Page 1

M2000

Operator’s Manual

Page 2

Table of Contents

I. INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

II. STANDARD EQUIPMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

III. OPTIONS AND ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

IV. UNPACKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

V. NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

VI. GETTING STARTED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

VII. VOLTAGE OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

VIII. CURRENT OUTPUT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

IX. SETPOINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

X. REMOTE INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

XI. REMOTE COMMANDS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

XII. SPECIFICATIONS

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

DC Voltage, Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

DC Current, Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

2

Page 3

I. INTRODUCTION

The Martel series M2000 calibrator is designed to be an accurate DC calibrator for R & D,

manufacturing and calibration lab applications. The units simple design and ease of operation allows users to quickly familiarize themselves with its operations and features. Time saving functions like the ability to save, recall and automatically cycle through setpoints for each

output range and a complete remote interface are several key features the M2000 offers.

II. STANDARD EQUIPMENT

• Power cord (for 120 VAC versions)

• Manual

• Certificate of Calibration

III. OPTIONS AND ACCESSORIES

• Panel mount kit (Martel P/N M2000-PMK)

• Low EMF Beryllium copper test leads

IV. UNPACKING

Upon receipt of shipment, inspect the container and equipment for any signs of damage.

Take particular note of any evidence of rough handling in transit. Immediately report any

damage to the shipping agent.

NOTE: The carrier will not honor any claims unless all shipping material is saved for their

examination.

After examining and removing contents, save packing material and carton in the event

re-shipment is necessary.

Remove the Packing List and verify that all equipment has been received. If there are any

questions about the shipment, please call Martel Electronics at 1-800-821-0023.

Check to see if your calibrator is complete. It should include: M2000 Calibrator

Instruction Manual

AC Line Cord

V. NOMENCLATURE

Front Panel Controls and Functions (Refer to Figure 1 for locations)

Fig. 1 Location Description Function

1 Cursor Control Keys Left and Right arrows control cursor placement.

Up and Down arrows increment or decrement the selected

decade.

2 Enter Key Used to acknowledge or accept a value entered through

the keypad. Note: The output will only go to the new

value after the enter key is pressed.

3 Data Entry Keys This numeric keypad is used to set the calibrator to a

specific output.

Several of the keys also act as “second function” keys.

3

Page 4

4

4 Primary Function Keys

VOLTS/mA Toggles through the Voltage and mA output ranges.

STBY/OPR Toggles between standby and operate modes.

2nd The “second function” key allows the use of the features

described by the second function keys.

CE The “clear entry” will clear the display if a mistake is made

during data entry.

5 Secondary Function Keys These keys perform second functions after the 2nd key has

been pressed.

CAL Used to set LCD contrast, backlight and interface

parameters RS-232 or GPIB (2001A).

For a complete electrical calibration the RS-232 mode is

used. Contact factory for more information.

SET Used to set a setpoint.

See

Section IX RCL Used to recall a setpoints.

AUTO Used to initiate auto setpoint.

See Section X LOCAL Used to regain local control.

6 Output Binding Posts These binding posts are made of a special copper alloy to

reduce thermal EMF’s. These posts support the use of

both standard banana plugs or discreet wires.

7 Display The 16 character by 2 line display is backlit and provides

all visual user feedback.

7A Range Field Displays the range and setpoint number if applicable.

7B OPR/STBY Displays the output state.

7C Unit Field Displays output units.

7D Value Field Displays output value.

Page 5

5

Refer to Figure 2 for locations

Fig. 2 Location Description Function

1 Voltage Selector and Removing this door allows the user to access the input

Fuse Holder voltage selector switch and the two (2) user replaceable

fuses.

2 On/Off Rocker Switch This is the main power switch for the M2000. It is a double

pole designed for safety.

3 AC Power Inlet This is a standard IEC universal AC input power connector

for worldwide line cord usage.

4 RS-232 Connector The male 9 pin “D” connector allows the M2000 to be con-

nected to any computers serial interface.

5 IEEE 488.2 Connector This connector is only installed on the M2000A for connec-

tion to an IEEE 488.2 (GPIB) Bus.

Figure 1

Front Panel Layout

Figure 2

Rear Panel Layout

1 Cursor Control and

output adjustment

keys

2 Enter or Return key

3 Numeric Data Entry and

2nd function keys

4 Primary Function Control

keys

5 Secondary Function Keys

6 Terillium/copper

output binding

posts

7 16 x 2 Backlit LCD

w/contrast control

7A

7B

7C

7D

4 RS-232 Connector

standard on both the

M2000 and M2000A

5 Optional IEEE 488.2

(GPIB) connector

(Note: M2000A ONLY)

1 Input Voltage

Selector and Fuse

holder (see maintenance section for

fuse specifications)

2 Main Power On/Off

Rocker Switch

3 Standard IEC AC Power

Inlet 120/240 VAC

Page 6

6

VI. GETTING STARTED

1. After unpacking the M2000 and becoming familiar with the nomenclature of the unit as

described in the previous section, the M2000 is ready to be operated.

2. Before attaching the power cord to the rear connector the voltage selector must be set

to the proper line voltage. To do this, remove the rear fuse cover found just above the

On/Off rocker switch (see Figure 2, item #1). Pull out the voltage selector connector and

set it for the proper line voltage using the following guidelines:

Line Voltage (50/60Hz) Selector Position

90 to 135 VAC 120 VAC position

220 to 250 VAC 240 VAC position

3. Once the voltage selection has been made, making sure the power switch is off, connect

the AC power cord to the M2000. (See figure 2, item #3 for reference).

4. Turn on the M2000 using the rear panel mounted rocker switch. The M2000 should

power up within a few seconds. For good stability it is best to leave the M2000 on all the

time.

NOTE: If power up does not occur within 30 seconds re-power the unit.

VII. VOLTAGE OUTPUT

1. To output a voltage, enter voltage mode by pressing the key. The calibrator will auto-range in voltage source based on the value of the outputted value. If you

want to lock the calibrator in a specific voltage range press the key followed

by the key.

2. Connect the unit under test (UUT) to the voltage output jacks of the M2000. See figure 3.

3. Using either cursor keys or numeric keypad, enter the desired output value. If the

numeric keypad is used for data, all entries must be acknowledged by pressing the

key.

4. When selecting an output on a new range the M2000 will be in the standby (STBY) mode

which puts the positive (+) output jack in a high impedance state (>100k ohm) for safety.

The output can be placed into the active state by pressing the key which

toggles between the standby and operate modes.

