Page 1

MARTIN® Brush Cleaner with

external Motor

Installation Instructions

M3289UK

Page 2

© Martin Engineering GmbH M3289UK-01/17

Page 3

1 Table of contents

1 Table of contents ............................................................. 1

2 Introduction ...................................................................... 3

2.1 Concerning these installation instructions.......................... 3

2.1.1 Scope ............................................................................3

2.1.2 Copyright ....................................................................... 3

2.1.3 Exclusion of liability .......................................................3

2.1.4 Reference to additional documents ............................... 4

2.1.5 Classification of the hazards.......................................... 5

2.2 Intended usage .................................................................. 6

2.2.1 Conveyor systems with open transfer systems ............. 6

2.2.2 Usage in explosion-protected areas .............................. 6

2.2.3 Restrictions on the use of the product ........................... 6

2.3 Occupational safety............................................................ 7

2.3.1 Safety information, occupational safety ......................... 7

2.3.2 Duties of the owner-operator ......................................... 7

2.3.3 Authorised personnel ..................................................... 7

3 Description of the product .............................................. 8

3.1 Design and function ........................................................... 8

3.2 Type clarification................................................................ 9

4 Preparing for the installation ........................................ 10

4.1 Before the installation....................................................... 10

4.1.1 Required materials and tools ....................................... 10

4.1.2 Preparatory measures ................................................. 10

5 Installation ...................................................................... 11

5.1 Safety information............................................................ 11

5.2 Installation process .......................................................... 12

5.2.1 Determination of the installation position ..................... 12

5.2.2 Installing the tensioner................................................. 16

5.2.3 Installing the cleaner.................................................... 17

5.2.4 Electrical connection.................................................... 19

5.2.5 Centring the mainframe beneath the conveyor belt ..... 20

5.2.6 Aligning the mainframe parallel to the conveyor belt... 22

5.2.7 Aligning the mainframe horizontally ............................. 23

5.2.8 Tensioning the secondary cleaner............................... 24

5.3 Test run..................................................... .......... ............. 26

5.4 Placement of warning labels and warning tags................ 28

6 Maintenance ................................................................... 29

6.1 Safety information............................................................ 29

6.2 Weekly maintenance........................................................ 29

6.3 Replacement of the cleaning elements............................ 31

6.3.1 Lowering of secondary cleaner.................................... 32

6.3.2 Replace cleaning elements ......................................... 34

7 Troubleshooting .............................................................37

7.1 Safety information............................................................ 37

7.2 Troubleshooting .............................................................. 37

8 Storage, de-installation, disposal ................................. 39

Table of contents

© Martin Engineering GmbH 1 M3289UK-01/17

Page 4

Table of contents

8.1 Packing and transportation .............................................. 39

8.2 Storage............................................................................. 39

8.3 De-installation .................................................................. 39

8.4 Disposal ........................................................................... 39

9 Part numbers ............................................................... ...40

9.1 Explanation of part numbers............................................ 40

9.2 MARTIN

®

Inspection doors .............................................. 40

9.3 Installation manuals ......................................................... 41

9.4 Warning labels / Warning tags......................................... 41

9.5 Accessories and options.................................................. 41

9.5.1 Inspection doors .......................................................... 41

9.5.2 Cleaning elements .......................................................41

®

9.6 Martin

Brush Cleaner....................................................... 42

9.6.1 Technical Specification Angular Gear Motor............... 46

10 Declaration of Incorporation ......................................... 47

© Martin Engineering GmbH 2 M3289UK-01/17

Page 5

2 Introduction

2.1 Concerning these installation instructions

Non-compliance with these installation instructions can result in loss

of compensation for damage and/or warranty claims.

2.1.1 Scope

These installation instructions apply solely for the product described

herein and are intended for those persons who install this product,

commission it, and monitor its usage.

2.1.2 Copyright

The products described and these installation instructions are

protected by copyright. Any reproduction without a licence will be

prosecuted. All rights to the present document are reserved,

including its reproduction and/or copying in any conceivable

manner. Reprints of this document require the written consent of

Martin Engineering.

Introduction

The technical standard at the time of delivery of the product and its

technical documentation are decisive as long as no other

information is provided. The product and documentation are subject

to technical changes without prior notification. Earlier documents

then lose their validity. Martin Engineering's General Terms of Sales

and Delivery shall apply.

2.1.3 Exclusion of liability

Martin Engineering guarantees the flawless function of its product in

accordance with its advertising, the published product information,

and its technical documentation. Martin Engineering shall assume no

liability for efficiency and flawless function if the product is used for a

purpose other than that described in the “Intended Use” section or for

damage resulting from the use of accessories and/or spare parts

which were not supplied and/or certified by Martin Engineering.

Martin Engineering products are designed for a long service life.

They correspond to the relevant, current state of the scientific and

technical art and have been thoroughly inspected before delivery.

Martin Engineering also carries out continuous further development

of products as well as product and market research.

Martin Engineering offers competent support whenever

malfunctions and/or technical problems occur. Suitable actions are

taken immediately. The warranty provisions of Martin Engineering

apply and can be sent to you as needed.

© Martin Engineering GmbH 3 M3289UK-01/17

Page 6

Introduction

2.1.4 Reference to additional documents

Reference is made in these installation instructions to the following

documents:

®

• Installation instructions for the MARTIN

inspection door

Publication no. M3127.

• Operating instructions for 3-phase motor DR.71-225, 315.

• Installation and operating instructions for gearboxes of type

series R..7, F..7, k..7, S..7, SPIROPLAN

®

W

The following standards and directives were complied with in the

preparation of these installation instructions:

• Machinery Directive (2006/42/EC)

• ISO/IEC Guide 37 “Installation instructions for products

used by consumers”, 1995 Edition

• DIN 1421 “Arrangement and numbering in texts”,

Edition 1983-01

• DIN/EN/ISO 12100 “Safety of machinery - General

principles for design - Risk assessment and risk reduction”,

Edition 2011-03.

• DIN/ISO 16016 “Technical product documentation Protection notices for restricting the use of documents and

products“, Edition 2007-12

• DIN/EN 60204-1 “Safety of machines - Electrical

Equipment of Machines, Part 1: General requirements”,

Edition 2007-06

• DIN/EN 1083-1; -2 Power-driven brushes Part 1:

Definitions and nomenclature” and “Part 2: Safety

requirements”, Edition 1997-07.

• DIN EN 82079-1 - Creation of user manuals - Structuring,

content and presentation, Part 1 General principles and

detailed requirements.

© Martin Engineering GmbH 4 M3289UK-01/17

Page 7

2.1.5 Classification of the hazards

DANGER!

Represents an immediately threatening danger which leads to

serious bodily injuries or death if not avoided.

WARNING!

Represents a possibly hazardous situation which could lead to

serious bodily injuries or death if not avoided.

CAUTION!

Represents a possibly hazardous situation which could lead to

minor bodily injuries and/or property damage if not avoided.

