Page 1

MC1000

Multi-Function

Calibrator

Page 2

Table of Contents

1. Introduction

1.1 Customer Service . . . . . . . . . . . . . . . .1

1.2 Standard Equipment . . . . . . . . . . . . . .1

1.3 Safety Information . . . . . . . . . . . . . . . .2

2. Quick Start Instructions

A. Key Functions . . . . . . . . . . . . . . . . . . . .6

B. Setpoints . . . . . . . . . . . . . . . . . . . . . . .7

3. Connection Diagrams & Instructions

A. Measuring High Voltage AC or DC . . .10

B. Measuring Low Voltage

and Frequency . . . . . . . . . . . . . . . . . .10

C. Measuring Current . . . . . . . . . . . . . . .11

D. Sourcing Current . . . . . . . . . . . . . . . .11

E. Simulating Current . . . . . . . . . . . . . . .12

F. Sourcing Voltage/

Resistance/Frequency . . . . . . . . . . . . .12

G. Sourcing a Thermocouple Signal . . . .13

H. Measuring Temperature Using a

Thermocouple . . . . . . . . . . . . . . . . . .13

I. Measuring Resistance (RTDs) . . . . . . .13

J. Sourcing Resistance (RTDs) . . . . . . . .15

4. Serial Communications . . . . . . . . . . . .15

5. Maintenance

A. Power Requirements . . . . . . . . . . . . .19

B. Calibration . . . . . . . . . . . . . . . . . . . . .19

C. Field Replacement Fuse . . . . . . . . . . .19

6. Specifications . . . . . . . . . . . . . . . . . . .20

7. Warranty . . . . . . . . . . . . . . . . . . . . . . .23

Page 3

1

MC-1000

1. Introduction

The MC1000 is designed to be a versatile, easy

to use multi-function calibrator with a simple

user interface. The following instructions will

allow the user to begin simple calibration tasks

by learning the basic operation of the keys and

their functions.

1.1 Customer Service

Corporate Office:

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-1433 800-821-0023

Fax: (603) 434-1653

Martel Electronics

3 Corporate Park Dr.

Derry, NH 03038

1.2 Standard Equipment

Check to see if your calibrator is

complete. It should include:

MC1000 Calibrator, Instruction Manual, Test

Leads, Rubber Boot and NIST Certificate.

Page 4

2

1.3 Safety information

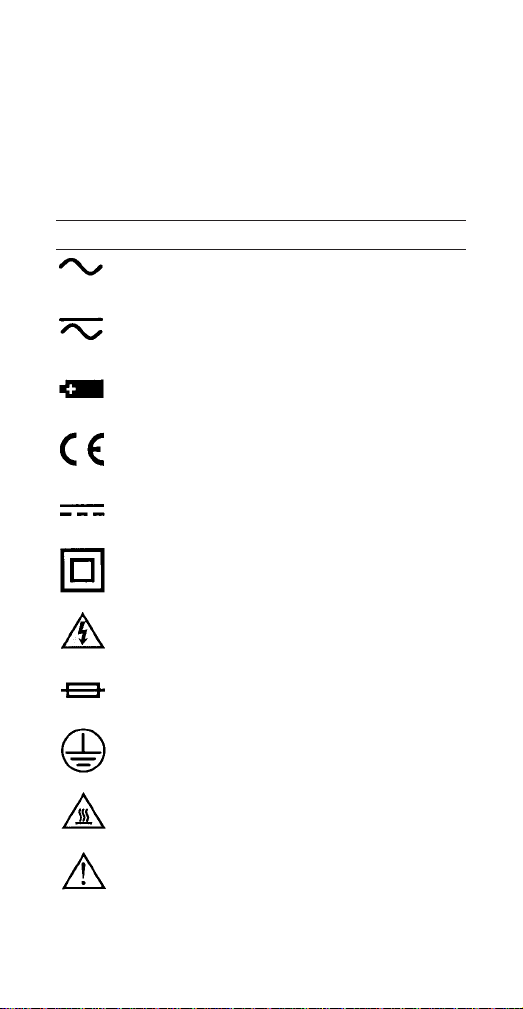

Symbols Used

The following table lists the International

Electrical Symbols. Some or all of these symbols may be used on the instrument or in this

manual.