NOTE: The standby mode is also activated if a fault occurs during operation such as an

overload or short circuit condition. For safety the standby mode is activated for the first

output over 30 VDC. Refer to the product specification section of this manual for maximum drive currents.

5. When small changes to an output value are required or if specific decades need to be

incremented or decremented the cursor controls offers a simple solution. The left and

right arrow keys move a cursor that is used to underscore any digit of the output. The

up/down arrow keys allow the digit to be incremented and decremented.

STBY/OPR

Enter

CAUTION

For best accuracy on the mV range use only test leads with

copper plugs. This will minimize thermal EMFs.

Volts/mA

Shift

Volts/mA

WARNING – To prevent electrical shock, only set

the line voltage with the power cord removed.

!

Page 7

7

VIII. CURRENT OUTPUT

1. To output currents of up to 100mA press the key until the milliamp output

range appears on the display.

2. Operation of the mA output is similar to voltage, operating where output values can be

selected or manipulated by using the numeric data entry keys or cursor controls.

NOTE: Standby mode is activated if the voltage compliance for a given output current is

exceeded. Trying to output a current with no connection made to the output jacks will

force the M2000 into standby mode.

See Figure 4.

3. The M2000 has a typical voltage compliance of 10V so that 4-20mA application loads up

to 500 ohms can be driven. At maximum current (100mA) the maximum load is 100

ohms.

V/mA

Figure 3

Connections for Outputting DC Voltage

Figure 4

Connections for Outputting DC Current

Page 8

8

IX. SETPOINTS

The M2000 offers functionality which allows the user to store and recall output levels (setpoints). Additional functionality allows the user to automatically step through a number of setpoints at a configurable interval. Up to 9 setpoints can be programmed for each range.

A. Setting a Setpoint

1. To set a setpoint go to the desired range and enter the desired output value.

2. Once you have entered the output value press the key followed by the

key.

3. Select the number of the setpoint in which the present output value is to be stored.

B. Recalling a Setpoint

1. To recall a setpoint press the key followed by the key.

2. Select the number of the setpoint you wish to recall.

C. Auto Setpoints

1. To initialize auto setpoint functionality, press the key followed by the

key.

2. Select the number of setpoints to be recalled. Setpoints step up from setpoint one to the

setpoint selected and then down.

3. Select the interval (in seconds) between setpoints.

NOTE: During auto setpoint mode the can be used. Pressing any other

key will cause the unit to exit this mode.

X. REMOTE INTERFACE

Setting up the RS-232 Port for Remote Control

The M2000 is fully programmable over an RS-232 link with a PC.

The RS-232 cable length for the port should not exceed 15 meters (50 feet), although longer

cable lengths are permitted if the load capacitance measured at a connection point (including

signal terminator) does not exceed 2500 pF.

RS-232 Port Setup Procedure

Serial parameters are fixed with the values shown below:

· 9600 baud

· 8 data bits

· 1 stop bit

· no parity

· Xon/Xoff

· EOL (end-of-line) character CR (Carriage Return)

A typical connection is shown in Figure 5. Note the use of a null modem cable for connection.

STBY/OPR

AUTO

2nd

RCL2nd

SET

2nd

CAUTION

When in auto setpoint mode the unit does not go to standby

even if the output goes above 30V.

Page 9

9

Setting up the IEEE-488 Port for Remote Control

The M2000 is fully programmable for use on the IEEE Standard 488 interface bus. The IEEE488 interface is also designed in compliance with supplemental standard IEEE-488.2, which

describes additional IEEE-488 features. Devices connected to the IEEE-488 bus are designated as talkers, listeners, talker/listeners, or controllers. Under remote control of an instrument,

the M2000 operates as a talker/listener.

A PC equipped with an IEEE-488 interface controls the M2000. Compatible software for IEEE488 operation, MET/CAL, may be purchased from Fluke.

When using the IEEE-488 remote control interface, there are two restrictions:

1. Number of Devices A maximum of 15 devices can be connected in a single IEEE-488

bus system.

2. Cable Length The total length of IEEE-488 cables used in one IEEE-488 system is 2

meters times the number of devices in the system, or 20 meters, whichever is less.

IEEE-488 Port Setup Procedure

Complete the following procedure to set up the M2000 for remote operations using the IEEE488 remote control port. The purpose is to select GPIB as the interface and to select the GPIB

address for the interface.

To set up the IEEE-488 port

1. Turn the M2000 power on and wait until the initialization procedure completes. You

may operate the M2000 during warm-up, but specifications are not guaranteed until

warm-up is complete.

2. Press SETUP ( + ).

3. Press until Remote Interface: is displayed.

4. Press the or key to select GPIB, if not already selected.

5. Press to accept the interface choice.

6. Press the or key to select the desired address. The factory default is 4.

7. Press to accept the address choice and exit the Setup menu.

See Figure 6 for a typical IEEE-488 connection

ENTER

▼▲

ENTER

▼▲

ENTER

0SHIFT

Figure 5

RS232 Remote Control connections

Figure 6

Typical IEEE-488 connections

Page 10

10

Changing Between Remote and Local Operation

In addition to Local mode (front panel operation) and remote, the M2000 can be placed in a

local lockout condition at any time by command of the controller. Combined, the local,

remote, and lockout conditions yield four possible operating states described as follows.

Local State

The M2000 responds to local and remote commands. This is normal front panel operation. All

remote commands are allowed to execute.

Local with Lockout State

Local with lockout is identical to local, except the M2000 will go into the remote with lockout

state instead of the remote state when it receives a remote command.

Remote State

When the M2000 is placed in remote, either via RS-232 REMOTE command, or via IEEE-488

asserting the REN line, it enters the remote state. The top line of the display changes to: REM.

Front panel operation is disabled except for the LOCAL (“–” key). Pressing “–”, using RS-232 to

send the command LOCAL, or IEEE-488 to send the GTL (Go To Local) message returns the

M2000 to the local state.

Remote with Lockout State

When the M2000 is placed in lockout, either via RS-232 LOCKOUT command, or via the IEEE488 message LLO, the M2000 front panel controls are totally locked out. The top line of the

display changes to: REM.

To return the M2000 to the local with lockout state, send the RS-232 LOCAL command or the

IEEE-488 GTL (Go To Local) message.

Table 3 summarizes the possible Operating state transitions. (For more information on IEEE488 GPIB messages, see "IEEE-488 Overview."