Introduction

NOTE

Contains comments about the installation and/or the product's

usage to point out situations which cause neither personal injury

nor property damage but include important information.

© Martin Engineering GmbH 5 M3289UK-01/17

Page 8

Introduction

2.2 Intended usage

2.2.1 Conveyor systems with open transfer systems

The secondary cleaner can only be used for the cleaning of

conveyor belts that are used for the transportation of bulk material.

It can be used on conveyor belts with a maximum belt width of

2000 mm and a maximum conveyor speed of 10 m/s.

Every other usage of this product is deemed as misuse. Please

contact Martin Engineering customer service if you would like to use

this product for a different purpose. We will be happy to assist you

with the product configuration.

These installation instructions describe the installation on conveyor

systems with encapsulated transfer systems. Various MARTIN

installation brackets can be used on open transfer systems.

Martin Engineering or one of its representatives can assist with the

positioning or with special solutions in cases where the installation

conditions are complicated such as insurmountable static

components or a head pulley as the tensioning station.

2.2.2 Usage in explosion-protected areas

This product may not be used in explosion-endangered areas.

2.2.3 Restrictions on the use of the product

The product specified here may only be used within the scope of the

specifications referred to above. Usage in a higher equipment

protection category or under other operating conditions than those

specified by Martin Engineering shall be deemed misuse a nd is only

permitted if approved by Martin Engineering.

Martin Engineering or one of its representatives can assist you with

the product configuration if you need to use this product for

a different purpose.

®

© Martin Engineering GmbH 6 M3289UK-01/17

Page 9

2.3 Occupational safety

2.3.1 Safety information, occupational safety

These installation instructions must be read through in their entirety

before work may be started on the product or on the conveyor

system supplied by the customer.

The owner-operator must ensure that all installation, inspection and

maintenance work is performed solely by trained specialists.

Work on conveyor systems and their accessories must always be

performed during shut-down. The procedures described in the

applicable installation instructions for shutting down the conveyor

belt system must always be complied with.

All of the safety devices and safeguards must be reattached and/or

made operational again immediately following completion of the

work.

The installation must be carried out to completion before the system

is started up. The flawless execution of all operating steps must be

tested before the conveyor system can be started up again. Please

observe all information on the installation and start-up of the

product.

Introduction

2.3.2 Duties of the owner-operator

This product's owner-operator must ensure that this product is

installed, serviced and used solely by those persons who

• know the rules regarding occupational safety and accident

prevention,

• were trained on using this product and have read and

understood these installation instructions.

2.3.3 Authorised personnel

Personnel are considered authorised when they have suitable

training and technical experience, can demonstrate knowledge of

the applicable standards and guidelines, and are able to evaluate

tasks in order to recognise critical situations at an early stage.

Operating, maintenance and installation personnel

Personnel are considered authorised when they have been trained

on using the product and have read and understood these operating

instructions in their entirety.

© Martin Engineering GmbH 7 M3289UK-01/17

Page 10

3 Description of the product

3.1 Design and function

The product is provided especially for cleaning difficult profile belts,

e.g. chevron or slatted belts, and baked-on material. It is largely

used as a single cleaning system; can however also be used in

combination with a main cleaner.

The product installation is centred below the head pulley so as to

feed the bulk solid back into the material stream. If by the use of this

product, the material handling process is interrupted or the product

contaminated, the user is responsible for taking any counter

measures necessary.

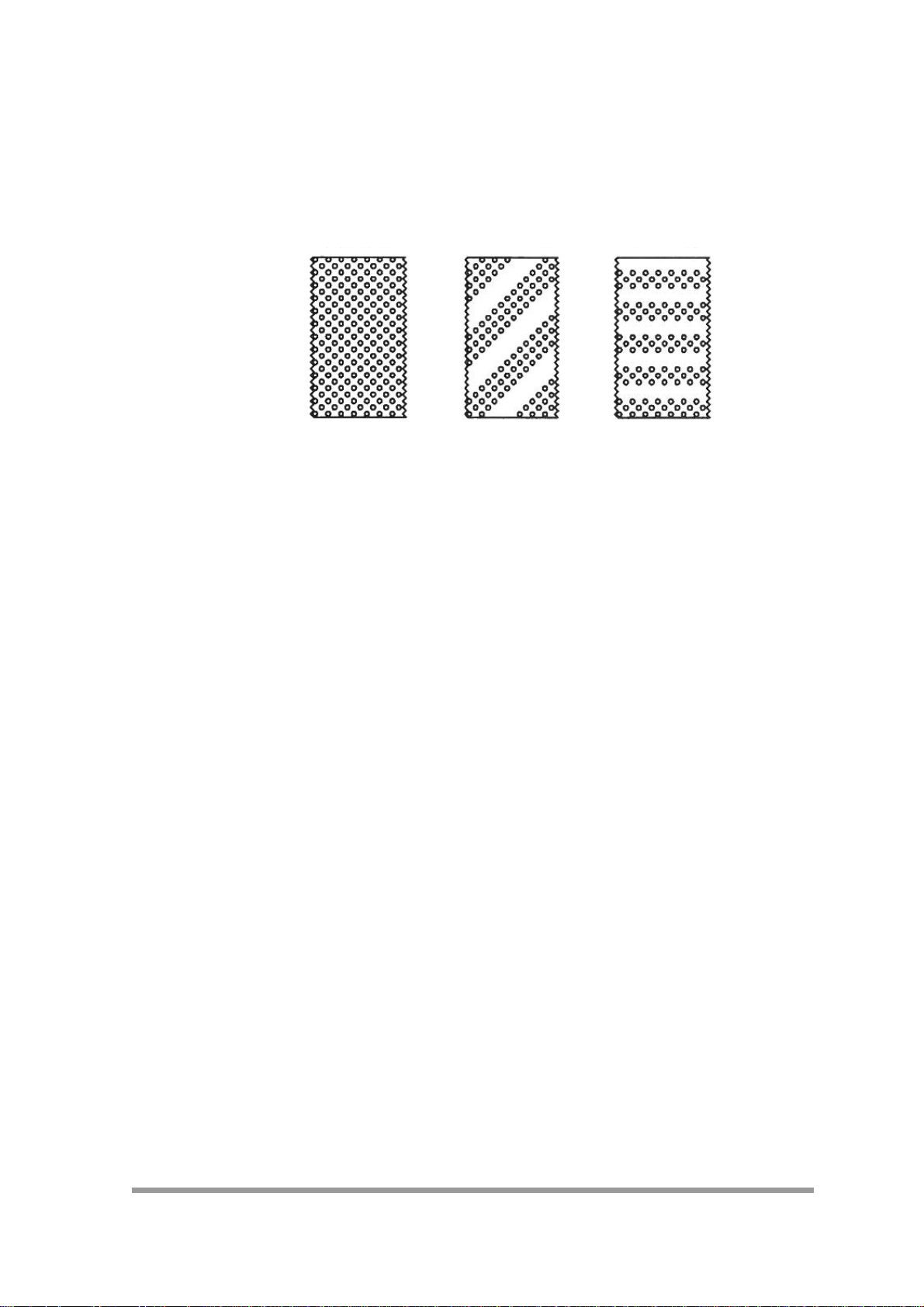

Various bristle materials can be selected for a very large range of

applications. For this, there are two different materials (polyester

and brass) available that are specified in more detail in the technical

data sheet. These are available for selection in three different bristle

patterns (full, spiral-shaped and straight).

