Page 1

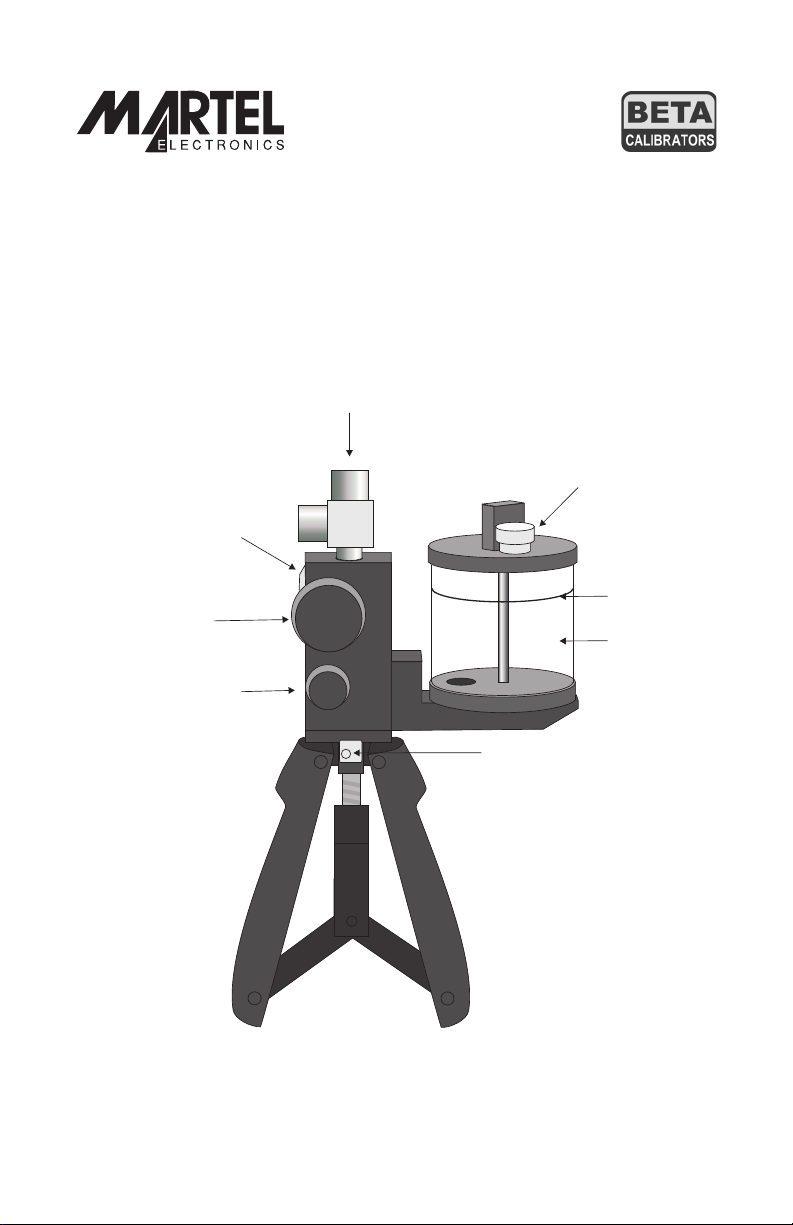

Hydraulic Hand Pump

Side Port 1/8” FNPT

for optional Relief

Valve only (P/N 1010050)

Vernier Control

Needle Bleed Valve

MECP10K

Top Port 1/4” FNPT

Fill Port and Cap

Fill Line

Media Reservoir

Stroke Limiter

Operating Instructions

Page 2

The MECP10K Hydraulic Hand Pump provides a hydraulic pressure

source up to 10,000 PSI. A wide variety of pressure media may be used;

distilled water, mineral based hydraulic oil, or up to hydraulic oil 100 (30W).

The seals are Fluorocarbon and the only other non-metallic materials are

plastic. Viscous oils above 30W should not be used.