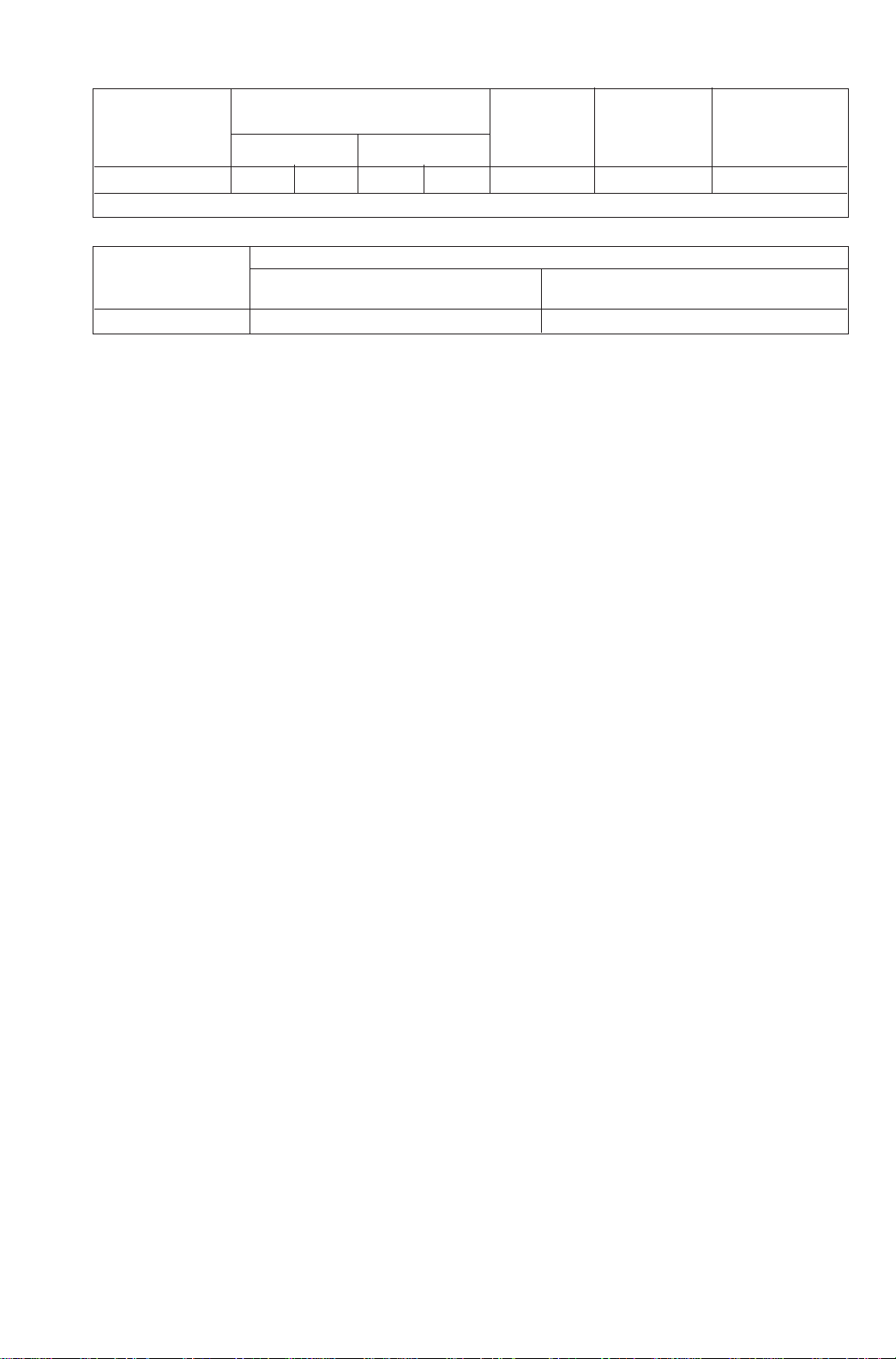

Table 3. Operating State Transitions

From To Front Panel GPIB Serial

Message Command

Local Remote MLA (REN True) REMOTE

Local with LLO LOCKOUT

Lockout

Remote Local Local key GTL or REN LOCAL

False

Remote with LLO LOCKOUT

Lockout

Local with Local REN False LOCAL

Lockout Remote with MLA (REN True) REMOTE

Lockout

Remote with Local REN False LOCAL

Lockout GTL

IEEE-488 Interface Overview

The IEEE-488 parallel interface sends commands as data and receives measurements and

messages as data. The maximum data exchange rate is 1 Mbyte, with a maximum distance of

20 meters for the sum length of the connecting cables. A single cable should not exceed 4

meters in length. Some commands are reserved for RS-232 serial operation because these

functions must be implemented as IEEE messages per the IEEE Standards. For example, the

command REMOTE could be sent as data over the IEEE-488 interface to place the M2000

into remote, but it is not because the IEEE Standards call for the remote function to be sent to

the device as the uniline message REN. This is also true for several other commands and

functions, as shown below, with their equivalent RS-232 emulation. A summary of IEEE-488

messages is shown in Table 4.

Page 11

11

Table 4. RS-232 Emulation of IEEE-488 Messages

IEEE-488 Message RS-232 Equivalent

GTL LOCAL command

GTR REMOTE command

LLO LOCKOUT command

SDC, DCL (not emulated on RS-232)

GET (not emulated on RS-232)

SPE, SPD (not emulated on RS-232)

UNL, UNT (not emulated on RS-232)

The IEEE-488 interface is based on the IEEE Standards 488.1 and 488.2. For detailed information, refer to the IEEE-488.1 and IEEE-488.2 standards.

Using Commands

Communications between the controller and the M2000 consists of commands, queries, and

interface messages. Although the commands are based on the 488.2 standard, they can be

used on either the IEEE-488 or RS-232 interface, except for a few specialized RS-232 commands described in "Commands for RS-232 Only." (For more information on command structures, see the IEEE 488.2 standard.)

Refer to Chapter XI, "Remote Commands" when you require additional information about

command references used in this chapter.

All commands and units may be entered in UPPER or lower case.

Types of Commands

The commands for the M2000 can be grouped into one or more categories, depending on

how they function. Each category is described below.

Device-Dependent Commands

Device-dependent commands are unique to the M2000. An example of a device-dependent

command is,

OUT 1 V

instructing the M2000 to source 1 volt dc.

Common Commands

Common commands are defined by the IEEE 488.2 standard and are common to most bus

devices. Common commands always begin with an * character. Common commands are

available whether you are using the IEEE-488 or RS-232 interface for remote control. An

example of a common command is,

*IDN?

instructing the M2000 to return the instrument identification string.

Query Commands

Query commands request information, which is returned as the command executes, or

placed in a buffer until requested. An example of a query, which always ends with a question

mark, is,

RANGE?

returning the M2000 dc voltage output range.