Description of the product

Only the same material and bristle pattern type can be used

together. A mixture of different material and bristle pattern is not

intended and must be checked in any individual case.

NOTE

An unfavourably or improperly installed product can disrupt the

conveyor process or contaminate the bulk material to be

transported.

The owner-operator is responsible for taking the required

countermeasures.

In the case of applications with contaminants, Martin Engineering

or one of its representatives can assist with the positioning or with

special solutions.

© Martin Engineering GmbH 8 M3289UK-01/17

Page 11

Description of the product

full trim spiral-shaped straight

3.2 Type clarification

There are three different bristle patterns available in the b rushes for

the product. A selection matrix for usage options is shown in the

appropriate data sheet.

© Martin Engineering GmbH 9 M3289UK-01/17

Page 12

4 Preparing for the installation

4.1 Before the installation

4.1.1 Required materials and tools

No special tools are required for the installation and maintenance of

the product.

4.1.2 Preparatory measures

NOTE

Perform the inspections carefully and completely as described.

The shipping company is liable for any transport damage!

Please contact the shipper with any damage claims.

NOTE

Preparing for the installation

An unfavourably or improperly installed product can disrupt the

conveyor process or contaminate the bulk material to be

transported.

The owner-operator is responsible for taking the required

countermeasures.

In the case of applications with contaminants, please seek the

advice of Martin Engineering or

one of its representatives.

1. Inspect the delivery for the following conditions:

• Is the delivery complete? Does the number of pallets/

crates/containers delivered match the number on th

d

elivery note?

• Do all of the transport packages appear to be undamaged?

Does damage to the packaging exist which indicate

d

amage to the product contained inside?

Always record any incompleteness or transport damage

2.

discovered in the delivery and have it confirmed by the

All damaged p

The delivery should include the following parts, dep

3.

the

scope of the order:

• Brush cleaners incl. two tensioners.

• Two Conveyor Products Warning Labels:

Part no. 23395

• Installation instructions

4. Report any missing or damaged parts to Martin Engineering

one

of its authorised dealers.

roducts must be kept for inspection.

e

s

shipper.

ending on

or

© Martin Engineering GmbH 10 M3289UK-01/17

Page 13

5 Installation

5.1 Safety information

NOTE

Read this section completely before starting any kind of work!

WARNING! RISK OF INJURY!

Body parts and/or clothing may get caught and pulled in by

rotating parts or by the moving conveyor belt.

Before any installation or maintenance work is carried out, ensure

that all power sources to the conveyor belt system and its

accessories are switched off and secured against unauthorised

reactivation. Use warning s igns!

Installation

WARNING! RISK OF EXPLOSION!

Increased risk when using a cutting torch or welding device in

closed rooms!

Check the gas and dust content of the air before usage.

NOTE

The chute wall on which the angular geared motor is installed is

designated in the following as the "operator side". The opposite

chute wall is referred to as the "opposite side".

© Martin Engineering GmbH 11 M3289UK-01/17

Page 14

Installation

5.2 Installation process

5.2.1 Determination of the installation position

The position of the axle and the tensioning device of the secondary

cleaner must be determined on both sides of the chute wall. In this

process, the positions are therefore determined for where the shaft

of the secondary cleaner is routed through the chute wall and/or

where the tensioner is installed on the chute wall.

The secondary cleaner is delivered jointly with a tensioner. This is

delivered as a work´s dismantled unit and will be installed together

with the secondary cleaner during the general installation.

The installation process for the secondary cleaner and the tensioner

is described in the supplied installation instructions.

An overview of the installation steps follows:

