Page 1

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-8179 800-821-0023

Fax: (603) 434-1653

Martel Electronics

PO Box 770

1F Commons Drive

Londonderry, NH 03053

Rev B P/N 0219406 05/07

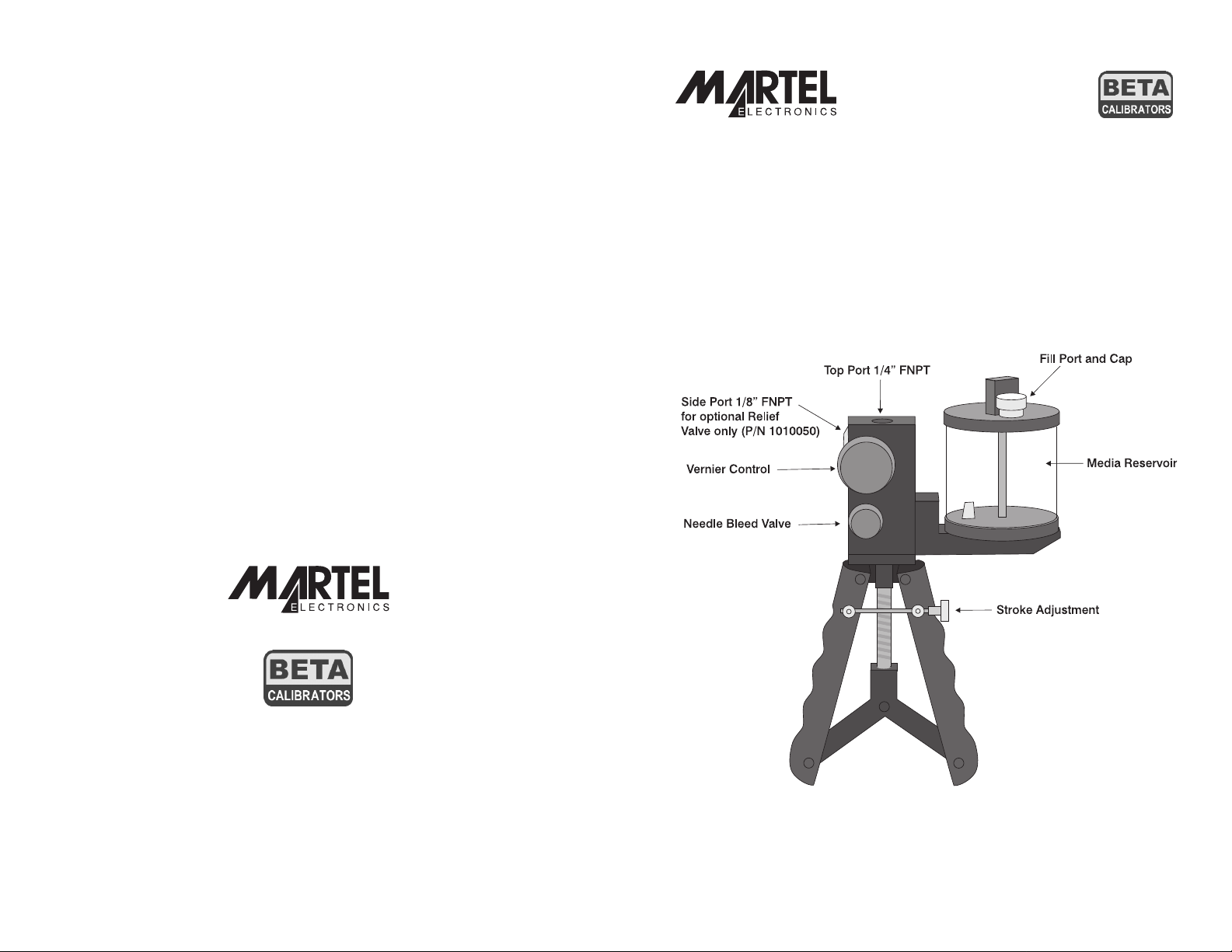

MECP10K

Hydraulic Hand Pump

Operating Instructions

Page 2

7. Manipulation of the needle valve, vernier control and the

handles can produce any pressure desired within the

MECP10K hand pump operating range (0 to 10,000 PSI).

8. CAUTION: To prevent personnel injury, the pressure must be

reduced to zero before disconnecting any element of the

system. When the calibration is completed, carefully open the

needle valve to release the pressure. NOTE: Opening the

needle valve releases the pressure media into the reservoir.

Do not allow the reservoir to overfill while venting. Store the

unit in a carrying case or another safe location. The MECP10K

may be stored with the operating fluid in the reservoir. It is

recommended that the fluid being utilized be identified so that

another potential operator of the MECP10K will be advised.

WARNING:

• Never use the MECP10K to generate pressure

greater than 10,000 PSI/700 Bar

• Never connect the MECP10K to a pressure source

• The 1/8” FNPT Port should only be used with optional

Relief Valve P/N 1010050

WARRANTY

Martel Electronics Corporation warrants the MECP10K hydraulic

pump against defects in materials and workmanship for a period of

twelve (12) months after date of sale. An invoice may be required as

proof of purchase for warranty claims. Damage due to

contamination or other misuse is not covered under this warranty.

If any product is to be returned, a “Return Material Authorization”

number may be obtained by calling our Customer Service

Department toll free at 1-800-821-0023 in the US or Canada or

+1-603-434-8179 outside the US. Access our RMA Form by using

www.martelcorp.com, under Customer Service.

The MECP10K Hydraulic Hand Pump provides a hydraulic

pressure source up to 10,000 PSI. A wide variety of pressure media

may be used but distilled water is the preferred fluid. The seals are

Fluorocarbon and the only other non-metallic materials are plastic.

Viscous oils should not be used.

CAUTION: Hydrocarbon fluids should never be used in oxygen

service applications.

1. Isolate the device to be calibrated. CAUTION: Do not connect

to high pressure sources. Safe operating procedures must be

exercised to avoid personal injury and damage to the

calibration system.

2. Remove the fill cap and fill the reservoir approximately

1

/2 - 2/3

full. Select a fluid compatible with the system and the

MECP10K. Do not allow the fluid level to drop below the

reservoir. (Doing so will allow air to be introduced into the test

system).

3. Care should be exercised to minimize the total test system

volume. Connect the device(s) to be calibrated to the pump

port(s) using fittings or braided hose with the appropriate

pressure ratings.

4. Adjust the vernier control to the mid position and close the

needle bleed valve.

5. NOTE: Air in the system should be minimized because it can

effect calibration and high pressure gases can be dangerous.

It may be necessary to "prime" the test system to eliminate

gases. Repeat until bubbles are not seen in the reservoir.

6. Close the needle valve and squeeze the handles until the

approximate desired pressure is reached. The vernier control

can be used to "fine tune" the pressure. Systems with large

volume may require additional bleeding. Continue until all

pressure points are calibrated. As higher pressures are

achieved, pumping force can be reduced by reducing the

stroke length using the continuously variable stroke

adjustment.

Loading...

Loading...