Interface Messages (IEEE-488)

Interface messages manage traffic on the IEEE-488 interface bus. Device addressing and

clearing, data handshaking, and commands to place status bytes on the bus are all directed

by interface messages. Some of the interface messages occur as state transitions of dedicat-

Page 12

ed control lines. The rest of the interface messages are sent over the data lines with the ATN

signal true. (All device-dependent and common commands are sent over the data lines with

the ATN signal false.)

An important thing to note about interface messages is that unlike device-dependent and

common commands, interface messages are not sent literally (in a direct way).

IEEE-488 standards define interface messages. Interface messages are handled automatically

in most cases.

Compound Commands

A compound command is two or more commands in a single command line. For example,

the following two commands could be entered individually,

OUT 1 V

OPER

where the M2000 sources 1 V dc, and then goes into operate, or they could be combined

into a compound command,

OUT 1 V ; OPER

using a semi-colon as a separator.

Overlapped Commands

Commands that begin execution but require slightly more time to complete are called overlapped commands, because they can be overlapped by the next command before they have

completed execution.

The command graphic Overlapped shows a check for overlapped commands.

You can use the command *WAI to wait until the overlapped command has completed execu-

tion before executing the next command. For example,

OUT 1 V ; *WAI

You can also use the status commands *OPC and *OPC? to detect completion of overlapped

commands. (See "Checking M2000 Status.")

Sequential Commands

Commands that execute immediately are called sequential commands.

The command graphic Sequential shows a check for sequential commands.

The majority of the commands are sequential.

Commands for RS-232 Only

The command graphic IEEE-488 RS-232 indicates RS-232 interface commands.

The IEEE-488 and RS-232 interfaces both send commands to the M2000 as data, except for

those IEEE-488 functions that must be implemented as a message as specified in the IEEE488 standards. For example, the RS-232 interface uses the command REMOTE to place the

M2000 in the Remote mode. Although the IEEE-488 interface could also send a command

REMOTE as data, it does not because this is one of the functions that must be implemented

per IEEE-488 Standards. The relationship between these IEEE-488 messages and the equivalent RS-232 emulation is shown in Table 5.

Table 5. Commands for RS-232 Only

IEEE-488 Message [1] RS-232 Equivalent

GTL LOCAL command

GTR REMOTE command

LLO LOCKOUT command

Commands for IEEE-488 Only

The command graphic IEEE-488 indicates commands that are used for the IEEE-488

interface. This is all the commands, except for those used for RS-232 operations. (See

"Commands for RS-232 Only.") All commands are transferred over the IEEE-488 as data,

X

X

X

X

12

Page 13

13

except for the commands LOCAL, REMOTE, and LOCKOUT, which are implemented per IEEE

Standards as messages.

Command Syntax

The following syntax rules apply to all the remote commands. Information about syntax of

response messages is also given.

Parameter Syntax Rules

Table 6 lists the units accepted in command parameters and used in responses. All commands and units may be entered in upper or lower case.

Table 6. Units Accepted in Parameters and Used in Responses

Units Meaning

uV Volts in units of microvolts

1

mV Volts in units of millivolts

1

V Volts in units of volts

kV Volts in units of kilovolts

1

uA Current in units of microamperes

1

mA Current in units of milliamps

1

A Current in units of amps

1. Parameter only

General Rules The general rules for parameter usage is as follows:

1. Numeric parameters may have up to 15 significant digits and their exponents can be in

the range +/-1.0E+/-20.

2. Including too many or too few parameters causes a command error.

3. Null parameters cause an error, e.g., the adjacent commas in OUT 1V, ,;OPER.

4. Expressions, for example 4+2*13, are not allowed as parameters.

Extra Space or Tab Characters

In the command descriptions, parameters are shown separated by spaces. One space after a

command is required (unless no parameters are required). All other spaces are optional.

Spaces are inserted for clarity in the manual and may be left in or omitted as desired. You can

insert extra spaces or tabs between parameters as desired. Extra spaces within a parameter

are generally not allowed, except for between a number and its associated multiplier or unit.

Terminators

Table 7 summarizes the terminator characters for both the IEEE-488 and RS-232 remote interfaces.

Table 7. Terminator Characters

Terminator ASCII Character Control Command Language

Command

Function Number Program Terminator Terminator

Carriage Return (CR) 13 Chr(13) <Cntl> M \n

Line Feed (LF) 10 Chr(10) <Cntl> J \r

Examples:

RS-232 Mode using a terminal OUT 1 V <Enter>

RS-232 Mode using a program Comm1.Output = "OUT 1 V" + Chr(10)

IEEE-488 Mode OUT 1 V

Page 14

IEEE-488 Interface The M2000 sends the ASCII character Carriage Return with the EOI control

line held high as the terminator for response messages. The M2000 recognizes the following

as terminators when encountered in incoming data:

• ASCII CR character

• Any ASCII character sent with the EOI control line asserted

RS-232 Interface The M2000 returns a Carriage Return (CR) character with each response.

The M2000 recognizes the following as terminators when encountered in incoming data:

• ASCII CR character

• ASCII LF character

Incoming Character Processing

The M2000 processes all incoming data as follows:

1. The most significant data bit (DIO8) is ignored.

2. All data is taken as 7-bit ASCII.

3. Lower-case or upper-case characters are accepted.

Response Message Syntax

In the command descriptions responses from the M2000 are described wherever appropriate.

In order to know what type of data to read in, refer to the first part of the entry under

"Response" in the tables.

14

Page 15

Checking M2000 Status

You have access to status registers, enable registers, and queues in the M2000 to indicate

various conditions in the instrument as shown in Figure 7. Some registers and queues are

defined by the IEEE-488.2 standard. The rest are specific to the Calibrator. In addition to the

status registers, the Service Request (SRQ) control line, and a 16-element buffer called the

Error Queue provide status information. Table 8 lists the status registers and gives the

read/write commands and associated mask registers.

Table 8. Status Register Summary

Status Register Read Write

Command Command

Serial Poll Status Byte (STB) *STB? —

Service Request Enable Register (SRE) *SRE? *SRE

Event Status Register (ESR) *ESR? —

Event Status Enable Register (ESE) *ESE? *ESE

Each status register and queue has a summary bit in the Serial Poll Status Byte.

Enable registers are used to mask various bits in the status registers and generate

summary bits in the Serial Poll Status Byte. For IEEE-488 interface operation, the

Service Request Enable Register is used to assert the SRQ control line on detection

of any status condition or conditions the programmer chooses. For RS-232

interface operation, the SRQSTR string is sent over the serial interface when the

SRQ line is set. (See the SRQSTR command description for more information.)