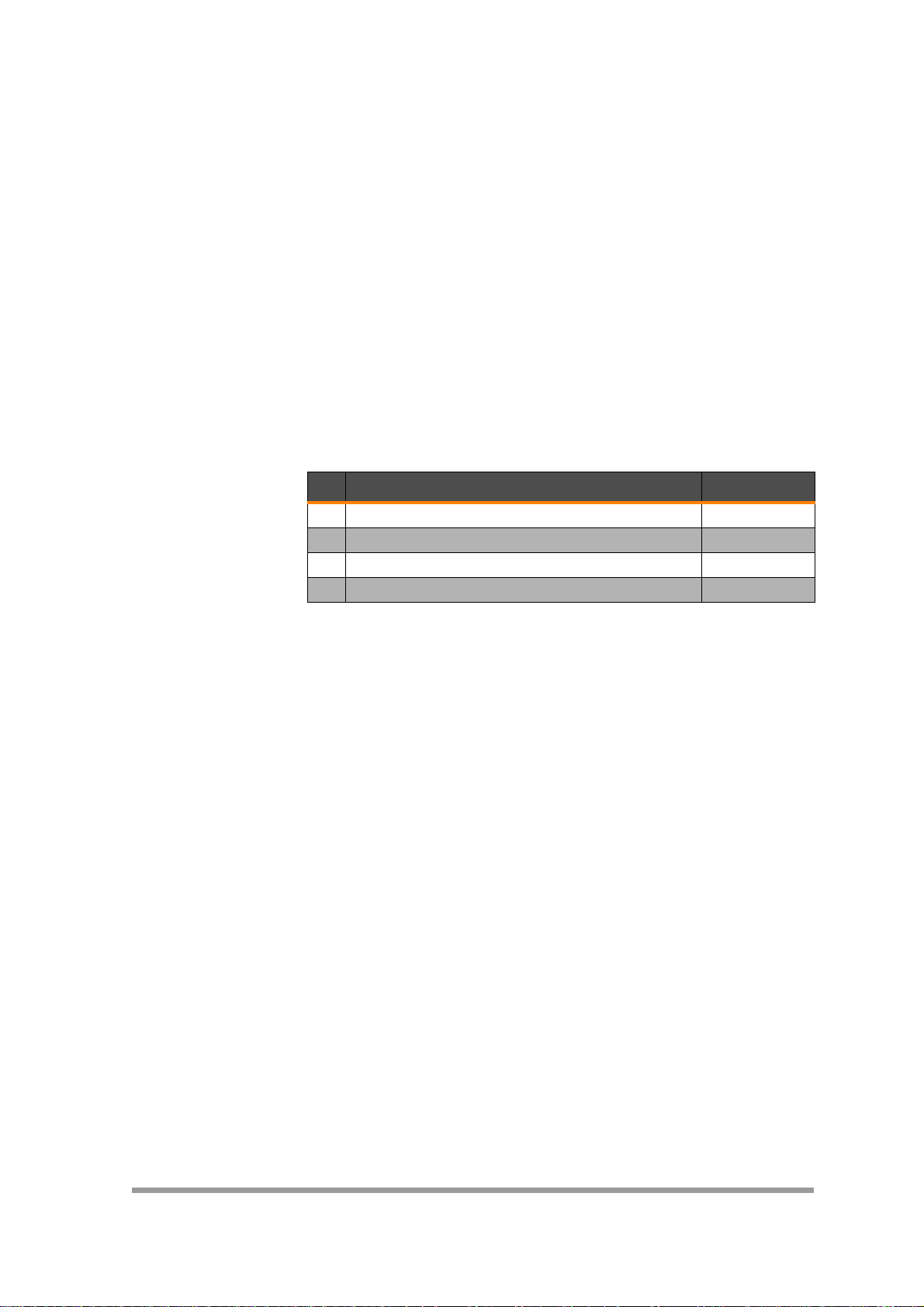

No. Installation step Instructions

1 Determining the installation position M3289

2 Installing the cleaner M3289

3 Installing the tensioner M3289

4 Tightening the cleaner M3289

Tab. 1:

Various on-site conditions requiring different work steps are

possible for the installation. These are presented as follows:

Installation on an encapsulated transfer system

• Follow the instructions given in Section 5.2.2.

Installation on an encapsulated transfer system with pre-existing

installation openings and air line brackets for belt cleaners.

• Follow the instructions given in Section 5.2.3.

Installation on an open transfer system

• Use the equipment provided at the site to comply with

d

imensions for correct installation.

the

© Martin Engineering GmbH 12 M3289UK-01/17

Page 15

NOTE

Martin Engineering recommends installing a MARTIN® inspection

door for the purpose of better accessibility for maintenance and

repairs.

NOTE

The secondary cleaner should ideally be installed near a head

pulley or a counter-pressure roller. The clearance should not be

more than 200 mm.

NOTE

The installation position is to be so selected that sufficient space is

®

available for the installation of the MARTIN

This distance should lie at least 350 mm outside the chute wall on

the operator side and at least 100 mm on the opposite side.

brush cleaner.

Installation

© Martin Engineering GmbH 13 M3289UK-01/17

Page 16

Installation

90

140

E

13,5

305

180

45

80

R45

min. 50

max. 200

Conveying direction

A

B

C

D

F

Fig. 1:

Pos. Description

A Conveyor belt

B Centre point of the driving drum

C Exit point of the conveyor belt from the driving drum

D Slot

E Installation holes in the tensioner

F Position of the brush ends of the conveyor belt cleaner

© Martin Engineering GmbH 14 M3289UK-01/17

Page 17

1. Deactivate the conveyor system and all accessories before

starting the installation work and secure them against

inadvertent reactivation.

2. Mark the vertical and horizontal centre line of the driving drum

on the operator side of the chute wall to determine the centre

point (B, Fig. 2) of the driving drum. Extend the vertical

centreline to determine the point C.

3. Mark a position (F, Fig. 2) at a distance from 50 to no more than

200 mm in the conveying direction (A, Fig. 2) from the point at

which the belt leaves the head pulley (C, Fig. 2).

4. Draw a vertical line at this position (F, Fig. 2) going downwards

at a right angle to the conveyor belt.

5. Use the dimensions from Figure 2 to mark the installation holes

for the tensioner.

6. Create the slot-shaped cut-out and installation holes as shown

in Figure 2.

7. Repeat steps 1 to 6 on the opposite side of the chute wall.

Installation

© Martin Engineering GmbH 15 M3289UK-01/17

Page 18

Installation

1

5.2.2 Installing the tensioner

Fig. 2:

1. Attach the tensioner (1, Fig. 3) to the chute wall using the

in

stallation holes shown in Fig. 2

2. Repeat step 1 on the opposite side.

© Martin Engineering GmbH 16 M3289UK-01/17

Page 19

5.2.3 Installing the cleaner

1

3

4

2

5

6

WARNING! RISK OF INJURY!

The secondary cleaner is heavy and can cause serious injuries if it

is dropped during lifting or moving.

Always use a suitable lifting device or engage the help of several

persons when lifting the brush cleaner. Do not stand under

hanging loads.

NOTE

Check the oil level in the angled gearbox of the motor before

installing.

Observe the information in the manufacturer's documentation

supplied with the device.

Fix the pillow block (3, Fig. 4) on both sides of the main shaft

1.

(2, Fig. 4) .

Installation

© Martin Engineering GmbH 17 M3289UK-01/17

Fig. 3:

2. Slide the main axle (2, Fig. 4) though the two slots (4, Fig. 4)

chute wall.

3. Secure the pillow blocks (3, Fig.

tensioners (6, Fig. 4).

the

4.

Insert the feather key into the axle, if not already done.

in

4) using the bolts (5, Fig. 4) to

Page 20

Installation

1

2

Fig. 4:

NOTE

Make sure that the feather key (2, Fig. 5) lies in the keyway

(1, Fig. 5) of the axle.

5. Push the angled gearbox motor with mounting plate for motor

torque support (1, Fig. 4) onto the shaft.

NOTE

The mounting plate must be installed from below onto the

tensioner. The angled gearbox motor should always be placed on

the shaft flush with the conveyor belt.

1

2

Fig. 5:

NOTE

The angled gearbox motor (1, Fig. 6) can only be mounted in the

transport direction (2, Fig. 6) on the left side, a changeover to the

right side is not possible.

6. Fix bolts (4, Fig. 4) of the pillow block on both sides with the

nuts.

© Martin Engineering GmbH 18 M3289UK-01/17

Page 21

5.2.4 Electrical connection

Transport direction

Transport direction

Conveyor belt

Cleaning elements

The electrical installation may only be performed by an electrician.

Comply with all laws, standards and directives which are applicable

for the company. Earth the electrical equipment in accordance with

the applicable regulations.

NOTE

Observe instructions in the manufacturer documentation on

making electrical connections!

Observer the installation instructions and wiring diagrams supplied

with the product. The angled gearbox motor must run such that the

cleaning elements move in the opposite

conveyor belt.

Installation

direction to that of the

© Martin Engineering GmbH 19 M3289UK-01/17

Fig. 6:

NOTE

Check the rotational direction of the cleaning elements before

commissioning!

Page 22

Installation

5.2.5 Centring the mainframe beneath the conveyor belt

CAUTION! RISK OF DAMAGE!

Off-track running can cause damage to the conveyor belt edge

and/or the

cleaning elements.

Alignment of the secondary cleaner in accordance with the

following instructions.

NOTE

The following displays are examples and can differ from the

secondary cleaner actually used.

2

1

A

Fig. 7:

Pos. Description

1 Chute wall

2 Driving drum

3 Cleaning elements

Tab. 2: Centring the secondary cleaner beneath the conveyor belt

1. Measure the clearances (A) and (B) between the edge of the

cleaning eleme

nts and the conveyor belt edge.

