install

one black wire from the LIVE plug-in of the LIGHT terminal to the black wire of the ceiling light.

FIGURE 50

SW2 TO “ON” POSITION

ON APEMs

1 2 3 4 5 6 7 8

STD

SAFETY

SAFETY

MODE

SAFETY

COM

ACCESSORY

RADIO

FIGURE 51

3 24V

2 RLY

1 GND

PHOTOEYE

SAFETY

CIRCUIT

TO POWER

CIRCUIT

OF BOTH

PHOTO-EYES

RADIO CONTROL WIRES

“SFTY”

LIGHT

e

G

r en

Ba

kl

c

e

W

hit

LIGHT

GND LIVE N

FIGURE 52

COPYRIGHT © 2008 MARTIN DOOR

STD

TO

COM

OF RX

PHOTOEYE

TO

N/O

OF RX

PHOTOEYE

Page 18

HAVING A PROBLEM?

Situation: Likely Cause and Solution

Opener does not

operate from either the

push button or

transmitter:

Opener operates from

transmitter but not from

push button:

Opener operates from

push button but not the

transmitter:

Door has a Close Delay

Door does not

open completely:

Door does not close

completely:

Door opens but will

not close at all:

Door reverses for no

apparent reason:

Opener strains as it

operates door:

The OPNG and CLSNG

LED remains illuminated

Door runs slow for an

extended time

Opener does not move

door at all:

Opener won't work due

to power failure:

Does opener have electricity? Plug a lamp into the grounded outlet. If it does not turn on, have a qualified electrician service the outlet.

Have you disengaged all locks on door? If not, do so.

Has snow or ice built up under door? Door may be frozen to ground. Remove any restrictions.

The garage door spring may be broken. Call a trained Martin Door Dealer to replace the spring and service the door.

Are wiring connections correct? Check optional push button wiring.

If opener does not run, check wiring connections at control box and check wires for shorts or breaks.

Has the opener learned the code of the transmitter? Repeat transmitter programming steps. See Page 13 and 14.

Have all transmitters been set with the same code? Repeat code learning procedure. See Page 13 and 14.

Does the transmitter indicator light blink when the transmitter button is pressed? If not, replace battery.

Follow steps in the “Clearing Service Due Reminder Instructions. See Page 11

Is something obstructing the door? Remove obstructions from the garage door area. Close the door disconnect emergency release.

Open and close door manually. If door has been working properly but now doesn't, increase the force and/or reduce the sensitivity. After

adjustment Is completed, repeat tests. See STEP 4 and 6. Maybe springs should be tightened. Tighten drive belt. Call a Martin Door Dealer.

Is something obstructing the door? Remove obstructions from garage door travel area.

If door has been working properly but now doesn't, increase the closing force and/or reduce the sensitivity. After adjustment Is completed,

repeat the tests. See STEP 4 and 6. Maybe springs are wound too tight. Tighten drive belt. Call a Martin Door Dealer.

Are optional photo eyes (if installed) obstructed with dust and spider webs, or out of line? Keep photo-eyes clean.

Check the optional photo eyes (if installed) for proper connection, alignment and cleanliness. Tighten drive belt.

Review and increase force and/or reduce sensitivity. After adjustment is completed, repeat the tests.

Is something obstructing the door? Clear ice, snow, sand or dirt from garage floor area where garage door closes. Also, push emergency

release lever up with door in closed position. Open door manually. If it is unbalanced call a trained Martin Dealer.

Review and increase force and/or reduce sensitivity. Tighten drive belt. Garage door may be too heavy for opener. Call a trained

Martin Door dealer.

Door may be out of balance or springs broken. Close the door and push emergency release lever up. Open and close door manually.

A properly balanced door will hold itself part way open while being supported entirely by its springs. If it does not, call a trained Martin

Door Dealer. DO NOT attempt to correct an unbalanced or damaged door. Call a trained Martin Door Dealer.

The drive belt tension may be too loose and slipping. Close door and disconnect power. Push the emergency release lever up. Tighten the

screw hook a few turns. Make sure lever is at 90 degrees. Push the emergency release lever down, connect power.

Springs are broken or door is out of balance. Call a trained Martin Door Dealer.

Door may be locked with a manual door lock. Disable or remove any manual door locks.

Push the emergency release lever up. Door can be opened and closed manually. When power is restored, reconnect at the exact location

of the disconnect. Open and close two cycles. If door does not work properly, perform “Calibration Reset”. See STEP 4

See STEP 6.

See STEP 4 and 6.

The drive belt tension may be too loose and slipping. Tighten the screw hook same as above. Open and close door two complete cycles for

computer to learn limits. Do a calibration reset. Push the emergency release lever down, connect power.