Serial Poll Status Byte (STB)

The Calibrator sends the serial poll status byte (STB) when it responds to a serial poll. This

byte is cleared (set to 0) when the power is turned on. The STB byte is defined as shown in

Figure 7. Refer to the *STB? Command for RS-232 interface operation for more information.

15

0

1

2

345

6

7

0

1

2

345

6

7

&

&

&

&

&

&

&

&

Logical OR

Event Status

Register

Read using *ESR?

Event Status

Enable Register

Read using *ESE?

Write using *ESE

PON0CME

EXE

DDE

QYE

0

OPC

0

00

0

1

2

3457

&

&

&

&

&

&

&

Logical OR

Status Byte Register

Service Request

Enable Register

ESB

MAV

Read using *SRE?

Write using *SRE

Error Queue

Read using ERR?

Read by Serial Poll

Read using *STB?

Service Request

Generation

SRQ

on

IEEE bus

Output Buffer

EAV

Data

Available?

Error

Available?

MSS

6

RQS

0

Figure 7

Status Register Overview

Read using FAULT?

Page 16

16

7 6 5 4 3 2 1 0

0

RQS

ESB MAV EAV 0 0 0

MSS

RQS Requesting service. The RQS bit is set to 1 whenever bits ESB, MAV, EAV, or ISCB

change from 0 to 1 and are enabled (1) in the SRE. When RQS is 1, the M2000

asserts the SRQ control line on the IEEE-488 interface. You can do a serial poll to

read this bit to see if the M2000 is the source of an SRQ.

MSS Master summary status. Set to 1 whenever bits ESB, MAV, EAV, or ISCB are 1 and

enabled (1) in the SRE. This bit can be read using the *STB? command in serial

remote control in place of doing a serial poll.

ESB Set to 1 when one or more ESR bits are 1.

MAV Message available. The MAV bit is set to 1 whenever data is available in the

M2000’s IEEE-488 interface output buffer.

EAV Error available. An error has occurred and an error is available to be read from the

error queue by using the FAULT? query.

Figure 8. Serial Poll Status Byte (STB) and Service Request Enable (SRE)

Service Request (SRQ) Line

IEEE-488 Service Request (SRQ) is an IEEE-488.1 bus control line that the M2000 asserts to

notify the controller that it requires some type of service. Many instruments can be on the

bus, but they all share a single SRQ line. To determine which instruments set SRQ, the

Controller normally does a serial poll of each instrument. The calibrator asserts SRQ whenever the RQS bit in its Serial Poll Status Byte is 1. This bit informs the controller that the M2000

was the source of the SRQ.

The M2000 clears SRQ and RQS whenever the controller/host performs a serial poll, sends

*CLS, or whenever the MSS bit is cleared. The MSS bit is cleared only when ESB and MAV

are 0, or they are disabled by their associated enable bits in the SRE register being set to 0.

Service Request Enable Register (SRE)

The Service Request Enable Register (SRE) enables or masks the bits of the Serial Poll Status

Byte. The SRE is cleared at power up. Refer to Figure 7 for the bit functions.

Programming the STB and SRE

By resetting (to 0) the bits in the SRE, you can mask (disable) associated bits in the serial poll

status byte. Bits set to 1 enable the associated bit in the serial poll status byte.

Event Status Register (ESR)

The Event Status Register is a two-byte register in which the higher eight bits are always 0,

and the lower eight bits represent various conditions of the M2000. The ESR is cleared (set to

0) when the power is turned on, and every time it is read.

Many of the remote commands require parameters. Improper use of parameters causes com-

mand errors to occur. When a command error occurs, bit CME (5) in the Event Status

Register (ESR) goes to 1 (if enabled in ESE register), and the error is logged in the error

queue.

Event Status Enable (ESE) Register

A mask register called the Event Status Enable register (ESE) allows the controller to enable

or mask (disable) each bit in the ESR. When a bit in the ESE is 1, the corresponding bit in the

ESR is enabled. When any enabled bit in the ESR is 1, the ESB bit in the Serial Poll Status

Byte also goes to 1. The ESR bit stays 1 until the controller reads the ESR or does a device

clear, a selected device clear, or sends the reset or *CLS command to the M2000. The ESE is

cleared (set to 0) when the power is turned on.

Page 17

Bit Assignments for the ESR and ESE

The bits in the Event Status Register (ESR) and Event Status Enable register (ESE) are

assigned as shown in Figure 9.

15 14 13 12 11 10 9 8

0 0 0 0 0 0 0 0

7 6 5 4 3 2 1 0

PON 0 CME EXE DDE QYE 0 OPC

PON Power on. This bit is set to 1 if line power has been turned off and on since the last

time the ESR was read.

CME Command error. The M2000's IEEE-488 interface encountered an incorrectly

formed command. (The command FAULT? fetches the latest error code in the error

queue, which contains error codes for the first 15 errors that have occurred.)

EXE Execution error. An error occurred while the M2000 tried to execute the last com-

mand. This could be caused, for example, by a parameter being out of range. (The

command FAULT? fetches the latest error in the error queue, which contains error

codes for the first 15 errors that have occurred.)

DDE Device-dependent error. An error related to a device-dependent command has

occurred.

QYE Query error. The M2000 was addressed to talk when no response data was avail-

able or appropriate, or when the controller failed to retrieve data on the output

queue.

OPC Operation complete. All commands previous to reception of a *OPC command

have been executed, and the interface is ready to accept another message.

Figure 9. Event Status Register (ESR) and Event Status Enable (ESE)

Programming the ESR and ESE

To read the contents of the ESR, send the remote command, *ESR?. The ESR is cleared (set

to 0) every time it is read. To read the contents of the ESE, send the remote command,

*ESE?. The ESE is not cleared when it is read. When you read either register, the M2000

responds by sending a decimal number that when converted to binary represents bits 0

through 15.

Output Queue

The output queue is loaded whenever a query is processed, and holds up to 250 characters.

The controller reads it with a statement such as a BASIC INPUT statement, removing what it

reads from the queue. If the queue is empty, the M2000 does not respond to the INPUT statement from the controller. The Message Available (MAV) bit in the Serial Poll Status Byte is 1 if

there is something in the output queue and 0 if the output queue is empty.

Error Queue

When a command error, execution error, or device-dependent error occurs, its error code is

placed in the error queue where it can be read by the FAULT? command. (See Chapter 5 for

a list of error messages.) Reading the first error with the FAULT? command removes that error

from the queue. A response of 0 means the error queue is empty. The error queue is cleared

when you turn off the power, and when you use the *CLS (Clear Status) common command.