Symbol Description

AC (Alternating Current)

AC-DC

Battery

CE Complies with European Union

Directives

DC

Double Insulated

Electric Shock

Fuse

PE Ground

Hot Surface (Burn Hazard)

Read the User’s Manual

(Important Information)

Page 5

3

Off

On

Canadian Standards Association

The following definitions apply to the terms

“Warning” and “Caution”.

• “Warning” identifies conditions and actions

that may pose hazards to the user.

• “Caution” identifies conditions and actions

that may damage the instrument being used.

Use the calibrator only as specified in this manual, otherwise injury and damage to the calibrator may occur.

Warning

To avoid possible electric shock or

personal injury:

• Do not apply more than the rated voltage.

See specifications for supported ranges.

• Follow all equipment safety procedures.

• Never touch the probe to a voltage source

when the test leads are plugged into the current terminals.

• Do not use the calibrator if it is damaged.

Before you use the calibrator, inspect the

case. Look for cracks or missing plastic. Pay

particular attention to the insulation surrounding the connectors.

• Select the proper function and range for your

measurement.

• Make sure the battery cover is closed and

latched before you operate the calibrator.

Page 6

4

• Remove test leads from the calibrator before

you open the battery door.

• Inspect the test leads for damaged insulation

or exposed metal. Check test leads continuity.

Replace damaged test leads before you use

the calibrator.

• When using the probes, keep your fingers

away from the probe contacts. Keep your fingers behind the finger guards on the probes.

• Connect the common test lead before you

connect the live test lead. When you disconnect test leads, disconnect the live test lead

first.

• Do not use the calibrator if it operates abnormally. Protection may be impaired. When in

doubt, have the calibrator serviced.

• Do not operate the calibrator around explosive gas, vapor, or dust.

• When using a pressure module, make sure

the process pressure line is shut off and

depressurized before you connect it or disconnect it from the pressure module.

• Disconnect test leads before changing to

another measure or source function.

• When servicing the calibrator, use only specified replacement parts.

• To avoid false readings, which could lead to

possible electric shock or personal injury,

replace the battery as soon as the battery

indicator appears.

• To avoid a violent release of pressure in a

pressurized system, shut off the valve and

slowly bleed off the pressure before you

attach the pressure module to the pressure

line.

Page 7

5

Caution

To avoid possible damage to calibrator or

to equipment under test:

• Disconnect the power and discharge all highvoltage capacitors before testing resistance

or continuity.

• Use the proper jacks, function, and range for

your measurement or sourcing application.

• To avoid mechanically damaging the pressure

module, never apply more than 10 ft-lb. of

torque between the pressure module fittings,

or between the fittings an the body of the

module.

• To avoid damaging the pressure module from

overpressure, never apply pressure above the

rated maximum printed on the module.

• To avoid damaging the pressure module from

corrosion, use it only with specified materials.

Refer to the pressure module documentation

for material compatibility.

Page 8

2. Quick Start Instructions

A. Key Functions

Key Function

Input/Output Toggles the function selected

from measurement mode to

source mode.

V/mA/Hz Selects between volts, mil-

liamps, and frequency modes

TC/RTD Selects between temperature

modes either T/C or RTD.

Ohms and mV ranges are also

included in these functions.

Ranges/Units This key toggles through all

the ranges for a chosen function. Example: If T/C mode is

selected the Range key toggles through the ranges J, K,

T, E, etc.

0-9 keys These keys allow a user to

enter an output value.

Example: to output 20 mA

select mA output and Press

the “2” key then the “0” key

followed by the “ENTER” key.

Arrow ↑↓ These keys allow small

changes to be made to an output value. Press either the up

or the down arrow key to set

the value as desired.

CE The clear entry key allows the

user to clear a value before the

enter key is pressed.

Shift This key has a blue text color

6

Page 9

and acts as a second function

key to all keys that have an

associated second function.

Features such as setpoints,

°F/°C, backlight and external

pressure module activation all

use the Shift key.

B. Setpoints

1. Storing Setpoints

The setpoint mode allows up to 9 setpoints to be stored in non-volitile memory for each range. The procedure is as

follows:

a. Set the output to the desired value.

b. Press shift followed by the “SET” key.

c. Choose the desired setpoint storage

location by pressing a key (1-9).

d. Enter a new value and repeat steps 1

thru 3 as needed, up to 9 setpoints for

each range can be stored.