COPYRIGHT © 2008 MARTIN DOOR

18

Page 19

DC4600 Model DC4600

5.5" (140) Width 6.5” (170)

11" (280) Height 8.7" (220)

4.75" (121) Depth 4.7” (120)

Watts 265

Amps Req.-115 Volts 2.2

Volts

Hertz (Hz)

115V

50/60 Hz

Current

½ hp

(700 N)

Supply

2.2:1 Circuit Board

6” – 7”

(150-180)

Circuit Board

Te mpe rature Range

Surge Suppression

Open and Close Limits

Instant Reverse

Push Buttons

Radio Controls

Automatic

Close Timer

Automatic Open,

Safe ty Te rm inal

Lighting Terminal

Lubrication Permanent

Unlimited

Continuous Cycle

Heat Build Up

Insignificant - Opener remains close to air

temperature

Cycles Per Hour

Current

Yes

Drive Reduction

Clea ra nce Re quired Above

Cente r of Torsion Tube/Shaft

Volta ge

Side Clearance Required

Beyond Lock-on/Side

Bearing Bracket

8.5"

(216)

Ratio

CONTROL BOX ASSEMBLY

Emerge ncy Release Assembly Standard on all units

MOTOR ASSEMBLY

Operating Temperature

Range

Overload Protection

2.5" (64)

Torsion Tube/Shaft Length

AC

5’ (1520)

17 Lbs. (37)

500 lbs (230)

OPENER SPECIFICATIONS

Minimum Door

Height

Model

DC4600

Max imum Door

Weight

Max imum Door

Height

15’ (4600)

Height

Width

Depth

Power

5.0" (130) beyond the lock-on/side

bearing bracket

Drive V-Belt

Approximate Weight Plus Packaging

Automatic

Standard in the down run cycle

Model

For optional loop detectors, photo eyes, radar,

edge sensor, etc.

For optional on/off lighting

Amps required per 100 watts at 115 Volts is .84

15 seconds to 4 minutes.

Not available for North America

Single Phase

Speed per second

"Run Time"

Soft Start/Soft Stop

(Adds Seconds to "Run Time")

Self calibrating to the height

of the garage door.

Computer Technology

V-Belt, Pulleys, and Worm Drive Gear Box

-30 F (-34 C) to 212 F (100 C)

-13 F (-22 C) to 212 F (100 C)

Built-in

Control Box Internal

Te mpe rature

Higher than the external temperatures, because

transformer heating warms internal air. This

feature allows for cold room installations

Direct (DC) Supplied from Control Box

42 Volts Supplied from Control Box Assembly

Force and Sensitivity

Settings

Factory preset and adjust automatically to light

and heavy garage doors. Can be slightly

re-adjusted and set (See Step 5).

One Button

Included

-13F(-25C) To 185F(85C)

. See STEP 6

-13F(-25C) To 167F(75C)

Maximum current is 3A

Amps required per 100 watts at 115 Volts is .84

Page 20

COPYRIGHT © 2008 MARTIN DOOR

Wide open section joint

l s n !C o i g Door

HIGH

RISK

Large

Holes

in

Track

M v no i g

Door!

Wide Open

Section Joint

Clos n

or!i g Do

Outside Lift

Cables

HIGH

RISK

HIGH

RISK

Track

Brackets

Closing Door!

HIGH

RISK

HIGH

RISK

Sharp

Track

lo

i D rC s ng oo !

Exposed

R

er

oll

HIGH

RISK

Track

Bracket

Holes

Inside

o D or

Door

HIGH

RISK

Wide Open

Section Joint

Wide

Open

Outside

SIDE VIEW

LOOSE NAILS

LOOSE LAG

SCREWS

TORSION

SPRING

CRACK

SPLIT

WOOD

Center Mount Torsion Springs

TORSION

SPRING

FRONT VIEW

HIGH RISK

Holes

COMMON HIGH RISK GARAGE DOOR AREAS

Exposed wide-open section joints, inside and outside . . . . . . . . . . . . . . . . . . . . . .

Exposed holes in tracks larger than 1/4" (7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposed track brackets fastening vertical tracks to jambs . . . . . . . . . . . . . . . . . . .

Exposed outside lift cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exposed rollers moving in vertical tracks with sharp leading edges. . . . . . . . . . . . .

Exposed center mount torsion springs bracket or side mount stretch springs . .

COMMON REPORTED SERIOUS INJURIES

Hands & fingers entrapped, severed or crushed. 1/3 are children.

Fingers entrapped or severed. Most are children.

Hands & arms entrapped, broken or severed. Most are children.

Entrapment or strangulation. Most are children.

Fingers entrapped, cut or severed.

Severing of body parts and death.

!

IF UNSURE, CALL A TRAINED MARTIN DOOR DEALER

Correct all “HIGH RISK” areas before installing opener.

If unable to correct “HIGH RISK” areas, replace with a new Martin Door.

Loading...

Loading...