The error queue contains up to 15 entries. If more than 15 errors occur, only the first 15 errors

are kept in the queue. A 16th entry in the queue is always an "error queue overflow" error, and

all later errors are discarded until the queue is at least partially read. The first errors are kept,

17

Page 18

because if many errors occur before the user can acknowledge and read them, the earliest

errors are the most likely to point to the problem. The later errors are usually repetitions or

consequences of the original problem.

Input Buffer Operation

As the M2000 receives each data byte from the controller, it places the bytes in a portion of

memory called the input buffer. The input buffer holds up to 250 data bytes and operates in a

first in, first out fashion.

IEEE-488 The M2000 treats the EOI IEEE-488 control line as a separate data byte and inserts

it into the input buffer if it is encountered as part of a message terminator. Input buffer operation is transparent to the program running on the controller. If the controller sends commands

faster than the M2000 can process them, the input buffer fills to capacity. When the input

buffer is full, the M2000 holds off the IEEE-488 bus with the NRFD (Not Ready For Data)

handshake line. When the M2000 has processed a data byte from the full input buffer, it then

completes the handshake, allowing the controller to send another data byte. The calibrator

clears the input buffer on power-up and on receiving the DCL (Device Clear) or SDC

(Selected Device Clear) messages from the controller.

RS-232 Under RS-232-C serial port remote control using ^S (<Cntl> S) XOFF protocol, the

M2000 issues a ^S XOFF when the input buffer becomes 80% full. The calibrator issues a

^Q (<Cntl> Q) XON when it has read enough of the input buffer so that it is less than 40%

full.

18

Page 19

XV. REMOTE COMMANDS

Introduction

Remote commands duplicate activities that can be initiated from the front panel in local

operation. Following the summary table is a complete alphabetical listing of all commands

complete with protocol details. Separate headings in the alphabetical listing provide the

parameters and responses, plus an example for each command. For information on using

commands, see "Remote Operation."

Command Summary by Function

Common Commands

Command Description

*CLS (Clear status.) Clears the ESR, the error queue, and the RQS bit in the status byte.

This command terminates pending operation complete commands (*OPC or *OPC?).

*ESE Loads a byte into the Event Status Enable register.

*ESE? Returns the contents of the Event Status Enable register.

*ESR? Returns the contents of the Event Status register and clears the register.

*IDN? Identification query. Returns the manufacturer, model number, and firmware revision

level of the Calibrator.

*OPC Enables setting of bit 0 (OPC for "Operation Complete") in the Event Status Register to

1 when all pending device operations are complete.

*OPC? Returns a 1 after all pending operations are complete. This command causes program

execution to pause until all operations are complete. (See also *WAI.)

*OPT? Returns a list of the installed hardware and software options.

*RST Resets the state of the instrument to the power-up state. This command holds off

execution of subsequent commands until it is complete. (Overlapped command.)

*SRE Loads a byte into the Service Request Enable register (SRE).

*SRE? Returns the byte from the Service Request Enable register.

*STB? Returns the status byte.

*TST? Initiates a series of self-tests, then returns a "0" for pass or a "1" for fail. If any faults are

detected, they are logged into the fault queue where they can be read by the FAULT?

query.

*WAI Prevents further remote commands from being executed until all previous remote

commands have been executed.

Output Commands

Command Description

FUNC? Returns the present output, measurement, or calibration function.

OPER Activates the M2000 output if it is in standby.

OPER? Returns the operate/standby setting.

OUT Sets the output of the M2000.

OUT? Returns the output amplitude of the M2000.

RANGE? Returns the present output range. (Voltage only).

RANGELCK Locks the present output range (Voltage only).

RANGELCK? Returns the RANGELOCK state (Voltage only).

STBY Deactivates the M2000 output if it is in Operate mode.

19

Page 20

RS-232 Port Commands

Command Description

LOCAL Puts the M2000 into the local state and disables lockout.

LOCKOUT Puts the M2000 into the lockout state. This command duplicates the

IEEE-488 LLO (Local Lockout) message.

REMOTE Puts the M2000 into the remote state. This command duplicates the

IEEE-488 REN (Remote Enable) message.

Status Commands

Command Description

FAULT? Returns the most recent error code in the M2000 error queue, then removes that error

code from the queue.

Error Code Listing

Error Message

Number Class Description

1 DDE Error queue overflow.

101 CME A non-numeric entry was received in a field that should contain a numeric

entry.

102 EXE The numeric field exceeds 10 characters.

105 EXE Entry is above upper limit for the selected output range.

106 EXE Entry is below lower limit for the selected output range.

107 EXE OUT? was received when the M2000 was not in a Source mode.

108 CME A required command parameter was missing.

110 CME An invalid RANGELCK parameter (not ON or OFF) was received.

111 EXE RANGELCK ON was received when the M2000 is not in Volts mode.

117 CME An unrecognizable command was received.

118 CME An invalid parameter was received.

120 EXE The serial input buffer overflowed

121 EXE The command string buffer overflowed.

122 QYE The serial output buffer overflowed.

123 DDE The output overloaded.

124 DDE M2000 is out of tolerance. This error is set after a failed initialization or a

failed *TST?.

125 DDE M2000 has a ADC failure. This error is set after a failed initialization or a

failed *TST?.

Remote Command Listing

The following is an alphabetical list of all M2000 commands and queries, including common

commands and device-dependent commands. Each command title includes a graphic that

indicates remote interface applicability, IEEE-488 and RS-232, and command group:

Sequential and Overlapped.

*CLS IEEE-488 RS-232 Sequential Overlapped

(Clear Status command) Clears the ESR, the error queue, and the RQS bit in the status byte.

This command terminates pending operation complete commands (*OPC or *OPC?).

Parameter: (None)

Example: *CLS

Clear the ESR, the error queue, and the RQS bit in the status byte.

XXX

20

Page 21

*ESE IEEE-488 RS-232 Sequential Overlapped

(Event Status Enable command) Loads a byte into the Event Status Enable (ESE) register.

(See "Event Status Enable Register (ESE)" )

Parameter: <value> (decimal equivalent of the ESE byte, 0 to 255)

Example: *ESE 140

Load decimal 140 (binary 10001100) to enable bits 7 (PON), 3 (DDE) and 2 (QYE).

*ESE? IEEE-488 RS-232 Sequential Overlapped

(Event Status Enable query) Returns the contents of the Event Status Enable (ESE) register.