A

3

NOTE

The conveyor belt must protrude around 50 to 100 mm from the

left and right sides. The cleaning elements must be centrally

aligned beneath the conveyor belt.

© Martin Engineering GmbH 20 M3289UK-01/17

Page 23

If these are not the same, the brush elements will shift on the main

1

2

1

2

axle.

Fig. 8:

Installation

2. Loosen locking collar (1, Fig. 9) and adjusting ring (5,

h sides.

bot

3.

Shift the cleaning elements so that clearance A is equal to

clearance B.

4. Tighten adjusting ring (5, Fig. 9) and securing ring (1,

h sides.

bot

Fig. 9) on

Fig. 9) on

© Martin Engineering GmbH 21 M3289UK-01/17

Page 24

Installation

5.2.6 Aligning the mainframe parallel to the conveyor belt

1

A

4

Fig. 9:

Pos. Description

1 Plan view of cleaning elements

2 Driving drum

3 Driving drum axis

4 Chute wall

Tab. 3: Top view of aligning cleaning elements parallel to conveyor belt

1. Measure the clearance on both sides between the mainframe

and

the head pulley or counter-pressure roller.

A

3

2

NOTE

The measurements must be the same on both sides. If not, the

tensioners must be re-positioned.

© Martin Engineering GmbH 22 M3289UK-01/17

Page 25

5.2.7 Aligning the mainframe horizontally

Installation

1

2

A

4

Fig. 10:

Pos. Description

1 Driving drum

2 Driving drum axis

3 Cleaning elements

4 Chute wall

Tab. 4: Aligning brush cleaner horizontally

1. Align the mainframe horizontally with respect to the head pulley

and

check whether the bristles rest evenly on the conveyor

2.

Tighten the tensioner clamping screws.

A

3

belt.

WARNING! RISK OF INJURY!

The mainframe may not protrude more than 10 mm beyond the

chute wall. Otherwise there is a danger of injury from the rotating

shaft.

The shaft can only be shortened on the drive-facing side and not

on the drive side.

Once the dimensions are correct and the secondary cleaner aligned,

this can be attached accordingly. If this is not the case, then the

mainframe must be reinstalled or repositioned.

© Martin Engineering GmbH 23 M3289UK-01/17

Page 26

Installation

5.2.8 Tensioning the secondary cleaner

NOTE

Perform the following steps carefully so that the MARTIN® brush

cleaner achieves the desired cleaning result.

CAUTION! RISK OF DAMAGE!

Excessive or uneven tightening of the conveyor belt cleaner on the

conveyor belt can cause material damage.

Only adjust conveyor belt cleaner according to specifications and

also ensure that the adjustments on both sides are the same.

NOTE

After the installation, the secondary cleaner must be adjusted to

the conveyor belt. In this, the cleaning elements should not be

pressed more than 3-4 mm against the conveyor belt.

Loosen the clamping screws (1, Fig. 12).

1.

Loosen the lock nut (4, Fig. 12).

2.

Loosen the securing nut (2, Fig. 12).

3.

NOTE

To avoid canting, both tensioners should be moved

simultaneously.

Turn the adjusting screw (3, Fig. 12) anticlockwise till the

4.

cleaning elements are pressed against the conveyor belt.

© Martin Engineering GmbH 24 M3289UK-01/17

Page 27

Installation

1

2

3

4

Fig. 11:

Pos. Description

1 Clamping screw

2 Securing nut

3 Adjusting screw

4 Lock nut

Tab. 5: Description of nuts and screws

5. Repeat working steps on the opposite side.

If the cleaning elements are in the correct position, tighten the

6.

clamping screws (1, Fig. 12

7.

Tighten the securing nut (4, Fig. 12).

8.

Tighten the lock nut (2, Fig. 12).

).

© Martin Engineering GmbH 25 M3289UK-01/17

Page 28

Installation

5.3 Test run

NOTE

Read through this section completely before starting any work on

the belt cleaner or on the customer's conveyor system.

CAUTION! FLYING OBJECTS!

Forgotten tools or installation parts can fall off of the running

conveyor belt and cause minor injuries and property damage.

Always remove any tools from the installation site and conveyor

belt upon completion of the installation work before switching on

the power supply.

WARNING! RISK OF INJURY!

Body parts and/or clothing may get caught and pulled in by

rotating parts or by the moving conveyor belt.

Before any installation or maintenance work is carried out, ensure

that all power sources to the conveyor belt system and its

accessories are switched off and secured against unauthorised

reactivation.

Use warning signs!

1. Thoroughly clean the external chute wall on the operator side

ve the tensioner. Affix Conveyor Products Warning L

abo

(Part No.

by the system operator (also refer to Fig. 13 on page 28).

23395) close to the product where they can be seen

abels

CAUTION! RISK OF DAMAGE!

Never operate the belt cleaner for longer than 15 minutes on the

running, unloaded conveyor belt. A risk of damage due to

overheating exists for the belt cleaner and/or the conveyor belt.

Only operate the belt cleaneron a running and fully loaded

conveyor belt.

2. Remove all tools and fire protection covers from the installati

site an

3.

Perform a 1-hour test run of the conveyor system.

Shut off the conveyor system after the test run, shut off the

4.

power supply and secure it against unauthorised reactivation.

5. Check whether all of the fastening parts are securely tightened.

Tighten a

d the conveyor belt.

ny loose connections.

on

© Martin Engineering GmbH 26 M3289UK-01/17

Page 29

6. Inspect the belt cleaner for the following conditions:

• Wear: a small amount of break-in wear is no

a

s the cleaning elements have adapted to the contou

e conveyor belt, this phenomenon ceases.

th

• Bulk material accumulation: No bulk material ma

a

ccumulate between the cleaning elements and the re

side.

Note the corresponding information in Section 7

7.

“Troubleshooting” in cases of excess wear, bulk material

accumula

tion or other problems.

rmal. As soon

Installation

r of

y

turn

© Martin Engineering GmbH 27 M3289UK-01/17

Page 30

Installation

No. 23395

! WARNING

Body parts and/or clothing may get caught and pulled in by rotating parts

or by the moving conveyor belt. Before any installation or maintenance work

is carried out, ensure that all power sources to the conveyor belt system and its

accessories are switched off and secured against inadvertent reactivation.

Use warning signs!

5.4 Placement of warning labels and warning tags

© Martin Engineering GmbH 28 M3289UK-01/17

Fig. 12:

Page 31

6 Maintenance

6.1 Safety information

NOTE

Maintenance inspections must be performed at least once a week.

Shorter maintenance intervals may be required depending on the

operating conditions.

NOTE

Read this section completely before starting any kind of work.

WARNING! RISK OF INJURY!

Body parts and/or clothing may get caught and pulled in by

rotating parts or by the moving conveyor belt.

Shut off the power supply to the conveyor system and its

accessories and secure it against unauthorised reactivation before

performing any maintenance work.