2. Recalling Setpoints

a. To recall a setpoint, press shift fol-

lowed by the”SPT” key.

b. You will be prompted to enter the

number of the desired setpoint location stored previously.

c. Press the desired location number and

the unit will go to that output.

3. Automated Stepping

The MC1000 can auto-step through

some or all of the stored setpoints for a

given range. The procedure is as follows:

a. Press “Shift” followed by auto.

b. “Auto SPT ?” will appear. Enter the

7

Page 10

ending setpoint location. Example: if

you have all 9 setpoints stored but

only want to step through the first 3

then enter “3” for this question.

c. The next screen prompts you to enter

the dwell time from 5 to 500 seconds.

Simply enter a number in that range.

Then press the “Enter” key.

d. Auto-step will begin.

e. To exit auto-step press “CE” key or

enter a value.

4. Manual Stepping

The MC1000 can be manually stepped

through all or some of the stored setpoints. The procedure is as follows:

a. Press “Shift” followed by “Man”.

b. Using the arrow keys, toggle up and

down through the stored setpoints.

c. To exit press CE or simply enter a new

output value.

5. Pressure Module Interface

The MC1000 has the capability to interface with a family of pressure modules

available from Martel. The procedure is

as follows:

a. Connect the pressure module to the

15 pin “D” connector on top of the

MC1000.

b. Press “Shift” followed by the “ ”

key.

c. Always zero the pressure module

before starting a calibration. Press

“Shift” followed by the “Zero” key.

Note: More detailed information can be found with

the instructions packaged with each module.

8910

Page 11

Page 12

3. Connection Diagrams &

Instructions

A. Measuring High Voltage AC or DC

1. Select the Voltage Input Mode. Use the

“Range” key to select either AC or DC input.

2. Connect the device to be measured as

shown in Figure 1.

! WARNING ! When measuring high voltage be

sure to use proper connections as shown in

Figure 1. Failure to do so will cause serious

damage to the calibrator.

B. Measuring Low Voltage and Frequency

1. Select the desired mode Voltage or

Frequency. Use the “Range” key to select the

proper range for the mode chosen.

2. Connect the device under test as shown in

Figure 2.

Figure 1.

Figure 2.

! WARNING ! Do not exceed 20 VDC at the

V/Ω/Hz input.

Page 13

11

C. Measuring Current

1. Select the mA input mode. Note: To power

the loop while reading current, select the

“mAPW” mode.

2. Connect the device under test as shown in

Figure 3.

3. Current can either be measured directly in

mA or as a percentage such that 4 to 20 mA

corresponds to 0 to 100%.

D. Sourcing Current

1. Select the mA output mode on the calibrator.

2. Connect device under test as shown in

Figure 4.

3. Enter the value of desired output current.

Note: If the loop is open “OL” will appear in the

display.

Figure 3.

Figure 4.

Page 14

12

E. Simulating Current

The MC1000 can act as a two-wire transmitter

and control a 4-20mA loop from the external

power supply for that loop.

1. Select the mA “2W” output mode.

2. Connect the device as shown in figure 5.

3. Enter the desired output.

F. Sourcing

Voltage/Resistance/Frequency

1. Select the proper operation mode: volts,

ohms, frequency.

2. Connect device under test as shown.

3. In the resistance or frequency modes use the

“Range” key to choose the desired range for

the mode you’re operating in.

4. The MC1000 is capable of driving up to ±1

mA on the Voltage and Frequency ranges

and is able to handle up to a 3 mA excitation

on the Resistance Simulation Range.

Exceeding these limits will result in a warning

on the display.

Figure 6.

Note: The frequency output is a 12 Volt square

wave with –.1 volt offset

Figure 5.

Page 15

13

I. Measuring Resistance (RTDs)

When measuring resistance (ohms) there are 3

choices when using the MC1000; 2-wire, 3wire, and 4-wire. While 4-wire offers the highest

accuracy, most industrial RTDs are a balance 3wire. Figure 9. shows how to hook up the

MC1000 for the 3 types of measurements.

1. Choose the desired RTD/ohms range by first

pressing the “TC/RTD” key to get into the

RTD mode. Then use the “Range” key to

select the desired range within the RTD

mode.