(See "Event Status Enable Register (ESE)" )

Response: <value> (decimal equivalent of the ESE byte, 0 to 255)

Example: *ESE? returns 133

Returns decimal 133 (binary 10000101) when bits 7 (PON), 2 (QYE), 1 (OPC) are enabled.

*ESR? IEEE-488 RS-232 Sequential Overlapped

(Event Status Register query) Returns the contents of the Event Status Register (ESR) and

clears the register. (See Event Status Register (ESR)" )

Response: <value> (decimal equivalent of the ESR byte, 0 to 255)

Example: *ESR? returns 189

Returns decimal 189 (binary 00111101) when bits 5 (CME), 4 (EXE), 3 (DDE), 2 (QYE) and 0

(OPC) are enabled.

FAULT? IEEE-488 RS-232 Sequential Overlapped

Returns the most recent error code from the error queue. If the queue is empty (no errors

have occurred) it returns 0. The command can be used when the previous command did not

do what it was intended to do.

For example, if a value for current output above 100 mA is entered, the FAULT? command

would return error code 105, entry is above upper limit for the selected output range.

FUNC? IEEE-488 RS-232 Sequential Overlapped

(Function query) Returns the present output, measurement, or calibration function. See the

response below for output and measurement modes.Responses:

DCV (dc volts function)

DCI (dc current function)

Example: FUNC? returns DCV

Returns DCV when the M2000 output function dc volts.

*IDN? IEEE-488 RS-232 Sequential Overlapped

(Identification query) Returns instrument model number, serial number, and firmware revision

levels for the main, encoder, and inguard CPUs.

Responses: (Indefinite ASCII) A message containing four fields separated by commas as fol-

lows:

1. Manufacturer

2. Model number

3. Serial number (always 0)

4. Firmware revision levels for the main, front panel, and inguard CPUs.

Example: *IDN? returns MARTEL, M2000,0,1.2

Returns Martel manufacturer, model M2000, serial number 0, firmware version 1.2.

XXX

XXX

XXX

XXX

XXX

XXX

21

Page 22

22

LOCAL IEEE-488 RS -232 Sequential Overlapped

(Local command) Puts the M2000 into the local state, clearing the remote state (see the

REMOTE command) and front panel lockout (see the LOCKOUT command). This command

duplicates setting the IEEE-488 REN line to false.

Parameter: (None)

Example: LOCAL

Set the instrument into the local state, clearing the remote state and front panel lockout (if

enabled).

LOCKOUT IEEE-488 RS -232 Sequential Overlapped

(Lockout command) Puts the M2000 into the lockout state when in remote control (see the

REMOTE command). This means no local operation at the front panel is allowed during

remote control. To clear the lockout condition, use the LOCAL command. This command

duplicates the IEEE-488 LLO (Local Lockout) message.

Parameter: (None)

Example: LOCKOUT

Set the instrument into the front panel lockout state. The front panels controls cannot be

used.

*OPC IEEE-488 RS -232 Sequential Overlapped

(Operations Complete command) Sets bit 0 (OPC) of the Event Status Register to 1 when all

pending device operations are complete. Also see the *ESR? command.

Parameter: (None)

Example: *OPC

Set bit 0 of the Event Status Register to 1 when all pending device operations are done.

*OPC? IEEE-488 RS -232 Sequential Overlapped

(Operations Complete query) Returns a 1 after all pending operations are complete. This

command causes program execution to pause until operations are complete. (See *WAI.)

Response: 1 (all operations are complete)

Example: *OPC? returns 1

Returns 1 when all pending operations are complete.

OPER IEEE-488 RS -232 Sequential Overlapped

(Operate command) Activates the M2000 output if it is in standby. This is the same as pressing the M2000 front panel key.

Parameter: (None)

Example: OPER

Connect the selected output to the M2000 front panel terminals. Also indicates OPR on the

display.

OPER? IEEE-488 RS -232 Sequential Overlapped

(Operate query) Returns the operate/standby setting.

Response: 1 (Operate)

0 (Standby)

Example: OPER? returns 1

Returns 1 when the M2000 is in operate.

XXX

STBY

OPR

XXX

XXX

XXX

XX

XX

Page 23

23

*OPT? IEEE-488 RS -232 Sequential Overlapped

(Options command) Returns a list of the installed hardware and software options.

Responses: <option string>,<option string>,(options list, separated by commas)

0 (no options are installed)

Example: *OPT? Returns 0

This command is reserved for future use.

OUT IEEE-488 RS -232 Sequential Overlapped

(Output command) Sets the output of the M2000 and establishes a new reference point for

the error mode. To source or measure a temperature, select the desired sensor and sensor

parameters first. (See the TSENS_TYPE, RTD_TYPE, and TC_TYPE commands.)

Use multipliers, k, m, u with the OUT command, as desired.

Parameters: <value> V Volts dc

<value> A Current dc

Examples: OUT 15.2 V (volts; 15.2 V)

OUT 1.2 mA (current; 1.2 mA)

Each example shows a value and unit, e.g., -15.2 V. If a value is entered without a unit, the

value of the existing output is changed, when logically allowed.

OUT? IEEE-488 RS -232 Sequential Overlapped

(Output query) Returns the output amplitude of the M2000. Multipliers (e.g., K or M) are not

used in the response.

Response: <amplitude value>,<units>

Examples: OUT? returns -1.520000E+01,V

OUT? returns 1.88300E-02,A

OUT? returns 1.23000E+00,V

OUT? returns 1.52000E+01,V

The respective values for the above examples are:

-15.2 V

18.83 mA

1.23 V

15.2 V

RANGE? IEEE-488 RS -232 Sequential Overlapped

(Range query) Returns the present voltage output range.

Response: <range>

Examples: V_0.1V (dc volts 100 mV range)

V_1V (dc volts 1V range)

V_10V (dc volts 10 V range)

V_100V (dc volts 100 V range)

Returns the symbolic name of the voltage output range.

RANGELCK IEEE-488 RS-232 Sequential Overlapped

(Range lock command) Locks or unlocks the present voltage range.

Parameter: ON Locks the present voltage range

OFF Unlocks the present voltage range.

RANGELCK? IEEE-488 RS-232 Sequential Overlapped

(Range command) Returns the RANGELOCK state 1 for ON or 0 for OFF.

Parameter: (None)

XXX

XXX

XXX

XXX

XXX

XXX

Page 24

REMOTE IEEE-488 RS-232 Sequential Overlapped

(Remote command) Places the M2000 into the remote state. This command duplicates the

IEEE-488 REN (Remote Enable) message. When the M2000 is in the remote state, and not

locked out, only the LOCAL key is active. If the front panel is locked out, no front panel keys

are active. See the LOCKOUT command. To unlock the front panel, use the LOCAL command, or cycle the M2000 power switch.