Use warning signs!

Maintenance

6.2 Weekly maintenance

1. Shut off the power supplies of the conveyor belt and any

add

itional equipment and secure them against unautho

reactivatio

2.

Remove all material deposits from the cleaning elements a

the

mainframe.

3.

Inspect whether all of the fastening parts are secure

tightene

4.

Check the cleaner tension and re-tighten if necessary.

Check the cleaning elements for wear, damage and missing

5.

parts.

n.

d. Tighten any loose con

NOTE

Check wear and adjustments once a month, adjust if necessary.

The cleaning elements must always make sufficient contact with

the conveyor belt.

rised

nd

ly

nections.

© Martin Engineering GmbH 29 M3289UK-01/17

Page 32

Maintenance

NOTE

Take the corresponding parts out of service if any indications of

functional disturbances are noticed. Contact Martin Engineering or

one of its representatives for support. Do NOT start up the

conveyor system until the cause of the problems has been

recognised and eliminated.

CAUTION! RISK OF DAMAGE!

Cleaning elements may not abrade under the height of the fixing

screws on the shaft or must still have at least an outer diameter of

90 mm, otherwise this can lead to serious material damage.

Inspect cleaning elements regularly and replace in time!

6. If the cleaning elements have a diameter of less than 90 mm,

the

se must be replaced in accordance with the instructio

Section 6

7.

Clean all the warning labels. Replace illegible warn

imme

Engineering or a

.3.

diately. Warning labels can be purchased from

contracted dealer.

ns in

ing labels

Martin

CAUTION! FLYING OBJECTS!

Forgotten tools or installation parts can fall off of the running

conveyor belt and cause minor injuries and property damage.

Always remove any tools from the installation site and conveyor

belt upon completion of the installation work before switching on

the power supply.

NOTE

The angled gearbox motor must be checked at least once a

month for oil level, oil change, leaks, etc. Observe instructions in

the manufacturer documentation on maintenance intervals!

NOTE

The bearing of the angled gearbox motor must be checked at least

once a week for lubrication, damage, running performance, etc.

Observe the information in the manufacturer's documentation

supplied with the device!

© Martin Engineering GmbH 30 M3289UK-01/17

Page 33

NOTE

The bearings are lubricated for continuous operation, and relubrication is not absolutely necessary. The bearings may need to be

relubricated under extreme conditions such as high temperatures,

temperature fluctuations and high dust exposure.

For example, the grease Arcanol MULTI2 (lithium soap on mineral

oil basis, viscosity at 40 °C >= ISO VG 68 mm²/s) can be used for

relubrication. This grease is suitable for temperatures from -30 °C

to +120 °C, or 75 °C continuous temperature. Refer to the corresponding documentation of the pillow blocks for additional information.

Relubrication intervals and quantities need to be defined as needed. The manufacturer specifies 60,000 h for speeds under

200 rpm.

8. Remove all tools from the working area.

9.

Switch on the conveyor system.

WARNING! RISK OF INJURY!

Body parts and/or clothing may get caught and pulled in by

rotating parts or by the moving conveyor belt.

Do not touch or reach into the conveyor system or its accessories

during operation.

Maintenance

10. Observe the brush cleaner and check its cleaning performance.

6.3 Replacement of the cleaning elements

WARNING! RISK OF INJURY!

Body parts and/or clothing may get caught and pulled in by

rotating parts or by the moving conveyor belt.

Before any installation or maintenance work is carried out, ensure

that all power sources to the conveyor belt system and its

accessories are switched off and secured against unauthorised

reactivation. Use warning s igns!

© Martin Engineering GmbH 31 M3289UK-01/17

Page 34

Maintenance

1

2

3

4

6.3.1 Lowering of secondary cleaner

The secondary cleaner must be lowered before carrying out

maintenance work or before de-installation.

The following steps are necessary for this:

1.

Loosen the clamping screws (1, Fig. 14

2.

Loosen the lock nuts (2, Fig. 14).

3.

Loosen the securing nuts (4, Fig. 14).

).

Fig. 13:

Pos. Description

1 Clamping screw

2 Securing nut

3 Adjusting screw

4 Lock nut

Tab. 6: Description of nuts and screws

© Martin Engineering GmbH 32 M3289UK-01/17

Page 35

4. Turn adjusting screw (3, Fig. 14) in the clockwise direction to

lo

wer the brush clea

ner.

NOTE

Lower the MARTIN® brush cleaner so that the cleaning elements

no longer touch the conveyor belt.

5.

Repeat working steps on the opposite side.

Maintenance

© Martin Engineering GmbH 33 M3289UK-01/17

Page 36

Maintenance

6.3.2 Replace cleaning elements

CAUTION! RISK OF INJURY!

The angled gearbox motor can be turned out of the way during the

dismantling.

Secure angled gearbox motor before dismantling.

NOTE

The old and new cleaning elements should always be the same

(material and pattern type).

Disconnect the power cable from the angled gearbox motor

1.

(if necessary).

Pull the angled gearbox motor (1, Fig. 15) off the shaft of

2.

secon

appropriately.

dary cleaner and lay it on a level, firm surface or se

the

cure

NOTE

Make sure that the electrical power cable does not remain hanging

and is not subjected to any mechanical strain. Secure

appropriately if the power cable has not been removed.

© Martin Engineering GmbH 34 M3289UK-01/17

Page 37

Maintenance

1

3

4

2

1

2

Fig. 14:

3. Loosen the bolts from both sides of the pillow block (3, Fig. 15)

and

pull it and the main shaft with the pillow blocks from t

chute.

Fig. 15: De-installation of the cleaning elements

Loosen screws in the locking ring (1, Fig. 16) and

4.

adjust

ment ring for the zigzag system (2, Fig. 16) at

pull off from th

and

e main shaft.

the

he

one side

© Martin Engineering GmbH 35 M3289UK-01/17

Page 38

Maintenance

1

Fig. 16:

5. Worn cleaning elements (1, Fig. 17) can now be replaced.

6. Install the secondary cleaner as in Section “Installin

cleane

r”.

g the

© Martin Engineering GmbH 36 M3289UK-01/17

Page 39

7 Troubleshooting

7.1 Safety information

NOTE

The product is exposed to many different types of bulk materials

and is often used under extreme operating and environmental

conditions. Malfunctions other than those listed below can

therefore occur.

In this case, either Martin Engineering or one of its representatives

can assist with the positioning or with special solutions. Do not

start up the conveyor system again until the fault has been

recognised and cleared.

7.2 Troubleshooting

Check the following items if excessively high wear on the cleaning

elements and/or unsatisfactory cleaning performance is noticed

following installation:

Troubleshooting

Symptom Cause Remedy

High wear on the

cleaning elements,

noise or vibration.

Inadequate cleaning

effect.

Tab. 7: Troubleshooting

The cleaner is too heavily

loaded.

The cleaner loading is too

lightly set.