H. Measuring Temperature Using a

Thermocouple

Figure 8.

G. Sourcing a Thermocouple Signal

TC wire must be used to achieve an accurate

calibration.

Figure 7.

Note: For best accuracy allow a 10 minute

warm-up period after the MC1000 is turned on.

Page 16

14

2. Make sure the MC1000 is in the Input Mode

(Note: that it will indicate 2, 3, or 4W in the

upper left corner of the LCD).

To set the desired wire configuration use the

“Up/Down arrow” keys to toggle through the

2, 3, and 4 wire modes.

Measuring a 2 Wire RTD or Using the

Continuity Function

Measuring a 3 Wire RTD

Measuring a 4 Wire RTD

Figure 9.

Page 17

15

4. Serial Communications

The MC1000 calibrator is equipped with a RS232 serial communications port, which is located on the top of the case.

Note: The user will require a special RS-232

cable to connect the calibrator to a computer or

terminal.

Communication

Once the cable is attached, set the communications program settings as follows:

Baud Rate = 9600

Data Bits = 8

Stop Bits = 1

Parity = None

Flow Control = Xon/Xoff

J. Sourcing Resistance Into a RTD

Transmitter

1. As described previously in section F the

MC1000 can source resistance in a RTD

Transmitter or measuring device. In many

cases the unit under test will require a 3 or 4

wire connection to achieve best accuracy.

Refer to Figure 10 for connection information.

Figure 10.

Page 18

The MC1000 calibrator can be used with

virtually any terminal emulation software. (i.e.

Procomm or HyperTerminal)

When connected properly, data will be transmitted as soon as the calibrator is turned on. The

data transmitted to the terminal or computer will

mirror that sent to the calibrators LCD display

and will be updated approximately every 0.4

seconds.

Serial Communications

Procedure for HyperTerminal

Program

1. From the Windows®XP desktop, click on

“Start”.

2. Click on “All Programs”.

3. Under the category “Accessories”, click on

“Communications”.

4. Click on “HyperTerminal”.

5. Next appears a screen labeled: CONNEC-

TION DESCRIPTION. In the box titled: Name,

enter a name for your program settings...

example: “MC Connection”. In a box titled:

Icon, click on the icon of your choice. Click

on the OK box to accept these entries.

6. Next appears a screen labeled: CONNECT

TO. In the box titled: Connect Using, select

the serial port that corresponds to the com-

puter serial port that you’ll be using to com-

municate to the MC1000 calibrator. Click on

the OK box to accept this entry.

7. Next appears a screen labeled: COM X

PROPERTIES (where X corresponds to the

serial port selected in step #6). Enter port

settings as follows:

(A.) Bits per second: 9600

(B.) Data bits: 8

(C.) Parity: None

16

Page 19

(D.) Stop Bits: 1

(E.) Flow Control: Xon/Xoff

Click OK box to accept these entries.

8. Hook up the MC1000 calibrator to the PC uti-

lizing the special Martel Electronics RS-232

cable as follows:

(A.) Plug the 9 pin connector end of the

cable to the appropriate serial port

on the computer.

(B.) With the MC1000 calibrator

switched off, plug the other end of

the cableplug the other end of the

cable into the DB-15 connector on

the top of the MC1000 calibrator.

9. Power up the MC1000 calibrator per the

appropriate instruction manual. The computer

screen should now be displaying data being

sent directly from the MC1000 calibrator.

Note: You may wish to save these settings

when exiting HyperTerminal. If so, click on the

OK box when prompted “Do you want to save

X?”, where X corresponds to the name entered

in Step #5.

Computer Controlled Operation

The MC1000 calibrator can be operated remotely via a computer or terminal. When connected

to a computer, via the RS-232 serial data port

and appropriate cabling, the user may control

the calibrator functions remotely by utilizing simple computer keyboard commands.