Parameter: (None)

Example: REMOTE

*RST IEEE-488 RS-232 Sequential Overlapped

(Reset Instrument command) Resets the M2000 to the power-up state. *RST holds off execu-

tion of subsequent commands until the reset operation is complete.

A reset action evokes the following commands and values:

Command Value

OUT 0 V

RANGE 0.1 V

STBY (No output)

Response: (None)

Example: *RST

Place the M2000 in a reset condition, evoking the commands and values shown above.

*SRE IEEE-488 RS-232 Sequential Overlapped

(Service Request Enable command) Loads a byte into the Service Request Enable (SRE) reg-

ister. (See "Service Request Enable Register (SRE)". Since bit 6 is not used (decimal value

64), the maximum entry is 255 - 64 = 191.

Parameter: <value> (the decimal equivalent of the SRE byte, 0 to 191)

Example: *SRE 48

Enable bits 4 (MAV), and 5 (ESR).

*SRE? IEEE-488 RS-232 Sequential Overlapped

(Service Request Enable query) Returns the byte in the Service Request Enable (SRE).

Response: <value> (the decimal equivalent of the SRE byte, 0 to 191)

Example: *SRE? returns 48

Returns 48 when bits 4 (MAV), and 5 (ESR) are enabled.

*STB? IEEE-488 RS-232 Sequential Overlapped

(Status Byte Register query) Returns the byte for the Status Byte Register. See "Status Byte

Register (STB)" in Chapter 4.

Response: <value> (the decimal equivalent of the STB byte, 0 to 255)

Example: *STB? returns 96

Returns 96 if bits 5 (ESR) and 6 (MSS) are set.

STBY IEEE-488 RS-232 Sequential Overlapped

(Standby command) Deactivates the M2000 output if it is in operate. This is the same as

pressing the M2000 front panel A key.

Parameter: (None)

Example: STBY

Disconnect the selected output from the M2000 front panel terminals.

XXX

XXX

XXX

XXX

XXX

XX

24

Page 25

*TST? IEEE-488 RS-232 Sequential Overlapped

(Self Test command) Initiates self-test and returns a 0 for pass or a 1 for fail. If any faults are

detected, they are displayed on screen (Terminal mode) or are logged into the fault queue

where they can be read by the FAULT? query (Computer mode).

Responses: 0 (fail self test)

1 (pass self test)

Example: *TST? returns 1

Returns 1 when self test passes.

*WAI IEEE-488 RS-232 Sequential Overlapped

(Wait-to-Continue command) Prevents further remote commands from being executed until all

previous remote commands have been executed. For example, if you send an OUT command, you can cause the M2000 to wait until the output has settled before continuing on to

the next command if you follow OUT with a *WAI command. The *WAI command is useful

with any overlapped command, preventing the M2000 from processing other commands until

the overlapped command is processed.

Example: *WAI

Process all existing commands before continuing.

XXX

XXX

25

Page 26

XVI. SPECIFICATIONS

General Specifications

Warm up time Twice the time since last warmed up, to a maximum of 30 minutes.

Settling time Less than 5 seconds for all functions and ranges except as noted.

Standard interface RS-232

Optional interface IEEE-488 (GPIB)

Temperature performance Operating 0 °C to 50 °C

Calibration (tcal) 18 °C to 28 °C

Storage -20 °C to 70 °C

Electromagnetic compatibility CE: Conforms to EN61326

Temperature coefficient Temperature coefficient for temperatures outside tcal ±5 °C is

10 % of the 90 day specification (or 1 year if applicable) per °C

Relative humidity Operating <80 % to 30 °C, <70% to 40 °C, <40 % to 50 °C

Storage <95 % noncondensing

Altitude Operating 3,050 m (10,000 ft) maximum

Nonoperating 12,200 m (40,000 ft) maximum

Safety EN 61010 Second, ANSI/ISA-S82.01-1994,

CAN/CSA-C22.2 No. 1010.1-92, NRTL

Analog low isolation 20 V

Line power Line Voltage (selectable) 100 V/120 V or 220 V/240 V

Line Frequency 47 to 63 Hz

Line Voltage Variation ±10 % about line voltage setting

Power consumption 15 VA maximum

Dimensions Height 13.3 cm (5.25 in) plus 1.5 cm (0.6 in) four feet on bottom

Width ¾ standard rack width

Depth 47.3 cm (18.6 in) overall

Weight (without options) 4 kg (9 lb)

DC Voltage Specifications, Output

Absolute Uncertainty,

tcal ±5 °C

± (ppm of output +µV) Stability

24 hours, ±1 °C Maximum

Ranges

1

90 days 1 year ± (ppm of output +µV) Resolution Burden

2

0 to 100.000 mV 25 3 30 3 5 ppm +2 1 µV 10 mA

0 to 1.00000 V 25 20 30 20 4 ppm +20 10 µV 10 mA

0 to 10.0000 V 25 200 30 200 4 ppm +200 100 µV 10 mA

0 to 100.000 V 25 2 mV 30 2 mV 5 ppm +1 mV 1 mV 1 mA

1. All outputs are positive only.

2. Remote sensing is not provided. Output resistance is < 1Ω.

Noise

Bandwidth 0.1 to 10 Hz p-p Bandwidth

Ranges ± (ppm of output +µV) 10 Hz to 10 kHz rms µV

0 to 100.000 mV 1 µV 6 µV

0 to 1.00000 V 10 µV 60 µV

0 to 10.0000 V 100 µV 600 µV

0 to 100.000 V 10 ppm+1 mV 20 mV

26

Page 27

27

DC Current Specifications, Output

Absolute Uncertainty,

tcal ±5 °C ± (ppm of output +µA) Maximum Maximum

Compliance Inductive

Ranges

1

90 days 1 year Resolution Voltage Load

0 to 100.000 mA 85 2 100 2 1 µA 10 V 100 mH

1. All outputs are positive only.

Noise

Bandwidth Bandwidth

Ranges

0.1 to 10 Hz p-p

10 Hz to 10 kHz rms µV

0 to 100.000 mA 2000 nA 20 µA

Page 28

0219051 Rev D 6/08

www.martelcorp.com

e-mail: sales@martelcorp.com

Fax: (603) 434-1653 Tel: (603) 434-1433

800-821-0023

Martel Electronics

3 Corporate Park Drive

Derry, NH 03038

Loading...

Loading...