Too high operating

temperature.

Cleaning elements do not

rotate with the rest.

Cleaning performance

inadequate due to high dirt

accumulation.

Cleaning elements are

worn.

Reduce the tension in the tensioner

(see Section 5.2.8).

Increase the pre-tension of the

tensioner. Die bristles of the

cleaning elements must be bent by

approx. 3-4 mm at the conveyor

belt.

The MARTIN

be used in the temperature range

0° C to +100° C.

Cleaning elements are not fixed to

the shaft; check fixing elements.

(zigzag system)

Install a pre-cleaner as an extra.

Renew cleaning elements, as

described in Section 6.3.2.

®

brush cleaner can

© Martin Engineering GmbH 37 M3289UK-01/17

Page 40

Troubleshooting

Symptom Cause Remedy

Unusual noises of

cleaning results.

Excessive

accumulation of

material

Uneven wear of the

cleaning elements

Motor gets hot, does

not rotate.

Maintenance intervals have

not been observed.

Wrong direction of rotation

of the angled gearbox

motor.

Impacts, conveyor belt

vibration. Motor imbalance,

heavy dirt on the cleaning

elements.

The cleaner loading is too

lightly set.

Cleaning elements have

increased material residues.

Cleaning elements are not

evenly arranged under the

conveyor belt.

Cleaning elements are not

centred on the belt loading.

Cleaning width too small.

Shaft touches the frame,

setting too high, brush

cleaner badly aligned.

Fibres on the brush or in the

bearing, bristles filled with

bulk material.

The angled gearbox motor must be

maintained at intervals of 10,000

working hours in accordance with

the documentation supplied.

The angled gearbox motor must

rotate in the direction opposite to

that of the conveyor belt.

Brush cleaner installed too far from

head pulley or return idler

removed. Align shaft to gearbox.

Wrong cleaning elements used.

Reduce the set distance of the

cleaning elements to the conveyor

belt.

Install cleaning elements of a

different trim type.

Align the brush cleaner horizontally

to the conveyor belt.

Check alignment, installation.

Adjust cleaning width.

Check and correct alignment,

installation; wrong brush type.

Tab. 7: Troubleshooting

© Martin Engineering GmbH 38 M3289UK-01/17

Page 41

8 Storage, de-installation, disposal

8.1 Packing and transportation

The products described here are packed and shipped by Martin

Engineering.

The products may be transported solely in the Martin Engineering

packaging.

The logistics company in charge of the shipment shall be

responsible for any damage and/or loss.

8.2 Storage

To ensure optimal function of the product, Martin Engineering

recommends storing its components in a dry place at room

temperature where they are protected against direct sunlight.

The best storage conditions are at temperatures ranging from +0 °C

to +30°C and 60% relative humidity.

Storage, de-installation, disposal

Martin Engineering guarantees that the stored products will remain

fully functional for at least 2 years under the storage conditions

specified here.

8.3 De-installation

The de-installation is carried out in the reverse order to that of the

installation (see Section 5.2.2, page 15).

8.4 Disposal

Assemblies and/or single parts of the Martin Engineering products

must be professionally disposed of after usage as follows.

• Complete assemblies must be dismantled, sort

material type, a

Comply with all nationally and internationally applicable disposal

regulations when disposing of the product.

ed by

nd separately disposed of.

© Martin Engineering GmbH 39 M3289UK-01/17

Page 42

9 Part numbers

Part numbers

This section lists the product designations with their associated part

numbers for the MARTIN

accessories.

Please always indicate the part numbers in every order.

®

Brush Cleaner system and its

9.1 Explanation of part numbers

Martin®Brush Cleaner

41580-aabccddeeffg-hh

a Belt width in inches

b Brush pattern version

F: Full

S: Spiral-shaped

L: Straight

c Bristle material

PB: Polyester (PBT)

BR: Brass

d Cleaning width in inches

e Main shaft material

MS: Mild steel (1.0037)

A2 Stainless steel (1.4031)

fVoltage (V)

11: 110

23: 230

40: 400

46: 460

g Frequency in Hertz

5: 50

6: 60

h Further options

X: Is simply incremented

9.2 MARTIN

With standard rubber door, up to 68 °C:

© Martin Engineering GmbH 40 M3289UK-01/17

®

Inspection doors

• 229 x 305 mm: Part no. CYAR-0912M.

• 305 x 356 mm: Part no. CYAR-1214M.

• 305 x 457 mm: Part no. CYAR-1218M.

• 457 x 610 mm: Part no. CYAR-1824M.

• 610 x 610 mm: Part no. CYAR-2424M.

Page 43

Part numbers

9.3 Installation manuals

9.4 Warning labels / Warning tags

9.5 Accessories and options

9.5.1 Inspection doors

• Martin® Inspection Door: Publication no. M3127.

• Conveyor Products Warning Label:

Part no. 23395

When installing the

transfer system, a MARTIN

improved accessibility during inspection and maintenance. This can

be purchased from Martin Engineering or a contracted dealer.

9.5.2 Cleaning elements

The cleaning elements for the

in various material and trim versions. The appropriate type of

material and trim is selected depending on the working conditions

(bulk material, temperature etc.). Please take further specifications

from the appropriate data sheet of the

L3863.

MARTIN

®

Brush Cleaner on an encapsulated

®

Inspection Door is recommended for

MARTIN

®

Brush Cleaner are available

MARTIN

®

Brush Cleaner

© Martin Engineering GmbH 41 M3289UK-01/17

Page 44

9.6 Martin®Brush Cleaner

11

13

12

1

8

Part numbers

2

4

5

10

9

3

7

6

OL

35

Fig. 17:

CW

IL

422

min. 503 /

max. 633

140

13,5

90

© Martin Engineering GmbH 42 M3289UK-01/17

Page 45

Part numbers

Item /

Pos.

11

2 1 Mainframe / Hauptachse 41581-18

3 2 Bearing pillow block / Stehlager-Gehäuseeinheit 41584-035-A

Qty /

Anz.

Description / Beschreibung P/N / Teile-Nr.

Spiroplan-Angle-Gearmotor / SpiroplanWinkelgetriebemotor

41582-XXX

4

52

62

7

81

91

10 2 Locking ring / Sicherungsring 41593-035-A

11 4

12 4

13 4

s.C. /

s.T.

2 Bearing mounting console / Lager Montagekonsole 41591

Spiral brush edging zick-zack system / Spiralbürste

Besatz Zick-Zack System

Fixing collar for Zick-Zack System / Stellring ZickZack System

Tensioner for Brush Cleaner / Spannvorrichtung für

Bürstenreiniger

Support plate for engine torque arm /

Aufnahmeblech für Motor-Drehmomentstütze

Feather keys DIN 6885-A, 6 x 6 x 70 mm /

Passfeder

HHC screw M6 x 20 - DIN 933, (1.0032) galv. /

Sechskantschraube

Washer flat M6 - DIN 125 A, (1.0032) galv. /

Unterlegscheibe

Washer spring M6 - DIN 127, (1.0032) galv. /

Federring

s.C. / s.T.