CAUTION: Hydrocarbon fluids should never be used in oxygen

service applications.

1. Isolate the device to be calibrated. CAUTION: Do not connect to

high pressure sources. Safe operating procedures must be

exercised to avoid personal injury and damage to the calibration

system.

2. Select a fluid compatible with the system and the MECP10K.

Remove the fill cap and fill the reservoir to the fill line. During usage

do not allow the fluid level to drop below 50% of the reservoir

capacity. (Doing so will allow air to be introduced into the test

system).

3. Care should be exercised to minimize the total test system volume.

Connect the device(s) to be calibrated to the pump port(s) using

fittings or braided hose with the appropriate pressure ratings.

4. Adjust the vernier control to the mid position and close the needle

bleed valve.

5. Push the stroke limiter into the prime mode to allow the handles to

have maximum travel. With the hose to the device under test open

to air squeeze the handles to begin the priming process. (See

figure 1). NOTE: This can take many strokes of the pump

depending on the volume of the system and if the pump has not

been used for a while. It is important to use the full stroke of the

handles to make sure a full charge of hydraulic fluid is pulled from

the reservoir with each stroke.

6. Once the fluid starts to exit the end of the hose connect the hose to

the device to be calibrated and continue to squeeze the handles

until the reference gauge starts to show a sharp rise in the

pressure. At this point squeeze the handles and push the stroke

limiter into the pump mode thereby limiting the stroke of handles.

NOTE: failure to use the stroke limiter will greatly reduce the

mechanical advantage the user has and will limit the maximum

pressure that can be generated with reasonable handle pressure.

7. NOTE: Air in the system should be minimized because it

can effect calibration and high pressure gases can be

dangerous. It may be necessary to "prime" the test system

to eliminate gases. Repeat until bubbles are not seen in the

reservoir.

Page 3

ZERO

BETA

CALIBRATORS

BETA PROGAUGE P.I.

MAX

CONFIG

MIN

ENTER

Figure 1.

8. Close the needle valve and squeeze the handles until the

approximate desired pressure is reached. The vernier control can

be used to "fine tune" the pressure. Systems with large volume may

require additional bleeding. Continue until all pressure points are

calibrated.

9. Manipulation of the needle valve, vernier control and the handles

can produce any pressure desired within the MECP10K hand pump

operating range (0 to 10,000 PSI).

10. CAUTION: To prevent personnel injury, the pressure must

be reduced to zero before disconnecting any element of

the system. When the calibration is completed, carefully open the

needle valve to release the pressure. NOTE: Opening the needle

valve releases the pressure media into the reservoir. Do not

allow the reservoir to overfill while venting. Store the unit in a

carrying case or another safe location. The MECP10K may be

Page 4

stored with the operating fluid in the reservoir. It is recommended

that the fluid being utilized be identified so that another potential

operator of the MECP10K will be advised.

WARNING:

• Never use the MECP10K to generate pressure

greater than 10,000 PSI/700 Bar

• Never connect the MECP10K to a pressure source

• The 1/8” FNPT Port should only be used with optional

Relief Valve P/N 1010050

WARRANTY

Martel Electronics Corporation warrants the MECP10K Hydraulic Hand

Pump against defects in materials and workmanship for a period of twelve

(12) months after date of sale. An invoice may be required as proof of

purchase for warranty claims. Damage due to contamination or other

misuse is not covered under this warranty.

To obtain warranty or non-warranty service download an RMA form from

www.martelcalibrators.com/pdf/martel_rma_form.pdf. Complete the form

and include it with the shipment. Send the product pre-paid using a

trackable shipment method to the address on the form. Martel is not

responsible for goods sent by postal mail without tracking information.

0219406 Rev D 10/11

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-1433 800-821-0023

Fax: (603) 434-1653

Martel Electronics

3 Corporate Park Drive

Derry, NH 03038

Loading...

Loading...