The following chart details which computer keys

control which MC1000 calibrator functions:

17

Page 20

Serial Input Description

A mA measurement

a mA source

I mA loop

i mA 2W Sim

V Volts measurement

v Volts source

M mV measurement

m mV source

E HVAC measure

e HVDC measure

K Khz measurement

k Khz source

H Hz measurement

h Hz source

P CPM measurement

p CPM source

W 2-wire measurement (Ohms and RTDs)

X 3-wire measurement (Ohms and RTDs)

Y 4-wire measurement (Ohms and RTDs)

T Thermocouple measurement (default Type J) use

"S" command to select sensor type

t Thermocouple source (default Type J) use "S"

command to select sensor type

C Selects Centigrade ( T/C - RTD )

F Selects Fahrenheit ( T/C - RTD )

R RTD measurement mode (default Pt100 385) use

"S" command to select sensor type

r RTD measurement mode (default Pt100 385) use

"S" command to select sensor type

0-9 Enter a source value using ascii characters

-,. 0,1,2,..,9,-,.terminated by <CR>(carriage

<CR> return)

D Single Broadcast of most recent display value and

units

d Single Broadcast of most recent display value

"S" Commands Select

Sensor Type

Serial Input Selection Entry Description

S No. T/C Type RTD Type

1 J Pt100 (3926)

2 K Pt100 (385)

3 T Pt100 (3916)

4 E Cu10

5 R Pt200 (385)

18

Page 21

19

Serial Input Selection Entry Description

S No. T/C Type RTD Type

6 S Pt500 (385)

7 B Pt1000 (385)

8 L NI120

9 U YSI

A N OHMS

BmV

® Microsoft, Windows, Windows NT, and MS-DOS are registered

trademarks of Microsoft Corporation. All other product names or

services identified throughout this manual are registered trademarks or trademarks of their respective companies.

5. Maintenance

A. Power Requirements

The MC1000 operates on 4 AA alkaline batteries

only.

B. Calibration

The MC1000 should hold its rated specifications for a minimum of one year. Given this,

annual re-calibration is required for best performance. See the customer service section (7.)

to contact Martel for re-calibration information.

C. Field Replacement Fuse

MC1000 comes with a field replaceable minifuse. This fuse protects the MC1000 inputs and

outputs. If an overload condition occurs and a

blown fuse is suspected perform the following

fuse check/replacement procedure:

1. Remove the four screws on the rear of the

MC1000 that hold the enclosure together.

NOTE: Two of the screws are under the battery compartment door.

2. With the case top open, locate the two socketed mini fuses mounted near the input/output connection jacks.

Page 22

20

6. Specifications

Pressure Module Dependent. Operates with Fluke 700 Series

Ranges: Modules

T/C Ranges: J, K, T, E, R, S, N, B, L, U including – 10 to 70mV

RTD Ranges: Pt 385 (100, 200, 500, 1000 ohms)

Pt 392, JIS, Ni120, CU10, YSI400

Ohms Ranges: 0 to 400.00 and 400.0 to 3200.0

mA Range: 0 to 24.000 mA

Voltage: (Low) Input 0-20.000 V, Output 0-20.000 V

(High) Input only 0-250 VDC or VAC

Frequency: Source

Measure

CPM 2.0-1000.0 0.0-1000.0

Hz 0-1000 0.0-1000.0

kHz 1.0-10.0 0.0-10.00

Continuity: 0 to 400.0 ohms, audible tone when under 10 ohms

Accuracy: T/C Type J: ±.3°C ±10 µV (±0.4°C total error)

RTD PT100: ±.1°C ±.075 Ω (±0.3°C total error)

Ohms (400): ±0.1 Ω

Ohms (3200): ±1.0 Ω

mA Compliance: Up to 1000 Ω load

Voltage Drive

Capability: 1 mA

RTD IEX-range: 0.01 mA to 3 mA

RTD Frequency

Response: 10 mS – works with all pulsed XMTR’s

Oper. Temp: -10°C to 50°C

Storage Temp: -40°C to 60°C

Loop Power: 4 AA alkaline batteries, 25 hours typical operating

time

Size: 7.5" x 4" x 1.5"

3. Remove one fuse at a time and check continuity using an ohmmeter. A good fuse will

read 10 ohms or less. A blown fuse will have

a very high reading and generally show as

an open circuit.

4. If a blown fuse is found replace with the

enclosed spare fuse.

5. To order more fuses contact Martel

Electronics and order part no. 3535039.