41587-035

41589-A

41592-A

41588-A-06-06-70

41081-06020BZP88

41088-06AZP

41090-06AZP

© Martin Engineering GmbH 43 M3289UK-01/17

Page 46

DIM

Part number /

Teilenummer

41580-18XXX12XXXXX-00 12 300 1000 1382 41581-18XXX 3

41580-24XXX20XXXXX-00 20 500 1150 1532 41581-24XXX 5

41580-30XXX24XXXXX-00 24 600 1300 1682 41581-30XXX 6

41580-36XXX28XXXXX-00 28 700 1450 1832 41581-36XXX 7

41580-42XXX36XXXXX-00 36 900 1600 1982 41581-42XXX 9

41580-48XXX40XXXXX-00 40 1000 1750 2132 41581-48XXX 10

41580-48XXX43XXXXX-00 43 1100 1750 2132 41581-48XXX 11

41580-54XXX47XXXXX-00 47 1200 1900 2282 41581-54XXX 12

41580-60XXX51XXXXX-00 51 1300 2050 2432 41581-60XXX 13

41580-66XXX59XXXXX-00 59 1500 2200 2582 41581-66XXX 15

CW

IL OL 1 4

[inch] [mm]

PN Item /

Teilenr. Pos.

Qty. Item /

Anz. / Pos.

Part numbers

41580-72XXX63XXXXX-00 63 1600 2350 2732 41581-72XXX 16

41580-78XXX71XXXXX-00 71 1800 2400 2882 41581-78XXX 18

© Martin Engineering GmbH 44 M3289UK-01/17

Page 47

Part numbers

Part number /

Teilenummer

41580-XXXXXXXMSXXX-00 41581-XXMS

41580-XXXXXXXA2XXX-00 41581-XXA2

PN Item /

Teilenr. Pos.

1

Part number /

Teilenummer

41580-XXXXXXXXX11X-00 41582-11X

41580-XXXXXXXXX23X-00 41582-23X

41580-XXXXXXXXX40X-00 41582-40X

41580-XXXXXXXXX46X-00 41582-46X

Part number /

Teilenummer

41580-XXXPBXXXXXXX-00 41586-10PBX

41580-XXXBRXXXXXXX-00 41586-10BRX

Part number /

Teilenummer

PN Item /

Teilenr. Pos.

2

PN Item /

Teilenr. Pos.

4

PN Item /

Teilenr. Pos.

4

Part number /

Teilenummer

41580-XXXXXXXXXXX5-00 41582-XXX5

41580-XXXXXXXXXXX6-00 41582-XXX6

Type of brush pattern /

Ausführung des

Bürstenbesatzes

PN Item /

Teilenr. Pos.

2

41580-XXFXXXXXXXXX-00 41586-10XXF Full seat / Voll

41580-XXSXXXXXXXXX-00 41586-10XXS

41580-XXLXXXXXXXXX-00 41586-10XXL Linear / Linear

© Martin Engineering GmbH 45 M3289UK-01/17

Spiral /

Spiralförmig

Page 48

9.6.1 Technical Specification Angular Gear Motor

• Operating voltage 110V-460V at 50/60 Hz 4-pole

(special voltages possible on request).

• Output: 0.55 kW

• Current consumption: 1.55 A at 400V/50Hz

• Ingress protection: IP55

• Protection class: ISO-F

• Speed: 135 rpm 50 Hz

• Peripheral speed: 0.4 m/s @ 50 Hz

• Operating temperatures: -20°C to +60°C

Part numbers

© Martin Engineering GmbH 46 M3289UK-01/17

Page 49

10 Declaration of Incorporation

Declaration of incorporation in accordance with

Machinery Directive (2006/42/EG)

Annex II B for the installation of an incomplete machine

We, Martin Engineering,

In der Rehbach 14 Tel.: +49 6123-97820

D-65396 Walluf Fax: +49 6123-75533

herewith declare that the product named in the following

Product designation:

Declaration of Incorporation

Conveyor belt cleaner

of make / type:

MARTIN

with serial number:

meets the following requirements:

Machinery Directive 2006/42/EC

DIN EN 618 - Equipment and systems for bulk materials

DIN/EN 1083-1; -2 Power-driven brushes

The following harmonised standards were particularly applied:

DIN EN ISO 12100 Safety of Machinery

Notified authority:

The installation instructions belonging to the product and the technical documentation are

enclosed with the product in their original version.

The commissioning of this product is prohibited until it has been determined that the system in

which it is to be installed meets the requirements of versions 98/37/EC and 2006/42/EC of the

EC Directive.

®

Brush Cleaner

not required

not required

Date: 21/01/2010

Manufacturer's signature: Managing director, Michael Hengl

© Martin Engineering GmbH 47 M3289UK-01/17

Page 50

PROBLEM SOLVED

™

Publication no. M3289UK-01/17 ©MARTIN ENGINEERING 2015

USA (Headquarters)

Martin Engineering

One Martin Place, 61345 Neponset (Illinois), USA

Tel. +1 (800) 544-2947; Fax +1 (800) 814-1553

info@martin-eng.com; www.martin-eng.com

European subsidiaries

Germany (Main European branch)

Martin Engineering GmbH

In der Rehbach 14, 65396 Walluf, Germany

Tel. +49 6123 97820; Fax +49 6123 75533

info@martin-eng.de; www.martin-eng.de

Great Britain

Martin Engineering Ltd.

8, Experian Way, NG2 Business Park,

Nottingham NG2 1EP, Nottinghamshire, Great Britain

Tel. +44 115 946 4746; Fax +44 115 946 5550

info@martin-eng.co.uk; www.martin-eng.co.uk

France

Martin Engineering SARL

50 Avenue d‘Alsace, 68025 Colmar Cedex, France

Tel. +33 389 20 63204; Fax +33 389 20 4379

info@martin-eng.fr; www.martin-eng.fr

Russia

OOO Martin Engineering

Ul. Bolshaya Dmitrovka, 23/1

125009 Moscow, Russia

Tel +7 495 181 33 43; Fax +7 499 720 62 12

info@martin-eng.ru; www.martin-eng.ru

Turkey

Martin Engineering Makina Sanayi ve

Ticaret Ltd.Sti

Yukari Dudullu Imes Sanayi Sitesi, B Blok 205 Sokak No.6

34775 Ümraniye Istanbul, Turkey

Tel. +90 216 4993 491; Fax +90 216 4993 490

info@martin-eng.com.tr; www.martin-eng.com.tr

Italy

Martin Engineering Italy Srl

Via Buonarroti, 43/A, 20064 Gorgonzola (MI), Italy

Tel. +39 295 3838 51; Fax +39 295 3838 15

info@martin-eng.it; www.martin-eng.it

Quality management system certified by DNV - ISO 9001

Subject to technical modifications

Loading...

Loading...