Page 1

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-8179 800-821-0023

Fax: (603) 434-1653

Martel Electronics

PO Box 770

1F Commons Drive

Londonderry, NH 03053

Rev B 7/06 P/N 0219057

MECP100

Pneumatic Hand Pump

Operating Instructions

The Martel MECP100 Hand Pump is designed to be a simple to use

pressure and vacuum source for calibrating process control

instrumentation. Combined with one of our pressure calibrators, the

MECP100 makes a complete Pressure/Vacuum Calibration System.

Operation

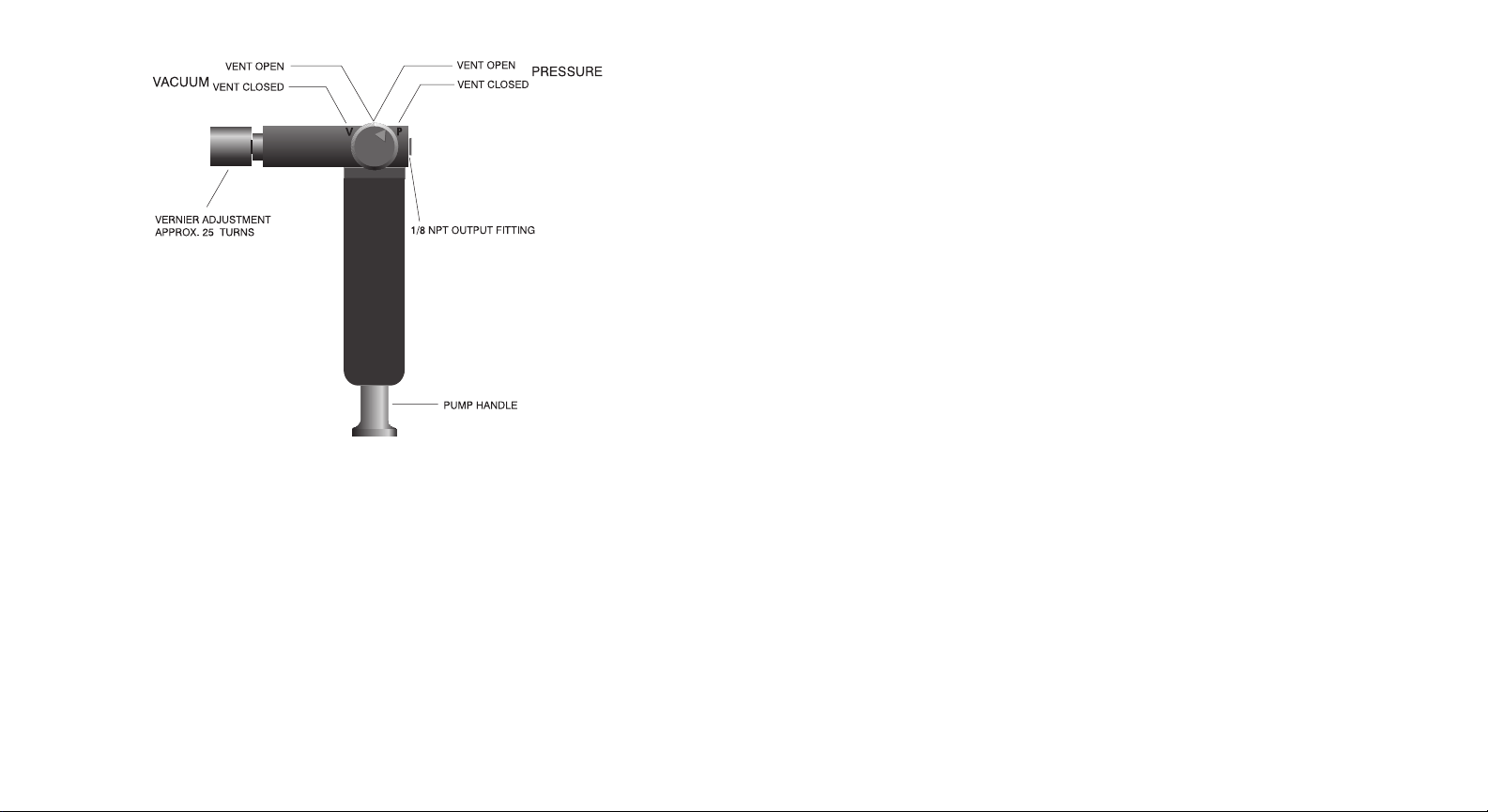

The drawing shows the operation of the controls on the MECP100. The

pump is designed for use with ambient air only. If there is a possibility that

contaminants may enter the pump the optional filter (Martel P/N 54-54067)

should be installed at the output fitting.

Page 2

4. Repeat the process several times using a new cotton swab each

time until there is no remaining evidence of contamination or dirt.

5. Operate the pump handles several times and recheck for

contamination.

6. Clean the o-ring assembly and the o-ring on the retention caps with

IPA and inspect the o-rings closely for any damage or excessive

wear. Replacements are included in the repair kit, if needed.

7. Inspect the springs for wear or loss of tension. They should be

approximately 8.6 mm long in the relaxed state. If shorter, they may

not provide sufficient sealing tension. Replace if needed.

8. Once all parts have been cleaned and inspected, reinstall the o-ring

and spring assembly into the valve body.

9. Reinstall the retention caps and gently tighten each cap.

10. Seal the output port and operate the pump to at least 50% of

capacity.

11. Release the pressure and repeat several times to ensure that the

o-rings seat properly.

WARRANTY

Martel Electronics Corporation warrants the MECP100 pneumatic pump

against defects in materials and workmanship for a period of twelve (12)

months after date of sale. An invoice may be required as proof of purchase

for warranty claims. Damage due to contamination or other misuse is not

covered under this warranty.

If any product is to be returned, a “Return Material Authorization”

number may be obtained by calling our Customer Service Department toll

free at 1-800-821-0023 in the US or Canada or +1-603-434-8179 outside

the US. Access our RMA Form by using www.martelcorp.com, under

Customer Service.

Pump Valve Assembly Cleaning Instructions

Occasionally, the MECP100 may not work properly due to dirt or other

contamination of the internal valve assembly. Use the following procedure

for cleaning the valve assembly. If this procedure does not fix the problem,

a repair kit (part number 1010043) may be ordered.

1. Using a small screwdriver, remove the 2 valve retention caps located

on opposite sides of the pump below the pressure/vacuum switch.

2. After the caps have been removed, gently remove the spring and

o-ring assembly.

3. Set aside the valve assemblies in a safe area and clean out the

valve body using a cotton swab soaked in IPA (isopropyl alcohol).

Loading...

Loading...