Page 23

21

Range & Accuracy

Range Min Max Accuracy

(% of reading ±

counts)

V Read (low) 0.000 20.000 0.015% ±2

VDC Read (high) 0.0 250.0 0.05% ±2

VAC Read (high) 0.0 250.0 0.5% ±2

V Source 0.000 20.000 0.015% ±2

mV Read -10.00 75.00 0.015% ±2

mV Source -10.00 75.00 0.015% ±2

mA Read 0.000 24.000 0.015% ± 2

mA Source 0.000 24.000 0.015% ± 2

CPM Source 2.0 1000.0 0.05%

Hz Source 1 1000 0.05%

KHz Source 1.0 10.0 0.25%

CPM Read 0.0 1000.0 0.05% ± 1

Hz Read 0.0 1000.0 0.05% ± 1

KHz Read 0.00 10.00 0.05% ± 1

Range Min Max Accuracy

Ohms Read (low) 0.00 400.00 0.1 ohm

Ohms Read (high) 400.0 1500.0 0.5 ohm

1500.1 3200.0 1.0 ohm

Range Min Max Excitation Accuracy

Current

Ohms Source (low) 5.00 400.00 0.1 to 0.5 mA 0.15 ohm

5.00 400.00 0.5 to 3 mA 0.1 ohm

Ohms Source (high) 400.0 1500.0 0.05 to 0.8 mA 0.5 ohm

1500.0 3200.0 0.05 to 0.4 mA 1.0 ohm

Thermocouple Read and Source (All errors included)

Range Min Max Accuracy

J Thermocouple -200.0 0.0 0.6°C

0.0 1200.0 0.4°C

K Thermocouple -200.0 0.0 0.8°C

0.0 1370.0 0.5°C

T Thermocouple -200.0 0.0 0.8°C

0.0 400.0 0.5°C

E Thermocouple -200.0 0.0 0.5°C

0.0 950.0 0.4°C

R Thermocouple -20 0.0 2.49°C

0 500 1.7°C

500 1750 1.3°C

S Thermocouple -20 0 2.4°C

0 500 1.7°C

500 1750 1.4°C

B Thermocouple 600 800 2.1°C

800 1000 1.7°C

1000 1800 1.3°C

Page 24

Thermocouple Read and Source (All errors included) (cont.)

Range Min Max Accuracy

L Thermocouple -200 0.0 0.45°C

0.0 900.0 0.4°C

U Thermocouple -200 0.0 0.7°C

0.0 400.0 0.45°C

N Thermocouple -200 0.0 1.1°C

0.0 1300.0 0.6°C

mV Read/Source -10.00 75.00 0.015% ±.02

mV

RTD Read and Source

Range Min Max Accuracy

Ni120 (672) -80.0 260.0 0.2°C

Pt100 (385) -200.0 800.0 0.33°C

Pt100(3926) -200.0 630.0 0.3°C

Pt100(3916) -200.0 630.0 0.3°C

Pt200(385) -200.0 630.0 0.8°C

Pt500(385) -200.0 500.0 0.3°C

500.0 630.0 0.4°C

Pt1000(385) -200.0 100.0 0.2°C

100.0 630.0 0.3°C

Cu10 -100.0 250.0 2.2°C

Cu50 -180.0 200.0 0.5°C

Cu100 -180.0 200.0 0.3°C

YSI400 15.00 50.00 0.05°C

22

Page 25

7. Warranty

Martel Electronics Corporation warrants all

products against material defects and workmanship for a period of twelve (12) months

after the date of shipment. Problems or defects

that arise from misuse or abuse of the instrument are not covered. If any product is to be

returned, a “Return Material Authorization” number must be obtained from our Customer

Service Department. This number must be indicated on the return package as notice to our

Receiving Department to accept the shipment.

Any package not so marked will not be accepted and will be returned to the shipper. Martel

will not be responsible for damage as a result

of poor return packaging. Out of warranty

repairs and recalibration will be subject to specific charges. Under no circumstances will

Martel Electronics be liable for any device or

circumstance beyond the value of the product.

23

Page 26

Page 27

Page 28

Rev G 10/08 0219041

Corporate Office:

www.martelcorp.com

e-mail: sales@martelcorp.com

Tel: (603) 434-1433 800-821-0023

Fax: (603) 434-1653

Martel Electronics

3 Corporate Park Dr.

Derry, NH 03038

Loading...

Loading...